Page 1

WD Series

Corrosion Resistant Heater

Installation, Operation & Maintenance Instructions

Specifications

odel Output Heater Motor Motor Motor Temp Ship Weight

M

umber KW Volts Phase BTU/HR Amps Volts Phase Amps Rise CFM lbs (kg)

N

D02112A 2 120 1 6,824 16.7 120 1 1.554 9 700 60 (27.2)

W

D02812A 2 208 1 6,824 9.6 208 1 0.896 9 700 60 (27.2)

W

D02212A 2 240 1 6,824 8.3 240 1 0.777 9 700 60 (27.2)

W

WD03112A 3 120 1 10,236 25.0 120 1 1.554 14 700 60 (27.2)

WD03812A 3 208 1 10,236 14.4 208 1 0.896 14 700 60 (27.2)

D03212A 3 240 1 10,236 12.5 240 1 0.777 14 700 60 (27.2)

W

D03712A 3 277 1 10,236 10.8 277 1 0.673 14 700 60 (27.2)

W

D03832A 3 208 3 10,236 8.3 208 1 0.896 14 700 60 (27.2)

W

D03232A 3 240 3 10,236 7.2 240 1 0.777 14 700 60 (27.2)

W

D03432A 3 480 3 10,236 3.6 480 1 0.388 14 700 60 (27.2)

W

WD05812A 5 208 1 17,060 24.0 208 1 0.896 23 700 60 (27.2)

WD05212A 5 240 1 17,060 20.8 240 1 0.777 23 700 60 (27.2)

WD05712A 5 277 1 17,060 18.1 277 1 0.673 23 700 60 (27.2)

WD05412A 5 480 1 17,060 10.4 480 1 0.388 23 700 60 (27.2)

WD05832A 5 208 3 17,060 13.9 208 1 0.896 23 700 60 (27.2)

WD05232A 5 240 3 17,060 12.0 240 1 0.777 23 700 60 (27.2)

WD05432A 5 480 3 17,060 6.0 480 1 0.388 23 700 60 (27.2)

WD05632A 5 600 3 17,060 4.8 240 1 1.8 23 1450 75 (34)

WD07812A 7.5 208 1 25,590 36.1 208 1 0.896 34 700 60 (27.2)

WD07212A 7.5 240 1 25,590 31.3 240 1 0.777 34 700 60 (27.2)

WD07712A 7.5 277 1 25,590 27.1 277 1 0.673 34 700 60 (27.2)

WD07412A 7.5 480 1 25,590 15.6 480 1 0.388 34 700 60 (27.2)

WD07832A 7.5 208 3 25,590 20.8 208 1 0.896 34 700 60 (27.2)

WD07232A 7.5 240 3 25,590 18.0 240 1 0.777 34 700 60 (27.2)

WD07432A 7.5 480 3 25,590 9.0 480 1 0.388 34 700 60 (27.2)

WD07632A 7.5 600 3 25,590 7.2 240 1 1.8 34 1450 75 (34)

WD10212A 10 240 1 34,120 41.7 240 1 0.777 22 1450 60 (27.2)

WD10712A 10 277 1 34,120 36.1 277 1 0.673 22 1450 60 (27.2)

WD10412A 10 480 1 34,120 20.8 480 1 0.388 22 1450 60 (27.2)

WD10832A 10 208 3 34,120 27.8 208 1 0.896 22 1450 60 (27.2)

WD10232A 10 240 3 34,120 24.1 240 1 0.777 22 1450 60 (27.2)

WD10432A 10 480 3 34,120 12.0 480 1 0.388 22 1450 60 (27.2)

WD10632A 10 600 3 34,120 9.6 240 1 1.8 33 2400 75 (34)

WD12812A 12.5 208 1 42,650 60.1 208 1 1.793 27 1450 60 (27.2)

WD12212A 12.5 240 1 42,650 52.1 240 1 1.554 27 1450 60 (27.2)

WD12832A 12.5 208 3 42,650 34.7 208 1 1.793 27 1450 60 (27.2)

WD12232A 12.5 240 3 42,650 30.1 240 1 1.554 27 1450 60 (27.2)

WD12432A 12.5 480 3 42,650 15.0 480 1 0.777 27 1450 60 (27.2)

WD12632A 12.5 600 3 42,650 12.0 240 1 1.8 27 2400 75 (34)

WD15812A 15 208 1 51,180 72.1 208 1 1.793 20 2400 110 (49.9)

WD15212A 15 240 1 51,180 62.5 240 1 1.554 20 2400 110 (49.9)

WD15412A 15 480 1 51,180 31.3 480 1 0.777 20 2400 110 (49.9)

WD15832A 15 208 3 51,180 41.6 208 1 1.793 20 2400 110 (49.9)

WD15232A 15 240 3 51,180 36.1 240 1 1.554 20 2400 110 (49.9)

WD15432A 15 480 3 51,180 18.0 480 1 0.777 20 2400 110 (49.9)

WD15632A 15 600 3 51,180 14.5 240 1 1.8 20 2400 125 (56.6)

WD20412A 20 480 1 68,240 41.7 480 1 0.777 26 2400 120 (54.4)

WD20232A 20 240 3 68,240 48.1 240 1 1.554 26 2400 120 (54.4)

WD20432A 20 480 3 68,240 24.1 480 1 0.777 26 2400 120 (54.4)

WD20632A 20 600 3 68,240 19.3 240 1 1.8 26 2400 135 (61.2)

WD25832A 25 208 3 85,300 69.4 208 1 1.793 33 2400 120 (54.4)

WD25232A 25 240 3 85,300 60.1 240 1 1.554 33 2400 120 (54.4)

WD25432A 25 480 3 85,300 30.1 480 1 0.777 33 2400 120 (54.4)

WD25632A 25 600 3 85,300 24.1 240 1 1.8 33 2400 135 (61.2)

WD30832A 30 208 3 102,360 83.3 208 1 1.793 39 2400 120 (54.4)

WD30232A 30 240 3 102,360 72.2 240 1 1.554 39 2400 120 (54.4)

WD30432A 30 480 3 102,360 36.1 480 1 0.777 39 2400 120 (54.4)

WD30632A 30 600 3 102,360 28.9 240 1 1.8 39 2400 135 (61.2)

WD39432A 39 480 3 133,068 46.9 480 1 0.777 51 2400 120 (54.4)

WD39632A 39 600 3 133,068 37.6 240 1 1.8 51 2400 135 (61.2)

NOTE: Heaters over 48 amps require supplemental fusing.

SAVE THESE INSTRUCTIONS

PPD 41616 12/13 5200-11199-002

Page 2

IMPORTANT INSTRUCTIONS

EXPOSED

EXPO

SED

EXPOSED

EXPOSED

E

X

P

O

S

E

D

E

X

P

O

S

E

D

WARNING

WHEN USING ELECTRIC APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE THE

RISK OF FIRE, ELECTRIC SHOCK, AND INJURY TO PERSONS, INCLUDING THE FOLLOWING:

1. Read all instructions before installing or using this heater.

2. This heater is a commercial/industrial product not intended

for use in a residential setting.

3. This heater has hot and arcing or sparking parts inside and

is not intended for use in hazardous atmospheres where

flammable vapors, gases, liquids or other combustible

atmospheres as defined in the National Electrical Code are

used or stored. Failure to comply can result in explosion or

fire.

4. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, etc. and

curtains at least 3 feet (0.9 m) from the front of the heater.

5. Extreme caution is necessary when any heater is used by or

near children or invalids and whenever the heater is left

operating and unattended.

INSTALLATION

!

6. Do not operate any heater after it malfunctions. Disconnect

power at service panel and have heater inspected by a reputable electrician before using.

7. Do not use outdoors.

8. To disconnect heater, turn controls to OFF, and turn OFF

power to heater circuit at main disconnect panel.

9. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock, fire,

or damage to the heater.

10. To prevent a possible fire, do not block air intake or exhaust

in any manner.

11. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

electric shock, or injury to persons.

12. When installing, see INSTALLATION INSTRUCTIONS for

additional warnings and precautions.

13. For safe and efficient operation, and to extend the life of your

heater, keep your heater clean - See MAINTENANCE

INSTRUCTIONS.

NOT FOR RESIDENTIAL USE.

INSTRUCTIONS

To prevent a possible fire, injury to persons or damage to the

heater, adhere to the following:

Important Note: This heater must be installed by a qualified

person.

1. Disconnect all power coming to heater at main service panel

before wiring or servicing.

2. All wiring procedures and connections must be in accordance with the National and Local Codes having jurisdiction

and the heater must be grounded.

CAUTION: All electrical conduit and fittings must be listed for

watertight applications to maintain the NEMA 4X enclosure

classification to prevent hose-directed water from entering electrical box.

3. Verify the power supply voltage coming to heater matches

the ratings as shown on the heater nameplate.

CAUTION: ENERGIZING HEATER AT A VOLTAGE GREATER

THAN THE VOLTAGE PRINTED ON THE NAMEPLATE WILL

DAMAGE THE HEATER AND VOID THE WARRANTY AND

COULD CAUSE A FIRE.

General

Heater Location Instructions:

Arrange units so their discharge air streams:

A. Are subjected to minimum interference from columns,

machinery and partitions.

B. Wipe exposed walls without blowing directly at them.

C. Are directed away from room occupants in comfort heating.

D. Are directed along the windward side when installed in a

building exposed to a prevailing wind.

WARNING

4. To reduce the risk of fire, do not store or use gasoline or other

flammable vapors and liquids in the vicinity of the heater.

5. The ceiling or wall mounting structure and the anchoring provisions must be of sufficient strength to support the combined

weight of the heater and mounting bracket. See

Specificatinos for total weight.

6. Heater must be mounted for horizontal air flow only. The

heater must be mounted at least 7’ (2134 mm) above the

floor to avoid accidental contact with the fan blade which

could cause injury.

7. Keep at least 5’ (1524 mm) clearance in front of the heater.

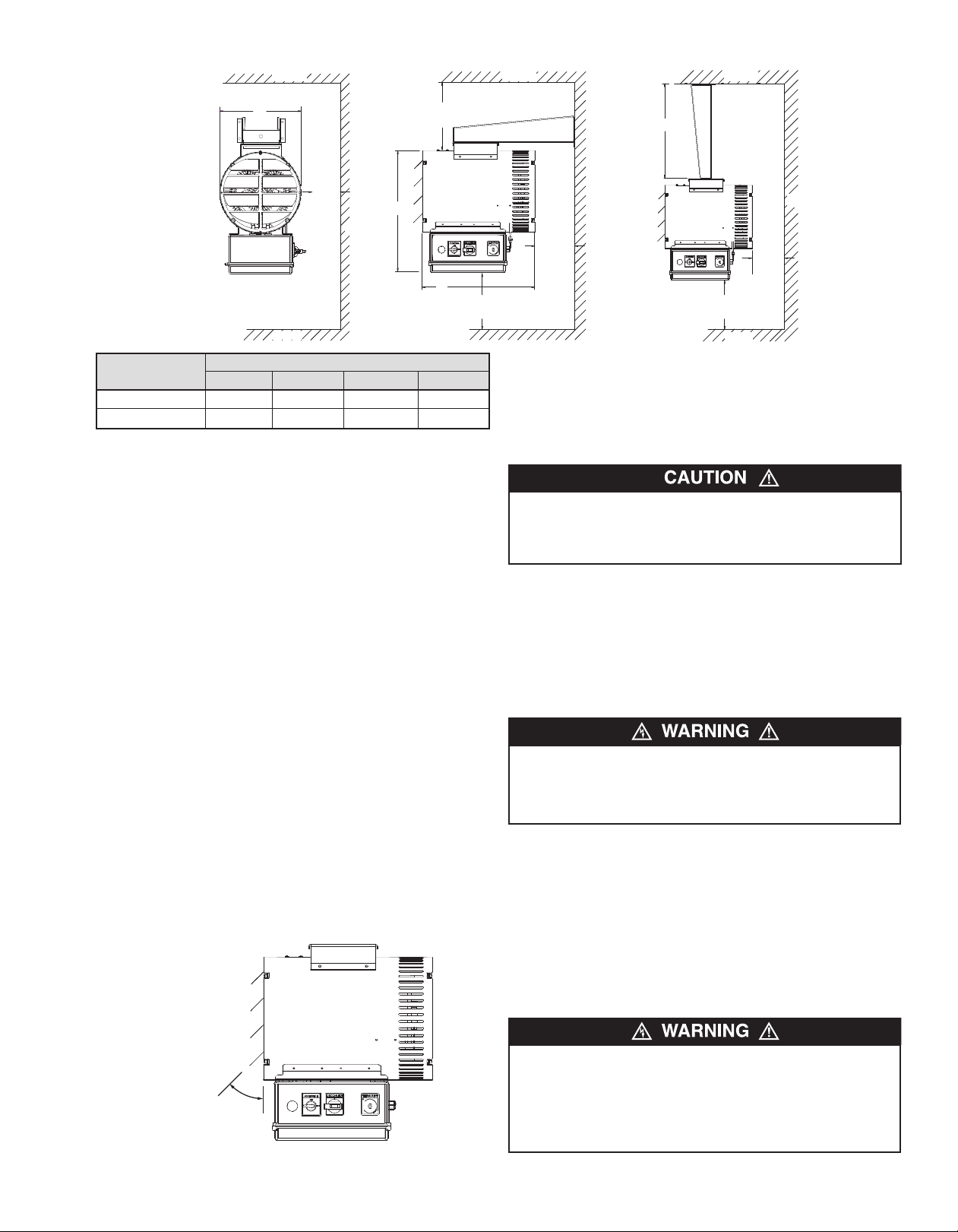

Refer to Figure 2 for side, top and back clearance requirements.

8. Do not mount mercury type thermostat directly on unit.

Vibration could cause heater to malfunction.

9. Outlet grille is factory formed with louvers set at a 45 ° angle.

This is the minimum angle allowable to avoid potential overheating. Louvers may be opened up to 90° if desired to allow

for better air throw by bending each louver outward. See

Figure 3.

If not provided with internal thermostat, locate remote thermostat

on interior partition walls or posts away from cold drafts, internal

heat sources and away from heater discharge air streams.

Figure 1

2

!

Page 3

A

Wall

Ceiling

Floor

6" Min.

(152 mm)

D

Ceiling

Wall

8" Min.

(203 mm)

B

Floor

7' Min.

(2134 mm)

7' Min.

(2134 mm)

9" Min.

(229 mm)

Wall

6"

(152 mm)

C

Ceiling

Floor

45° Minimum

Angle

Figure 2

Dimensions Inches (mm)

kW AB C D

2-10 13 (330) 19.5 (495) 18 (457) 19.5 (495)

12.5-39.0 20 (508) 31 (787) 27 (686) 24.2 (615)

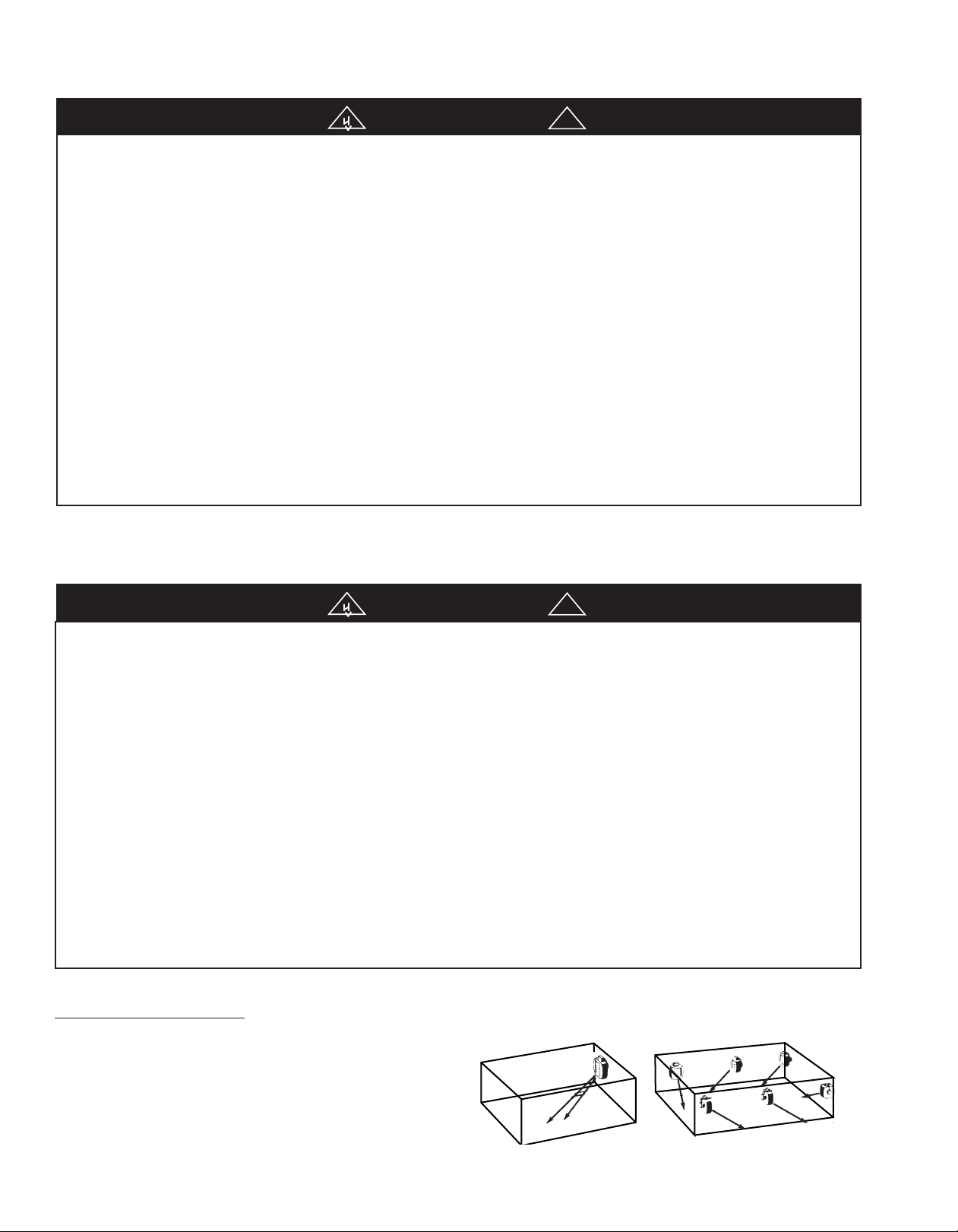

Small rooms can be heated by one unit heater. Where two walls

are exposed, the heater should be mounted as shown in

Figure 1.

Large rooms require multi-unit installations. Number and capacity of units will be determined by volume of building and square

feet of floor area to be heated. Arrange units to provide perimeter

air circulation where each unit supports the air stream from

another.

Mounting Heaters with supplied Universal

Mounting Bracket

NOTICE — These heaters are designed for wall and ceiling

mounting with horizontal air discharge only. Other modes of

mounting voids factory warranty.

1. Height above floor

A. In areas where ceiling height is more than 12 feet (3658

mm), recommended mounting height is approximately 10

feet (3048 mm) to underside of heater.

B. For ceiling heights of 12 feet (3658 mm) or less, maximum

mounting height is determined by use of the mounting

bracket offered for these heaters. Minimum spacing to ceiling is 9” (229 mm). (See Figure 2.)

C.In either case the minimum mounting height is 7 feet (2134

mm) from floor to bottom of heater. (Figure 2)

2. Spacing to adjacent walls (See Figure 2).

A. Rear of case to back wall 6” (152mm) minimum.

B. Side of case to side wall 8” (203 mm) minimum.

NOTE: If two or more units are operated in the same enclosed

air space, their discharges should be directed to aid in development of mass air movement for uniform heat dispersal.

Wiring

Refer to wiring diagram included with the unit.

The wiring diagram can be found on the inside of the door to the

wiring compartment. Should you have any questions, please

contact Technical Service at 800-642-4328. Have your model

number found on the name plate for reference.

ALL ELECTRICAL CONDUIT AND FITTINGS MUST BE LISTED

FOR WATERTIGHT APPLICATIONS TO MAINTAIN THE NEMA

4X ENCLOSURE CLASSIFICATION TO PREVENT HOSE

DIRECTED WATER FROM ENTERING ELECTRICAL BOX.

NOTE: All electrical wiring must be done according to National

Electrical and local codes by a qualified person.

IMPORTANT NOTE - Installation Screw Lug Torque: During

transportation it is possible screw lug connections can loosen.

After installation, before power is turned on to the heater, check

all screw lug connections for tightness to a recommended minimum torque of 35 in-lbs. (3.9 N-m). A tool is included for tightening lugs in hard to reach locations

ELECTRIC SHOCK HAZARD. ANY INSTALLATION INVOLVING ELECTRIC HEATERS MUST BE PERFORMED BY A

QUALIFIED PERSON AND MUST BE EFFECTIVELY

GROUNDED IN ACCORDANCE WITH THE NATIONAL

ELECTRICAL CODE TO ELIMINATE SHOCK HAZARD.

1. Connect heater according to the voltage and frequency specified on the nameplate.

2. All units are provided with control and power terminal blocks

for customer’s connection.

3. Protection against overheating is provided by an internal

automatic thermal cutout (manual reset cutout optional)

which opens the electric circuit if the normal air-flow is

restricted or stopped. Cutout automatically energizes heater

on removal of the obstruction. If optional manual reset is

tripped, determine cause before re-energizing.

Figure 3 - Louver Adjustment

THE SYSTEM DESIGNER IS RESPONSIBLE FOR THE

SAFETY OF THIS EQUIPMENT AND SHOULD INSTALL

ADEQUATE BACK-UP CONTROLS AND SAFETY DEVICES

WITH THEIR ELECTRIC HEATING EQUIPMENT. WHERE THE

CONSEQUENCES OF FAILURE COULD RESULT IN

PERSONAL INJURY OR PROPERTY DAMAGE, BACK-UP

CONTROLS ARE ESSENTIAL.

3

Page 4

4. Heaters are equipped with fan delay control. This control continues fan operation for a short time after elements are deenergized to dissipate residual heat.

NOTE: If a Manual-Reset Cutout option is provided, the RESET

button will be marked and accessible on the control panel. This

safety control will operate only if the heater overheats.

FAN BLADE ROTATION MUST BE CHECKED. IF AIRFLOW IS

NOT MOVING OUT THROUGH THE OUTLET GRILLE,

INTERCHANGE ANY TWO OF THE THREE INCOMING

SUPPLY POWER LEADS ON THREE-PHASE UNITS ONLY.

Optional Equipment

• Built-in Thermostat (bulb and capillary type) for automatic

temperature control. The thermostat controls the heating

elements and fan simultaneously to achieve set temperature.

The Lo setting of the thermostat is approximately 40˚F and

the Hi setting is approximately 90˚F.

• Mode Switch (heater on, heater off, fan only) to permit air

flow with or without energizing the heating elements. The

switch is accessible from outside the NEMA 4X enclosure.

• Pilot Light to indicate when heating elements are energized.

• Internal Fusing

• Manual Reset Limit

• ON/OFF Switch

• For wiring diagram containing options, see label on inside

cover of terminal box.

OPERATING

INSTRUCTIONS

1. Heater must be properly installed before operation.

2. To check out the installation, turn the Mode Switch to the

OFF position. Turn power ON to the heater at the main disconnect panel and check to see that the heater is not operating. If it is operating, disconnect power and check wiring.

3. Rotate built-in (or remote mounted) thermostat clockwise to

the highest heat setting. With Heat-Cool Switch in OFF position, heater should not operate.

4. Turn Heat-Cool Selector Switch to the Fan Only position. The

fan should come on and operate with no heat.

5. Turn Heat-Cool Selector Switch to the Heat position. The fan

and heater should come on producing heat.

6. The heater should be allowed to operate with the thermostat

at max or high heat until room temperature reaches the

desired level. The thermostat should then be rotated counterclockwise until the heater elements turn off (an audible click).

This should set the thermostat to cycle the heater on and off

to maintain the ambient temperature. Fine adjustments may

need to be made to obtain the desired room ambient. Slight

rotating of the thermostat in the clockwise direction will

increase the room ambient while rotation in the counterclockwise direction will lower the room ambient. If remote

thermostat is provided, follow the instructions provided with

thermostat

NOTE: A built in fan delay will cause the fan to run after the elements turn off to dissipate residual heat.

NOTE: If a Disconnect Switch option is provided, this switch will

be accessible from the outside of the control box and will be

marked ON and OFF accordingly. In the OFF position, the

heater will not operate.

DO NOT TAMPER WITH OR BYPASS ANY SAFETY LIMITS

INSIDE HEATER.

MAINTENANCE

INSTRUCTIONS

It is important to keep this heater clean. Your heater will give you

years of service and comfort with only minimum care. To assure

efficient operation follow the simple instructions below.

ALL SERVICING BEYOND SIMPLE CLEANING THAT

REQUIRES DISASSEMBLY SHOULD BE PERFORMED BY

QUALIFIED SERVICE PERSONNEL.

TO REDUCE RISK OF FIRE AND ELECTRIC SHOCK OR

INJURY, DISCONNECT ALL POWER COMING TO HEATER

AT MAIN SERVICE PANEL AND CHECK THAT THE ELEMENT

IS COOL BEFORE SERVICING OR PERFORMING

MAINTENANCE.

User Cleaning Instructions:

1. Turn off power to heater and allow elements to cool.

2. Vacuum or hose off heater with water (at city pressure)

before activating for next heating season to remove accumulated dust or lint which otherwise may smoke or incinerate on

initial heat up.

3. Return power to heater and check to make sure it is operating properly.

Maintenance Cleaning Instructions:

(To be performed only by Qualified Service Personnel)

At least annually, the heater should be cleaned and serviced by

a qualified service person to assure safe and efficient operation.

This should include as necessary, vacuuming dust and debris

from the elements and fan, and check all screw lug connections

for tightness to a recommended minimum torque of 35 in-lbs.

(3.9 N-m) using the included tool(s) for hard to reach lugs if necessary. After completing the cleaning and servicing, the heater

should be fully reassembled and checked for proper operation.

IMPORTANT NOTE: For heaters used in a hose down application, it is recommended that periodically after the heater has

been hosed down (with power off at panel) the wiring enclosure

cover be opened and the interior inspected for water penetration.

If water is discovered, the heater must be repaired by a qualified

electrician to assure the seals are properly installed.

During each cleaning, all seals should be inspected for damage

as it is critical that they maintain a water tight seal. If damage is

discovered (such as tears or cracking), they should be replaced

or repaired with an appropriate silicone sealant.

4

Page 5

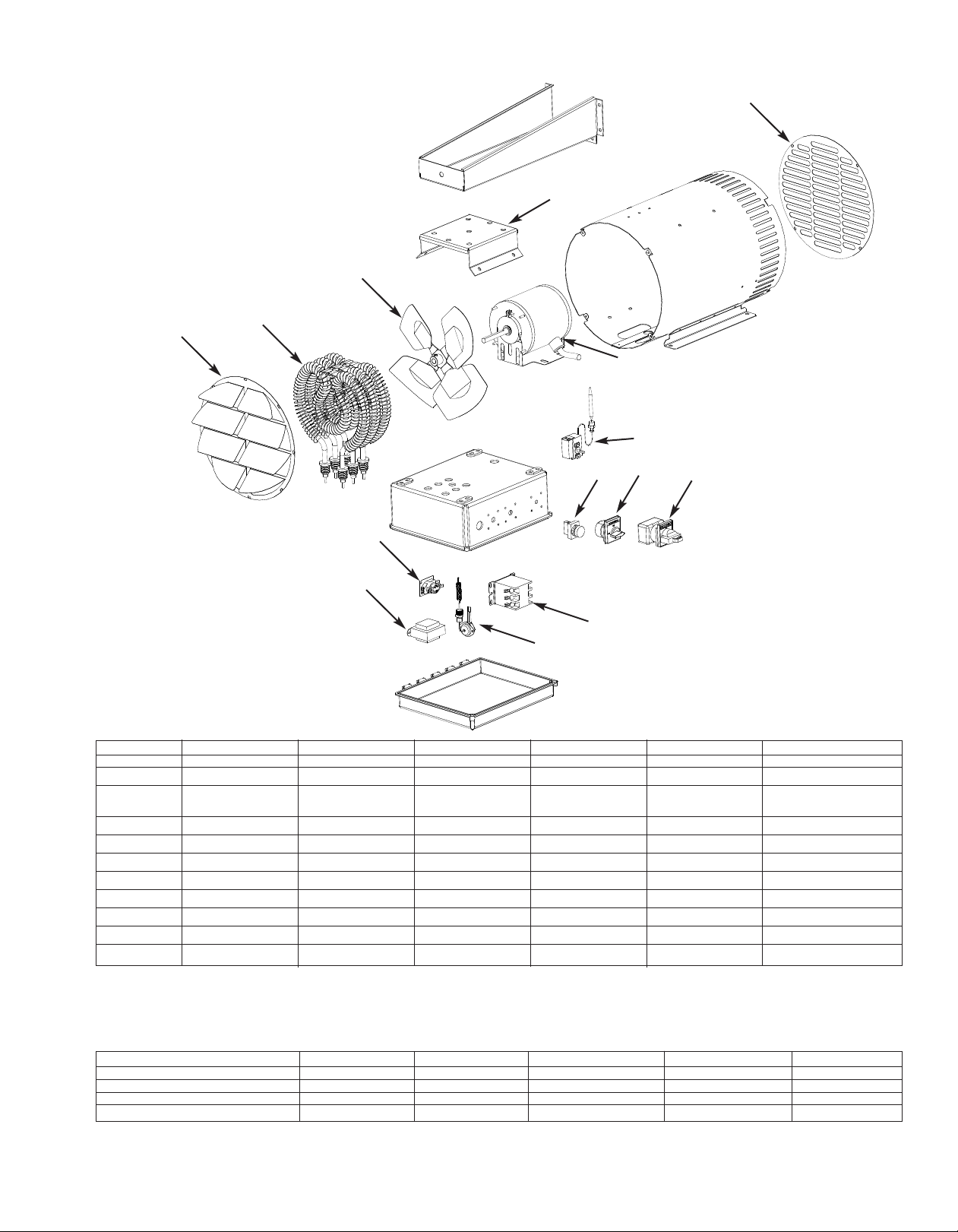

Replacement Parts

5

4

2

6

1

10

13

11

12

14

8

9, 9A

7, 7A

3

Elements (1)

Heater KW 120 V 208 V 240 V 277 V 480 V 600 V

2 1802-11012-001 1802-11012-002 1802-11012-003 --

3 1802-11012-001 1802-11012-002 1802-11012-003 1802-11012-004 1802-11012-004

5-1802-11012-005 1802-11012-006 1802-11012-007 1802-11012-008 1PH 1802-11012-027

7.5 - 1802-11012-011 1802-11012-012 1802-11012-009 1802-11012-008 1802-11012-027

10 - 1802-11012-010 1802-11012-011 1802-11012-012 1802-11012-013 1802-11012-028

12.5 - 1802-11013-001 1802-11013-002 - 1802-11013-003 1802-11013-021

15 - 1802-11013-004 1802-11013-005 - 1802-11013-006 1802-11012-027

20 --1802-11013-007 - 1802-11013-008 1802-11012-010

25 - 1802-11013-001 1802-11013-002 - 1802-11013-003 1802-11012-011

30 - 1802-11013-004 1802-11013-005 - 1802-11013-006 1802-11013-022

39 ----1802-11013-009 1802-11013-023

1802-11012-007 3 PH

Mechanical Parts and Cutout - KW Dependent

Heater KW Fan Blade (2) Limit (3) Mounting Bracket(4) Inlet Grill (5) Outlet Grill (6)

2kw, 3kw, 5kw, 7.5kw 1210-11007-003 4520-11013-000 1215-11081-000 2504-11018-000 2504-11019-001

10kw 1210-11007-002

12.5kw 1210-11008-000 4520-11013-001 1215-11081-001 2504-11020-000 2504-11021-001

15kw, 20kw, 25kw, 30kw, 39kw 1210-11008-001

5

Page 6

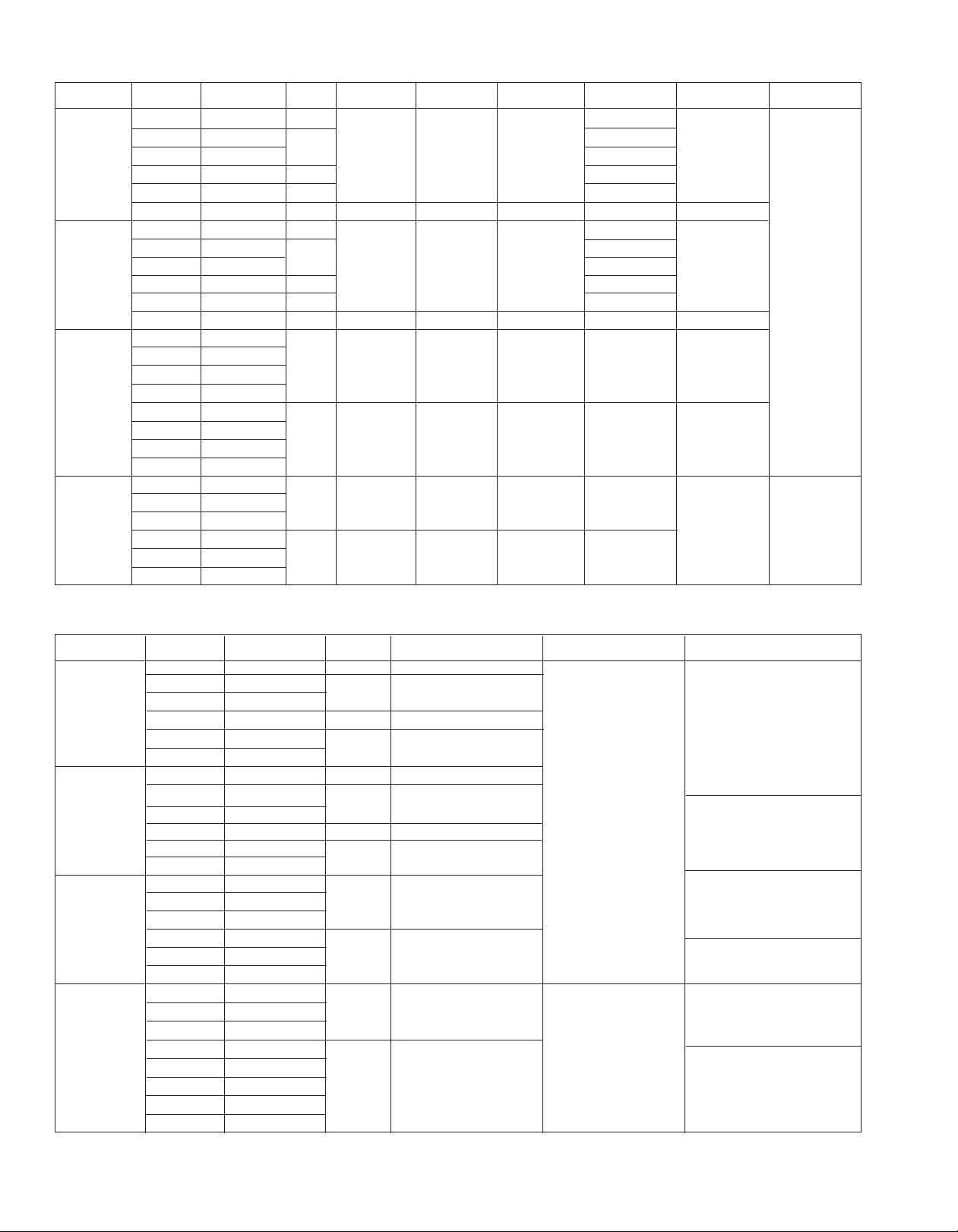

Electrical Parts

eater KW Voltage Voltage Phase Contactor (7) Contactor (7A) Relay(8) Transformer (9) Transformer (9A) (Not Shown)

H

kw, 3kw, 120 24 1 5018-0006-000 N/A 5018-11005-000 5814-0003-006 N/A 5823-0004-002

2

kw, 7.5kw, 208 24 1 or 3 5814-0003-000 (480V also req

5

10kw 240 24 5814-0003-000 2900-0030-000)

kw, 3kw, 120 120 1 5018-0006-001 N/A 5018-11005-001 N/A N/A

2

5kw, 7.5kw, 208 120 1 or 3 5814-0003-003

10kw 240 120 5814-0003-003

nfused 208 24 3 5018-0006-000 5018-11005-000 5814-0003-000

U

large units 240 24 5814-0003-000

12.5kw,15kw, 480 24 5814-0003-002

Fused 208 24 1 5018-0006-000 5018-11005-000 5814-0003-000 480034002

large units 240 24 5814-0003-000

Heater Line Heater Control Heater Fan Delay Terminal Block

277 24 1 5814-0003-001

80 24 1 or 3 5814-0003-002

4

00 24 3 5018-0006-000 5018-0005-004 5018-11005-000 5814-0003-000 490015027

6

277 120 1 5814-0003-004

480 120 1 or 3 5814-0003-005

00 120 3 5018-0006-001 5018-0005-005 5018-11005-001 5814-0003-003 490015027

6

600 24 5018-0005-004 5018-11005-000 5814-0003-000 490015027

08 120 3 5018-0006-001 5018-11005-001 5814-0003-003

2

40 120 5814-0003-003

2

480 120 5814-0003-005

600 120 5018-0005-005 5018-11005-001 5814-0003-003 490015027

480 24 5814-0003-002

08 120 1 5018-0006-001 5018-11005-001 5814-0003-003

2

240 120 5814-0003-003

480 120 5814-0003-005

Electrical Parts (Continued)

Heater KW Voltage Voltage Phase Motor (10) (Accy) (Accy)

2kw, 3kw, 120 24 1 3900-11029-002 5216-11016-000 3510-11009-000

5kw, 7.5kw, 208 24 1 or 3 3900-11029-000

10kw 240 24

2kw, 3kw, 120 120 1 3900-11029-002 3510-11009-001

5kw, 7.5kw, 208 120 1 or 3 3900-11029-000

10kw 240 120

Unfused 208 24 3 3900-11031-000 3510-11009-000

large units 240 24

12.5kw,15kw 480 24

Fused 208 24 1 3900-11031-000 5216-11016-000 3510-11009-000

large units 240 24

Heater Line Heater Control Heater Mode Switch (11) Pilot Light Green (12)

277 24 1 3900-11029-001

480 24 1 or 3 3900-11029-000

600 24 3

277 120 1 3900-11029-001

480 120 1 or 3 3900-11029-000

600 120 3

600 24 3

208 120 3 3900-11031-000 3510-11009-001

240 120

480 120

600 120 3

480 24

208 120 1 3900-11031-000 3510-11009-001

240 120

480 120

6

Page 7

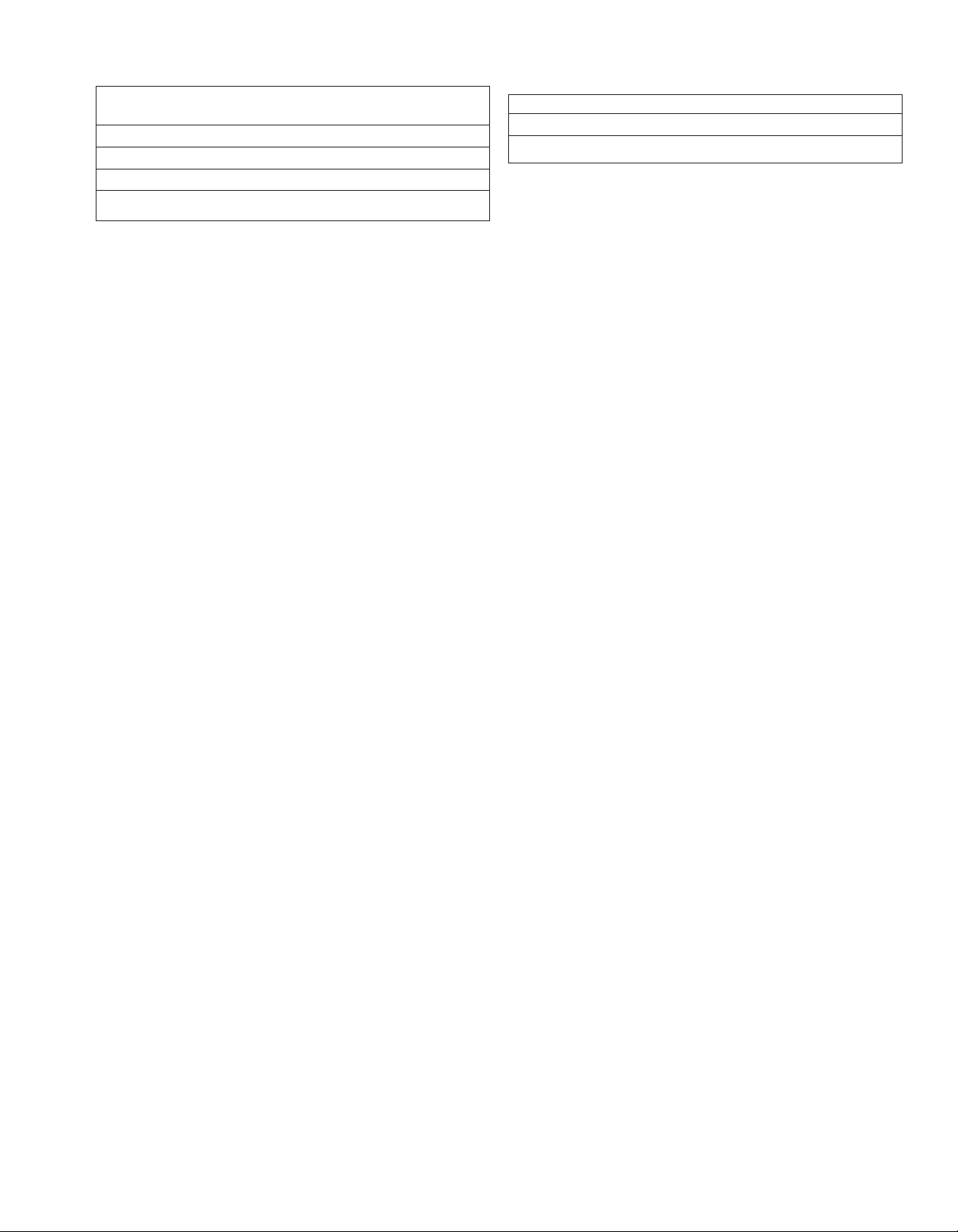

Disconnect Switch (14) Miscellaneous

Size Part

Amps Number

40 4529-11009-031

60 4529-11009-032

100 4529-11009-033

125 4529-11009-034

Description Part Number

Thermostat (13) 5813-11010-000

Gasket (Not Shown) 5206-11009-000

7

Page 8

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation.

LIMITED WARRANTY

This warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to

equipment improperly installed or wired or maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of

the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to

Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center

or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such

repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS

AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

PPD 41616 12/13 5200-11199-002

Page 9

Serie WD

Calefactor resistente

a la corrosión

Instrucciones de instalación, operación y mantenimiento

Especificaciones

úmero Potencia Tensión BTU/h Consumo Tensión Fases Consumo Sobreelev. Caudal de Peso para

N

de modelo kW (volts) Fases de salida del calef- del motor del motor delmotor (A) de temp. aire (cfm) transporte,

WD02112A 2 120 1 6,824 16.7 120 1 1.554 9 700 60 (27.2)

WD02812A 2 208 1 6,824 9.6 208 1 0.896 9 700 60 (27.2)

WD02212A 2 240 1 6,824 8.3 240 1 0.777 9 700 60 (27.2)

WD03112A 3 120 1 10,236 25.0 120 1 1.554 14 700 60 (27.2)

WD03812A 3 208 1 10,236 14.4 208 1 0.896 14 700 60 (27.2)

WD03212A 3 240 1 10,236 12.5 240 1 0.777 14 700 60 (27.2)

WD03712A 3 277 1 10,236 10.8 277 1 0.673 14 700 60 (27.2)

WD03832A 3 208 3 10,236 8.3 208 1 0.896 14 700 60 (27.2)

WD03232A 3 240 3 10,236 7.2 240 1 0.777 14 700 60 (27.2)

WD03432A 3 480 3 10,236 3.6 480 1 0.388 14 700 60 (27.2)

WD05812A 5 208 1 17,060 24.0 208 1 0.896 23 700 60 (27.2)

WD05212A 5 240 1 17,060 20.8 240 1 0.777 23 700 60 (27.2)

WD05712A 5 277 1 17,060 18.1 277 1 0.673 23 700 60 (27.2)

WD05412A 5 480 1 17,060 10.4 480 1 0.388 23 700 60 (27.2)

WD05832A 5 208 3 17,060 13.9 208 1 0.896 23 700 60 (27.2)

WD05232A 5 240 3 17,060 12.0 240 1 0.777 23 700 60 (27.2)

WD05432A 5 480 3 17,060 6.0 480 1 0.388 23 700 60 (27.2)

WD05632A 5 600 3 17,060 4.8 240 1 1.8 23 1450 75 (34)

WD07812A 7.5 208 1 25,590 36.1 208 1 0.896 34 700 60 (27.2)

WD07212A 7.5 240 1 25,590 31.3 240 1 0.777 34 700 60 (27.2)

WD07712A 7.5 277 1 25,590 27.1 277 1 0.673 34 700 60 (27.2)

WD07412A 7.5 480 1 25,590 15.6 480 1 0.388 34 700 60 (27.2)

WD07832A 7.5 208 3 25,590 20.8 208 1 0.896 34 700 60 (27.2)

WD07232A 7.5 240 3 25,590 18.0 240 1 0.777 34 700 60 (27.2)

WD07432A 7.5 480 3 25,590 9.0 480 1 0.388 34 700 60 (27.2)

WD07632A 7.5 600 3 25,590 7.2 240 1 1.8 34 1450 75 (34)

WD10212A 10 240 1 34,120 41.7 240 1 0.777 22 1450 60 (27.2)

WD10712A 10 277 1 34,120 36.1 277 1 0.673 22 1450 60 (27.2)

WD10412A 10 480 1 34,120 20.8 480 1 0.388 22 1450 60 (27.2)

WD10832A 10 208 3 34,120 27.8 208 1 0.896 22 1450 60 (27.2)

WD10232A 10 240 3 34,120 24.1 240 1 0.777 22 1450 60 (27.2)

WD10432A 10 480 3 34,120 12.0 480 1 0.388 22 1450 60 (27.2)

WD10632A 10 600 3 34,120 9.6 240 1 1.8 33 2400 75 (34)

WD12812A 12.5 208 1 42,650 60.1 208 1 1.793 27 1450 60 (27.2)

WD12212A 12.5 240 1 42,650 52.1 240 1 1.554 27 1450 60 (27.2)

WD12832A 12.5 208 3 42,650 34.7 208 1 1.793 27 1450 60 (27.2)

WD12232A 12.5 240 3 42,650 30.1 240 1 1.554 27 1450 60 (27.2)

WD12432A 12.5 480 3 42,650 15.0 480 1 0.777 27 1450 60 (27.2)

WD12632A 12.5 600 3 42,650 12.0 240 1 1.8 27 2400 75 (34)

WD15812A 15 208 1 51,180 72.1 208 1 1.793 20 2400 110 (49.9)

WD15212A 15 240 1 51,180 62.5 240 1 1.554 20 2400 110 (49.9)

WD15412A 15 480 1 51,180 31.3 480 1 0.777 20 2400 110 (49.9)

WD15832A 15 208 3 51,180 41.6 208 1 1.793 20 2400 110 (49.9)

WD15232A 15 240 3 51,180 36.1 240 1 1.554 20 2400 110 (49.9)

WD15432A 15 480 3 51,180 18.0 480 1 0.777 20 2400 110 (49.9)

WD15632A 15 600 3 51,180 14.5 240 1 1.8 20 2400 125 (56.6)

WD20412A 20 480 1 68,240 41.7 480 1 0.777 26 2400 120 (54.4)

WD20232A 20 240 3 68,240 48.1 240 1 1.554 26 2400 120 (54.4)

WD20432A 20 480 3 68,240 24.1 480 1 0.777 26 2400 120 (54.4)

WD20632A 20 600 3 68,240 19.3 240 1 1.8 26 2400 135 (61.2)

WD25832A 25 208 3 85,300 69.4 208 1 1.793 33 2400 120 (54.4)

WD25232A 25 240 3 85,300 60.1 240 1 1.554 33 2400 120 (54.4)

WD25432A 25 480 3 85,300 30.1 480 1 0.777 33 2400 120 (54.4)

WD25632A 25 600 3 85,300 24.1 240 1 1.8 33 2400 135 (61.2)

WD30832A 30 208 3 102,360 83.3 208 1 1.793 39 2400 120 (54.4)

WD30232A 30 240 3 102,360 72.2 240 1 1.554 39 2400 120 (54.4)

WD30432A 30 480 3 102,360 36.1 480 1 0.777 39 2400 120 (54.4)

WD30632A 30 600 3 102,360 28.9 240 1 1.8 39 2400 135 (61.2)

WD39432A 39 480 3 133,068 46.9 480 1 0.777 51 2400 120 (54.4)

WD39632A 39 600 3 133,068 37.6 240 1 1.8 51 2400 135 (61.2)

NOTA: los calefactores de más de 48 A requieren fusibles adicionales.

ctor (A) (volts) (ºF) lb (kg)

a

GUARDE ESTAS INSTRUCCIONES

PPD 41616 12/13 5200-11199-002

Page 10

INSTRUCCIONES IMPORTANTES

EXPOSED

EXPO

SED

EXPOSED

EXPOSED

E

X

P

O

S

E

D

E

X

P

O

S

E

D

ADVERTENCIA

AL UTILIZAR ARTEFACTOS ELÉCTRICOS, PARA REDUCIR EL

RIESGO DE INCENDIO, CHOQUE ELÉCTRICO Y LESIONES PERSONALES DEBEN OBSERVARSE SIEMPRE ALGUNAS PRECAUCIONES BÁSICAS, COMO LAS SIGUIENTES:

1. Lea todas las instrucciones antes de instalar o utilizar este

calefactor.

2. Este calefactor es un producto comercial/industrial, que no está

destinado a su empleo en un entorno residencial.

3. Este calefactor tiene en su interior piezas calientes y piezas en las

que se producen arcos o chispas, y no está destinado a su empleo

en atmósferas peligrosas en las que se usen o almacenen vapores,

gases o líquidos inflamables u otras atmósferas combustibles como

las define el Código Eléctrico Nacional de los EE. UU. Si esto no se

cumple, puede producirse una explosión o incendio.

4. Cuando está en funcionamiento, el calefactor está muy caliente.

Para evitar quemaduras, no deje que su piel haga contacto directo

con las superficies calientes. Mantenga los materiales combustibles

como muebles, almohadas, ropas de cama, papeles, ropas, cortinas, etc. a 0.9 m (3 pies) como mínimo del frente del calefactor.

5. Se necesita extremo cuidado al utilizar cualquier calefactor junto a

o cerca de niños o inválidos, y en todo momento en que el calefactor quede funcionando y desatendido.

ADVERTENCIA

!

6. No opere ningún calefactor después de que haya tenido una falla

de funcionamiento. Desconecte la alimentación eléctrica en el

tablero de servicio y haga revisar el calefactor por un electricista

calificado antes de usarlo.

7. No use el equipo en exteriores.

8. Para desconectar el calefactor, lleve los controles a la posición

APAGADO (OFF) y desconecte la alimentación del circuito del calefactor en el tablero de desconexión principal.

9. No inserte ni permita que entren objetos extraños en ninguna abertura de ventilación o de descarga, porque esto puede ser causa de

choque eléctrico, incendio o daño al calefactor.

10. Para evitar un posible incendio, no bloquee de ningún modo la

entrada ni la descarga de aire.

11. Utilice este calefactor únicamente de la manera descrita en este

manual. Cualquier otra forma de uso no recomendada por el fabricante puede ser causa de incendio, choque eléctrico o daños personales.

12. Al realizar la instalación, vea las advertencias y precauciones adicionales en las INSTRUCCIONES DE INSTALACIÓN.

13. Para garantizar una operación segura y eficiente, y para extender

la vida útil de su calefactor, manténgalo limpio. Vea las INSTRUCCIONES DE MANTENIMIENTO.

NO ES PARA USO RESIDENCIAL.

!

Para evitar un posible incendio, lesiones personales o daños al calefactor, observe lo siguiente:

Nota importante: este calefactor debe ser instalado por una persona

competente.

1. Antes de proceder a tareas de conexionado o de reparación del

calefactor, desconecte toda la alimentación eléctrica que llega al

mismo desde el tablero principal de servicio.

2. Todos los procedimientos de cableado y conexiones deben hacerse

de conformidad con los códigos nacionales y locales que tengan

jurisdicción, y el calefactor debe estar conectado a tierra.

ATENCIÓN: todos los conductos y accesorios de conexionado deben

estar aprobados (Listed) para aplicaciones estancas, a fin de mantener

la clasificación de gabinete NEMA 4X para prevenir que el agua dirigida por una manguera ingrese a la caja eléctrica.

3. Verifique que la tensión de alimentación provista al calefactor coincida con la tensión nominal indicada en la placa de características del

mismo.

ATENCIÓN: SI SE ENERGIZA UN CALEFACTOR CON UNA TENSIÓN MAYOR QUE EL VALOR DE TENSIÓN IMPRESO EN LA PLACA

DE CARACTERÍSTICAS, SE DAÑARÁ EL CALEFACTOR, SE ANULARÁ LA GARANTÍA, Y PODRÍA PRODUCIRSE UN INCENDIO.

INSTRUCCIONES DE

INSTALACIÓN

Información general

Instrucciones sobre la ubicación del calefactor:

Disponga las unidades de manera que las corrientes de aire de

descarga:

A. Estén sujetas a un mínimo de interferencia a causa de columnas,

maquinaria y tabiques;

B. Se deslicen por las paredes expuestas sin impactar directamente

contra ellas;

4. Para reducir el riesgo de incendio, no almacene ni use gasolina u

otros vapores y líquidos inflamables en las cercanías del calefactor.

5. La estructura de montaje en el cielorraso o en la pared, así como los

medios de anclaje, deben ser suficientemente resistentes para

soportar el peso combinado del calefactor y del soporte de montaje.

Vea el peso total en Especificaciones.

6. El calefactor debe montarse para flujo de aire horizontal únicamente.

El calefactor debe montarse a 2134 mm (7') por encima del piso

como mínimo, a fin de evitar el contacto accidental con la paleta del

ventilador, que podría causar lesiones.

7. Mantenga un espacio libre de 1524 mm (5’) como mínimo al frente

del calefactor. Para ver los requisitos de espacio libre lateral, superior y posterior consulte la Figura 2.

8. No monte un termostato del tipo de mercurio directamente sobre la

unidad. La vibración podría hacer que el calefactor funcione mal.

9. La rejilla de salida está formada en fábrica con celosías colocadas

en un ángulo de 45°. Este es el ángulo mínimo admisible para evitar

un posible sobrecalentamiento. Las celosías pueden abrirse hasta a

90° si se desea, para permitir un mayor alcance del chorro de aire al

doblar cada celosía hacia afuera. Vea la Figura 3.

C. Se dirijan lejos de los ocupantes de la habitación en aplicaciones de

calefacción ambiental;

D. Se dirijan a lo largo del lado de donde viene el viento, cuando se

instalan en un edificio expuesto a un viento preponderante.

Localice el termostato en postes o paredes divisorias interiores, lejos de

corrientes de aire frío, fuentes de calor internas y de las corrientes de

aire de descarga de calefactores.

EXPU

EXPU

EXPUESTA

ESTA

EXPUESTA

EXPUESTA

EXPUESTA

Figura 1

10

ESTA

Page 11

A

Wall

Ceiling

Floor

6" Min.

(152 mm)

D

Ceiling

Wall

8" Min.

(203 mm)

B

Floor

7' Min.

(2134 mm)

7' Min.

(2134 mm)

9" Min.

(229 mm)

Wall

6"

(152 mm)

C

Ceiling

Floor

45° Minimum

Angle

Cielorraso

Pared

iso

Figura 2

P

Dimensiones, pulgadas (mm)

kW AB C D

2-10 13 (330) 19.5 (495) 18 (457) 19.5 (495)

12.5-39.0 20 (508) 31 (787) 27 (686) 24.2 (615)

Las habitaciones pequeñas pueden usar una unidad calefactora única.

Cuando hay dos paredes expuestas, el calefactor debe montarse como

se muestra en la Figura 1.

Las habitaciones grandes requieren instalaciones de unidades múltiples.

La cantidad y la capacidad de las unidades se determinará de acuerdo

con el volumen del edificio y el área de piso (pies cuadrados) a calefaccionar. Disponga las unidades para proporcionar una circulación de aire

perimetral, en la que cada unidad soporte la corriente de aire de otra.

Montaje de los calefactores con el soporte de montaje

universal provisto

AVISO — estos calefactores están diseñados para montaje en pared o

en cielorraso con descarga de aire horizontal únicamente. Los otros

modos de montaje anulan la garantía de fábrica.

1. Altura sobre el piso

A. En áreas en las que la altura del cielorraso sea mayor de 3658

mm (12 pies), la altura de montaje recomendada es aproximadamente 3048 mm (10 pies), medida desde la cara inferior del calefactor.

B. Para alturas de cielorraso de 3658 mm (12 pies) o menores, la

altura de montaje máxima está determinada por el uso del

soporte de montaje que se ofrece con estos calefactores. El espaciado mínimo al cielorraso es 229 mm (9”). (Vea la Figura 2).

C. En uno u otro caso, la altura de montaje mínima es 2134 mm (7

pies), medida desde el piso hasta el fondo del calefactor. Figura

2.

2. Espaciado respecto a las paredes adyacentes

(vea la Figura 2).

A. Desde la parte trasera del gabinete hasta la pared posterior: mín.

152 mm (6").

B. Desde el costado del gabinete hasta la pared lateral: mín.

203 mm (8").

NOTA: si se hacen funcionar dos o más unidades en el mismo espacio

de aire cerrado, sus descargas deben dirigirse de manera de ayudar al

desarrollo del movimiento de la masa de aire, a fin de lograr una dispersión uniforme del calor.

Cielorraso Cielorraso

ared

Pared

iso

P

iso

P

P

Conexionado

Consulte el diagrama de conexionado incluido con la unidad.

El diagrama de conexionado puede encontrarse en el interior de la puerta del compartimiento de cables. Si tiene preguntas que hacer,

comuníquese con el Servicio Técnico llamando al 800-642-4328. Tenga

como referencia el número de modelo que se encuntra en la placa de

identificación.

TODOS LOS CONDUCTOS Y ACCESORIOS DE CONEXIONADO

DEBEN ESTAR APROBADOS (LISTED) PARA APLICACIONES

ESTANCAS, A FIN DE MANTENER LA CLASIFICACIÓN DE GABINETE

NEMA 4X PARA PREVENIR QUE EL AGUA DIRIGIDA POR UNA

MANGUERA INGRESE A LA CAJA ELÉCTRICA.

NOTA: todo el cableado eléctrico debe hacerse de acuerdo con el

Código Eléctrico Nacional de los EE. UU. y los códigos locales.

NOTA IMPORTANTE - Par de apriete de los terminales de tornillo en

la instalación: Durante el transporte es posible que las conexiones de

los terminales de tornillo se aflojen. Después de la instalación, antes de

conectar la alimentación eléctrica al calefactor, revise las conexiones de

los terminales de tornillo para verificar que cumplan con el valor de par

de apriete recomendado de 3.9 N·m (35 lb·pulg.). Se incluye una herramienta para apretar los terminales en ubicaciones difíciles de alcanzar.

RIESGO DE CHOQUE ELÉCTRICO. TODA INSTALACIÓN QUE

INCLUYA CALEFACTORES ELÉCTRICOS DEBE SER REALIZADA

POR UNA PERSONA COMPETENTE Y DEBE ESTAR CONECTADA A

TIERRA DE MANERA EFECTIVA, DE ACUERDO CON EL CÓDIGO

ELÉCTRICO NACIONAL DE LOS EE. UU., A FIN DE ELIMINAR EL

RIESGO DE CHOQUE ELÉCTRICO.

1. Conecte el calefactor únicamente a un circuito apto para la tensión

(V), corriente (A) y frecuencia (Hz) especificadas en la placa de características.

2. Todas las unidades están provistas de borneras de control y de alimentación eléctrica para las conexiones del cliente.

3. Se ha provisto una protección contra sobrecalentamiento por medio

de un interruptor térmico automático (el interruptor con reposición

manual es opcional) que abre el circuito eléctrico si se restringe o

interrumpe el flujo de aire normal. El interruptor vuelve a energizar el

calefactor de manera automática cuando se elimina la obstrucción.

Si se dispara el dispositivo de reposición manual opcional, determine la causa antes de volver a energizar el calefactor.

Figura 3 - Ajuste de las celosías

EL DISEÑADOR DEL SISTEMA ES RESPONSABLE DE LA SEGURIDAD

DE ESTE EQUIPO, Y DEBE INSTALAR CONTROLES DE RESPALDO Y

DISPOSITIVOS DE CONTROL ADECUADOS CON SU EQUIPO DE

CALEFACCIÓN ELÉCTRICA. ALLÍ DONDE LAS CONSECUENCIAS DE

UNA FALLA PODRÍAN PROVOCAR LESIONES PERSONALES O DAÑOS

MATERIALES, LOS CONTROLES DE RESPALDO SON

IMPRESCINDIBLES.

11

Page 12

4. Los calefactores están equipados con un control de retardo de ventilador. Este control hace que continúe la operación del ventilador

durante un tiempo breve después de que los elementos calefactores

se hayan desenergizado, a fin de disipar el calor residual.

NOTA: si se suministra la opción de interruptor térmico con reposición

manual, el botón REPOSICIÓN (RESET) estará marcado y será accesible en el panel de control. Este control de seguridad funcionará únicamente si se sobrecalienta el calefactor.

DEBE VERIFICARSE LA ROTACIÓN DE LA PALETA DEL VENTILADOR. SI NO HAY FLUJO DE AIRE QUE PASE A TRAVÉS DE LA

REJILLA DE SALIDA, INTERCAMBIE DOS CUALESQUIERA DE LOS

TRES CABLES DE CONEXIÓN DE ALIMENTACIÓN ELÉCTRICA (EN

UNIDADES TRIFÁSICAS ÚNICAMENTE).

Equipos opcionales

• Termostato incorporado (del tipo de bulbo y capilar) para control

automático de la temperatura. El termostato controla los elementos

calefactores y el ventilador simultáneamente a fin de alcanzar la

temperatura de ajuste. La temperatura de ajuste en la posición 'Bajo'

(Lo) del termostato es aproximadamente 4.4 ºC (40 ºF), y en la posición 'Alto' (Hi) es aproximadamente 32.2 ºC (90 ºF).

• Selector de modo (calefactor encendido, calefactor apagado, ventilador únicamente) para permitir el flujo de aire a la vez que se energizan o no los elementos calefactores. El interruptor es accesible

desde afuera del gabinete NEMA 4X.

• Luz indicadora (piloto) para indicar que los elementos calefactores

están energizados.

• Fusible interno

• Límite térmico con reposición manual

• Interruptor Encendido/Apagado (ON/OFF)

• Para ver los diagramas de conexionado que contienen las opciones,

vea la etiqueta en el interior de la cubierta de la caja de terminales.

INSTRUCCIONES DE

NO ALTERE NI PUENTEE NINGÚN LÍMITE DE SEGURIDAD

INTERNO DEL CALEFACTOR.

INSTRUCCIONES DE

MANTENIMIENTO

Es importante mantener limpio este calefactor. Su calefactor le brindará

muchos años de servicio y confort con sólo un mínimo de cuidado. Para

asegurar un funcionamiento eficiente, observe las instrucciones simples

que se indican a continuación.

TODO SERVICIO, MÁS ALLÁ DE UNA SIMPLE LIMPIEZA,

QUE REQUIERA UN DESMONTAJE DEBE SER REALIZADO

POR PERSONAL DE SERVICIO CALIFICADO.

PARA REDUCIR EL RIESGO DE INCENDIO Y DE CHOQUE

ELÉCTRICO O LESIONES, DESCONECTE TODA LA ALIMENTACIÓN ELÉCTRICA QUE LLEGA AL CALEFACTOR EN

EL TABLERO PRINCIPAL DE SERVICIO Y VERIFIQUE QUE

EL ELEMENTO CALEFACTOR ESTÉ FRÍO ANTES DE

PRESTAR SERVICIO O DE REALIZAR EL MANTENIMIENTO.

OPERACIÓN

1. El calefactor debe instalarse correctamente antes de ponerlo

en funcionamiento.

2. Para revisar la instalación, lleve el Selector de modo a la posición

Apagado (OFF). Conecte la alimentación eléctrica al calefactor en el

tablero de desconexión principal y verifique que el calefactor no esté

funcionando. Si funciona, desconecte la alimentación eléctrica y

revise el cableado.

3. Haga girar el termostato en sentido horario hasta la posición de

calor máximo. Con el selector Calor-Frío en la posición Apagado

(OFF), el calefactor no debe funcionar.

4. Lleve el selector Calor-Frío (Heat-Cool) a la posición Ventilador

únicamente (Fan Only). El ventilador debe encenderse y funcionar

sin calor.

5. Lleve el selector Calor-Frío (Heat-Cool) a la posición Calor (Heat).

El ventilador y el calefactor deben encenderse, y debe haber

producción de calor.

6. Debe permitirse al calefactor funcionar con el termostato en la posición de calor máximo hasta que la temperatura de la habitación

alcance el nivel deseado. Luego debe hacerse rotar el termostato

en sentido antihorario hasta que los elementos calefactores se

apaguen (debe oírse un clic). Esto debe permitir que el termostato

haga describir al calefactor ciclos de encendido y apagado para

mantener esta temperatura. Es posible que se necesite hacer

ajustes finos para obtener la temperatura ambiente deseada en la

habitación. Al hacer girar ligeramente el termostato en sentido

horario aumentará la temperatura ambiente de la habitación, mientras que al hacerlo en sentido antihorario disminuirá la temperatura

ambiente de la habitación.

NOTA: el retardo de ventilador incorporado hará que el ventilador funcione después de que los elementos se apaguen, a fin de disipar el

calor residual.

NOTA: si se suministra la opción del interruptor de desconexión, el

mismo será accesible desde el exterior de la caja de control y estará

marcado con las leyendas Encendido (ON) y Apagado (OFF). En la

posición Apagado (OFF), el calefactor no funcionará.

Instrucciones de limpieza de mantenimiento:

1. Desconecte la alimentación eléctrica del calefactor y deje

que los elementos calefactores se enfríen.

2. Antes de activar el calefactor para una nueva temporada de calefacción, límpielo por aspiración o lávelo con manguera, con agua a la

presión de suministro, para eliminar el polvo y la pelusa acumulados

que podrían generar humo o quemarse en el calentamiento inicial.

3. Vuelva a conectar la alimentación eléctrica al calefactor y asegúrese

de que funcione correctamente.

Maintenance Cleaning Instructions:

(a realizarse únicamente por personal de servicio calificado)

Al menos una vez por año, un técnico de servicio calificado debe limpiar

y prestar servicio al calefactor para garantizar un funcionamiento seguro

y eficiente. Esto debe incluir, según sea necesario, la aspiración del

polvo y los desperdicios de los elementos calefactores y del ventilador, y

la revisión de las conexiones de los terminales de tornillo para verificar

que cumplan con el valor de par de apriete recomendado de 3.9 N·m

(35 lb·pulg.). Si fuera necesario, use la(s) herramienta(s) incluida(s) para

los terminales ubicados en lugares difíciles de alcanzar. Después de terminada la limpieza y servicio, el calefactor debe volver a montarse completamente y verificarse que funcione correctamente.

NOTA IMPORTANTE: para el caso de los calefactores que se lavan con

manguera, se recomienda realizar periódicamente lo siguiente. Después

del lavado (con la alimentación eléctrica desconectada en el tablero

principal), abra la cubierta del compartimiento de cables e inspeccione

el interior para comprobar si ha habido penetración de agua. Si se

descubre agua, debe hacerse reparar el calefactor por un electricista

competente para aseguar que los sellos estén instalados correctamente.

Durante cada limpieza deben inspeccionarse todos los sellos para

comprobar si presentan daños, ya que esto es fundamental para que

mantengan un sellado estanco. Si se encuentran daños (como

desgarros o grietas), los sellos deben reemplazarse o repararse con un

sellador de silicona apropiado.

12

Page 13

Piezas de repuesto

5

4

2

6

1

10

13

11

12

14

8

9, 9A

7, 7A

3

Elementos calefactores (1)

Calefactor KW 120 V 208 V 240 V 277 V 480 V 600 V

2 1802-11012-001 1802-11012-002 1802-11012-003 --

3 1802-11012-001 1802-11012-002 1802-11012-003 1802-11012-004 1802-11012-004

5-1802-11012-005 1802-11012-006 1802-11012-007 1802-11012-008 1PH 1802-11012-027

7.5 - 1802-11012-011 1802-11012-012 1802-11012-009 1802-11012-008 1802-11012-027

10 - 1802-11012-010 1802-11012-011 1802-11012-012 1802-11012-013 1802-11012-028

12.5 - 1802-11013-001 1802-11013-002 - 1802-11013-003 1802-11013-021

15 - 1802-11013-004 1802-11013-005 - 1802-11013-006 1802-11012-027

20 --1802-11013-007 - 1802-11013-008 1802-11012-010

25 - 1802-11013-001 1802-11013-002 - 1802-11013-003 1802-11012-011

30 - 1802-11013-004 1802-11013-005 - 1802-11013-006 1802-11013-022

39 ----1802-11013-009 1802-11013-023

1802-11012-007 3 PH

Piezas mecánicas e interruptor térmico según potencia (kW)

Potencia del calefactor (kW) Paleta del ventilador (2) Limite (3) Soporte de montaje (4) Rejilla de entrada (5) Rejilla de salida (6)

2kw, 3kw, 5kw, 7.5kw 1210-11007-003 4520-11013-000 1215-11081-000 2504-11018-000 2504-11019-001

10kw 1210-11007-002

12.5kw 1210-11008-000 4520-11013-001 1215-11081-001 2504-11020-000 2504-11021-001

15kw, 20kw, 25kw, 30kw, 39kw 1210-11008-001

13

Page 14

Piezas eléctricas

Potencia del Tensión de Tensión de Fases del Retardo de Bornera

calefactor (kW) línea del controldel calefactor Contactor (7) Contactor (7A) ventilador Transformador (9) ransformador (9A) (No se muestra)

kw, 3kw, 120 24 1 5018-0006-000 N/A 5018-11005-000 5814-0003-006 N/A 5823-0004-002

2

5kw, 7.5kw, 208 24 1 or 3 5814-0003-000 (480V also req

10kw 240 24 5814-0003-000 2900-0030-000)

2kw, 3kw, 120 120 1 5018-0006-001 N/A 5018-11005-001 N/A N/A

5kw, 7.5kw, 208 120 1 or 3 5814-0003-003

10kw 240 120 5814-0003-003

Unfused 208 24 3 5018-0006-000 5018-11005-000 5814-0003-000

large units 240 24 5814-0003-000

12.5kw,15kw, 480 24 5814-0003-002

Fused 208 24 1 5018-0006-000 5018-11005-000 5814-0003-000 480034002

large units 240 24 5814-0003-000

calefactor calefactor Relé (8)

77 24 1 5814-0003-001

2

80 24 1 or 3 5814-0003-002

4

00 24 3 5018-0006-000 5018-0005-004 5018-11005-000 5814-0003-000 490015027

6

77 120 1 5814-0003-004

2

80 120 1 or 3 5814-0003-005

4

00 120 3 5018-0006-001 5018-0005-005 5018-11005-001 5814-0003-003 490015027

6

600 24 5018-0005-004 5018-11005-000 5814-0003-000 490015027

08 120 3 5018-0006-001 5018-11005-001 5814-0003-003

2

240 120 5814-0003-003

480 120 5814-0003-005

600 120 5018-0005-005 5018-11005-001 5814-0003-003 490015027

480 24 5814-0003-002

208 120 1 5018-0006-001 5018-11005-001 5814-0003-003

240 120 5814-0003-003

480 120 5814-0003-005

Piezas eléctricas (continuación)

Potencia del Tensión de Tensión de Fases del Selector de modo (11) Luz indicadora

calefactor (kW) línea del control del calefactor Motor (10) (accesorio) (piloto) verde (12) (accesorio)

2kw, 3kw, 120 24 1 3900-11029-002 5216-11016-000 3510-11009-000

5kw, 7.5kw, 208 24 1 or 3 3900-11029-000

10kw 240 24

277 24 1 3900-11029-001

480 24 1 or 3 3900-11029-000

600 24 3

2kw, 3kw, 120 120 1 3900-11029-002 3510-11009-001

5kw, 7.5kw, 208 120 1 or 3 3900-11029-000

10kw 240 120

277 120 1 3900-11029-001

480 120 1 or 3 3900-11029-000

600 120 3

Unfused 208 24 3 3900-11031-000 3510-11009-000

large units 240 24

12.5kw,15kw 480 24

600 24 3

208 120 3 3900-11031-000 3510-11009-001

240 120

480 120

600 120 3

Fused 208 24 1 3900-11031-000 5216-11016-000 3510-11009-000

large units 240 24

480 24

208 120 1 3900-11031-000 3510-11009-001

240 120

480 120

14

Page 15

Interruptor de desconexión (14) Otras piezas

Calibre Número

(A) de pieza

40 4529-11009-031

60 4529-11009-032

100 4529-11009-033

125 4529-11009-034

Descripción Número de pieza

Termostato (13) 5813-11010-000

Junta (no se muestra) 5206-11009-000

15

Page 16

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos de fabricación y de materiales por 1 año desde la fecha de

GARANTÍA LIMITADA

instalación. Esta garantía no se aplica a daños debidos a accidente, mal uso o alteración, ni a los casos en que la tensión eléctrica conectada supere a la tensión

nominal -indicada en la placa de características- en más de 5 %, ni a equipos que hayan sido instalados o cableados incorrectamente, o mantenidos en forma

que no cumpla lo indicado en las instrucciones de instalación del producto. Todo reclamo por trabajos en garantía debe acompañarse con una prueba de la fecha

de instalación.

El cliente será responsable de todos los costos incurridos en el retiro o reinstalación de productos, incluyendo los costos de mano de obra y los costos de envío

incurridos para regresar productos a un Centro de Servicio de Marley Engineered Products. Dentro de las limitaciones de esta garantía, las unidades que no

funcionan deben regresarse al centro de servicio autorizado Marley más cercano, o al Centro de Servicio de Marley Engineered Products, y nosotros lo

repararemos o reemplazaremos, a nuestra opción, sin cargo para usted, con el flete de retorno pagado por Marley. Se acuerda que tal reparación o reemplazo es

el único recurso que Marley Engineered Products pone a su disposición.

LAS GARANTÍAS EXPUESTAS MÁS ARRIBA TOMAN EL LUGAR DE TODA OTRA GARANTÍA, EXPRESA O IMPLÍCITA, Y POR LA PRESENTE SE

DECLINA Y EXCLUYE DE ESTE ACUERDO TODA GARANTÍA IMPLÍCITA DE COMERCIABILIDAD Y ADECUACIÓN A UN PROPÓSITO PARTICULAR QUE

EXCEDA LAS GARANTÍAS EXPRESAS ANTEDICHAS. MARLEY ENGINEERED PRODUCTS NO SE HARÁ RESPONSABLE POR DAÑOS CONSIGUIENTES

QUE SE PRODUZCAN CON RESPECTO AL PRODUCTO, EN BASE YA SEA A NEGLIGENCIA, AGRAVIO, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados o jurisdicciones no permiten la exclusión o limitación de daños incidentales o consiguientes, de modo que la exclusión o limitación expresada

más arriba puede no aplicarse a su caso. Esta garantía le da derechos legales específicos, y usted puede tener también otros derechos, que varían de un estado o jurisdicción a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano comuníquese con Marley Engineered Products en Bennettsville, SC, Estados Unidos,

llamando al 1-800-642-4328. Toda mercadería regresada a la fábrica debe ser acompañada por una autorización de retorno y una etiqueta de identificación de

servicio, disponibles ambas en Marley Engineered Products. Cuando solicite la autorización de retorno, incluya todos los números de catálogo mostrados en los

productos.

CÓMO OBTENER SERVICIO EN GARANTÍA, PIEZAS DE

REPUESTO E INFORMACIÓN GENERAL

1. Servicio o repuestos en garantía 1-800-642-4328

2. Compra de repuestos 1-800-654-3545

3. Información general sobre productos www.marleymep.com

Nota: cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

PPD 41616 12/13 5200-11199-002

Page 17

Série WD

Radiateur résistant à

la corrosion

Instructions d’installation, d’utilisation et d’entretien

Spécifications

N° Puissance Ampères Volts Phase Ampères Montée Poids

modèle kW Volts Phase BTU/H radiateur moteur moteur moteur en temp. CFM lbs (kg)

WD02112A 2 120 1 6,824 16.7 120 1 1.554 9 700 60 (27.2)

WD02812A 2 208 1 6,824 9.6 208 1 0.896 9 700 60 (27.2)

WD02212A 2 240 1 6,824 8.3 240 1 0.777 9 700 60 (27.2)

D03112A 3 120 1 10,236 25.0 120 1 1.554 14 700 60 (27.2)

W

D03812A 3 208 1 10,236 14.4 208 1 0.896 14 700 60 (27.2)

W

D03212A 3 240 1 10,236 12.5 240 1 0.777 14 700 60 (27.2)

W

D03712A 3 277 1 10,236 10.8 277 1 0.673 14 700 60 (27.2)

W

D03832A 3 208 3 10,236 8.3 208 1 0.896 14 700 60 (27.2)

W

D03232A 3 240 3 10,236 7.2 240 1 0.777 14 700 60 (27.2)

W

D03432A 3 480 3 10,236 3.6 480 1 0.388 14 700 60 (27.2)

W

WD05812A 5 208 1 17,060 24.0 208 1 0.896 23 700 60 (27.2)

WD05212A 5 240 1 17,060 20.8 240 1 0.777 23 700 60 (27.2)

WD05712A 5 277 1 17,060 18.1 277 1 0.673 23 700 60 (27.2)

WD05412A 5 480 1 17,060 10.4 480 1 0.388 23 700 60 (27.2)

WD05832A 5 208 3 17,060 13.9 208 1 0.896 23 700 60 (27.2)

WD05232A 5 240 3 17,060 12.0 240 1 0.777 23 700 60 (27.2)

WD05432A 5 480 3 17,060 6.0 480 1 0.388 23 700 60 (27.2)

WD05632A 5 600 3 17,060 4.8 240 1 1.8 23 1450 75 (34)

WD07812A 7.5 208 1 25,590 36.1 208 1 0.896 34 700 60 (27.2)

WD07212A 7.5 240 1 25,590 31.3 240 1 0.777 34 700 60 (27.2)

WD07712A 7.5 277 1 25,590 27.1 277 1 0.673 34 700 60 (27.2)

WD07412A 7.5 480 1 25,590 15.6 480 1 0.388 34 700 60 (27.2)

WD07832A 7.5 208 3 25,590 20.8 208 1 0.896 34 700 60 (27.2)

WD07232A 7.5 240 3 25,590 18.0 240 1 0.777 34 700 60 (27.2)

WD07432A 7.5 480 3 25,590 9.0 480 1 0.388 34 700 60 (27.2)

WD07632A 7.5 600 3 25,590 7.2 240 1 1.8 34 1450 75 (34)

WD10212A 10 240 1 34,120 41.7 240 1 0.777 22 1450 60 (27.2)

WD10712A 10 277 1 34,120 36.1 277 1 0.673 22 1450 60 (27.2)

WD10412A 10 480 1 34,120 20.8 480 1 0.388 22 1450 60 (27.2)

WD10832A 10 208 3 34,120 27.8 208 1 0.896 22 1450 60 (27.2)

WD10232A 10 240 3 34,120 24.1 240 1 0.777 22 1450 60 (27.2)

WD10432A 10 480 3 34,120 12.0 480 1 0.388 22 1450 60 (27.2)

WD10632A 10 600 3 34,120 9.6 240 1 1.8 33 2400 75 (34)

WD12812A 12.5 208 1 42,650 60.1 208 1 1.793 27 1450 60 (27.2)

WD12212A 12.5 240 1 42,650 52.1 240 1 1.554 27 1450 60 (27.2)

WD12832A 12.5 208 3 42,650 34.7 208 1 1.793 27 1450 60 (27.2)

WD12232A 12.5 240 3 42,650 30.1 240 1 1.554 27 1450 60 (27.2)

WD12432A 12.5 480 3 42,650 15.0 480 1 0.777 27 1450 60 (27.2)

WD12632A 12.5 600 3 42,650 12.0 240 1 1.8 27 2400 75 (34)

WD15812A 15 208 1 51,180 72.1 208 1 1.793 20 2400 110 (49.9)

WD15212A 15 240 1 51,180 62.5 240 1 1.554 20 2400 110 (49.9)

WD15412A 15 480 1 51,180 31.3 480 1 0.777 20 2400 110 (49.9)

WD15832A 15 208 3 51,180 41.6 208 1 1.793 20 2400 110 (49.9)

WD15232A 15 240 3 51,180 36.1 240 1 1.554 20 2400 110 (49.9)

WD15432A 15 480 3 51,180 18.0 480 1 0.777 20 2400 110 (49.9)

WD15632A 15 600 3 51,180 14.5 240 1 1.8 20 2400 125 (56.6)

WD20412A 20 480 1 68,240 41.7 480 1 0.777 26 2400 120 (54.4)

WD20232A 20 240 3 68,240 48.1 240 1 1.554 26 2400 120 (54.4)

WD20432A 20 480 3 68,240 24.1 480 1 0.777 26 2400 120 (54.4)

WD20632A 20 600 3 68,240 19.3 240 1 1.8 26 2400 135 (61.2)

WD25832A 25 208 3 85,300 69.4 208 1 1.793 33 2400 120 (54.4)

WD25232A 25 240 3 85,300 60.1 240 1 1.554 33 2400 120 (54.4)

WD25432A 25 480 3 85,300 30.1 480 1 0.777 33 2400 120 (54.4)

WD25632A 25 600 3 85,300 24.1 240 1 1.8 33 2400 135 (61.2)

WD30832A 30 208 3 102,360 83.3 208 1 1.793 39 2400 120 (54.4)

WD30232A 30 240 3 102,360 72.2 240 1 1.554 39 2400 120 (54.4)

WD30432A 30 480 3 102,360 36.1 480 1 0.777 39 2400 120 (54.4)

WD30632A 30 600 3 102,360 28.9 240 1 1.8 39 2400 135 (61.2)

WD39432A 39 480 3 133,068 46.9 480 1 0.777 51 2400 120 (54.4)

WD39632A 39 600 3 133,068 37.6 240 1 1.8 51 2400 135 (61.2)

REMARQUE : Les radiateurs de plus de 48 ampères nécessitent une protection par fusibles supplémentaire.

CONSERVEZ CES INSTRUCTIONS

PPD 41616 12/13 5200-11199-002

Page 18

INSTRUCTIONS IMPORTANTES

EXPOSED

E

X

P

O

SED

EXPOSED

EXPOSED

E

XPO

S

E

D

E

X

P

O

S

E

D

AVERTISSEMENT

LORS DE L’UTILISATION D’APPAREILS ÉLECTRIQUES, DES

PRÉCAUTIONS DE BASE DOIVENT TOUJOURS ÊTRE SUIVIES

AFIN DE RÉDUIRE LE RISQUE DE DÉPART D'INCENDIE, DE

COMMOTION ÉLECTRIQUE ET DE BLESSURES AUX

PERSONNES, INCLUANT CELLES QUI SUIVENT :

1. Lisez toutes les instructions avant d’installer ou d’utiliser le

radiateur.

2. Ce radiateur est un produit commercial/industriel, non prévu pour

une utilisation en résidentiel.

3. Ce radiateur comporte des pièces intérieures brûlantes qui

génèrent des arcs ou des étincelles électriques, il ne doit pas être

utilisé dans des atmosphères dangereuses, où sont entreposés ou

utilisés des vapeurs ou liquides inflammables, ou d’autres combustibles tels que définis par NEC (norme électrique américaine).

La non-observation de cette consigne peut entraîner explosion ou

départ d’incendie.

4. Ce radiateur est chaud quand il est en fonctionnement. Pour éviter

des brûlures, ne laissez pas de peau nue toucher ses surfaces

chaudes. Maintenez les matières combustibles comme le mobilier,

les oreillers, la literie, les papiers, les vêtements et les couvertures,

à au moins 3 pieds (90 cm) de distance de l’avant du radiateur.

5. Il faut faire très attention quand un radiateur quelconque est utilisé

par des enfants ou des personnes invalides ou près d’eux, et à

chaque fois que le radiateur est laissé en marche sans surveillance.

AVERTISSEMENT

!

6. N’utilisez plus un radiateur s’il a présenté des dysfonctionnements.

Débranchez son alimentation au panneau de distribution du secteur

et faites-le inspecter par un bon électricien avant de le réutiliser.

7. Ne l’utilisez pas à l’extérieur.

8. Pour déconnecter le radiateur, passez sa commande sur arrêt (Off)

et coupez le secteur en amont au panneau de distribution.

9. N’insérez pas d’objets étrangers, et ne permettez pas qu’il en entre,

dans toute ouverture d’admission ou d’évacuation, car cela peut

causer une commotion électrique ou un départ d’incendie, ou

endommager le radiateur.

10. Pour éviter un possible départ d’incendie, n'obstruez en aucune

façon les admissions et les échappements d’air.

11. N’utilisez ce radiateur que comme c’est décrit dans ce manuel.

Toute autre utilisation non recommandée par le constructeur peut

entraîner un départ d’incendie, une commotion électrique ou des

blessures aux personnes.

12. Lors de l’installation, voyez les INSTRUCTIONS D’INSTALLATION

pour des mises en gardes et précautions supplémentaires.

13. Pour un fonctionnement sûr et efficace, et pour prolonger sa durée

de service, gardez votre radiateur propre – Voyez les

INSTRUCTIONS D’ENTRETIEN.

RADIATEUR NON PRÉVU POUR UNE UTILISATION RÉSIDENTIELLE.

!

Pour éviter un possible départ d’incendie, des blessures corporelles ou

des dommages au radiateur, respectez ces consignes :

Remarque importante: Ce radiateur doit être installé par une personne

qualifiée.

1. Débranchez toute alimentation secteur arrivant au panneau de service principal avant de câbler ou d’intervenir pour du service.

2. Toutes les procédures de câblage et les raccordements doivent être

en conformité avec les normes nationales et locales applicables, et

le radiateur doit être relié à la terre.

ATTENTION : Tous les conduits et raccords électriques doivent être

listés pour des applications étanches, afin de maintenir la classification

NEMA 4X du coffret, qui évite que de l’eau envoyée par jet n’entre dans

le boîtier électrique.

3. Vérifiez que la tension du secteur arrivant au radiateur correspond

bien aux valeurs spécifiées sur sa plaque signalétique.

ATTENTION : ALIMENTER LE RADIATEUR AVEC UNE TENSION

DÉPASSANT LA VALEUR IMPRIMÉE SUR LA PLAQUE SIGNALÉTIQUE ENDOMMAGERA LE RADIATEUR ET ANNULERA SA

GARANTIE, ET CELA PEUT PROVOQUER UN DÉPART D’INCENDIE.

4. Pour réduire le risque de départ d’incendie, n’entreposez pas et

INSTRUCTIONS

D'INSTALLATION

Généralités

Instructions de localisation du radiateur:

Disposez les radiateurs de façon à ce que leur flux d’air envoyé :

A. Soit soumis à un minimum d’interférence venant de colonnes,

machines ou cloisons.

B. Passe sur les murs exposés sans souffler directement dessus.

C. Ne soit pas dirigé vers des occupants de la pièce en chauffage de

confort.

n’utilisez pas d’essence ou d’autres produits inflammables sous

forme de liquide ou de vapeurs à proximité du radiateur.

5. La structure de montage au plafond ou au mur et les dispositions

d’ancrage doivent avoir une résistance suffisante pour supporter le

poids du radiateur et de son support de montage. Consultez les

Spécifications pour le poids total de radiateur.

6. Le radiateur ne doit être monté que pour un flux d’air horizontal. Le

radiateur peut être monté à au moins 7’ (231,4 cm) au-dessus du sol,

pour éviter un contact accidentel avec la pale de ventilateur qui pourrait causer une blessure.

7. Gardez au moins 5’ (152,4 cm) d’espacement sur l’avant du radiateur. Référez-vous à la Figure 2 pour les besoins en espacement sur

les côtés, en haut et en bas.

8. Ne montez pas de thermostat de type au mercure directement sur le

radiateur. La vibration pourrait causer un dysfonctionnement du radiateur.

9. La grille de sortie d’air est déterminée en usine avec ses volets fixés

à un angle de 45°. C’est l’angle minimal permis pour éviter une surchauffe potentielle. Ces volets peuvent être ouverts jusqu’à 90° si

vous le souhaitez pour permettre un meilleur envoi d’air, en écartant

chaque volet vers l’extérieur. Voyez la Figure 3.

D. Soit dirigé le long du côté face au vent quand l’installation est dans

un bâtiment soumis à un vent dominant.

Placez le thermostat sur des cloisons de séparation intérieures ou des

poteaux, à l’écart des courants d’air froids, des sources de chaleur

intérieures et à distance des évacuations d’air du radiateur.

EXPO

EXPOSÉ

EXPO

SÉ

EXPOSÉ

EXPOSÉ

EXPOSÉ

Figure 1

18

SÉ

Page 19

A

Wall

Ceiling

Floor

6" Min.

(152 mm)

D

Ceiling

Wall

8" Min.

(203 mm)

B

Floor

7' Min.

(2134 mm)

7' Min.

(2134 mm)

9" Min.

(229 mm)

Wall

6"

(152 mm)

C

Ceiling

Floor

45° Minimum

Angle

Plafond

Cloison

ol

Figure 2

S

Dimension en pouces (mm)

kW AB C D

2-10 13 (330) 19.5 (495) 18 (457) 19.5 (495)

12.5-39.0 20 (508) 31 (787) 27 (686) 24.2 (615)

Des petites pièces peuvent être réchauffées avec un seul radiateur.

Quand deux murs sont exposés, le radiateur doit être monté comme

c’est montré en Figure 1.

Des pièces plus grandes nécessitent l’installation de plusieurs radiateurs.

Le nombre et la capacité des radiateurs sont à déterminer en fonction du

volume de bâtiment et de la surface en mètres carrés des zones à

réchauffer. Disposez les radiateurs pour fournir une ventilation du

périmètre, chaque radiateur renforçant le flux d'air du précédent.

Montage de radiateurs avec support de montage

universel fourni

AVIS — Ces radiateurs sont conçus pour un montage au plafond ou sur

un mur avec envoi d’air horizontal uniquement. Tout autre mode de

montage annulerait la garantie.

1. Hauteur au-dessus du sol

A. Dans des zones où la hauteur de plafond fait plus de 12 pieds

(365,8 cm), la hauteur de montage recommandée est d’environ 10

pieds (304,8 cm), du sol au dessous du radiateur.

B. Pour des hauteurs de plafond de 12 pieds (365,8 cm) ou moins, la

hauteur de montage maximale est déterminée par l’utilisation du

support de montage offert avec ces radiateurs. L’écartement par

rapport au plafond doit être au moins de 9" (22,9 cm). (Voyez la

Figure 2).

C. Dans tous les cas la hauteur de montage minimale est de 7 pieds

(213,4 cm) du sol au dessous du radiateur. (Voyez la Figure 2).

2. Écartement par rapport à des parois adjacentes (Voyez la Figure 2).

A. De l’arrière de l’enceinte au mur d’adossement, 6” (15,2 cm) au

minimum.

B. Du côté de l’enceinte au mur latéral, 8” (20,3 cm) au minimum.

REMARQUE : Si deux radiateurs ou plus sont activés dans le même

espace clos, leurs décharges d’air doivent être dirigées pour contribuer

au mouvement de la masse d’air afin d’assurer une dispersion

homogène de la chaleur.

Plafond Plafond

loison

Cloison

ol

S

ol

S

C

Câblage

Référez-vous au schéma de câblage fourni avec le radiateur.

Ce schéma de câblage se trouve sur l’intérieur de la porte du compartiment de câblage. Pour toute question, veuillez contacter le service technique au 800-642-4328. Ayez sous la main votre référence de modèle,

que vous trouvez sur sa plaque signalétique.

TOUS LES CONDUITS ET RACCORDS ÉLECTRIQUES DOIVENT

ÊTRE LISTÉS POUR DES APPLICATIONS ÉTANCHES, AFIN DE

MAINTENIR LA CLASSIFICATION NEMA 4X DU COFFRET, QUI

ÉVITE QUE DE L’EAU ENVOYÉE PAR JET N’ENTRE DANS LE BOÎTIER ÉLECTRIQUE.

REMARQUE : Tout le câblage électrique doit être effectué par une personne qualifiée, en conformité avec la norme américaine (NEC) et les

normes locales.

NOTE IMPORTANTE - Couple des bornes à vis d’installation :

Durant le transport il est possible que les connexions par cosses à

visser se soient desserrées. Après l’installation, avant de mettre sous

tension l’appareil de chauffage, vérifiez toutes les connexions par borne

à vis, leur serrage doit être à un couple d’au moins 35 in-lbs. (3,9 N-m).

Un outil est inclus pour resserrer les vissages des cosses dans les

endroits difficiles à atteindre.

TOUS LES CONDUITS ET RACCORDS ÉLECTRIQUES DOIVENT

ÊTRE LISTÉS POUR DES APPLICATIONS ÉTANCHES, AFIN DE

MAINTENIR LA CLASSIFICATION NEMA 4X DU COFFRET, QUI

ÉVITE QUE DE L’EAU ENVOYÉE PAR JET N’ENTRE DANS LE BOÎTIER ÉLECTRIQUE.

1. Branchez le radiateur sur une alimentation secteur conforme (tension/ampérage/fréquence) à la spécification de la plaque signalétique.

2. Tous les radiateurs sont fournis avec des borniers de commandes et

l’alimentation secteur pour les raccordements par le client.

3. Des protections contre une surchauffe sont assurées par une

coupure thermique automatique (coupure avec restauration manuelle

en option) qui ouvre le circuit électrique d’alimentation si le flux normal d’air est gêné ou obstrué. Le dispositif réactive automatiquement

le radiateur si la cause de l’obstruction est éliminée. En cas de dispositif optionnel à restauration manuelle, il faut déterminer et solutionner la cause avant de réactiver.

LE CONCEPTEUR DU SYSTÈME EST RESPONSABLE DE LA SÉCURITÉ DE CET ÉQUIPEMENT, ET DOIT INSTALLER DES CONTRÔLES DE SECOURS ET DES DISPOSITIFS DE SÉCURITÉ AVEC

Figure 3 - Réglage des volets

45° d’angle

au minimum

SES APPAREILS BLESSURES CORPORELLES OU DES DÉGÂTS

MATÉRIELS, DES CONTRÔLES DE SECOURS SONT DE

CHAUFFAGE ÉLECTRIQUES. LÀ OÙ DES CONSÉQUENCES DE

PANNE PEUVENT ENTRAÎNER DES ESSENTIELS.

19

Page 20

4. Les radiateurs sont équipés d’une commande de temporisation de

ventilateur. Cette commande fait poursuivre l’activation du ventilateur

un court délai après la désactivation des éléments de chauffe, afin

de dissiper leur chaleur résiduelle.

REMARQUE: Si une option de restauration manuelle de la coupure sur

dépassement de limite est fournie, un bouton de restauration marqué

RESET sera accessible sur le tableau de commandes. Ce dispositif de

sécurité ne déclenchera que si le radiateur passe en surchauffe.

LE SENS DE ROTATION DE LA PALE DE VENTILATEUR DOIT

ÊTRE VÉRIFIÉ. S’IL N’Y A PAS DE FLUX D’AIR QUI SORT DE

LA GRILLE D’ÉVACUATION, PERMUTEZ DEUX DES TROIS

FILS D’ARRIVÉE DE L’ALIMENTATION, SUR LES MODÈLES

EN SECTEUR TRIPHASÉ UNIQUEMENT.

Équipement optionnel

• Thermostat intégré (type à bulbe ou capillaire) pour un contrôle

automatique de la température. Le thermostat contrôle simultanément les éléments de chauffe et le ventilateur pour atteindre et

maintenir la température fixée.

Son réglage bas (Lo) du thermostat est pour environ 40°F (4,4 °C)

et son réglage haut (Hi) pour environ 90°F (32,2 °F).

• Commutateur de mode (radiateur activé, radiateur désactivé, ventilation uniquement) fait passer un flux d’air, toute en faisant chauffer

ou non les éléments. Ce commutateur est accessible depuis l’extérieur de l’enceinte NRMA 4X.

• Voyant indicateur pour signaler que les éléments de chauffe sont

activés.

• Fusible interne

• Détecteur de limite à restauration manuelle

• Commutateur M/A (On/Off)

• Pour trouver un schéma de câblage contenant ces options, voyez

celui collé sur l’intérieur du couvercle du boîtier de raccordement.

INSTRUCTIONS

D’UTILISATION

1. Le radiateur doit être correctement installé avant d’être mis en

marche.

2. Pour contrôler l’installation, passez le commutateur de mode en

position d’arrêt (Off). Envoyez l’alimentation secteur vers le radiateur

à partir du tableau de distribution en amont et constatez que le radiateur ne fonctionne pas. Si le radiateur chauffait déjà, débranchez-le

et vérifiez le câblage.

3. Faites tourner la consigne du thermostat en sens horaire sur la position de demande de chauffe la plus forte. Avec son commutateur de

mode toujours en position d’arrêt (Off) le radiateur ne chauffe pas.

4. Passez ce commutateur de mode en position de ventilation uniquement. Le ventilateur doit démarrer et souffler de l’air non réchauffé.

5. Passez ce commutateur de mode en position de chauffe. Le ventilateur doit s’activer et souffler de l’air réchauffé par les éléments du

radiateur.

6. Le radiateur doit être laissé en fonctionnement dans ce dernier mode

avec la consigne de thermostat à une valeur de température élevée

ou à fond, jusqu’à ce que la température de la pièce atteigne le

niveau voulu. Le réglage du thermostat doit alors être ramené en

sens antihoraire jusqu’à la désactivation des éléments de chauffe (un

déclic est audible). Cela devrait permettre au thermostat

d’activer/désactiver par cycles le radiateur afin de maintenir cette

température. Des ajustements fins peuvent être nécessaires pour

obtenir la température ambiance désirée dans la pièce. Le fait de

tourner légèrement le réglage de thermostat en sens horaire élèvera

un peu la température ambiante, en sens antihoraire l’abaissera un

peu.

REMARQUE: Une temporisation de ventilateur intégrée prolongera son

activation une fois que les éléments de chauffe sont désactivés, afin de

dissiper leur chaleur résiduelle.

REMARQUE: Si une option de commutateur M/A est fournie, ce commutateur sera accessible depuis l’extérieur du tableau de commandes et

sera marqué ON et OFF. En position d’arrêt OFF le radiateur ne fonctionnera pas.

NE TOUCHEZ PAS ET NE CONTOURNEZ PAS LES LIMITES

DE SÉCURITÉ À L’INTÉRIEUR DU RADIATEUR .

INSTRUCTIONS

D’ENTRETIEN

Il est important de garder propre le radiateur. Votre radiateur vous fournira des années de bon service et de confort avec juste un minimum de

soins. Pour assurer son fonctionnement efficace, suivez les instructions

simples ci-dessous :

TOUTE INTERVENTION DE SERVICE AU-DELÀ D’UN

SIMPLE NETTOYAGE, QUI NÉCESSITE UN DÉMONTAGE,

DEVRA ÊTRE RÉALISÉE PAR DU PERSONNEL DE