Page 1

Service Bulletin

Title: WideLine rigging hardware torque adjustment

Bulletin #: WLX0001 Issue Date: December 15, 2008

Passionate About Sound

Description

When subjected to continuous or severe vibration during transport, it is possible for some of the screws attaching the rigging

hardware to the WL3082 and WL212-sw (WideLine 8 Series) or WL2102-w and WL218-sw (WideLine 10 Series) to loosen. Since this

could cause difficulty in rigging or unwanted rattles, QSC recommends that system owners inspect all rigging hardware before the

next system use.

This bulletin applies to enclosures manufactured before December 2007. These units will have serial numbers with a date code of

1107 or earlier (the date code comprises the first four digits of the serial number, in

Models Affected: WideLine 8 Series and WideLine 10 Series

Bulletin Revision: B

Production Range: All before December 2007 (serial number 1107xxxxx and earlier)

mmyy

format).

Instructions

Tools and materials required

• Power drill-screwdriver with adjustable torque clutch

• Torque wrench—set to 60 in-lb (5 ft-lb) or 7 N-m

• Loctite® QuickStix™ 248™ medium-strength threadlocker stick

(for technical information, availability, distribution, etc., go to

http://www.loctite.com)

• T25 and T30 TORX™ bits; Phillips head (cross) bits

Procedure

This is the factory recommended method for tightening the rigging hardware. To access the rigging screws on the WideLine 10

cabinets (WL2102-w and WL218-sw) it will be necessary to remove all rigging knuckles.

CAUTION: The torque required to properly tighten the screws is only 60 in-lb (5 ft-lb) or 7 N-m; this is considerably less than is used

in installing a spark plug or many other common mechanical assemblies. Use an appropriate small torque wrench to ensure that you

neither overtighten nor undertighten the screws.

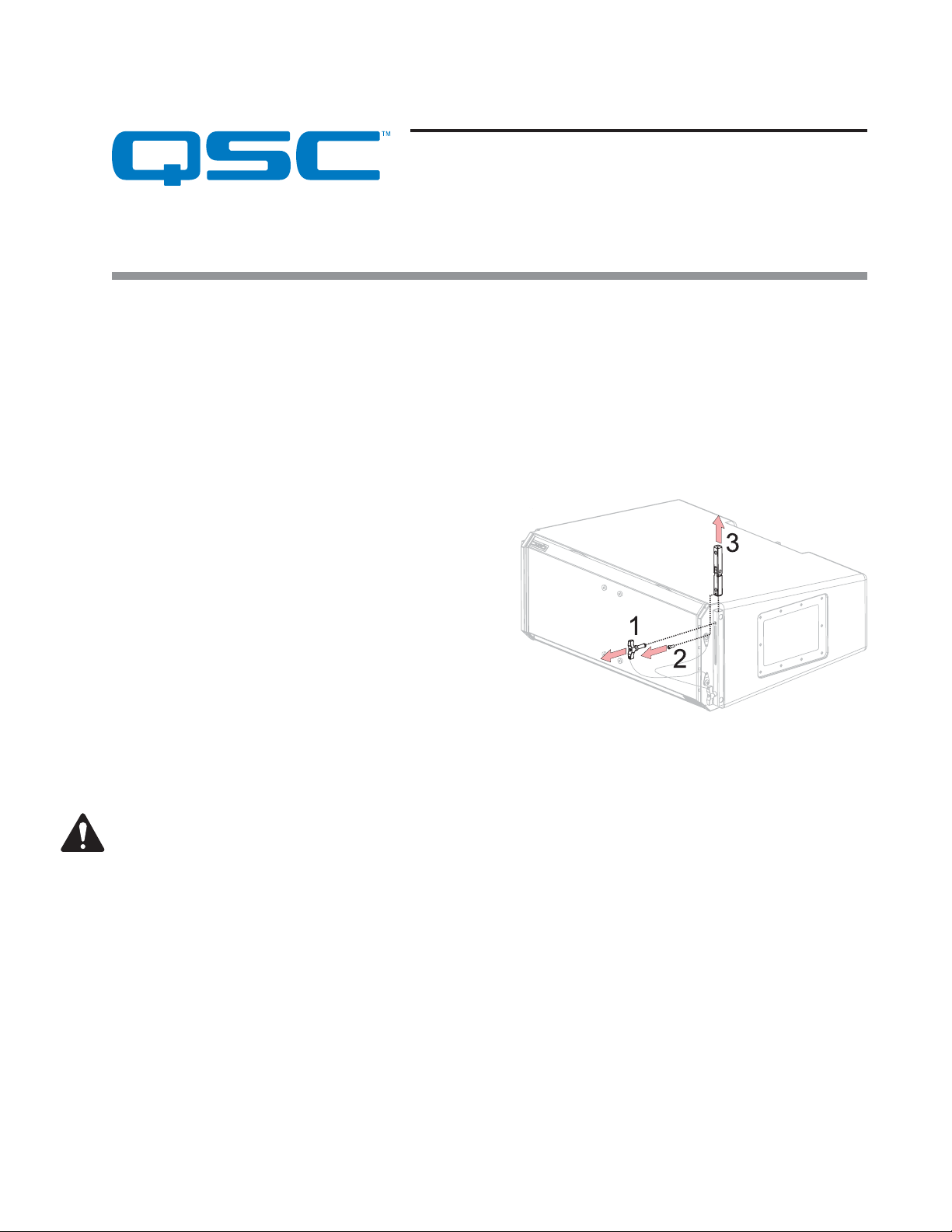

1. WL2102-w and WL218-sw only: Remove the knuckle from the rigging channel by first unscrewing the TORX cap head screw

and then sliding the knuckle out (see Figure 1). Note the orientation of the knuckle, to ensure proper reinstallation at the

completion of this procedure.

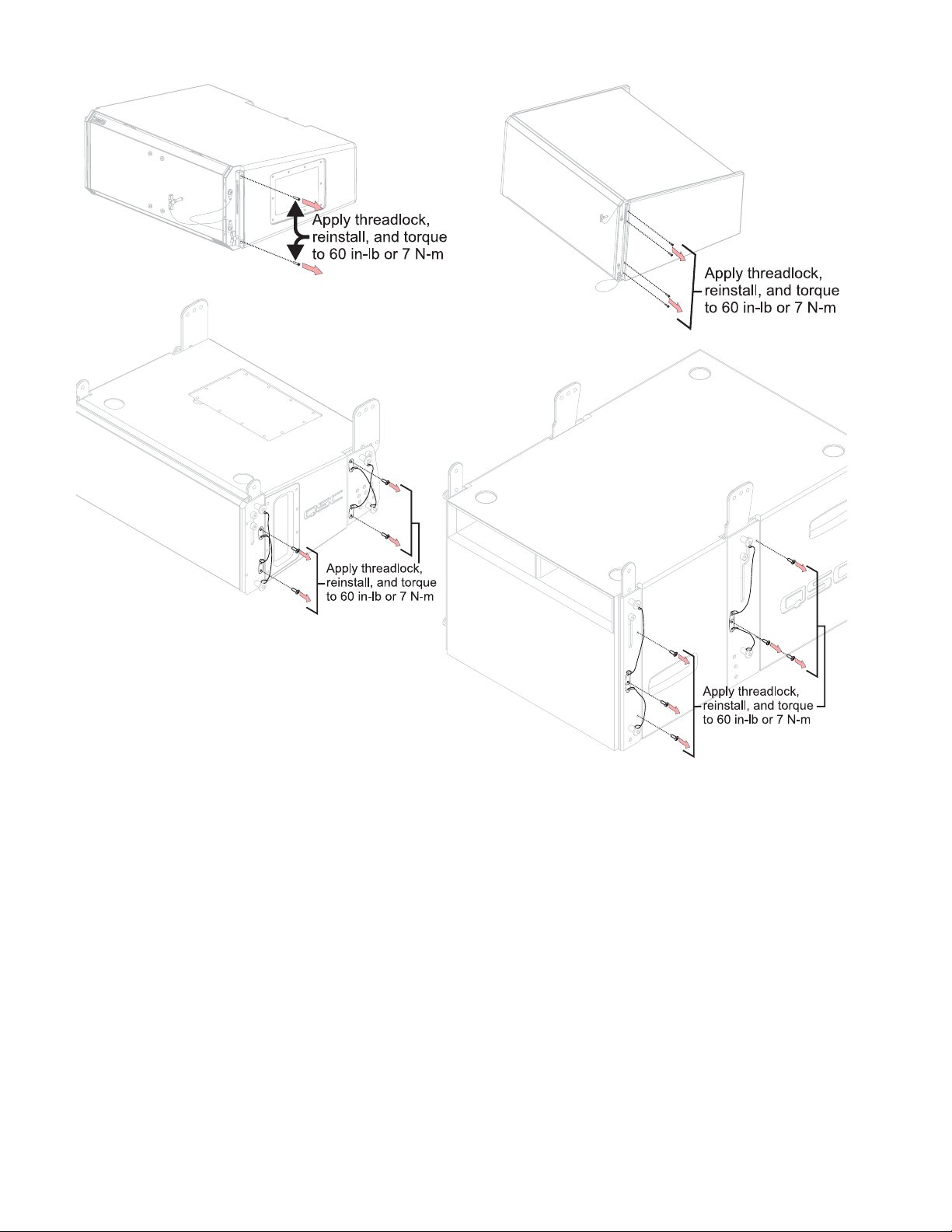

2. All models: Remove the TORX screws that hold the rigging channel or channels to the enclosure (two screws and one channel

on the WL2102-w; four screws and one channel on the WL218-sw; four screws and two channels on the WL3082; six screws

and two channels on the WL212-sw). Apply a dab of Loctite QuickStix 248 to the thread at the end of each screw. See Figure 2.

3. All models: Reinstall the screws through the rigging channel into the enclosure, using a power drill-screwdriver at its

torque setting to lightly secure the screws.

On the WideLine 8 WL3082 and WL212-sw cabinets, attach the anchors of the rigging pin lanyards as shown in Figure 2 when

you reinstall the screws.

Figure 1. Removing the knuckle from the rigging channel.

lowest

Continued on next page

➜

1WLX0001 rev. B

Page 2

WL2102-w

WL3082

WL218-sw

WL212-sw

Figure 2. Removing the rigging channel screws. Apply threadlock,

then reinstall and torque them. The WL2102-w has two screws on

each side, while the WL218-sw and WL3082 have four, and the

WL212-sw has six. On the WideLine 8 cabinets, the anchors of the

rigging pin lanyards must be attached as shown when the screws

are reinstalled.

➜ Continued

4. WL3082 and WL212-sw only: Remove the screws in the rigging bars (three screws on the WL3082; two screws on the

WL212-sw). See Figure 3. These screws may have either TORX or Phillips heads. Apply a dab of Loctite QuickStix 248 to the

thread at the end of each screw. Reinstall and lightly secure the screws using a power drill-screwdriver at its lowest torque

setting.

5. All models: Use the torque wrench, set to 60 in-lb or 7 N-m, to tighten the screws to the proper torque.

6. WL2102-w and WL218-sw only: Reinstall the knuckle into the channel, while making sure its orientation is correct (Figure 4).

Fasten the cap head screw to the knuckle.

7. All models: Repeat steps 1 through 6 with the rigging channel or channels on the other end of the loudspeaker enclosure.

8. WL2102-w and WL218-sw only: Remove all twelve screws on the input plate/rear rigging point and apply Loctite QuickStix

248.

Continued on next page

➜

2 WLX0001 rev. B

Page 3

WL3082

Figure 3. Removing the rigging bar screws. Apply

threadlock, then reinstall and torque them. The WL3082

has three screws on each side, while the WL212-sw has

two.

Figure 4. WL2102-w and

WL218-sw only: Correct

orientation of the knuckle

for reinstallation.

WL212-sw

Figure 5. Removing the 12 rear angle plate screws. Apply threadlock,

then reinstall and torque them.

➜ Continued

9. WL2102-w and WL218-sw only: Reinstall the screws using a power drill-screwdriver at its lowest torque setting to lightly

secure the screws. Torque all of them to 60 in-lb or 7 N-m (Figure 5).

Quality review: Testing rigging hardware

All models: Rig the boxes together as they will be hung. Verify that all the parts are correctly oriented and tightly secured as

described in the procedure above (including the two front tubes and the rear angle plates). Vary the splay of each box to verify that

the knuckles are properly installed.

Regular inspection

All models: QSC recommends that the rigging hardware and attachments be inspected for damage and tightness before every lift.

Secure all loose components and replace any damaged parts before suspending the enclosure.

Loctite is a registered trademark, and QuickStix and 248 are trademarks, of the Henkel Corporation.

TORX is a trademark of Camcar LLC.

3WLX0001 rev. B

Page 4

Contact information

If you need any further information regarding this service procedure, please contact QSC Technical Services at the addresses or numbers below.

Telephone:

Fax:

Skype ID:

E-mail:

Web sites:

Postal and parcel address:

4 WLX0001 rev. B

1-800-772-2834 (within USA only)

+1 (714) 957-7150

+1 (714) 754-6173

qscaudio

tech_support@qscaudio.com

www.qscaudio.com (product info/support)

www.qscstore.com (on-line accessory and replacement component sales)

QSC Audio Products, LLC

Technical Services Group

1665 MacArthur Blvd.

Costa Mesa, CA 92626 USA

Loading...

Loading...