Page 1

D Series

Fan Forced

Wall & Ceiling Heaters

Installation & Maintenance Instructions

Dear Owner,

Congratulations! Thank you for purchasing this Marley Engineered Products product. You have made a

wise investment selecting the highest quality product in the heating industry. Please carefully read the

installation and maintenance directions shown in this manual. You should enjoy years of efficient heating comfort with this product from Marley Engineered Products... the industry’s leader in design, manufacturing, quality and service.

... The Employees of

Marley Engineered Products

!

Read Carefully - These instructions are written to help

you prevent difficulties that might arise during installation.

Studying the instructions first may save you considerable

time and money later. Observe the following procedures,

and cut your installation time to a minimum. TO REDUCE

RISK OF FIRE OR ELECTRIC SHOCK:

1. Disconnect all power coming to heater at main service panel

before wiring or servicing.

2. All wiring must be in accordance with National and Local

Electrical Codes and the heater must be grounded.

3. Verify the power supply voltage coming to heater matches the

ratings printed on the heater nameplate before energizing.

4. This heater is hot when in use. To avoid burns, do not let bare

skin touch hot surfaces.

WARNING

SAVE THESE INSTRUCTIONS

5. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock, fire,

or damage to the heater.

6. Do not block air intakes or exhaust in any manner. Keep combustible materials, such as crates, drapes, etc., away from

heater. Do not install behind doors, furniture, towels, or

boxes. Do not install in ceiling at wattage greater than 1000.

7. A heater has hot and arcing or sparking parts inside. Do not

use it in areas where gasoline, paint, or flammable liquids are

used or stored.

8. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

electric shock, or injury to persons.

9. This heater is not approved for use in corrosive atmospheres

such as marine, green house, or chemical storage areas.

1

Page 2

CAUTION

M

BLK

BLK

L2

RED

L1

GND

TSTAT

PILOT

LT.

AUTO

LIMIT

TCO

240/208 V

AUTO

LIMIT

2000 WATTS

M

BLK

L2

RED

L1

GND

TSTAT

PILO T

LT.

240/208 V

1000 WATTS

M

RED

GND

TSTAT

PILOT

LT.

AUTO

LIMIT

TCO

120 V

NL

1000 WATTS

M

WHT

BLK

BLK

WHT

RED

GND

TSTAT

PILOT

LT .

AUT O

LIMIT

TCO

120 V

NL

1500 WA TTS

TCO

L

N

L

N

!

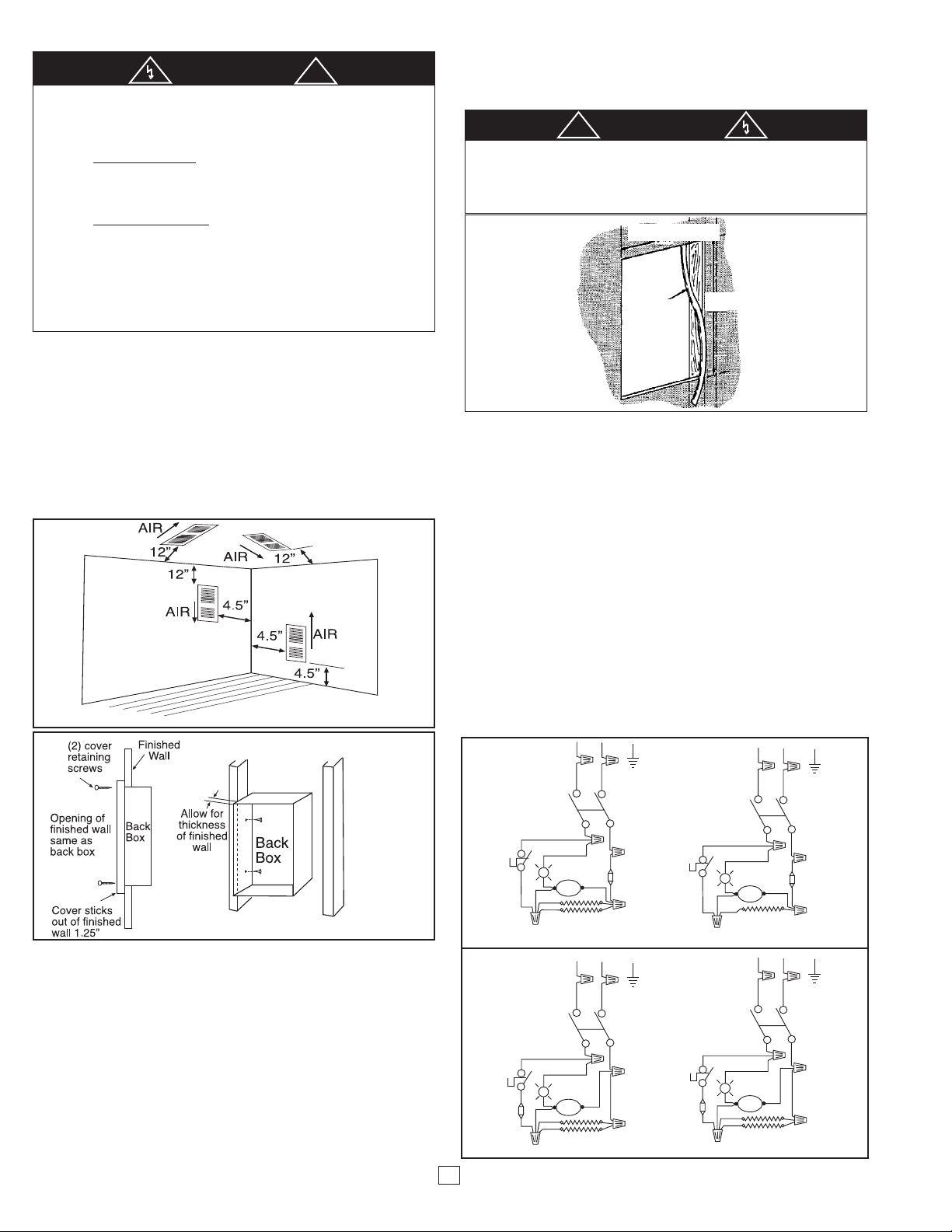

TO REDUCE RISK OF FIRE, ELECTRIC SHOCK, OR DAMAGE TO

HEATER, OBSERVE THE FOLLOWING:

1. Do not install heater without backbox.

2. Observe the following minimum clearances:

For wall mounting:

Heater to floor - 4.5” (114 mm)

Heater to any adjacent surface - 4.5” (114 mm)

Heater to ceiling - 12” (305 mm)

For ceiling mounting:

Heater to adjacent wall - 12” (305 mm)

3. The heater is hot when in use. Do not install heater behind door,

behind towel rack, in closet, where curtains or drapes could touch or

be damaged by the heat.

4. Keep electrical cords, bedding, furniture, and other combustibles

away from heater.

The D-Series heaters are designed for recessed installation in 2 x 4 or

larger wall studs or ceiling joists using the model D-BB back box with the

discharge grille (the smaller grille) to the top or bottom (see Figure 1). The

heater may be wired using standard building (60 degrees C minimum)

wire. Refer to the specification chart for appropriate wire size for the

heater to be used.

All units in the D series rated 1000 watts and less may be installed

recessed in the ceiling. If installed in the ceiling the heater may be oriented in any direction.

Heaters are also approved for surface mounting on walls or ceilings.

Refer to instructions for installation of the DSMK Surface Mounting

Frame.

Figure 1

5. Bring power supply wiring cable to the back box. Install a cable clamp

and install into the back box, leaving at least 6" (152mm) of cable

inside the back box for connection to the heater lead wires.

NOTE B: Lead holes for a #8 sheet metal screw have been provided in the

!

CAUTION

AN ELECTRICAL SHOCK, FIRE, OR WATER DAMAGE COULD

RESULT IF WIRING OR PIPING IS DAMAGED DURING CUTTING.

MAKE SURE ALL WIRING AND PIPING ARE CLEAR OF AREA

BEFORE CUTTING.

9-1/8” (231mm)

Supply

12-5/8” (320mm)

Cable

Figure 3

sides of the back box. (See Figure 2).

INSTALLATION OF BACK BOX

IN EXISTING CONSTRUCTION

1. Determine which side of the back box is to be mounted against a wall stud

or ceiling joist. See Figure 2.

2. Carefully mark and cut a hole in the wall or ceiling measuring 9-1/8"

(231mm) wideby 12-5/8” (320mm) high with one side of the hole along the

edge of a wall stud or ceiling joist. See Figure 3

3. Bring the power supply wiring cable to the heater mounting location, allow-

ing approximately 10" (254mm) length for use in installation.

4. Remove fan deck from back box by removing 2 screws.

5. Remove knockout in the back box, install a cable clamp onto power supply

cable and install the cable into the back box, leaving approximately 6"

(152mm) of cable inside the back box for connection to the heater lead

wires.

6. Fitthe backbox intothe opening by slidingthe supply wiring cable into position. Back box must be installed with front edge flush with the finished surface. Secure the back box to stud using two nails or screws. (See note B).

Figure 2

INSTALLATION OF BACK BOX IN NEW

CONSTRUCTION

NOTE A: If the finished wall is already up, follow instructions for “INSTAL-

LATION OF BACK BOX IN EXISTING CONSTRUCTION.”

1. Determine which side of the back box is to be mounted against a

stud or ceiling joist. (see Figure 2). Allow for the thickness of the finished surface when installing the back box. The edge of the back

box must be installed flush with the finished surface. Markings on

the side of the back box for 1/2" or 5/8" finishing wall are provided .

2. Remove fan deck from back box by removing 2 screws.

3. Position the back box on the stud or joist location desired and secure

using two nails or screws as shown in figure 2.

4. Remove one knockout in the back box for entry of supply wiring

cable.

Figure 4

2

Page 3

INSTALLATION OF HEATER

ASSEMBLY INTO BACK BOX

1. Re-install fan deck using two screws.

2. Connect field supply wiring to heater pigtail leads (See figure 4).

Connect field ground wire to green ground lead wire.

3. Install front cover. Push on thermostat knob.

CAUTION

To insure proper grounding of heater and prevent a possible electric

shock, the field supply ground wire must be attached to heater green

ground lead wire.

CAUTION

To prevent possible wiring damage, cut excess supply wires inside

backbox to provide approximately 6” (152 mm) for connection to

heater leads. After connections are made, make sure connections

are tight and all wiring is positioned away from fan blade and heating

element.

!

!

CHECK OPERATION AND SET THERMOSTAT

1. Switch on power supply to heater.

2. Rotate thermostat knob fully clockwise. Heating element and fan should

come on, causing warm air to flow from discharge grille.

3. Allow heater to operate until room is comfortable, then rotate thermo-

stat counter-clockwise until thermostat clicks. The unit will continue to

cycle on and off to maintain temperature.

4. Increaseor decrease the setting as required until the desired room tem-

perature is maintained.

For best results, the heater should be left “ON” constantly during the

heating season as the thermostat, when properly set, will maintain the

desired room temperature. In the counter-clockwise position, the heater

will remain off. This unit was shipped with a plug button to render the

thermostat tamper resistant. Remove the thermostat knob and insert

plug button in clearance hole guide.

For ceiling mounted units, a remote wall mounted line voltage thermostat

may be installed to control the unit. Follow instructions for the wall thermostat. Turn the thermostat knob on the unit to full clockwise position for

maximum heat, remove the knob and insert plug button in clearance hole

guide. Set your wall thermostat to desired set point.

SPECIFICATIONS

MODEL WIRE

O. VOLTS AMPS WATTS BTU/HR SIZE

N

D1012C 120 8.3 1000 3413 14 awg

D1512 120 12.6 1500 5120 12 awg

08 3.6 750 2560 14 awg

D1024C

2

240 4.2 1000 3413 14 awg

D2024

208 7.2 1500 5120 14 awg

240 8.3 2000 6826 14 awg

OPERATION NOTICE

Your heater is equipped with an automatic reset limit control that will

automatically turn the heater OFF to prevent a fire if the heater

overheats. Should this occur, the indicator light will illuminate and will

continue to shine until the limit resets.

!

THE ILLUMINATED INDICATOR LIGHT SIGNIFIES THE HEATER HAS

BEEN SUBJECTED TO SOME ABNORMAL CONDITION CAUSING IT

TO OVERHEAT. CHECK HEATER TO INSURE THAT IT HAS NOT BEEN

BLOCKED IN ANY MANNER (IF SO, REMOVE BLOCKAGE). IF THERE

IS NO INDICATION OF BLOCKAGE, IT IS RECOMMENDED THAT

HEATER BE CHECKED BY A REPUTABLE ELECTRICIAN OR REPAIR

SERVICE TO INSURE THE HEATER HAS NOT BEEN DAMAGED.

CAUTION

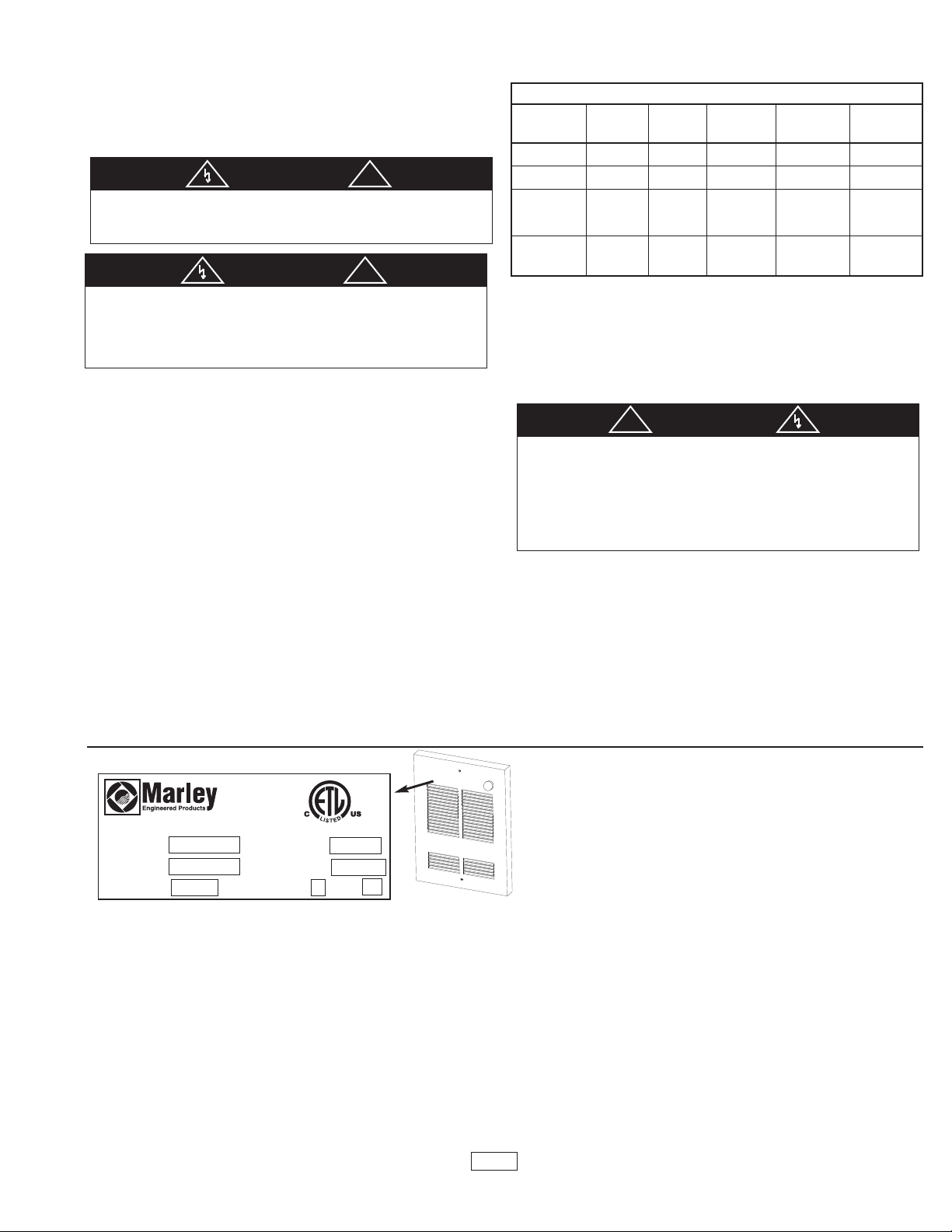

IMPORTANT INFORMATION

Bennettsville, SC 29512 USA

MODEL

WATTS

AMPS

D2024

2000/1500

8.3/7.2

DATE

VOLTS

PH

1

MM-YY

240/208

Hz

60

3

Page 4

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date

LIMITED WARRANTY

of installation This warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5%

above the nameplate voltage; nor to equipment improperly installed or wired or maintained in violation of the productʼs installation instructions.

All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs

incurred to return products to Marley Engineered Products Service Center.Within the limitations of this warranty, inoperative units should be

returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our

option, at no charge to you with return freight paid by Marley. It is agreed that such repair or replacement is the exclusive remedy available from

Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE

HEREBY DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR

CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply

to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328.

Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley

Engineered Products. When requesting return authorization, include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

4

05/10Part No. 5200-2469-003

ECR 38742

Page 5

Calentadores de pared y

cieloraso de tiro forzado

Serie D

Instrucciones de instalación y mantenimiento

Estimado propietario:

¡Felicitaciones! Gracias por haber comprado este nuevo calefactor, fabricado por una división de

Marley Engineered Products. Usted ha hecho una sabia inversión al seleccionar un producto de la más

alta calidad de la industria de la calefacción. Por favor, lea atentamente las instrucciones de instalación

y mantenimiento indicadas en este manual. Usted disfrutará de muchos años de confort de calefacción

eficiente con este producto de Marley Engineered Products… líder de la industria en diseño manufacturación, calidad y servicio.

…Los empleados de Marley

Engineered Products

ADVERTENCIA

!

Leer cuidadosamente - Estas instrucciones están redactadas

para ayudar a prevenir dificultades que pueden originarse durante

la instalación. El estudiar primero las instrucciones puede ahorrar

mucho tiempo y dinero después. Observar los procedimientos

siguientes y disminuir al máximo el tiempo de instalación. PARA

REDUCIR EL RIESGO DE INCENDIO O CHOQUE ELECTRICO:

1. Desconectar la electricidad entrante al calentador en el panel principal de

servicio antes de conectar o prestar servicio.

2. Todo el cableado debe conformar con los Códigos Eléctricos y Nacionales

y el calentador debe estar conectado a tierra.

3. Antes de activar, verificar que el voltaje de la electricidad de alimentación

corresponda con las clasificaciones nominales impresas en la placa de

especificaciones del calentador.

4. Este calentador está caliente al usar. Para evitar quemaduras, no permitir

que la piel expuesta toque las superficies calientes.

5. No insertar ni permitir que objetosextrañosentren en las aberturas de ven-

GUARDAR ESTAS INSTRUCCIONES

tilación o escape ya que esto puede causar un choque eléctrico, incendio

o daños al calentador.

6. No bloquear las tomas de aire o escapes. mantener los materiales combustibles tales como cajones, cortinados, etc., alejados del calentador. No

instalardetrás de puertas, muebles, toallas o cajas. No instalar en el cieloraso a vatajes mayores de 1000.

7. Un calentador tiene partes calientes o productoras de arco eléctrico adentro.No usar en áreas donde se usano almacenangasolina,pintura o líquidos inflamables.

8. Usar este calentador de la manera descripta en este manual. Cualquier

otrouso no recomendado por el fabricante puede causar incendio,choque

eléctrico o lesiones a las personas.

9. Estecalentadorno está aprobadoparausaren atmósferascorrosivas tales

como marinas, de invernadero o áreas de almacenamiento químico.

5

Page 6

PRECAUCION

M

BLK

BLK

L2

RED

L1

GND

TSTAT

PILOT

LT .

AUTO

LIMIT

TCO

240/208 V

AUT O

LIMIT

2000 WATTS

M

BLK

L2

RED

L1

GND

TSTAT

PILO T

LT.

240/208 V

1000 WATTS

M

RED

GND

TSTAT

PILO T

LT.

AUT O

LIMIT

TCO

120 V

NL

1000 WATTS

M

WHT

BLK

BLK

WHT

RED

GND

TSTAT

PILO T

LT.

AUTO

LIMIT

TCO

120 V

NL

1500 WA TTS

TCO

L

N

L

N

!

PARA REDUCIR EL RIESGO DE INCENDIO, CHOQUE ELECTRICO O DAÑOS AL

CALENTADOR, OBSERVAR LO SIGUIENTE:

. No instalar el calentador sin la caja posterior.

1

. Observar las distancias mínimas siguientes:

2

ara montaje de pared

P

alentador a piso: 4.5" (114mm)

C

Calentador a cualquier superficie adyacente: 4.5" (114mm)

Calentador a cieloraso: 12" (305mm)

Para montaje de cieloraso:

alentador a pared adyacente: 12"(305mm)

. El calentador está caliente cuando está en uso. No instalar el calentador detrás de

3

C

uertas, toalleros, en closets, donde las cortinas o colgaduras puedan tocar o ser

p

añados por el calor.

d

4. Mantener los cordones eléctricos, ropa de cama, muebles y otros combustibles,

alejados del calentador.

Los calentadores de Serie D están diseñados para instalación empo-

trada en montantes grandes de pared de 2x4 o viguetas usando el modelo D-BB de caja posterior con la rejilla de descarga (la rejilla más

pequeña) al tope o fondo (ver la Figura 1). El calentador puede cablearse

usando cable estándar (60 grados C mínimo) de edificación. Para el

tamaño apropiado del cable a usarse, referirse a la tabla de especificaciones.

Todas las unidades en la Serie D de clasificación nominal de 100

vatios o menos pueden instalarse empotradas en el cieloraso. Si se instala en el cieloraso, el calentador puede orientarse en cualquier dirección.

Los calentadores están aprobados también para montaje de superficie en paredes o cielorasos. Referirse a las instrucciones para instalar el

Marco de Montaje de Superficie DSMK.

AIRE

IRE

A

AIRE

(2) Tornillos

retenedores de

la cubierta

Abertura de la

pared termi-

nada

igual que la

pared posteri-

or

Paletas de cubiertafuera

de la pared terminada

1.25"

INSTALACION DE LA CAJA POSTERIOR EN NUEVA

NOTA A: Si la pared terminada ya ha sido completada, seguir las instruc-

ciones de "INSTALACION DE LA CAJA POSTERIOR EN CONSTRUCION

EXISTENTE."

1. Determinar cuál lado de la caja posterior se va a montar contra un mon-

p

Pared termi-

nada

Permitir

aja

C

osterior

espacio

para el

espesor de

la pared ter-

minada

CONSTRUCCION

Caja

posterior

Figura 1

AIRE

Figura 2

tante de pared o vigueta de cieloraso (ver la Figura 2). Al instalar la caja

posterior, permitir espacio para el espesor de la pared terminada. El borde

de la caja posterior debe instalarse al ras con la superficie terminada. Se

proporcionan marcas en el lado de la caja posterior para paredes terminadas de 1/2" ó 5/8".

2. Extraer la plataforma del ventilador de la caja posterior extrayendo 2

tornillos.

3. Colocar la caja posterior en posición sobre la ubicación deseada del mon-

tante de pared o vigueta de cieloraso, y asegurar usando dos clavos o

tornillos según se muestra en la Figura 2.

4. Perforar uno de los orificios ciegos en la caja posterior para la entrada del

cableado de alimentación.

5. Traer el cableado de electricidad a la caja posterior. Instalar una mordaza

de cable e instalar dentro de la caja posterior, dejando 6" (152mm) por lo

menos de cable dentro de la caja posterior para conectar a los cables guía

del calentador.

NOTA B: Se han provisto orificios guía para un tornillo No. 8 de lámina de

metal, a los lados de la caja posterior (Ver la Figura 2).

PRECAUCION

!

PUEDE RESULTAR UN CHOQUE ELECTRICO, INCENDIO O DAÑOS POR

AGUA SI EL CABLEADO O LA CAÑERIA RESULTADAÑADA AL CORTAR. ASE-

URARSE QUE TODO EL CABLEADO Y LA CAÑERIA ESTEN FUERA DEL

G

REA ANTES DE CORTAR.

A

9-1/8” (231mm)

Cable de alimentación

12-5/8” (320mm)

Figura 3

INSTALACION DE LA CAJA POSTERIOR EN

1. Determinar cuál de los lados de la caja posterior se va a montar contra

un montante de pared o vigueta de cieloraso. Ver la Figura 2.

2. Marcar y cortar cuidadosamente en la pared o cieloraso midiendo 9-1/8"

(231mm) de ancho por 12-5/8" (320mm) de alto con un lado del orificio

a lo largo del borde del montante de pared o vigueta de cieloraso.

Ver la Fig. 3.

3. Traer el cableado de alimentación de electricidad a la ubicación de

montaje del calentador, permitiendo 10" (254mm) aprox. de largo para

usar en la instalación.

4. Extraer la plataforma del ventilador de la caja posterior extrayendo los

2 tornillos.

5. Perforar el orificio ciego en la caja posterior, instalar una mordaza de

cable sobre el cable de alimentación de electricidad e instalar el cable

dentro de la caja posterior, dejando 6" (152mm) aproximadamente de

cable dentro de la caja posterior para conexión con los cables guía del

calentador.

6. Calzar la caja posterior dentro de la abertura deslizando el cableado de

alimentación en posición. La caja posterior debe instalarse con el borde

delantero al ras con la superficie terminada. Asegurar la caja posterior

al montante usando dos clavos o tornillos. (Ver la Nota B)

Figura 4

AUTOLIMITADOR

AUTOLIMITADOR

TCO

6

CONSTRUCCION EXISTENTE

TIERRA

ROJO

EGRO

N

1

L

L2

TERMOSTATO

LUZ

PILOTO

AUTOLIMITADOR

TCO

2000 VATIOS

NEGRO

TERMOSTATO

LUZ

PILOTO

BLANCO

TIERRA

ROJO

NEGRO

N

L

AUTOLIMITADOR

TCO

1500 VATIOS

OJO

R

L1

TERMOSTATO

LUZ

PILOTO

1000 VATIOS

NEGRO

ROJO

TERMOSTATO

L

LUZ

PILOTO

1000 VATIOS

EGRO

N

L2

BLANCO

NEGRO

IERRA

T

TCO

TIERRA

N

Page 7

INSTALACION DEL CONJUNTO DEL CALENTADOR DENTRO

DE LA CAJA POSTERIOR

1. Reinstale la plataforma del ventilador usando dos tornillos.

2. Conectar el cableado de alimentación de campo a las guías flexibles del

calentador (Ver la Figura 4). Conectar el cable de conexión a tierra de

campo al cable verde guía de conexión a tierra.

3. Instalar la cubierta delantera. Presionar la perilla del termostato.

PRECAUCION

El cable de alimentación de campo debe estar fijado al cable verde guía

de conexión a tierra.

PRECAUCION

Para prevenir posibles daños al conexionado corte el exceso de longitud de los cables de alimentación dentro de la caja posterior, de manera de dejar aproximadamente 152 mm (6 pulgadas) para la conexión

a los cables del calefactor. Después de haber hecho las conexiones,

asegúrese de que estén firmes y de que todo el conexionado esté

posicionado lejos de la paleta del ventilador y del elemento calefactor.

!

!

VERIFICAR LA OPERACION Y GRADUAR EL TERMOSTATO

1. Conectar la alimentación de electricidad al calentador.

2. Girar la perilla del termostato completamente a la derecha. Deben encen-

derse el elemento térmico y el ventilador, causando que el aire caliente

fluya desde la rejilla de descarga.

3. Permitir que el calentador funcione hasta que el cuarto se sienta confort-

able, a continuación girar el termostato a la izquierda hasta que el termostato calce en su lugar. La unidad continuará ciclando entre encendido

y apagado para mantener la temperatura.

4. Incrementar o disminuir la graduación según requerido hasta que se man-

tenga la temperatura deseada del cuarto.

Para obtener los mejores resultados, el termostato debe dejarse encendido

("ON") en todo momento durante la sesión de calefacción, ya que el termostato, cuando está bien graduado, mantendrá la temperatura deseada del

cuarto. En la posición contraria a las agujas del reloj el calentador se mantendrá apagado. Esta unidad se envió con un botón de tapón para impedir la

manipulación del termostato. Extraer la perilla del termostato e insertar el

botón de tapón en la guía de separación del orificio.

Para las unidades montadas en el cieloraso, puede instalarse un termostato

remoto de pared de voltaje de línea, para controlar la unidad. Seguir las

instrucciones para el termostato de pared. Para obtener un efecto térmico

máximo, girar completamente la perilla del termostato en el sentido de las

agujas del reloj, extraer la perilla e insertar el botón de tapón en la guía de

separación del orificio. Graduar el termostato de pared al punto deseado de

control.

ESPECIFICACIONES

NO. DE TAMAÑO

ODELO VOLTIOS

M

D1012C 120 8.3 1000 3413 14 awg

D1512 120 12.6 1500 5120 12 awg

08 3.6 750 2560 14 awg

D1024C

2

240 4.2 1000 3413 14 awg

D2024

Su calentador está equipado con un control automático de regraduación que

lo apaga automáticamente (OFF) para prevenir un incendio si el calentador

se calienta excesivamente. So ocurriera esto, se ilumina la luz del indicador y

continúa encendida hasta que el límite se regradúa.

208 7.2 1500 5120 14 awg

240 8.3 2000 6826 14 awg

!

LA LUZ ENCENDIDA DEL INDICADOR SIGNIFICA QUE EL CALENTADOR HA

STADO SUJETO A ALGUNA CONDICION ANORMAL CAUSANDO QUE

E

E CALIENTE EXCESIVAMENTE. INSPECCIONAR EL CALENTADOR PARAASE-

S

URARSE QUE NO HA SIDO BLOQUEADO (DE SERLO ELIMINAR EL BLO-

G

QUEO). PARAASEGURARSE QUE EL CALENTADOR NO HA SIDO DAÑADO, SE

RECOMIENDA QUE EL MISMO SEA INSPECCIONADO POR UN ELECTRICISTA

O SERVICIO DE REPARACIONES, DE BUENA REPUTACION.

A

MPS

ATIOS

V

AVISO DE OPERACION

PRECAUCION

TU/HR

B

EL CABLE

D

INFORMACION IMPORTANTE

Bennettsville, SC 29512 USA

MODEL

VATIOS

AMP.

D2024

2000/1500

8.3/7.2

DATE

VOLTIOS

PH

1

MM-YY

240/208

Hz

60

7

Page 8

GARANTIA LIMITADA

Todos los productos fabricados por Marley Engineered Products se garantizan contra defectos en mano de obra y materiales por

un año a partir de la fecha de instalación, excepto los elementos térmicos que están garantizados contra defectos en mano de

bra y materiales por cinco años a partir de la fecha de instalación. Esta garantía no se aplica a daños causados por accidente,

o

mal uso o alteración; ni tampoco donde el voltaje conectado es mayor de 5% del voltaje de la placa de nombre; ni al equipo

instalado o cableado o mantenido impropiamente en violación de las instrucciones de instalación del producto. Todos los reclamos por trabajo de garantía deben estar acompañados por prueba de la fecha de instalación.

El cliente será responsable por todos los costos incurridos en la extracción o reinstalación de los productos, incluyendo costos

de mano de obra y costos de transporte incurridos en devolver los productos al Centro de Servicio de Marley Engineered

Products, y repararemos o reemplazaremos, a nuestra opción, sin cargo para Ud., con el flete de retorno pagado por Marley. Se

acuerda en que tal reparación o reemplazo es el remedio exclusivo disponible de Marley Engineered Products.

LAS GARANTIAS DE ARRIBA SON A CAMBIO DE TODAS LAS OTRAS GARANTIAS EXPRESAS O IMPLICITAS Y TODAS

LAS GARANTIAS EXPRESAS DE COMERCIALIZACION Y APTITUD PARA UN PROPOSITO PARTICULAR QUE EXCEDAN

LAS GARANTIAS EXPRESAS MENCIONADAS PREVIAMENTE SON RECHAZADAS Y EXCLUIDAS DEL PRESENTE

ACUERDO. MARLEY ENGINEERED PRODUCTS NO SERA RESPONSABLE POR PERJUICIOS CONSECUENTES ORIGINADOS CON RESPECTO AL PRODUCTO, YA SEA BASADO EN NEGLIGENCIA, LEY, RESPONSABILIDAD ESTRICTA O

CONTRATO.

Algunos Estados no permiten la exclusión o limitación de perjuicios incidentales o consecuentes, de manera que la exclusión o

limitación de arriba puede no aplicarse a Ud. Esta garantía le otorga derechos legales específicos, y Ud. también puede tener

otros derechos que varían de Estado a Estado.

Consulte con Marley Engineered Products en Bennettsville, SC, al 1-800-642-4328, para la dirección de su centro autorizado de

servicio más cercano. La mercadería devuelta a la fábrica debe estar acompañada por una autorización de devolución y una etiqueta de identificación de servicio, ambos disponibles de Marley Engineered Products. Incluya todos los números de catálogo

mostrados en los productos, al requerir autorización de devolución.

COMO OBTENER SERVICIO EN GARANTIA,

PIEZAS DE REPUESTO E INFORMACION GENERAL

1. Servicio o repuestos, en garantía: 1-800-642-4328

2. Compra de piezas de repuesto: 1-800-654-3545

3. Información general sobre productos: www.marleymep.com

Nota: Cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

8

05/10Part No. 5200-2469-003

ECR 38742

Page 9

Radiateurs muraux et de

plafond à ventilation forcée

Série D

Notice dʼinstallation et dʼentretien

Cher utilisateur,

Félicitations ! Nous vous remercions d'avoir fait l'acquisition de ce nouveau radiateur fabriqué par une division de Marley

Engineered Products. Vous avez fait un bon investissement en choisissant un appareil de qualité imbattable. Veuillez lire

attentivement et suivre scrupuleusement les consignes de ce manuel concernant l'installation et l'entretien. Nous sommes

sûrs que vous bénéficierez de nombreuses années de confort grâce à cet appareil de chauffage efficace de Marley

Engineered Products... le numéro 1 du secteur du chauffage en matière de conception, fabrication, qualité et service.

...Les employés de

Marley Engineered Products

AVERTISSEMENT

!

À lire soigneusement – Ces instructions sont écrites pour

vous aider à éviter les difficultés qui pourraient survenir lors de

l'installation. En étudiant d'abord ces instructions vous pouvez

économiser un temps considérable et de l'argent plus tard.

Observez les procédures qui suivent et amenez votre temps d'installation à un minimum. POUR RÉDUIRE LES RISQUES D'IN-

CENDIE OU DE COMMOTION ÉLECTRIQUE :

1. Débranchez toute alimentation allant au radiateur au niveau du panneau

de distribution avant de câbler ou entretenir.

2. Réalisez tout le câblage en conformité avec les règlements nationaux et

locaux et reliez le radiateur à la terre.

3. Vérifiez que la tension d'alimentation secteur arrivant au radiateur correspond à la prescription sur sa plaque d'identification avant de l'alimenter.

4. Le radiateurest chauden fonctionnement. Pour ne pas vous brûler, ne laissez pas la peau nue toucher ses surfaces chaudes.

5. N'insérez pas et ne laissez pas pénétrer d'objet étranger dans une ouver-

CONSERVEZ CES INSTRUCTIONS

turede ventilation ou d'évacuation car cela pourrait causer une commotion

électrique ou le feu, ou endommager le radiateur.

6. Ne bloquez en aucune manière les prises et évacuations d'air. Gardez les

matériaux combustibles, comme emballages, tentures, etc …loin du radiateur. Ne l'installez pas derrière porte, meuble, porte serviette ou coffret. Ne

montez pas au plafond de radiateur de plus de 1 000 watt.

7. Un radiateur comporte des parties chaudes et susceptibles de provoquer

arc ou étincelles électriques. Ne l'utilisez pas dans des zones ou de

l'essence, de la peinture, ou des liquides inflammables sont utilisés ou

entreposés.

8. N'utilisez le radiateur que comme décrit dans ce manuel. Toute autre utilisation non recommandée par le constructeur peut provoquer incendie,

électrocution ou dommages corporels.

9. Ce radiateur n'est pas approuvé pour une utilisation sous atmosphère corrosive comme l'air marin, l'intérieur d'une serre ou un entrepôt de produits

chimiques.

9

Page 10

ATTENTION

M

BLK

BLK

L2

RED

L1

G

ND

TSTAT

PILOT

LT .

AUTO

LIMIT

TCO

240/208 V

AUT O

LIMIT

2000 WATTS

M

BLK

L2

RED

L1

GND

TSTAT

PILO T

LT.

240/208 V

1000 WATTS

M

RED

GND

TSTAT

PILO T

LT.

AUT O

LIMIT

TCO

120 V

NL

1000 WATTS

M

WHT

BLK

BLK

WHT

RED

GND

TSTAT

PILO T

LT.

AUTO

LIMIT

TCO

120 V

NL

1500 WA TTS

TCO

L

N

L

N

!

POUR RÉDUIRE LES RISQUES D'INCENDIE, DE COMMOTION ÉLECTRIQUE OU

ES DÉGÂTS DANS LE RADIATEUR, SUIVEZ CES RECOMMANDATIONS :

D

. N'installez pas le radiateur sans caisson arrière.

1

2. Observez les espacements minimum suivants :

En montage mural :

adiateur au plancher – 114 mm (4,5")

R

adiateur à toute surface adjacente - 114 mm (4,5")

R

Radiateur à plafond – 305 mm (12")

n montage plafond :

E

adiateur à mur adjacent - 305 mm (12")

R

3. Le radiateur est chaud en fonctionnement. Ne l'installez pas derrière porte ou porte

serviette ou dans unplacard,ni où rideauxou tentures pourraientle toucher ou être

ndommagés par la chaleur proche.

e

. Maintenez les câbles électriques, la literie,le mobilier et tout ce qui est combustible

4

éloignés du radiateur.

es radiateurs Série D sont conçus pour une installation encastrée entre des

L

oteaux muraux de 2x4 pouces ou plus grands ou des solives de plafond en utilisant

p

le caisson arrière modèle D-BB avec la grille de soufflage (la plus petite) en haut ou

en bas (voir le Schéma 1). Le radiateur peut être alimenté en utilisant le câblage

standard de bâtiment (minimum 60°C). Reportez-vous au tableau de spécifications

pour trouver la taille de fil appropriée en fonction du modèle de radiateur.

outes les unités de la Série D de 1 000 watt et moins peuvent être installées

T

encastrées dans le plafond. Quand il est au plafond le radiateur peut être orienté

dans n'importe quelle direction.

es radiateurs sont également approuvés pour être montés en surface au pla-

L

ond ou sur les cloisons. Reportez-vous aux instructions d'installation du support de

f

ontage en surface DSMK.

m

INSTALLATION DU CAISSON ARRIÈRE DANS UNE

Schéma 1

t fixez-le dans lecaisson, en laissant aumoins152 mm (6")de câble dans le caisson

e

our le raccordement sur les fils d'alimentation du radiateur.

p

OTE B : Des trous de passage pour vis de tôle #8 sont prévus sur les côtés du caisson

N

arrière (Voir Schéma 2).

ATTENTION

!

NE DÉCHARGE ÉLECTRIQUE, UN INCENDIE OU UNE FUITE D'EAU PEU-

U

VENT RÉSULTER D'UN DOMMAGE À UNE CONDUITE ÉLECTRIQUE OU UNE

CANALISATION PENDANT LA DÉCOUPE. ASSUREZ-VOUS QU'IL N'Y A NI

ONDUITE NI CANALISATION DANS LA ZONE À PERCER.

C

9-1/8” (231mm)

Câble d'alimentation

12-5/8” (320mm)

Schéma 3

INSTALLATION DU CAISSON ARRIÈRE DANS UNE CON-

1. Déterminez quel côté du caisson arrière sera monté contre le poteau de cloison ou

la solive de plafond (voir Schéma 2).

2. Marquez soigneusement puis percez une cavité dans la cloison ou le plafond

mesurant 231 mm (9 1/8") de large sur 320 mm (12 5/8") de haut, avec un de ses

côtés contre un poteau de cloison ou une solive de plafond (Voir Schéma 3).

3. Amenez le câble d'alimentation électrique à l'emplacement du montage du radia-

teur, en lui laissant environ 254 mm (10") pour la suite de l'installation.

4. Démontez la plate-forme de ventilateur du caisson en enlevant les deux vis.

5. Libérez une entrée défonçable dans le caisson pour le passage du câble d'ali-

mentation secteur. Installez le câble dans le caisson, en laissant au moins 152 mm

(6") de câble dans le caisson pour le raccordement sur les fils d'alimentation du

radiateur.

6. Présentez le caisson arrière dans sa niche découpée en glissant le câble d'ali-

mentation. Le caisson doit être installé avec son rebord avant affleurant la surface

extérieure du revêtement. Fixez le caisson en utilisant deux clous ou vis (Voir Note

B).

STRUCTION TERMINÉE

(2) vis de main-

tien du couver-

cle

Ouverture

dans la cloi-

son égale au

caisson

Couvercle dépassant du

revêtement de cloisonde

32 mm (1,25")

NOTE A : Si le revêtement de la cloison est déjà posé, suivez les instructions dans

"INSTALLATION DU CAISSON ARRIÈRE DANS UNE CONSTRUCTION TERMINÉE".

1. Déterminez quel côté du caisson arrière sera monté contre le poteau de cloison ou

la solive de plafond(voir Schéma 2). Laissez la place pour l'épaisseurdu revêtement

de surface en mettant le caisson en place. Le dessus du caisson doit affleurer le

niveau qu' aura le revêtement posé. Des repères sur le caisson indiquent des épaisseurs de revêtement de 12,7 mm (1/2") et 15,9 mm (5/8").

2. Démontez la plate-forme de ventilateur du caisson en enlevant les deux vis.

Revêtement

de cloison

Prévoir l'é-

Caisson

paisseur du

arrière

revêtement

de cloison

CONSTRUCTION NEUVE

Caisson

arrière

Schéma 2

3. Positionnez lecaisson arrièrecontre le poteau ou la solive à l'endroit voulu et fixez-le

en utilisant deux clous ou vis comme montré sur le Schéma 2.

4. Libérez une entrée défonçable dans le caisson pour le passage du câble d'alimentation secteur.

5. Amenez le câble d'alimentation secteur dans le caisson. Installez un collier de câble

Schéma 4

10

LIMITE

A

LIMITE

AUTO

TERRE

ROUGE

NOIR

1

L

L2

THERMOSTAT

UTO

OYANT

V

LIMITE

TCO

LIMITE

A

UTO

2000 W

NOIR

BLANC

TERRE

NOIR

ROUGE

THERMOSTAT

PHASE

VOYANT

LIMITE

TCO

NEUTRE

LIMITE

AUTO

TCO

1500 W

HERMOSTAT

T

VOYANT

LIMITE

NOIR

THERMOSTAT

PHASE

VOYANT

LIMITE

1000 W

ROUGE

1

L

1000 W

ROUGE

N

L2

BLANC

NOIR

OIR

TCO

NEUTRE

ERRE

T

TERRE

Page 11

INSTALLATION DE L'ASSEMBLAGE DE RADIATEUR DANS LE

CAISSON ARRIÈRE

. Remettez en place la plate-forme de ventilateur avec ses deux vis.

1

. Reliez les arrivées du câble secteur aux terminaisons d'alimentation à queue de

2

ochon (Voir le Schéma 4). Reliez le fil d'arrivée de terre au fil vert de masse du radi-

c

teur.

a

3. Installez le couvercle frontal. Appuyez sur le bouton de thermostat.

ATTENTION

Pour assurer une bonne mise à la terre du radiateur et éviter une

éventuelle commotion électrique, le fils d'arrivée de terre doit être relié

au fil vert de masse du radiateur.

ATTENTION

Pour éviter de possibles dommages au câblage, couper l'excédent de

fils d'alimentation dans le boîtier arrière afin de n'en laisser qu'environ

152 cm (6") pour le raccordement avec les fils du chauffage. Une fois

ces raccordements faits, s'assurer qu'ils sont bien serrés et que tout le

câblage chemine à l'écart de la pale de ventilateur et de l'élément

chauffant.

!

!

SPÉCIFICATIONS

MODÈLE DIM.

O. VOLTS. AMPS. WATTS BTU/HR CÂBLE

N

D1012C 120 8.3 1000 3413 14 awg

D1512 120 12.6 1500 5120 12 awg

08 3.6 750 2560 14 awg

D1024C

D2024

Votre radiateur est muni d'une coupure automatique sur contrôle de limite qui

va arrêter automatiquement l'élément chauffant pour éviter une inflammation

en cas de surchauffe. Si cela se produit le voyant indicateur s'allume et reste

allumé jusqu'à ce que la température limite ne soit plus dépassée.

2

240 4.2 1000 3413 14 awg

208 7.2 1500 5120 14 awg

240 8.3 2000 6826 14 awg

REMARQUE SUR LE FONCTIONNEMENT

VÉRIFICATION DE FONCTIONNEMENT ET RÉGLAGE

DU THERMOSTAT

1. Mettez le radiateur sous tension secteur.

2. Faites tourner le bouton du thermostat à fond dans le sens des aiguilles d'une montre. L'élément chauffant et le ventilateur doivent s'actionner, créant un flux d'air chaud

n sortie de la grille de soufflage.

e

. Laissez le radiateur fonctionner jusqu'à ce que la température ambiante soit

3

gréable, puis ramenez le bouton du thermostat en ses contraire des aiguilles d'une

a

montre jusqu'à l'audition d'un clic. L'appareil va seul se couper et se remettre en

action pour maintenir la température du point de consigne.

4. Augmentez ou diminuez ce point de consigne pour obtenir la température ambiante

voulue.

Pour les meilleurs résultats le radiateur doit être laissé en permanence en position de

marche (ON) pendant la saison de chauffe, puisque le thermostat quand il est correctement réglé maintien la pièce à la température voulue. En position de thermostat à fond

dans le sens inverse des aiguilles d'une montre le radiateur reste coupé. L'appareil est

livré avec un bouchon pour rendre le réglage de thermostat inviolable. Enlevez le bouton

du thermostat réglé et insérez le bouchon dans le guidage de trou de dégagement.

Pour les appareils montés au plafond, un thermostat à distance alimenté par secteur

peut être installé sur un mur pour contrôler le radiateur. Suivez les instructions pour ce

thermostat mural.Tournez le thermostat d'origine du radiateur en position ouverte à fond

pour un réglage de chaleur maximale, enlevez son bouton et mettez le bouchon dans le

guidage de trou de dégagement. Réglez votre thermostat mural au point de consigne

voulu.

INFORMATIONS IMPORTANTES

Bennettsville, SC 29512 USA

MODÉLE

WATTS

AMPS

D2024

2000/1500

8.3/7.2

DATE

VOLTS

PH

1

MM-YY

240/208

Hz

60

ATTENTION

!

L'ÉCLAIRAGE DU VOYANT SIGNIFIE QUE LE RADIATEUR A ÉTÉL'OBJETD'UNE

CONDITION DE FONCTIONNEMENT ANORMAL AYANT ENTRAÎNÉ UNE SUR-

HAUFFE. VÉRIFIEZ LE RADIATEUR POUR VÉRIFIER QUE LA VENTILATION

C

N'A PAS ÉTÉ BLOQUÉE D'UNE FAÇON OU D'UNE AUTRE (ET ENLEVEZ LE

LOCAGE S'IL Y A LIEU). S'IL N'Y A PAS DE RAISON MÉCANIQUE VISIBLE IL

B

EST RECOMMANDÉ DE FAIRE VÉRIFIER LE RADIATEUR PAR UN

LECTRICIEN COMPÉTENT OU UN SERVICE DE RÉPARATION POUR

É

VÉRIFIER QUE L'APPAREIL N'A PAS ÉTÉ ENDOMMAGÉ.

11

Page 12

GARANTIE LIMITÉE

Tous les produits visés par ces instructions sont garantis contre les vices de fabrication et de matériau pour une durée de 1 an

à compter de la date dʼinstallation, à lʼexception des éléments chauffants qui sont garantis contre tout vice de fabrication ou de

matériau pour une durée de cinq ans à compter de la date dʼinstallation. Cette garantie ne sʼapplique pas dans le cas de dommage attribuable à un accident, un mauvais usage ou une modification. La garantie ne sʼapplique pas non plus si la tension dʼutilisation est supérieure de 5% à la tension indiquée sur la plaque signalétique, ni si lʼinstallation, le câblage ou lʼentretien de lʼappareil ne sont pas conformes aux instructions contenues dans ce feuillet. Toute demande en vertu de la garantie doit être accompagnée dʼune preuve dʼachat montrant la date.

Le client assume tous les frais associés à lʼenlèvement ou à la réinstallation du produit, y compris les frais de main-dʼœuvre et

les frais dʼenvoi des produits à un centre de service Marley Engineered Products. En vertu de cette garantie, les appareils

défectueux devraient être retournés au centre du service Marley le plus près ou à Marley Engineered Products Service Center,

et nous réparerons ou remplacerons lʼappareil, à notre choix, sans frais. Lʼappareil vous sera retourné sans frais. Il est entendu

que la réparation ou le remplacement sont les seules solutions offertes par Marley.

CETTE GARANTIE REMPLACE TOUTE AUTRE GARANTIE CLAIREMENT EXPRIMÉE OU SOUS-ENTENDUE ET TOUTE

GARANTIE SOUS-ENTENDUE AYANT TRAIT À LʼAPPLICATION DU PRODUIT À UNE UTILISATION AUTRE QUE CELLE

INDIQUÉE DANS LA GARANTIE QUI PRÉCÈDE EST SANS VALEUR ET NʼEST PAS VISÉE PAR LA PRÉSENTE ENTENTE.

MARLEY ENGINEERED PRODUCTS NʼEST PAS RESPONSABLE DES DOMMAGES AU PRODUIT RÉSULTANTS DʼUNE

NÉGLIGENCE, DʼUN TORT, DʼUNE RESPONSABILITÉ STRICTE OU DU CONTRAT.

Certaines provinces interdisent la restriction quant à la responsabilité. Il est donc possible que la restriction qui précède ne sʼapplique pas dans votre cas. Cette garantie vous confère des droits spécifiques. Il est possible que vous ayez dʼautres droits, ces

derniers varient selon les provinces.

Pour obtenir lʼadresse du centre de service le plus près de chez vous, communiquez avec Marley Engineered Products,

Bennettsville, SC, USA au 1-800-642-4328. Tout produit retourné à lʼusine doit être accompagné dʼune autorisation de retour et

dʼun bon dʼindentification. Vous pouvez vous procurer ces documents à lʼadresse qui précède. Au moment de demander une

autorisation de retour, assurez-vous dʼindiquer toutes les références au catalogue qui figurent sur le produit.

COMMENT OBTENIR DES INFORMATIONS GÉNÉRALES ET

DEMANDER UNE RÉPARATION OU DES PIť CES SOUS GARANTIE

1. Réparations et piéces sous garantie 1-800-642-4328

2. Achat de piéces de rechange 1-800-654-3545

3. Informations générales sur les produits www.marleymep.com

Remarque : Lorsque vous demandez de l'assistance, ayez toujours en main

1. Le numéro de modéle du produit

2. La date de fabrication

3. Numéro ou description de la piéce

12

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

05/10Part No. 5200-2469-003

ECR 38742

Loading...

Loading...