Page 1

SLQDB

Slim Line Draft Barrier

Convection Heaters

Dimensions

Type Height Width Length

SLQDB

Installation, Operation & Maintenance Instructions

GENERAL

This heater is designed to provide years of efficient, trouble free operation as a primary or supplemental heat source for comfort

heating in residential and commercial applications. Installation or use of this product in any manner not described within this manual

will void the warranty and could result in injury, damage to property, or permanent damage to heater.

4” 2-5/8” 24” to 12’

152mm 69mm 610mm to 3658mm

IMPORTANT INSTRUCTIONS

WARNING

WHEN USING ELECTRICAL APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE

THE RISK OF FIRE, ELECTRIC SHOCK, AND INJURY TO

PERSONS, INCLUDING THE FOLLOWING:

1. Read all instructions before installing or using the heater.

2. A heater has hot and arcing or sparking parts inside. Do not

use in areas where gasoline or flammable liquids are used

or stored.

3. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, and curtains away from heater.

!

4. To prevent a possible fire, do not block air intakes or

exhaust in any manner.

5. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock or

fire, or damage the heater.

6. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

is disconnected at main disconnect or service panel before

installing or servicing this heater.

7. SLQDB model with 188 watts per linear foot or less, without

wire mesh, are ETL listed for residential use.

8. SLQDB model at 188 watts per linear foot must be mounted above finished floor with a clearance of 2 inches.

SAVE THESE INSTRUCTIONS

Page 2

Table A - SLQDB (Technical Data)

CEILING

FLOOR FLOOR

DRAPES

HEATER

WALL

WALL

CEILING

MIN. 1/2”

(13 mm)

MIN. 2”

(51 mm)

MIN. 2-1/2”

(64 mm)

MIN. 1/2”

(13 mm)

MIN. 6”

(152 mm)

HEATER

DRAPES

Catalog Length Watts Total

Number "L" per ft. Watts 120V 208V 240V 277V 347V 600V

22100 100 200 -- 1.0 -- -- -- -22150 24” 150 300 2.5 1.4 1.3

22188 (610mm) 188 376 3.1 1.8 1.6 1.4 -- -02100 100 200 1.7 1.0 0.8 -- -- --

02125 28" 125 250 2.1 1.2 1.0 0.9 -- -02150 (711mm) 150 300 2.5 1.4 1.3 1.1 -- --

2188 188 376 3.1 1.8 1.6 1.4 -- --

0

03100 100 300 2.5 1.4 1.3 1.1 -- --

03125 3' 125 375 3.1 1.8 1.6 1.4 1.1 --

3150 (914mm) 150 450 3.8 2.2 1.9 1.6 1.3 --

0

03188 188 564 4.7 2.7 2.4 2.0 1.6 --

4100 100 400 3.3 1.9 1.7 1.4 1.2 --

0

4125 4' 125 500 4.2 2.4 2.1 1.8 1.4 --

0

04150 (1219mm) 150 600 5.0 2.9 2.5 2.2 1.7 -04188 188 752 6.3 3.6 3.1 2.7 2.2 1.3

05100 100 500 4.2 2.4 2.1 1.8 1.4 0.8

05125 5' 125 625 5.2 3.0 2.6 2.3 1.8 1.0

05150 (1524mm) 150 750 6.3 3.6 3.1 2.7 2.2 1.3

5188 188 940 7.8 4.5 3.9 3.4 2.7 1.6

0

06100 100 600 5.0 2.9 2.5 2.2 1.7 1.0

06125 6' 125 750 6.3 3.6 3.1 2.7 2.2 1.3

6150 (1829mm) 150 900 7.5 4.3 3.8 3.2 2.6 1.5

0

06188 188 1128 9.4 5.4 4.7 4.1 3.3 1.9

7100 100 700 -- 3.4 2.9 2.5 2.0 1.2

0

7125 7' 125 875 -- 4.2 3.6 3.2 2.5 1.5

0

07150 (2134mm) 150 1050 -- 5.0 4.4 3.8 3.0 1.8

07188 188 1316 -- 6.3 5.5 4.8 3.8 2.2

08100 100 800 -- 3.8 3.3 2.9 2.3 1.3

08125 8' 125 1000 -- 4.8 4.2 3.6 2.9 1.7

08150 (2438mm) 150 1200 -- 5.8 5.0 4.3 3.5 2.0

8188 188 1504 -- 7.2 6.3 5.4 4.3 2.5

0

09100 100 900 -- 4.3 3.8 3.2 2.6 1.5

09125 9' 125 1125 -- 5.4 4.7 4.1 3.2 1.9

09150 (2743mm) 150 1350 -- 6.5 5.6 4.9 3.9 2.3

09188 188 1692 -- 8.1 7.1 6.1 4.9 2.8

10100 100 1000 -- 4.8 4.2 3.6 2.9 1.7

10125 10' 125 1250 -- 6.0 5.2 4.5 3.6 2.1

10150 (3048mm) 150 1500 -- 7.2 6.3 5.4 4.3 2.5

10188 188 1880 -- 9.0 7.8 6.8 5.4 3.1

Amperage

--

-- --

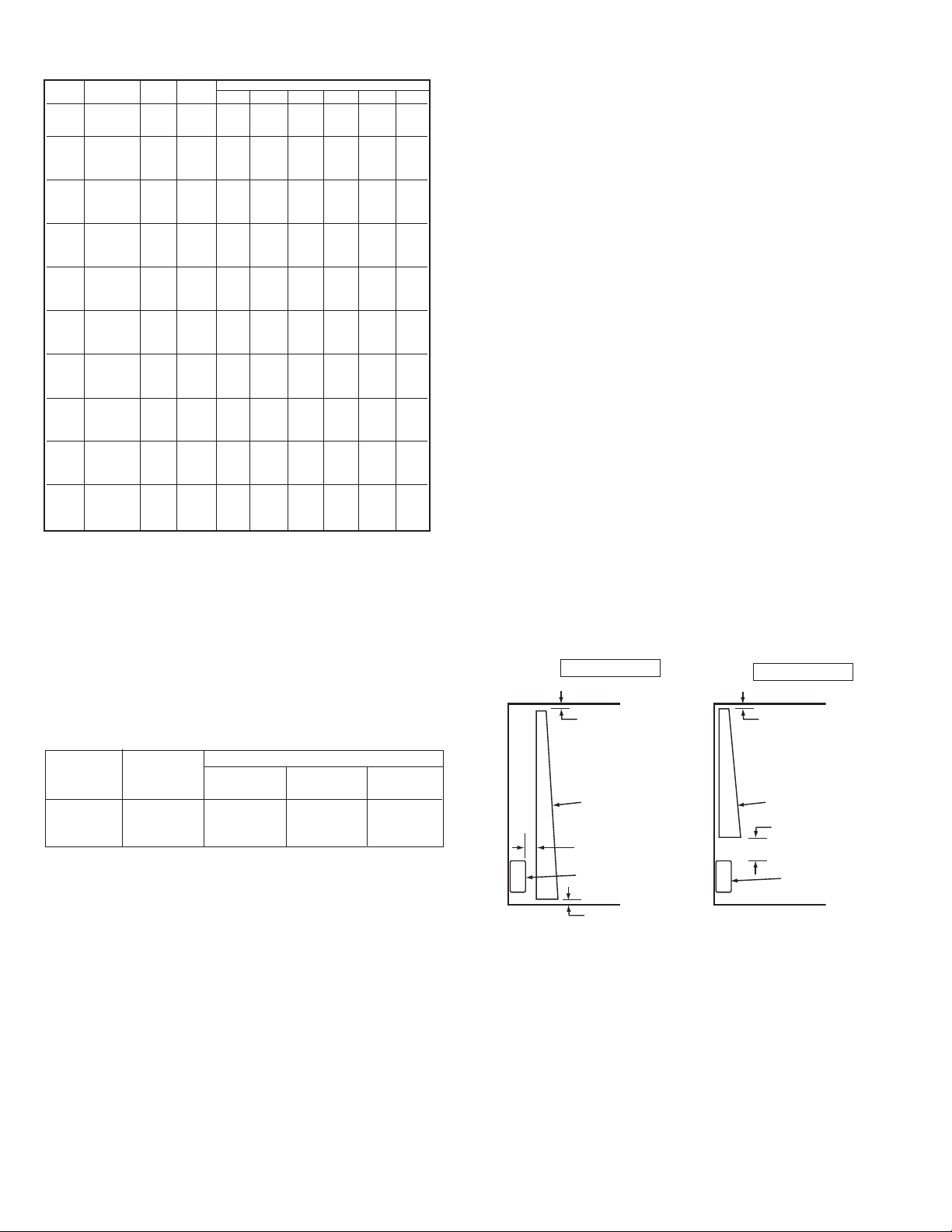

Clearance Chart:

For safe and efficient operation, maintain at least the following

minimum clearances at all times(see Fig. 1):

Bottom of Heater to Finished Floor:

• For models 188 watts per foot or more, bottom of units must

be mounted at least 2” off floor.

• Bottom Inlet Models:

- 100-188 watts per foot – 2 inch (51 mm)

Top of Heater to Ceiling (all models):

- Minimum 36 inches (914 mm)

Top of Heater to Bottom of Drapes (See Example 2):

- Minimum 6 inches (152 mm)

IMPORTANT NOTE:

as vinyl blinds) may become damaged by the heated air from

the heater and should not be installed above the heater.

Front of Heater to Full Length Drapes (See Example 1):

- Minimum between bottom of drapes and floor – 2-1/2 inches

(64 mm)

- Minimum between top of drapes and ceiling – 1/2 inch (13

mm)

- Minimum between front of heater and nearest fold of drape –

2 inches (51 mm)

Top of Heater to Bottom of Window Sill:

- Minimum 12 inches (305 mm)

Certain fabrics and vinyl materials (such

Table B. Sizing Field Installed Wiring

Max. No.

wire installed

in wireway

5

4

2

Up to 2

conductors

7 Amps

9 Amps

12.0 Amps

Copper wire

size 90º C

No. 12 AWG

No. 10 AWG

No. 8 AWG

Maximum Allowable Current

3 to 4

conductors

5 Amps

7 Amps

conductors

4.5 Amps

6 Amps

10 Amps

4 to 5

-

Example 1

Fig. 1: Clearance for Drapery

2

Example 2

Page 3

INSTALLATION INSTRUCTIONS

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

are disconnected at main disconnect or service panel

before installing this heater.

2. Wiring procedures and connections must be in accordance

with the National Electrical Code (NEC) and local codes.

Refer to Wiring Diagram on heater and Figure 8. Make sure

all electrical connections are tight to prevent possible overheating. Use Copper Supply Wire Only.

3. Verify the electrical power supply voltage matches the voltage rating as printed on the heater nameplate.

CAUTION - Never connect a heater to a voltage greater than

the nameplate voltage as this will damage the heater and

could cause a fire.

4. Do not install the heater against combustible low-density

cellulose fiberboard surfaces, against or below vinyl wall

coverings, or below any materials that may be damaged by

heat such as vinyl or plastic blinds, curtains, etc.

5. Do not install heater below an electrical convenience receptacle (outlet).

CAUTION

6.

electrical cords (including telephone and computer cables),

drapes, and other furnishings away from heater. For efficient and safe operation, we recommend maintaining a minimum of 6 inches (152 mm) clearance above and in front of

the heater at all times. See Clearances Chart for minimum

clearance requirements.

7. To reduce the risk of fire, do not store or use gasoline or

other flammable vapors or liquids in the vicinity of the

heater.

8. Do not install heater upside down or in any position other

than as shown in this manual.

9. Do not recess heater in wall or install heater inside any type

enclosure as this will cause heater to overheat and could

create a hazard.

10. When mounting heater, use care when drilling mounting

holes and mounting heater to building structure to avoid

damaging internal heater components. Be sure to loosen

mounting screws ½ turn to allow for expansion and contraction.

11. Do not remove or bypass the safety limit control(s) (thermal

protectors) as this could allow heater to become a fire hazard, see heater wiring diagram supplied with heater.

12. The factory installed wires inside wireway are used to connect the built-in controls. Limit the maximum current to no

more than 45 total amp. Refer to instructions and current

capacity rating as provided with the accessory.

13. Heaters that are not installed end to end must have end

caps installed to cover exposed ends of heater.

14. Do not allow objects to be placed on top of heater as they

may be damaged or create a fire hazard.

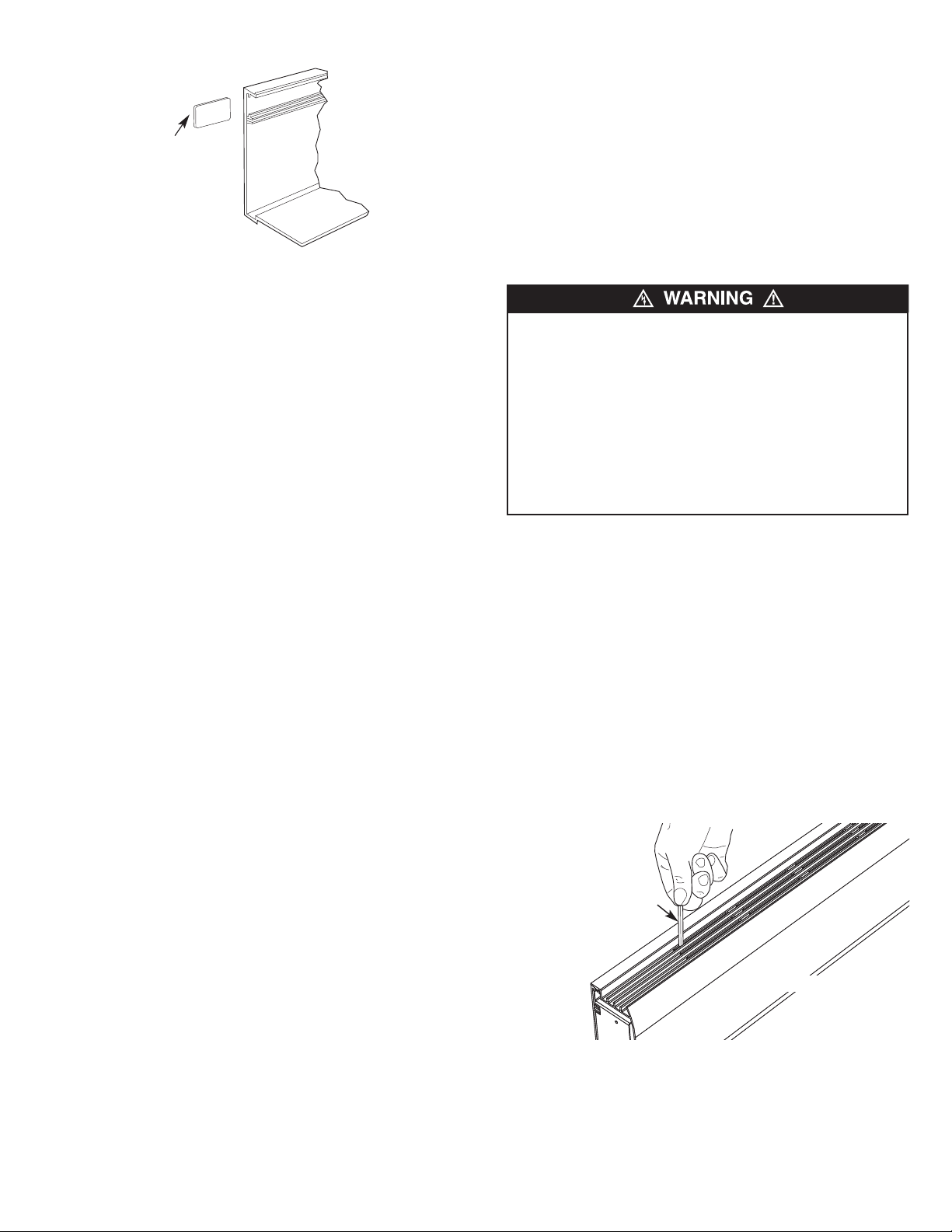

15. To avoid damaging heater, do not use a screw driver to

separate front cover from back housing. Use only a putty

knife as shown, see Fig. 2

16. Before energizing, make sure front cover is properly locked

onto the back housing along the entire length of the heater,

see Fig. 5. Do not operate heater without front cover

installed.

– Heater operates at high temperatures. Keep

Rough in Wire

1. Run branch circuit of proper voltage and wire size to location

of left or right junction box as indicated on heater wiring diagram. Basic heaters are prewired and can be connected to

branch circuit at either end. Heaters with controls are

prewired for connection to branch circuit at one end only

(refer to heater wiring diagram). However, heater can be

wired from opposite end by running wires through heater

wireway. See Fig. 3 for knockout locations.

2. If it is necessary to run wires through the heater wireway,

use Table B to size the field installed wiring.

3. The factory installed wires in the heater wireway can be

loaded up to 45 amps. Refer to Table C for maximum length

of heater run when the heaters are connected in parallel.

Disconnect Switch:

Thermostat:

Transformer Relay:

Power Relay

Pneumatic/Electric

Switch

NOTE:

For mix of watt densities, calculate amp draw. Do not

exceed 45 amps.

4. Standard 90º C wiring must be used in junction boxes, wire-

ways, blank sections, filler sections and corner sections.

20 amps @ 120-277 VAC

25 amps @ 120-240 VAC

22 amps @ 277 VAC

25 amps @ 120-240 VAC

22 amps @ 277 VAC

17 amps @ 347 VAC

12 amps @ 600 VAC

25 amps @ 120-277 VAC

25 amps @ 120-277 VAC

Room Layout

Refer to heating plans for exact room arrangement of heaters

(with or without thermostats and/or relays and/or switches and

accessories).

Check the heater section dimensions and the additional wall

length required for filler sections or blank sections before starting wall-to-wall type installation. Be certain all heaters and

accessories needed are at hand and are of correct finish.

Mounting Height (see Clearance Chart)

NOTE:

Up to 3/4” thick floor covering, such as carpets, tiles,

linoleum, etc., may be installed around and under the heater

without adversely affecting the performance of the heaters.

At correct height, draw a pencil line on the wall, level and/or

parallel with the window sill. Minimum mount heights above the

floor shall be as follows.

Installation of Single Unit

NOTE:

For ease of installation, it is important that the sequence

of operation indicated below be followed in order. For heaters

with more than one heat deck, heat decks may be wired in parallel or each heat deck may be supplied by separate circuit. See

heater nameplate for current load for each heat deck.

1. Remove unit from carton and discard external pads and

plastic wrap.

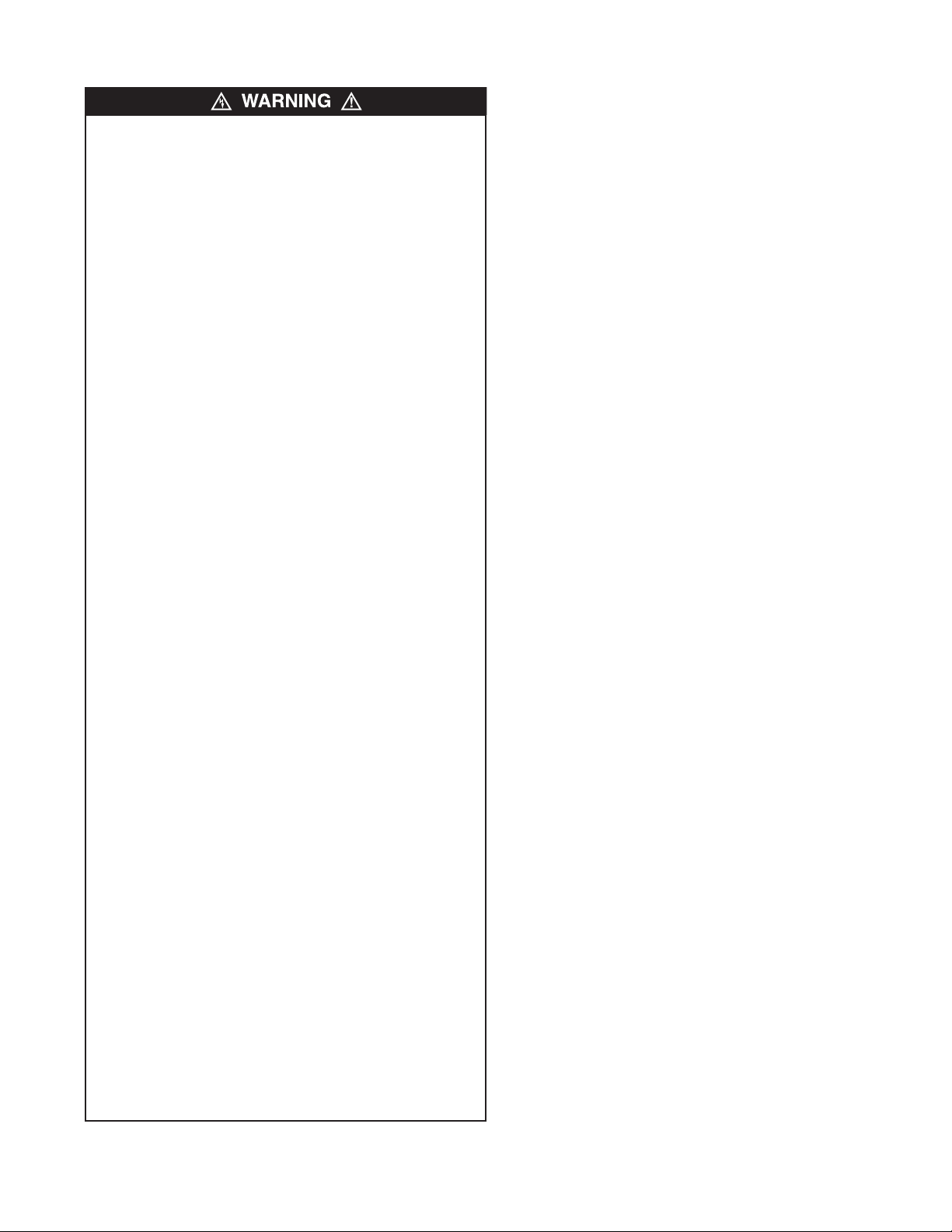

2. Remove front cover by laying the heater on its back and

inserting a putty knife (or other thin, wide blade tool, 1”

[25mm] wide minimum) approximately 6” (152mm) from the

end of the heater and prying up as shown in Fig.2. This will

spring the snap lock closure open. Repeat as required down

the length of the heater until the front cover completely disengages from the heater back.

3

Page 4

D

X

E

D

C

E

H

W

B

A

5/8” hole

1-3/8”

(35mm)

KO

7/8”

(22mm)

KO

7/8”

(22mm)

KO

1-3/8”

(35mm)

KO

1-23/32”

(44mm)

KO

Junction

Box

Back

Bottom

Cabinet front

cover

Putty knife or

other wide blade

tool

Recommended

mounting holes

drill area (for

wall mounting

Cabinet

back

housing

Fig. 2

NOTE:

Illustration shown only

to take off front cover.

3. Remove appropriate electrical knockouts from either junction

box. See Fig. 3 for location of knockouts. If heater is to be

pedestal mounted, consult pedestal kit installation instructions.

4. Drill the required size mounting holes in the heater housing

(See Fig. 2 for recommended mounting hole location.)

5. Hold heater housing against the wall to check for evenness

of wall. Do not draw heater against an uneven wall surface. If

an uneven wall is encountered, use shims to keep the heater

housing straight.

SLQDB

1.27” (32)

A

2.00”(51)

B

1.63” (41)

C

D

E

H

W

1.00(25.4)

X

1.37”(35)

1.53”(39)

1.81”(46)

1.25”(32)

in. (mm)

Pedestal placement and

KOs shown are for standard

units. Custom enclosures

and/or heat decks will have

pedestal placement and

KOs in various locations.

Consult factory.

Fig. 3

6. Run proper size branch circuit to the junction box through the

selected knockout.

7. Mount the heater on the wall using screws, bolts or anchors

(by installer) to suit the wall construction.

8. Tighten mounting screw and back off 1/2 turn to allow for

expansion and contraction of the heater.

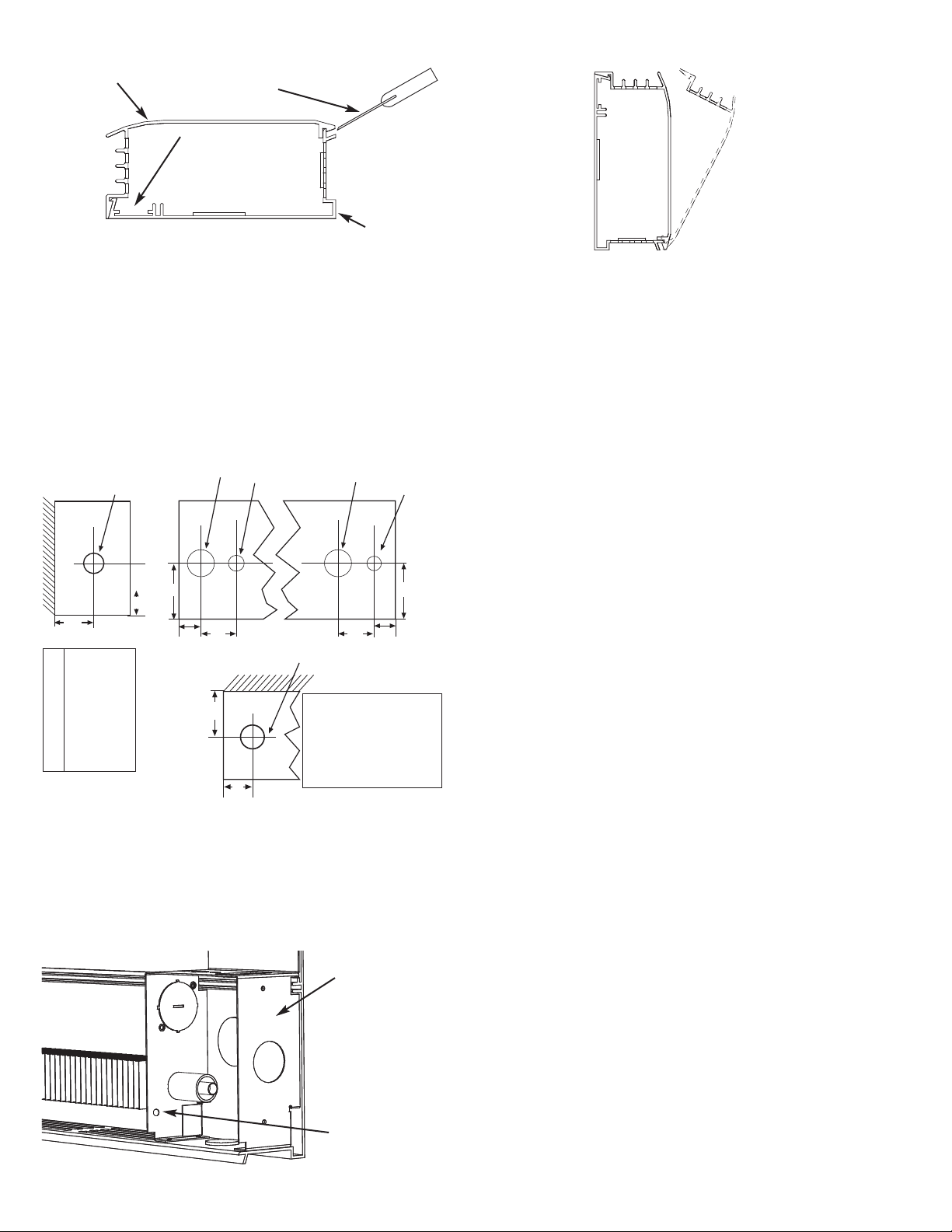

Junction Box

Ground Screw

Fig. 4

Fig. 5

9. Following the wiring diagram secured to the heater, make

electrical connections. Ground the heater using the ground

screw provided. See Fig. 4.

10.Replace front cover by latching the bottom front edge of the

front cover over the bottom front edge of the back and pushing the cover straight back to latch the top rear edge of the

back with the top rear edge of the front cover. See Fig. 5.

Installation of Multiple Wall to Wall Units

NOTE:

of operations indicated below be followed in order.

1. Repeat Steps 1 & 2 from Single Unit Installation.

2. Refer to wiring diagram for power supply entry and remove

3. If filler sections, inside corners, outside corners, splice kits or

NOTE:

and is to have a filler section at either end, the filler must not

cover the access to those controls.

4. If the run of the heaters includes an inside corner or an out-

5. Drill the required size mounting holes in all the heater hous-

6. Hold heater housings against wall to check for evenness of

7. Run proper size branch circuit to the junction box through the

8. Mount the heaters on the wall using screws, bolts or anchors

9. Following the wiring diagram secured to the heater, make the

10.Replace front covers following Step 10 under

4

For ease of installation, it is important that the sequence

appropriate electrical knockout (Fig. 3) from the heater in

which power supply connections are to be made. The power

supply may be brought into the end of one heater and the

remaining heaters may be connected in parallel using the

wireway. Use Table B to size the field installed wiring in the

wireway or use Table A to determine the maximum length or

heater run possible using the factory installed wire in the

heater wireway.

end caps are to be used, consult convector accessory installation instructions. If units are to be pedestal mounted, consult the convector accessories installation instructions.

If a heater has a disconnect switch and/or thermostat

side corner, mount corner to wall (see accessory installation

instructions packed with corners), then mount heater.

ings. (See Fig. 2 for recommended mounting hole location.)

the wall. Do not draw the heaters against an uneven wall

surface. If an uneven wall is encountered, use shims to keep

the heater housing straight.

selected knockout.

(by installer) which suit the wall construction. Alignment tabs

can be inserted in adjoining back housings to assure even

alignment. See Fig. 6 for details.

electrical connections. Refer to Fig. 8 to connect the other

heaters in parallel. Grounding of the other heaters is accomplished by connecting a jumper wire (not supplied) between

the two adjacent heaters.

Single Unit

Installation

, (See Fig. 5.)

Page 5

Alignment

Tab

Fig. 6

Back

Housing

Blank Sections

Blank sections, if any, are installed in the same manner as the

heaters.

OPERATION INSTRUCTIONS

1. After heater(s) are completely assembled and installed, set

thermostat or operating controls for NO HEAT and energize

the heater circuit (s). Verify the heater(s) are not producing

heat.

2. Adjust thermostat or operating control to call for heat. Allow

heater(s) to operate for a few minutes and verify all heaters

are producing heat.

Note:

during initial start up, heaters may exhibit a new smell

and possibly some slight smoke from the manufacturing

residues on the heating element. Allow heaters to operate for

approximately 30 minutes to dissipate these residues.

Ventilating the area may be desired.

3. To set thermostat or operating controls to maintain desired

comfort level, allow heaters to operate until room ambient

temperature reaches the desired level. The thermostat or

operating control can then be adjusted to maintain this temperature.

Note:

when built-in thermostat and/or disconnect switch is/or

provided, access to these controls will be through grille openings

at either end of the heater. To rotate the thermostat shaft will

require a small flat blade screw driver. The disconnect switch is

a rocker switch that can be operated with the same screw driver

or tool through the openings.

4. If built-in thermostat is provided, after room reaches desired

comfort level, rotate thermostat shaft counterclockwise until

the thermostat clicks. This should allow the thermostat to

cycle the heater on and off to maintain this temperature.

Rotation in the clockwise direction will allow the heater to

remain ON MORE and will maintain a HIGHER room ambient. Likewise, rotation in the counterclockwise direction will

result in the heater remaining ON LESS and the room ambient will be LOWER. If remote thermostat or other types of

controls are provided, refer to the instructions provided with

these controls for proper operation.

IMPORTANT NOTE:

safety limit (Thermal Protector– see Fig. 8) to automatically turn

off the heater if it is blocked or otherwise overheats due to an

abnormal condition. The heaters should not be cycling off on

this safety control during normal use. If this is occurring, check

heater installation to assure it has adequate clearances and the

free airflow around heater is not restricted. If heater continues

to cycle on this safety control, discontinue using until it can be

inspected and/or repaired by a qualified electrician.

These heaters are provided with a built-in

MAINTENANCE INSTRUCTIONS

Your heater will give your years of service and comfort with only

minimal care. The user can perform periodic cleaning of the

exterior cabinet, but all other interior cleaning and servicing

should be done by a qualified service person.

Note:

For efficient and safe operation, airflow must not be

restricted in and around the heater. As air moves through the

heater by convection, dust and lint may accumulate in the

heater and around the heating element that needs to be cleaned

periodically. It is recommended that your heater be cleaned and

inspected for damage at least annually (or more often if

needed).

1. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit(s) coming to

heater is/are disconnected at main disconnect or service

panel before servicing this heater. Allow heater to cool

before cleaning to prevent a possible burn.

Note

Be sure all power is disconnected to heater before

cleaning or servicing.

2. Use care when cleaning element fins to avoiding damaging

1. The exterior of the heater may be cleaned with a damp cloth.

2. To clean interior of heater will require the removal of the front

3. With front cover removed, a vacuum cleaner or compressed

Fig. 7

4. As a matter of normal maintenance, check remainder of

5. Replace front cover as shown in Fig. 5 making sure it is

More than one power source may enter heater.

:

fins. Note also that fins are sharp and may cause cuts so

avoid contact.

However, do not use harsh cleaners, polishes, or waxes as

these may damage the surface or leave a residue that will

discolor.

cover. To remove the front cover, disengage the top rear

snap-lock first. Use an “L” shaped tool, such as an Allen

Wrench, to lift up under the webs between the back row of

slots (See Fig. 7). Start at either end and lift up on the front

cover until the tension in the cover pulls the cabinet apart.

Continue moving along the length of the heater until the

cover comes off.

air can be used to clear dust and lint from inside heater and

around the heating element. Fins are sharp and may cause

cuts so avoid contact by hands. Use care to not damage the

aluminum fins.

Allen Wrench or

other 90º tool

Front Cover

heater for damage or possible maintenance issues while

cover is removed and make any repairs needed.

locked in position along length of heater. Restore power to

heater and verify it is operating properly.

5

Page 6

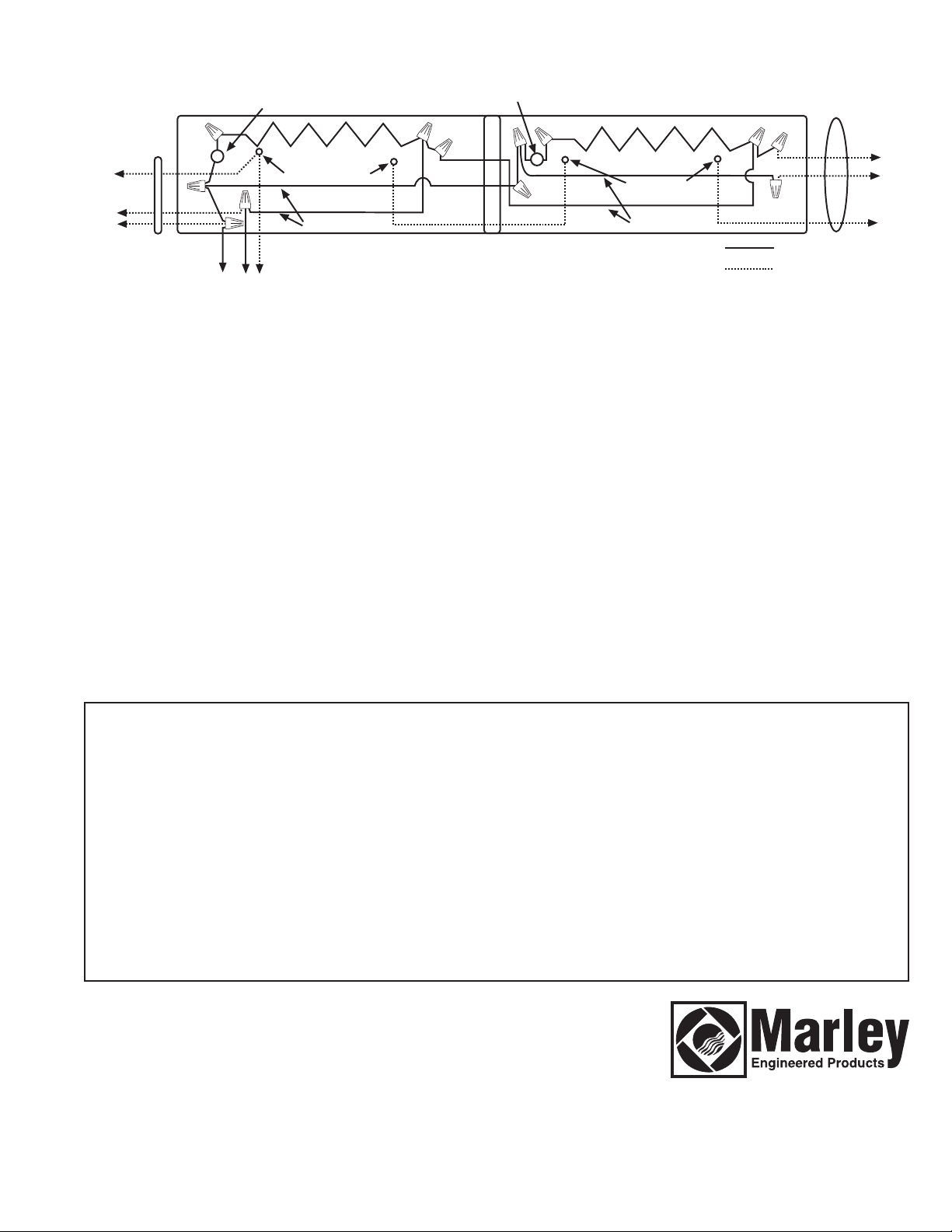

No. 10 Wires

Factory Wiring

Field Wiring

Element

Element

Ground Screw

Ground Screws

Thermal Protector

Thermal Protector

Power Supply to Circuit Breaker

To other

heater

To other

heater

No. 10 Wires

Typical Wiring of Multiple Heaters (without controls)

Fig. 8

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

1-800-642-4328

1-800-654-3545

www.marleymep.com

Part No. 5200-11072-000

PPD 15761

07/11

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 7

Calefactores de convección

tipo barrera, línea delgada,

SLQDB

Dimensiones

Tipo Altura Ancho Longitud

SLQDB

Instrucciones de instalación, operación y mantenimiento

GENERALIDADES

Este calefactor está diseñado para proporcionar años de funcionamiento eficiente sin problemas como fuente de calor principal o

complementaria para calefacción en aplicaciones residenciales y comerciales. La instalación o uso de este producto de una manera diferente a la descrita en este manual anulará la garantía y podría resultar en lesiones, daño a la propiedad, o daño permanente al calefactor.

6” 2-5/8” 24” a 12’

152 mm 69 mm 610 mm a 3658 mm

INSTRUCCIONES IMPORTANTES

ADVERTENCIA

AL UTILIZAR APARATOS ELÉCTRICOS, SIEMPRE DEBEN

SEGUIRSE PRECAUCIONES BÁSICAS PARA REDUCIR EL

RIESGO DE INCENDIO, DESCARGA ELÉCTRICA Y

LESIONES A PERSONAS, INCLUYENDO LO SIGUIENTE:

1. Lea todas las instrucciones antes de instalar o utilizar el

calefactor.

2. Un calefactor tiene en su interior piezas calientes, piezas

que forman arcos eléctricos o piezas que producen chispa.

No utilice en áreas donde se utilice o almacene gasolina o

líquidos inflamables.

3. Este calefactor estará caliente mientras está en uso. Para

evitar quemaduras, no permita que la piel desnuda haga

contacto con las superficies calientes. Mantenga alejados

del calefactor los materiales combustibles tales como muebles, almohadas, ropa de cama, papeles, ropa y cortinas.

!

4. Para evitar un posible incendio, no obstruya de ninguna

manera las entradas o salida del aire.

5. No inserte ni permita que objetos extraños ingresen a las

aberturas de ventilación o de salida, ya que esto podría

causar una descarga eléctrica, incendio, o podría dañar el

calefactor.

6. Podrían producirse lesiones graves o la muerte por descarga eléctrica. Antes de instalar o suministrar servicio de

mantenimiento a este calefactor, verifique que el circuito de

suministro de energía eléctrica que llega al calefactor está

desconectado en el interruptor de desconexión principal o

panel de servicio.

7. El modelo SLQDB con 188 watts por pie lineal o menos, sin

malla de alambre, tiene la certificación ETL para uso residencial.

8. El modelo SLQDB con 188 watts por pie lineal debe montarse sobre piso acabado con un espacio libre de 2 pulgadas.

GUARDE ESTAS INSTRUCCIONES

Page 8

Tabla A - SLQDB (Datos técnicos)

CEILING

FLOOR FLOOR

DRAPES

HEATER

WALL

WALL

CEILING

MIN. 1/2”

(13 mm)

MIN. 2”

(51 mm)

MIN. 2-1/2”

(64 mm)

MIN. 1/2”

(13 mm)

MIN. 6”

(152 mm)

HEATER

DRAPES

Número de

Longitud Watts Watts Amperaje

catálogo "L" por pie total 120 V 208 V 240 V 277 V 347 V 600 V

22100 100 200 -- 1.0 -- -- -- -22150 24” 150 300 2.5 1.4 1.3

22188 (610 mm) 188 376 3.1 1.8 1.6 1.4 -- -02100 100 200 1.7 1.0 0.8 -- -- --

02125 28" 125 250 2.1 1.2 1.0 0.9 -- -02150 (711 mm) 150 300 2.5 1.4 1.3 1.1 -- --

2188 188 376 3.1 1.8 1.6 1.4 -- --

0

03100 100 300 2.5 1.4 1.3 1.1 -- --

03125 3' 125 375 3.1 1.8 1.6 1.4 1.1 --

3150 (914 mm) 150 450 3.8 2.2 1.9 1.6 1.3 --

0

03188 188 564 4.7 2.7 2.4 2.0 1.6 --

4100 100 400 3.3 1.9 1.7 1.4 1.2 --

0

4125 4' 125 500 4.2 2.4 2.1 1.8 1.4 --

0

04150 (1219 mm) 150 600 5.0 2.9 2.5 2.2 1.7 -04188 188 752 6.3 3.6 3.1 2.7 2.2 1.3

05100 100 500 4.2 2.4 2.1 1.8 1.4 0.8

05125 5' 125 625 5.2 3.0 2.6 2.3 1.8 1.0

05150 (1524 mm) 150 750 6.3 3.6 3.1 2.7 2.2 1.3

5188 188 940 7.8 4.5 3.9 3.4 2.7 1.6

0

06100 100 600 5.0 2.9 2.5 2.2 1.7 1.0

06125 6' 125 750 6.3 3.6 3.1 2.7 2.2 1.3

6150 (1829 mm) 150 900 7.5 4.3 3.8 3.2 2.6 1.5

0

06188 188 1128 9.4 5.4 4.7 4.1 3.3 1.9

7100 100 700 -- 3.4 2.9 2.5 2.0 1.2

0

7125 7' 125 875 -- 4.2 3.6 3.2 2.5 1.5

0

07150 (2134 mm) 150 1050 -- 5.0 4.4 3.8 3.0 1.8

07188 188 1316 -- 6.3 5.5 4.8 3.8 2.2

08100 100 800 -- 3.8 3.3 2.9 2.3 1.3

08125 8' 125 1000 -- 4.8 4.2 3.6 2.9 1.7

08150 (2438 mm) 150 1200 -- 5.8 5.0 4.3 3.5 2.0

8188 188 1504 -- 7.2 6.3 5.4 4.3 2.5

0

09100 100 900 -- 4.3 3.8 3.2 2.6 1.5

09125 9' 125 1125 -- 5.4 4.7 4.1 3.2 1.9

09150 (2743 mm) 150 1350 -- 6.5 5.6 4.9 3.9 2.3

09188 188 1692 -- 8.1 7.1 6.1 4.9 2.8

10100 100 1000 -- 4.8 4.2 3.6 2.9 1.7

10125 10' 125 1250 -- 6.0 5.2 4.5 3.6 2.1

10150 (3048 mm) 150 1500 -- 7.2 6.3 5.4 4.3 2.5

10188 188 1880 -- 9.0 7.8 6.8 5.4 3.1

-- --

--

Diagrama de espacios libres:

Para un funcionamiento seguro y eficiente, siempre mantenga los siguientes espacios libres mínimos (vea Fig. 1):

Entre la parte inferior del calefactor y el piso con acabado:

• Para los modelos de 188 watts por pie o más, la parte inferior de las

unidades debe montarse a al menos 2” de distancia del piso.

• Modelos con entrada de aire inferior (por abajo):

- 100 a 188 watts por pie – 2 pulgadas (51 mm)

Entre la parte superior del calefactor y el techo/cielo raso (todos los

modelos):

- 36 pulgadas (914 mm) mínimo

Entre la parte superior del calefactor y la parte inferior de cortinas (Vea

el ejemplo 2):

- 6 pulgadas (152 mm) mínimo

NOTA IMPORTANTE:

persianas de vinilo) podrían dañarse por el aire caliente procedente del

calefactor y no deben instalarse encima del calefactor.

Entre la parte delantera del calefactor y cortinas de longitud completa

(Vea el ejemplo 1):

- Distancia mínima entre la parte inferior de cortinas y el piso – 2-1/2

pulgadas (64 mm)

- Distancia mínima entre la parte superior de cortinas y el techo/cielo

raso – 1/2 pulgada (13 mm)

- Distancia mínima entre la parte delantera del calefactor y el pliegue

más cercano de la cortina – 2 pulgadas (51 mm)

Entre la parte superior del calefactor y la parte inferior del antepecho de

ventana (base de la ventana):

- 12 pulgadas (305 mm) mínimo

Ciertas telas y materiales de vinilo (tales como

Tabla B. Dimensiones de los alambres de instalación en campo

Tamaño de

alambre de

cobre para

90°C

No. 12 AWG

No. 10 AWG

No. 8 AWG

Número Máx.

de alambres

instalados en

conducto

interno

5

4

2

Corriente máxima permisible

Hasta 2

alambres

7 ampères

9 ampères

12.0 ampères

alambres

5 ampères

7 ampères

10 Amps

3 a 4

4 a 5

alambres

4.5 ampères

6 ampères

-

Ejemplo 1

CIELO RASO CIELO RASO

1-1/2” min.

(13 mm)

PARED

PISO PISO

2” min.

(51 mm)

CALEFACTOR

2-1/2” min.

(64 mm)

PARED

Fig. 1: Espacio libre para cortinas

8

Ejemplo 2

1-1/2” min.

(13 mm)

CORTINASCORTINAS

6” min.

(152 mm)

CALEFACTOR

Page 9

INSTRUCCIONES DE INSTALACIÓN

PARA REDUCIR EL RIESGO DE INCENDIO Y DESCARGA ELÉCTRICA O LESIONES A PERSONAS, CUMPLA LO SIGUIENTE:

1. Podrían producirse lesiones graves o la muerte por descarga eléctrica. Antes de instalar este calefactor, verifique que el circuito de

suministro de energía eléctrica que llega al calefactor está

desconectado en el interruptor de desconexión principal o el panel

de servicio.

2. Las conexiones y procedimientos de cableado deben realizarse de

acuerdo con el Código Eléctrico Nacional (NEC) y los códigos

locales. Consulte el Diagrama de cableado del calefactor y la

Figura 8. Verifique que todas las conexiones eléctricas están apretadas para evitar posible sobrecalentamiento. Sólo utilice alambre

de cobre para el alambre de suministro de energía eléctrica.

3. Verifique que el voltaje de suministro de energía eléctrica coincide

con la capacidad nominal de voltaje impresa en la placa de datos

del calefactor.

PRECAUCIÓN

4. No instale el calefactor contra superficies combustibles de tabla de

fibra de celulosa de baja densidad, contra o debajo de cubiertas de

vinilo de pared, o debajo de materiales que pudieran dañarse por

el calor tales como persianas, cortinas de vinilo o plástico, etc.

5. No instale el calefactor debajo de un tomacorriente eléctrico.

PRECAUCIÓN

6.

Mantenga alejados del calefactor, los cables eléctricos (incluyendo

los cables de teléfonos y computadoras), las cortinas y otros muebles. Para un funcionamiento eficiente y seguro, recomendamos

mantener siempre un espacio libre mínimo de 6 pulgadas (152

mm) encima y al frente del calefactor. Vea el Diagrama de

Espacios Libres para ver los requisitos de espacio libre mínimo.

7. Para reducir el riesgo de incendio, no almacene ni utilice gasolina

ni otros vapores o líquidos inflamables cerca del calefactor.

8. No instale el calefactor de manera invertida o en cualquier posición

diferente a la mostrada en este manual.

9. No instale el calefactor de manera empotrada en la pared ni instale

el calefactor dentro de ningún tipo de encerramiento ya que esto

causará que el calefactor se sobrecaliente y podría crear un peligro de seguridad.

10. Al montar el calefactor, tenga cuidado al taladrar los orificios de

montaje y al montar el calefactor en la estructura de la edificación

para evitar dañar los componentes internos del calefactor.

Asegúrese de aflojar _ vuelta los tornillos de montaje para permitir

la expansión y contracción.

11. No remueva ni puentee el(los) control(es) de límite de seguridad

(protectores térmicos) ya que esto podría permitir que el calefactor

se vuelva un peligro de incendio – vea el diagrama de cableado del

calefactor suministrado con el calefactor.

12. Los alambres instalados en fábrica dentro del conducto superficial

interno se utilizan para conectar los controles incorporados. Limite

la corriente máxima a no más de 45 amperios en total. Consulte las

instrucciones y la capacidad nominal de corriente según se suministran con el accesorio.

13. Los calefactores que no están instalados extremo con extremo

deben tener tapas de extremo instaladas para cubrir los extremos

expuestos del calefactor.

14. No permita que se coloquen objetos encima de calefactor ya que

éstos podrían dañarse o crear un peligro de incendio.

15. Para evitar dañar el calefactor, no utilice un destornillador para

separar la cubierta delantera de la carcasa trasera. Sólo utilice una

espátula según se muestra, vea la Fig. 2

16. Antes de energizar, verifique que la cubierta delantera está asegurada apropiadamente sobre la carcasa trasera a lo largo de todo el

calefactor, vea la Fig. 5. No ponga en funcionamiento el calefactor sin la cubierta delantera instalada.

– El calefactor funciona a altas temperaturas.

Preparación preliminar del cableado

1. Tienda un circuito de derivación de voltaje y tamaño de alambre

apropiados hasta el sitio de la caja de conexiones izquierda o

derecha según se indica en el diagrama de cableado del calefactor.

Los calefactores básicos están precableados y pueden conectarse

al circuito de derivación en cualquier extremo. Los calefactores con

controles están precableados para conexión con el circuito de

derivación en un (1) extremo únicamente (consulte el diagrama de

cableado del calefactor). Sin embargo, el calefactor puede cablearse

desde el extremo opuesto tendiendo los alambres a través del conducto superficial interno del calefactor. Vea la Fig. 3 para conocer

las ubicaciones de las tapas precortadas removibles.

2. Si es necesario tender alambres a través del conducto superficial

interno del calefactor, utilice la Tabla B para dimensionar los alambres instalables en campo.

3. Los alambres instalados en fábrica en el conducto superficial interno

del calefactor pueden cargarse hasta 45 amperios. Consulte la

Tabla C para obtener la longitud máxima del cableado (tendido) del

calefactor cuando los calefactores se conectan en paralelo.

Interruptor de desconexión:

Termostato:

Relé del transformador:

Relé de potencia

Interruptor eléctrico/neumático

NOTA:

Para la mezcla de densidades de potencia (watts), calcule el

consumo de amperios. No exceda de 45 amperios.

4. Deben utilizarse alambres estándar para 90°C en las cajas de

conexiones, los conductos superficiales internos, las secciones de

espacios libres, las secciones de relleno, las secciones de esquina.

20 amps @ 120-277 VAC

25 amps @ 120-240 VAC

22 amps @ 277 VAC

25 amps @ 120-240 VAC

22 amps @ 277 VAC

17 amps @ 347 VAC

12 amps @ 600 VAC

25 amps @ 120-277 VAC

25 amps @ 120-277 VAC

Disposición en salón

Consulte los planos de calefacción para obtener la disposición exacta

en salón de los calefactores (con o sin termostatos y/o relés y/o interruptores y accesorios).

Antes de iniciar la instalación del tipo pared a pared, estudie las dimensiones de las secciones de calefactor y la longitud de pared adicional

requerida para las secciones de relleno o las secciones de espacios

libres. Verifique que todos los calefactores y accesorios necesarios

están disponibles y tienen el acabado correcto.

Altura de montaje (vea la tabla de espacios libres)

NOTA:

Puede instalarse cubierta de piso de hasta _” de espesor, tal

como alfombras, baldosas, linóleo, etc. alrededor y debajo del calefactor

sin afectar adversamente el desempeño de los calefactores.

En la altura correcta, dibuje una línea con lápiz en la pared, a nivel y/o

en paralelo con el antepecho de ventana (base de la ventana). Las

alturas de montaje mínimas sobre el piso deberán ser las siguientes.

Instalación de unidad sola

NOTA:

Para facilidad de instalación, es importante seguir en orden la

secuencia de operación indicada abajo. Para los calefactores con más

de una plataforma de calor, las plataformas de calor pueden cablearse

en paralelo o cada plataforma de calor puede alimentarse mediante un

circuito separado. Vea la placa de datos del calefactor para conocer la

carga de corriente para cada plataforma de calor.

1. Saque la unidad de la caja de cartón y deseche las almohadillas

externas y la envoltura plástica.

2. Saque la cubierta delantera colocando el calefactor sobre su parte

trasera e insertando una espátula (u otra herramienta de pala ancha

delgada, 1” [25mm] de ancho como mínimo) aproximadamente 6”

(152mm) a partir del extremo del calefactor y haciendo palanca

hacia arriba según se muestra en la Fig.2. Esto abrirá el cierre de

sujeción a presión. Repita según se requiera a todo lo largo del

calefactor hasta que la cubierta delantera se desenganche completamente de la parte trasera del calefactor.

9

Page 10

D

X

E

D

C

E

H

W

B

A

5/8” hole

1-3/8”

(35mm)

KO

7/8”

(22mm)

KO

7/8”

(22mm)

KO

1-3/8”

(35mm)

KO

1-23/32”

(44mm)

KO

Junction

Box

Back

Bottom

Cubierta delantera

del gabinete

Espátula u otra

herramienta de

pala ancha

Área recomendada para taladrado

de los orificios de

montaje (para

montaje en pared

Carcasa

trasera del

gabinete

Fig. 2

NOTA:

La ilustración se muestra únicamente

para el desmonte de la cubierta delantera

3. Remueva las tapas precortadas removibles apropiadas de cualquier

caja de conexiones. Vea la Fig. 3 para conocer la ubicación de las

tapas precortadas removibles. Si el calefactor se montará en

pedestal, consulte las instrucciones de instalación del pedestal.

4. Taladre los orificios de montaje de tamaño requerido en la carcasa

del calefactor (vea la Fig. 2 para conocer la ubicación recomendada

de los orificios de montaje).

5. Sostenga la carcasa del calefactor contra la pared para verificar la

uniformidad de la pared. No instale el calefactor contra una superficie de pared irregular. Si se encuentra una pared irregular, utilice

cuñas para mantener recta la carcasa del calefactor.

Orificio de 5/8”

aja de

C

conexiones

SLQDB

1.27” (32)

A

2.00”(51)

B

1.63” (41)

C

1.37” (35)

D

1.53” (39)

E

1.81” (46)

H

1.25” (32)

W

1.00 (25.4)

X

pouces (mm)

apa

T

precortada

1-3/8” (35 mm)

Parte trasera

apa

T

precortada

7/8” (22 mm)

Tapa precortada

1-23/32”

(44 mm)

Parte

inferior

apa

T

precortada

1-3/8” (35 mm)

La ubicación del pedestal y las

tapas precortadas mostradas

son para las unidades estándares. Los gabinetes hechos a la

medida y/o las plataformas de

calor tendrán la ubicación del

pedestal y las tapas precortadas

en diferentes ubicaciones.

Consulte a la fábrica.

T

precortada

7/8” (22 mm)

Fig. 3

6. Tienda un circuito de derivación de tamaño apropiado hasta la caja

de conexiones a través de la tapa precortada removible seleccionada.

7. Monte el calefactor en la pared utilizando tornillos, pernos o anclajes

(suministrados por el instalador) según la construcción de la pared.

Caja de

conexiones

Tornillo de

Fig. 4

conexión a tierra

apa

Fig. 5

8. Apriete el tornillo de montaje y retrocédalo 1/2 vuelta para permitir la

expansión y contracción del calefactor.

9. Siguiendo el diagrama de cableado fijado al calefactor, realice las

conexiones eléctricas. Conecte a tierra el calefactor utilizando el

tornillo de conexión a tierra suministrado. Vea la Fig. 4.

10. Coloque nuevamente la cubierta delantera enganchando el borde

delantero inferior de la cubierta delantera sobre el borde delantero

inferior de la carcasa y empujando la cubierta hacia atrás en línea

recta para enganchar el borde trasero superior de la carcasa con el

borde trasero superior de la cubierta delantera. Vea la Fig. 5.

Instalación de unidades múltiples de pared a pared

NOTA:

Para facilidad de instalación, es importante seguir en orden la

secuencia de operaciones indicada abajo.

1. Repita los pasos 1 y 2 de la Instalación de unidad sola.

2. Consulte el diagrama de cableado para ver la entrada del alambre(s)

de alimentación de energía y remueva la tapa precortada removible

apropiada (Fig. 3) del calefactor en que deben realizarse las conexiones de alimentación de energía. El alambre(s) de alimentación de

energía puede introducirse en el extremo de un (1) calefactor y los

calefactores restantes pueden conectarse en paralelo utilizando el

conducto superficial interno de alambres. Utilice la Tabla B para

dimensionar los alambres instalables en campo en el conducto superficial interno o utilice la Tabla A para determinar la longitud máxima o

el tramo de calefactor accesible utilizando el alambre instalado en

fábrica en el conducto superficial interno del calefactor.

3. Si deben utilizarse secciones de relleno, esquinas interiores, esquinas

exteriores, kits de empalmes o tapas de extremo, consulte las instrucciones de instalación de los accesorios del calefactor de convección.

Si las unidades deben montarse en pedestal, consulte las instrucciones de instalación de los accesorios del calefactor de convección.

NOTA:

Si un calefactor tiene un interruptor de desconexión y/o termostato, y debe tener una sección de relleno en cualquier extremo, la sección

de relleno no debe cubrir el acceso a estos controles.

4. Si el tramo de calefactores incluye una esquina interior o una esquina

exterior, monte la esquina a la pared (vea las instrucciones de instalación de accesorios incluidas con las esquinas), luego monte el calefactor.

5. Taladre orificios de montaje de tamaño requerido en todas las car-

casas de los calefactores. (Vea la Fig. 2 para conocer la ubicación

recomendada de los orificios de montaje).

6. Sostenga las carcasas de los calefactores contra la pared para veri-

ficar la uniformidad de la pared. No instale los calefactores contra una

superficie de pared irregular. Si se encuentra una pared irregular, utilice cuñas para mantener recta la carcasa del calefactor.

7. Tienda un circuito de derivación de tamaño apropiado hasta la caja

de conexiones a través de la tapa precortada removible seleccionada.

8. Monte los calefactores en la pared utilizando tornillos, pernos o ancla-

jes (suministrados por el instalador) que correspondan con el tipo de

construcción de la pared. Las lengüetas de alineación pueden insertarse en las carcasas traseras adyacentes para garantizar una alineación uniforme. Vea la Fig. 6 para obtener detalles.

9. Siguiendo el diagrama de cableado fijado al calefactor, realice las

conexiones eléctricas. Consulte la Fig. 8 para conectar los otros calefactores en paralelo. La conexión a tierra de los otros calefactores se

logra conectando un alambre de puente (no suministrado) entre dos

calefactores adyacentes.

10

Page 11

Lengüeta de

alineación

Fig. 6

10. Coloque nuevamente las cubiertas delanteras siguiendo el Paso 10

Instalación de unidad sola

de la

Carcasa

trasera

, (vea la Fig. 5.)

Secciones de espacios libres

Las secciones de espacios libres, si hay alguna, se instalan de la misma

manera como se instalan los calefactores.

INSTRUCCIONES DE MANEJO

1. Después que el(los) calefactor(es) estén completamente ensambla-

dos e instalados, coloque el termostato o los controles de funcionamiento en NO HEAT (NO CALOR) y energice el(los) circuito(s).

Verifique que el(los) calefactor(es) no están produciendo calor.

2. Ajuste el termostato o el control de operación para pedir calor.

Permita que el calefactor(es) funcione durante unos pocos minutos y

verifique que todos los calefactores están produciendo calor.

Nota:

Durante la puesta en funcionamiento inicial, los calefactores

podrían presentar un olor a nuevo y posiblemente algo de humo leve

por los residuos de fabricación en el elemento calefactor. Permita que

los calefactores funcionen durante aproximadamente 30 minutos para

disipar estos residuos. Podría ser deseable ventilar el área.

3. Para ajustar el termostato o los controles de operación para que

mantengan el nivel de comodidad deseado, permita que los calefactores funcionen hasta que la temperatura ambiente alcance el nivel

deseado. En este momento, el termostato o el control de operación

puede ajustarse para mantener esta temperatura.

Nota:

Cuando se suministra un interruptor de desconexión y/o un termostato incorporado, el acceso a estos controles será a través de las

aberturas de rejilla en cualquier extremo del calefactor. Para girar el eje

del termostato se requerirá un destornillador de cabeza plana pequeño.

El interruptor de desconexión es un interruptor tipo balancín que puede

manejarse con el mismo destornillador o una herramienta a través de

las aberturas.

4. Si el calefactor está equipado con un termostato incorporado,

después que el salón alcance el nivel de comodidad deseado, gire

en sentido antihorario el eje del termostato hasta que el termostato

haga clic. Esto debe permitir que el termostato encienda y apague el

calefactor para mantener esta temperatura. La rotación en sentido

horario permitirá que el calefactor permanezca ENCENDIDO

DURANTE MÁS TIEMPO y mantendrá una MAYOR temperatura

ambiente. Igualmente, la rotación en sentido antihorario hará que el

calefactor permanezca ENCENDIDO DURANTE MENOS TIEMPO y

la temperatura ambiente será INFERIOR. Si se suministran termostato remoto u otros tipos de controles, consulte las instrucciones

suministradas con esos controles para un funcionamiento apropiado.

NOTA IMPORTANTE:

de seguridad incorporado (Protector térmico – vea la Fig. 8) para apagar

automáticamente el calefactor si éste se obstruye o se sobrecalienta de

otro modo debido a una condición anormal. Los calefactores no deben

ciclar (apagarse y encenderse) por este control de seguridad durante el

uso normal. Si esto está ocurriendo, revise la instalación del calefactor

para garantizar que éste tiene los espacios libres adecuados y que el

flujo de aire libre alrededor del calefactor no está restringido. Si el calefactor continúa ciclando (apagándose y encendiéndose) por este control

de seguridad, interrumpa su uso hasta que pueda ser inspeccionado y/o

reparado por un electricista capacitado.

Estos calefactores se suministran con un límite

INSTRUCCIONES DE MANTENIMIENTO

Su calefactor le proporcionará años de servicio y comodidad con sólo

un mínimo de cuidado. El usuario puede realizar la limpieza periódica

del gabinete exterior, pero toda la demás limpieza interior y el servicio

de mantenimiento deben ser realizados por una persona de servicio

capacitada.

Nota:

Para un funcionamiento eficiente y seguro, el flujo de aire no debe

estar restringido hacia adentro y alrededor del calefactor. A medida que

el aire se mueve por convección a través del calefactor, el polvo y

pelusas podrían acumularse dentro del calefactor y alrededor del elemento calefactor que debe limpiarse periódicamente. Se recomienda

limpiar e inspeccionar su calefactor en busca de daños, de manera

anual como mínimo (o más frecuentemente en caso de necesitarse).

1. Podrían producirse lesiones graves o la muerte por descarga eléctrica. Antes de suministrar servicio de mantenimiento a este calefactor, verifique que el(los) circuito(s) de suministro de energía

eléctrica que llega(n) al calefactor está(n) desconectado(s) en el

interruptor de desconexión principal o el panel de servicio. Antes

de limpiar, permita que el calefactor se enfríe para evitar una posible quemadura.

Nota: Más de una (1) fuente de energía podría ingresar al calefactor.

Antes de limpiar o suministrar servicio de mantenimiento, verifique

que toda energía que alimenta el calefactor está desconectada.

2. Tenga precaución al limpiar las aletas del elemento calefactor para

evitar dañar las aletas. Además observe que las aletas son filosas

y podrían causar cortaduras, de modo que evite hacer contacto

con éstas.

1. El exterior del calefactor puede limpiarse con un trapo húmedo. Sin

embargo, no utilice limpiadores fuertes, limpiametales o ceras, ya que

éstos podrían dañar la superficie o dejar un residuo que producirá

decoloramiento.

2. Para limpiar el interior del calefactor se requerirá el desmontaje de la

cubierta delantera. Para desmontar la cubierta delantera, primero

desenganche el seguro de cierre a presión trasero superior. Utilice

una herramienta en forma de “L”, tal como una llave Allen, para levantar debajo de la rejilla entre la hilera trasera de ranuras (vea la Fig. 7).

Comience en cualquier extremo y levante la cubierta delantera hasta

que la tensión en la cubierta desprenda el gabinete. Continúe moviéndose a todo lo largo del calefactor hasta que la cubierta se suelte.

3. Con la cubierta delantera desmontada, puede utilizarse una aspiradora o aire comprimido para remover el polvo y las pelusas del interior

del calefactor y alrededor del elemento calefactor. Las aletas son

filosas y podrían causar cortaduras, de modo que evite el contacto

con las manos. Tenga cuidado para no dañar las aletas de aluminio.

Llave Allen u

otra herramienta

de 90°.

Cubierta delantera

Fig. 7

4. Como asunto de mantenimiento normal, revise el resto del calefactor

en busca de daño o posibles problemas de mantenimiento mientras la

cubierta está desmontada, y realice cualquier reparación necesaria.

5. Coloque nuevamente la cubierta delantera según se muestra en la

Fig. 5 verificando que quede asegurada en posición a todo lo largo

del calefactor. Restaure la energía hacia el calefactor y verifique que

está funcionando apropiadamente.

11

Page 12

No. 10 Wires

Factory Wiring

Field Wiring

Element

Element

Ground Screw

Ground Screws

Thermal Protector

Thermal Protector

Power Supply to Circuit Breaker

To other

heater

To other

heater

No. 10 Wires

Cableado típico de múltiples calefactores (sin controles)

Protector térmico

rotector térmico

P

Elemento calefactor

ornillo de

T

Hacia otro

calefactor

Suministro de energía hacia interruptor automático (Breaker)

conexión a tierra

lambres No. 10

A

Fig. 8

Elemento calefactor

Tornillo de

conexión a tierra

Alambres No. 10

Cableado de fábrica

Cableado en campo

Hacia otro

alefactor

c

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos en manufactura y materiales durante un (1) año a partir de la fecha

GARANTÍA LIMITADA

instalación, excepto los elementos calefactores los cuales están garantizados contra defectos en manufactura y materiales durante cinco años a partir de la fecha de instalación. Esta garantía no aplica a daño por accidente, uso incorrecto, o alteración; ni donde el voltaje conectado sea superior en 5% al voltaje indicado en la placa de datos;

ni se aplica a equipo instalado o cableado o mantenido de manera inapropiada en violación de las instrucciones de instalación del producto. Todas las reclamaciones de

trabajo de garantía deben incluir un documento que compruebe la fecha de instalación.

El cliente será responsable de todos los costos incurridos en la remoción o reinstalación de productos, incluyendo los costos de mano de obra, y los costos de envío incurridos para devolver los productos al Centro de Servicio de Marley Engineered Products. Dentro de las limitantes de esta garantía, las unidades inoperantes deben devolverse al centro de servicio autorizado Marley más cercano o al Centro de Servicio de Marley Engineered Products, y nosotros repararemos o reemplazaremos, según nuestra elección, sin costo para usted, con el costo de envío de regreso pagado por Marley. Se acuerda que dicha reparación o reemplazo es el remedio exclusivo disponible

de parte de Marley Engineered Products.

LAS ANTERIORES GARANTÍAS REEMPLAZAN CUALQUIER OTRA GARANTÍA EXPRESA O IMPLÍCITA, Y TODAS LAS GARANTÍAS IMPLÍCITAS DE MERCADEABILIDAD Y ADECUADIBILIDAD PARA UN PROPÓSITO EN PARTICULAR QUE EXCEDEN LAS GARANTÍAS EXPRESAS MENCIONADAS SON DENEGADAS MEDIANTE ESTE DOCUMENTO Y EXCLUIDAS DE ESTE ACUERDO. MARLEY ENGINEERED PRODUCTS NO SERÁ RESPONSABLE POR DAÑOS CONSECUENCIALES

QUE SURJAN CON RESPECTO AL PRODUCTO, ESTÉN O NO BASADOS EN NEGLIGENCIA, INFRACCIÓN, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados no permiten la exclusión o la limitación de los daños resultantes o adicionales, de modo que la anterior exclusión o limitación podría no aplicarse a usted.

Esta garantía le otorga derechos legales específicos, y además, usted podría tener otros derechos que varían de un estado a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano, comuníquese con Marley Engineered Products en Bennettsville, SC, en el teléfono: 1-800-642-

4328. La mercancía devuelta a la fábrica debe incluir una autorización de devolución y la etiqueta de identificación de servicio, las cuales pueden conseguirse en Marley

Engineered Products. Al solicitar la autorización de devolución, incluya todos los números de catálogo mostrados en los productos.

CÓMO OBTENER EL SERVICIO DE GARANTÍA Y LAS PIEZAS

DE GARANTÍA, Y ADEMÁS, INFORMACIÓN GENERAL

1. Servicio o Piezas de Garantía

2. Compra de Piezas de Repuesto

3. Información General de Productos

Nota:

Al solicitar servicio, siempre tenga a mano lo siguiente:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número o descripción de la pieza

1-800-642-4328

1-800-654-3545

www.marleymep.com

Pieza No. 5200-11072-000

PPD 15761

07/11

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 13

SLQDB

Radiateurs à convection

minces

Dimensions

Type Hauteur Largeur Longueur

SLQDB

Instructions d’installation, d’utilisation et d’entretien

GÉNERALITÉS

Ce radiateur est conçu pour fournir des années de fonctionnement efficace et sans soucis comme source de chaleur principale ou

auxiliaire, pour du chauffage de confort dans des applications résidentielles et commerciales. L’installation ou l’utilisation de ce produit d’une manière non décrite ici annulera la garantie et pourrait entraîner des blessures, des dégâts matériels ou des dommages

permanents sur le radiateur.

6” 2-5/8” 24” à 12’

152 mm 69 mm 610 mm à 3658 mm

INSTRUCTIONS IMPORTANTES

AVERTISSEMENT

LORS DE L’UTILISATION D’APPAREILS ÉLECTRIQUES,

DES PRÉCAUTIONS DE BASE DOIVENT TOUJOURS ÊTRE

SUIVIES AFIN DE RÉDUIRE LE RISQUE DE DÉPART D'INCENDIE, DE COMMOTION ÉLECTRIQUE ET DE

BLESSURES AUX PERSONNES, INCLUANT CELLES QUI

SUIVENT :

1. Lisez toutes les instructions avant d’installer ou d’utiliser le

radiateur.

2. Un radiateur comporte à l’intérieur des parties chaudes, et

pouvant produire un arc ou des étincelles électriques. Ne

l’utilisez pas dans des zones où de l’essence ou des

liquides inflammables sont utilisés.

3. Ce radiateur est chaud quand il est en fonctionnement. Pour

éviter des brûlures, ne laissez pas de peau nue toucher ses

surfaces chaudes. Maintenez les matières combustibles,

comme les meubles, les oreillers et la literie, les papiers, les

habits et les rideaux, à distance du radiateur.

4. Pour éviter un possible départ d’incendie, n'obstruez en

!

aucune façon les admissions et les échappements d’air.

5. N’insérez pas d’objets étrangers, et ne permettez pas qu’il

en entre, dans toute ouverture d’admission ou d’évacuation,

car cela peut causer une commotion électrique ou un départ

d’incendie, ou endommager le radiateur.

6. Une blessure sérieuse voire mortelle peut résulter d’une

commotion électrique. Assurez-vous que le circuit du

secteur d’alimentation électrique arrivant au radiateur est

bien débranché en amont à l’interrupteur général ou au panneau de service avant d’intervenir pour installer ou dépanner ce radiateur.

7. Les modèle SLQDB de 188 watts ou moins par pied de

longueur, sans grillage métallique, sont listés ETL pour une

utilisation résidentielle.

8. Le modèle SLQDB de 188 watts par pied de longueur doit

être monté au-dessus d’un sol avec finition avec un écartement d’au moins 2 pouces (5 cm).

CONSERVEZ CES INSTRUCTIONS

Page 14

Tableau A - SLQDB (Données techniques)

CEILING

FLOOR FLOOR

DRAPES

HEATER

WALL

WALL

CEILING

MIN. 1/2”

(13 mm)

MIN. 2”

(51 mm)

MIN. 2-1/2”

(64 mm)

MIN. 1/2”

(13 mm)

MIN. 6”

(152 mm)

HEATER

DRAPES

N° au Longueur Watts Total en

catalogue "L" par pied Watts 120 V 208 V 240 V 277 V 347 V 600 V

22100 100 200 -- 1.0 -- -- -- -22150 24” 150 300 2.5 1.4 1.3

22188 (610 mm) 188 376 3.1 1.8 1.6 1.4 -- -02100 100 200 1.7 1.0 0.8 -- -- --

02125 28" 125 250 2.1 1.2 1.0 0.9 -- -02150 (711 mm) 150 300 2.5 1.4 1.3 1.1 -- --

2188 188 376 3.1 1.8 1.6 1.4 -- --

0

03100 100 300 2.5 1.4 1.3 1.1 -- --

03125 3' 125 375 3.1 1.8 1.6 1.4 1.1 --

3150 (914 mm) 150 450 3.8 2.2 1.9 1.6 1.3 --

0

03188 188 564 4.7 2.7 2.4 2.0 1.6 --

4100 100 400 3.3 1.9 1.7 1.4 1.2 --

0

4125 4' 125 500 4.2 2.4 2.1 1.8 1.4 --

0

04150 (1219 mm) 150 600 5.0 2.9 2.5 2.2 1.7 -04188 188 752 6.3 3.6 3.1 2.7 2.2 1.3

05100 100 500 4.2 2.4 2.1 1.8 1.4 0.8

05125 5' 125 625 5.2 3.0 2.6 2.3 1.8 1.0

05150 (1524 mm) 150 750 6.3 3.6 3.1 2.7 2.2 1.3

5188 188 940 7.8 4.5 3.9 3.4 2.7 1.6

0

06100 100 600 5.0 2.9 2.5 2.2 1.7 1.0

06125 6' 125 750 6.3 3.6 3.1 2.7 2.2 1.3

6150 (1829 mm) 150 900 7.5 4.3 3.8 3.2 2.6 1.5

0

06188 188 1128 9.4 5.4 4.7 4.1 3.3 1.9

7100 100 700 -- 3.4 2.9 2.5 2.0 1.2

0

7125 7' 125 875 -- 4.2 3.6 3.2 2.5 1.5

0

07150 (2134 mm) 150 1050 -- 5.0 4.4 3.8 3.0 1.8

07188 188 1316 -- 6.3 5.5 4.8 3.8 2.2

08100 100 800 -- 3.8 3.3 2.9 2.3 1.3

08125 8' 125 1000 -- 4.8 4.2 3.6 2.9 1.7

08150 (2438 mm) 150 1200 -- 5.8 5.0 4.3 3.5 2.0

8188 188 1504 -- 7.2 6.3 5.4 4.3 2.5

0

09100 100 900 -- 4.3 3.8 3.2 2.6 1.5

09125 9' 125 1125 -- 5.4 4.7 4.1 3.2 1.9

09150 (2743 mm) 150 1350 -- 6.5 5.6 4.9 3.9 2.3

09188 188 1692 -- 8.1 7.1 6.1 4.9 2.8

10100 100 1000 -- 4.8 4.2 3.6 2.9 1.7

10125 10' 125 1250 -- 6.0 5.2 4.5 3.6 2.1

10150 (3048 mm) 150 1500 -- 7.2 6.3 5.4 4.3 2.5

10188 188 1880 -- 9.0 7.8 6.8 5.4 3.1

Ampérage

-- --

--

Tableau d’écartements :

Pour un fonctionnement sûr et efficace, maintenez au moins les écartements suivants en permanence (Voir la Fig. 1) :

Bas du radiateur jusqu’à la finition de sol :

• Pour des modèles de 188 watts par pied ou plus, le bas des appareils

doit être surélevé d’au moins 2 pouces (51 mm) par rapport au sol.

• Modèles à admission par le fond :

- 100-180 watts par pied – 2 pouces (51 mm)

Dessus du radiateur au plafond (tous les modèles) :

- Au minimum 36 pouces (914 mm)

Dessus du radiateur au bas des rideaux surmontant le radiateur (Voir

l’exemple 2) :

- Distance minimale de 6 pouces (152 mm)

REMARQUE IMPORTANTE :

(comme des stores en vinyle) peuvent être endommagés par l’air

réchauffé venant du radiateur, et ne doivent être installés au-dessus

de lui.

Devant du radiateur par rapport à des rideaux de hauteur complète (Voir

l’exemple 1) :

- Distance minimale entre le bas des rideaux et le sol – 2-1/2 pouces

(64 mm)

- Distance minimale entre le haut des rideaux et le plafond – 1/2 pouce

(13 mm)

- Distance minimale entre l’avant du radiateur et le pli le plus proche

des rideaux – 2 pouces (51 mm)

Dessus du radiateur au bas de l’appui de fenêtre :

- Distance minimale de 12 pouces (305 mm)

Certains tissus et matériaux en vinyle

Tableau B. Calibre du câblage installé sur site

Calibre de fil

en cuivre

pour 90 °C

Nombre

max. de fils

dans le

chemin de

Jusqu’à 2

conducteurs

câble

No. 12 AWG

No. 10 AWG

No. 8 AWG

5

4

2

7 ampères

9 ampères

12.0 ampères

Courant maximal admis

3 à 4

conducteurs

5 ampères

7 ampères

conducteurs

4.5 ampères

6 ampères

10 Amps

4 à 5

-

Example 1

PLAFOND PLAFOND

1-1/2” min.

(13 mm)

MUR

SOL SOL

2” min.

(51 mm)

RADIATEUR

2-1/2” min.

(64 mm)

Fig. 1 : Écartement pour les draperies

14

Example 2

1-1/2” min.

(13 mm)

RIDEAUXRIDEAUX

MUR

6” min.

(152 mm)

RADIATEUR

Page 15

INSTRUCTIONS D'INSTALLATION

POUR RÉDUIRE LE RISQUE DE DÉPART D’INCENDIE, DE COMMOTION ÉLECTRIQUE ET DE BLESSURES AUX PERSONNES,

OBSERVEZ LES CONSIGNES SUIVANTES :

. Une blessure sérieuse voire mortelle peut résulter d’une commotion

1

lectrique. Assurez-vous que le circuit du secteur d’alimentation élec-

é

rique arrivant au radiateur est bien débranché en amont à l’interrupteur

t

énéral ou au panneau de service avant d’installer ce radiateur.

g

. Les procédures de câblage et les connexions doivent être en confor-

2

ité avec la norme électrique américaine (NEC) et les normes locales.

m

éférez-vous au schéma de câblage du radiateur en Figure 8. Assurez-

R

vous que toutes les connexions électriques sont bien serrées pour

éviter une possible surchauffe. N’utilisez que des fils d’alimentation en

cuivre.

3. Vérifiez que la tension du secteur correspond à la tension nominale

telle qu’imprimée sur la plaque signalétique du radiateur.

ATTENTION – Ne branchez jamais un radiateur sur une source de tension

supérieure à celle de sa plaque signalétique, car cela l'endommagerait et

pourrait causer un départ d'incendie.

4. N’installez pas le radiateur contre des surfaces inflammables de panneaux de fibre en cellulose de faible densité, contre ou sous des revêtements muraux en vinyle, ou sous tous les matériaux pouvant être

endommagés par la chaleur, comme des stores en vinyle ou en plas-

ique, des rideaux, etc.

t

5. N’utilisez pas le radiateur sous une prise d’alimentation secteur.

ATTENTION

6.

Maintenez les cordons électriques (dont les câbles du téléphone et de

l’ordinateur), les tentures et autres parties de l’ameublement à distance

du radiateur. Pour un fonctionnement sûr et efficace, nous recommandons de garder 6 pouces (152 mm) d’écartement au-dessus et devant

le radiateur en permanence. Consultez le tableau d’écartements pour

les exigences en distance minimale.

7. Pour réduire le risque de départ d’incendie, n’entreposez pas et n’utilisez pas d’essence ou d’autres produits inflammables sous forme de

liquide ou de vapeurs à proximité du radiateur.

8. N’installez pas le radiateur à l’envers ou dans toute position qui ne

serait pas montrée dans ce manuel.

9. N’encastrez pas le radiateur dans un mur, ou ne l’installez pas dans un

quelconque type d’enceinte, car cela provoquerait sa surchauffe et

pourrait créer un danger.

10. Au montage du radiateur, faites attention pour percer les trous de montage et en fixant le radiateur sur la structure du bâtiment, pour éviter

d’endommager des composants internes. Assurez-vous de desserrer

les vis de fixation d’un demi tour pour permettre l’expansion et la contraction.

11. N’enlevez pas et ne contournez pas le(s) contrôle(s) de limite de sécurité (protections thermiques) car cela pourrait faire du radiateur un

risque de départ d’incendie, consultez le schéma de câblage du radiateur fourni avec lui.

12. Les fils installés en usine dans le chemin de câbles sont utilisés pour

connecter les commandes intégrées. Limitez le courant maximal à 45

ampères. Reportez-vous aux instructions et à la spécification de

courant fournies avec l’appareil.

13. Les radiateurs qui ne sont pas installés bout-à-bout doivent avoir des

capuchons d’extrémité placés pour couvrir leurs extrémités exposées.

14. Ne laissez pas placer d'objets sur le dessus du radiateur, ils pourraient

être endommagés et créer un risque de départ d'incendie.

15. Pour éviter d’endommager le radiateur, n’utilisez pas de tournevis pour

séparer le couvercle avant du coffret arrière. N’utilisez qu’un couteau à

mastiquer comme montré sur la Figure 2.

16. Avant la mise sous tension, assurez-vous que le couvercle avant est

bien installé sur le carter arrière, sur toute la longueur du radiateur,

voyez le Figure 5. Ne faites pas fonctionner un radiateur sans que son

couvercle avant soit en place.

– Le radiateur fonctionne à des températures élevées.

Câblage de préparation

1. Tirez une branche de circuit secteur, avec la bonne tension et une

taille de fils correcte, jusqu’à l’emplacement du boîtier de raccordement de gauche ou de droite, comme indiqué sur le schéma de

câblage du radiateur. Les radiateurs de base sont précâblés et peuvent se connecter au secteur d’un côté ou de l’autre. Les radiateurs

avec commandes sont câblés à l’avance pour un raccordement au

circuit d’alimentation d’un seul côté (reportez-vous au schéma de

câblage du radiateur). Cependant un radiateur peut être câble

depuis l’extrémité opposée en tirant des fils au travers sans son

chemin de câble. Voyez la Figure 3 pour l’emplacement des trous à

enfoncer.

2. S’il est nécessaire de faire traverser des fils dans le radiateur, utilisez

le Tableau B pour déterminer le calibre du câblage installé sur site.

3. Les fils installés en usine dans le chemin de câble du radiateur

peuvent supporter jusqu’à 45 ampères. Référez-vous au Tableau C

pour la longueur maximale du tronçon dans les radiateurs quand des

radiateurs sont branchés en parallèle.

Interrupteur de coupure :

Thermostat :

20 ampères sous 120-277 V CA

25 ampères sous 120-240 V CA

22 ampères sous 277 V CA

Relais de transformateur :

25 ampères sous 120-240 V CA

22 ampères sous 277 V CA

17 ampères sous 347 V CA

12 ampères sous 600 V CA

Relais d’alimentation :

25 ampères sous 120-277 V CA

Commutateur pneumatique/

électrique :

Pneumatic/Electric

REMARQUE :

En cas de mélange des puissances, calculez les

25 ampères sous 120-277 V CA

25 amps @ 120-277 VAC

ampères consommés. Ne dépassez pas 45 ampères.

4. Du câblage standard pour 90 °C doit être utilisé dans les boîtiers de

raccordement, les chemins de câble, les sections vides, les sections

de remplissage et les sections d’angle.

Disposition de la pièce

Référez-vous aux plans de chauffage pour l’arrangement exact des radiateurs dans la pièce (avec ou sans thermostat et/ou relais et/ou interrupteurs et accessoires.

Vérifiez les dimensions de section des radiateurs et la longueur de mur

additionnelle nécessaire pour les sections vides ou de remplissage

avant de commencer une installation de type mur-à-mur. Assurez-vous

que tous les radiateurs et accessoires nécessaires sont à portée de

main et que leur finition est correcte.

Hauteur de montage (consultez le Tableau d’écartements)

REMARQUE

une moquette, des carreaux, du linoléum, etc. peut s’installer autour et

en-dessous du radiateur sans effet néfaste sur sa performance. À la

bonne hauteur, tracez une ligne au crayon sur le mur, horizontale et/ou

parallèle avec l’appui de fenêtre. Les hauteurs minimales de montage

au-dessus du sol doivent être celles-ci :

: Un revêtement de sol d’épaisseur jusqu’à 3/4”, comme

Installation d’un seul readiateur

REMARQUE :

séquence des opérations indiquées ci-après soit suivie dans l’ordre.

Pour les radiateurs avec plus d’un module de chauffe, ces modules peuvent être câblés en parallèle, ou chacun peut recevoir son alimentation

d’un circuit séparé. Consultez la plaque signalétique du radiateur pour la

charge de courant de chaque module de chauffe.

1. Sortez l’appareil de son carton et jetez les cales extérieures et l’entourage en plastique.

2. Enlevez le couvercle avant en couchant le radiateur sur le dos et en

insérant un couteau à mastiquer (ou un autre outil à lame fine et

large d’au moins 1” [25 mm]) à environ 6” (152 mm) de l’extrémité

du radiateur, et en le dissociant comme montré en Fig.2. Cela va

déclencher l’ouverture du verrouillage. Recommencez si nécessaire

en vous déplaçant le long du radiateur, jusqu’au désengagement

complet du couvercle hors du carter arrière du radiateur.

15

Pour faciliter l’installation, il est important que la

Page 16

D

X

E

D

C

E

H

W

B

A

5/8” hole

1-3/8”

(35mm)

KO

7/8”

(22mm)

KO

7/8”

(22mm)

KO

1-3/8”

(35mm)

KO

1-23/32”

(44mm)

KO

Junction

Box

Back

Bottom

Couvercle avant

du coffret

Couteau à

mastiquer ou

autre outil à

lame large

Zone de recommandée pour le

perçage des trous

de montage (pour

montage mural)

Carter

arrière du

coffret

Fig. 2

REMARQUE :

Illustration montrée uniquement

pour le désengagement du couvercle avant.

3. Ouvrez les ouvertures à enfoncer pour électricité appropriées de l'un

des boîtiers de raccordement. Voyez la Figure 3 pour l’emplacement

de ces ouvertures à enfoncer. Si le radiateur est monté sur socle,

consultez les instructions d’installation du kit de socle.

4. Percez les trous de montage de la taille voulue dans le carter du

radiateur (Voyez la Figure 2 pour l’emplacement recommandé des

trous de montage).

5. Positionnez le carter du radiateur contre la cloison pour vérifier sa

planéité. Ne forcez pas le radiateur contre une surface murale inégale. Si la cloison est irrégulière, utilisez des cales pour garder le

carter de radiateur droit.

Trou de 5/8"

oîtier de

B

raccordement

1.27” (32)

A

2.00”(51)

B

1.63” (41)

C

1.37” (35)

D

1.53” (39)

E

1.81” (46)

H

1.25” (32)

W

1.00 (25.4)

X

pouces (mm)

rou à enfon-

T

cer de 1-3/8”

(35 mm)

Dos

rou à enfon-

T

cer de 7/8”

(22 mm)

Trou à enfoncer

de 1-23/32”

(44 mm)

Fond

rou à enfon-

T

cer de 1-3/8”

(35 mm)

L’emplacement de socle et de

trous à enfoncer montré concerne des unités standard. Les

coffrets et/ou les modules de

chauffe sur mesures auront leur

emplacement de socle et de

trous à différents endroits.

Consultez l’usine.

T

enfoncer de

7/8” (22 mm)

Fig. 3

6. Amenez une branche de circuit d’alimentation secteur au boîtier de

raccordement au travers du trou enfoncé choisi.

7. Montez le radiateur sur la cloison en utilisant des vis, des boulons

ou des ancrages (fournis par l’installateur) en fonction du type de

structure murale.

Boîtier de

raccordement

Vis de terre

Fig. 4

rou à

Fig. 5

8. Serrez bien les vis de fixation, puis dévissez-les d’un demi-tour pour

permettre au radiateur de se dilater et de se rétracter.

9. Réalisez les raccordements électriques en suivant le schéma de

câblage fixé au radiateur. Reliez le radiateur à la terre en utilisant la

vis de terre fournie. Voir la Figure 4.