Page 1

MODEL NO. MUH35C

Unit Heater Fan-Forced

Built-in Thermostat

Installation, Operation & Maintenance Instr uctions

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered Products.

You have made a wise investment selecting the highest quality product in the heating industry.

Please carefully read the installation and maintenance instructions shown in this manual. You should enjoy

years of efficient heating comfort with this product from Marley Engineered Products... the industry’s leader in

design, manufacturing, quality and service.

... The Employees of

Marley Engineered Products

WARNING

Read Carefully - These instructions contain vital information

for the proper installation, use and efficient operation of the

heater. Carefully read these instructions before installation,

operation, or cleaning of the heater. Failure to adhere to the

instructions could result in fire, electric shock, serious personal

injury, death or property damage. Save these instructions and

review frequently for continuing safe operation and instructing

future users.

IMPORTANT NOTE:

As received, heater is for hard wire installation and complies

with UL Standard 2021 and CSA Standard C22.2 No. 46M1988.

For Field Conversion to a Moveable Electric Heater, Model

PHCS1B Cord Kit must be installed. With Cord Kit installed,

complies with UL Standard 1278 and CSA Standard C22.2

No. 46-M1988. Refer to user instructions provided with Cord

Kit when using as a movable heater.

1. Use minimum 60 °C copper wire only.

2. Observe wall, floor, and ceiling clearance requirements

(page 2).

3. All wiring must conform to National and Local electrical

codes, and the heater must be grounded as a precaution

against possible electrical shock.

4. All electrical power must be disconnected at main service

box before installation, inspection, cleaning, or servicing of

this heater.

5. Check heater voltage and amperage on back of heater to

make sure it agrees with the electric service supplied.

!

6. Ground fault circuit protection is required if heater is used in

damp areas such as basements or garages. This heater is

not suitable for use in wet or very humid locations.

7. Do not use outdoors.

8. Never locate heater where it may fall into a bathtub or other

water container.

9. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock, fire,

or damage the heater.

10. To prevent a possible fire, do not block air intakes or

exhaust in any manner. Do not use on soft surfaces, like a

bed, where openings may become blocked. Clean as often

as necessary to prevent dust from clogging the grille or element fins. Keep all electrical cords, drapes, paper, plastics

and other combustibles away from heater.

11. Heater air flow must be directed parallel to or away from

adjacent walls.

12. A heater has hot and arcing or sparking parts inside. Do not

use it in areas where gasoline, paint, or flammable liquids

are used or stored.

13. If this heater or its power supply cable become damaged or

malfunction in any way, disconnect power at main service

panel, discontinue use, and have unit repaired by a reputable repair service.

14. Do not operate heater without stand.

15. When heater is to be wall or ceiling mounted, the anchoring

provisions must be of sufficient strength to support the total

weight of the heater plus the weight of the mounting provisions. Failure to properly secure the supporting members of

the building structure could allow the heater to fall.

SAVE THESE INSTRUCTIONS

Page 2

Specifications

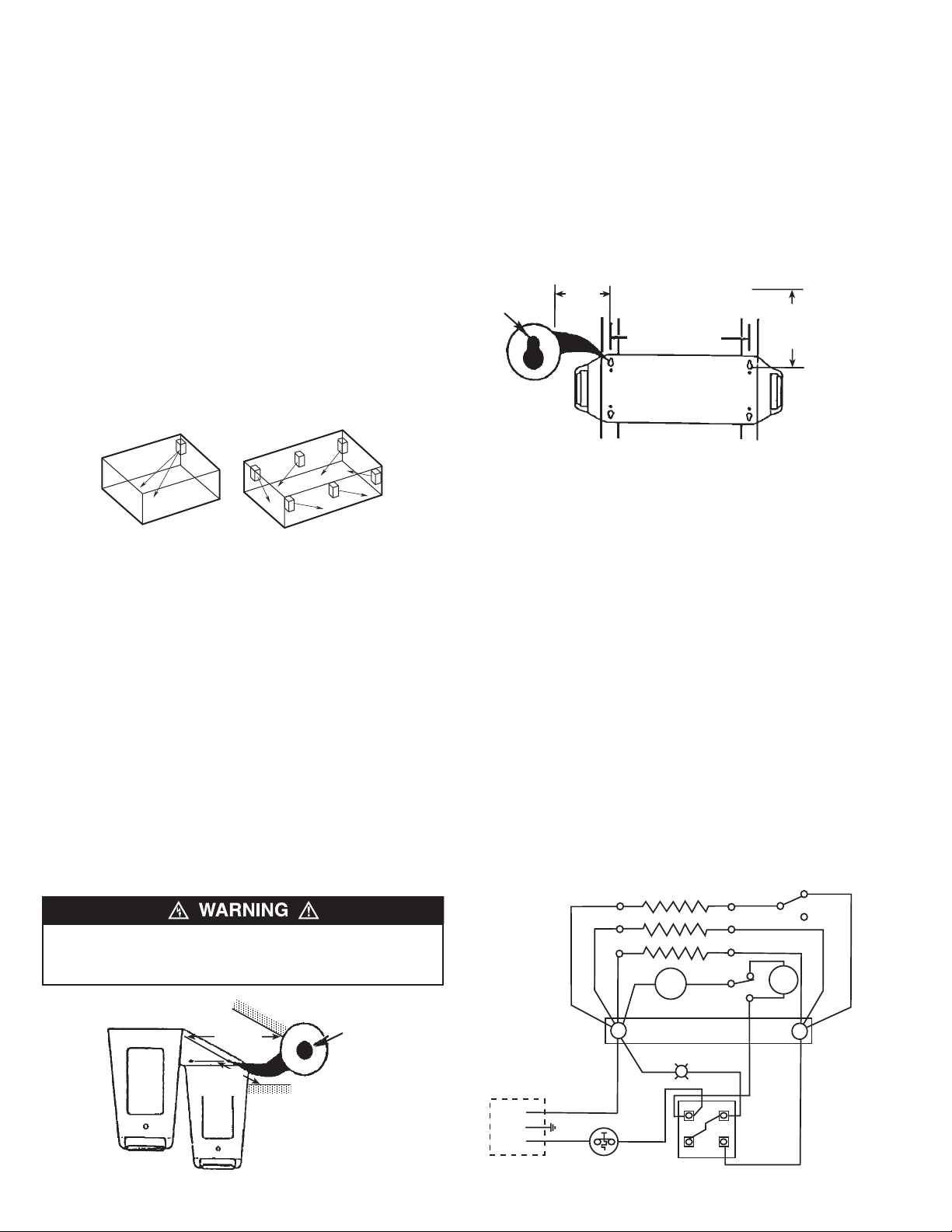

MIN

8" TO

CEILING

TO WALL

MIN 8"

MIN. 8"

TO WALL

MIN. 8"

TO WALL

ELEMENTS FRONT

MIDDLE

REAR

HEAT SW.

HI

LOW

1

2

3

2

3

1

AUTO

FAN SW.

ON

TERMINAL BLOCK

6

4

INDICATOR LIGHT

MANUAL RESET

THERMAL LIMIT

BLACK

GREEN

BLACK

SUPPLY LEADS

WIRING COMPARTMENT

FAN

DELAY

MOTOR

L1

OFF

CYL

L2

THERMOSTAT

Heater Voltage 240 / 208 VAC Amps

KW Rating: @240V 5.0 kW High 21

3.3 kW Low 14

@208V 3.7 kW High 18

2.5 kW Low 12

imensions: 16”H x 21”W x 8”D

D

Weight: 22 lbs

GENERAL

Location of Heater

This heater has user controls. It may be desirable to reach

these controls after installation.

he direction of air flow should not be restricted by columns,

T

machinery, etc., and the air flow should wipe exposed walls

rather than blowing directly at them. When more than one

heater is used in a area, the heaters should be arranged so that

the air discharge of each heater supports the air flow of the others to provide best circulation of warm air.

Mounting Height

When air flow of the heater is directed vertically, the minimum

mounting height is 6 feet, and the maximum mounting height is

15 feet. When the air flow of the heater is directed horizontally,

the minimum recommended mounting height is 6 feet, and the

maximum recommended height is 8 feet.

CEILING MOUNT

This heater may be mounted to any ceiling that will support the

weight of the heater.

First remove the mounting stand from the heater, then remove

four rubber grommets from stand. Secure stand to structural

members of ceiling with four 1/4” diameter bolts (not provided).

In wood joist use 1-1/2” long lag bolts. In steel beams use

machine bolts secured with nuts and lockwashers. Never use

bolts smaller than 1/4” diameter.

Replace the heater in the stand and tighten knobs to lock in

place. Two large rubberwashers go between heater and stand,

one on either side.

WALL MOUNT

SEE WARNING NO. 15.

This heater may be mounted on any wall that will support the

weight of the heater. First remove the mounting stand from the

heater, then remove four rubber grommets from stand. Secure

stand to structural members of wall with four 1/4” dia. X 1-1/2”

long lag bolts (not provided). In masonry walls use metal

expansion shields or toggle bolts. Never use bolts smaller than

1/4” diameter.

Replace the heater in the stand and tighten knobs to lock in

place. Two large rubber washers go between heater and stand,

one on either side.

KEYHOLE

SLOT

USE

K

F

MOUNTING

EYHOLES

OR WALL

OUNTING

M

OLES

H

RE 16” O.C.

A

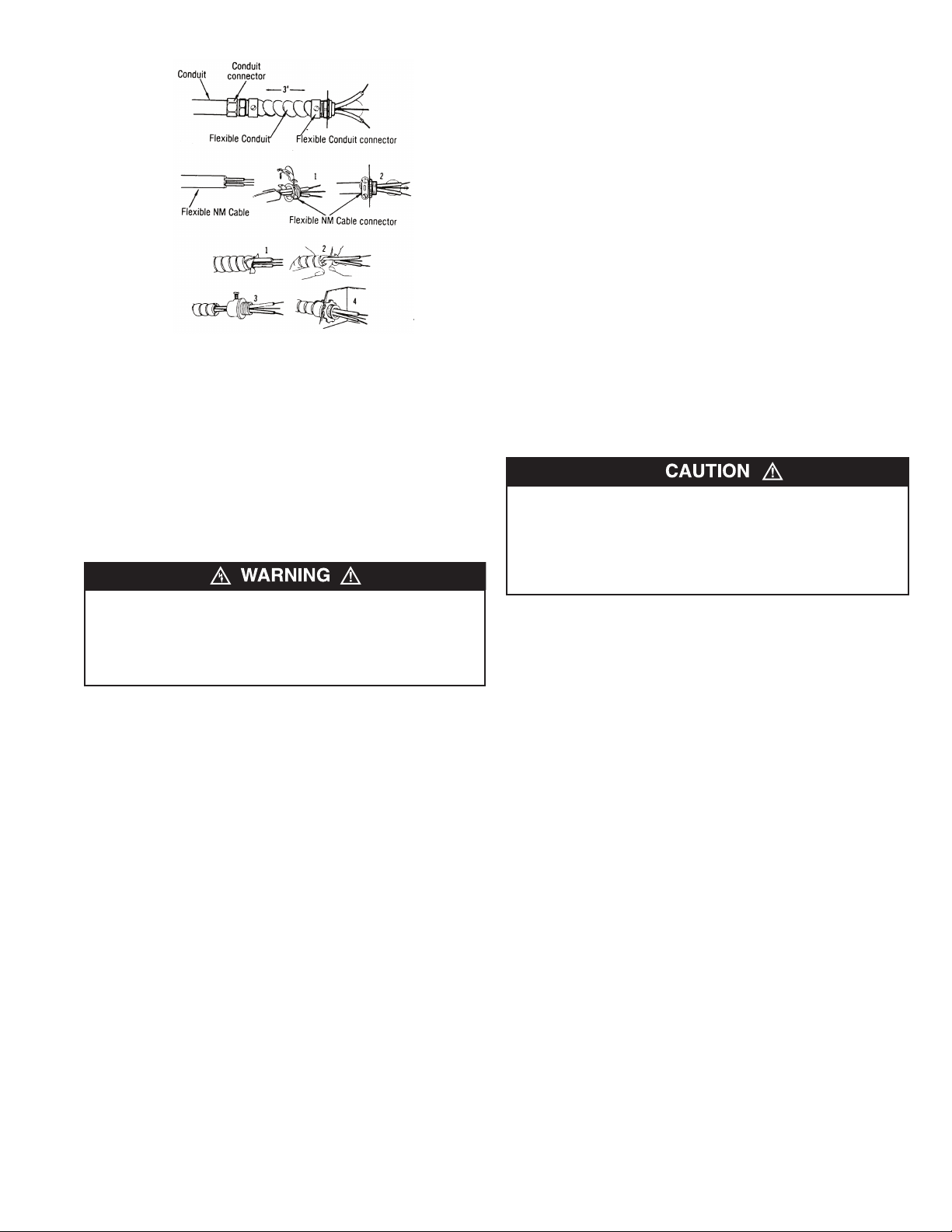

CONNECTING THE POWER

Hardware Needed

You also will need the following hardware which you can pur-

chase from your local hardware store or electrical supply house:

• Enough 10 gauge copper wire to run power from the service

box to the heating unit. Copper wire must have a minimum

temperature rating of 60 degrees C. DO NOT USE

ALUMINUM WIRE WITH THIS UNIT.

• Proper wire connectors for your application. (See illustration

that follows.)

For certain applications, conduit may be required. Check local

electrical codes. Also, if you run the wiring in conduit and wish

to be able to turn the heater, be sure to purchase enough flexible conduit to allow the heater to be turned.

Loosen the two screws that secure the wiring compartment

cover to the upper right hand area of the back of the heater and

remove the cover.

Attach the cable connector to the cover as shown above and

slide the 10 gauge wire through the cable connector. Pull

enough of the wire through the connector so you will have

enough wire to work with when you make the connections.

TO PREVENT HEATER FROM POSSIBLY FALLING, DO NOT

USE KEYHOLE SLOTS FOR CEILING MOUNT APPLICATION. SEE ALSO WARNING NO. 15.

CIRCULAR

HOLE

USE CIRCULAR

HOLES FOR

CEILING MOUNTING. DO NOT

USE KEYHOLES.

2

Page 3

Connectors, cable, and hardware used to wire the MUH35C

Connect the field wiring to the heater wiring as shown in the

wiring diagram.

After connecting the wiring, replace the wiring compartment

cover making sure none of the wires are pinched between the

cover and the heater. Tighten the screws securely.

Optional Plug-in Connection

If this heater is intended to be converted to a cord-connected

model, the QMark model number PHCS1B cord assembly must

be used. Refer to the instructions packed with the cord assembly for installing the cord onto the heater.

THE MUH35C MAY BE CONVERTED TO A CORD CONNECTED MODEL ONLY BY THE ADDITION OF THE QMARK

MODEL NUMBER PHCS1B CORD ASSEMBLY. THE USE OF

ANY OTHER CORD MAY RESULT IN A FIRE OR ELECTRICAL SHOCK.

or chemical cleaners as these may harm the finish.

f heater is used in a very dusty location, use a vacuum cleaner

I

dust brush to remove dust and other foreign material from the

grilles.

SERVICE

This heater does not require any routine maintenance other than

occasional cleaning to prevent clogging of intake grille opening.

To clean air intake grille, use vacuum with brush attachment or

high pressure air. The motor is permanently lubricated.

Do not operate the heater if the heater malfunctions or has been

damaged in any manner.

Call the toll-free number listed for assistance.

To Reset Safety Thermal Limit Control

Your heater is equipped with a manual reset safety thermal limit

control that will automatically turn the heater off to prevent a fire

if the heater overheats. This control is located on front of the

heater just above the thermostat and is marked “PUSH TO

RESET”. To reset, allow the heater to cool then simply push the

red button in until it snaps. The heater should immediately

return to normal operation.

OPERATION OF THE SAFETY THERMAL LIMIT CONTROL

INDICATES THE HEATER HAS BEEN SUBJECTED TO

SOME ABNORMAL CONDITION. IT IS RECOMMENDED

THAT THE HEATER BE CHECKED BY A REPUTABLE ELECTRICIAN OR REPAIR SERVICE TO INSURE THE HEATER

HAS NOT BEEN DAMAGED.

HEATING OPERATION

To operate the heater, first select either high or low position on

the heat selector switch, then turn the thermostat knob as far as

it will go in the clockwise direction. The indicator light will come

on and remain on as long as the heater is in the operating

mode. When the room temperature reaches the desired level,

slowly turn the thermostat knob counterclockwise until the thermostat clicks. The indicator light will remain on. The heater will

automatically cycle off and on as needed to maintain desired

temperature. To shut heater off, turn thermostat knob as far as it

will go in the counterclockwise direction until the indicator light is

off.

The fan selector switch allows continuous or cycling fan operation by selecting either the “ON” or “Auto” position, respectively.

Automatic Fan Delay: This heater incorporates an automatic

fan delay. When the thermostat calls for heat, fan action is

delayed momentarily until the heating element is warm. When

the thermostat is satisfied, the fan continues to operate until the

heating element is cool. This action prevents circulation of cold

air, and avoids exposing unit to residual heat, thus providing

higher comfort level and prolonged element life.

CLEANING

Turn thermostat off. Disconnect electrical power before cleaning

heater. Use a soft cloth for dusting. For cleaning use only a

damp rag and nonabrasive dish detergent. Do not use abrasive

3

Page 4

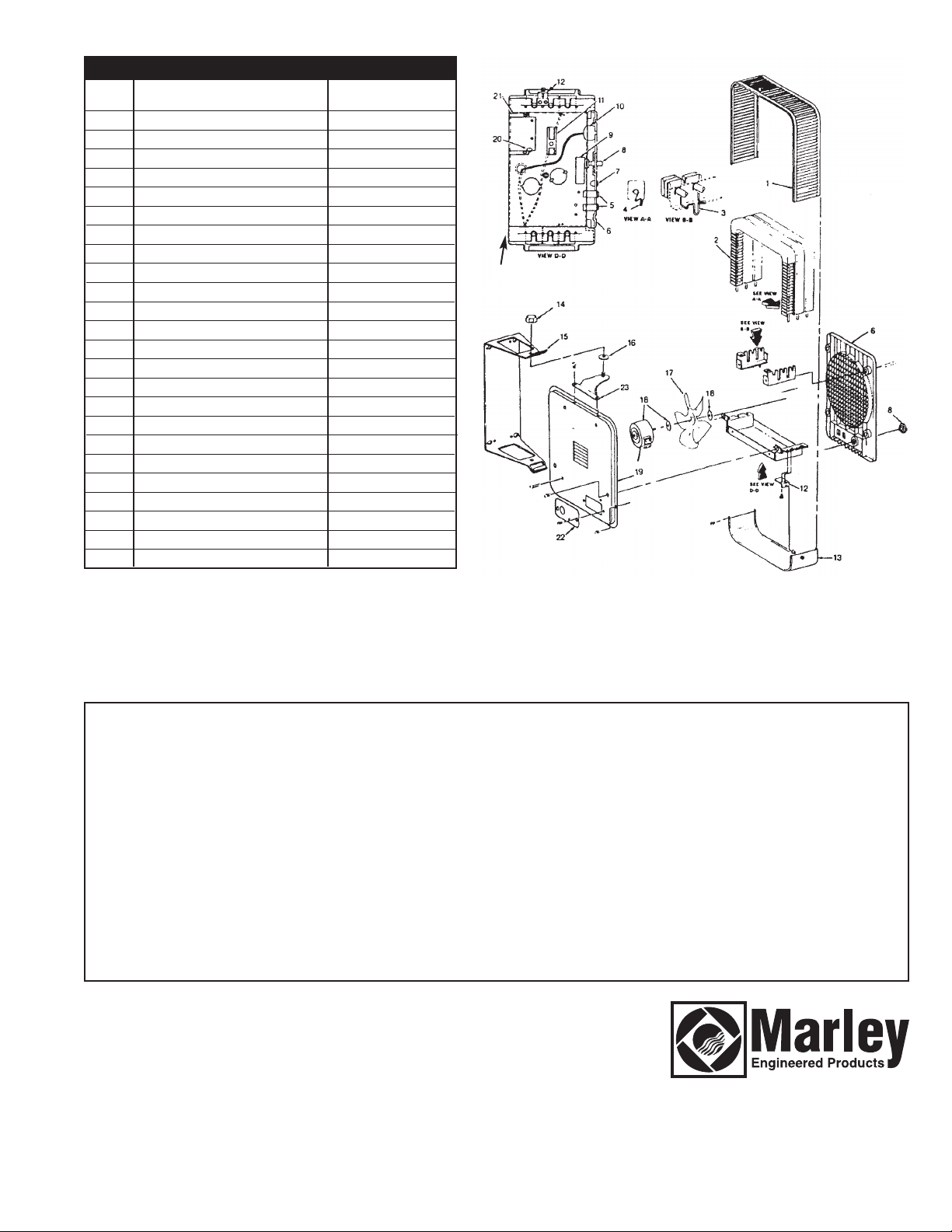

REF.

NO

.

1

2.

3.

.

4

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

RENEWAL PARTS IDENTIFICATION

DESCRIPTION

Guard, Element

Element Assembly

Spring, Element

Spring, Capillary

Switch, Rocker

Grille

Indicator Light

Knob, Thermostat

Thermostat

Limit, Manual Reset

Block Terminal

racket, Cover Screw

B

Cover, Control Comp.

Knob, Stand

Stand, Portable

Washer, Rubber

Blade, Fan

Motor

Case, Back

Bushing, Strain Relief

Wiring Comp. Divider

Wiring Cover Plate

Bracket, Mounting

Fan Delay

PART NUMBER

2504-0011-001

1802-0087-032

5208-0073-000

5208-0072-000

S99814893A000

1402-2154-001

3510-2007-000

3301-2012-001

5813-2018-000

4520-11004-000

5823-0003-001

1215-0291-000

1402-0336-000

3301-2018-000

5210-2000-004

W10814895A000

1210-2000-000

3900-2002-006

1425-2005-002

25221-70011

1614-2000-000

4503-2010-002

1215-2001-002

4520-0010-000

4

2

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-2197-006

ECR 38424

08/09

Page 5

Calentador Unitario

Ventilador de tiro forzado - Termostato integrado

MODELO NO. MUH35C

Instrucciones de instalación, operación y mantenimiento

Estimado propietario:

¡Felicitaciones! Gracias por comprar este nuevo calefactor fabricado por Marley Engineered Products.

Al seleccionar el producto de más alta calidad de la industria de calefacción, usted ha hecho una sabia inversión. Por favor,

lea cuidadosamente las instrucciones de instalación y mantenimiento incluídas en este manual. Así podrá disfrutar de años

de calefacción confortable y eficiente con este producto de Marley Engineered Products... el líder de la industria en diseño, fabricación, calidad y servicio.

... Los empleados de

Marley Engineered Products

ADVERTENCIA

Lea cuidadosamente - Estas instrucciones contienen infor-

mación vital para la instalación, uso y eficiente operación del

calentador. Lea cuidadosamente estas instrucciones antes de

instalar, operar o limpiar el calentador. El no adherirse a las

instrucciones puede resultar en incendio, choque eléctrico,

lesiones personales graves, fallecimiento o daños a la

propiedad. Guarde estas instrucciones y revíselas frecuentemente para una operación segura continuada y para instruir a

los futuros usuarios.

Nota importante:

El calefactor viene destinado a una instalación fija, y cumple

con las normas UL 2021 y CSA C22.2 Nº 46-M1988.

Para una conversión en el terreno a Calefactor Eléctrico Móvil

debe instalarse el Juego de Cordón Modelo PHCS1B. Con el

Juego de Cordón instalado, el equipo cumple con las normas

UL 1278 y CSA C22.2 Nº 46-M1988. Cuando lo utilice como

calefactor móvil, consulte las instrucciones para el usuario que

se proporcionan con el Juego de Cordón.

1. Use un mínimo de cable de cobre de 60ºC solamente.

2. Observe los requerimientos de separación de pared, piso y

cieloraso (página 2).

3. Todo el cableado debe conformar con los códigos eléctricos

nacionales y locales y el calentador debe estar conectado a

tierra como precaución contra un choque eléctrico posible.

4. Antes de instalar, inspeccionar, limpiar o prestar servicio a

este calentador, debe desconectarse toda la potencia

eléctrica en la caja maestra de servicio.

5. Inspeccione el voltaje y amperaje en la parte posterior del

calentador para asegurarse que concuerda con el servicio

eléctrico provisto.

6. Si el calentador se usa en áreas húmedas tales como

sótanos o garages, se requiere protección de circuito de

!

falla de conexión a tierra. Esto no es conveniente para usar

en ubicaciones mojadas o muy húmedas.

7. No use al aire libre.

8. Nunca ubique el calentador donde puede caer dentro de

una bañera u otro recipiente de agua.

9. No inserte ni permita que objetos extraños entren a ninguna apertura de ventilación o escape ya que esto puede

causar un choque eléctrico, incendio o daños al calentador.

10. No bloquee de ninguna manera las tomas de aire o los

escapes, para prevenir un posible incendio. No use sobre

superficies blandas, tales como una cama, donde las aberturas pueden quedar bloqueadas. Limpie tan a menudo

como sea necesario para evitar que el polvo tape la rejilla o

las aletas del elemento. Mantenga todos los cordones eléctricos, cortinas, papel, plásticos y otros combustibles alejados del calentador.

11. El flujo de aire del calentador debe dirigirse paralelo a o alejado de las paredes adyacentes.

12. Un calentador tiene adentro piezas calientes y productoras

de arcos eléctricos o de chispas. No use en áreas donde

estén almacenados gasolina, pintura o líquidos inflamables.

13. Desconecte la potencia en el panel maestro de servicio,

interrumpa el uso y haga que la unidad sea reparada por un

servicio de reparación de buena reputación, si este calentador o su cable de suministro de potencia resulta dañado

o funciona mal.

14. No opere el calentador sin la base.

15. Cuando el calentador debe montarse en la pared o cieloraso, las provisiones de anclaje deben tener suficiente

resistencia como para sostener el peso total del calentador

más el peso de las provisiones de montaje. El no asegurar

adecuadamente los miembros de apoyo de la estructura del

edificio puede permitir la caída del calentador.

CONSERVE ESTAS INSTRUCCIONES

Page 6

Especificacions

MIN. 8"

TO WALL

MIN. 8"

TO WALL

MIN

8" TO

CEILING

TO WALL

MIN 8"

ELEMENTS FRONT

MIDDLE

REAR

HEAT SW.

HI

LOW

1

2

3

2

3

1

AUTO

FAN SW.

ON

TERMINAL BLOCK

6

4

INDICATOR LIGHT

MANUAL RESET

THERMAL LIMIT

BLACK

GREEN

BLACK

SUPPLY LEADS

WIRING COMPARTMENT

FAN

DELAY

MOTOR

L1

OFF

CYL

L2

THERMOSTAT

Voltaje del calentador 240 / 208 VCA Amp.

Clasificación nominal de KV

imensiones: 16” Alt. x 21” A x 8” L

D

Peso: 22 lbs

: @240V 5.0 Kv Alto 21

3.3 Kv Bajo 14

@208V 3.7 Kv Alto 18

2.5 Kv Bajo 12

CHAVETERA

se las chavet-

U

eras para montarse en la pared.

8" MIN.

A LA

PARED

Los orificios de mon-

aje son de 16" O.C.

t

8" MIN.

AL CIELO-

RASO

GENERAL

Ubicación del Calentador

Este calentador tiene controles del usuario. Puede ser deseable

poder alcanzar esos controles después de la instalación.

a dirección del flujo de aire no debe ser restringida por colum-

L

nas, maquinarias, etc. y el flujo de aire debe pasar por las paredes expuestas en lugar de soplar directamente sobre ellas.

Cuando se usa más de un calentador en un área, los calentadores deben disponerse de tal manera que la descarga de aire

de cada calentador sostenga el flujo de aire de los otros para

proveer la mejor circulación de aire caliente.

Altura de montaje

Cuando el flujo de aire del calentador se dirige verticalmente, la

altura mínima de montaje es de 6 pies y la altura máxima de

montaje es de 15 pies. Cuando el flujo de aire del calentador se

dirige horizontalmente, la altura mínima recomendada de montaje es de 8 pies.

MONTAJE DE CIELORASO

Este calentador puede montarse en cualquier cieloraso que

sostenga el peso del calentador.

PARA PREVENIR QUE EL CALENTADOR POSIBLEMENTE

CAIGA, NO USE RANURAS DE CHAVETERAS PARA APLICACION DE MONTAJE DE CIELORASO. VEA TAMBIEN LA

ADVERTENCIA NO. 15.

Primero extraiga la base de montaje del calentador, a continuación extraiga de la base cuatro anillos protectores. Asegure la

base a los miembros estructurales del cieloraso con cuatro pernos de 1/4" de diámetro (no provistos). En las vigas de madera

use pernos gruesos de 1-1/2". En vigas de metal use pernos de

máquina asegurados con tuercas y arandelas de seguridad.

Nunca use pernos más pequeños de 1/4" de diámetro.

8" MIN. A

LA PARED

USE ORIFICIOS CIRCULARES

PARA MONTAJE DE

CIELORASO. NO USE

CHAVETERAS

ORIFICIO CIRCULAR

Vuelva a colocar el calentador en la base y ajuste las perillas

para asegurar en su lugar. Hay dos arandelas grandes de goma

entre el calentador y la base, una en cada lado.

MONTAJE DE PARED

EA LA ADVERTENCIA NO. 15

V

Este calentador puede montarse en cualquier pared que sosten-

ga el peso del calentador. Primero extraiga la base de montaje

del calentador, a continuación extraiga cuatro anillos de goma

de la base. Asegure la base a los miembros estructurales de la

pared con cuatro gruesos largos de 1/4" de diám. x 1-1/2" de

largo (no provistos). En paredes de mampostería use protectores de expansión de metal o pernos acodillados. Nunca use

pernos más pequeños de 1/4" de diámetro.

Vuelva a colocar el calentador en la base y ajuste las perillas

para calzar en su lugar. Hay dos arandelas grandes de goma

entre el calentador y la base, una en cada lado.

CONEXION DE LA POTENCIA

Ferretería requerida

Usted necesitará también la siguiente ferretería que puede com-

prar de su tienda local o tienda de suministros eléctricos:

• Suficiente alambre de cobre de calibre 10 para conectar la

potencia desde la caja de servicio a la unidad calentadora.

El alambre de cobre debe tener una clasificación nominal

mínima de temperatura de 60 grados C. NO USE

ALAMBRE DE ALUMINIO CON ESTA UNIDAD.

• Conectores adecuados de alambre para su aplicación. (Vea

la ilustración siguiente)

Pueden requerirse conductos para ciertas aplicaciones.

Consulte los códigos eléctricos locales. También, si usted tiende

el cableado en un conducto y desea girar el calentador,

asegúrese de comprar suficientes conductos flexibles para permitir girar el calentador.

SW. TERMICO

AUTO

Español 2

NEGRO

VERDE

NEGRO

GUIASNEGRAS

DE SUMINISTRO

COMPARTIMIENTO DE

CABLEADO

LIMITETERMICO DE

REPOSICION MANUAL

ELEMENTOS DELANTEROS

MEDIO

POSTERIOR

MOTOR

VENTILADOR SW

BLOQUE TERMINAL

LUZ INDICADORA

APAGADO

CICL.

TERMOSTATO

DEMORA

DEL VENTI-

LADOR

ALTO

BAJO

Page 7

Conducto

Cable NM Flexible

Conectores, cable y ferretería usados para cablear el MUH35C

Conector del

conducto

Conducto flexible

onector del Conducto Flexible

C

Conector del Cable NM Flexible

Afloje los dos tornillos que aseguran la cubierta del compartimiento de cableado al área superior derecha de la parte posterior del calentador y extraiga la cubierta.

Fije el conector del cable a la cubierta según se ilustra arriba y

deslice el cable de calibre 10 a través del conector del cable.

Tire suficiente cable a través de los conectores como para

poder trabajar cuando efectúa las conexiones.

Conecte el cableado de campo al cableado del calentador

según ilustrado en el diagrama de cableado.

Después de conectar el cableado, vuelva a colocar la cubierta

del compartimiento de cableado asegurándose que ninguno de

los cables esté presionado entre la cubierta y el calentador.

Conexion Opcional de Enchufe

Si el calentador va a ser convertido en un modelo conectado a

cordón, debe usarse el conjunto de cordón de número de modelo PHCS1B. Para instalar el cordón en el calentador, refiérase a

las instrucciones incluidas con el conjunto del cordón.

EL MUH35C PUEDE CONVERTIRSE A UN MODELO

CONECTADO A CORDON POR LA ADICION DE UN CONJUNTO DE CORDON DE NUMERO DE MODELO PHCS1B

SOLAMENTE. EL USO DE CUALQUIER OTRO CORDON

PUEDE RESULTAR EN INCENDIO O CHOQUE ELECTRICO.

Demora automática del ventilador: Ese calentador incorpora

una demora automática del ventilador. Cuando el calentador

emanda calor, se demora momentáneamente la acción del

d

ventilador hasta que se caliente el elemento térmico. Cuando el

termostato está satisfecho, el ventilador continúa operando

hasta que el elemento térmico esté frío. Esta acción impide la

irculación de aire frío y evita exponer la unidad al calor resid-

c

ual, proveyendo así un nivel más elevado de confort y duración

prolongada del elemento.

LIMPIEZA

Apague el termostato. Antes de limpiar el calentador,

desconecte la potencia eléctrica. Para limpiar el polvo use una

tela suave. Para limpiar use un trapo húmedo y un detergente

de cocina no abrasivo, solamente. No use limpiadores abrasivos

o químicos ya que los mismos pueden ser perjudiciales.

Use un cepillo de polvo de aspiradora para limpiar el polvo y

otros materiales extraños de las rejillas, si el calentador se usa

en una ubicación muy polvorienta.

SERVICIO

Este calentador no requiere ningún mantenimiento de rutina que

no sea una limpieza ocasional, para impedir el taponamiento de

la abertura de la rejilla de toma. Para limpiar la rejilla de toma

use una aspiradora con aditamento de cepillo o aire a alta presión. El motor está permanentemente lubricado.

No opere el calentador si el mismo funciona mal o ha sido

dañado de alguna manera.

Llame al número teléfono gratis para recibir ayuden.

Regraduacion del Control del Limite Termico del

Seguridad

Su calentador está equipado con un control del límite térmico de

seguridad que apagará automáticamente el calentador para

impedir un incendio si el calentador se calienta en exceso. El

control está ubicado en la parte delantera del calentador justo

arriba del termostato y está marcado "PUSH TO RESET"

("EMPUJE PARA REGRADUAR"). Para regraduar, permita que

el calentador se enfríe y a continuación simplemente empuje el

botón rojo hasta que calce. El calentador debe retornar inmediatamente a la operación normal.

OPERACION DEL CALENTADOR

Para operar el calentador, seleccione primero la posición alta o

baja en el conmutador del selector térmico, a continuación gire

la perilla del termostato tanto como sea posible en la dirección

de las agujas del reloj. Se encenderá la luz indicadora y permanecerá encendida mientras el calentador esté en el modo de

operación. Cuando la temperatura del cuarto alcanza el nivel

deseado, gire lentamente la perilla del termostato en sentido

contrario a las agujas del reloj hasta que el termostato emita un

sonido "click". La luz indicadora permanecerá encendida. El

calentador ciclará automáticamente a apagado y encendido

según se necesita para mantener la temperatura deseada. Para

apagar el calentador, gire la perilla del termostato tanto como

sea posible en la dirección contraria a las agujas del reloj hasta

que se apague la luz indicadora.

El conmutador de selector del ventilador permite una operación

continua o de ciclado del ventilador seleccionando respectivamente la posición "ON" o "Auto".

Español 3

LA OPERACION DEL CONTROL DEL LIMITE TERMICO DE

SEGURIDAD INDICA QUE EL CALENTADOR HA ESTADO

SOMETIDO A ALGUNA CONDICION ANORMAL. SE

RECOMIENDA QUE EL CALENTADOR SEA INSPECCIONADO POR UN ELECTRICISTA DE BUENA REPUTACION O

SERVICIO DE REPARACION PARA ASEGURAR QUE EL

CALENTADOR NO HAYA SIDO DAÑADO.

Page 8

IDENTIFICACION DE LAS PIEZAS DE REPUESTO

NO. DE

REF.

1.

2.

.

3

.

4

.

5

.

6

7.

8.

9.

0.

1

1.

1

2.

1

3.

1

14.

15.

16.

17.

8.

1

9.

1

0.

2

21.

22.

23.

24.

25.

DESCRIPCION

Guarda del elemento

Conjunto del elemento

Resorte del elemento

apilar del resorte

C

onmutador oscilante

C

ejilla

R

uz indicadora

L

Perilla del termostato

Termostato

Límite de la regraduación manual

Bloque terminal

oporte, Tornillo de la cubierta

S

ubierta, Componente de control

C

erilla, Base

P

Base, Portátil

Anillo, Base

Hélice, Ventilador

otor

M

Caja, Parte Posterior

Buje, Escape de Esfuerzo

Comp. de cableado, divisor

Cableado, Placa de Cubierta

Soporte, Montaje

Arandela, Goma

Demora del Ventilador

NO. DE PIEZA

2504-0011-001

1802-0087-032

208-0073-000

5

208-0072-000

5

99814893A000

S

402-2154-001

1

3510-2007-000

3301-2012-001

5813-2018-000

520-11004-000

4

823-0003-001

5

215-0291-000

1

1402-0336-000

3301-2018-000

5210-2000-004

2502-2000-000

210-2000-000

1

3900-2002-006

1425-2005-002

25221-70011

614-2000-000

1

503-2010-002

4

1215-2001-002

W10814895A000

4520-0010-000

25

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos de fabricación y de materiales por 1 año desde la fecha de

GARANTÍA LIMITADA

instalación. Esta garantía no se aplica a daños debidos a accidente, mal uso o alteración, ni a los casos en que la tensión eléctrica conectada supere a la tensión nominal -indicada en la placa de características- en más de 5 %, ni a equipos que hayan sido instalados o cableados incorrectamente, o mantenidos en

forma que no cumpla lo indicado en las instrucciones de instalación del producto. Todo reclamo por trabajos en garantía debe acompañarse con una prueba de

la fecha de instalación.

El cliente será responsable de todos los costos incurridos en el retiro o reinstalación de productos, incluyendo los costos de mano de obra y los costos de envío

incurridos para regresar productos a un Centro de Servicio de Marley Engineered Products. Dentro de las limitaciones de esta garantía, las unidades que no

funcionan deben regresarse al centro de servicio autorizado Marley más cercano, o al Centro de Servicio de Marley Engineered Products, y nosotros lo

repararemos o reemplazaremos, a nuestra opción, sin cargo para usted, con el flete de retorno pagado por Marley. Se acuerda que tal reparación o reemplazo

es el único recurso que Marley Engineered Products pone a su disposición.

LAS GARANTÍAS EXPUESTAS MÁS ARRIBA TOMAN EL LUGAR DE TODA OTRA GARANTÍA, EXPRESA O IMPLÍCITA, Y POR LA PRESENTE SE

DECLINA Y EXCLUYE DE ESTE ACUERDO TODA GARANTÍA IMPLÍCITA DE COMERCIABILIDAD Y ADECUACIÓN A UN PROPÓSITO PARTICULAR QUE

EXCEDA LAS GARANTÍAS EXPRESAS ANTEDICHAS. MARLEY ENGINEERED PRODUCTS NO SE HARÁ RESPONSABLE POR DAÑOS CONSIGUIENTES

QUE SE PRODUZCAN CON RESPECTO AL PRODUCTO, EN BASE YA SEA A NEGLIGENCIA, AGRAVIO, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados o jurisdicciones no permiten la exclusión o limitación de daños incidentales o consiguientes, de modo que la exclusión o limitación expresada

más arriba puede no aplicarse a su caso. Esta garantía le da derechos legales específicos, y usted puede tener también otros derechos, que varían de un estado o jurisdicción a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano comuníquese con Marley Engineered Products en Bennettsville, SC, Estados Unidos,

llamando al 1-800-642-4328. Toda mercadería regresada a la fábrica debe ser acompañada por una autorización de retorno y una etiqueta de identificación de

servicio, disponibles ambas en Marley Engineered Products. Cuando solicite la autorización de retorno, incluya todos los números de catálogo mostrados en los

productos.

CÓMO OBTENER SERVICIO EN GARANTÍA, PIEZAS DE

REPUESTO E INFORMACIÓN GENERAL

1. Servicio o repuestos en garantía 1-800-642-4328

2. Compra de repuestos 1-800-654-3545

3. Información general sobre productos www.marleymep.com

Nota: cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Número de parte 5200-2197-006

ECR 38424

08/09

Page 9

MODÈLE NoMUH35C

Radiateur individuel

À air pulsé - thermostat intégré

Instructions d'installation, d’utilisation et d'entretien

Cher propriétaire,

Félicitations! Merci pour l’achat de cet appareil de chauffage fabriqué par Marley Engineered Products. Vous avez fait un

investissement judicieux en choisissant un produit de la meilleure qualité qui soit. Veuillez lire attentivement les instructions

d’installation et d’entretien figurant dans ce manuel. Vous allez désormais profiter d'une chaleur confortable pendant

plusieurs années, grâce à ce produit fabriqué par Marley Engineered Products... une entreprise jouissant d'une excellente

réputation au niveau de la conception technique, de la fabrication, de la qualité et du service.

... Les employés de

Marley Engineered Products

AVERTISSEMENT

Lire attentivement - Cette feuille d'instructions contient de

l'information vitale pour effectuer la bonne installation et la

bonne utilisation du radiateur et assurer son fonctionnement

efficace. Lire attentivement ces instructions avant de procéder

à l'installation, à l'utilisation ou au nettoyage du radiateur. Ne

pas suivre ces instructions peut entraîner un incendie, une

électrocution, des blessures graves, voire la mort ou des

dégâts matériels importants. Garder les instructions et les

consulter fréquemment pour assurer un fonctionnement sûr en

permanence et pour informer les futurs utilisateurs.

Importante remarque :

Tel qu'il est reçu, le radiateur est prévu pour une installation

câblée en fixe, en conformité avec les normes UL 2021 et

CSA C22.2 N° 46-M1988. En cas de conversion sur site en

radiateur électrique mobile, il faut installer le kit de cordon d'alimentation modèle PHCS1B. L'installation avec ce kit en place

répond aux normes UL 1278 et CSA C22.2 N° 46-M1988. Se

reporter aux instructions pour l'utilisateur fournies avec le kit

de cordon en cas d'utilisation en radiateur mobile.

1. Utiliser uniquement un fil de cuivre de 60 ˚C minimum.

2. Respecter les dégagements réglementaires par rapport au mur,

plafond, plancher (page 2).

3. Tout le câblage doit être conforme aux codes électriques locaux et

nationaux et le radiateur doit être mis à la terre à titre de précaution

contre les électrocutions.

4. Toute alimentation électrique doit être débranchée au panneau

d'alimentation principal avant d'installer, inspecter, nettoyer ou

entretenir le radiateur.

5. Vérifier que la tension d'alimentation et l'ampérage au dos du radi-

!

ateur sont compatibles avec la tension du secteur.

6. Il faut protéger le circuit par une terre s'il est utilisé dans des lieux

humides comme les sous-sols ou les garages. Ce radiateur ne doit

pas être utilisé dans les lieux très humides.

7. Ne pas utiliser ce radiateur en plein-air.

8. Ne placez jamais le radiateur dans un endroit où il peut tomber

dans une baignoire ou dans un autre récipient contenant de l'eau.

9. Ne pas insérer et ne pas laisser de corps étrangers entrer par les

ouvertures de ventilation ou de sortie d'air car cela peut causer une

électrocution, un incendie ou une détérioration du radiateur.

10. Pour éviter un incendie, ne pas boucher les prises d'air ni les sorties d'air. Ne pas utiliser le radiateur sur une surface molle, comme

un lit, où les ouvertures peuvent se boucher. Nettoyer aussi souvent que possible pour éviter que la poussière ne bouche la grille

ou les ailettes de l'élément. Gardez tous les fils électriques, rideaux,

papiers, plastiques et autres combustibles à l'écart du radiateur.

11. L'air doit sortir du radiateur parallèle aux murs adjacents.

12. Un radiateur contient des pièces chaudes et produisant des arcs

électriques ou des étincelles. Ne pas l'utiliser dans des zones de

remisage ou d'utilisation d'essence, de peinture ou d'autres liquides

inflammables.

13. Si le radiateur ou son cordon sont endommagés ou fonctionnent

mal de quelque manière que ce soit, couper le courant au panneau

d'alimentation principal, arrêter de se servir du radiateur et le faire

réparer par un technicien qualifié.

14. Ne pas faire fonctionner le radiateur sans support.

15. Si le radiateur doit être fixé au mur ou au plafond, les dispositifs

d'ancrage doivent être assez forts pour supporter tout le poids du

radiateur plus celui du dispositif de fixation. Ne pas bloquer correctement les supports de la structure du bâtiment peut faire

tomber le radiateur.

CONSERVER CES INSTRUCTIONS

Page 10

Charactéristiques

MIN

8" TO

CEILING

TO WALL

MIN 8"

MIN. 8"

TO WALL

MIN. 8"

TO WALL

ELEMENTS FRONT

MIDDLE

REAR

HEAT SW.

HI

LOW

1

2

3

2

3

1

AUTO

FAN SW.

ON

TERMINAL BLOCK

6

4

INDICATOR LIGHT

MANUAL RESET

THERMAL LIMIT

BLACK

GREEN

BLACK

SUPPLY LEADS

WIRING COMPARTMENT

FAN

DELAY

MOTOR

L1

OFF

CYL

L2

THERMOSTAT

Tension du radiateur 240 / 208 Vca A

Puissance nominale en kw

: à 240V 5,0 Kv max 21

3,3 Kv min 14

à 208V 3,7 Kv max 18

2,5 Kv min 12

imensions: 406 mm h x 533 mm l x 203 mm p

D

Poids: 10 kg

GÉNÉRALITÉS

Emplacement du radiateur

Ce radiateur a des boutons de commande. Il peut être

ouhaitable de les atteindre après l'installation.

s

La sortie d'air ne doit pas être restreinte par des colonnes, des

machines, etc. et l'air doit sortir en frôlant les murs exposés

plutôt que de souffler directement sur eux. Lorsque plus d'un

radiateur est utilisé dans la zone, les radiateurs doivent être disposés pour que la sortie d'air de chaque radiateur supporte la

sortie d'air des autres pour assurer une meilleure circulation de

l'air chaud.

Hauteur de fixation

Lorsque l'air sort verticalement du radiateur, la hauteur minimum

de fixation est de 1,8 m et la maximum de 4,6 m. Lorsque le

débit d'air sort horizontalement du radiateur, la hauteur minimum

de fixation recommandée est de 1,8 m et la maximum de 2.4 m.

FIXATION AU PLAFOND

Ce radiateur peut être fixé à tout plafond qui supporte le poids

du radiateur.

Commencer par déposer le support de fixation du radiateur, puis

déposer quatre rondelles en caoutchouc du support. Bloquer le

support aux membres structurels du plafond avec quatre

boulons de 1/4 po de diamètre (non fournis). Dans les solives

de bois, utiliser des tire-fonds longs de 1 1/2 po. Dans les

poutres en acier utiliser des boulons décolletés bloqués par des

écrous et des rondelles frein. Ne jamais utiliser de boulons de

moins de 1/4 po de diamètre.

Remettre le radiateur dans le support et serrer les boutons pour

bloquer en place. Deux grosses rondelles en caoutchouc vont

entre le radiateur et le support, une de chaque côté.

MIN. DE

203 mm PAR

RAPPORT

AU MUR

MIN. DE

203 mm PAR

RAPPORT

AU

MUR

UTILISER DES TROUS

CIRCULAIRES POUR

FIXER LE RADIATEUR

AU PLAFOND. NE PAS

UTILISER DE TROUS

EN FORME DE TROU

DE SERRURE.

TROU CIRCULAIRE

POUR EMPÊCHER LE RADIATEUR DE TOMBER, NE PAS

UTILISER DE FENTES EN FORME DE TROU DE SERRURE

POUR LE FIXER AU PLAFOND, CONSULTER AUSSI

L'AVERTISSEMENT Nº 15.

FIXATION AU MUR

VOIR L'AVERTISSEMENT Nº 15

ENTE EN TROU

F

E SERRURE

D

UTILISER DES

FENTES EN TROU

E SERRURE POUR

D

FIXER LE RADIATEUR AU MUR

203 mm

MIN PAR RAP-

PORT

AU MUR

TROUS DE FIXA-

TION ESPACÉS DE

06 MM CENTRE À

4

CENTRE

Ce radiateur peut être fixé sur n'importe quel mur qui supporte

le poids du radiateur. Tout d'abord, retirer le support de fixation

du radiateur, puis déposer quatre rondelles en caoutchouc du

support. Bloquer le support sur les poutres structurelles du mur

avec quatre tire-fonds de 1/4 po de diamètre longs de 38 mm

(non fournis). Dans les murs en maçonnerie, utiliser des

blindages d'expansion métalliques ou des boulons de scellement. Ne jamais utiliser de boulons de moins de 1/4 po.

Remettre le radiateur dans le support et serrer les boutons pour

bloquer en place. Deux grandes rondelles en caoutchouc vont

entre le radiateur et le support, une de chaque côté.

BRANCHER L'ALIMENTATION

Matériel nécessaire

Il faut également le matériel suivant à acheter chez le quincailli-

er local ou dans un magasin de fournitures électriques :

• Assez de fil de cuivre de jauge 10 pour amener l'alimentation

du boîtier d'alimentation au radiateur. Le fil de cuivre doit

avoir une température nominale minimum de 60 degrés C.

NE PAS UTILISER DE FIL EN ALUMINIUM AVEC CE

RADIATEUR.

• des connecteurs de fils appropriés pour votre application.

(Voir l'illustration suivante).

COMMUTATEUR

CHAUFFAGE

AUTO

Français 2

FILS D'ALIMENTATION

NOIR

VERT

NOIR

COMPARTIMENT DE CÂBLAGE

DISJONCTEUR THERMIQUE

À RÉARMEMENT MANUEL

ÉLÉMENTSAVANT

INTERMÉDIAIRE

ARRIÈRE

MOTEUR

TÉMOIN LUMINEUX

ARRÊT

CYCLE

THERMOSTAT

COMMUTATEUR

VENTILATEUR

BORNIER

03 mm MIN

2

AR RAP-

P

ORT AU

P

LAFOND

P

DÉLAI

VENTILA-

TEUR

MAX

MIN

Page 11

Connecteur

Conduit

Câble flexible NM

Connecteurs, câbles et matériel utilisés pour câbler le MUH35C

de conduit

Conduit flexible

onnecteur de conduit flexible

C

Connecteur de câble flexible NM

Pour certaines applications, un conduit peut s'avérer nécessaire.

Consulter les codes électriques locaux à ce sujet. De plus, si le

câblage est passé dans un conduit, pour pouvoir mettre le radiateur en marche, s'assurer d'acheter assez de conduit flexible

pour cela.

Desserrer les deux vis qui bloquent le couvercle du compartiment de câblage sur le côté supérieur droit du dos du radiateur

et déposer le couvercle.

Fixer le connecteur de câble sur le couvercle comme illustré cidessus et glisser le fil de jauge 10 dans le connecteur de câble.

Tirer assez de fil dans le connecteur pour pouvoir faire les connexions.

Connecter le câblage d'alimentation au câblage du radiateur

comme illustré dans le schéma de câblage.

Après avoir connecté le câblage, remettre en place le couvercle

du compartiment de câblage en s'assurant qu'aucun fil ne soit

pincé entre le couvercle et le radiateur. Serrer fermement les

vis

CONNEXION OPTIONNELLE PAR PRISE

Si ce radiateur doit être converti en modèle connecté par un cordon, il faut utiliser le fil numéro de modèle PHCS1B. Consulter

les instructions jointes au fil pour l'installer sur le radiateur.

LE MUH35C PEUT ÊTRE CONVERTI EN UN MODÈLE CONNECTÉ PAR FIL UNIQUEMENT PAR L'ADDITION DU FIL

QMARK NUMÉRO DE MODÈLE PHCS1B. L'UTILISATION

DE TOUT AUTRE CORDON PEUT ENTRAÎNER UN

INCENDIE OU UNE ÉLECTROCUTION.

CHAUFFAGE

Pour utiliser le radiateur, commencer par sélectionner la position

max ou min sur le commutateur de chauffage, puis tourner le

bouton du thermostat à fond dans le sens des aiguilles d'une

montre. Le témoin lumineux s'allume et reste allumé tant que le

radiateur est en mode de fonctionnement. Lorsque la température ambiante atteint le niveau désiré, tourner lentement le bouton du thermostat dans le sens inverse des aiguilles d'une montre jusqu'à ce que le thermostat clique. Le témoin lumineux

reste allumé. Le radiateur fait automatiquement des cycles de

marche et d'arrêt autant de fois que nécessaire pour atteindre la

température désirée. Pour couper le radiateur, tourner le bouton du thermostat à fond dans le sens inverse des aiguilles

d'une montre jusqu'à ce que le témoin lumineux s'éteigne.

Le commutateur du ventilateur permet un fonctionnement continu ou intermittent du ventilateur en choisissant respectivement

es positions "ON" (marche) ou "auto".

l

Délai automatique de ventilateur : Ce radiateur comporte un

délai automatique de ventilateur. Lorsque le thermostat

emande de la chaleur, l'action du ventilateur est retardée

d

momentanément jusqu'à ce que l'élément chauffant soit chaud.

Lorsque le thermostat est satisfait, le ventilateur continue de

fonctionner jusqu'à ce que l'élément chauffant soit frais. Cette

ction empêche la circulation de l'air froid et évite d'exposer l'ap-

a

pareil à la chaleur résiduelle, assurant ainsi plus de confort et

une durée de vie prolongée de l'élément.

NETTOYAGE

Couper le thermostat. Débrancher l'alimentation avant de nettoyer le radiateur. Utiliser un chiffon doux pour le dépoussiérer.

Le nettoyer avec un chiffon humide et du produit vaisselle non

abrasif. Ne pas utiliser de nettoyants abrasifs ni chimiques car

ils peuvent abîmer le fini.

Si le radiateur est utilisé dans un lieux très poussiéreux, utiliser

une brosse dépoussiérante d'aspirateur pour retirer la poussière

et les corps étrangers des grilles.

ENTRETIEN

Ce radiateur ne nécessite pas d'entretien de routine à part le

nettoyage occasionnel pour éviter le colmatage de l'ouverture de

la grille d'air d'admission. Pour nettoyer cette grille, utiliser un

aspirateur équipé d'une brosse ou de l'air haute pression. Le

moteur est lubrifié en permanence.

Ne pas utiliser le radiateur s'il est défectueux ou s'il a été détérioré de quelque manière que ce soit.

Appelez au numéro sans frais pour de l'aide.

POUR RÉARMER LE DISJONCTEUR THERMIQUE

Le radiateur est équipé d'un disjoncteur thermique à réarmement manuel qui coupe automatiquement le radiateur pour

empêcher un incendie en cas de surchauffe du radiateur. Il est

sur le devant du radiateur juste au-dessus du thermostat et est

marqué "PUSH TO RESET" (POUSSER POUR RÉARMER).

Pour le réarmer, laisser le radiateur refroidir puis appuyer simplement sur le bouton rouge jusqu'à ce qu'il s'enclenche. Le

radiateur doit retourner immédiatement au fonctionnement normal.

LE FONCTIONNEMENT DU DISJONCTEUR THERMIQUE

INDIQUE QUE LE RADIATEUR A ÉTÉ SOUMIS À UNE CONDITION ANORMALE. IL EST RECOMMANDÉ DE FAIRE

INSPECTER LE RADIATEUR PAR UN ÉLECTRICIEN OU UN

DÉPANNEUR QUALIFIÉS POUR VÉRIFIER QU'IL N'EST PAS

ENDOMMAGÉ.

Français 3

Page 12

IDENTIFICACION DE LAS PIEZAS DE REPUESTO

NO. DE

REF.

1.

2.

.

3

.

4

.

5

.

6

7.

8.

9.

0.

1

1.

1

2.

1

3.

1

14.

15.

16.

17.

8.

1

9.

1

0.

2

21.

22.

23.

24.

25.

DESCRIPCION

Guarda del elemento

Conjunto del elemento

Resorte del elemento

apilar del resorte

C

onmutador oscilante

C

ejilla

R

uz indicadora

L

Perilla del termostato

Termostato

Límite de la regraduación manual

Bloque terminal

oporte, Tornillo de la cubierta

S

ubierta, Componente de control

C

erilla, Base

P

Base, Portátil

Anillo, Base

Hélice, Ventilador

otor

M

Caja, Parte Posterior

Buje, Escape de Esfuerzo

Comp. de cableado, divisor

Cableado, Placa de Cubierta

Soporte, Montaje

Arandela, Goma

Demora del Ventilador

NO. DE PIEZA

2504-0011-001

1802-0087-032

208-0073-000

5

208-0072-000

5

99814893A000

S

402-2154-001

1

3510-2007-000

3301-2012-001

5813-2018-000

520-11004-000

4

823-0003-001

5

215-0291-000

1

1402-0336-000

3301-2018-000

5210-2000-004

2502-2000-000

210-2000-000

1

3900-2002-006

1425-2005-002

25221-70011

614-2000-000

1

503-2010-002

4

1215-2001-002

W10814895A000

4520-0010-000

25

Tous les produits fabriqués par Marley Engineered Products sont garantis contre les défauts de fabrication et de matériau pendant une année à compter de leur date

GARANTIE LIMITÉE

d’installation, sauf les éléments chauffants, lesquels sont garantis contre les défauts de fabrication et de matériau pendant dix ans à compter de la date d’installation.

Cette garantie ne couvre pas les dommages causés par un accident, une mauvaise utilisation ou une altération et ne s’applique pas si la tension d’alimentation dépasse

de 5% ou plus celle de la plaque signalétique, si l’équipement est mal installé, mal câblé ou mal entretenu, contrairement aux instructions d’installation et d’utilisation du

produit. Toutes les réclamations sous garantie doivent être accompagnées d’une preuve de date d’installation.

Le client sera responsable de tous les coûts encourus pour enlever et réinstaller le produit, ce qui inclut les frais de main d’œuvre et les frais de port encourus pour

retourner le produit au centre de réparation de la société Marley Engineered Products. Sous réserve des restrictions figurant dans cette garantie, tout appareil

défectueux doit être retourné au centre de réparation agréé par Marley le plus près ou au centre de réparation de la société Marley Engineered Products. Il sera ensuite

gratuitement réparé ou remplacé, à notre discrétion, et les frais de port de retour seront pris en charge par Marley. Il est entendu que cette réparation ou ce remplacement constitue le seul et unique recours disponible auprès de la société Marley Engineered Products.

LA GARANTIE CI-DESSUS REMPLACE ET PRÉVAUT SUR TOUTE AUTRE GARANTIE EXPRESSE OU IMPLICITE ET TOUTE GARANTIE IMPLICITE DE COMMERCIALISATION OU DE CONVENANCE À UN USAGE QUELCONQUE ALLANT AU-DELÀ DE LA GARANTIE EXPRESSE CI-DESSUS EST PAR LES PRÉSENTES

RÉFUTÉE ET EXCLUE DE CETTE ENTENTE. LA SOCIÉTÉ MARLEY ENGINEERED PRODUCTS NE PEUT SOUS AUCUNE CIRCONSTANCE ÊTRE RESPONSIBLE DE QUELQUE DOIMMAGE ACCESSOIRE ASSOCIÉ À CE PRODUIT, SANS QU’IL SOIT POSSIBLE D’INVOQUER UNE NÉGLIGENCE, UN DÉLIT CIVIL, UNE

RESPONSABILITÉ STRICTE OU UNE OBLIGATION CONTRACTUELLE.

Puisque certaines juridictions interdisent d’exclure ou de limiter les dommages indirects et accessoires, il est possible que les exclusions et restrictions ci-dessus ne s’appliquent pas à vous. Cette garantie vous accorde des droits juridiques spécifiques, mais il est possible que vous ayez également d’autres droits selon votre lieu de résidence.

Pour connaître l’adresse du centre de réparation agréé le plus près, contactez la société Marley Engineered Products à Bennettsville (Caroline du Sud) au 1-800-642-

4328. Les produits retournés à l’usine doivent être accompagnées d’un numéro d’autorisation de retour et d’une étiquette d’identification de service, tous deux

disponibles auprès de la société Marley Engineered Products. Lorsque vous demandez une autorisation de retour, indiquez tous les numéros de catalogue indiqués sur

les produits.

POUR OBTENIR UNE RÉPARATION OU DES

PIÈCES SOUS GARANTIE, DE MÊME QUE DES

INFORMATIONS GÉNÉRALES

1. Réparations et pièces sous garantie 1-800-642-4328

2. Achat de pièces de rechange 1-800-654-3545

3. Informations générales sur les produits www.marleymep.com

Remarque : Lorsque vous demandez une intervention, ayez toujours

en main les informations suivantes :

1. Numéro de modèle du produit

2. Date de fabrication

3. Numéro de pièce ou description

Numéro de pièce 5200-2197-006

ECR 38424

08/09

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...