Page 1

QLogic 12000 Hardware Installation Guide

D000140-001 B

Page 2

QLogic 12000 Hardware Installation Guide

S

Information furnished in this manual is believed to be accurate and reliable. However, QLogic Corporation assumes no

responsibility for its use, nor for any infringements of patents or other rights of third parties which may result from its

use. QLogic Corporation reserves the right to change product specifications at any time without notice. Applications

described in this document for any of these products are for illustrative purposes only. QLogic Corporation makes no

representation nor warranty that such applications are suitable for the specified use without further testing or

modification. QLogic Corporation assumes no responsibility for any errors that may appear in this document.

Document Revision History

Revision B, March, 2010

Changes Sections Affected

12800-120 installation procedures

12300 18-port information

8x configuration procedures

12300 Six-port license information

All

Page ii D000140-001 B

Page 3

Table of Contents

Preface

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

License Agreements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1 Installation

Planning the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Cable Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Cable Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Cable Handling and Bend Radius . . . . . . . . . . . . . . . . . . . . . . . 1-3

Uninterruptible Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Installation Tasks Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Tools and Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Check the Installation Site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Mark the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

12200/12300 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Four Post Standard-Depth Rack Installation . . . . . . . . . . . . . . . . . . . . 1-7

Mounting Hardware Kit Contents:. . . . . . . . . . . . . . . . . . . . . . . . 1-7

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

12200 Four Post Shallow-Depth Rack Installation . . . . . . . . . . . . . . . 1-9

Mounting Hardware Kit Contents:. . . . . . . . . . . . . . . . . . . . . . . . 1-9

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

12800-040 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Mounting Hardware Kit Contents: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Installation Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

12800-120 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Mounting Hardware Kit Contents: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Installation Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

12800-180 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Mounting Hardware Kit Contents: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

D000140-001 B iii

Page 4

QLogic 12000 Hardware Installation Guide

Selecting a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Installation Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

12800-360 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Mounting Hardware Kit Contents: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Selecting a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Locating Rack Mounting Posts for Front and Back Cable Routing 1-35

Installation Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Connect Equipment to the Ports and Power On the System . . . . . . . . . . . . 1-47

Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-48

Bringing Up the System For the First Time . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

Start-up Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

Changing the Switch IP Address and Default Gateway via the CLI . . 1-49

Updating the Management Module IP Addresses in a Redundant

Management Configuration (12800-040, 12800-180 and 12800-360) 1-51

Enabling 8X Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-52

Creating an 8x Port: 12200/12300 . . . . . . . . . . . . . . . . . . . . . . . 1-53

Creating an 8x Port: 12800 Series . . . . . . . . . . . . . . . . . . . . . . . 1-55

Component LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

Management Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

Module Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

Module Attention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

Chassis Status and Attention . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-59

Fault Tolerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-59

Service Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-59

Master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-59

MRL Active . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-60

Leaf Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-61

IB Port LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-61

Module Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-61

Module Attention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-61

Spine Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-62

Module Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-62

Module Attention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-62

SEEB Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-63

RJ45 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-63

MRL Active . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-63

S

iv D000140-001 B

Page 5

QLogic 12000 Hardware Installation Guide

A

12200 and 12300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-64

IB Port LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-64

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-64

Attention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-64

RJ45 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-65

12800 Fans and Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-65

Fan LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-65

Power Supply LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-66

Switch-Based QLogic Fabric Manager License Key . . . . . . . . . . . . . . . . . . 1-67

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-68

QLogic 12000 Six-Port Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-74

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-75

A QLogic 12000 Series Product Specifications

Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

12200 and 12300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Cooling and Thermal Management: . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

12800 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Power Distribution Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

B Safety and Regulatory Compliance Information

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Statement 1: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Statement 2: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Statement 3: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Statement 4: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Statement 5: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Statement 6: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Statement 7: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

C Serial Port Pinouts

D FRU Replacement

QLogic 12200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Chassis Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

QLogic 12300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

D000140-001 B v

Page 6

QLogic 12000 Hardware Installation Guide

Chassis Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Fan/Power Supply Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

QLogic 12800 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Power Supply Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Leaf Module Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

Spine Module Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Management Module Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . D-10

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-10

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-10

S

vi D000140-001 B

Page 7

Preface

This manual describes the hardware installation and initial configuration tasks

for the QLogic 12000 series that includes:

• The QLogic 12200 36-port fixed-configuration InfiniBand switch

• The QLogic 12300 36-port configurable InfiniBand switch

• The QLogic 12300 18-port configurable InfiniBand switch

• The QLogic 12800 series:

12800-040

12800-120

12800-180

12800-360

This manual is organized as follows:

Preface describes the intended audience and technical support.

Section 1 describes the hardware installation and initial configuration tasks.

Appendix A provides product specification information.

Appendix B provides product safety and regulatory information.

Appendix B provides serial port pinout information.

Appendix C provides FRU replacement information.

Intended Audience

This manual is intended to provide network administrators and other qualified

personnel a reference for hardware installation and initial configuration for the

switches.

License Agreements

Refer to the QLogic Software End User License Agreement for a complete listing

of all license agreements affecting this product.

D000140-001 B Page 1

Page 8

Preface

Technical Support

Technical Support

Customers should contact their authorized maintenance provider for technical

support of their QLogic switch products. QLogic-direct customers may contact

QLogic Technical Support; others will be redirected to their authorized

maintenance provider.

Visit the QLogic support Web site listed in Contact Information for the latest

firmware and software updates.

Availability

QLogic Technical Support for products under warranty is available during local

standard working hours excluding QLogic Observed Holidays.

Contact Information

Support Headquarters QLogic Corporation

S

4601 Dean Lakes Blvd.

Shakopee, MN 55379

USA

QLogic Web Site www.qlogic.com

Technical Support Web Site support.qlogic.com

Technical Support Email support@qlogic.com

Technical Training Email tech.training@qlogic.com

Support phone numbers are available in

the Contact Support area of the QLogic

support website:

support.qlogic.com

Page 2 D000140-001 B

Page 9

1 Installation

This section describes how to install and configure for first-time use:

• The QLogic 12000 switches in a network environment.

Planning the Installation

The 12000 is designed to be installed in an existing 19-inch equipment rack or

server rack.

NOTE:

These switches are designed for a four-post server cabinet. Do not mount in

a two-post telco cabinet.

Racks should conform to conventional standards. Use the American National

Standards Institute (ANSI)/Electronic Industries Association (EIA) standard

ANSI/EIA-310-D-92 and International Electrotechnical Commission (IEC) 297

Racks should meet the following mechanical recommendations:

• Four-post, 19" rack to facilitate easy maintenance

• Universal mounting rail hole pattern identified in IEC Standard 297

• Mounting holes flush with the rails to accommodate the chassis

NOTE:

Operation is subject to the following conditions:

Use a rack grounding kit and a ground conductor that is carried back to earth or to

another suitable building ground. Ground the equipment rack to earth ground.

Provide enough room to work on the equipment. Clear the work site of any

unnecessary materials. Make sure the equipment will have enough clearance for

front and rear access.

D000140-001 B 1-1

Page 10

Installation

Planning the Installation

Cable Requirements

Cable Distances

When planning the location of the switches, consider the distance limitations for

signaling, EMI, and connector compatibility. It is recommended that the user does

not exceed specified transmission rate and distance limits.

Cable Guidelines

NOTE:

Building and electrical codes vary depending on the location. Comply with

all code specifications when planning the site and installing cable.

When running cable to the equipment, consider the following:

• Do not run cables where they can be stepped on or rolled over.

• Be sure cables are intact with no cuts, bends, or nicks.

• If the user is making a cable, ensure that the cable is properly crimped.

S

• Provide proper strain relief for IB cables.

• Support cables using a cable manager mounted above connectors to avoid

unnecessary weight on the cable bundles.

• Bundle cable using velcro straps to avoid injuring cables.

• Keep all ports and connectors free of dust.

• Untwisted Pair (UTP) cables can build up Electrostatic Discharge (ESD) charges

when being placed into a new installation. Before installing category 5 UTP

cables, discharge ESD from the cable by plugging it into a port on a system that

is not powered on.

• When required for safety and fire rating requirements, plenum-rated cable can

be used. Check the local building codes to determine when it is appropriate to

use plenum-rated cable, or refer to IEC standard 850.

1-2 D000140-001 B

Page 11

A

Cable Handling and Bend Radius

Provide proper strain relief by adhering to the following guidelines:

Table 1-1. IB Copper Cable Guidelines

Installation

Planning the Installation

IB Copper Cable Bend Radii

American Wire Gauge (AWG)

Size Cable

26 2.43 inches

28 2.28 inches

30 1.98 inches

For copper cable, the temporary 90-degree bend can never be more than 0.5

inches tighter than the values listed above for any assembly. This is the absolute

minimum sustained bend radius for each cable AWG size. This measurement is

the distance from the switch panel to the point where the cable makes a

90-degree bend. In other words, this number includes the distance from the

connector stand-off from the panel surface.

Bend Radius

Figure 1-1 Copper Cable Bend Radius

D000140-001 B 1-3

Page 12

Installation

Planning the Installation

Fiber Optic Standard Cable 25 millimeters

S

Table 1-2. IB Fiber Optic Cable Guidelines

IB Fiber Optic Cable Bend Radii

Cable Type Bend Radius

NOTE: A 50mm diameter is the smallest circle limit

Figure 1-2 Fiber Optic Bend Radius

Uninterruptible Power Supply

Consider the following when selecting Uninterruptible Power Supply (UPS)

equipment:

• The minimum amperage requirements for a UPS:

• Calculate VA (Volt-Amps): Locate the voltage and amperage requirements

for each piece of equipment (usually located on a sticker on the back or bottom

of the equipment). Multiply the numbers together to get VA.

• Add the VA from each piece of equipment together to find the total VA

requirement. Then add 30% to determine the minimum amperage

requirements for the UPS.

• Transition time (the time necessary for the UPS to transfer from utility power to

full-load battery power).

• The longest potential time period the UPS might be required to supply backup

power.

• Whether or not the UPS unit also provides online protection.

1-4 D000140-001 B

Page 13

A

Installation Tasks Checklist

To perform the actual switch installation, the site implementation engineer must

perform the following tasks, which are detailed in this section.

CAUTION!

Be sure to review the safety information before starting the installation and

during the installation process (refer to Appendix B).

1. Check the installation site to verify the installation of cabinet power feeds, rails,

and grounding.

2. Unpack the equipment and inspect for any shipping damage. Any shipping

damage should be reported to the shipping company.

3. Verify that the equipment shipped matches the packing list.

4. Mark the rack and install the mounting rails.

5. Physically install the switch in the rack.

Installation

Installation Tasks Checklist

Tools and Equipment Required

• An ESD wrist strap

• A #2 Phillips screwdriver

• An M6 HEX nut wrench

• Pen (felt-tip) to mark the mounting holes

• Lifting device (e.g., pallet jack) for the 12800-360 and 12800-180

Check the Installation Site

The switches are designed to be installed in an existing server cabinet (not a telco

cabinet), where it can be mounted in a standard equipment rack.

Be sure of the following:

• The cabinet has a full earth ground to provide reliable grounding.

• There is enough room to work on the equipment.

• The equipment will have enough clearance for front and rear access.

• The IB cables can be accessed easily.

• Water or moisture cannot enter the switch.

• The ambient temperature stays between

50° - 113°F (5° - 40° C).

• Cabinet doors do not interfere with front-to-back air flow.

The cabinet should have its own switchable power distribution. If the switch has two

power supplies, it is suggested that a cabinet with dual power distribution units is

used.

D000140-001 B 1-5

Page 14

Installation

Installation Tasks Checklist

It is recommended that cabinet anti-tip devices are used. This is especially true if

installing or removing a switch in the upper half of the cabinet when the lower half

is empty.

Mark the Rack

Allow enough vertical space in the rack for each specific switch installation.

1. Determine the location in the rack of the bottom of the switch.

2. Mark the upper (if applicable) and lower mounting positions on the vertical rails

on the front of the rack.

3. Mark the upper (if applicable) and lower mounting positions on the vertical rails

on the back of the rack.

S

1-6 D000140-001 B

Page 15

A

12200/12300 Installation

This section describes the rack mounting instructions for the 12200 and 12300:

Four Post Standard-Depth Rack Installation

In a standard-depth rack, the distance between the front and back mounting posts

is ~28" (700mm). Mounting rails for the 12200 and 12300 are adjustable to

accommodate racks with 26"-33" between mounting posts.

Mounting Hardware Kit Contents:

• One pair of mounting rails adjustable for 26"-33" installation range

• One pair of hat rails, left and right

• #6-32 screws

• M6 cage nuts

•M6 screws

Installation

12200/12300 Installation

Installation

1. Install the hat rails on each side of the switch using three (3) #6-32 screws per

rail. Torque screws to 8in-lb. A typical installation is shown in Figure 1-3. On

the 12300, hat rails are installed with mounting ears towards the power supply

side of the switch. On the 12200, hat rails are installed with mounting ears

towards the port side of the switch.

Figure 1-3 12200 and 12300 Hat Rails

2. Install eight (8) cage nuts into rack posts, two (2) cage nuts per post. Install the

mounting rails and fasten to cage nuts using six (6) M6 screws. Torque screws

to 30in-lb. Do not install two (2) screws in lower locations on equipment

installation side of the rack until the switch is installed in the rack. Note the

D000140-001 B 1-7

Page 16

Installation

12200/12300 Installation

orientation of mounting rails in Figure 1-4. The rails are shown from the front

side of the rack for 12300 or from the port side of the rack for 12200.

S

Figure 1-4 Installing the Rack Rails

1-8 D000140-001 B

Page 17

A

Installation

12200/12300 Installation

3. Slide the switch into the mounting rails and fasten with M6 screws, one (1) per

side. Torque screws to 30in-lb.

Figure 1-5 12200 and 12300 Four Post Standard Rack Mounting

12200 Four Post Shallow-Depth Rack Installation

In a shallow-depth rack, the distance between the front and back mounting posts

is ~16" (400mm). Mounting rails for the 12200 are adjustable to accommodate

racks with 14"-20" between mounting posts.

Mounting Hardware Kit Contents:

• One pair of C-brackets

• One pair of hat rails, left and right

• #6-32 screws

• M6 cage nuts

D000140-001 B 1-9

Page 18

Installation

12200/12300 Installation

•M6 screws

Installation

1. Install the hat rails with mounting ears towards the port side of the switch. Fasten

with three (3) #6-32 screws per rail. Torque screws to 8in-lb.

S

Figure 1-6 12200 Hat Rails

2. Install six (6) cage nuts into the rack posts. Two cage nuts into posts on the

front side of the rack and four cage nuts into posts in the rear of the rack. Note

that the front of the rack is where the switch is installed.

1-10 D000140-001 B

Page 19

A

Installation

12200/12300 Installation

3. Install two C-brackets in the rear of the rack. Fasten to the rack posts with four

(4) M6 screws. Slide the switch from the front of the rack into the C-brackets

and fasten to the front posts with two (2) M6 screws. Torque to 30in-lb.

Figure 1-7 12200 Four Post Shallow Rack Mounting

D000140-001 B 1-11

Page 20

Installation

12800-040 Installation

12800-040 Installation

NOTE:

The following procedures are for installing the switch using variable

distances between the front and rear rack posts.

Mounting Hardware Kit Contents:

NOTE:

The mounting kit contains all of the necessary parts for installing and

mounting the switch into a 19" 4-post server rack, with a distance between

front and rear rack posts ranging from 28" - 33" (711mm - 838mm).

• Support Rails

•HAT Brackets

• C-Brackets

S

• #8-32 Flat Head Screws

• M6 Mounting Screws

• M6 Clip Nuts

1-12 D000140-001 B

Page 21

A

Installation Tasks

1. Install the clip nuts. Install M6 clip nuts in the following locations on EIA rails:

Figure 1-8 Clip Nut Installation Locations

Installation

12800-040 Installation

For improved stability, orient the clip nuts as shown (i.e., orient the flanges

horizontally):

Figure 1-9 Clip Nut Orientation

D000140-001 B 1-13

Page 22

Installation

12800-040 Installation

2. Install support rails in the rack. Fasten with two (2) M6 screws per EIA rail to

S

pre-installed clip nuts and torque to 30 in-lb.

Figure 1-10 Support Rail Installation

3. Orient the chassis such that mounting flanges are in the front of the rack. Install

the chassis in the rack. Fasten chassis to the rack with four (4) M6 screws.

Torque to 30in-lb.

WARNING!!

Fully-loaded:

43kg (95lbs)

To avoid injury, use a team of people appropriate to the weight of the

product and in conjunction with applicable laws and guidelines.

4. Fasten chassis to the rack with four (4) M6 screws. Torque to 30in-lb.

1-14 D000140-001 B

Page 23

A

Installation

12800-040 Installation

Figure 1-11 Rack Installation

5. If applicable, replace the door(s) on the rack.

D000140-001 B 1-15

Page 24

Installation

12800-120 Installation

12800-120 Installation

NOTE:

The mounting kit contains all of the necessary parts for installing and

mounting the switch into a 19" 4-post server rack, with a distance between

front and rear rack posts ranging from 28" - 33" (711mm - 838mm).

Mounting Hardware Kit Contents:

NOTE:

The mounting kit contains all of the necessary parts for installing and

mounting the switch into a 19" 4-post server rack, with a distance between

front and rear rack posts ranging from 28" - 33" (711mm - 838mm).

• Support Rails

•HAT Brackets

• C-Brackets

S

• #8-32 Flat Head Screws

• M6 Mounting Screws

• M6 Clip Nuts

1-16 D000140-001 B

Page 25

A

Installation Tasks

1. If applicable, remove the doors of the rack.

2. Install the clip nuts Install M6 clip nuts in the following locations on EIA rails:

Figure 1-12 Clip Nut Installation Locations

Installation

12800-120 Installation

For improved stability, orient the clip nuts as shown (i.e., orient the flanges

horizontally):

Figure 1-13 Clip Nut Orientation

D000140-001 B 1-17

Page 26

Installation

12800-120 Installation

NOTE:

It is recommended that 12800-120 is installed into the rack at 5U or 6U

location. This locates the chassis approximately 12" from the floor and

allows the chassis to be moved onto the support rails by sliding off of the

pallet.

3. Install support rails in the rack. Fasten with two (2) M6 screws per EIA rail to

S

pre-installed clip nuts and torque to 30 in-lb.

Figure 1-14 Support Rail Installation

1-18 D000140-001 B

Page 27

A

Installation

12800-120 Installation

4. Install two (2) rear mounting Hat Brackets on the chassis and fasten with #8-32

screws. There are four (4) screws per bracket. Torque to 30in-lb.

Figure 1-15 Hat Bracket Installation

5. Orient the chassis such that mounting flanges are in the front of the rack. Install

the chassis in the rack.

D000140-001 B 1-19

Page 28

Installation

12800-120 Installation

WARNING!!

To avoid injury, do not manually lift the chassis when fully loaded. Use a

mechanized lift whenever possible. For a manual lift, unload the product

FRUs to minimize the weight. Use a team of people appropriate to the weight

of the product, and in conjunction with applicable laws and guidelines.

S

Chassis only:

34kg (74lbs)

Fully-loaded:

91kg (199lbs)

Figure 1-16 Mounting Flange Installation

1-20 D000140-001 B

Page 29

A

Installation

12800-120 Installation

6. Fasten the chassis to the rack with eight (8) M6 screws. Torque to 30in-lb.

Figure 1-17 Chassis Installation

D000140-001 B 1-21

Page 30

Installation

12800-120 Installation

7. Slide two (2) C-brackets over the Hat brackets that are pre-installed on the

S

chassis.

Figure 1-18 C Bracket Installation

1-22 D000140-001 B

Page 31

A

Installation

12800-120 Installation

8. If applicable, install the optional cable management guides. Fasten to the EIA

rails with M6 screws. Torque all screws to 30in-lb.

Figure 1-19 Cable Management Installation

9. If applicable, replace the door(s) on the rack.

D000140-001 B 1-23

Page 32

Installation

12800-180 Installation

12800-180 Installation

Mounting Hardware Kit Contents:

NOTE:

The mounting kit contains all of the necessary parts for installing and

mounting the switch into a 19" 4-post server rack, with a distance between

front and rear rack posts ranging from 28" - 33" (711mm - 838mm).

• Support Rails

•HAT Brackets

• C-Brackets

• #8-32 Flat Head Screws

• M6 Mounting Screws

• M6 Clip Nuts

S

Selecting a Rack

The 12800-180 is a large InfiniBand switch capable of supporting up to 432

InfiniBand ports operating at QDR speed. It is designed for installations in

standard-width, 19"-mount server racks (total width of a rack is typically 24").

However, to effectively route and manage such a large number of cables, it is

recommended that a wide server rack is used for installation of 12800-180

switches. Wide 19"-mount server racks are typically 30-32" in total width.

Installation Tasks

NOTE:

It is recommended that 12800-180 is installed into the rack at 5U or 6U

location. This locates the chassis approximately 12" from the floor and

allows the chassis to be moved onto the support rails by sliding off of the

pallet.

1-24 D000140-001 B

Page 33

A

Installation

12800-180 Installation

1. If applicable, remove the doors of the rack.

2. Install M6 clip nuts in the following locations on EIA rails for U5 installation. For

U6 installation, increment clip nut locations by one U.

Figure 1-20 Clip Nut Locations

D000140-001 B 1-25

Page 34

Installation

12800-180 Installation

S

For improved stability, orient the clip nuts as shown (i.e., orient the flanges

horizontally):

Figure 1-21 Clip Nut Orientation

1-26 D000140-001 B

Page 35

A

Installation

12800-180 Installation

3. Install support rails in the rack. Fasten with two (2) M6 screws per EIA rail to

pre-installed clip nuts and torque to 30 in-lb.

Figure 1-22 Support Rail Installation

D000140-001 B 1-27

Page 36

Installation

12800-180 Installation

4. Install four (4) rear mounting brackets to the chassis and fasten with #8-32

S

screws. There are four (4) screws per bracket. Torque to 30in-lb.

Figure 1-23 Flat Bracket Installation

5. Orient the chassis such that mounting flanges are in the front of the rack. Install

the chassis in the rack.

1-28 D000140-001 B

Page 37

A

Installation

12800-180 Installation

WARNING!!

Chassis only:

45kg (100lbs)

Fully-loaded:

125kg (270lbs)

To avoid injury, when fully loaded do not lift manually. Use a mechanized lift

only. If a manual lift is necessary, first unload all field replaceable units

(FRUs) to minimize weight. Use a team of people appropriate to the weight

of the product and in conjunction with applicable laws and guidelines.

D000140-001 B 1-29

Page 38

Installation

12800-180 Installation

6. Fasten the mounting flanges using M6 screws to the clip nuts that are

S

pre-installed in the rack. There are six (6) screws per mounting flange. Torque

to 30in-lb.

Figure 1-24 Mounting Flange Installation

1-30 D000140-001 B

Page 39

A

Installation

12800-180 Installation

7. Slide four (4) C-brackets over the HAT brackets that are pre-installed on the

chassis.

Figure 1-25 U Bracket Installation

D000140-001 B 1-31

Page 40

Installation

12800-180 Installation

8. If applicable, install the optional cable management guides. Fasten to the EIA

S

rails with M6 screws. Torque all screws to 30in-lb.

Figure 1-26 Cable Management Guide Installation

9. If applicable, replace the door(s) on the rack.

1-32 D000140-001 B

Page 41

A

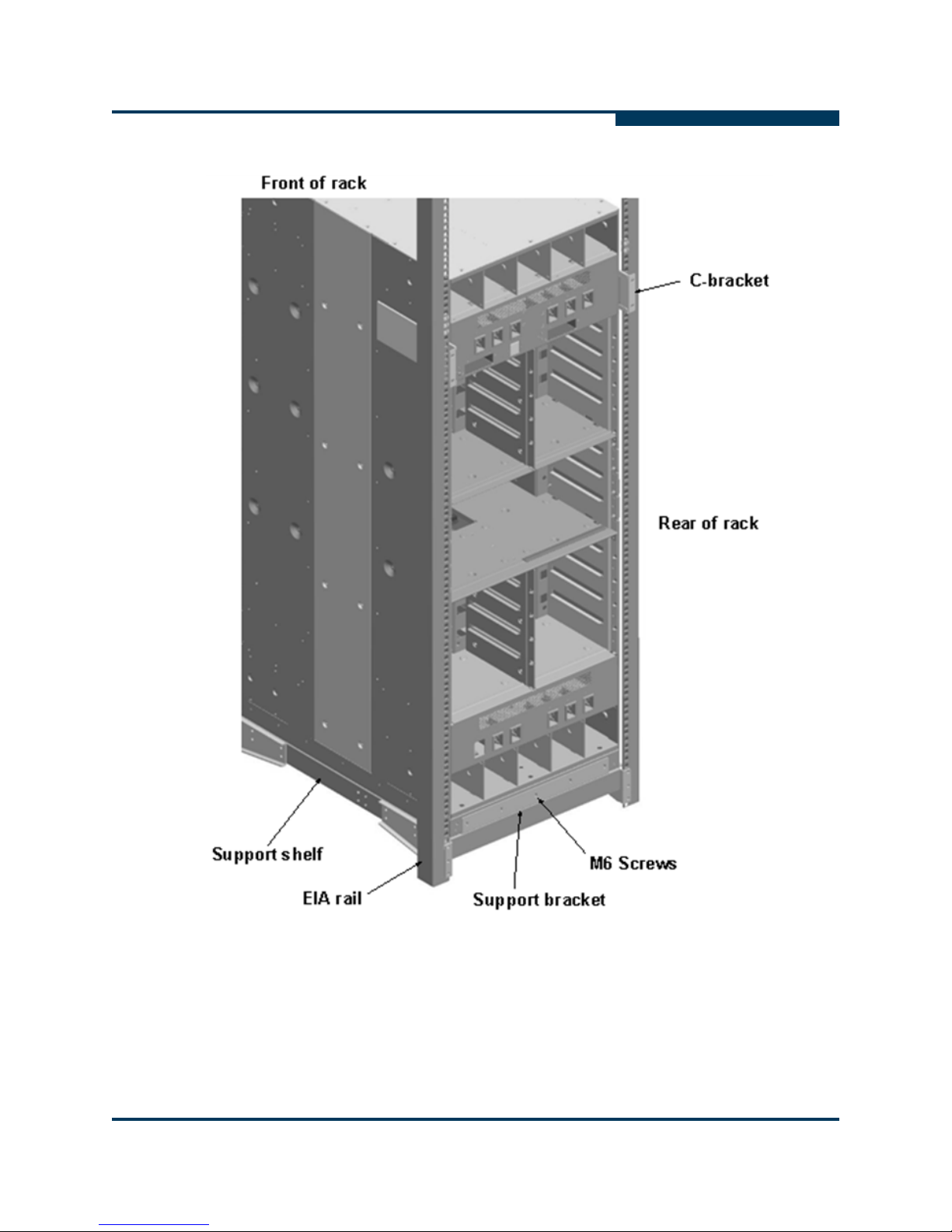

12800-360 Installation

Mounting Hardware Kit Contents:

NOTE:

The following procedures are for installing the switch using variable

distances between the front and rear rack posts.

• Mounting Kit containing:

• Support Shelf

•HAT Brackets

• C-Brackets

• #10 Mounting screws

• M6 Mounting Screws

• M6 Clip Nuts

Installation

12800-360 Installation

Selecting a Rack

12800-360 is the largest in the 12800-series of switches, capable of supporting up

to 864 InfiniBand ports operating at QDR speed. To facilitate installation and

management of such a large number of cables, the 12800-360 switch was

designed with cables in the front and the rear of the chassis. This reduces cable

density and improves cable management and accessibility.

To effectively route and manage cables, it is recommended that a wide server rack

is used for installation of the 12800-360 switch. These instructions are for

installation in a typical wide server rack 797mm wide x 1021mm deep, or similar,

with adjustable vertical EIA rails.

D000140-001 B 1-33

Page 42

Installation

12800-360 Installation

S

Figure 1-27 12800-360 Front and Rear Cabling

1-34 D000140-001 B

Page 43

A

Locating Rack Mounting Posts for Front and Back Cable Routing

In a typical rack, front EIA rails are positioned approximately 50mm from the front

face of a rack. With a chassis mounted flush with the front rails, space available in

the front the rack is insufficient for cable routing. To allocate enough space in the

front of the rack to route 300+ cables, the two front rails should be recessed

135mm from the front of the rack. The rear EIA rails should be positioned such

that the distance between mounting surfaces of front and rear EIA rails is 642mm.

Additionally, airflow recirculation control panels should be installed in a rack to

minimize airflow recirculation between the hot and cold isles. Recirculation

control panels for wide racks and installation instructions are available from rack

suppliers.

Figure 1-28 Locating Mounting Posts

Installation

12800-360 Installation

D000140-001 B 1-35

Page 44

Installation

12800-360 Installation

Installation Tasks

NOTE:

It is recommended that 12800-360 is installed into the rack at 5U or 6U

location. This will locate the chassis approximately 12" from the floor and

will allow the chassis to be moved onto the support rails by sliding off the

pallet.

1. Install clip nuts: If applicable, remove the doors of the rack. Install M6 clip

nuts in the following locations on EIA rails for U5 installation. For U6

installation, increment clip nut locations by one U (1.75”).

S

Figure 1-29 Clip Nut Installation

1-36 D000140-001 B

Page 45

A

Installation

12800-360 Installation

For improved stability, orient the clip nuts as shown (i.e., orient the flanges

horizontally):

Figure 1-30 Clip Nut Orientation

2. Attach four (4) mounting brackets to the support shelf as shown in

Figure 1-31. Align the brackets with "B" marks on a support shelf and fasten

with six (6) M6 HEX screws per bracket. Use a HEX socket wrench to

tighten the screws. Torque the screws to 120in-lb.

D000140-001 B 1-37

Page 46

Installation

12800-360 Installation

3. Attach the support bracket to the support shelf and fasten with seven (7)

S

#10-32 flat head screws. Torque screws to 30in-lb.

Figure 1-31 Support Shelf Assembly

1-38 D000140-001 B

Page 47

A

Installation

12800-360 Installation

4. Install the support shelf into the rack. Fasten the M6 screws to pre-installed

clip nuts and torque to 30 in-lb. There are three (3) screws per mounting

bracket.

Figure 1-32 Attaching the Support Shelf to the Rack

5. Orient and position the chassis for installation in the rack.

D000140-001 B 1-39

Page 48

Installation

12800-360 Installation

WARNING!!

To avoid injury, do not lift manually. Use a mechanized lift only.

S

Chassis only:

90kg (197lbs)

Fully-loaded:

244kg (535lbs)

1-40 D000140-001 B

Page 49

A

Installation

12800-360 Installation

6. Orientation of the chassis on a pallet: The chassis has been packaged on

sliding surfaces to facilitate installation in a rack by sliding off of the pallet

and on the support shelf. Remove the rear foam block to expose sliding

surfaces. The rear of the chassis is oriented towards a cutout in the bottom

tray.

Figure 1-33 Loading from the Pallet

D000140-001 B 1-41

Page 50

Installation

12800-360 Installation

7. Position the chassis on front on the rack. Use pallet jack to move the

S

chassis. Orient the chassis on a pallet in front of the rack as shown. Chassis

rear should be facing front of the rack. For installations in racks arranged in

rows, distance between adjacent rows of racks (width on a cold isle) should

be greater than 36" to be able to move the chassis on a pallet through a cold

isle.

Figure 1-34 Positioning the Switch

1-42 D000140-001 B

Page 51

A

Installation

12800-360 Installation

8. Installing the chassis in the rack: Align the chassis with the rack. Raise the

chassis using a pallet jack such that the bottom of the chassis is at or slightly

higher than the top surface of the support shelf pre-installed in the rack.

Lock the pallet jack wheels. Use a group of people to push the chassis from

the front to slide it off the pallet and on the support shelf. The chassis should

be inserted into the rack until the rear of the chassis base is against the rear

support bracket.

Figure 1-35 Sliding the Switch off the Pallet

D000140-001 B 1-43

Page 52

Installation

12800-360 Installation

9. Fasten the front of the chassis to the rack by installing the front support

Figure 1-36 Fasten the Chassis to the Front of the Rack

S

bracket and fasten to the base of the chassis with five (5) M6 screws. Fasten

to the support shelf with seven (7) #10-32 screws. Torque to 30 in-lb.

10. Fasten the rear of the chassis to the rack: Fasten the rear support bracket to

the base of the chassis with five (5) M6 screws. Torque to 30 in-lb.

11. Install two (2) C-brackets by sliding over the H-brackets that are pre-installed

on the chassis.

1-44 D000140-001 B

Page 53

A

Installation

12800-360 Installation

Figure 1-37 Fasten the Chassis to the Back of the Rack

D000140-001 B 1-45

Page 54

Installation

12800-360 Installation

12. Attach the cable management guides.

S

If applicable, attach the cable management guides to the front and rear EIA

mounting rails, and fasten with M6 screws to the pre-installed clip nuts. The

guides should be installed such that the wireframe supports line up with the

chassis leaf module slots. There are four (4) guides in the front of a rack and

four (4) in the rear of a rack.

Figure 1-38 Attaching Cable Management Guides

13. If applicable, replace the door(s) on the rack.

1-46 D000140-001 B

Page 55

Installation

A

Connect Equipment to the Ports and Power On the System

Connect Equipment to the Ports and Power On

the System

NOTE:

Before connecting equipment, it is important to understand the locations of

the serial and Ethernet ports on the 12200, 12300 and 12800 series. For the

12200 and 12300, these are located on the switch IB port side. For the 12800

series, these are located on the Serial, Ethernet, Chassis EEPROM Board

(SEEB) modules. Each SEEB module communicates with a Management

Module (MM) on the opposite side of a 12800 chassis.

Figure 1-39 12200 and 12300 Serial and Ethernet Ports

Figure 1-40 12800 Series Serial and Ethernet Ports (SEEB Module)

D000140-001 B 1-47

Page 56

Installation

Connect Equipment to the Ports and Power On the System

1. Connect a Category 5 or 6 (Cat 5/6) Ethernet cable to the RJ-45 connector(s)

on the switch. Connect the other end of the Cat 5/6 to an OOB LAN workstation,

another switch or a hub.

2. Connect the switch to IB-enabled host(s)/switch(es) using QDR QSFP IB

cables, or to DDR host(s)/switch(es) using a QSFP-CX4 cable.

NOTE:

Make sure all cables latch securely into the corresponding port connectors.

If the IB cable connector is not properly oriented to fit onto the port

receptacle (i.e., while attempting to insert the cable in the port), do not twist

the connector to achieve the correct orientation. Instead, reach back a few

feet on the cable, and twist the bulk cable to allow the connector to rotate to

the proper orientation. Doing this prevents all of the rotational forces from

acting right at the connector terminations.

CAUTION!

It is important to provide strain relief for the IB cable connector.

S

Connecting Power

NOTE:

For each power supply installed, a power cord must be installed in

corresponding power inlet.

1. Provide strain relief for the power cable(s).

2. If necessary, replace the fascia(s) over the switch fans.

3. Connect the power cables to a power distribution unit (PDU) or a proper AC

power outlet.

4. When the switch is plugged into an AC power outlet:

a. The system powers up.

b. The fans start.

c. The system performs a power-on self test (POST).

NOTE:

For the 12800 switches, make certain the DC On switch is illuminated. If it is

not, press the button to supply power.

5. The switch, power supply, and fan LEDs light up.

1-48 D000140-001 B

Page 57

A

Bringing Up the System For the First Time

Bringing Up the System For the First Time

Start-up Procedures

1. Power up the switch.

2. From its flash image on the management module, the switch begins its boot

process.

NOTE:

If the DB9 port of the SEEB module or the RS232 port on the 12200/12300 is

connected to a terminal emulation program, the user will be able to view the

switch boot process. Be certain to use a null-modem/crossover serial cable

for the console port. For users assembling their own cable, refer to

Appendix C for serial port pinout information. The settings for the terminal

emulation device should be:

•8 data bits

•no parity bits

Installation

• 1 stop bit

• 57.6K baud

• Use VT100 emulation.

• Flow control = XON/XOFF

3. Verify the IP address with the command line interface (CLI) command

showChassisIpAddr command. The system returns the information similar

to the following:

Chassis IP Address: 192.168.100.9 Net mask: 255.255.240.0

Changing the Switch IP Address and Default Gateway via the

CLI

The command line interface (CLI) can be accessed via Telnet, SSH, the SEEB

module DB-9 or 12200/12300 RS-232 serial port(s).

1. Determine the CLI access method (i.e., Telnet, SSH, or Serial).

D000140-001 B 1-49

Page 58

Installation

Bringing Up the System For the First Time

NOTE:

If using a serial port, skip to Step 6. Steps 2 through 5 are for those users

accessing the switch via Telnet or SSH. For the 12800 series, make certain

to connect to the SEEB serial port associated witht the Master Management

Module (MM). These are:

• 12800-040: MM 201

• 12800-120: MM 207

• 12800-180: MM 211

• 12800-360: MM 227

2. Connect appicable serial cables to the RS-232/DB-9 ports of the switch.

Connect the other end to a workstation. If using a terminal emulation device,

the settings should be:

•8 data bits

•no parity bits

S

• 1 stop bit

• 57.6K baud

• Use VT100 emulation.

• Flow control = XON/XOFF

3. If using Telnet or SSH, access the switch with the following command:

open 192.168.100.9

4. The system prompts for a user name. In order to change the IP address and

default gateway, the user must be logged in as the administrator. At the prompt

enter:

admin

5. The system prompts for a password. At the prompt enter:

adminpass

The system responds with:

Welcome to the <SWITCH> CLI. Type 'list' for the list of

commands.

6. To change the switch IP address enter:

setChassisIpAddr -h ipaddress -m netMask

where -h ipaddress is the new IP address in dotted decimal (i.e.,

xxx.xxx.xxx.xxx) format, and -m netMask is the new subnet mask in dotted

decimal (i.e., xxx.xxx.xxx.xxx) format.

1-50 D000140-001 B

Page 59

A

7. To change the switch default gateway IP address enter:

setDefaultRoute -h ipaddress

where -h ipaddress is the new default gateway IP address in dotted decimal

(i.e., xxx.xxx.xxx.xxx) format.

8. To to exit the CLI enter:

logout

Bringing Up the System For the First Time

Updating the Management Module IP Addresses in a

Redundant Management Configuration (12800-040,

12800-120, 12800-180 and 12800-360)

Each management module must have a unique IP address that is different than the

chassis IP address of the switch. Therefore, a redundantly-managed switch will

have multiple unique IP addresses.The default IP addresses are:

12800-040

• Chassis: 192.168.100.9

Installation

• Management Module 201: 192.168.100.10

• Management Module 202: 192.168.100.11

12800-120

• Chassis: 192.168.100.9

• Management Module 207: 192.168.100.10

• Management Module 208: 192.168.100.11

12800-180

• Chassis: 192.168.100.9

• Management Module 211: 192.168.100.10

• Management Module 212: 192.168.100.11

12800-360

• Chassis: 192.168.100.9

• Management Module 227: 192.168.100.10

• Management Module 228: 192.168.100.11

It is necessary for each management module to have a unique IP address for the

following reasons:

• Unique IP addresses are used when sending syslog messages from a managed

spine to a syslog server.

• Gives the user the ability to ping each management spine separately.

D000140-001 B 1-51

Page 60

Installation

Bringing Up the System For the First Time

• If the IP addresses are not unique, collisions will occur, causing IP operations to

fail.

To update the IP address on a management module, do the following:

1. Ensure that the module is connected to a COM port on a serial terminal device

via the RS-232 port (12200/12300) or DB-9 port (12800 series).

2. Get to a [boot]: prompt by following Step a or b.

a. If the management module is running and displays the -> prompt, enter the

following command at the console:

reboot now

Then press Enter.

b. If the module is not running, power on the switch.

3. When the system displays image1 or image2, press the Spacebar to interrupt

the auto load sequence before the counter expires (within 5 seconds).

4. At the [boot]: prompt type the following:

S

moduleip <NEW IP ADDRESS>

Then press Enter.

NOTE:

For versions previous to 5.0.2, use the command

NOTE:

This command changes the IP address for image1 and image2 on each

module.

5. At the [boot]: prompt enter reboot, and press Enter. Upon reboot the IP

address is changed. Repeat for the second Management Module.

Enabling 8X Ports

Users can enable 8X (10 Gbps) ports by combining two (2) 4X ports together (also

known as a “DUO”). The first port in a DUO is known as the master port; the second

port is the partner or slave port. The following CLI commands can enable 8x ports:

ismPortSetWidth: sets the supported link width for an individual IB port.

ismChassisSetWidth: sets the supported link width for all chassis IB

ports.

ismIslSetWidth: sets the supported link width for all interswitch link (ISL)

IB ports. This command is only available 12800-series switches.

spineip.

NOTE:

This section focuses on enabling 8x external cable ports. For details on

1-52 D000140-001 B

Page 61

A

each command, refer the QLogic 12000 CLI Reference Guide.

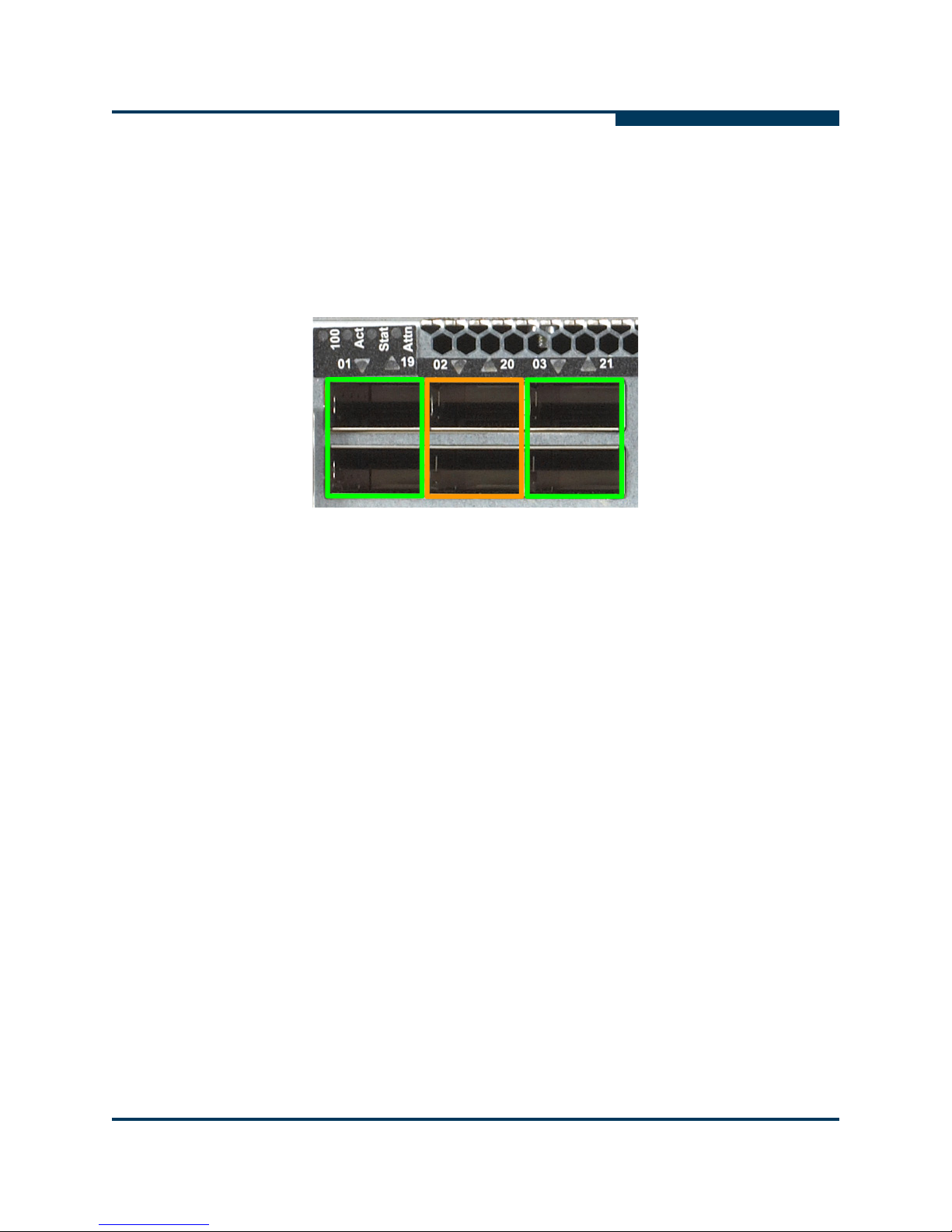

Creating an 8x Port: 12200/12300

For the 12200 and 12300 switches, 8x DUOs are set up by combining the 4X port

on the bottom row with the 4X port directly above it (e.g., port 1 with port 19, port 2

with 20, port 3 with port 21, etc.):

Figure 1-41 12200/12300 8x DUOs

Installation

Bringing Up the System For the First Time

For example, to combine ports 2 and 20:

1. Log into the switch CLI with the login admin and password adminpass.

2. Enable port 2 with a command similar to:

ismPortSetWidth Cable02 7 -bounce.

and press Enter.

3. Enable port 20 using same command as above, changing the port number

(i.e., Cable20).

4. At the switch, unplug and reinsert the cables to the physical ports. After

reinserting the first cable, the user has four (4) seconds to reinsert the

second cable associated with the 8x connection before the link begins

training.

NOTE:

For proper 8x functionality, it is required that both QSFP cables for a DUO

D000140-001 B 1-53

Page 62

Installation

Bringing Up the System For the First Time

are from the same manufacturer, as well as the same length.

5. After reinserting the cables, bring up Chassis Viewer. The 8X ports are

displayed as shown in Figure 1-42 where both ports of the DUO have LEDs

on.

Figure 1-42 8X Ports Enabled

6. From the Chassis Viewer main menu, click on Port Stats then IB Port Stats

to display the IB Port Statistics screen. The 8X port (for DUO of cable ports

10 and 28) is displayed as shown in Figure 1-43:

Figure 1-43 8X Port Statistics

S

The first port of the group (port 10) is shown as active and Up, while the other

port in the DUO (port 28) is displayed as down and Disabled.

1-54 D000140-001 B

Page 63

A

Creating an 8x Port: 12800 Series

For the 12800 switches, 8x DUOs are set up on the leaf modules as follows:

UHP Leaf (18 4x QDR ports): combine the 4X port on the bottom row with the 4X

port directly above it (e.g., port 1 with port 10, port 2 with 11, port 3 with port 12,

etc.).

UHD Leaf (24 4x QDR ports): for ports 1 through 18, combine the 4X port on the

bottom row with the 4X port directly above it (e.g., port 1 with port 10, port 2 with

11, port 3 with port 12, etc.). For ports 19 through 24 DUOs are made by combing

the ports sequentially (i.e., port 19 and port 20, port 21 and port 22, and port 23

and port 24).

Figure 1-44 12800 Leaf Module 8x DUOs

Installation

Bringing Up the System For the First Time

For example, to combine ports 8 and 17 on UHP leaf 111 in a 12800-180 switch:

1. Log into the switch CLI with the login admin and password adminpass.

2. Enable port 8 with a command similar to:

ismPortSetWidth L111P08 7 -bounce.

and press Enter.

3. Enable port 17 using same command as above, changing the port number

(i.e., L111P17).

4. At the switch, unplug and reinsert the cables to the physical ports. After

reinserting the first cable, the user has four (4) seconds to reinsert the

second cable associated with the 8x connection before the link begins

training.

D000140-001 B 1-55

Page 64

Installation

Bringing Up the System For the First Time

NOTE:

For proper 8x functionality, it is required that both QSFP cables for a DUO

are from the same manufacturer and the same length.

5. After reinserting the cables, bring up Chassis Viewer. The 8X ports are

displayed as shown in Figure 1-45 where both ports of the DUO have LEDs

on.

Figure 1-45 8X Ports Enabled

6. From the Chassis Viewer main menu, click on Port Stats then IB Port Stats

to display the IB Port Statistics screen. The 8X port (for DUO of cable ports 8

and 17) is displayed as shown in Figure 1-46:

S

Figure 1-46 8X Port Statistics

1-56 D000140-001 B

Page 65

A

Installation

Bringing Up the System For the First Time

The first port of the group (port 8) is shown as active and Up, while the other

port in the DUO (port 17) is displayed as down and Disabled.

D000140-001 B 1-57

Page 66

Installation

Component LEDs

Component LEDs

Management Module

Figure 1-47 Management Module LEDs

Module Status

The status LED indicates one of the following conditions:

S

• Steady Green - the module is operating normally.

• Blinking Green - LED test state.

• Off - module is in the removable state.

Module Attention

The Attention LED indicates one of the following conditions:

• Off - the system functioning normally.

• Steady Amber - the system requires some attention, which could indicate one

of the following conditions:

• The switch temperature is at a warning level on the module.

• The switch silicon temperature is at a warning level (approximately 90 degrees

• DC voltages on the board are slightly out of tolerance (12V Bulk, 5V, 3.3V

• The module can no longer function properly. The system will take the

• Blinking Amber (once every four seconds) - LED test state, which could indicate

one of the following conditions:

C).

and 1.8V are all monitored).

appropriate actions to ensure that no damage is done to its components.

• Bulk power is stable.

• The module DC-to-DC converter is enabled.

• The module is not removable.

1-58 D000140-001 B

Page 67

A

Chassis Status and Attention

The chassis status LED is Green when the system is functioning normally.

The chassis status LED is Amber when one of the following conditions exists:

• Any Fan Alarm is amber.

• Any power supply AC OK LED is off.

• Any power supply DC OK LED is off

• Any spine module Attention LED is on, or it has been determined that a spine is

not functioning (even if it is unable to light the LED).

• Any leaf module Attention LED is on, or it has been determined that a leaf is not

functioning (even if it is unable to light the LED).

The chassis status LED is Amber when the system can no longer function properly

and indicates one of the following conditions:

• No functional fan trays are present.

• No functional spines are present.

Installation

Component LEDs

• No functional leaves are present.

The chassis status LED is off when:

• There are no functional power supplies present.

• There are no management cards in the system

• AC power has been removed from the system.

Fault Tolerant

The Chassis Fault Tolerant (FT) LED indicates the following condition:

• Steady Green - the chassis is populated with a full complement of fans as well

as N+1 power.

Service Required

The Chassis Service Required (SVC) LED is not currently implemented.

Master

The Master LED is Green when module is acting as the master Management Module

(i.e., it is the master MM).

D000140-001 B 1-59

Page 68

Installation

Component LEDs

MRL Active

S

The MRL Active LED is Green when mechanical release latch (MRL) thumbscrew

is secured to the Serial, Ethernet, Chassis EEPROM Board (SEEB).

Figure 1-48 MRL Active LED

1-60 D000140-001 B

Page 69

A

Leaf Module

Installation

Component LEDs

Figure 1-49 Leaf Module LEDs

IB Port LEDs

Each module IB port has a Green IB link status LED that provide the following

indications:

• On - the logical link is up (port is in the Active state).

• Off - the physical link is down (port is in the Down state).

Module Status

The status LED indicates one of the following conditions:

• Steady Green - the module is operating normally.

• Blinking Green - LED test state.

• Off - module is in the removable state.

Module Attention

The Attention LED indicates one of the following conditions:

D000140-001 B 1-61

Page 70

Installation

Component LEDs

• Off - the system functioning normally.

• Steady Amber - the system requires some attention, which could indicate one

of the following conditions:

• The switch temperature is at a warning level on the module.

• The switch silicon temperature is at a warning level (approximately 90 degrees

• DC voltages on the board are slightly out of tolerance (12V Bulk, 5V, 3.3V

• The module can no longer function properly. The system will take the

• Blinking Amber (once every four seconds) - LED test state.

Spine Module

Figure 1-50 Spine Module LEDs (Double Spine Shown)

S

C).

and 1.8V are all monitored).

appropriate actions to ensure that no damage is done to its components.

Module Status

The status LED indicates one of the following conditions:

• Steady Green - the module is operating normally.

• Blinking Green - LED test state.

• Off - module is in the removable state.

Module Attention

The Attention LED indicates one of the following conditions:

• Off - the system functioning normally.

• Steady Amber - the system requires some attention, which could indicate one

of the following conditions:

• The switch temperature is at a warning level on the module.

1-62 D000140-001 B

Page 71

A

• The switch silicon temperature is at a warning level (approximately 90 degrees

• DC voltages on the board are slightly out of tolerance (12V Bulk, 5V, 3.3V

• The module can no longer function properly. The system will take the

• Blinking Amber (once every four seconds) - LED test state.

SEEB Module

Installation

Component LEDs

C).

and 1.8V are all monitored).

appropriate actions to ensure that no damage is done to its components.

Figure 1-51 SEEB Module LEDs

RJ45 LEDs

The RJ45 connectors have two LEDs, Act and 100. The 100 LED is Green when

a 100Mbps link is connected. The Act LED is Amber when an Ethernet link has

been established, and blinking when the link is active.

MRL Active

The MRL Active LED is Green when the mechanical release latch (MRL) thumbsrew

is secured to the Serial, Ethernet, Chassis EEPROM Board (SEEB) and a

Management Module is installed in the front of the chassis.

D000140-001 B 1-63

Page 72

Installation

Component LEDs

12200 and 12300

S

Figure 1-52 12200 and 12300LEDs

IB Port LEDs

Status

Attention

Each module IB port has a Green IB link status LED that provide the following

indications:

• On - the logical link is up (port is in the Active state).

• Off - the physical link is down (port is in the Down state).

The status LED indicates one of the following conditions:

• Steady Green - the module is operating normally.

• Blinking Green - LED test state.

• Off - module is in the removable state.

The Attention LED indicates one of the following conditions:

• Off - the system functioning normally.

• Steady Amber - the system requires some attention, which could indicate one

of the following conditions:

• The switch temperature is at a warning level on the module.

• The switch silicon temperature is at a warning level (approximately 90 degrees

C).

1-64 D000140-001 B

Page 73

A

• DC voltages on the board are slightly out of tolerance (12V Bulk, 5V, 3.3V

and 1.8V are all monitored).

• The module can no longer function properly. The system will take the

appropriate actions to ensure that no damage is done to its components.

• Blinking Amber (once every four seconds) - LED test state.

RJ45 LEDs

The RJ45 connectors have two LEDs, Act and 100. The 100 LED is Green when

a 100Mbps link is connected. The Act LED is Green when an Ethernet link has

been established, and blinking when the link is active.

12800 Fans and Power Supplies

Fan LEDs

Figure 1-53 12800 Fan LEDs

Installation

Component LEDs

Fan LEDs indicate the following status(es):

• Green indicates that the fan is functioning properly.

• Amber indicates that the following warning condition exists:

• A single fan failure when the rotation speed is less than 4000 RPM or greater

than 10950 RPM.

D000140-001 B 1-65

Page 74

Installation

Component LEDs

• Green and Amber on indicates a possible problem, including:

• The fan tray is not responding to commands for configuration and

temperature-related operations.

• A fan is not responding to commands for temperature and speed related

operations.

• The fan speed has fallen below the minimum allowed RPM for a fan.

Power Supply LEDs

S

Figure 1-54 12800 Power Supply LEDs

Each power supply has three LEDs: DC OK, AC OK and Alarm. Following are the

status definitions for each.

DC OK

• Green indicates that DC power is normal.

• Off indicates a DC power failure or no DC power is present.

AC OK

• Green indicates that AC power is normal.

• Off indicates a AC power failure or no AC power is present.

Alarm

• Amber indicates a fault condition, failed fan, over temperature condition.

1-66 D000140-001 B

Page 75

Installation

A

Switch-Based QLogic Fabric Manager License Key

Switch-Based QLogic Fabric Manager License

Key

If purchased, certain packages of the InfiniBand Fabric Suite entitle the user to the

switch-based QLogic Fabric Manager. Refer to the licensing documentation that

comes with the InfiniBand Fabric Suite for instructions on generating the license key.

Figure 1-55 InfiniBand Fabric Suite Licensing Information

D000140-001 B 1-67

Page 76

Installation

Switch-Based QLogic Fabric Manager License Key

Procedures

1. Record the IFS serial number.

2. Go to the QLogic Feature Activation/License Key web site

http://lk.qlogic.com

Figure 1-56 License Key Activation Center 1

.

S

3. Enter the InfiniBand Fabric Suite serial number. Click Continue. The system

validates the serial number and displays the following screen:

Figure 1-57 License Key Activation Center 2

1-68 D000140-001 B

Page 77

A

Installation

Switch-Based QLogic Fabric Manager License Key

4. Click Activate License Key and click Continue. The following screen is

displayed:

Figure 1-58 License Key Activation Center 3

D000140-001 B 1-69

Page 78

Installation

Switch-Based QLogic Fabric Manager License Key

5. Enter your email address in the Email: and Confirm Email: text boxes.

Click Continue. The following screen is displayed:

Figure 1-59 License Key Activation Center 4

S

1-70 D000140-001 B

Page 79

A

Installation

Switch-Based QLogic Fabric Manager License Key

6. Enter all applicable information. For the City: and/or the Zip/Postal Code

entries, click on the flashlight hyperlinks. The following is displayed:

Figure 1-60 License Key Activation Center 5

7. In the City: and Zip: text boxes, enter the applicable information and click

Search. Alternatively, search through the list of cities, click the applicable

radio button, then click Search. The following is displayed:

Figure 1-61 License Key Activation Center 6

D000140-001 B 1-71

Page 80

Installation

Switch-Based QLogic Fabric Manager License Key

8. If the information is correct, click Close. The following screen is displayed:

Figure 1-62 License Key Activation Center 7

S

1-72 D000140-001 B

Page 81

A

Installation

Switch-Based QLogic Fabric Manager License Key

9. Click Continue. The following screen is displayed:

Figure 1-63 License Key Activation Center 8

10. In the GUID: text box, enter the FRU GUID of the following applicable

components:

QLogic 12300 chassis

QLogic 12800 series Management Module to be used as the master

subnet manager

Master and redundant switch-based QLogic Fabric Manager

Click Continue. A license key will be emailed.

D000140-001 B 1-73

license keys can be generated by entering the GUID of the

primary and redundant management modules in the GUID: text

boxes.

Page 82

Installation

Switch-Based QLogic Fabric Manager License Key

NOTE:The FRU GUID can be found:

On the label of each FRU.

Using the Chassis Viewer, the View FRU button for each

applicable chassis or module FRU.

For the12300 via the switch Command Line Interface (CLI), using

the command showIBNodeDesc.

For the 12800 series via the switch Command Line Interface

(CLI), using the command ShowInventory. From the system

output, locate the GUID of the Management Module that will be

used to apply the license key.

S

1-74 D000140-001 B

Page 83

A

QLogic 12000 Six-Port Upgrade

Users can order a six-port License Key upgrade for the QLogic 12300-BS18

advanced 40Gb/s QDR InfiniBand switch. Refer to the licensing documentation that

comes with the QLogic 12300-BS18 switch for instructions on generating the license

key.

Figure 1-64 InfiniBand Fabric Suite Licensing Information

Installation

QLogic 12000 Six-Port Upgrade

D000140-001 B 1-75

Page 84

Installation

QLogic 12000 Six-Port Upgrade

Procedures

1. Record the 12300-BS18 serial number.

2. Go to the QLogic Feature Activation/License Key web site

http://lk.qlogic.com

Figure 1-65 License Key Activation Center

S

.

3. Enter the 12300-BS18 serial number. Click Continue. The system validates

the serial number and moves to the next screen.

4. Click Activate License Key and click Continue.

5. Enter your email address in the Email: and Confirm Email: text boxes.

Click Continue.

6. Enter all applicable contact information. Click Continue.

7. Enter the transaction code and switch GUID, then click Continue.

NOTE:The FRU GUID can be found:

On the label of each 12300-BS18 switch.

Using the Chassis Viewer, the View FRU button for each

applicable chassis.

For the12300-BS18 via the switch Command Line Interface

(CLI), using the command showIBNodeDesc.

8. If the information displayed is correct, click Yes.

9. Review the end-user license agreement, then click Agree.

10. The screen displays the generated license key, along with the updated port

count status. To send this information to another user, enter an email

address and click Send. When finished, click Done.

1-76 D000140-001 B

Page 85

A QLogic 12000 Series

Product Specifications

Physical Specifications

All products within the 12200, 12300 and 12800 Director series are designed to be

installed in industry-standard 19-inch four-post server racks.

Racks should conform to conventional standards. Use the American National

Standards Institute (ANSI)/Electronic Industries Association (EIA) standard

ANSI/EIA-310-D-92 and International Electrotechnical Commission (IEC) 297.

These racks are commercially available in various depths. It is recommended to

use rack with minimum of 36" depth to facilitate cable installation and routing. Other

physical attributes are shown in the table below.

NOTE: The 12000 series products should not be installed in two-post

telecommunication racks.

Table A-1. 12000 Physical Attributes

Model # 12200 12300 12800-040 12800-120 12800-180 12800-360

Height (rack

units/inches)

Depth

(without

cables)

Width 17.32" (440mm)

Max weight

(lb./kg.)

D000140-001 B A-1

1U/1.75" 1U/1.75" 5U/8.75” 10U/17.5" 14U/24.5" 29U/50.7”

24” 25 3/4" (654mm)

15/6.8 26/11.8 100/45.5 155/70.5 285/129.3 536/243.1

Page 86

QLogic 12000 Series Product Specifications

Environmental Specifications

Environmental Specifications

Operating temperature:

5° - 40°C at sea level, altitude derating 1°C per 300m to 2,400m

Non-operating temperature:

-40°C to 65°C

Relative humidity (non-condensing):

Operating 5% - 85%; Non-operating 5% - 90%

12200 and 12300

Cooling and Thermal Management:

Cooling:

Air cooled with a hot plug fan/power tray, three fans per tray, 40mm,

12VDC (12300)

S

Power

Four fans, no fan trays (12200)

Front-to-back airflow

NOTE:

The 12200 also offers a reversed airflow model

Power Supply:

Two redundant, hot plug fan/power supplies (12300)

90/264 VAC operation

275W max power per supply

Input: 90–264V AC, 47–63Hz, 1 Phase, 3.6A max current at 100VAC

Inrush Current: 13A @ 115VAC, 6.5A @ 230VAC

Power Factor: 95% @ 230VAC, 50% load

Power Inlet Plug: two IEC 320-c14 connectors for independent AC

inputs (12300)

A-2 D000140-001 B

Page 87

A

12800 Series

All 12800 series switches use the same fan tray modules -- intake and exhaust -and share the same thermal management attributes listed below. The quantity of

fan tray modules used in each system is defined in the following table:

Maximum

InfiniBand

Ports

Maximum

Leaf Modules

QLogic 12000 Series Product Specifications

12800 Series

Table A-2. 12800 Product Configurations

Model # 360 180 120 040

864 432 288 96

36 18 12 4

Maximum

Spine

Modules

Management

Modules

Fan Trays

(Intake/

Exhaust)

Power

Supplies

• Fan Tray:

Hot plug with one axial, brushless, 12V fans per Fan Tray

• Chassis airflow:

Front-to-back

• Power supply airflow:

Front to back

NOTE:It is recommended that the 120, 180 and 360 be installed as

follows:

Intake fan side towards the cold aisle

9 Double 4 Double,

1 Single

2 2 2 2

10/10 5/3 5/3 4/0

12 6 4 4

2 Double,

1 Single

1 Double

Exhaust fan side towards the hot aisle

• Thermal management:

Temperatures of all major heat producing components are continuously

monitored by system management modules. Fan speed is monitored and

automatically adjusted by system management modules to maintain

D000140-001 B A-3

Page 88

QLogic 12000 Series Product Specifications

12800 Series

appropriate temperatures of major heat producing components. Monitoring

is performed via a two wire I2C interface to each Fan Tray.

Power Specifications

All products within the 12800 series use a common switching power supply. System

power attributes are shown in the table below. Power supplies are are N+1

redundant and hot pluggable.

NOTE:

An AC power cord is required for each power supply. Refer to the table

below.

Table A-3. System Power Attributes

Model # 12800-360 12800-180 12800-120 12800-040

Maximum # of

Power

Supplies

Maximum

wattage, fully

configured

Minimum

required

power

supplies

Power

supplies

required for

DC (N+1)

redundancy

Power

supplies

required for

AC

redundancy

Maximum

output per

supply

Input voltage 90-264 VAC autoranging

Input

frequency and

phase

S

12 6 4 4

7,455 3,654 2,735 922

6 3 3 2

7 4 3 2

12 6 4 2

1200 Watts

47-63 Hz

A-4 D000140-001 B

Page 89

A