Page 1

ST4X Series

Slope Top Convector

Installation, Operation & Maintenance Instructions

EMA 4

lo

c

n

s

n

o

.

A

su

tr

:

L

r

c

u

To

X Slo

is

e

n

tio

e

r

p

ma

.

d

c

e

v

n

o

C

p

To

e

s

le

in

ta

f s

o

e

d

ility

ib

s

s

o

p

e

th

ce

u

GENER

N

e

Th

e

e

Th

t c

h

tig

CAUTION

n

w

o

d

IMPORTANT INSTRUCTIONS

s

a

w

ic

d

io

r

e

p

e

r

e

h

s w

a

e

r

a

in

n

tio

lla

ta

s

in

r

fo

d

e

d

n

te

in

is

r

to

t me

n

tme

r

a

mp

o

c

g

in

ir

w

e

th

d

n

a

n

sio

o

r

r

t co

n

e

v

e

r

p

l to

e

te

s

s

to

r

e

w

o

p

e

t th

a

th

d

e

d

n

mme

o

c

e

r

, it is

k

c

o

h

ic s

ctr

le

e

r

fo

WARNING

!

h

th

d

FILE # 0026740A.

ith

w

n

w

o

EMA 4

ts N

e

b

r

te

a

e

h

e

w

.

d

e

ir

s

e

is d

r

te

a

r

te

a

w

a

r

fo

ts

n

me

e

ir

u

q

e

X r

h

s

a

w

g

in

r

u

d

d

te

c

e

n

n

o

c

is

d

e

CAUTION - TO REDUCE RISK OF FIRE AND ELECTRIC

SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

1. Read all instructions carefully before using this heater. This

instruction sheet contains vital information for the proper

installation, use, and efficient operation of the heater.

Carefully read the manual before installation , operation or

cleaning of the heater. Failure to adhere to the instructions

could result in fire, electric shock, death, serious personal

injury, or property damage.

2. It is recommended that drapery be kept a minimum of four

(4”) inches from the top or front of heater.

3. This heater is not intended for residential use.

4. The heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces.

5. A heater has hot and arcing or sparking parts inside. To

reduce the risk of fire, do not store or use gasoline or other

flammable vapors and liquids in the vicinity of the heater.

SAVE THESE INSTRUCTIONS

6. To prevent a possible fire, do not block air intakes or

exhaust in any manner. Do not use on soft surfaces, like a

bed, where openings may become blocked.

7. To reduce the possibility of electric shock, it is recommended the power to the heater be disconnected during wash

down.

8. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock or

fire, or damage the heater.

9. Supply voltage must be the same as heater voltage. Check

heater nameplate and supply voltage before energizing.

10. Supply wiring must be rated minimum 75ºC. Use copper

wire only.

11. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

electric shock, or injury to persons.

Page 2

INSTALLATION INSTRUCTIONS

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

are disconnected at main disconnect or service panel

before installing this heater.

2. Wiring procedures and connections must be in accordance

with the National Electrical Code (NEC) and local codes.

Refer to Wiring Diagram on heater and Figure 2. Make sure

all electrical connections are tight to prevent possible overheating. Use Copper Supply Wire Only.

3. Verify the electrical power supply voltage matches the voltage rating as printed on the heater nameplate.

CAUTION - Never connect a heater to a voltage greater than

the nameplate voltage as this will damage the heater and

could cause a fire.

4. Do not install the heater against combustible low-density

cellulose fiberboard surfaces, against or below vinyl wall

coverings, or below any materials that may be damaged by

heat such as vinyl or plastic blinds, curtains, etc.

5. Do not install heater below an electrical convenience receptacle (outlet).

CAUTION

6.

Electrical Cords (including telephone and computer cables),

Drapes, and Other Furnishings Away From Heater. For efficient and safe operation, we recommend maintaining a minimum of 6 inches (152 mm) clearance in front of the heater

at all times. See Clearances Chart for minimum clearance

requirements.

7. To reduce the risk of fire, do not store or use gasoline or

other flammable vapors or liquids in the vicinity of the

heater.

8. Do not install heater upside down or in any position other

than as shown in this manual.

9. Do not recess heater in wall or install heater inside any type

enclosure as this will cause heater to overheat and could

create a hazard.

10. When mounting heater, use care when drilling mounting

holes and mounting heater to building structure to avoid

damaging internal heater components. Be sure to loosen

mounting screws ½ turn to allow for expansion and contraction.

11. Do not remove or bypass the safety limit control(s) as this

could allow heater to become a fire hazard – see heater

wiring diagram supplied with heater and Figure 2.

12. Do not allow object to be placed on top of heater as they

may be damaged or create a fire hazard.

13. Before energizing, make sure front cover is properly

attached to back housing and all screws are installed as

intended. Do not operate heater without front cover

installed.

14. This heater is not approved for use in hazardous or corrosive environments such as marine, green house, or chemical storage areas.

15. Optional built-in controls are not compatible with the NEMA

4X Series slope top convectors.

– Heater Operates at High Temperatures. Keep

Clearance Information

IMPORTANT NOTE:

heater must have adequate airflow. Therefore, locate heater so

that it is not likely to be blocked or damaged and do not allow

anything to be placed against or near the front of heater. It is

recommended that at least 6 inches (152 mm) clearance be

maintained in front of the heater.

For safe and efficient operation, maintain at least the following

minimum clearances:

Bottom of Heater to Finished Floor:

- May be installed on floor. However, for best performance,

install bottom of heater approximately 3 inches (76 mm) off

floor.

Top of Heater to Bottom of Nearest Drapes or Window Sill

Above Heater:

- Minimum 6 inches (152 mm)

IMPORTANT NOTE:

as vinyl blinds) may become damaged by the heated air from

the heater and should not be installed above the heater.

Front of Heater to Full Length Drapes in Front of Heater:

- Minimum between bottom of drapes and floor – 2-1/2 inches

(64 mm)

- Minimum between top of drapes and ceiling – 1/2 inch

(13 mm)

- Minimum between front of heater and nearest fold of drape –

3 inches (76 mm)

For efficient and safe operation, the

Certain fabrics and vinyl materials (such

Mounting and Wiring

NOTE:

National Electric Code and local codes using at least 75°C type

RH, THW or equivalent insulated wire. See chart (Important

Information) for amp loads.

NOTE:

Each heater must be mounted individually.

1. Locate on vertical wall with length of heater positioned hori-

2. When selecting a mounting location, refer to the

3. Remove front cover by removing screws at bottom of cover

4. Mount the rear panel assembly of the heater to the wall

5. Open wiring box cover by loosening each latch screw, sliding

6. Make the proper connections following the wiring diagram

7. Install the front cover by hooking the top edge of the cover

8. Close the wiring box cover by replacing the latches over the

2

Electrical wiring is to be sized in accordance with

This heater is not capable of being mounted in groups.

zontally. This heater must be mounted above finished flooring. Do not allow carpeting or other objects to block the

recessed drain ports at the base of the heater.

Clearance

Information

and lifting cover out and up.

using the 3/16” (4.7mm) diameter mounting holes. See

dimension chart for mounting hole quantity (mounting

screws and wall anchors are not supplied).

the latches sideways, and rotating them off of the lip of the

wiring box cover.

(Fig 2).

a. Wire must be routed from the floor or wall to the heater

wiring box using the appropriate conduit. NEMA 4X conduit and hub are required for NEMA 4X applications.

b. Grounding connector must be connected to the green

ground wire.

over the top edge of rear panel and attaching the bottom lip of

the cover to the rear panel using screws removed in step 3.

lip of the wiring box cover and tightening the latch screws.

for appropriate mounting limitations.

Page 3

AUTO RESET

THERMAL LIMIT

(N)

GL2L1

ELEMENT

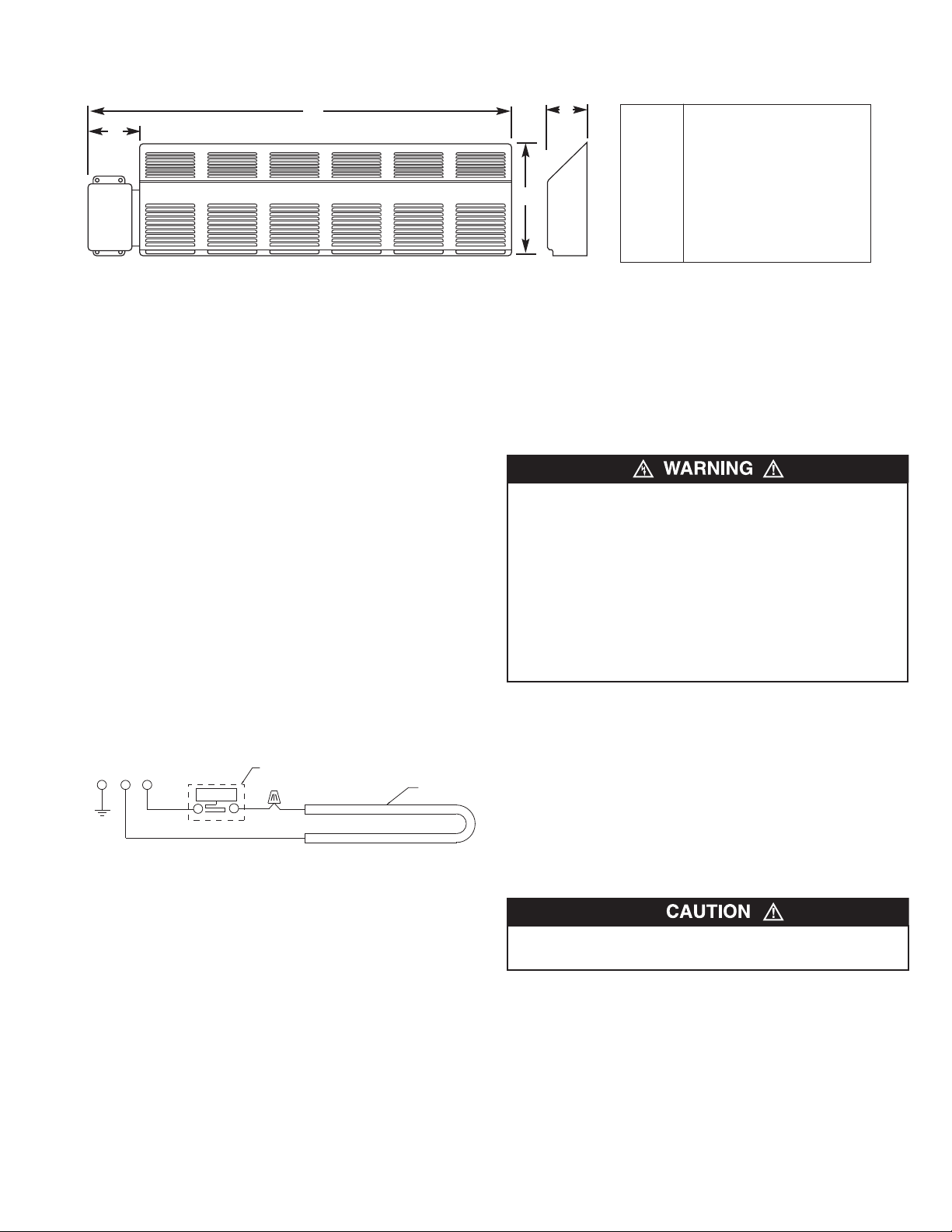

Dimensions

A

4”

Figure 1

OPERATING INSTRUCTIONS

1. This heater must be properly installed before it is used.

2. When using an external thermostat, refer to the installation

and operating instructions provided with thermostat.

3. On initial start up and check out, before heater is energized,

rotate thermostat shaft to the full counter-clockwise (lowest

heat) setting. Connect power to the heater and check to verify the heater is not heating. If heating, disconnect and

check wiring.

4. Rotate thermostat shaft to the full clockwise (CW) (max heat)

setting and allow heater to operate for at least 5 minutes and

verify it is heating.

5. Allow heater to operate until room ambient reaches desired

comfort level and then slowly rotate thermostat shaft counterclockwise (CCW) until you hear or feel a click. This will provide a set point to allow the thermostat to cycle the heater on

and off to maintain this approximate temperature. Some

slight adjustments may be necessary to fine tune the heater

to provide the most desired room comfort. To increase time

heater stays on and increase the room temperature, slightly

rotate the thermostat in the CW direction. Likewise, to

reduce the room temperature, slightly rotate the thermostat

in the CCW direction.

Figure 2. Wiring Diagram

3”

Wattage Dimension “A” (Length)

500 28” (709mm)

750 36” (912mm)

1000 48” (1216mm)

10”

1250 60” (1520mm)

1500 72” (1824mm)

2000 96” (2432mm)

2500 120” (3040mm)

MAINTENANCE INSTRUCTIONS

For efficient and safe operation and to extend the life of the

heaters, they should be cleaned and inspected for damage at

least annually (preferably at the beginning of the heater season)

or more often in dirty environments. Other than cleaning, your

heaters require no other preventative maintenance. The user

can perform some basic cleaning of the heater. All other servicing is to be done by qualified service personnel.

SERIOUS INJURY OR DEATH COULD RESULT FROM

ELECTRIC SHOCK. MAKE SURE ELECTRICAL POWER

SUPPLY CIRCUIT COMING TO HEATER IS DISCONNECTED AT MAIN DISCONNECT OR SERVICE PANEL BEFORE

CLEANING OR SERVICING THIS HEATER. ALLOW

HEATER TO COOL BEFORE CLEANING TO PREVENT A

POSSIBLE BURN.

NOTE:

HEATER. BE SURE ALL POWER IS DISCONNECTED TO

HEATER BEFORE CLEANING OR SERVICING.

To Clean Heater

1. Heater cabinet may be cleaned using a damp cloth to

2. A vacuum cleaner and /or compressed air may be used to

MORE THAN ONE POWER SOURCE MAY ENTER

remove dust that may have accumulated on surfaces. Do

not use harsh cleaners and waxes on surfaces since these

could damage the finish or discolor in use.

remove dust and lint that may have accumulated inside

heater around element fins. If heater must be dissembled for

cleaning, removed the screws securing front cover and

remove front cover to allow for access to inside. Use care

when cleaning element fins to avoiding damaging fins.

FINS ARE SHARP AND MAY CAUSE CUTS SO AVOID

CONTACT

3. After cleaning and servicing, replace front cover and screws

removed making sure cover is properly secured at top and

bottom.

4. Energize heater and check for correct operation.

3

Page 4

TO REPAINT

The baked enamel finish was chosen to blend with interior

decor. If you wish to repaint the heaters, use high quality

household enamel. No primer is necessary. However, light

sanding is recommended. Do not use rubber base paint. Paint

heater front cover only. Do not paint heating element or

protector.

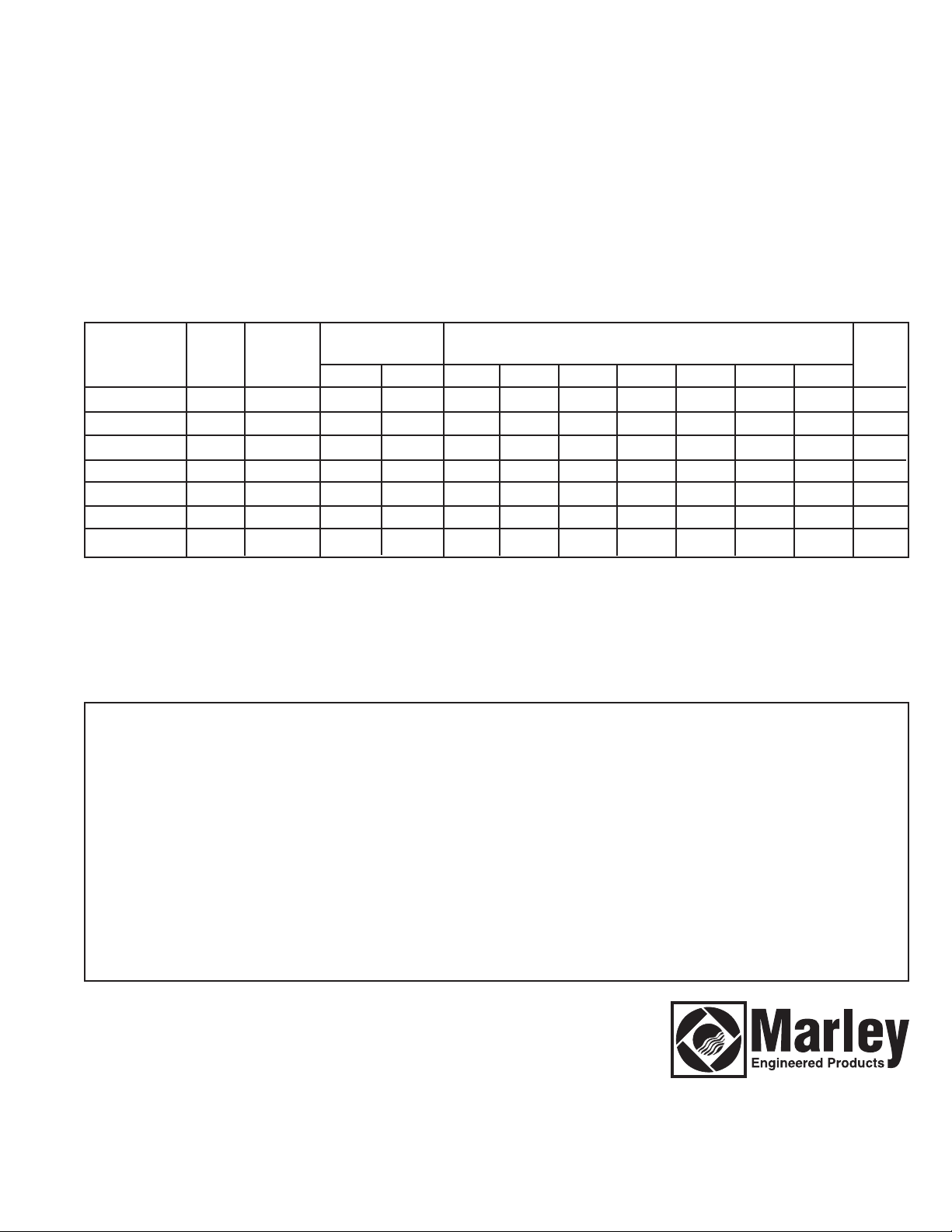

IMPORTANT INFORMATION

Catalog

Number*

ST4X02500

ST4X03750

ST4X041000

ST4X051250

ST4X061500

ST4X082000

ST4X102500

Length

28”

36”

48”

60”

72”

96”

102”

Nominal

Watt/Ft.

250

250

250

250

250

250

250

Total Heating

Capacity

Watts

500

750

1000

1250

1500

2000

2500

1706

2560

3412

4266

5120

6824

8532

120V BTU/Hr.

4.2

6.3

8.3

10.4

12.5

16.7

20.8

Amperage

208V 240V 277V 347V 480V

2.4

3.6

4.8

6.0

7.2

9.6

12.0

2.1

3.1

4.2

5.2

6.3

8.3

10.4

1.8

2.7

3.6

4.5

5.4

7.2

9.0

1.4

2.2

2.9

3.6

4.3

5.8

7.2

1.0

1.6

2.1

2.6

3.1

4.2

5.2

600V

.8

1.3

1.7

2.1

2.5

3.3

4.2

Ship

Wt.

Lbs.

17 lbs

22 lbs

27 lbs

33 lbs

38 lbs

45 lbs

50 lbs

*Catalog number shown in above table will be followed by a three-digit suffix indicating voltage and phase

121 = 120V/1Ø 271 = 277V/1Ø

201 = 208V/1Ø 341 = 347V/1Ø

241 = 240V/1Ø 601 = 600V/1Ø

LIMITED WARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

Note:

When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

Part No. 5200-2595-001

1-800-642-4328

1-800-654-3545

www.marleymep.com

ECR38672

12/10

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 5

Series ST4X

Convector con

inclinación superior

Instrucciones de instalación, operación y mantenimiento

INSTRUCCIONES IMPORTANTES

REGISTRO Nº 0026740A.

E

gabi

l

LIDADES

A

ncl

con i

or

e est

net

una const

ar

educi

a r

par

ón super

naci

i

á hecho de acer

ucci

r

a pr

l

r

i

ón est

obabi

or

o i

anca.

dad de choque el

i

l

noxi

dabl

e par

est

4X

A

M

E

N

á dest

a pr

éct

nado a su i

i

l

r

eveni

se r

co,

i

r

a cor

ecom

GENER

onvect

C

l

E

agua.

a asegur

par

ATENCIÓN:

ADVERTENCIA

ATENCIÓN: PARA REDUCIR EL PELIGRO DE INCENDIO Y

CHOQUE ELÉCTRICO O DAÑOS PERSONALES, OBSERVE LO

SIGUIENTE:

1. Lea cuidadosamente todas las instrucciones antes de utilizar este

calefactor. Esta hoja de instrucciones contiene información vital

para la instalación y uso correctos y el funcionamiento eficiente del

calefactor. Léala cuidadosamente antes de proceder a la instalación, operación o limpieza del calefactor. Si no se observan estas

instrucciones existe riesgo de incendio, choque eléctrico, muerte,

lesiones personales graves y daños materiales.

2. Se recomienda mantener los cortinados a una distancia de diez

(10) cm / cuatro (4) pulgadas de la parte superior o el frente del

calefactor.

3. Este calefactor no está destinado al uso residencial.

4. Cuando está en funcionamiento, el calefactor está muy caliente.

Para evitar quemaduras, no deje que su piel haga contacto directo

con las superficies calientes.

5. Un calefactor tiene en su interior piezas calientes, y piezas en

donde se producen arcos o chispas. Para reducir el riesgo de

incendio, no almacene ni use gasolina u otros vapores y líquidos

inflamables en las cercanías del calefactor.

nst

y el

ón,

osi

r

enda desconect

i

6. Para evitar un posible incendio, no bloquee de ningún modo las

7. Para reducir la probabilidad de choque eléctrico, se recomienda

8. No inserte ni permita que entren objetos extraños en ninguna aber-

9. La tensión de alimentación eléctrica debe ser igual a la tensión indi-

10. Los cables de alimentación eléctrica deben tener una especifi-

11. Utilice este calefactor únicamente en la forma prevista en este

par

com

entradas o la descarga de aire. No lo utilice en superficies blandas,

como una cama, en las que las aberturas puedan quedar bloqueadas.

desconectar la alimentación eléctrica del calefactor durante el lavado.

tura de ventilación o de descarga, porque esto puede ser causa de

choque eléctrico o incendio, o de daños al calefactor.

cada en el calefactor. Revise la placa de características del calefactor y la tensión de alimentación eléctrica antes de energizar el

equipo.

cación de temperatura de 75 ºC como mínimo. Utilice únicamente

cables de cobre.

manual. Cualquier otra forma de uso no recomendada por el fabricante puede ser causa de incendio, choque eléctrico o daños personales.

o de cabl

ent

i

m

i

t

ón el

aci

ent

m

i

a al

l

ar

os que se desea r

es en l

ugar

ón en l

aci

al

es cum

éct

eal

pl

ca del

i

r

e con l

cal

os r

ef

equi

act

t

si

dur

or

avados per

l

zar

i

ódi

i

os N

ant

cos con

4X

A

M

E

avado.

l

e el

GUARDE ESTAS INSTRUCCIONES

Page 6

INSTRUCCIONES DE INSTALACIÓN

PARA REDUCIR EL PELIGRO DE INCENDIO, CHOQUE ELÉCTRICO O DAÑO A LAS PERSONAS, OBSERVE LO SIGUIENTE:

1. Un choque eléctrico podría producir lesiones graves o la muerte.

Asegúrese de que el circuito de alimentación eléctrica del calefactor esté desconectado en el tablero de servicio o desconectador

principal, antes de instalar este calefactor.

2. Los procedimientos de cableado y las conexiones deben estar de

acuerdo con el Código Eléctrico Nacional (NEC) de los EE. UU. y

los códigos locales. Consulte el Diagrama de conexionado que

está en el calefactor y en la Figura 2. Asegúrese de que todas las

conexiones eléctricas estén firmes, para evitar posibles sobrecalentamientos. Utilice cables de alimentación de cobre únicamente.

3. Verifique que la tensión de alimentación eléctrica coincida con la

tensión nominal que está impresa en la placa de características del

calefactor.

PRECAUCIÓN: no conecte nunca un calefactor a una tensión mayor

que la nominal que se indica en la placa de características, ya que esto

dañará el calefactor y podría originar un incendio.

4. No instale el calefactor contra superficies de tableros de fibra de

celulosa de baja densidad, contra o debajo de revestimientos de

pared vinílicos, ni debajo de ningún material que pueda dañarse

por el calor, como cortinas o persianas vinílicas o plásticas, etc.

5. No instale el calefactor debajo de un tomacorriente eléctrico.

PRECAUCIÓN:

6.

Mantenga los cordones eléctricos (incluidos los cables de teléfono

y de computadora), cortinados y otros elementos del mobiliario,

alejados del calefactor. Para garantizar un funcionamiento eficiente y seguro, recomendamos mantener en todo momento un

espacio libre de 152 mm (6 pulgadas) como mínimo, frente al calefactor. Vea los requisitos de espacios libres mínimos en el Cuadro

de espacios libres.

7. Para reducir el riesgo de incendio, no almacene ni use gasolina u

otros vapores y líquidos inflamables en las cercanías del calefactor.

8. No instale el calefactor en posición invertida ni en cualquier otra

posición diferente de la que se muestra en esta hoja de instrucciones.

9. No instale el calefactor embutido en la pared ni dentro de gabinetes de ningún tipo, ya que esto hará que se sobrecaliente, lo que

podría crear un riesgo.

10. Durante la instalación tenga cuidado cuando perfore los agujeros

de montaje y monte el calefactor en la estructura del edificio, para

evitar dañar componentes internos del calefactor. No olvide aflojar

los tornillos de montaje ½ vuelta, a fin de permitir la expansión y la

contracción.

11. No retire ni puentee el (los) control(es) de límite de seguridad, ya

que esto podría crear en el calefactor un riesgo de incendio; vea el

diagrama de conexionado del calefactor, que se incluye en el calefactor y se reproduce en la Figura 2.

12. No permita la colocación de objetos sobre el calefactor, ya que

pueden dañarse o crear un riesgo de incendio.

13. Antes de energizar, asegúrese de que la cubierta frontal esté correctamente fijada al gabinete trasero, y que todos los tornillos

estén instalados como se previó. No haga funcionar el calefactor

sin haber instalado la cubierta frontal.

14. Este calefactor no está aprobado para su utilización en entornos

peligrosos o corrosivos como áreas marítimas, invernaderos o

lugares de almacenamiento de productos químicos.

15. Los controles incorporados opcionales no son compatibles con los

convectores con inclinación superior de la serie NEMA 4X.

el calefactor funciona a altas temperaturas.

Información sobre espacios libres

NOTA IMPORTANTE:

seguro, el calefactor debe contar con una circulación de aire adecuada.

Por lo tanto, coloque el calefactor de modo que no haya posibilidad de que

sufra bloqueos o daños, y no permita que se coloque nada contra el frente

del calefactor ni cerca del mismo. Se recomienda mantener un espacio

libre de 152 mm (6 pulgadas) como mínimo, frente al calefactor.

Para garantizar un funcionamiento seguro y eficiente, mantenga como

mínimo los espacios libres que se indican a continuación:

Del fondo del calefactor al piso terminado:

- Puede instalarse sobre el piso. Sin embargo, para obtener el mejor

desempeño, instale el fondo del calefactor a unos 76 mm (3 pulgadas)

encima del piso.

Del extremo superior del calefactor al extremo inferior del alféizar de ventana o cortinados más cercanos situados arriba del calefactor:

- Mínimo: 152 mm (6 pulgadas)

NOTA IMPORTANTE:

sianas vinílicas) pueden sufrir daños por el aire caliente proveniente del

calefactor, y no deben instalarse sobre el mismo.

Del frente del calefactor a cortinados largos situados frente a él:

- Mínimo entre el borde inferior de los cortinados y el piso: 64 mm (2-1/2

pulgadas)

- Mïnimo entre el borde superior de los cortinados y el cielorraso: 13 mm

(1/2 pulgada)

- Mïnimo entre el frente del calefactor y el pliegue más cercano del cortinado: 76 mm (3 pulgadas)

para garantizar un funcionamiento eficiente y

algunas telas y materiales vinílicos (como las per-

Montaje y conexionado

NOTA:

el conexionado eléctrico debe dimensionarse de acuerdo con el

Código Eléctrico Nacional de los EE. UU. y los códigos locales, con cables

aislados de 75 ºC como mínimo, de tipo RH, THW o equivalente. Vea las

cargas en A en el cuadro ‘Información importante’.

NOTA:

este calefactor no es apto para montarse en grupos. Cada calefactor debe montarse en forma individual.

1. Colóquelo en una pared vertical, con el lado más largo del calefactor

posicionado en forma horizontal. Este calefactor debe montarse sobre

un piso terminado. No permita que las alfombras u otros objetos bloqueen los orificios de drenaje embutidos que están en la base del

calefactor.

2. Al seleccionar una ubicación de montaje, consulte la

espacios libres

3. Retire la cubierta frontal quitando los tornillos de la cara inferior de la

cubierta y levantándola hacia afuera y arriba.

4. Monte en la pared el conjunto de panel trasero del calefactor medi-

ante los agujeros de montaje de 4.7 mm (3/16") de diámetro. Vea la

cantidad de los agujeros de montaje en el cuadro de dimensiones (no

se suministran los tornillos de montaje ni los anclajes a la pared).

5. Abra la cubierta de la caja de conexiones; para ello afloje cada tornillo

de sujeción, deslice los sujetadores hacia un lado, y hágalos girar

fuera del reborde de la cubierta.

6. Haga las conexiones correctas de acuerdo con el diagrama de conex-

ionado (Fig. 2).

a. Los cables deben encaminarse desde el piso o pared hasta la caja

de conexiones del calefactor por medio del conducto apropiado.

Para aplicaciones NEMA 4X se requiere un conducto y boca de

conexión NEMA 4X.

b. El conector de puesta a tierra debe conectarse al cable verde de

puesta a tierra.

7. Instale la cubierta frontal enganchando el borde superior de la

cubierta sobre el borde superior del panel trasero, y fijando el reborde

inferior de la cubierta al panel trasero mediante los tornillos que se

quitaron en el paso 3.

8. Cierre la cubierta de la caja de conexiones; para ello vuelva a colocar

los sujetadores sobre el reborde de la cubierta y apriete los tornillos

de fijación.

para ver las limitaciones de montaje aplicables.

Información sobre

6

Page 7

AUTO RESET

THERMAL LIMIT

(N)

GL2L1

ELEMENT

Dimensiones

A

4”

Figura 1

INSTRUCCIONES DE OPERACIÓN

1. Este calefactor debe instalarse correctamente antes de usarlo.

2. Al utilizar un termostato externo, consulte las instrucciones de instalación y operación provistas con el mismo.

3. En la puesta en marcha y verificación iniciales, antes de energizar el

calefactor haga girar el eje del termostato hasta la posición extrema

en sentido antihorario (calor mínimo). Conecte la alimentación eléctrica al calefactor y verifique que el mismo no esté calentando. Si

está calentando, desconecte y revise el cableado.

4. Haga girar el eje del termostato hasta la posición extrema en sentido horario (calor máximo), deje funcionar el calefactor durante 5

minutos como mínimo, y verifique que esté calentando.

5. Deje funcionar el calefactor hasta que el ambiente de la habitación

alcance el nivel de confort deseado, y luego haga girar lentamente

el eje del termostato en sentido antihorario hasta oír o sentir un 'clic'.

Esto proporciona un valor de ajuste, para que el termostato haga

hacer ciclos de encendido y apagado al calefactor a fin de mantener

aproximadamente este valor de temperatura. Para lograr una sintonía fina del calefactor a fin de alcanzar el confort óptimo en la

habitación, puede que sean necesarios algunos ajustes pequeños.

Para aumentar el tiempo en que el calefactor permanece encendido

y aumentar la temperatura de la habitación, haga girar ligeramente

el termostato en sentido horario. De manera similar, para reducir la

temperatura de la habitación haga girar ligeramente el termostato en

sentido antihorario.

LÍMITE TÉRMICO CON

REPOSICIÓN AUTOMÁTICA

Figura 2. Diagrama de conexionado

ELEMENTO

CALEFACTOR

3”

Potencia Dimensión ‘A’

(watts) (longitud)

500 709 mm (28”)

750 912 mm (36”)

10”

1000 1216 mm (48”)

1250 1520 mm (60”)

1500 1824 mm (72”)

2000 2432 mm (96”)

2500 3040 mm (120”)

INSTRUCCIONES DE MANTENIMIENTO

Para garantizar un funcionamiento eficiente y seguro y para extender la

vida útil de los calefactores, estos deben limpiarse e inspeccionarse

para ver si presentan daños una vez al año como mínimo (preferiblemente el comienzo de la temporada de uso del calefactor), o más a

menudo en entornos muy cargados de suciedad. Sus calefactores no

requieren ningún otro mantenimiento preventivo que la limpieza. El

usuario puede realizar la limpieza básica del calefactor. Los demás servicios deben estar a cargo de personal de servicio calificado.

UN CHOQUE ELÉCTRICO PODRÍA PRODUCIR LESIONES GRAVES

O LA MUERTE. ASEGÚRESE DE QUE EL CIRCUITO DE ALIMENTACIÓN ELÉCTRICA DEL CALEFACTOR ESTÉ DESCONECTADO EN EL TABLERO DE SERVICIO O DESCONECTADOR PRINCIPAL, ANTES DE LIMPIAR O PRESTAR SERVICIO A ESTE CALEFACTOR. DEJE ENFRIAR EL CALEFACTOR ANTES DE LIMPIARLO,

PARA PREVENIR UNA POSIBLE QUEMADURA.

NOTA:

PUEDE INGRESAR AL CALEFACTOR MÁS DE UNA FUENTE

DE ALIMENTACIÓN. ASEGÚRESE DE QUE TODA LA ALIMENTACIÓN ELÉCTRICA ESTÉ DESCONECTADA ANTES DE LA

LIMPIEZA O EL SERVICIO.

Para limpiar el calefactor

1. El gabinete del calefactor puede limpiarse con un paño húmedo

para eliminar el polvo que pueda haberse acumulado en las superficies. No utilice limpiadores o ceras agresivas en las superficies, ya

que podrían dañar el acabado o alterar el color durante el uso.

2. Para eliminar el polvo y la pelusa que se podrían haber acumulado

dentro del calefactor y alrededor de las aletas de los elementos

calefactores, puede utilizarse una aspiradora y/o aire comprimido. Si

se debe desmontar el calefactor para su limpieza, quite los tornillos

que aseguran la cubierta frontal y luego quite la misma, para permitir el acceso al interior. Tenga cuidado al limpiar las aletas de los

elementos calefactores, para evitar dañarlas.

LAS ALETAS SON AGUZADAS Y PUEDEN CAUSAR CORTES; POR

ESO, EVITE EL CONTACTO

3. Después de la limpieza y el servicio, vuelva a colocar la cubierta

frontal y los tornillos que había quitado; asegúrese de que la cubierta esté correctamente sujeta arriba y abajo.

4. Energice el calefactor y verifique que su funcionamiento sea

correcto.

7

Page 8

PARA REPINTAR

El acabado con esmalte horneado se eligió para combinar con la decoración interior. Si desea repintar los calefactores, utilice un esmalte de

uso doméstico de alta calidad. No se necesita primario. Sin embargo, se

recomienda realizar antes un lijado suave. No utilice pintura a base de

caucho. Pinte sólo la cubierta frontal del calefactor. No pinte el elemento

calefactor ni el protector.

INFORMACIÓN IMPORTANTE

Peso p/

trans-

porte, lb

.8

17 lbs

22 lbs

27 lbs

33 lbs

38 lbs

45 lbs

50 lbs

Número de

catálogo *

ST4X02500

ST4X03750

ST4X041000

ST4X051250

ST4X061500

ST4X082000

ST4X102500

Longitud

28”

36”

48”

60”

72”

96”

102”

Watts/pie

nominales

250

250

250

250

250

250

250

Capacidad

térmica total

Watts

500

750

1000

1250

1500

2000

2500

1706

2560

3412

4266

5120

6824

8532

120 V BTU/h

10.4

12.5

16.7

20.8

4.2

6.3

8.3

Corriente, A

208 V 240 V 277 V 347 V 480 V

2.4

3.6

4.8

6.0

7.2

9.6

12.0

2.1

3.1

4.2

5.2

6.3

8.3

10.4

1.8

2.7

3.6

4.5

5.4

7.2

9.0

1.4

2.2

2.9

3.6

4.3

5.8

7.2

1.0

1.6

2.1

2.6

3.1

4.2

5.2

600 V

1.3

1.7

2.1

2.5

3.3

4.2

*El número de catálogo que se muestra en la tabla anterior estará seguido de un sufijo de tres dígitos que indica la tensión y la cantidad de fases.

121 = 120 V / 1 fase 271 = 277 V / 1 fase

201 = 208 V / 1 fase 341 = 347 V / 1 fase

241 = 240 V / 1 fase 601 = 600 V / 1 fase

GARANTÍA LIMITADA

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos en manufactura y materiales durante un (1) año a partir de la fecha

instalación, excepto los elementos calefactores los cuales están garantizados contra defectos en manufactura y materiales durante cinco años a partir de la fecha de

instalación. Esta garantía no aplica a daño por accidente, uso incorrecto, o alteración; ni donde el voltaje conectado sea superior en 5% al voltaje indicado en la placa

de datos; ni se aplica a equipo instalado o cableado o mantenido de manera inapropiada en violación de las instrucciones de instalación del producto. Todas las reclamaciones de trabajo de garantía deben incluir un documento que compruebe la fecha de instalación.

El cliente será responsable de todos los costos incurridos en la remoción o reinstalación de productos, incluyendo los costos de mano de obra, y los costos de envío

incurridos para devolver los productos al Centro de Servicio de Marley Engineered Products. Dentro de las limitantes de esta garantía, las unidades inoperantes deben

devolverse al centro de servicio autorizado Marley más cercano o al Centro de Servicio de Marley Engineered Products, y nosotros repararemos o reemplazaremos,

según nuestra elección, sin costo para usted, con el costo de envío de regreso pagado por Marley. Se acuerda que dicha reparación o reemplazo es el remedio exclusivo disponible de parte de Marley Engineered Products.

LAS ANTERIORES GARANTÍAS REEMPLAZAN CUALQUIER OTRA GARANTÍA EXPRESA O IMPLÍCITA, Y TODAS LAS GARANTÍAS IMPLÍCITAS DE MERCADEABILIDAD Y ADECUADIBILIDAD PARA UN PROPÓSITO EN PARTICULAR QUE EXCEDEN LAS GARANTÍAS EXPRESAS MENCIONADAS SON DENEGADAS MEDIANTE ESTE DOCUMENTO Y EXCLUIDAS DE ESTE ACUERDO. MARLEY ENGINEERED PRODUCTS NO SERÁ RESPONSABLE POR DAÑOS CONSECUENCIALES QUE SURJAN CON RESPECTO AL PRODUCTO, ESTÉN O NO BASADOS EN NEGLIGENCIA, INFRACCIÓN, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados no permiten la exclusión o la limitación de los daños resultantes o adicionales, de modo que la anterior exclusión o limitación podría no aplicarse a usted.

Esta garantía le otorga derechos legales específicos, y además, usted podría tener otros derechos que varían de un estado a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano, comuníquese con Marley Engineered Products en Bennettsville, SC, en el teléfono:

1-800-642-4328. La mercancía devuelta a la fábrica debe incluir una autorización de devolución y la etiqueta de identificación de servicio, las cuales pueden conseguirse

en Marley Engineered Products. Al solicitar la autorización de devolución, incluya todos los números de catálogo mostrados en los productos.

CÓMO OBTENER EL SERVICIO DE GARANTÍA Y LAS PIEZAS

DE GARANTÍA, Y ADEMÁS, INFORMACIÓN GENERAL

1. Servicio o piezas de garantía

2. Compra de piezas de repuesto

3. Información general de productos

1-800-642-4328

1-800-654-3545

www.marleymep.com

Part No. 5200-2595-001

ECR38672

12/10

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 9

Série ST4X

Convecteur à dessus incliné

Instructions d’installation, d’utilisation et d’entretien

INSTRUCTIONS IMPORTANTES

nox pour

i

er

O

LITÉS

A

N

eur

N

our

P

E

M

évi

r

édui

4X

A

er

t

à dessus i

osi

r

a cor

l

a possi

e l

r

on,

bi

ncl

l

i

et

é d’

t

né est

i

son com

une com

pr

GÉNÉR

Le convect

en aci

ATTENTI

avage.

l

évu pour

m

i

t

par

on él

i

ot

m

une i

ent

de câbl

i

r

ect

age r

que,

épond aux exi

ecom

r

est

l

i

m

on dans des zones où un l

i

at

l

al

nst

AVERTISSEMENT

gences N

andé de couper

E

!

avage pér

de const

4X

A

M

ent

m

i

al

’

l

FILE # 0026740A.

que à l

odi

i

uct

r

ect

on él

i

at

eau est

’

on ét

i

que du r

i

r

dési

anche à l

adi

é.

r

at

on cof

S

eau.

’

pendant

eur

est

et

r

f

e

l

POUR RÉDUIRE LE RISQUE DE DÉPART D’INCENDIE, DE COMMOTION ÉLECTRIQUE ET DE BLESSURES AUX PERSONNES,

OBSERVEZ LES CONSIGNES SUIVANTES :

1. Lisez toutes les instructions avant d’utiliser ce radiateur. Cette fiche

d'instructions contient des informations vitales pour une installation

et une utilisation correctes du radiateur. Lisez soigneusement ce

manuel avant d'installer et d'utiliser le radiateur, ou de le nettoyer.

Le non-respect de ces instructions peut entraîner un départ d'incendie, une commotion électrique, une blessure grave voire

mortelle, ou des dégâts matériels.

2. Il est recommandé de maintenir les tentures à au moins 4 pouces

(10 cm) du haut ou de l’avant du radiateur.

3. Ce radiateur n’est pas prévu pour une utilisation domestique.

4. Ce radiateur est chaud quand il est en fonctionnement. Pour éviter

des brûlures, ne laissez pas de peau nue toucher ses surfaces

chaudes.

5. Un radiateur comporte à l’intérieur des parties chaudes, et pouvant

produire un arc ou des étincelles électriques. Pour réduire le risque

de départ d’incendie, n’entreposez pas et n’utilisez pas d’essence

ou d’autres produits inflammables sous forme de liquide ou de

vapeurs à proximité du radiateur.

CONSERVEZ CES INSTRUCTIONS

6. Pour éviter un possible départ d’incendie, n'obstruez en aucune

façon les admissions et les échappements d’air. Ne l’utilisez pas

sur des surfaces molles, comme un lit, où des ouvertures pourraient être obstruées.

7. Pour réduire la possibilité d’une commotion électrique, il est recommandé de couper l’alimentation électrique du radiateur pendant le

lavage.

8. N’insérez pas d’objets étrangers, et ne permettez pas qu’il en entre,

dans toute ouverture d’admission ou d’évacuation, car cela peut

causer une commotion électrique ou un départ d’incendie, ou

endommager le radiateur.

9. La tension du secteur d’alimentation doit correspondre à la spécification du radiateur. Vérifiez la plaque signalétique et la tension

disponible avant la mise sous tension.

10. Le câblage d’alimentation doit supporter au moins 75 °C. N’utilisez

que des fils en cuivre.

11. N’utilisez ce radiateur que comme c’est décrit dans ce manuel.

Toute autre utilisation non recommandée par le constructeur peut

causer un départ d’incendie, une commotion électrique ou des

blessures corporelles.

Page 10

INSTRUCTIONS D'INSTALLATION

POUR RÉDUIRE LE RISQUE DE DÉPART D’INCENDIE, DE COMMOTION ÉLECTRIQUE ET DE BLESSURES AUX PERSONNES,

OBSERVEZ LES CONSIGNES SUIVANTES :

1. Une blessure sérieuse voire mortelle peut résulter d’une commotion électrique. Assurez-vous que le circuit du secteur d’alimentation électrique arrivant au radiateur est bien débranché en amont à

l’interrupteur général ou au panneau de service avant d’installer ce

radiateur.

2. Les procédures de câblage et les connexions doivent être en conformité avec la norme électrique américaine (NEC) et les normes

locales. Référez-vous au schéma de câblage du radiateur en

Figure 2. Assurez-vous que toutes les connexions électriques sont

bien serrées pour éviter une possible surchauffe. N’utilisez que des

fils d’alimentation en cuivre.

3. Vérifiez que la tension du secteur correspond à la tension nominale

telle qu’imprimée sur la plaque signalétique du radiateur.

ATTENTION – Ne branchez jamais un radiateur sur une source de tension supérieure à celle de sa plaque signalétique, car cela l'endommagerait et pourrait causer un départ d'incendie.

4. N’installez pas le radiateur contre des surfaces inflammables de

panneaux de fibre en cellulose de faible densité, contre ou sous

des revêtements muraux en vinyle, ou sous tous les matériaux

pouvant être endommagés par la chaleur, comme des stores en

vinyle ou en plastique, des rideaux, etc.

5. N’utilisez pas le radiateur sous une prise d’alimentation secteur.

ATTENTION

6.

élevées. Maintenez les cordons électriques (dont les câbles du

téléphone et de l’ordinateur), les tentures et autres parties de

l’ameublement à distance du radiateur. Pour un fonctionnement sûr

et efficace, nous recommandons de garder 6 pouces (152 mm) d’écartement au-dessus et devant le radiateur en permanence.

Consultez le tableau d’écartements pour les exigences en distance

minimale.

7. Pour réduire le risque de départ d’incendie, n’entreposez pas et

n’utilisez pas d’essence ou d’autres produits inflammables sous

forme de liquide ou de vapeurs à proximité du radiateur.

8. N’installez pas le radiateur renversé ou dans toute autre position

autre que celle montrée dans ce manuel.

9. N’encastrez pas le radiateur dans un mur, ou ne l’installez pas

dans un quelconque type d’enceinte, car cela provoquerait sa surchauffe et pourrait créer un danger.

10. Au montage du radiateur, faites attention pour percer les trous de

montage et en fixant le radiateur sur la structure du bâtiment, pour

éviter d’endommager des composants internes. Assurez-vous de

desserrer les vis de fixation d’un demi tour pour permettre l’expansion et la contraction.

11. N’enlevez pas et ne contournez pas le(s) contrôle(s) de limite de

sécurité car cela pourrait faire du radiateur un risque de départ d’incendie – consultez le schéma de câblage du radiateur fourni avec

lui et la Figure 2.

12. Ne laissez pas placer d'objets sur le dessus du radiateur, ils pourraient être endommagés et créer un risque de départ d'incendie.

13. Avant la mise sous tension, assurez-vous que le couvercle du

devant est bien fixé sur le coffret arrière, et que toutes les vis sont

placées comme prévu. Ne faites pas fonctionner le chauffage sans

que ce couvercle soit en place.

14. Ce chauffage n’est pas prévu pour être utilisé dans des environnements dangereux ou corrosifs, comme dans des zones marines,

des serres ou des entrepôts de produits chimiques.

15. Les contrôles optionnels intégrés ne sont pas compatibles avec les

convecteurs Série NEMA 4X à dessus incliné.

– Le radiateur fonctionne à des températures

Informations sur les écartements

REMARQUE IMPORTANTE :

radiateur doit bénéficier d’une circulation d’air adéquate. De ce fait, disposez le radiateur de façon à ce qu’il n’ait pas de possibilités d’être bloqué ou endommagé, et ne laissez rien être placé contre ou près de l’avant du radiateur. Il est recommandé de conserver un écartement d’au

moins 6 pouces (152 mm) à l’avant du radiateur.

Pour un fonctionnement sûr et efficace, maintenez au moins les écartements suivants en permanence :

Bas du radiateur jusqu’à la finition de sol :

- Installation sur le sol possible. Cependant pour la meilleure performance, installez plutôt le radiateur à environ 3 pouces (76 mm) audessus du sol.

Dessus du radiateur au bas des rideaux surmontant le radiateur :

- Distance minimale de 6 pouces (152 mm)

REMARQUE IMPORTANTE :

(comme des stores en vinyle) peuvent être endommagés par l’air

réchauffé venant du radiateur, et ne doivent être installés au-dessus

de lui.

De l’avant du radiateur aux rideaux sur toute la longueur

devant lui :

- Distance minimale entre le bas des rideaux et le sol –

2-½ pouces (64 mm)

- Distance minimale entre le haut des rideaux et le plafond – 1/2 pouce

(13 mm)

- Distance minimale entre l’avant du radiateur et le pan le plus proche

des rideaux – 2 pouces (76 mm)

Pour un fonctionnement efficace et sûr, le

Certains tissus et matériaux en vinyle

Montage et câblage

REMARQUE :

mité avec la norme électrique américaine ou les normes locales, en utilisant un fil isolé pour 75 °C, de type RH, THW, ou équivalent. Consultez

le tableau (Informations importantes) pour les charges en courant.

REMARQUE :

mité avec la norme électrique américaine ou les normes locales, en utilisant de fil isolé pour 75 °C, de type RH, THW, ou équivalent. Consultez

le tableau (Informations importantes) pour les charges en courant.

REMARQUE : Ce radiateur ne peut être monté pour s’intégrer dans un

groupe. Chaque radiateur doit être monté individuellement.

1. Placez-le sur un mur vertical avec sa longueur à l’horizontale. Ce

radiateur doit être monté au-dessus de la finition du sol. Ne laissez

pas de tapis ou d’autres objets obstruer les ports de drainage renfoncés à la base du radiateur.

2. Au moment du choix de l’emplacement de montage, consultez

Informations sur les écartements pour connaître les limitations appropriées de montage.

3. Enlevez le couvercle de l’avant en ôtant les vis du bas du couvercle,

puis en le levant pour le sortir.

4. Montez l’ensemble de panneau arrière du radiateur sur le mur en utilisant les vis de montage de diamètre 3/16” (4,7 mm). Consultez le

tableau des dimensions pour la quantité de trous de montages (les

vis de montage et les chevilles d’ancrage ne sont pas fournies).

5. Ouvrez le boîtier de câblage en desserrant chacune des vis de verrous, puis en glissant les verrous latéralement et en les faisant tourner pour les sortir de la lèvre dans le couvercle du boîtier de câblage.

6. Réalisez les connexions voulues en suivant le schéma de câblage

(Figure 2).

a. Le câblage doit être acheminé depuis le sol ou le mur jusqu’au

radiateur, en utilisant un conduit approprié. Un conduit et un

embout de qualité NEMA 4X doivent être utilisés pour les applications NEMA 4X.

b. Le connecteur de mise à la terre doit être relié au fil vert d’arrivée

de terre.

7. Installez le couvercle de l’avant en accrochant son bord supérieur sur

le bord supérieur du panneau arrière, et en fixant sa lèvre inférieure

sur le panneau arrière à l’aide des vis ôtées à l’étape 3.

8. Fermez le couvercle du boîtier de câblage en replaçant les verrous

par-dessus sa lèvre et en serrant ces vis.

Le câblage électrique doit être dimensionné en confor-

Le câblage électrique doit être dimensionné en confor-

10

Page 11

AUTO RESET

THERMAL LIMIT

(N)

GL2L1

ELEMENT

Dimensions

A

4”

Figure 1

INSTRUCTIONS D’UTILISATION

1. Le radiateur doit être correctement installé avant d’être utilisé.

2. Si vous utilisez un thermostat extérieur, référez-vous aux instructions

d’installation et d’utilisation fournies avec ce thermostat.

3. Au moment du démarrage et du contrôle initial, avant la mise sous

tension du radiateur, tournez la tige de réglage du thermostat vers la

position de consigne de chauffage minimale (en sens antihoraire).

Branchez l’alimentation secteur au radiateur et vérifiez qu’il ne

commence pas à chauffer. S’il chauffe déjà, débranchez-le et vérifiez le câblage.

4. Faites ensuite tourner la tige de réglage du thermostat complètement en sens horaire (demande maximale de chauffe) et laissez

fonctionner le radiateur pendant au moins 5 minutes en vérifiant qu’il

chauffe bien.

5. Laisser le radiateur chauffer jusqu’à ce que la température ambiante

atteigne le niveau de confort désiré, puis faites tourner lentement la

tige de réglage du thermostat en sens antihoraire jusqu’à l’audition

ou au ressenti d’un déclic. Cela va fournir le point de consigne

permettant au thermostat d’activer/désactiver le radiateur afin de

maintenir approximativement la température correspondante.

Quelques petits ajustements peuvent être nécessaires pour le

réglage fin du radiateur et sa fourniture du niveau de confort ambiant

optimal. Pour augmenter la durée d’activité du radiateur et augmenter la température de la pièce, tournez un petit peu le réglage du

thermostat en sens horaire. De la même façon, pour réduire la température ambiante, tournez un petit peu le réglage du thermostat en

sens antihoraire.

LIMITEUR THERMIQUE À

RESTAURATION AUTO

Figure 2 – Schéma de câblage

ÉLÉMENT DE

CHAUFFE

3”

Puissance Dimension “A”

(Watts) (Longueur)

500 28” (709 mm)

750 36” (912 mm)

10”

1000 48” (1216 mm)

1250 60” (1520 mm)

1500 72” (1824 mm)

2000 96” (2432 mm)

2500 120” (3040 mm)

INSTRUCTIONS D’ENTRETIEN

Pour un fonctionnement efficace et sûr et pour prolonger la durée de

service des radiateurs, il faut les nettoyer et les inspecter pour des dommages éventuels au moins une fois par an (de préférence au début de

la saison de chauffage), ou plus souvent dans des environnements

sales. En dehors de ce nettoyage, vos radiateurs ne demandent pas

d’autre entretien préventif. L’utilisateur peut effectuer lui-même un nettoyage élémentaire du radiateur. Toute autre intervention est réservée

au personnel de service qualifié.

UNE BLESSURE SÉRIEUSE VOIRE MORTELLE PEUT RÉSULTER

D’UNE COMMOTION ÉLECTRIQUE. ASSUREZ-VOUS QUE LE CIRCUIT D’ALIMENTATION SECTEUR ARRIVANT AU RADIATEUR EST

DÉBRANCHÉ EN AMONT À L’INTERRUPTEUR GÉNÉRAL OU AU

PANNEAU DE SERVICE AVANT D’INTERVENIR POUR DU NETTOYAGE OU DU SERVICE SUR CE RADIATEUR. LAISSEZ LE RADIATEUR REFROIDIR AVANT DE LE NETTOYER POUR ÉVITER DE

POSSIBLES BRÛLURES.

REMARQUE :

TATION ÉLECTRIQUE DANS LE RADIATEUR. ASSUREZ-VOUS

QUE TOUTE L’ALIMENTATION SECTEUR DU RADIATEUR EST

COUPÉE AVANT UNE INTERVENTION. POUR NETTOYAGE OU

SERVICE.

Nettoyage du radiateur

1. Le carter de radiateur peut être nettoyé en utilisant un chiffon

humide pour enlever la poussière qui peut s’être accumulée sur les

surfaces. N’utilisez pas de nettoyants forts ni de cires sur les surfaces car cela pourrait endommager leur finition ou la décolorer à

l’usage.

2. Un aspirateur et/ou de l’air comprimé peuvent être utilisés pour

enlever la poussière et la peluche qui peuvent s’être accumulées

dans le radiateur autour des ailettes d’élément. Si le radiateur doit

être démonté pour son nettoyage, ôtez les vis retenant le couvercle

de l’avant et sortez-le pour accéder à l’intérieur. Faites attention en

nettoyant les ailettes de l’élément de chauffe pour éviter de les

endommager.

IL PEUT ENTRER PLUS D’UNE SOURCE D’ALIMEN-

LES AILETTES SONT TRANCHANTES ET PEUVENT CAUSER DES

COUPURES,

ÉVITEZ DONC DE LES TOUCHER DIRECTEMENT

3. Après une intervention de nettoyage ou de service, remettez en

place le couvercle de l’avant en vous assurant qu’il est bien fixé en

haut et en bas.

4. Remettez le radiateur sous tension et vérifiez son bon fonctionnement.

11

Page 12

NOUVELLE PEINTURE

La finition en émail au four a été choisie pour se fondre dans le décor de

l'intérieur. Si vous souhaitez repeindre vos radiateurs, utilisez une peinture émaillée domestique de bonne qualité. Un apprêt n’est pas nécessaire avant de repeindre. Cependant un ponçage préliminaire léger est

recommandé. N’utilisez pas de peinture caoutchoutée. Ne repeignez

que le couvercle de l’avant. Ne peignez pas sur l’élément de chauffe ni

sur son protecteur.

IMPORTANTES INFORMATIONS

Poids

d’expédi-

tion en

livres

17 lbs

22 lbs

27 lbs

33 lbs

38 lbs

45 lbs

50 lbs

N° au cata-

logue

ST4X02500

ST4X03750

ST4X041000

ST4X051250

ST4X061500

ST4X082000

ST4X102500

Lon-

gueur

28”

36”

48”

60”

72”

96”

102”

Watts/

pied

250

250

250

250

250

250

250

Capacité totale

de chauffe

Watts

500

750

1000

1250

1500

2000

2500

1706

2560

3412

4266

5120

6824

8532

120 V BTU/H

10,4

12,5

16,7

20,8

4,2

6,3

8,3

Ampérage

208 V 240 V 277 V 347 V 480 V

2,4

3,6

4,8

6,0

7,2

9,6

12,0

2,1

3,1

4,2

5,2

6,3

8,3

10,4

1,8

2,7

3,6

4,5

5,4

7,2

9,0

1,4

2,2

2,9

3,6

4,3

5,8

7,2

1,0

1,6

2,1

2,6

3,1

4,2

5,2

600 V

0,8

1,3

1,7

2,1

2,5

3,3

4,2

*Le N° au catalogue montré dans le tableau qui précède sera suivi d’un suffixe à trois chiffres indiquant la tension et la phase du

secteur d’alimentation.

121 = 120 V/Mono 271 = 277 V/Mono

201 = 208 V/mono 341 = 347 V/Mono

241 = 240 V/Mono 601 = 600 V/ Mono

GARANTIE LIMITÉE

Tous les produits fabriqués par Marley Engineered Products sont garantis contre les défauts dus à la main-d'oeuvre et aux matériaux pendant un an à compter de leur date

d'installation, à l'exception des éléments chauffants qui eux portent une garantie dans les mêmes conditions de cinq ans. Cette garantie ne s'applique pas pour des dommages résultant d'accident, de mésusage ou d'altération ; ni si l'appareil a été branché sur un secteur faisant 5 % de plus que la tension de sa plaque signalétique ; ni si

l'appareil a été mal installé ou mal câblé ou mal entretenu, en ne respectant pas les instructions d'installation et d'entretien. Toutes les demandes portant sur du travail dans

le cadre de la garantie doivent être accompagnées d'une preuve de la date d'installation.

Le client gardera à sa charge tous les coûts encourus pour le démontage et la réinstallation des produits, incluant les coûts de main d'oeuvre et les coûts de transport pour

envoyer les produits au centre de service de Marley Engineered Products. Compte tenu des limitations de cette garantie, les unités présentant un dysfonctionnement doivent

être retournées au centre de service Marley agréé le plus proche, ou directement au centre de service de Marley Engineered Products, et nous le réparerons ou le remplacerons, à notre choix, sans frais, et nous vous renverrons un appareil en port prépayé par Marley. Vous devez convenir que cette réparation ou ce remplacement sera

le seul remède fourni par Marley Engineered Products.

LES GARANTIES QUI PRÉCÈDENT TIENNENT LIEU DE TOUTES AUTRES FORMES DE GARANTIES, EXPLICITES OU IMPLICITES, INCLUANT CELLES DE

VALEUR MARCHANDE OU D'ADÉQUATION À UNE FINALITÉ PARTICULIÈRE. TOUT CE QUI EXCÈDERAIT LES GARANTIES ÉNONCÉES PLUS HAUT EST ICI

REJETÉ ET EXCLU DE CE CONTRAT. MARLEY ENGINEERED PRODUCTS NE SERA PAS TENU POUR RESPONSABLE DE DOMMAGES CONSÉCUTIFS SURVENANT EN RELATION AVEC CE PRODUIT, QU'ILS VIENNENT DE NÉGLIGENCE, DE TORT, DE RESPONSABILITÉ ABSOLUE OU CONTRACTUELLE.

Certaines provinces ne permettent pas l'exclusion ou la limitation des dommages accessoires ou consécutifs, de ce fait l'exclusion ou la limitation qui précède peut ne pas

s'appliquer dans votre cas. Cette garantie vous donne des droits légaux spécifiques, et vous pouvez également avoir d'autres droits qui varient d’une province à l'autre.

Pour obtenir l'adresse du centre de service agréé le plus proche de chez vous, contactez Marley Engineered Products à Bennettsville, SC, au 1-800-642-4328. Les

marchandises retournées à l'usine doivent être accompagnées par une autorisation de renvoi et une étiquette d'identification de service, toutes deux fournies par Marley

Engineered Products. Quand vous demandez une autorisation de renvoi, incluez tous les numéros d'identification relevés sur les produits concernés.

COMMENT OBTENIR DU SERVICE ET DES PIÈCES DANS LE CADRE

DE LA GARANTIE ET DES INFORMATIONS GÉNÉRALES

1. Service et pièces sous garantie

2. Pièces détachées à acheter

3. Informations générales sur les produits

Remarque :

1. Référence de modèle du produit

2. Date de fabrication

3. Numéro ou description de pièce

Pour obtenir le service sous garantie vous devez toujours avoir préparé :

N° de document 5200-2595-001

1-800-642-4328

1-800-654-3545

www.marleymep.com

ECR38672

12/10

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...