Page 1

GENERAL RELEASE DOCUMENT

CONSULT FACTORY FOR CURRENT REVISION

REVISIONS

REVISION

DESCRIPTION

APPROVED

DATE

1.0

Preliminary

Luis Vargas

8/13/2010

SPECIFICATION CONTROL DRAWING

Q-TECH CORPORATION

10150 W. JEFFERSON BLVD.

CULVER CITY, CA 90232-3510

PREPARED BY:

Luis Vargas

DATE

8/13/2010

LOW PROFILE 24 PIN FLAT-PACK HYBRID CRYSTAL

OSCILLATOR, VCXO, CLASS S,

Standard Design For Sine Wave up to 350MHz

UNLESS OTHERWISE

SPECIFIED, DIMENSIONS

ARE IN INCHES.

TOLERANCES:

3 PLACE DECIMAL = .005

2 PLACE DECIMAL = .02

1 PLACE DECIMAL = .1

FRACTIONS = ± 1/16

ANGLES = 2 DEGREES

CHECKED BY:

QUALITY

DATE

DRAWING NO.:

QTV714, QVT715 and QTV716

Sine-Wave 24 Flat Pack

REVISION

1.0

RELEASED BY:

DOCUMENT CONTROL

APPROVED BY:

ENGINEERING

DATE

SCALE

NONE

SIZE

A

CAGE CODE

51774

SHEET 1 of 7

Page 2

QTV714, QTV715 and QTV716

Sine-Wave 24 Flat Pack

REV.

Q-TECH Corporation

10150 W. Jefferson Blvd.

Culver City, CA 90232

SIZE

A

CAGE NO.

51774

Sheet 2 of 7

1.0

1.0 SCOPE

This specification establishes the detail requirements for low profile hybrid, hermetically sealed, Sine-

Wave output Voltage Controlled crystal oscillators (VCXO) for use in space flight missions.

2.0 APPLICABLE DOCUMENTS

The following documents of the latest issue form a part of this drawing to the extent specified herein.

2.1

Specifications and Standards

SPECIFICATIONS

MILITARY

MIL-S-19500

Semiconductor Devices, General Specification For

MIL-PRF-55310

Crystal Oscillators, General Specification For

MIL-PRF-38535

Integrated Circuits, (Microcircuits) Manufacturing, General Specification For

MIL-PRF-38534

Hybrid Microcircuits, General Specification For

STANDARDS

MILITARY

MIL-STD-202

Test Methods for Electronic and Electrical Component Parts

MIL-STD-883

Test Methods and Procedures for Microelectronics

MIL-STD-1686

Electrostatic Discharge Control Program for Protection of Electrical and

Electronics Parts, Assemblies and Equipment.

2.2 Conflicting Requirements

In the event of conflict between requirements of this specification and other requirements of the

applicable detail drawing, the precedence in which requirements shall govern, in descending order, is

as follows:

a) Applicable Customer purchase order.

b) Applicable detail drawing.

c) This specification.

d) Other specifications or standards referenced in 2.1 herein.

2.3 Customer Purchase Order Special Requirements

Additional special requirements shall be specified in the applicable Customer purchase order when

additional requirements or modifications specified herein are needed for compliance to special

program or product line requirements.

3.0 PERFORMANCE REQUIREMENTS

3.1 General Definition

The VCXO is a high reliability signal generator that provides a sine-wave output. The VCXO has been

designed to operate in a spaceflight environment with an expected lifetime in excess of 15 years.

Lifetime is defined as the sum of operational and storage environments.

Page 3

QTV714, QTV715 and QTV716

Sine-Wave 24 Flat Pack

REV.

Q-TECH Corporation

10150 W. Jefferson Blvd.

Culver City, CA 90232

SIZE

A

CAGE NO.

51774

Sheet 3 of 7

1.0

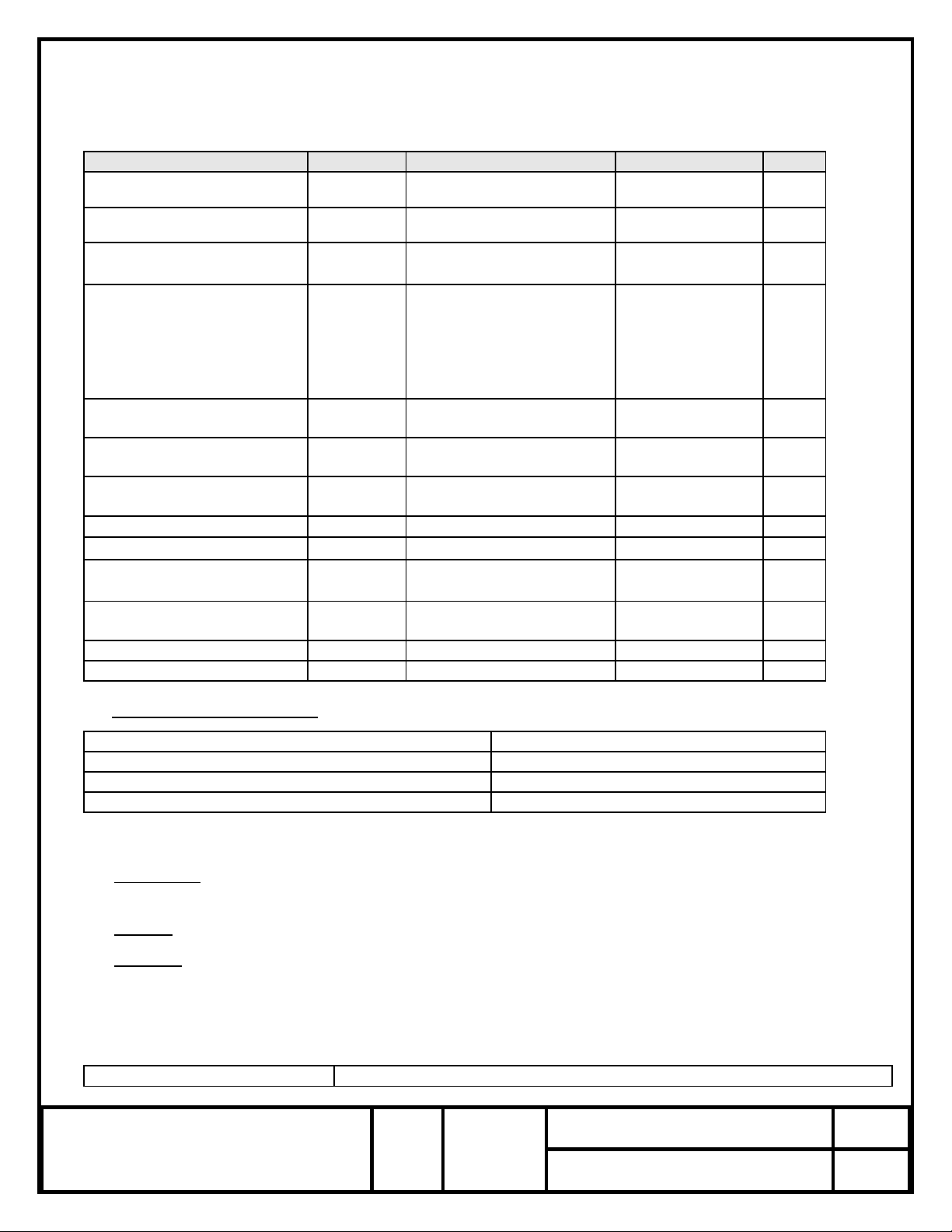

3.1.1 Electrical Characteristics

PARAMETER

SYMBOL

CONDITIONS

VALUE

UNIT

Frequency Nom.

fo

-

See part number

generation table

MHz

Supply voltage, Nom.

Vs

Vs±5%

See part number

generation table

V

Input Current, max.

Is

Vs, nom. / Ta=+25°C Vc/fo,

and 50Ω load

50

mA

Overall Frequency stability

(including Operating

Temperature, ±5% Load

Change, ±5% Supply Voltage

change. 10 year aging, and

radiation)

Δf/fc (Ta)

Contact factory for other

options available

See part number

generation table

ppm

Voltage Control Range For

Frequency Adjustment Min.

Vc

DC

See part number

generation table

Volts

Control Voltage at which fo

will occur at 25°C

Vc/fo

DC

½Vc ±0.5

Volts

Frequency)Pulling)range, Min

Δf/Vc

Over the voltage control

range

See part number

generation table

ppm

Linearity, max.

Δf/V

-

10

%

Input impedance, min.

Zin

-

10.0

KΩ

Modulation freq. bandwidth,

min.

MBW (-3dB)

Vs, nom. / Ta=+25°C Vc/fo,

and 50Ω load

10.0

KHz

Output level Min.

Sine Class S, 100 krads (Si)

total dose Min

See part number

generation table

dBm

Harmonics Max.

-20

dBc

Sub-harmonics Max.

-30

dBc

3.2 Absolute Maximum Rating

Supply Voltage

0 to +16.5 VDC

DC Input Current

50 mA maximum

Storage Temperature range

-62°C to +125°C

Lead Temperature (Soldering, 10 seconds)

300°C

3.2.1 Physical Characteristics

3.2.1.1 Dimensions

- The VCXO outline dimensions and terminal connections shall be as shown in Figure 1

herein.

3.2.1.2 Weight

- The VCXO shall weigh less than or equal to 25 grams.

3.2.1.3 Materials

- The VCXO package body and lead finish shall be gold in accordance with MIL-PRF-38534.

3.2.2 Environmental Conditions

Sine Vibration

MIL-STD-202, Method 204, TC “D”

Page 4

QTV714, QTV715 and QTV716

Sine-Wave 24 Flat Pack

REV.

Q-TECH Corporation

10150 W. Jefferson Blvd.

Culver City, CA 90232

SIZE

A

CAGE NO.

51774

Sheet 4 of 7

1.0

Random Vibration

MIL-STD-202, Method 214 TC “I-K” (15 minutes per axis)

Shock

MIL-STD-202, Method 213, TC “F”

Acceleration

MIL-STD-883, Method 2001, TC “A”

Altitude

50,000 feet minimum to deep space

Radiation

Radiation testing is not performed, but these VCXOs have been acceptable for

use in environments up to 100K rads by analysis of the components used.

Only bipolar semiconductors are employed. A copy of the parts list and

materials can be provided for review.

The electronics used in the VCXO shall be single event latchup free.

Electrostatic Discharge Sensitivity

The VCXO supplied to this drawing shall be considered to be electrostatic

discharge sensitive and require further protection and shall use one of the

packaging requirements in accordance with MIL-PRF-38534, Category A,

Section 5.3.2.4 Transportability.

The VCXO shall be capable of being transported by air, ship or road when

packaged in a suitable container.

3.3 Design and Construction

The design and construction of the crystal oscillator shall be as specified herein. As a minimum, the

oscillators shall meet the design and construction requirements of MIL-PRF-55310, except element

evaluation shall be as specified in 3.3.1.

Operation

Design, Construction &

Component Screen (see 3.3.2)

MIL-PRF-55310 Class S

Workmanship

M883, Method 2017 for Class S

Screening

MIL-PRF-55310 Class S

Non-Destruct Wire Bond Pull

100%, M883, Method 2023 (2.4 grams)

Internal Visual

MIL-STD-883, methods 2017 & 2032 condition K (class S). During the time

interval between final internal visual inspection and preparation for sealing,

hybrid crystal oscillators shall be stored in a dry, controlled environment as

defined in MIL-STD-883, method 2017 or in a vacuum bake oven.

Stabilization Bake

48 hrs minimum @ +150 C M883, Method 1008 TC B

Thermal Shock

M883, Method 1011, TC A

Temperature Cycling

M883, Method 1010, TC B

Constant Acceleration

M883, Method 2001, TC A (5000 gs, Y1 Axis only)

Seal Test (fine & gross)

100% Method 1014, (TC A1 for fine leak and TC C for gross leak)

PIND

M883, Method 2020, TC B

Electrical Test

Frequency, Output levels, Input Current@ +25 C

Burn-In (Powered with load)

+125 C for 240 hours

Electrical Test

Frequency, Output levels, Input Current

@ +25°C & Temp Extremes listed on the Electrical Specification

Radiographic

M883, Method 2012 class S

Group A

100%

Group B (30 day Aging @ +70 C)

100%

External visual

883 Method 2009

3.3.1 All piece parts shall be derived from lots that meet the element evaluation requirements of MIL-PRF38534, Class K, with the following exceptions:

Page 5

QTV714, QTV715 and QTV716

Sine-Wave 24 Flat Pack

REV.

Q-TECH Corporation

10150 W. Jefferson Blvd.

Culver City, CA 90232

SIZE

A

CAGE NO.

51774

Sheet 5 of 7

1.0

Active elements

a) Visual inspection of silicon on sapphire microcircuits.

Semicircular crack(s) or multiple adjacent

cracks, not in the active area, starting and terminating at the edge of the die are acceptable.

Attached (chip in place) sapphire is nonconductive material and shall not be considered as foreign

material and will be considered as nonconductive material for all inspection criteria.

b) Subgroup 4, Scanning Electron Microscope (SEM) inspection.

The manufactu rer may allow the die

distributor, at his option, to select two (2) dic e fro m a w a ffle pack (co n tain ing a max imum qua ntit y

of 100 die), visually inspect for the worst case metallization of the 2 dice, and take SEM

photographs of the worst case.

c) Subgroup 5 radiation tests.

Subgroup 5 radiation tests are not required unless otherwise specified

in the detail purchase order.

3.3.2 Processes

- Processes used for manufacturing the VCXO are selected on the basis of their ability to

meet the quality requirements for space High Reliability manufacturing. Travelers or Process Cards are

used in the manufacturing and testing of all of the VCXO Series, and might be available for customer

review. Copies of these Travelers can be provided with the VCXOs at time of shipment if so specified

on the purchase order

.

3.3.3 Interchangeability - Each VCXO shall be interchangeable without using a special selection process.

3.3.4 Product Marking

- Each unit shall be permanently marked with the manufacturer's name or symbol,

part number, lot date code number, and serial number. The unit shall be marked with the outline of

an equilateral triangle near pin 1 to show that it contains devices which are sensitive to electrostatic

discharge.

3.4 Parts Program

Devices delivered to this specification represent the standardized Parts, Materials and Processes (PMP)

Program developed, implemented and certified for advanced applications and extended environments.

3.4.1 Quartz Crystal Resonator

- The crystal resonator used shall be constructed using a 4-point mount

premium synthetic swept Quartz and procured to Q-TECH SCD. (For the Engineering models, nonswept quartz may be used).

3.5 Traceability Requirements

Material, element and process traceability requirements shall be as specified by MIL-PRF-38534 for

Class K hybrids.

3.6 Data

3.6.1. Design Documentation

- When required by the purchase order, design, topography, process and flow

charts for all assembly/inspection and test operation for devices to be supplied under this specification

on the initial procurement shall be established and shall be available in-plant for review by the

procuring activity upon request. This design documentation shall be sufficient to depict the physical

and electrical construction of the devices supplied under the specification and shall be traceable to the

specific parts, drawings or part type numbers to which it applies, and to the production lot(s) and

inspection lot codes under which devices are manufactured and tested so that revisions can be

identified.

3.6.2. Technical Data Package

- When required by the purchase order, the following design documentation

and information is deliverable 30 days prior to the start of production. The Technical Data Package

shall consist of the following:

Page 6

QTV714, QTV715 and QTV716

Sine-Wave 24 Flat Pack

REV.

Q-TECH Corporation

10150 W. Jefferson Blvd.

Culver City, CA 90232

SIZE

A

CAGE NO.

51774

Sheet 6 of 7

1.0

a) Assembly drawing(s).

b) All electrical schematics and drawings

not considered proprietary

.

c) The assembly and screening travelers to be used on-line to manufacture the devices supplied to

this specification.

d) Parts and materials list.

3.7 Test Report

A test report is supplied with each shipment of oscillators and includes the following information, as a

minimum:

a) A Certificate of Conformance to all specifications and purchase order requirements. As a minimum,

the Certificate of Conformance shall include the following information:

Purchase order number.

Applicable part number.

Manufacturers lot number.

Lot date code.

b) Parts and materials traceability information.

c) Certificate of crystal sweeping.

d) Manufacturing lot traveler.

e) Screening attributes and variables data as applicable.

f) Quality conformance inspection attributes and variables data as applicable.

g) Radiographic inspection negatives.

3.8 Engineering Models

Engineering Models are fit, form, and function representative of Flight Models and of commercial

construction using commercial parts of same generic type as Flight Models. Completed oscillators are

not screened.

NOTES:

This oscillator is offered to meet the specifications above and is not guaranteed to meet any other

requirements.

Page 7

QTV714, QTV715 and QTV716

Sine-Wave 24 Flat Pack

REV.

Q-TECH Corporation

10150 W. Jefferson Blvd.

Culver City, CA 90232

SIZE

A

CAGE NO.

51774

Sheet 7 of 7

1.0

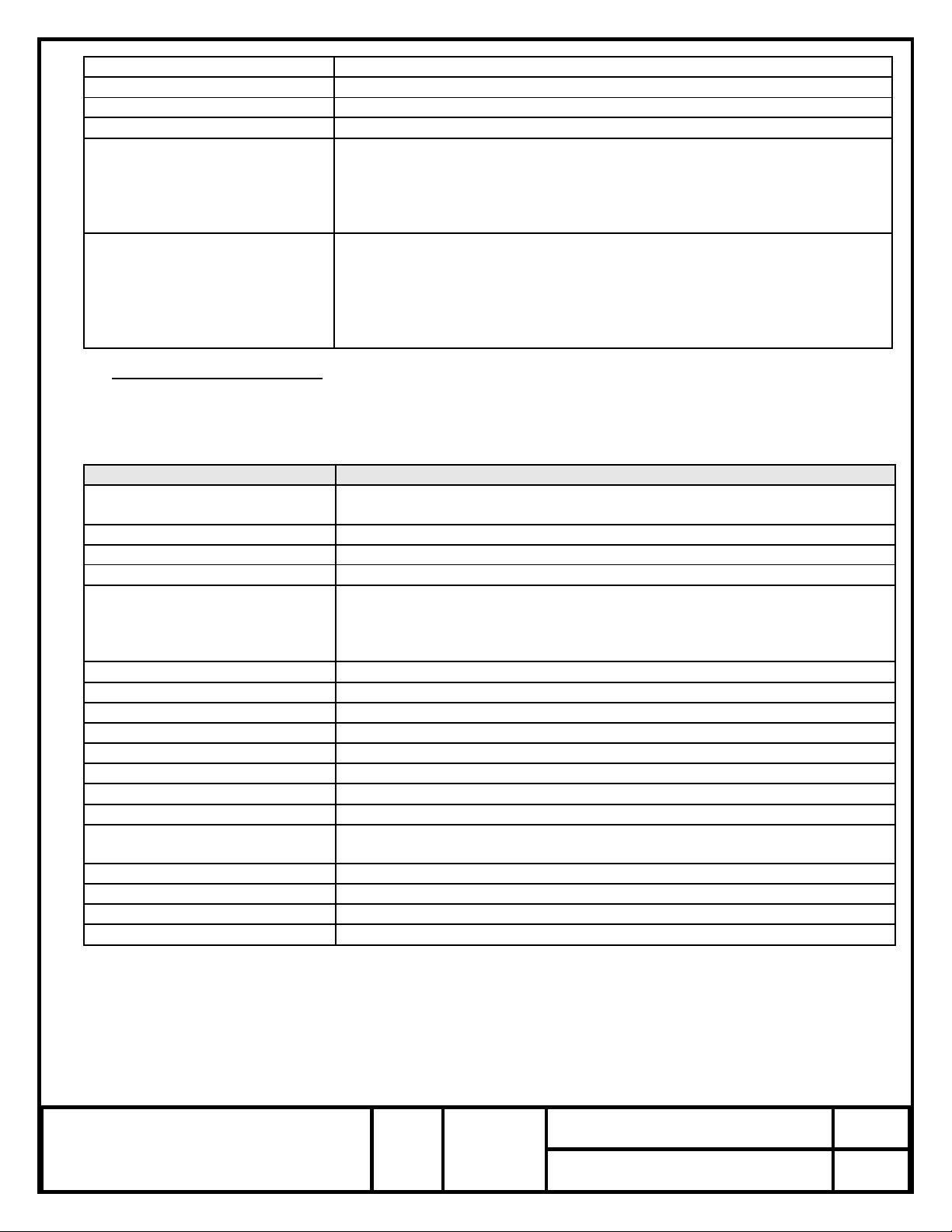

22X .100 TYP.

12

24

13

1

Q-TECH

PART NUMBER

FREQUENCY

D/C

USA

S/N

.210 MAX.

ESD SYMBOL FOR PIN NO. 1

24X .010 ± .002

.975 MAX.

1.275 MAX.

NON-ACCUMULATIVE

24X .015 ±.003

2X 1.100

24X .072 ± .007

2X .500 MIN.

2X .085 REF.

▀ PART NUMBER GENERATION

SERIES

Output type and

supply voltage

TEMPERATURE RANGE (°C)/ Max. Overall

Stability/ Min. Frequency Pulling

and Voltage Control Range

Level

FREQUENCY

(MHz)

4: SINE WAVE +3dBm ..5V

N: 0.....+50°C

±25 ppm

±50 ppm Vc=0.5..4.5V

E: Eng. Model

10……..350

5: SINE WAVE +7dBm ….12V

P: 0.....+70°C

±35 ppm

±70 ppm Vc=0.5..6.0V

M: Flight Model

6: SINE WAVE +7dBm ..15V

Q: 20…+70°C

±40 ppm

±80 ppm Vc=0.5..6.0V

R: 40…+85°C

±45 ppm

±90 ppm Vc=0.5..6.0V

U: -55.+125°C

±65 ppm

±130 ppm Vc=0.5..6.0V

QTV71:

24 Pin

Flat Pack

(See note 1 below)

1. Variations from standard specification are available, please contact factory.

EXAMPLE:

QTV715URM-100.000000 would be a Flight Model

version HF VCXO, 24 pin SMD flat pack, sine-wave 12 volts, overall

frequency stability (Overall Frequency stability (including operating temperature, ±5% Load Change, ±5% Supply

Voltage change, 10 year aging, and radiation) ±45 ppm over -40…+85°C, @ 50 MHz with frequency pulling range from

minimum of 90 ppm below center frequency at 0.5V to a minimum of 90 ppm above center frequency at 6V.

QTV715URE-100.000000

would be a Engineering Model version HF VCXO, 24 pin SMD flat pack, sine-wave 12 volts,

overall frequency stability (including operating temperature, ±5% Load Change, ±5% Supply Voltage change, 10 year

aging, and radiation)) ±45 ppm over -40…+85°C, @ 50 MHz with frequency pulling range from minimum of 90 ppm below

center frequency at 0.5V to a minimum of 90 ppm above center frequency at 6V.

FIGURE 1 INTERFACE CONTROL DRAWING

24 pin Flat-Pack

PIN NO.

DESIGNATION

1

Control Voltage

2 - 11

NC

12

Ground/Case

13

RF Output

14 - 23

NC

24

Supply Voltage

NOTES:

• Dimensions are in inches.

• Lead numbers are for reference only and

are not marked on the unit.

• A triangle symbol is marked on the corner of

the package to indicate Pin 1

• All pins with NC function may not be

connected as external tie or connections

(Pins may be connected internally).

Loading...

Loading...