Page 1

RMX™ Series

2RU models

▲▲

▲ RMX 850

▲▲

▲▲

▲ RMX 1450

▲▲

▲▲

▲ RMX 1850HD

▲▲

▲▲

▲ RMX 2450

▲▲

QSC Audio Products, LLC

Costa Mesa, CA 92626 USA

www.qscaudio.com

Technical Service Manual

*TD-000098-00*

TD-000098-00

Rev. C

Page 2

Page 3

Technical Service Manual

RMX 850

RMX 1450

RMX 1850HD

RMX Series

RMX 2450

QSC Audio Products, LLC

Technical Services Group

Phone: 1-800 QSC AUDIO (1-800-772-2834) USA only

+1 (714) 957-7150

Fax: +1 (714) 754-6173

Postal: 1665 MacArthur Blvd.

Costa Mesa, California 92626 USA

E-mail: tech_support@qscaudio.com

Web: http://www.qscaudio.com (product information and support)

http://www.qscstore.com (parts and accessory sales)

Copyright 2001, 2002, 2005, 2008 QSC Audio Products, LLC All rights reserved.

Document # TD-000098-00, Rev. C. Released June 2008.

RMX Series Technical Service Manual (2RU models) 1

TD-000098-00 rev. C

Page 4

RMX Series Performance Specifications

RMX 850 RMX 1450 RMX 1850HD RMX 2450

OUTPUT POWER

in watts

FTC: 20 Hz–20 kHz @ 0.1% THD, both channels driven

8Ω per channel 185 260 350 450

4Ω per channel 280 400 550 650

EIA: 1 kHz @ 0.1% THD, both channels driven

8Ω per channel 200 280 360 500

4Ω per channel 300 450 600 750

1 kHz @ 1% THD, typical, both channels driven

2Ω per channel 430 700 900 1200

Bridge Mono:

8Ω, 20 Hz–20 kHz, 0.1% THD 530 800 1300

8Ω, 1 kHz, 0.1% THD 600 900 1200 1500

4Ω, 1 kHz, 1% THD, typical 830 1400 1800 2400

DYNAMIC HEADROOM 2 dB @ 4Ω

DISTORTION

SMPTE-IM < 0.01% < 0.01% < 0.02% < 0.02%

FREQUENCY RESPONSE 20 Hz–20 kHz, +0/-1 dB

(at 10 dB below rated output power) -3 dB points: 5 Hz and 50 kHz

DAMPING FACTOR > 300 @ 8Ω

NOISE (unweighted 20 Hz to 20 kHz, below rated output) 100 dB 100 dB 100 dB 100 dB

VOLTAGE GAIN 31.6× (30 dB) 40× (32 dB) 46× (33 dB) 50× (34 dB)

INPUT SENSITIVITY, V RMS

full rated power @ 8Ω 1.15v (+3.4 dBu) 1.15v (+3.4 dBu) 1.16v (+3.5 dBu) 1.23v (+4.0 dBu)

INPUT IMPEDANCE 10 kΩ unbalanced

20 kΩ balanced

CONTROLS Front: AC switch, Ch. 1 and Ch. 2 gain

Rear: 10-position DIP switch

INDICATORS POWER: Green LED CLIP: Red LED, 1 per channel

SIGNAL: Yellow LED, 1 per channel

CONNECTORS Input: Active balanced; XLR and ¼" (6.3 mm) TRS, tip and pin 2 positive, and barrier strip

Output: “Touch-Proof” binding posts and Neutrik Speakon™

COOLING Continuously variable speed fan, back-to-front air flow

AMPLIFIER PROTECTION Full short circuit, open circuit, thermal, ultrasonic, and RF protection

Stable into reactive or mismatched loads

LOAD PROTECTION Turn-on/turn-off muting (all models)

AC coupling AC coupling

Triac crowbar (each channel) Triac crowbar (each channel)

OUTPUT CIRCUIT TYPE AB AB H H

AB: Class AB+B complementary linear output

H: Class AB+B complementary linear output with Class H 2-step high efficiency circuit

DIMENSIONS 19.0" (48.3 cm) wide, 3.5" (8.9 cm) tall (2 rack spaces)

15.9" (40 cm) deep (rack mounting to rear support ears)

WEIGHT Shipping: 41 lb. (18.6 kg) 46 lb. (20.9 kg) 50.5 lb. (23 kg) 50.5 lb. (23 kg)

Net: 35 lb. (15.9 kg) 40 lb. (18.2 kg) 44.5 lb. (20.2 kg) 44.5 lb. (20.2 kg)

POWER REQUIREMENTS Available for 120 or 220–240 VAC, 50/60 Hz

1

2

POWER CONSUMPTION

(both channels driven)

Multiply currents by 0.5 for 230V units

1. Typical—Measured with pink noise signal on all channels at 1/8 of full average power. Producing peaks that occasionally reach the amp’s clipping point, this level approximates the maximum operating

level before clipping affects sound quality. These data would be the amp’s typical worst-case current.

2. Full—Measured with pink noise signal on all channels at 1/3 of full average power. Music at this level would typically produce massive clipping. In a class B amplifier, this would be the approximate

point of maximum heat production.

3. Max—Measured with continuous sine wave signal on all channels at a point of slight clipping (1% THD). This represents a “test bench” scenario and does not resemble any real-world usage.

@ 120 VAC

eldI

8

ΩΩΩΩΩ

4

ΩΩΩΩΩ

2

ΩΩΩΩΩ

lacipyT

A5.0

A3A1.4A4.7

A5.4A6.6A5.11

A5.6*A5.9*A71

3

lluF

xaM

8

ΩΩΩΩΩ

4

ΩΩΩΩΩ

2

ΩΩΩΩΩ

eldI

1

2

lacipyT

lluF

A5.0

A7.3A4.5A01

A6A6.9A61

A3.9*A7.41*A52

3

xaM

Typical1Full2Max

0.8 A

Idle

3.9 A 6.9 A 12.6 A

8

ΩΩΩΩΩ

6.1 A 11.2 A 20.7 A

4

ΩΩΩΩΩ

8.7 A 16.6 A* 32 A*

2

ΩΩΩΩΩ

3

8

ΩΩΩΩΩ

4

ΩΩΩΩΩ

2

ΩΩΩΩΩ

eldI

1

2

lacipyT

lluF

A6.0

A4A7.9A4.61

A3.6A6.51A72

A2.9*A32*A14

xaM

3

US patents pending

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

2 QSC Audio Products, LLC

Page 5

Table of Contents

RMX Series Performance Specifications ...................................................................................................................................................... 2

1. Introduction ..................................................................................................................................................................................................... 5

1.1 Restriction of Hazardous Substances Directive (RoHS)................................................................................................................................ 5

1.2 QSC serial numbers ....................................................................................................................................................................................... 5

1.3 Service bulletins ............................................................................................................................................................................................. 5

1.4 The well-equipped service bench .................................................................................................................................................................. 6

1.5 Working with surface-mount components ................................................................................................................................................... 6

1.6 Series description .......................................................................................................................................................................................... 8

1.7 Technical descriptions and theory of operation ........................................................................................................................................... 8

2. Component identification and pinout ..................................................................................................................................................... 11

3. Troubleshooting: Symptoms, causes, & remedies ................................................................................................................................ 13

3.1 Excessive current draw ................................................................................................................................................................................ 13

3.2 Protection, muting, and turn-on/turn-off delay problems ......................................................................................................................... 13

3.3 Faults with signal present ........................................................................................................................................................................... 14

3.4 Instability ...................................................................................................................................................................................................... 14

3.5 Power supply and rail balancing problems ................................................................................................................................................. 15

4. RMX calibration procedures ...................................................................................................................................................................... 16

4.1 Setting bias .................................................................................................................................................................................................. 16

4.2 Setting positive and negative current limits .............................................................................................................................................. 16

5. Servicing RMX amplifiers ........................................................................................................................................................................... 18

5.1 Mechanical disassembly and re-assembly .................................................................................................................................................. 18

6. Replacement parts ....................................................................................................................................................................................... 19

6.1 RMX850 Replacement Parts ....................................................................................................................................................................... 19

6.2 RMX1450 Replacement Parts ..................................................................................................................................................................... 22

6.3 RMX1850HD Replacement Parts ................................................................................................................................................................. 25

6.4 RMX2450 Replacement Parts ..................................................................................................................................................................... 29

7. Schematics and diagrams .......................................................................................................................................................................... 33

7.1 RMX Assembly/Disassembly Diagram 1 of 2

(All models) ................................................................................................................................................................................................. 33

7.2 RMX Assembly/Disassembly Diagram 2 of 2

(All models) ................................................................................................................................................................................................. 34

7.3 RMX 850 Schematic Diagram 1 of 3

Channel 1 ................................................................................................................................................................................................... 35

7.4 RMX 850 Schematic Diagram 2 of 3

Channel 2 ................................................................................................................................................................................................... 36

7.5 RMX 850 Schematic Diagram 3 of 3

Power Supply ............................................................................................................................................................................................. 37

7.6 RMX 1450 Schematic Diagram 1 of 3

Channel 1 ................................................................................................................................................................................................... 38

7.7 RMX 1450 Schematic Diagram 2 of 3

Channel 2 ................................................................................................................................................................................................... 39

7.8 RMX 1450 Schematic Diagram 3 of 3

Power Supply ............................................................................................................................................................................................. 40

7.9 RMX 1850HD Schematic Diagram 1 of 3

Channel 1 ................................................................................................................................................................................................... 41

7.10 RMX 1850HD Schematic Diagram 2 of 3

Channel 2 ................................................................................................................................................................................................... 42

7.11 RMX 1850HD Schematic Diagram 3 of 3

Power Supply ............................................................................................................................................................................................. 43

7.12 RMX 2450 Schematic Diagram 1 of 4

Channel 1 ................................................................................................................................................................................................... 44

RMX Series Technical Service Manual (2RU models) 3

TD-000098-00 rev. C

Page 6

Table of Contents (continued)

7.13 RMX 2450 Schematic Diagram 2 of 4

Channel 2 ................................................................................................................................................................................................... 45

7.14 RMX 2450 Schematic Diagram 3 of 4

Power Supply ............................................................................................................................................................................................. 46

7.15 RMX 2450 Schematic Diagram 4 of 4

Power Supply Revision .............................................................................................................................................................................. 47

7.16 RMX Power Transformer Configurations

March 2007 and later ................................................................................................................................................................................ 48

7.17 RMX 850 Chassis Wiring Diagram ............................................................................................................................................................ 49

7.18 RMX 1450 Chassis Wiring Diagram .......................................................................................................................................................... 50

7.19 RMX 1850HD and RMX 2450 Chassis Wiring Diagram ........................................................................................................................... 51

4 QSC Audio Products, LLC

Page 7

1. Introduction

1.1 Restriction of Hazardous Substances Directive (RoHS)

Since April 2006, all RMX Series amplifiers are manufactured to conform to the European Union’s RoHS Directive, which reduces the

amount of hazardous substances allowed in products for sale within its member nations. In electronic equipment such as audio power

amplifiers, this applies primarily to certain toxic heavy metals, such as lead, which may be present in electronic components, solder, and

other parts.

RoHS-compliant materials

When servicing RoHS-compliant amplifiers, it is important for the service technician to use only RoHS-compliant components and solder

(lead-free). All replacement parts provided by QSC for RoHS-compliant products are certified as RoHS compliant.

RoHS-compliant tools

Soldering irons and desoldering apparatus used on RoHS-compliant products must also not be contaminated by hazardous substances,

such as lead. Therefore, you cannot use the same soldering and desoldering tools for RoHS-compliant products and solder as you do for

non-compliant products and solder. You must either use separate soldering irons, desoldering tools and braid, etc., or at the very least

designate separate tips and braids and use only the appropriate ones. If you contaminate a tip or braid, even inadvertently, by using it on

a non-compliant product or solder, you should no longer use it with RoHS-compliant products or solder.

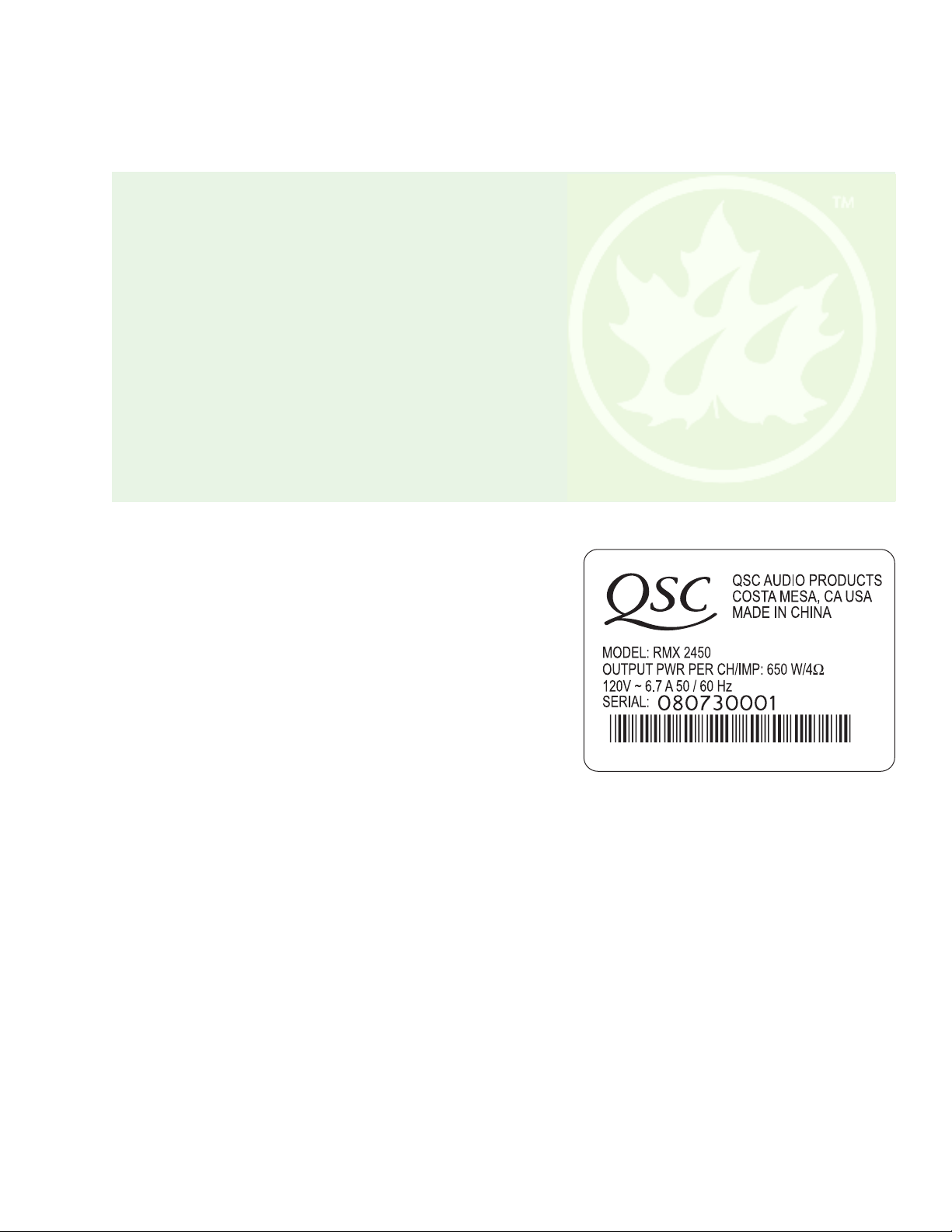

1.2 QSC serial numbers

Serial numbers on QSC RMX series amplifiers are nine digits long. The first

four digits are a manufacturing date code in

are the sequential identifying number for each individual amplifier. For

example, a serial number of 0807xxxxx would indicate that the amplifier was

built in 08/2007, or August 2007. The date code is important for determining

whether an amplifier is subject to a service bulletin, covered by a warranty (in

the absence of original purchase records), etc.

The amplifier’s serial number can be found on a label on the rear panel. The

label also indicates the model number, power rating, 4Ω current draw, and the

AC mains voltage the amplifier was made for.

Certain design changes that the RMX amplifiers have undergone commenced

with a particular date code; for example, the RMX amplifiers with a date code

of 0406 or later conform to the European Union’s RoHS Directive and must be

serviced only with lead-free solder and soldering irons that are not contaminated with lead or other heavy metals covered by the directive.

mmyy

format; the last five digits

Figure 1.1. The label displays two vital pieces of

information: the amplifier’s serial number and

operating voltage

1.3 Service bulletins

Contact QSC Technical Services to make sure you have the most up-to-date service bulletins for RMX Series amplifiers. Service bulletins

may be distributed in hard copy, via fax, and electronically (Adobe Acrobat PDF) via CD-ROMs, FTP from the QSC web site

(www.qscaudio.com), and e-mail.

These service bulletins had been issued at the time this manual was printed:

• RMX0001, “Q205 Lead Stress” (RMX2450 only)

• RMX0002, “RMX Turn-on Delay” (all RMX models)

• RMX0003, “RMX2450 Turn-off Mute” (RMX2450)

• RMX0004, “RMX2450 AC Wire Routing” (RMX 2450)

• RMX0005, “RMX2450 AC Wire Replacement” (RMX2450)

• RMX0006, “RMX2450 IRFZ44N Field Effect Transistors (RMX2450)

RMX Series Technical Service Manual (2RU models) 5

TD-000098-00 rev. C

Page 8

1.4 The well-equipped service bench

To properly service RMX amplifiers, a technician needs the right tools. The

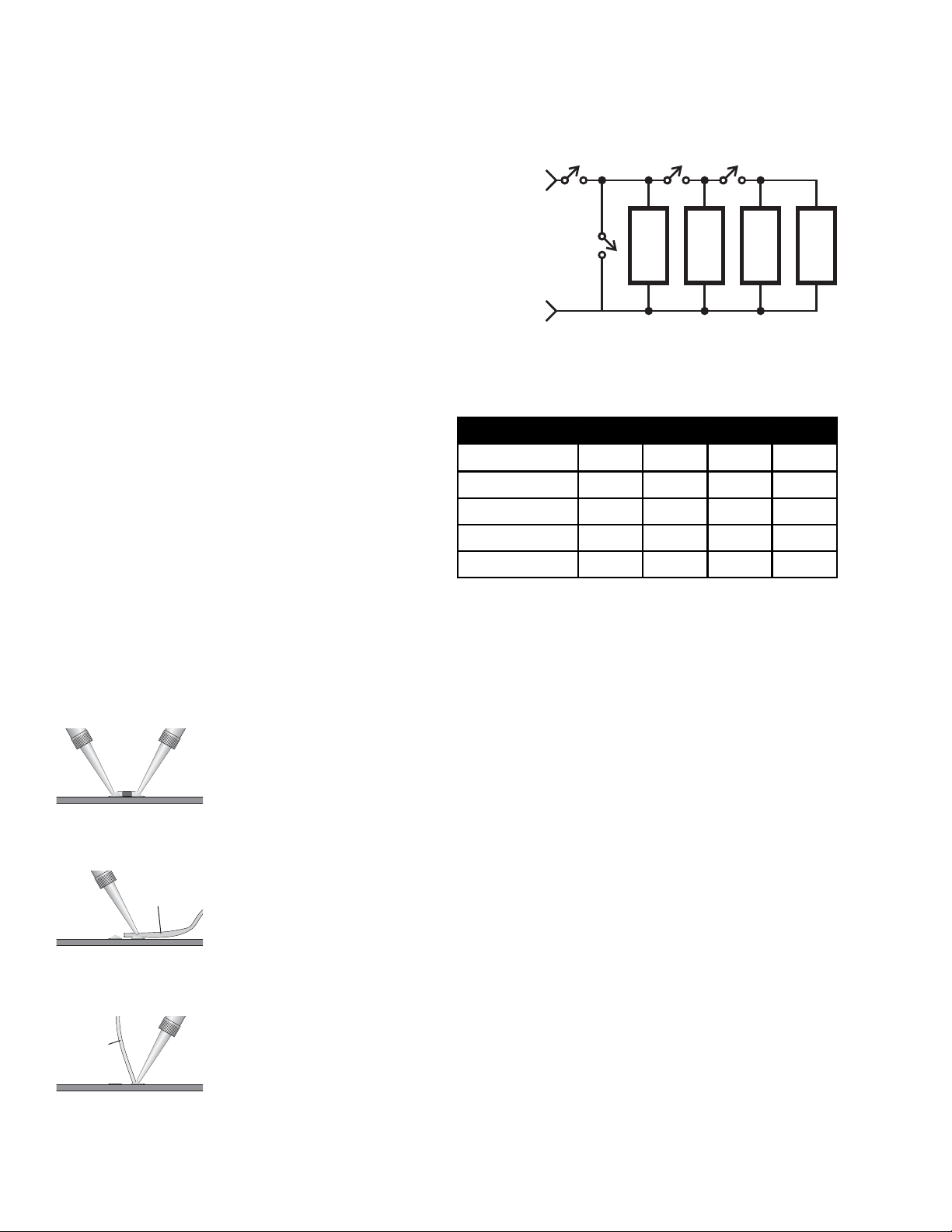

SW1 SW2 SW3

technician’s service bench should have the following equipment:

• Digital multimeter with RMS AC voltage and current

R1 R2

R3 R4

• Digital clamp-on ammeter

• Dual-trace oscilloscope

• Audio distortion analyzer

SW4

8Ω 8Ω 8Ω 8Ω

• Non-inductive load resistors, configurable as 8 ohms (min. 500 watts capacity),

as 4 ohms (min. 750 watts capacity), and 2 ohms (min. 1200 watts capacity);

see Figure 1.2 and Table 1.1.

• Variable AC voltage source, such as a Variac or Powerstat variable transformer, with a rated current capacity of up to 25A (for 120V models) or 12A (for

230V models)

Figure 1.2. Load resistor bank

R1: 8 , 500W non-inductiveΩ

R2–R4: 8 , 300W min. non-inductiveΩ

• Low-distortion audio sine wave generator

• Philips and flat screwdrivers

• Soldering iron with a fine tip, 25–60W recommended (if you

service both RoHS-compliant and non-compliant amplifiers, you

will need separate soldering and desoldering equipment for

each)

• Appropriate rosin-core solder (use only RoHS compliant leadfree solder for RoHS-compliant amplifers; for non-RoHS

amplifiers, use a 60/40 or 63/37 Pb/Sn alloy)

Table 1.1. Load resistor bank switch truth table

SW1 SW2 SW3 SW4

∞Ω (no load)

OFF•••

ON OFF OFF OFF

8Ω

ON ON OFF OFF

4Ω

ON ON ON OFF

2Ω

• Long-nose pliers

• Diagonal cutters

0Ω (short circuit)

ON • • ON

• Wire strippers

Automated test equipment, such as an Audio Precision workstation, is very useful for servicing RMX amplifiers. Contact QSC Technical

Services to obtain applicable AP test files.

1.5 Working with surface-mount components

RMX amplifiers, like many modern electronic products, use surface-mount technology (SMT) components

where appropriate in order to make high-density circuitry that is reliable and economical to manufacture.

SMT components in the RMX amps are used in the small-signal and control circuits, so they do not handle

significant amounts of power; therefore, they are subject to very little stress and should seldom fail.

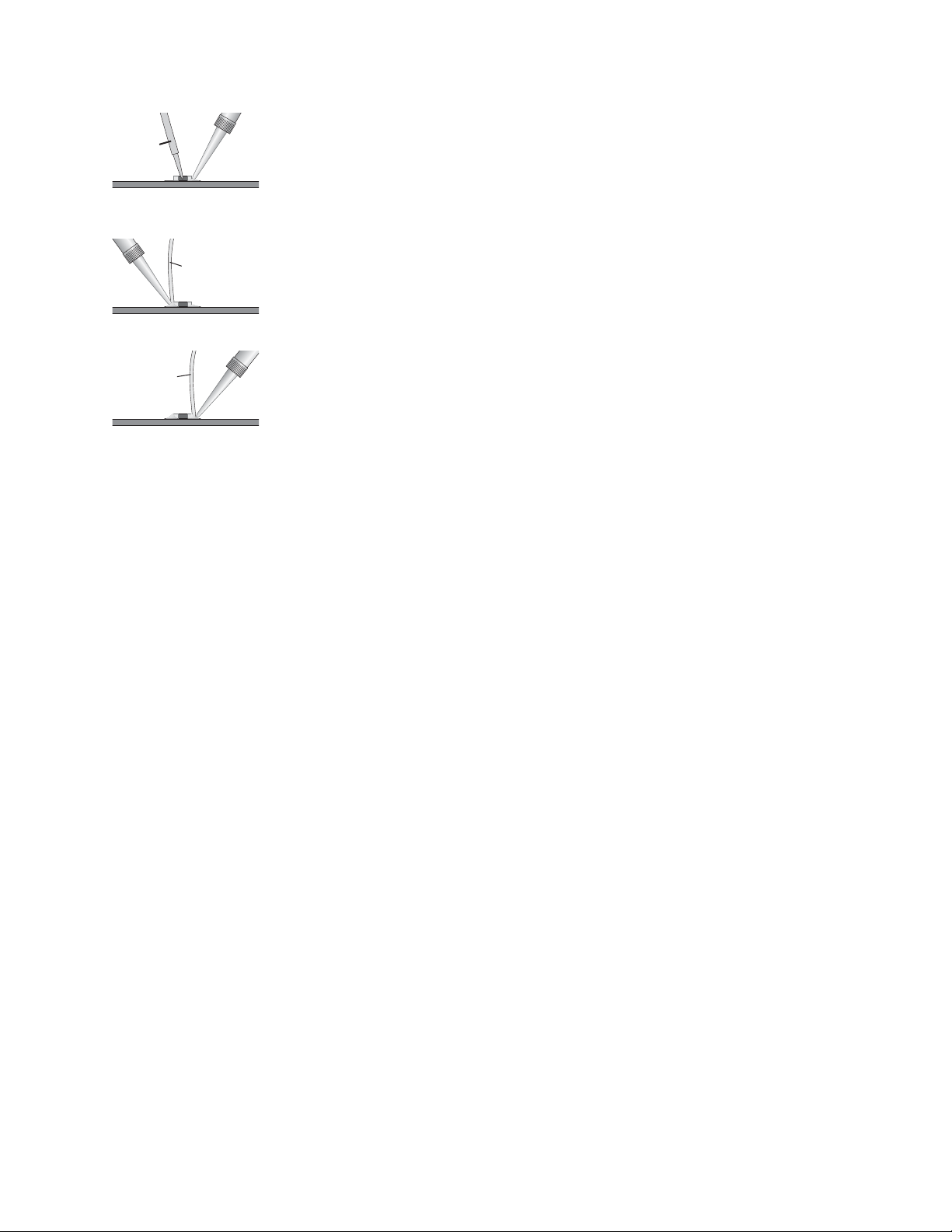

Figure 1.3.

Solder braid

Figure 1.4.

Solder

Figure 1.5.

6 QSC Audio Products, LLC

Sometimes they do fail, or they require replacement for a performance upgrade or modification. Thus, it is

important to know how to work with SMT components.

Specialized tools and equipment exist for soldering, unsoldering, and removing SMT components quickly

and efficiently, but they are often expensive. Most SMT repairs, though, can be handled reasonably well with

common tools and equipment, such as tweezers, solder braid, and fine-tip soldering irons. The original

factory components are tacked to the board with a spot of glue, so you might have to apply some force to

break the adhesive.

Two-terminal components (resistors, capacitors, diodes, etc.)

Removal

1 Use two soldering irons, preferably about 25 to 40 watts, with fine tips.

2 With a soldering iron in each hand, hold one tip on the solder at one end of the component and the

other tip on the other end (Figure 1.3).

3 Once the solder melts on both ends, grip the component between the two tips and lift it from the

circuit board.

4 Use solder braid and a soldering iron to remove the solder from the two pads (Figure 1.4).

Page 9

Tweezers

Figure 1.6.

Figure 1.7.

Solder

Insertion

1 With a soldering iron and appropriate solder, melt just enough solder onto one pad to create a small

mound (Figure 1.5).

2 Grasp the component in the middle with tweezers. Melt the small mound of solder with the iron and

place the component across the two pads (in the correct orientation, if the component is sensitive to

direction) and press it flat against the circuit board, with one end of the component immersed in the

melted solder (Figure 1.6).

3 Hold the component in place and take the soldering iron away. Let the solder harden to tack the

component in place.

4 Fully solder the other end of the component to its pad. Let the solder harden (Figure 1.7).

5 Fully solder the tacked end of the component to its pad (Figure 1.8).

Solder

Figure 1.8.

3 When the solder on both ends melts, grip the component between the two tips and lift it from the circuit board. You might need to

quickly touch the pad on the middle terminal with a soldering iron to melt any remaining solder that might be holding the component

down.

4 Use solder braid and a soldering iron to remove the solder from the three pads.

Insertion

1 With a soldering iron and appropriate solder, melt just enough solder onto one pad to create a small mound of solder.

2 Grasp the component with tweezers. Melt the small mound of solder with the iron and place the component in the correct orientation

across the three pads and press it flat against the circuit board, with one terminal of the component pressed into the melted solder.

3 Hold the component in place and take the soldering iron away. Let the solder harden to tack the component in place.

4 Fully solder the other terminals of the component to their pads. Let the solder harden.

5 Fully solder the tacked terminal of the component to its pad.

Removal

1 With a soldering iron and solder braid, remove as much solder as possible from the middle terminal of

the component.

2 With a soldering iron in each hand, hold one tip on the solder at the terminal at one end of the

component and the other tip on the terminal at the other end.

Multi-pin components (ICs, etc.)

Removal

Removing a multi-pin SMT component is a delicate procedure. Ideally, you should use a soldering iron with an attachment that allows you

to heat all the pins simultaneously.

If such a soldering device is not available, use this procedure:

1 Use a soldering iron and solder braid to remove as much solder as possible from the pins of the component.

2 With fine tweezers, carefully try to lift each pin to see if it’s free. If it’s not, touch it with the tip of the soldering iron and if necessary,

use the solder braid to remove the remaining solder.

3 Repeat the process until all the pins are free and you can remove the component.

Insertion

1 With a soldering iron and appropriate solder, melt just enough solder onto one pad to create a small mound of solder. It is usually

easiest to use a pad that corresponds to one of the end or corner pins of the component.

2 Grasp the component with tweezers. Melt the small mound of solder with the iron and place the component in the correct orientation

upon its pads and gently press it flat against the circuit board, with the appropriate terminal of the component pressed into the

melted solder.

3 Hold the component in place and take the soldering iron away. Let the solder harden to tack the component in place.

4 Fully solder the other terminals of the component to their pads. Let the solder harden.

5 Fully solder the tacked terminal of the component to its pad.

Three-terminal components (transistors, etc.)

RMX Series Technical Service Manual (2RU models) 7

TD-000098-00 rev. C

Page 10

1.6 Series description

QSC’s RMX Series amplifiers are entry-level professional audio

products, designed for good, basic performance and reliability at

low price. The series comprises six two-channel models; this

manual covers the four two-rack-space models: the RMX850,

RMX1450, RMX1850HD and RMX2450. See page 2 for complete

specifications. The three-rack-space models—the RMX4050HD

and the RMX5050—are covered by another service manual.

The RMX850 and RMX1450 have single-sided printed circuit

boards. The RMX1850HD and RMX2450 use double-sided boards.

1.7 Technical descriptions and theory of operation

Note: Some of these descriptions concern circuitry that is

duplicated in the amplifier’s two channels. For the sake of

simplicity, the descriptions are of Channel 1 only. Components in

Channel 1 have a 3-digit designation with “1” as the first digit;

their equivalents in Channel 2 have a “2” as the first digit,

followed by the same two numerals. For example, R122 and R222

have identical functions in their respective channels.

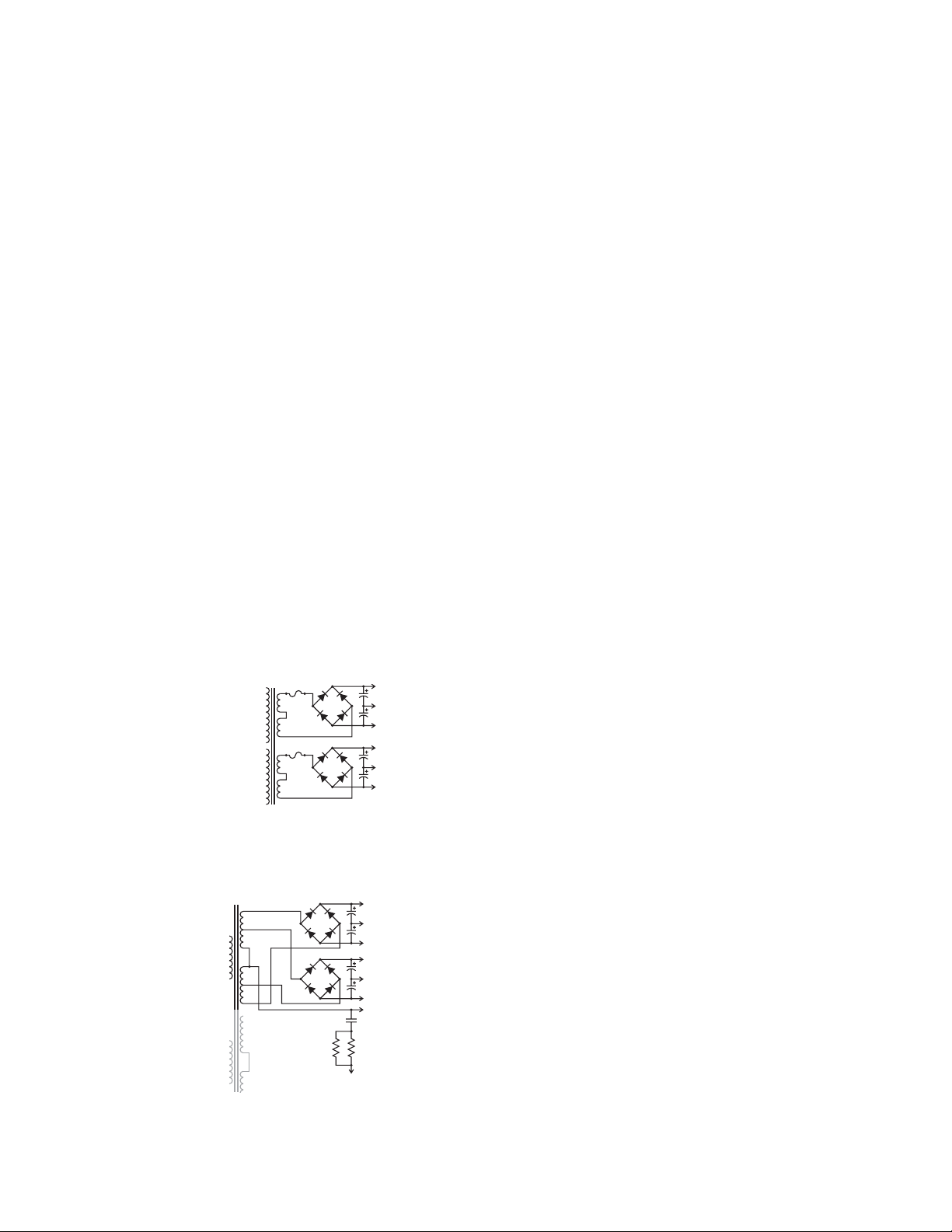

Power supplies

Unlike other recent QSC amplifiers, the RMX line uses strictly

conventional power supplies, with large transformers that operate

at the 50 or 60 Hz frequency of the AC line. The electrical current

in the secondary circuitry is converted to DC through a full-wave

bridge rectifier. The resulting 100 or 120 Hz ripple is filtered out by

large capacitors that also serve as current reservoirs for shortterm, transient demands.

The supply provides a bipolar set

of supply rails for each channel,

with equal quiescent positive and

negative voltages, as shown in

Figure 1.9. Note that unlike many

bipolar supplies for complementary transistor arrangements, the

secondary windings are not

Figure 1.9

connected to ground at the center.

This is because the output transistors are directly mounted to the

heat sink, metal-to-metal, to

maximize heat transfer; this

grounds the collectors,

requiring somewhat

different output and power

supply arrangements. The

grounded-collector concept

is described later in this

chapter.

In the RMX1850HD and

RMX2450, the secondaries

To Channel 2 Center Tap

are tapped to provide an

Figure 1.10

+Vcc

-Vcc

+Vcc

-Vcc

+110V

-110V

+55V

-55V

Ch. 1 Center Tap

0.047 µF

12 5W×2Ω

Channel 1

Channel 2

Channel 1

intermediate set of bipolar rails for the Class H output circuitry.

Figure 1.10 shows one channel. Class H operation is described

later in this chapter.

The 24-volt cooling fan is driven by a separate DC supply that is

powered by a 20-volt tap on the transformer primary. To minimize

fan noise, the fan speed is controlled by varying its actual DC

voltage in response to the amplifier’s heat sink temperatures. An

optocoupler isolates the fan control circuitry from the thermal

sensors.

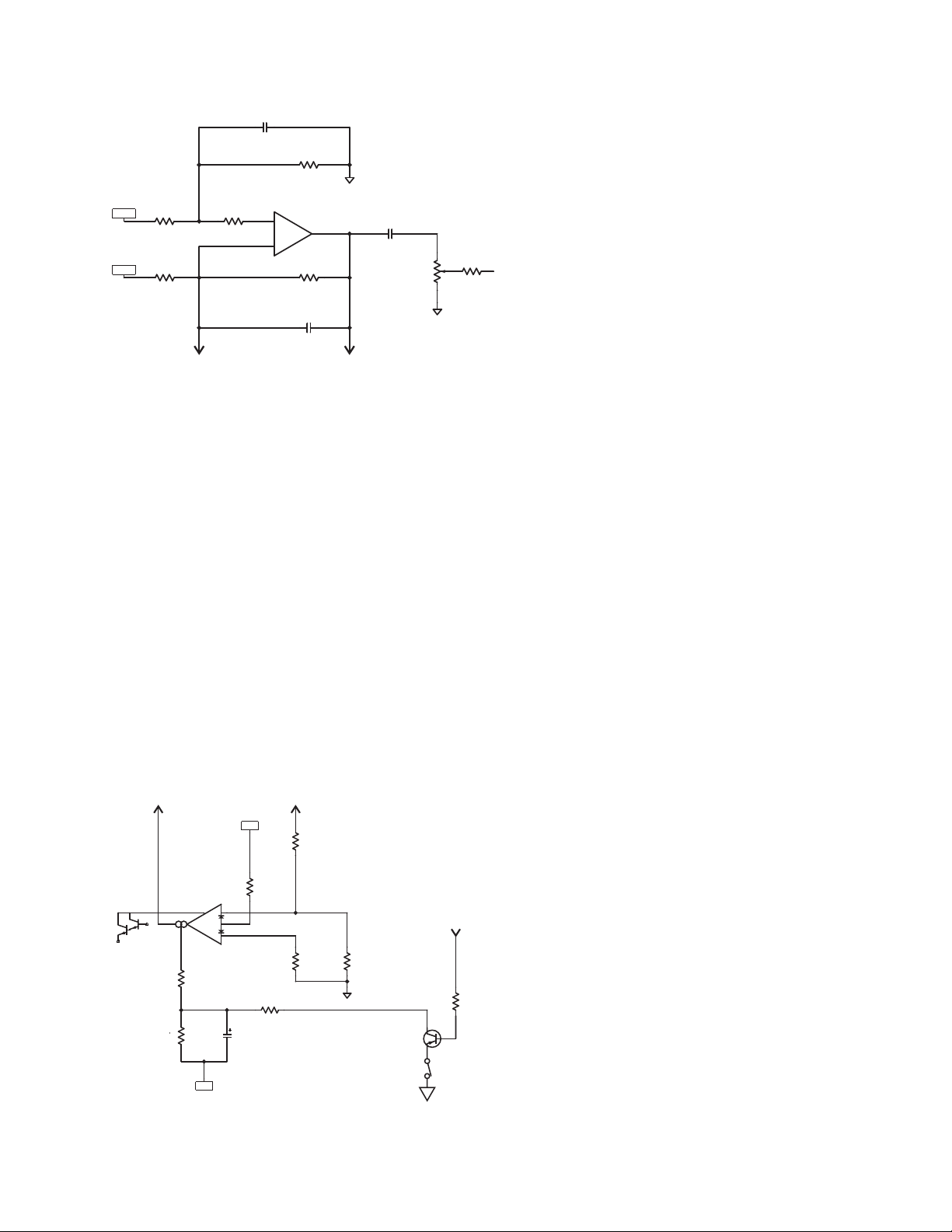

Audio circuitry

The audio inputs are balanced to offer a reasonably high amount

of common-mode noise rejection. The input balancing is done

using a single op amp (one half of an NE5532 dual op amp)

arranged as a differential amplifier. The degree of common-mode

rejection is dependent on a close match between the input

resistors (R100 and R101 in Figure 1.11) and between the feedback

resistor and the shunt resistor (R105 and R106). The circuitry uses

1% precision resistors to ensure at least 40 dB of common-mode

rejection.

The feedback and shunt capacitors, C101 and C103, add a firstorder high-frequency roll-off, down 3 dB at 88.4 kHz (over two

octaves above the high end of the audio spectrum). This makes the

amplifier less susceptible to RF interference, high-frequency

oscillations, etc.

Also in this stage, the feedback loop contains one half of an NE5517

(equivalent to the more familiar LM13600) dual operational

transconductance amplifier (Figure 1.12). The OTA is part of the clip

limiter circuitry; when the clip limiter is activated, a control voltage

increases the transconductance of the OTA, which essentially

decreases the impedance of the feedback loop and reduces the

gain of the stage in order to reduce the amount of clipping.

The gain control uses a linear potentiometer, but the impedances

loading the wiper to ground make the pot approximate an audio

taper over most of its rotation. After the wiper, RC networks roll

off the low end, if the LF filter is set for that channel, at either 30

or 50 Hz, depending on the DIP switch setting on the rear panel.

8 QSC Audio Products, LLC

Page 11

C101

180p-5%

+IN_A

-IN_A

R100

10.0K

^R_0805

R101

10.0K

^R_0805

R102

1K

^R_0805

^C_0805

R105

10.0K

^R_0805

NE5532

U101:1

+

3

-

2

R106

10.0K

^R_0805

C103

180p-5%

A1

C106

1

47µF NP

R112

2.5K

2.5K LINEAR

RIGHT ANGLE POT

CW

R113

W

274

^R_0805

CCW

A1

To LM13600 operational

transconductance amp

Figure 1.11

The next active device is another 5532 op amp, U101:2. Its output

drives the driver transistors, which in turn drive the output transistors. The output section has a Class AB+B configuration; the

drivers (a complementary pair, Q105 and Q106, comprising an NPN

MJE15032 and a PNP MJE 15033) are class AB. A series network

of two diodes and a 100-ohm trimpot provide the small amount of

forward bias on the transistor pair to keep crossover distortion

minimal. In parallel with the trimpot is a 50-ohm thermistor with a

negative temperature coefficient; as the circuitry warms, its

resistance decreases. This reduces VBE on both Q105 and Q106,

decreasing the bias current to reduce the threat of thermal runaway.

The base of each driver transistor is tied to ground through a diode

and a 2.2 kΩ trimpot in series; these set the current limiting

threshold for their respective signal polarities.

The collector of each driver transistor directly drives the bases of

its output transistors, which are the main power-handling signal

devices. If you’re not familiar with the grounded-collector scheme,

To input op amp U101:1

+14V

R108

7.50K

^R_0805

R107

U10:1

LM13600M

11

5

7

R103

R104

1

10.0K

^R_0805

150K

^R_1206

-14V

8

+

-

C105

39K

^R_0805

3

2

4

^R_0805

100

R111

^R_0805

A1

100-25V

R110

270

^R_0805

R109

100

3906

Q100

From clip

detection

820

R115

CLIP LIMIT

SWITCH

(Open to defeat

clip limiter)

^R_1206

Figure 1.12

the arrangement of the output transistors might look somewhat

backwards: PNP transistors connected to the positive voltage rail,

and NPN on the negative rail. Not only that, but the transistors

attached to the positive rail are for pulling the output voltage

negative, and the ones on the negative rail swing the output

positive. The collectors all connect to ground, which allows them

to be mounted directly to the heat sink—metal-to-metal, without

insulators in between—for the best possible transfer of heat away

from the transistors. The emitters of the PNP and NPN transistors

are coupled through resistors to the positive and negative supply

rails, respectively, forming banks of common-emitter circuits

driving the supply rails. Consequently, the devices drive the rails

with the audio signal, which rides atop the DC. The output to the

speaker load is taken from the point between the positive and

negative reservoir capacitors; this is also where the negative

feedback is taken from. The nature of this arrangement, with audio

signal riding on the supply rails, is why the power supply has no

ground reference.

Another unusual characteristic of the grounded-collector output

section is that the signal at the output to the speaker is actually

opposite in polarity to the signal at the op amp output. This is why

the negative feedback resistor, R122, connects to the op amp’s

non-inverting input instead of the inverting input.

The output point of the circuit couples to the output connector

through an RLC network (R160, R161, R162, L100, and C124) that

serves as a high-frequency snubber and also helps keep the amp

circuitry stable when driving capacitive loads.

Clip detection

The output of the op amp also drives a group of four diodes (D102,

D103, D105, and D106) arranged as a full-wave rectifier. Normally,

the op amp’s output signal level is about 1 volt or less, which is all

it takes to drive the driver transistors.

But because this point is within the overall feedback loop, when

clipping occurs, the op amp approaches full open-loop gain and

puts out a much higher signal voltage to try to make the output

signal track the input. The four diodes rectify the voltage to drive

the clip indicator LED, LD100. The current exiting the full-wave

rectifier passes to ground through R127 and also drives the base of

transistor Q100 through R115. If the clip limiter is switched on,

Q100’s emitter is grounded, and when the voltage across R127

goes sufficiently negative to forward-bias Q100, which sends

current through R111 and R103 into the amplifier bias input of the

operational transconductance amplifier (OTA), U10:1. The OTA is in

the negative feedback loop of U101:1, and increasing its

transconductance essentially reduces the impedance of the

feedback loop, which reduces the gain of the op amp stage. This

reduces the signal level until the amount of clipping is minimal.

When the clipping stops, Q100 is no longer forward-biased, and

the gain returns to normal.

RMX Series Technical Service Manual (2RU models) 9

TD-000098-00 rev. C

Page 12

DC protection

Power saved

The RMX1850HD and RMX2450 have a crowbar circuit, based on a

triac and two silicon controlled rectifiers, on the output to protect

against DC faults. If an amp channel puts out a DC voltage, which

could be the result of a component or circuit failure, it will first

trigger either D119 or D120, depending on the polarity of the

voltage. The triggered SCR will in turn trigger triac Q113, shorting

the output to ground through fuse F100. The fuse will blow,

safeguarding the speaker load from the DC fault.

The output sections of the RMX850 and RMX1450 are AC coupled.

form a voltage divider between the two channel outputs. If the

output signals are mirror images, the voltage at the junction of the

resistors (bus BR_BAL) will be zero. If the signals are not mirror

images—for example, one channel is defunct, distorting, or

reduced in gain—a voltage will appear on BR_BAL. Through DIP

switch 7, the BR_BAL bus becomes bus BR_CUT and feeds the

bases of transistors Q8 and Q6, which are part of a 4-transistor

circuit across the +15V and -15V rails that supply the op amps and

the input circuitry. If the voltage on BR_CUT goes positive enough

to forward-bias Q8, the transistor’s collector will collapse the +15V

rail. At the same time, the emitter current from Q8 will flow

Class H

The RMX1850HD and RMX2450 utilize a two-step

Class H output section. It is essentially a Class AB+B

circuit but with two sets of bipolar supply rails. On

both the positive and the negative sets of rails, a

comparator circuit, called a “step driver,” compares

the audio signal to the lower rail voltage. When

necessary to fully reproduce the signal’s voltage

swing—just before the instantaneous signal voltage

reaches the lower rail voltage—the step driver turns

on a TMOS power FET to pull the output transistors’

supply rail up from the lower voltage to the higher

one, and then back down again when the signal

allows. By keeping the transistors’ supply rails low

whenever possible, the devices dissipate less unused

power and generate less waste heat, making the

amplifier more efficient than a straight class AB

amplifier with the same power points (Figure 1.13).

The comparators are 311-type ICs: U170 on the

positive step and U171 on the negative. Each one

drives a high-gain complementary transistor pair

(2N3904 + 2N3906), which drive the gate of their

respective MOSFET.

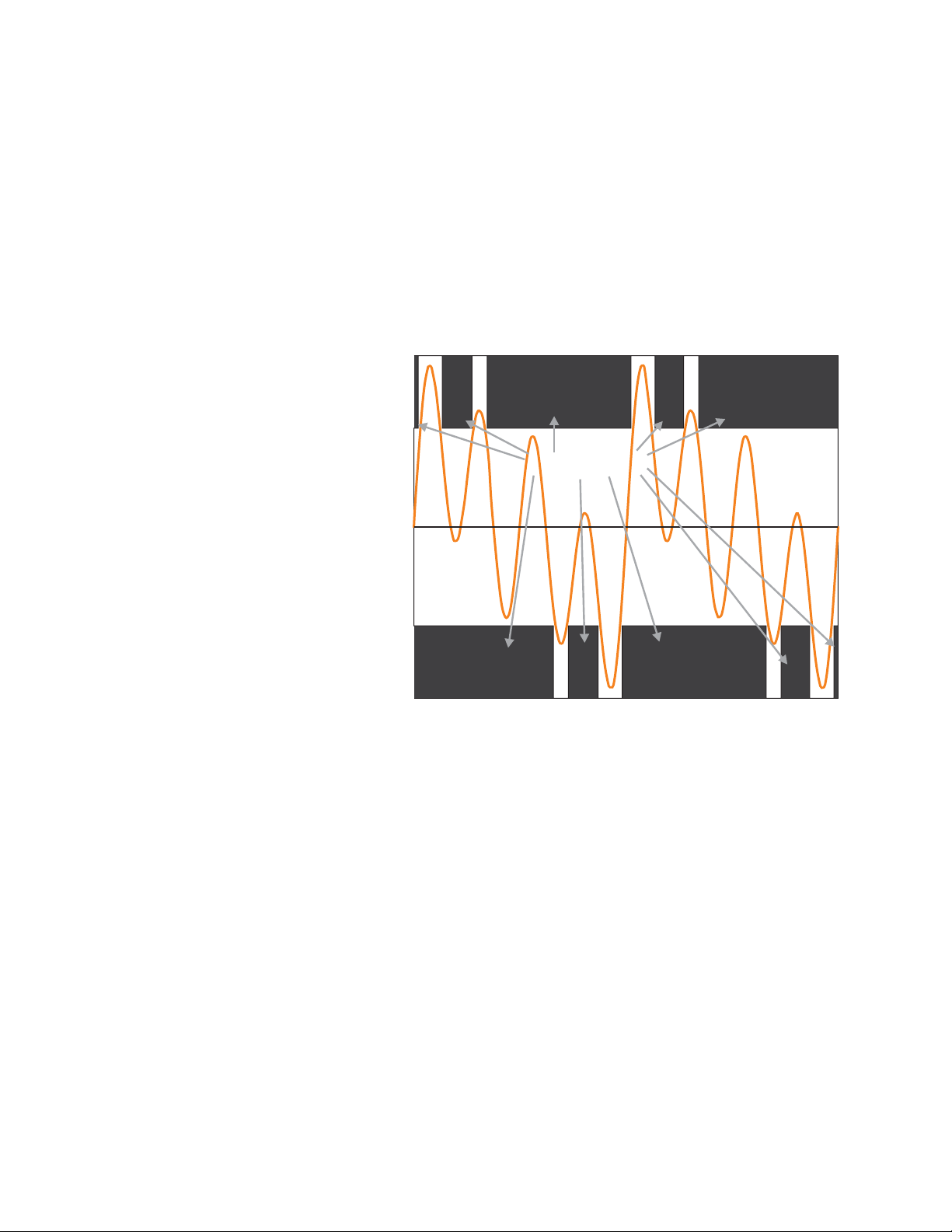

+V

HI

+V

LO

Power saved

0

-V

LO

-V

HI

Figure 1.13. A two-tier class H amplifier circuit operates on the lower voltage

rails until the signal amplitude requires the higher voltage.

Bridged mono operation and protection

When the amplifier is operated in bridged mono, its two channels

work in tandem to produce up to twice the voltage swing that a

single channel is capable of. To do this, Channel 2 produces a

signal identical to Channel 1’s, but opposite in polarity—in other

words, a mirror image.

Channel 2’s signal feed (bus BR_MONO_FEED) is an attenuated

through R25 and into the emitter of Q7, forward-biasing it, too.

The collector of Q7 will then collapse the -15V rail.

Similarly, if BR_BAL goes sufficiently negative, it will forward-bias

Q6, in turn forward-biasing Q9, and these will collapse the ±15V

rails.

With the rails collapsed, the op amp and the input circuitry will not

function, which will mute the audio.

version of the signal on Channel 1’s speaker bus. Closing DIP

switch #6 (set to “BRIDGE MONO ON”), connects the

BR_MONO_FEED bus on Channel 1 to the BR_RET bus on Channel

2. The BR_RET bus drives the non-inverting input of op amp

U201:2 directly.

With two channels operating as one, but each having its own

feedback and protection circuitry, it is vital to keep both running as

mirror images. A protection circuit monitors the balance between

Channel 1’s and Channel 2’s signals. Resistors R22 and R23 (R22A,

R22B, R23A, and R23B on the RMX2450) are equal in value and

10 QSC Audio Products, LLC

Page 13

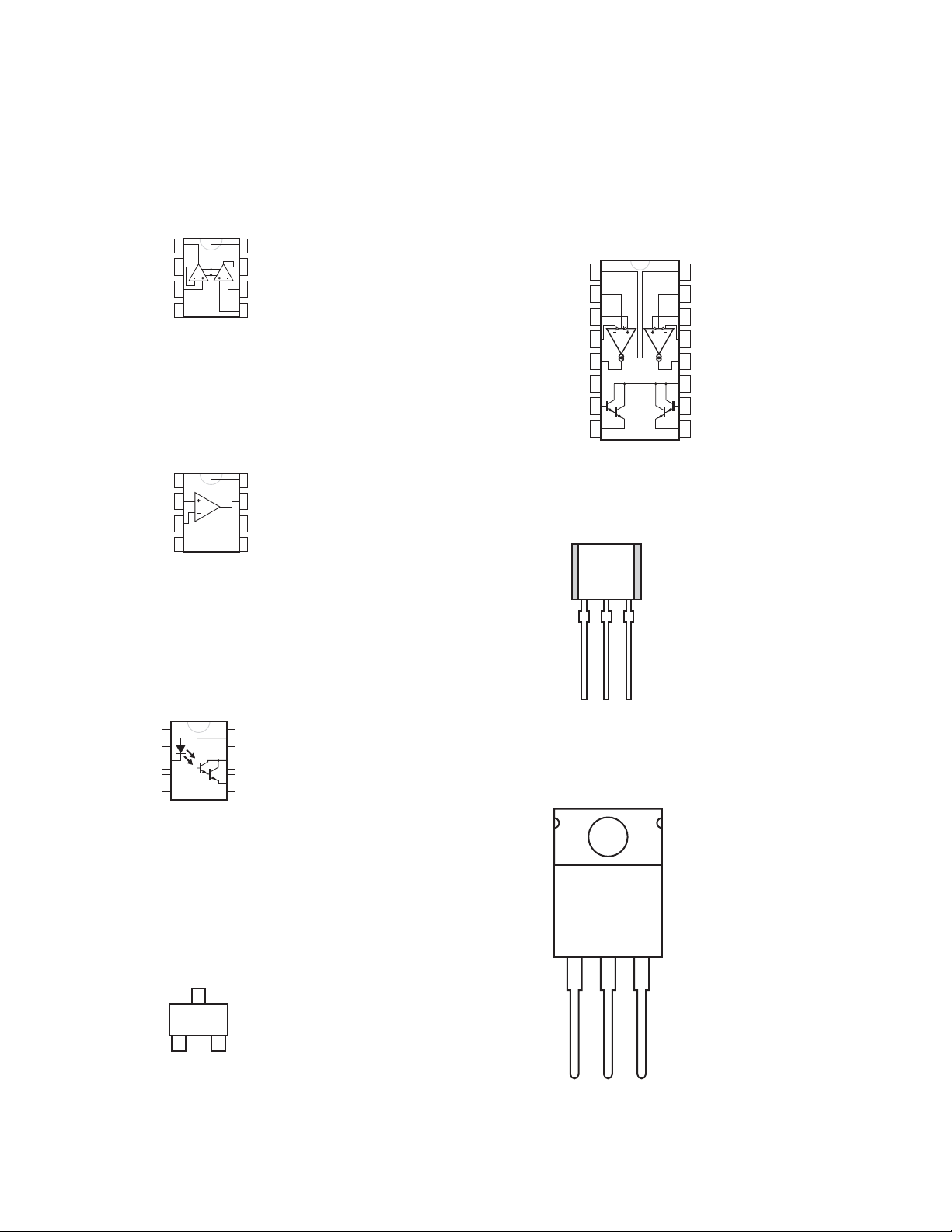

2. Component identification and pinout

NE5532AN Dual operational amplifier

(part number IC-000211-GP; was 3130-2430-0)

OUTPUT A

INVERTING

INPUT A

NON-INVERTING

INPUT A

V-

1

2

3

4

AB

V+

8

OUTPUT B

7

INVERTING

6

INPUT B

NON-INVERTING

5

INPUT B

LM311 Voltage comparator

(part number IC-000214-GP; was 3130-9240-0)

GROUND 1

NON-INVERTING

INPUT

INVERTING

INPUT

1

2

3

V-

4

V+

8

OUTPUT

7

BALANCE/

6

STROBE

BALANCE

5

NE5517D Dual operational transconductance

amplifier

(may be substituted by LM13600 or LM13700)

(part number IC-000212-GP; was 3131-9730-0)

AMP BIAS INPUT A

DIODE BIAS A

NON-INVERTING

INPUT A

INVERTING INPUT A

OUTPUT A

BUFFER INPUT A

BUFFER OUTPUT A

1

2

3

4

5

V-

6

7

8

AB

AMP BIAS INPUT B

16

DIODE BIAS B

15

NON-INVERTING

14

INPUT B

INVERTING INPUT B

13

OUTPUT B

12

V+

11

BUFFER INPUT B

10

BUFFER OUTPUT B

9

2N5064 Sensitive gate thyristor

(part number QD-000350-10; was 4860-5250-5)

4N29 Opto-isolator

(part number IC-000213-GP; was 3130-9270-0)

1

2

3

6

5

4

2N3904 (NPN) Small-signal transistor

(part number QD-000204-GP; was 4860-0640-3)

2N3906 (PNP) Small-signal transistor

(part number QD-000205-GP; was 4853-9060-3)

C

3

12

BE

KAG

IRFZ44 TMOS power field effect transistor

(part number QD-000347-GP; was 490F-Z440-5)

GDS

RMX Series Technical Service Manual 11

Page 14

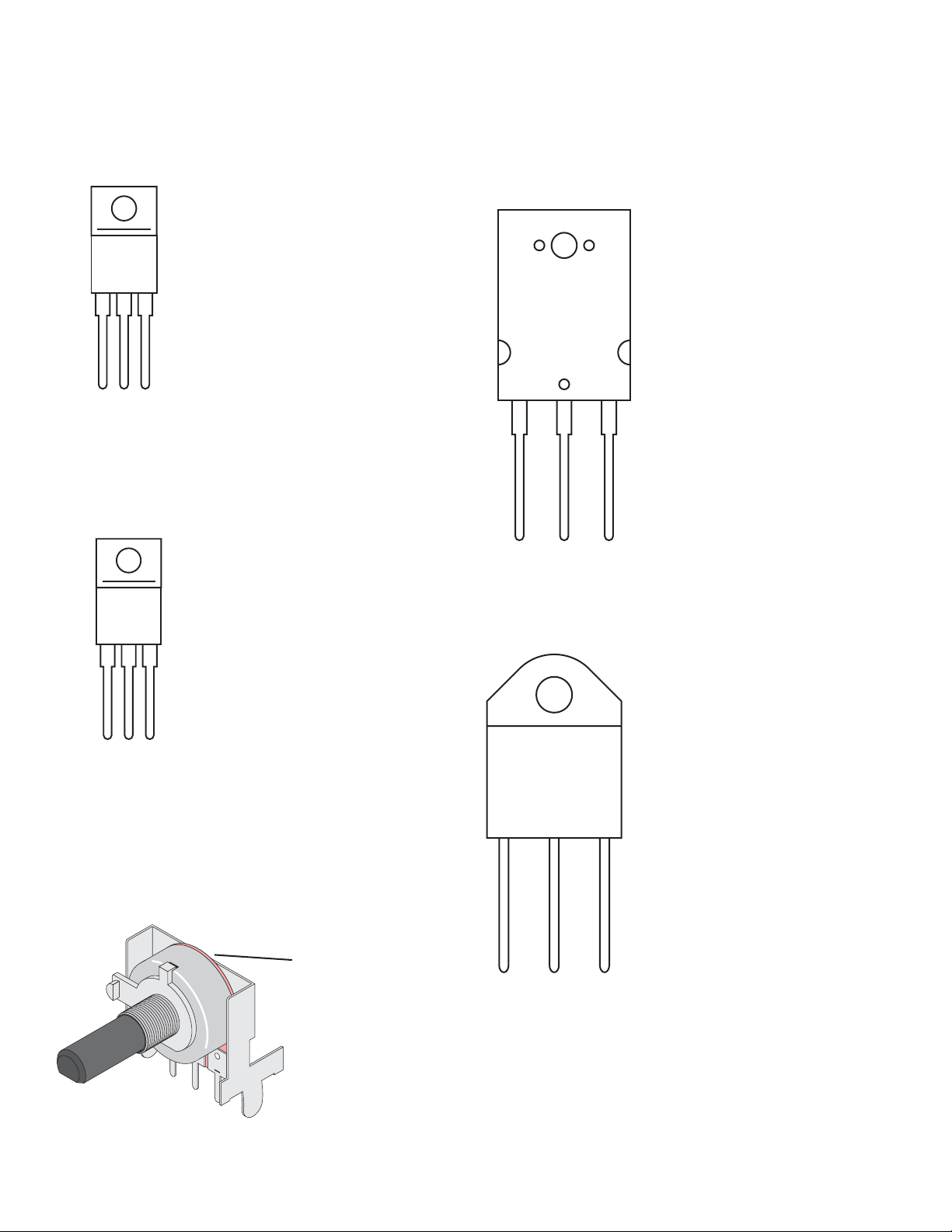

MAC224 Triac (discontinued; see BTA41 triac

below)

(part number QD-000221-GP; was 8910-0482-0)

G

MT1

MT2

MJE15032 (NPN) Driver transistor

(part number QD-000207-GP; was 4860-5020-5)

MJE15033 (PNP) Driver transistor

(part number QD-000210-GP; was 4860-5030-5)

2SC5200 (PNP) Power transistor

(part number QD-000209-GP; was 4860-5050-5)

2SA1943 (NPN) Power transistor

(part number QD-000208-GP; was 4860-5060-5)

TOSHIBA

B C E

BCE

ΩΩ

10 k

Ω Potentiometer (gain control)

ΩΩ

(part number PT-310006-GP; was 4750-6200-0; used

April 2002 and earlier with 10 µF C106)

ΩΩ

2.5 k

Ω Potentiometer (gain control)

ΩΩ

(part number PT-225000-GP; was 4751-0420-0; used May

2002 and later with 47 µF C106)

potentiometer value

printed on back

BTA41 Triac

(part number QD-000261-GP; replaces discontinued

MAC224 Triac)

A1 A2 G

Note: To install the BTA41 Triac on a channel module circuit board

that originally held a MAC224 Triac, first mount it to an adapter

(QSC part number SR-000117-00) and then solder the adapter to

the circuit board. See Service Bulletin RMX0008 for more

information. The Triac and adapter are available together as a kit,

QSC part number SG-000522-00.

12 QSC Audio Products, LLC

Page 15

3. Troubleshooting: Symptoms, causes, & remedies

When first checking the operation of an amplifier on the bench, always turn your variable transformer down to zero before plugging the

amplifier in. After you turn the amplifier on, gradually turn up the AC voltage as you observe the amplifier’s behavior and its current

draw; this will help you determine what, if anything, is wrong with it. If you see or smell smoke, flames, or any other signs of short

circuits or excessive current draw, quickly turn the AC back down to zero. If no such problems occur, it is usually safe to turn the AC up to

the amplifier’s full operating voltage for further testing.

3.1 Excessive current draw

The customer complains of blowing circuit breakers or fuses, or

burning smell or smoke.

Symptoms covered:

• Fuses blow immediately

• The amplifier quickly gets very hot

• Line circuit breakers trip at turn-on

• The amplifier hums loudly and the chassis vibrates

• The amplifier emits smoke

• The amplifier gives off a burning smell

If the symptoms indicate a possible problem in the channel circuits

or output sections, you can isolate either channel module from the

power supply by pulling its fuses from the AC board.

Possible situations:

Excessive current with no signal present

If the amplifier seems to run hot and draws higher-than-normal

current when idling at full AC voltage, the cause could be bias

misadjustments in the output circuitry of one or both channels. See

the calibration procedures in the next section. In the RMX2450, the

cause might also be blown step FETs; see service bulletin RMX0006.

Fast increase in current draw (current increases rapidly at

only a few volts AC)

• The main bridge rectifiers BR100 and/or BR200 (all models) and

BR101 and/or BR201 (RMX2450) is reversed or shorted.

• Supply clamp diode pairs D117 and D118 and/or D217 and D218

is reversed or shorted.

• The drivers and/or power transistors is shorted on both polarities

(NPN

and

PNP) on one or both channels.

Moderate increase in current draw (current increases

slowly, doesn’t become excessive until about ¼ of the

amplifier’s full AC operating voltage)

• One polarity’s drivers and/or power transistors (NPN or PNP) is

shorted, on one or both channels.

• Individual supply clamp diodes D117, D118, D217, or D218 is

reversed or shorted.

• Bias diodes D108, D109, D208, or D209 or bias trimpots R131 or

R231 is open.

Slow increase in current draw (current doesn’t become

excessive until about half of the amplifier’s full AC

operating voltage; amplifier may pass signal)

• The bias is severely misadjusted, or bias diodes D108, D109,

D208, or D209 is defective.

• An oscillation is causing excessive current demand.

Runaway current draw (current increases sharply at about

25 to 33% of the amplifier’s full AC operating voltage)

One or more reservoir capacitors is reversed. CAUTION: the gas

buildup in a reversed electrolytic capacitor can cause it

to vent explosively. Immediately turn off power and let the

capacitor cool down before replacing it.

3.2 Protection, muting, and turn-

on/turn-off delay problems

The customer complains of amplifier locking up, or not turning on

and off correctly.

Symptoms covered:

• Both channels do not come out of protect

• Amplifier will not thermally shut down when it should

• Power LED doesn’t light

• Too little or too much muting delay

• No clip limiting

• Fan doesn’t run, or runs always at high speed

Possible situations:

Both channels stay in protect after turn-on

• Q4 or Q5 is shorted base-to-emitter.

• Voltage across D8 should be 14 to 15 volts DC. If it is low, check

D8 and R10; also, C7 and C8 is leaky.

• D9, R4, and/or R7 is open.

RMX Series Technical Service Manual 13

Page 16

The amplifier will not thermally shut down when it overheats

Check for shorted D9, R4, or R7; check also for open LD1 (“POWER”

LED), R2, or R5.

Too much or too little muting delay

• Excessive delay at turn-on: check for open LD1, R2, or R5; check

for incorrect R10 or R15; check for shorted D9; also see service

bulletin RMX0002.

• Too short at turn-on (amplifier unmutes before the circuits stabilize,

causing a thump): check for incorrect or bad C7, C8, or R10.

• Amplifier doesn’t stay muted at turn-off: see service bulletin

RMX0003

Power LED doesn’t light

Check for open or shorted LD1; check R2.

No clip limiting

• U10 is defective.

• DIP switches SW1:1 or SW1:10 is defective.

Fan doesn’t run

• The fan is defective.

• Check the fan connection to the AC board.

• Check R1 and BR1 on the AC board.

Fan runs always on high speed

• Q3 and/or U2 are shorted.

• Check PTC thermistors R4 and R7.

3.3 Faults with signal present

The customer compains that the amplifier passes a signal but

doesn’t run correctly.

The output signal collapses when driving a normal speaker

load

• R139, R140, R239, and/or R240 is misadjusted.

• Check R118, R119, R218, and R219.

The supply rails are OK with no signal but collapse with a signal

• C112, C113, C212, and/or C213 is leaky.

• Check C114, C124, C214, and C224.

The amplifier gets too hot with no load

• Bias trimpots R131 or R231 are misadjusted, burned, or open.

• Bias diodes D108, D109, D208 and/or D209 are incorrect (should

be 1N4934).

• If the amplifier is producing high-frequency oscillations, check

C114, C124, C214, and C224.

• Check resistors R136, R137, R236, and R237.

• Op amp U101 or U201 is unstable.

One channel clips prematurely

• R146 or R147 (Channel 1) or R246 or R247 (Channel 2) are open.

• R139 or R140 (Channel 1) or R239 or R240 (Channel 2) are misadjusted.

• Check R157, R158, R198 (RMX1850HD and RMX2450 only),

D115, and D116 (Channel 1) or R157, R258, R298 (RMX1850HD

and RMX2450 only), D215, and D216 (Channel 2).

• (RMX850 and RMX1450) Check R118 and R119 (Channel 1) or

R218 and R219 (Channel 2).

• R130 or R132 (Channel 1) or R230 or R232 (Channel 2) is open.

Excessive hum in loudspeaker when no signal is present

(RMX850 and RMX1450)

Check R118, R119, R218, and R219.

Excessive current draw with signal present (RMX1850HD

and RMX2450)

• Check triacs Q113 and Q213.

• Check D119, D120, D219 and D220.

Symptoms covered:

• The output signal breaks up or is distorted

• “Ringing” sound in loudspeaker when no audio signal is present

• The output signal collapses when driving a normal speaker load

• Supply rails OK with no signal, but collapse when a signal passes

• The amplifier gets too hot

• One channel clips prematurely

• Excessive hum in loudspeaker when no audio signal is present

Possible situations:

The output signal breaks up or is distorted

• (RMX850 and RMX1450) Check the hum-null resistors R118,

R119, R218, and R219.

• Check the ground traces for continuity among speaker ground,

input ground, and AC ground.

“Ringing” sound in loudspeaker when no audio signal is

present

• Check C114, C124, C214 and C224.

• Check or replace dual op amp U101 or U201.

14 QSC Audio Products, LLC

3.4 Instability

The customer complains of gain problems, spurious noises, or oscillations.

Symptoms covered:

• General output distortion

• “Ringing” sound in loudspeaker trailing an audio signal

• Excessive crossover distortion

• The output waveform appears fuzzy on an oscilloscope

Distinguish among the different symptoms of fuzziness (instability),

ringing (momentary instability after a transition), crossover distortion (often causing ringing), or general distortion.

Possible situations:

General distortion in the output signal

• Severe distortion, at any load, often with abnormally high

current draw: check the slew rate capacitors C114, C115, and

Page 17

C116 (Channel 1) or C214, C215, and C216 (Channel 2).

• Moderate distortion, especially with light loading: stability

capacitors C124 and C126 (Channel 1) or C224 and C226 is too

high in capacitance; also check the slew rate capacitors C114,

C115, and C116 (Channel 1) or C214, C215, and C216 (Channel

2), and the output filter resistors R161, R162, R154, and R155

(Channel 1) or R261, R262, R254, or R255 (Channel 2).

• Distortion with low gain: check the feedback shunt components

R120, R138, and C125 (Channel 1) or R220, R238, or C225

(Channel 2); also check for broken circuit traces around the

components; U101 (Channel 1) or U201 (Channel 2) is defective

or its socket is contaminated.

Ringing sound trailing the audio signal

• This usually indicates marginal instability and is usually

triggered by the signal passing through zero volts (the crossover

point). Check the stability components and output filters.

• With a sine wave test signal, use an oscilloscope to check for

excessive crossover notch at the output signal’s zero crossings.

Excessive crossover distortion (unbalanced, asymmetrical,

or excessively large crossover notch)

• Severe crossover discontinuity: bias diodes D108 or D109

(Channel 1) or D208 or D209 (Channel 2) are shorted.

• Moderate discontinuity: bias diodes D108 or D109 (Channel 1)

or D208 or D209 (Channel 2) are out of spec.

• R131 (Channel 1) or R231 (Channel 2) is defective.

• Base resistors R136 or R137 (Channel 1) or R236 or R237

(Channel 2) are open. Also check the NTC thermistors R134

(Channel 1) or R234 (Channel 2).

3.5 Power supply and rail

balancing problems

Symptoms covered:

• Insufficient or excessive current limiting into a shorted load

• Op amp rails too high with a shorted load

• Uneven voltages on supply rails

A channel’s output current should remain unaffected when driving

resistive loads as low as 2 ohms per channel. When driving a short

circuit, the current limiting circuit should collapse the output to a

lower current. This is done by dropping the op amp’s supply rails

from a normal ±14–15 volts down to about ±5–6 volts. Normally,

the output signal helps replenish the op amp supply rails through

D115 and D116 (Channel 1) and D215 and D216 (Channel 2), but a

short circuit or excessively low load impedance prevents the

replenishment, and the op amp rails collapse because they can’t

supply enough current to let the op amp drive both the clip LED and

the driver transistors. The current limit trimpots R139, R140, R239,

and R240 permit adjustment of the current limit thresholds. See

the RMX calibration section of this manual for adjustment

procedures.

Possible situations:

Excessive current into short (insufficient limiting)

• If the op amp rails are dropping to ±5 to 6 volts as they should:

the 5.6V zener diodes D107 and/or D110 (Channel 1) or D207

and/or D210 (Channel 2) are reversed or shorted.

• If high crossover distortion is present: bias diodes D108 or D109

(Channel 1) or D208 or D209 (Channel 2) are shorted.

Excessive current into short (op amp rails are not dropping)

• The op amp U101 (Channel 1) or U201 (Channel 2) is defective,

with insufficient output current.

• Clip LED LD100 (Channel 1) or LD200 (Channel 2) and/or its

rectifying diodes (Channel 1: D102, D103, D105, D106; Channel 2:

D202, D203, D205, D206) are open.

• When driving a short circuit, the output section’s positive and

negative supply rail voltages should be equal, within 3 volts. If

they aren’t, check D107, D110, R146, and R147 (Channel 1) or

D207, D210, R246, and R247 (Channel 2).

Weak current into 2

limiting)

• Bias resistors R130 and R132 (Channel 1) or R230 and R232

(Channel 2) are too high.

• Driver transistors (Channel 1: Q105, Q106; Channel 2: Q205,

Q206) have very low gain.

• One or more emitter resistors in the output section are open.

Current OK at 2

• LD100, D102, D103, D105, or D106 (Channel 1), or LD200, D202,

D203, D205, or D206 (Channel 2), are shorted.

• Zener voltage of diodes D107 or D110 (Channel 1), or D207 or

D210 (Channel 2), is too high.

Current limits properly into short, but current is weak at 2

• If the op amp rails are low (< 14–15 volts) when driving a 2ohm load

(Channel 1, all models), R198 (Channel 1, RMX1850HD and

RMX2450 only) and diodes D115 and D116 (Channel 1, all

models), or R257 and R258 (Channel 2, all models), R298

(Channel 2, RMX1850HD and RMX2450 only) and diodes D215

and D216 (Channel 2, all models).

• If the op amp rails are normal (14–15 volts) when driving a 2-ohm

load

weak driver transistors, open output transistors, or open emitter

resistors. Check the value of the driver transistors’ emitter

resistors, too: R146 and R147 (Channel 1) or R246 and R247

(Channel 2).

Rail voltages unequal

The balance between the positive and negative rail voltages is set

by a voltage divider comprising resistors R118 and R119 (Channel

1) and R218 and R219 (Channel 2). If the amplifier channel passes

a signal but clips unevenly due to unequal rail voltages, this

voltage divider is the likely culprit.

without

without

ΩΩ

Ω or short (excessive or premature

ΩΩ

ΩΩ

Ω, weak into short

ΩΩ

clipping, check the resistors R157 and R158

clipping, usually the output section gain is too low:

ΩΩ

Ω

ΩΩ

RMX Series Technical Service Manual 15

Page 18

4. RMX calibration procedures

4.1 Setting bias

Always set the bias

• after replacing any output or driver transistor.

• after replacing any diode or resistor in the driver/output circuitry.

• if the amplifier seems to run too hot at idle.

• if the amplifier exhibits crossover distortion.

The bias network sets the quiescent base current in the NPN and

PNP driver transistors, which in turn sets the quiescent current in

the output transistors. The driver transistors should both be slightly

“on” at idle so that the transitions of the signal voltage between

positive and negative are smooth and free of gaps or glitches. Too

much bias current will cause the amplifier to run hotter than it

should, especially at idle, while too little will cause noticeable

crossover distortion, especially at low signal levels.

The amplifier circuitry must be cool, or at least within a couple

degrees of ambient air temperature, and the top cover must be

removed. If the driver and output transistors are significantly

warmer than the ambient air, leave the amplifier off and let it cool

before proceeding.

Before turning the amplifier on to set bias on one or both channels,

familiarize yourself with the locations of the trimpots (R131 and

R231) and the voltage measuring points so you can work quickly but

thoroughly. If the amplifier warms up before you finish setting the

bias, you will need to shut the amplifier off and let it cool down

before you resume.

Tools and resources you will need:

• Small flat screwdriver (non-conductive) for adjusting trimpots

• DC voltmeter

• AC power

Procedure

1. Turn the amplifier’s gain controls all the way down. No test

signal is needed.

2. Plug the amplifier into an appropriate AC source. Turn the

amplifier on.

3. Channel 1: While measuring the DC voltage across resistor R146,

adjust trimpot R131 to obtain the voltage listed in Table 1.

4. Channel 2: While measuring the DC voltage across resistor R246,

adjust trimpot R231 to obtain the voltage listed in Table 1.

After setting the bias, calibrate the positive and negative current

limiting; instructions for the procedure follow below.

4.2 Setting positive and negative

current limits

Tools and resources you will need

• Oscilloscope

• 2-ohm resistive load (rated for at least 1200 watts)

• Shorting connector for amplifier output

• Variable AC transformer (e.g., Variac, Powerstat, etc.) rated for

25A (120V) or 12A (230V). Make sure the AC supply is appropriate for the amplifier.

• 1 kHz audio sine wave generator

• Digital multimeter

• Clamp-on digital current meter (e.g., Fluke 30 Clamp Meter)

• Small flat screwdriver (non-conductive) for adjusting trimpots

Procedure

1. Set the audio sine generator to 1 kHz at 1 volt RMS and

connect it to Channel 1's input. Connect a 2-ohm load and the

oscilloscope probe across Channel 1's output.

2. Turn up Channel 1's gain control partway. On the oscilloscope

you should see the amplitude of the sine wave increase

accordingly.

3. Turn the gain control back down and apply a short circuit

across the output terminals of Channel 1. Clamp a current

probe either onto one of the brown wires running to the AC

switch or onto the gray output wire from channel 1's module.

4. Turn the gain control all the way up. Adjust trimpots R139 and

R140 equally until the current measured falls within the range

shown in Table 1.

5. Turn the gain control all the way down and remove the short

circuit so the channel drives the 2-ohm load. Turn the gain control

back up until the output clips. The voltage at which the signal

starts to clip should fall within the range shown in Table 1. If the

clipping is asymmetrical, that is, the signal clips on either the

positive or negative side first, adjust R139 to make it symmetrical.

6. Turn the gain control down. If the amp has begun to warm up

shut it off and let it cool a few minutes before proceeding with

Channel 2.

7. Repeat steps 1 through 5 for Channel 2. Use trimpots R239 and

R240 to adjust the current limiting in steps 11 and 12.

8. Turn both channels’ gain controls all the way down. Clamp the

ammeter onto one of the amp’s AC wires and check the amp’s

idle current. If the amplifier is still at about room temperature,

the idle current should match the value shown in Table 1.

16 QSC Audio Products, LLC

Page 19

Table 1: Bias and current limit adjustments

Calibrations Adjust RMX850 RMX1450 RMX1850HD RMX2450

Channel 1 bias: DC voltage across R146 R131 0.16 V 0.14 V 0.07 V 0.07 V

Channel 2 bias: DC voltage across R246 R231 0.16 V 0.14 V 0.07 V 0.07 V

Output current into shorted load

AC current when driving shorted load*

Channel 1: R139 & R140

Channel 2: R239 & R240

Channel 1: R139 & R140

Channel 2: R239 & R240

4–4.5 A 4–5 A 7.5–8.5 A 8.5–9 A

3.75–4.5 A 4.5–5.5 A 4.5–5.5 A 5.5–6.5 A

Channel 1: Adjust R139

Clipping voltage into 2 ohms (RMS)

for symmetry

Channel 2: Adjust R239

26–29 V 33.5–37.5 V 42–44 V 44–49 V

for symmetry

Channel 1: Adjust R139

Clipping voltage into 2 ohms (peak)

for symmetry

Channel 2: Adjust R239

36.8–41 V 47.4–53 V

for symmetry

Idle AC demand* (at ambient temperature;

higher when hot)

*Figures shown are for 120V amplifiers; multiply current by 0.5 for 230V or 1.2 for 100V.

0.4 A,

±10%

0.4 A,

±10%

59.3

0.6 A,

–62.2 V

±10%

62.2–69.3 V

0.6 A,

±10%

RMX Series Technical Service Manual 17

Page 20

5. Servicing RMX amplifiers

5.1 Mechanical disassembly and

re-assembly

Replacing components will usually require removing the channel

modules and/or AC board from the amplifier chassis, especially on the

RMX850 and RMX1450, which have single-side printed circuit

boards. The RMX2450 has double-side boards; many of the throughhole components on the upper side of the board can be unsoldered

and soldered from the top side of the board, so removing modules or

boards is not always necessary.

See the fold-out assembly guides on pages 25 and 26 in this

manual for assistance.

NOTE: As viewed from the front of the amplifier, the left channel

module is Channel 1 and the right is Channel 2

RMX2450; its right module is Channel 1, and its left is Channel 2.

Removing the channel modules

1. Disconnect the amplifier from AC power and allow at least 10

minutes for internal voltages to bleed down.

2. Using a Philips screwdriver, remove the screws that fasten the

top cover to the chassis. Also remove the top cover’s four

recessed screws that fasten it to the heat sinks. As you

remove screws, set them aside, but also make note of where

each type is used so you can properly re-assemble the

amplifier.

3. Lift the top cover up at the rear and carefully pull it toward the

back, removing the five hooks on the front edge from their slots

in the chassis.

4. Pull the gain control knobs straight off from the potentiom-

eter shafts.

5. Tip the amplifier up on its side and remove the four screws

that fasten the heat sinks to the chassis.

6. Set the amplifier back down and remove the screws that

mount the channel modules to the chassis standoffs. There

are six screws in the left module and five in the right one.

7. Remove the four screws that fasten the fan, fan shroud, and

fan guard to the chassis. Lift the fan shroud out from the

chassis; this will give you room to properly remove the

modules from the chassis.

8. Disconnect the wire and cable connections to the channel

modules. All of the connections are either detachable headers

or ¼-inch quick-connect tabs that are disconnected by pulling

them straight up. No unsoldering is necessary.

except

in the

9. Slide the channel modules toward the back so the potentiom-

eter shafts and front panel LEDs are clear of their holes in the

front panel. Lift the channel modules out from the chassis.

10. Re-assembly is the opposite of disassembly.

Removing the AC board

The AC board provides AC voltage selection, rectification of the

transformer secondary current, and a regulated DC supply for the

cooling fan. It seldom needs to be replaced unless it is physically

damaged itself. Most failures involving the AC board can be

repaired through replacement of individual components.

WARNING: Regulatory agencies require that any operating

voltage conversions from 120 volts to any other voltage be done

only

by QSC’s factory service. Any other operating voltage

conversions may be done only by a QSC-authorized service center

or international distributor.

1. Disconnect the amplifier from AC power and allow at least 10

minutes for internal voltages to bleed down.

2. Remove the four screws that fasten the fan, fan shroud, and

fan guard to the chassis. Lift the fan shroud out from the

chassis.

3. Disconnect the wires that connect to the channel modules. All

of the large single wires attach to the channel modules with

¼-inch quick-connect tabs that are detached by pulling them

straight up. The remaining three black wires disconnect at the

left channel module with a detachable header.

If you are planning to replace the AC board with another,

carefully cut each of the transformer wires connecting to the

board just above its solder tab. You must leave enough slack

to allow connection to the new AC board. Remove the old

heat shrink tubing from the wires and strip the wire ends

about 0.25 inch or 6.3 mm.

4. Remove the five screws that attach the AC board to the

chassis standoffs. Lift the board out from the chassis.

5. Re-assembly is the opposite of disassembly. If you’re using a

new AC board, slide new pieces of heat shrink tubing over the

transformer wires before you solder them to the appropriate

tabs on the board; after soldering, cover the joints with the

tubing and use a heat gun or other heat source to shrink them

tightly.

18 QSC Audio Products, LLC

Page 21

6. Replacement parts

6.1 RMX850 Replacement Parts

QSC part # Old QSC part # Description Qty. Notes or Component Reference

Misc.

CH-000198-GP 4134-8432-0 RACK-MOUNT BRACKET 2

CO-000211-GP 2113-1144-0 AC INLET, 250V 15A 1

MS-000138-GP 8900-9050-1 DC FAN 24V 80X80 (+5V) 1

PL-000147-GP 2444-1001-1 KNOB RMX PLASTIC BLACK 2

SW-000086-GP 5200-3532-0 CIRCUIT BREAKER 10A 1 For 120V models

SW-000088-GP 5200-4717-0 ROCKER POWER SWITCH 1

SW-000093-GP 5200-4730-0 CIRCUIT BREAKER 5A 1 For 230V models

WC-000181-GP 7010-9640-0 AC CORD 15A, 14 AWG, ISA 1 For 120V models

WC-000213-GP 7009-8620-0 AC CORD SET CE 1 For 230V models

*XF-000117-GP 1806-2505-0 POWER TRANSFORMER RMX850 120V/230V 1 Discontinued; replaced by XF-000314-GP and XF-000315-GP

XF-000314-GP 1806-3983+0000 TRANSFORMER, 230V,RMX850 1 For 230V models

XF-000315-GP 1806-3982+0000 TRANSFORMER, 120V,RMX850 1 For 120V models

WP-008502-00 AC Board Assembly

CA-422005-GP 153R-224K-5-Y1 CM 250V 0.22uF 10% RL 2 C127, C227

CA-810006-GP 157Q-108M-5-X9E 1000UF 35V 20% ELECTROLYTIC 1 C6

HW-000020-GP 4134-8851-0 FUSE HOLDER 6.3MM 4 REF: F100, F200

IC-000213-GP 3130-9270-0 IC 4N29 1 U2

MS-000126-GP 5400-0831-0 HEATSINK, BRIDGE RECTIFIER 1 REF: Q3

MS-000129-GP 5100-1030-3A FUSE T10A 125V/250V 2 F100, F200

QD-000200-GP 4840-1760-0 DIODE RECT 1A 200V DB103 1 BR1

QD-000214-GP 4860-2620-5 TR TIP31C SAMSUNG 1 Q3

QD-000227-GP 4840-2150-0 BRIDGE RECTIFIER 400V 25A 2 BR100, BR200

RE-000005-GP 8910-0273-0 POLYSWITCH 1.1A 0.15 OHM 1.5W 1 R1

RE-000270-GP 8910-0275-0 THERMAL NTC 30A 1 OHM 1 R21

RE-012004-GP 4719-121J-1-X RMF 2W 120 OHM 5% 1 R17

RE-120003-GP 4701-202J-C RCF 1/8W 2K 5% ATS 1 R13

RE-168002-GP 4701-682J-C RCF 1/8W 6.8K 5% ATS 2 R9, R14

4701-474J-C RCF 1/8W 470K 5% ATS 1 R12

WP-008503-00 Channel 1 Module Assembly (left)

CA-233004-GP 153F-332J-5-KW CM 50V .0033UF 5% RL 2 C117, C118

CA-322006-GP 153F-223J-5-LQ CM 50V 0.022UF 5% RL 2 C116, C119

CA-368004-GP 153R-683J-5-WWM 0.068UF 5% 250V FILM DIPPED 1 C124

CA-547008-GP 157R-475M-5-OV 4.7UF 20% 250V ELECTRO RAD 1 C7

CA-647005-GP 157F-476M-5-LU CE 50V 47UF 20% RL 1 C8

CA-847001-GP 8910-0062-0 CE 80V 4700U 20% RL 25X 2 C120, C121

PT-110002-GP 4756-1016-3-06 TRIM POT,100,20 PCNT,0.15W,, 1 R131

QD-000198-GP 3700-4531-G LED 4.7MM GRN W/STAND 1 LD1

QD-000202-GP 4804-0040-1 DIODE IN4004 AL 5 D1, D11, D12, D117, D118

QD-000203-GP 4838-15V6-2 DIOD ZNR 15V 1W SILICON EPIT 2 D8, D15

QD-000206-GP 4804-9340-2 DIOD RECT FAST, IN4934 AT 2 D108, D109

QD-000207-GP 4860-5020-5 XISTOR NPN 250V 0.5A MJE15032 1 Q105

QD-000208-GP 4860-5060-5 TR 2SA1943 T0-3P (L) 3 Q103, Q107, Q109

QD-000209-GP 4860-5050-5 TR 2SC5200 T0-3P (L) 3 Q108, Q110, Q112

QD-000210-GP 4860-5030-5 XISTOR PNP 250V MJE15033 1 Q106

QD-000211-GP 4860-8890-0 TR MPSA06 VCE 80V NS 1 Q5

*QD-000212-GP 4837-5B10-2 DIODE ZENER 1/2W 5.5-5.8V 2 D107, D110 (December 2003 and earlier)

*QD-000269-GP * DIODE ZENER 5.1V 5% .25W DO-35 2 D107, D110 (January 2004 and later)

RE-.02201-GP 471A-022K-5-N 0.22 OHM 5% 3W THK FLM 6 R142, R148, R149, R152, R153, R159

RE-.56006-GP 4719-5R6J-1-X RMF 2W 5.6 OHM 5% 1 R160

RE-.68001-GP 4718-6R8J-1-X RMF 1W 6.8 OHM 5% 2 R146, R147

RE-000250-GP 8910-0488-0 NTC RES 50 OHM 1 R134

(was PCB-QZ010C-PSU)

(was PCB-QZ010C-PWR1)

RMX Series Technical Service Manual (2RU models) 19

TD-000098-00 rev. C

Page 22

RMX850 Channel 1 Module Assembly (continued)

QSC part # Old QSC part # Description Qty. Notes or Component Reference

RE-000260-GP 8910-0274-0 THERMAL PTC 60C 100 OHM 1 R7

RE-001201-GP 471B-120J-1-X 12 5% 5W METAL OXIDE FILM 2 R161, R162

RE-002202-GP 4718-220J-2-P RMF 1W 22R 5% AT FP 2 R136, R137

RE-082005-GP 471B-821J-1-X RMF 5W 820 OHM 5% AL METAL 2 R157, R158

RE-120007-GP 471B-202J-1-X RMF 5W 2K 5% AL METAL 2 R133, R135

RE-122006-GP 4756-2226-3-06 SVR 2.2K H3 7X7 2 R139, R140

RE-215006-GP 4719-153J-1-X RMF 2W 15K 5% AL METAL 2 R2, R5

XF-000190-GP 1804-1030-0 SPRING COIL 2uH 1 L100

Channel 1 SMT parts

CA-210011-GP 150H-102J-6-CF CC 100V 0.001U 5% 1206 1 C114

CA-222007-GP 150F-222K-6-CF 50V .0022UF 10% 1206 1 1 C115

QD-000201-GP 4804-1480-3 DIODE LL4148 SM 15 D2–D7, D9, D14, D104, D111–D116

QD-000204-GP 4860-0640-3 XISTOR NPN 60V 200MA 3904 SOT-23 4 Q8, Q9, Q101, Q102

QD-000205-GP 4853-9060-3 XISTOR PNP 40V 0.2A TR3906 SOT-23 3 Q4, Q6, Q7

QD-000213-GP 4860-5110-3 TR KST42 1 Q1

RE-004702-GP 4720-470J-J RMG 1/10W 47 OHM 5% 0805 2 R25, R124

RE-082003-GP 4721-821J-6 RMG 1/8W 820 OHM 5% 1206 2 R130, R132

RE-115004-GP 4720-152J-J RMG 1/10W 1.5K 5% 0805 1 R129

RE-120004-GP 4720-202J-J RMG 1/10W 2K 5% 0805 1 R 8

RE-168002-GP 4721-682J-6 RCF 1/8W 6.8K 5% ATS 1 R19

RE-210006-GP 4720-103J-J RMG 1/10W 10K 5% 0805 1 R128

RE-247004-GP 4721-473J-6 RMG 1/8W 47K 5% 1206 1 R125

RE-315003-GP 4721-154J-6 RMG 1/8W 150K 5% 1206 1 R10

RE-322001-GP 4721-224J-6 RMG 1/8W 220K 5% 1206 2 R18, R27

RE-322002-GP 4720-224J-J RMG 1/10W 220K 5% 0805 1 R26

RE-347002-GP 4721-474J-6 RMF 1/8W 470K 5% ATS 1 R15

RE-410002-GP 4721-105J-6 RMG 1/8W 1M 5% 1206 2 R3, R6

WP-008504-00 Channel 2 Module Assembly (right)

CA-233004-GP 153F-332J-5-KW CM 50V .0033UF 5% RL 2 C217, C218

CA-322006-GP 153F-223J-5-LQ CM 50V .022UF 5% RL 2 C216, C219

CA-368004-GP 153R-683J-5-WWM 0.068UF 5% 250V FILM DIPPED 1 C224

CA-415004-GP 153F-154J-5-NLM 0.15UF,5%,50V,CM,,RBT,7.5X 4 C108, C109, C208, C209

CA-422006-GP 153F-224J-5-NLM CM 50V 0.22UF 5% RL 2 C107, C207

CA-610020-GP 157F-106M-5-LUN CE 50V 10UF 20% RLT 5 X 11 2 C106, C206

CA-710009-GP 157E-107M-5-KW CE 25V 100UF 20% RL 2 C105, C205

CA-722006-GP 157E-227M-5-PU CE 25V 220UF 20% RL 4 C112, C113, C212, C213

CA-847001-GP 8910-0062-0 CE 80V 4700UF 20% RL 25X 2 C220, C221

CO-000222-GP 2101-1991-0 8-PIN IC SOCKET 2 REF: U101, U201

IC-000211-GP 3130-2430-0 IC NE5532 OP AMP 2 U101, U201

PT-110002-GP 4756-1016-3-06 TRIM POT,100,20 PCNT,0.15W,, 1 R231

*PT-225000-GP *4751-0110-0 RES VAR 2.5K RT ANGLE PCB 2 R112, R212 (May 2002 and later)

*PT-310006-GP *4750-6200-0 VR V012CPH, D-SHAFT 10K 2 R112, R212 (April 2002 and earlier)

QD-000197-GP 3700-4529-R LED 4.7MM RED W/STAND 2 LD100, LD200

QD-000199-GP 3700-4530-Y LED 4.7MM W/STAND YELLOW 2 LD101, LD201

QD-000202-GP 4804-0040-1 DIODE IN4004 AL 4 D10, D13, D217, D218

QD-000203-GP 4838-15V6-2 DIOD ZNR 15V 1W SILICON EPIT 4 D100, D101, D200, D201

QD-000206-GP 4804-9340-2 DIOD RECT FAST, IN4934 AT 2 D208, D209

QD-000207-GP 4860-5020-5 XISTOR NPN 250V 0.5A MJE15032 1 Q205

QD-000208-GP 4860-5060-5 TR 2SA1943 T0-3P (L) 3 Q203, Q207, Q209

QD-000209-GP 4860-5050-5 TR 2SC5200 T0-3P (L) 3 Q208, Q210, Q212

QD-000210-GP 4860-5030-5 XISTOR PNP 250V MJE15033 1 Q206

*QD-000212-GP 4837-5B10-2 DIODE ZENER 1/2W 5.5-5.8V 2 D207, D210 (December 2003 and earlier)

*QD-000269-GP * DIODE ZENER 5.1V 5% .25W DO-35 2 D207, D210 (January 2004 and later)

RE-.02201-GP 471A-022K-5-N 0.22 OHM 5% 3W THK FLM 6 R242, R248, R249, R252, R253, R259

RE-.56006-GP 4719-5R6J-1-X RMF 2W 5.6 OHM 5% 1 R260

RE-.68001-GP 4718-6R8J-1-X RMF 1W 6.8 OHM 5% 3 R20, R246, R247

RE-000250-GP 8910-0488-0 NTC RES 50 OHM 1 R234

RE-000260-GP 8910-0274-0 THERMAL PTC 60C 100 OHM 1 R4

RE-001201-GP 471B-120J-1-X 12 5% 5W METAL OXIDE FILM 2 R261, R262

(was PCB-QZ010C-PWR2)

20 QSC Audio Products, LLC

Page 23

RMX850 Channel 2 module (continued)

QSC part # Old QSC part # Description Qty. Notes or Component Reference

RE-002202-GP 4718-220J-2-P RMF 1W 22 5% AT FP 2 R236, R237

RE-082005-GP 471B-821J-1-X RMF 5W 820 OHM 5% AL METAL 2 R257, R258

RE-120007-GP 471B-202J-1-X RMF 5W 2K 5% AL METAL 2 R233, R235

RE-122006-GP 4756-2226-3-06 SVR 2.2K H3 7X7 2 R239, R240

RE-190903-GP 4717-9091-2 RMF 1/2W 9.09K 1% AT 1 R123