Page 1

Q-TECH

0.170 MAX.

0.018±.003

(0.46±0.08)

(4.318 MAX.)

0.550±.0.005

(13.970±0.13)

0.350±0.005

(8.89±0.13)

0.100±.005

0.200±.005

(2.54±0.13)

(5.080±0.13)

(7.620±0.13)

(9.525 max.)

P/N

FREQ.

D/C S/N

Q-TECH

4

3

1

2

.130 MAX.

0.300±.005

0.375 max.

3.302 MAX.

0.39

(9.91)

0.13

(3.30)

0.13

(3.30)

0.07

(1.78)

0.20

(5.08)

0.27

(6.86)

COR PORATI ON

Description

Q-Tech’s surface-mount QT78 Series oscillators consist

of an IC 5Vdc, 3.3Vdc, 2.5Vdc, 1.8Vdc clock square

wave generator and a round AT high-precision quartz

crystal built in a rugged surface-mount ceramic J-lead

miniature package.

QT78 SERIES

HIGH RELIABILITY MINIATURE CRYSTAL CLOCK OSCILLATORS

1.8 to 5.0Vdc - 15kHz to 150MHz

Features

• Made in the USA

• ECCN: EAR99

• DFARS 252-225-7014 Compliant:

Electronic Component Exemption

• USML Registration # M17677

• Available as QPL MIL-PRF-55310/27, /28, and /30

• Broad frequency range from 15kHz to 150MHz

• Rugged 4 point mount design for high shock and

vibration

• ACMOS, HCMOS, TTL or LVHCMOS logic

• Tri-State Output Option (D)

• Hermetically sealed ceramic SMD package

• Fundamental and 3rd Overtone designs

• Low phase noise

• Custom designs available

• Q-Tech does not use pure lead or pure tin in its

products

• RoHS compliant

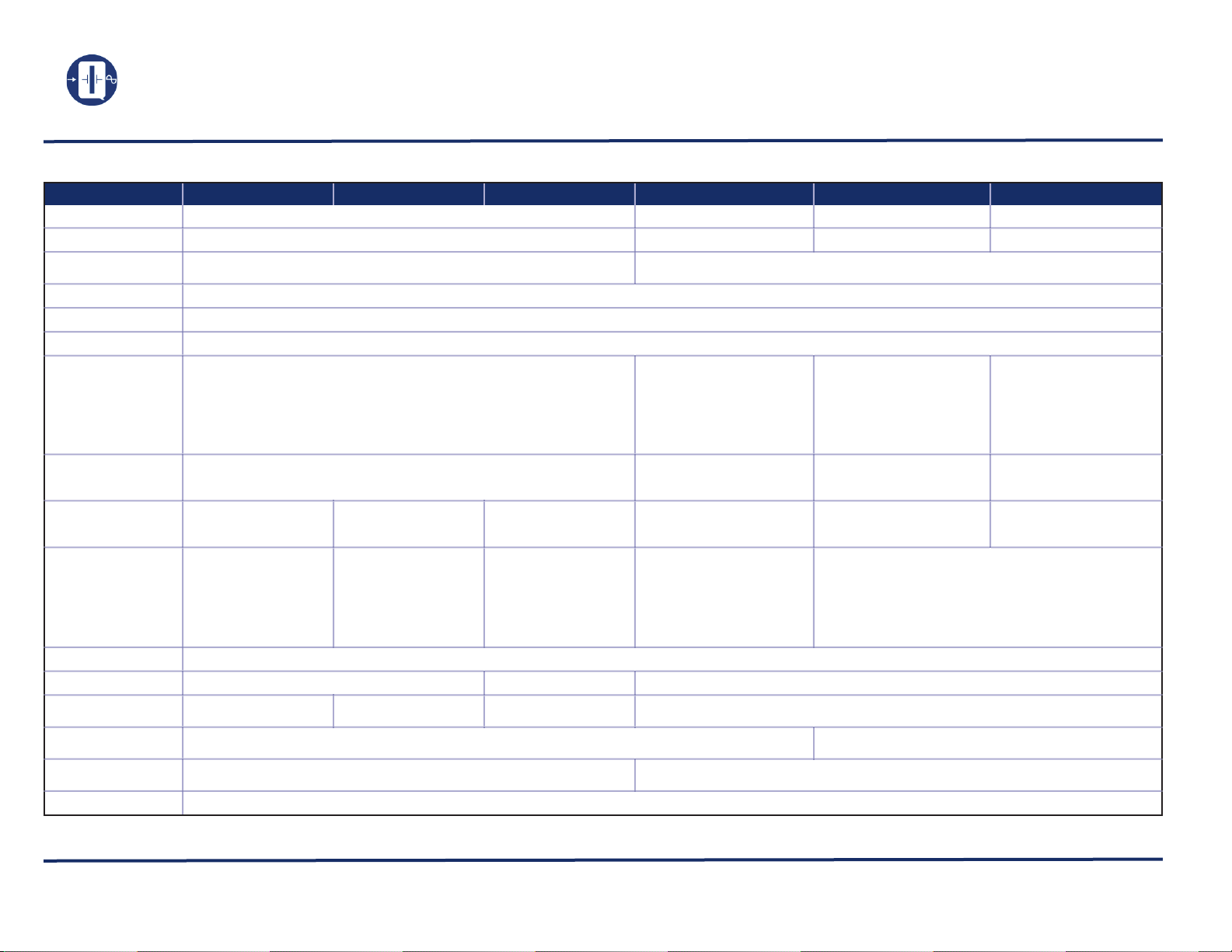

Package Specifications and Outline

Pin No.

1

2

3

4

Function

TRISTATE or NC

GND/CASE

OUTPUT

VDD

Applications

• Designed to meet today’s requirements for low

voltage applications

• Wide military clock applications

• Smart munitions

• Navigation

• Industrial controls

• Microcontroller driver

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-t ech.c om

QT78 (Revision H, January 2011) (ECO #10085)

Dimensions are in inches (mm)

Package Information

• Package material: 90% AL2O

• Lead material: Kovar

• Lead finish: Gold Plated: 50μ ~ 80μ inches

Nickel Underplate: 100μ ~ 250μ inches

• Weight: 1.1g typ., 3.0g max.

3

1

Page 2

Q-TECH

COR PORATI ON

Electrical Characteristics

QT78 SERIES

HIGH RELIABILITY MINIATURE CRYSTAL CLOCK OSCILLATORS

1.8 to 5.0Vdc - 15kHz to 150MHz

Parameters QT78AC

Output frequency range (Fo)

Supply voltage (Vdd) 5.0Vdc ± 10% 3.3Vdc ± 10%

Maximum Applied Voltage

(Vdd max.)

Frequency stability (∆F/∆T)

Operating temperature (Topr)

Storage temperature (Tsto)

25 mA max. - 16MHz ~ < 32MHz

Operating supply current

(Idd) (No Load)

Symmetry

(50% of ouput waveform or

1.4Vdc for TTL)

Rise and Fall times

(with typical load)

Output Load

6ns max. - Fo < 30MHz

3ns max. - Fo ≥ 30 - 85MHz

(between 10% to 90%)

15pF // 10kohms

50pF max. or 10TTL

for (Fo < 60MHz)

30pF max. or 6TTL

for (Fo ≥ 60MHz)

35 mA max. - 32MHz ~ < 60MHz

45 mA max. - 60MHz ~ ≤ 85MHz

45/55% max. - 15kHz ~ < 15MHz

QT78HC

15kHz — 85.000MHz (*) 15kHz — 150.000MHz (*)

-0.5 to +7.0Vdc -0.5 to +5.0Vdc

20 mA max. - 15kHz ~ < 16MHz

40/60% max. - 15 ~ ≤ 85MHz

(Tighter symmetry available)

7ns max. - Fo < 30MHz

3ns max. - Fo ≥ 30 - 85MHz

(between 10% to 90%)

15pF // 10kohms

(2LSTTL)

QT78T

5ns max. - Fo < 30MHz

3ns max. - Fo ≥ 30 - 85MHz

(between 0.8V to 2.0V)

10TTL (Fo < 60MHz)

6TTL (Fo ≥ 60MHz)

QT78L

See Option codes

See Option codes

-62ºC to + 125ºC

3 mA max. - 15kHz ~ < 500kHz

6 mA max. - 500kHz ~ < 16MHz

10 mA max. - 16MHz ~ < 32MHz

20 mA max. - 32MHz ~ < 60MHz

30 mA max. - 60MHz ~ < 100MHz

40 mA max. - 100MHz ~ < 130MHz

50 mA max. - 130MHz ~ ≤150MHz

45/55% max. - 15kHz ~ < 15MHz

40/60% max. - 15 ~ ≤ 150MHz

(Tighter symmetry available)

6ns max. - 15kHz ~ < 40MHz

3ns max. - 40 ~ ≤ 150MHz

(between 10% to 90%)

15pF // 10kohms

(30pF max. for F ≤ 50MHz)

QT78N

125.000kHz — 133.000MHz

2.5Vdc ± 10%

3 mA max. - 125kHz ~ < 500kHz

6 mA max. - 500kHz ~ < 40MHz

15 mA max. - 40MHz ~ < 60MHz

25 mA max. - 60MHz ~ < 85MHz

35 mA max. - 85MHz ~ ≤ 133MHz

45/55% max. - 125kHz ~ < 15MHz

40/60% max. - 15 ~ ≤ 133MHz

(Tighter symmetry available)

5ns max. - 125kHz ~ < 40MHz

3ns max. - 40 ~ ≤ 133MHz

(between 10% to 90%)

15pF // 10kohms

QT78R

125.000kHz — 100.000MHz

1.8Vdc ± 10%

4 mA max. - 125kHz ~ < 40MHz

10 mA max. - 40MHz ~ < 50MHz

20 mA max. - 50MHz ~ < 85MHz

25 mA max. - 85MHz ~ ≤ 100MHz

45/55% max. - 125kHz~ < 15MHz

40/60% max. - 15 ~ ≤ 100MHz

(Tighter symmetry available)

5ns max. - 125kHz ~ < 40MHz

3ns max. - 40 ~ ≤ 100MHz

(between 10% to 90%)

Start-up time (Tstup) 5ms max.

Output voltage (Voh/Vol)

Output Current (Ioh/Iol)

Enable/Disable

Tristate function Pin 1

Jitter RMS 1σ (at 25ºC)

Aging (at 70ºC)

0.9 x Vdd min.; 0.1 x Vdd max. 2.4V min.; 0.4V max.

± 24mA max.

± 8mA max.

VIH ≥ 2.2V Oscillation;

VIL ≤ 0.8V High Impedance

8ps typ. - < 40MHz

5ps typ. - ≥ 40MHz

(*) Frequency as low as 1kHz without tristate function available. Contact Q-Tech for details.

-1.6 mA/TTL

+40 µA/TTL

± 5ppm max. first year / ± 2ppm max. per year thereafter

0.9 x Vdd min.; 0.1 x Vdd max.

± 4mA max.

VIH ≥ 0.7 x Vdd Oscillation;

VIL ≤ 0.3 x Vdd High Impedance

15ps typ. - < 40MHz

8ps typ. - ≥ 40MHz

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-t e ch.co m

QT78 (Revision H, January 2011) (ECO #10085)

2

Page 3

Q-TECH

COR PORATI ON

Ordering Information

Sample part number

QT78HCD9M-85 . 0 0 0 M Hz

QT78 HC D9M-85.000MHz

5.0Vdc

QT78 SERIES

HIGH RELIABILITY MINIATURE CRYSTAL CLOCK OSCILLATORS

1.8 to 5.0Vdc - 15kHz to 150MHz

3.3Vdc

Sample part number

QT78LD6M-150 . 0 0 0 M Hz

QT78 LD6M-150.000MHz

T = Standard

S = Solder Dip (*)

Logic:

AC = ACMOS

HC = HCMOS

T = TTL

Tristate Option

Blank = No Tristate

D = Tristate

Frequency vs. Temperature Code:

1 = ± 100ppm at 0ºC to +70ºC

4 = ± 50ppm at 0ºC to +70ºC

5 = ± 25ppm at -20ºC to +70ºC

6 = ± 50ppm at -55ºC to +105ºC

9 = ± 50ppm at -55ºC to +125ºC

10 = ± 100ppm at -55ºC to +125ºC

11 = ± 50ppm at -40ºC to +85ºC

12 = ± 100ppm at -40ºC to +85ºC

14 = ± 20ppm at -20ºC to +70ºC

15 = ± 25ppm at -40ºC to +85ºC

Output frequency

Blank=No Screening

M=Per MIL-PRF-55310, Level B

2.5Vdc

Sample part number

QT78ND12M-13 3 . 0 0 0 MHz

QT78 ND12 M-133.000MHz

T = Standard

S = Solder Dip (*)

Output frequency

Screening Options:

T = Standard

S = Solder Dip (*)

Tristate Option

Blank = No Tristate

D = Tristate

Frequency vs. Temperature Code:

1 = ± 100ppm at 0ºC to +70ºC

4 = ± 50ppm at 0ºC to +70ºC

5 = ± 25ppm at -20ºC to +70ºC

6 = ± 50ppm at -55ºC to +105ºC

9 = ± 50ppm at -55ºC to +125ºC

10 = ± 100ppm at -55ºC to +125ºC

11 = ± 50ppm at -40ºC to +85ºC

12 = ± 100ppm at -40ºC to +85ºC

14 = ± 20ppm at -20ºC to +70ºC

15 = ± 25ppm at -40ºC to +85ºC

Output frequency

Blank=No Screening

M=Per MIL-PRF-55310, Level B

1.8Vdc

Sample part number

QT78RD1M-100 . 0 0 0 M Hz

QT78 RD1 M-100.000MHz

T = Standard

S = Solder Dip (*)

Output frequency

Screening Options:

Tristate Option

Blank = No Tristate

D = Tristate

Frequency vs. Temperature Code:

1 = ± 100ppm at 0ºC to +70ºC

4 = ± 50ppm at 0ºC to +70ºC

5 = ± 25ppm at -20ºC to +70ºC

6 = ± 50ppm at -55ºC to +105ºC

9 = ± 50ppm at -55ºC to +125ºC

10 = ± 100ppm at -55ºC to +125ºC

11 = ± 50ppm at -40ºC to +85ºC

12 = ± 100ppm at -40ºC to +85ºC

14 = ± 20ppm at -20ºC to +70ºC

15 = ± 25ppm at -40ºC to +85ºC

Screening Options:

Blank=No Screening

M=Per MIL-PRF-55310, Level B

Tristate Option

Blank = No Tristate

D = Tristate

Frequency vs. Temperature Code:

1 = ± 100ppm at 0ºC to +70ºC

4 = ± 50ppm at 0ºC to +70ºC

5 = ± 25ppm at -20ºC to +70ºC

6 = ± 50ppm at -55ºC to +105ºC

9 = ± 50ppm at -55ºC to +125ºC

10 = ± 100ppm at -55ºC to +125ºC

11 = ± 50ppm at -40ºC to +85ºC

12 = ± 100ppm at -40ºC to +85ºC

14 = ± 20ppm at -20ºC to +70ºC

15 = ± 25ppm at -40ºC to +85ºC

Screening Options:

Blank=No Screening

M=Per MIL-PRF-55310, Level B

Frequency stability vs. temperature codes may not be available in all frequencies.

For Non-Standard requirements, contact Q-Tech Corporation at Sales@Q-Tech.com

Packaging Options Other Options Available For An Additional Charge

• Standard packaging in anti-static plastic tube (60pcs/tube)

• Tape and Reel (1,000pcs/reel) is available for an additional

charge.

Specifications subject to change without prior notice.

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-t ech.c om

QT78 (Revision H, January 2011) (ECO #10085)

• (*) Hot Solder Dip Sn60 per MIL-PRF 55310

• P. I. N. D. test

(MIL-STD 883, Method 2020)

3

Page 4

QT78 SERIES

0 20 40 60 80 100 120 140 160

180

200 220 240 260

280

300 320 340 360 380 400 420 Time (s)

25

50

75

100

125

150

175

200

225

250

TEMP(*C)

0

60s min.

120s max.

60s min.

120s max.

225º min.

240º max.

60s min.

150s max.

240º

Ramp down (6ºC/s Max)

Ramp up (3ºC/s Max)

TYPICAL REFLOW PROFILE FOR Sn-Pb ASSEMBLY

FEEDING (PULL) DIRECTION

ø13.0±0.5

2.5

4.80±0.1

5º MAX

ø1.5

2.0

1.75±0.1

0.3±.005

ø1.5

2.0±0.1

5.5±0.1

10.01±0.1

4.0±0.1

ø178±1orø330±1

26

24.0±0.3

16±0.1

14.53

±0.1

120º

Q-TECH

COR PORATI ON

Reflow Profile Embossed Tape and Reel Information For QT78

The five transition periods for the typical reflow process are:

• Preheat

• Flux activation

• Thermal equalization

• Reflow

• Cool down

HIGH RELIABILITY MINIATURE CRYSTAL CLOCK OSCILLATORS

1.8 to 5.0Vdc - 15kHz to 150MHz

Environmental Specifications

Q-Tech Standard Screening/QCI (MIL-PRF55310) is available for all of our QT78 Products. Q-Tech can also customize screening

and test procedures to meet your specific requirements. The QT78 product is designed and processed to exceed the following test

conditions:

Temperature cycling MIL-STD-883, Method 1010, Cond. B

Constant acceleration MIL-STD-883, Method 2001, Cond. A, Y1

Seal: Fine and Gross Leak MIL-STD-883, Method 1014, Cond. A and C

Burn-in 160 hours, 125°C with load

Aging 30 days, 70°C, ±1.5ppm max

Vibration sinusoidal MIL-STD-202, Method 204, Cond. D

Shock, non operating MIL-STD-202, Method 213, Cond. I (See Note 1)

Thermal shock, non operating MIL-STD-202, Method 107, Cond. B

Ambient pressure, non operating MIL-STD-202, 105, Cond. C, 5 minutes dwell time minimum

Resistance to solder heat MIL-STD-202, Method 210, Cond. B

Moisture resistance MIL-STD-202, Method 106

Terminal strength MIL-STD-202, Method 211, Cond. C

Resistance to solvents MIL-STD-202, Method 215

Solderability MIL-STD-202, Method 208

ESD Classification MIL-STD-883, Method 3015, Class 1 HBM 0 to 1,999V

Moisture Sensitivity Level J-STD-020, MSL=1

Note 1: Additional shock results successfully passed on 16MHz, 40MHz, and 80MHz

QT78 (Revision H, January 2011) (ECO #10085)

Dimensions are in mm. Tape is compliant to EIA-481-A.

Reel size vs. quantity:

Reel size (Diameter in mm)

178

330

Environmental Test Test Conditions

• Shock 850g peak, half-sine, 1 ms duration (MIL-STD-202, Method 213, Cond. D modified)

• Shock 1,500g peak, half-sine, 0.5ms duration (MIL-STD-883, Method 2002, Cond. B)

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-t ech.c om

Please contact Q-Tech for higher shock requirements

Qty per reel (pcs)

250

1,000

4

Page 5

Q-TECH

Vdd

GND

0.1xVdd

0.9xVdd

VOH

VOL

Tr Tf

TH

T

0.5xVdd

SYMMETRY = x 100%

TH

T

-

-

Output

Ground

4

3

2

0.1µF

15pF

1

Tristate Function

Power

supply

10k

mA

Vdc

+

+

+

(*)

or

0.01µF

QT78

(*) CL includes probe and jig capacitance

Typical test circuit for CMOS logic

Frequency-Temperature Curves QT78RD-70MHz 1.8Vdc

-40

-30

-20

-10

10

20

30

40

-55 -50 -45 -40 -35 -30 -25 -20 -15 -10 -5 0510 15 20 25 30 35

Temp (ºC)

PP M

40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125

0

45º 45º

Hybrid Case

Substrate

Die

D/A epoxy

D/A epoxy

Heat

Die

R1

D/A epoxy

Substrate

D/A epoxy

Hybrid Case

R2 R3 R4 R5

JA JC CA

Die

T

T

T

C

A

J

CA

JC

COR PORATI ON

QT78 SERIES

HIGH RELIABILITY MINIATURE CRYSTAL CLOCK OSCILLATORS

1.8 to 5.0Vdc - 15kHz to 150MHz

Output Waveform (Typical)

Frequency vs. Temperature Curve

Test Circuit

The Tristate function on pin 1 has a built-in pull-up resistor typical 50kΩ, so it can

be left floating or tied to Vdd without deteriorating the electrical performance.

Thermal Characteristics

The heat transfer model in a hybrid package is described in

figure 1.

Heat spreading occurs when heat flows into a material layer of

increased cross-sectional area. It is adequate to assume that

spreading occurs at a 45° angle.

The total thermal resistance is calculated by summing the

thermal resistances of each material in the thermal path

between the device and hybrid case.

RT = R1 + R2 + R3 + R4 + R5

The total thermal resistance RT (see figure 2) between the heat

source (die) to the hybrid case is the Theta Junction to Case

(Theta JC) in°C/W.

• Theta junction to case (Theta JC) for this product is 30°C/W.

• Theta case to ambient (Theta CA) for this part is 100°C/W.

• Theta Junction to ambient (Theta JA) is 130°C/W.

Maximum power dissipation PD for this package at 25°C is:

• PD(max) = (TJ (max) – TA)/Theta JA

• With TJ = 175°C (Maximum junction temperature of die)

• PD(max) = (175 – 25)/130 = 1.15W

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-t ech.c om

QT78 (Revision H, January 2011) (ECO #10085)

(Figure 1)

(Figure 2)

5

Page 6

Q-TECH

COR PORATI ON

Period Jitter

As data rates increase, effects of jitter become critical with

its budgets tighter. Jitter is the deviation of a timing event of

a signal from its ideal position. Jitter is complex and is

composed of both random and deterministic jitter

components. Random jitter (RJ) is theoretically unbounded

and Gaussian in distribution. Deterministic jitter (DJ) is

bounded and does not follow any predictable distribution.

DJ is also referred to as systematic jitter. A technique to

measure period jitter (RMS) one standard deviation (1σ) and

peak-to-peak jitter in time domain is to use a high sampling

rate (>8G samples/s) digitizing oscilloscope. Figure shows

an example of peak-to-peak jitter and RMS jitter (1σ) of a

QT78AC-24MHz, at 5.0Vdc.

QT78 SERIES

HIGH RELIABILITY MINIATURE CRYSTAL CLOCK OSCILLATORS

1.8 to 5.0Vdc - 15kHz to 150MHz

Phase Noise and Phase Jitter Integration

RMS jitter (1σ): 5.37ps Peak-to-peak jitter: 43ps

Phase noise is measured in the frequency domain, and is expressed as a ratio of signal power to noise power measured in a 1Hz

bandwidth at an offset frequency from the carrier, e.g. 10Hz, 100Hz, 1kHz, 10kHz, 100kHz, etc. Phase noise measurement is made

with an Agilent E5052A Signal Source Analyzer (SSA) with built-in outstanding low-noise DC power supply source. The DC source

is floated from the ground and isolated from external noise to ensure accuracy and repeatability.

In order to determine the total noise power over a certain frequency range (bandwidth), the time domain must be analyzed in the

frequency domain, and then reconstructed in the time domain into an rms value with the unwanted frequencies excluded. This may be

done by converting L(f) back to Sφ(f) over the bandwidth of interest, integrating and performing some calculations.

Symbol

∫L(f)

Sφ (f)=(180/Π)x√2 ∫L(f)df

RMS jitter = Sφ (f)/(fosc.360°) Jitter(in seconds) due to phase noise. Note Sφ (f) in degrees.

Integrated single side band phase noise (dBc)

Spectral density of phase modulation, also known as RMS phase error (in degrees)

Definition

The value of RMS jitter over the bandwidth of interest, e.g. 10kHz to 20MHz, 10Hz to 20MHz, represents 1 standard deviation of

phase jitter contributed by the noise in that defined bandwidth.

Figure below shows a typical Phase Noise/Phase jitter of a QT78AC6, 5.0Vdc, 80MHz clock at offset frequencies 10Hz to 5MHz, and

phase jitter integrated over the bandwidth of 12kHz to 1MHz.

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-t ech.c om

QT78 (Revision H, January 2011) (ECO #10085)

6

Loading...

Loading...