Page 1

INSTALLATION

INSTRUCTIONS

Page 2

Boston Rangehood

Photo courtesy of TMA Kitchen Design

2

Condor Rangehood Installation Instructions

Page 3

Important Information

4

Instructions for Models

BCM / EYR / BAL

Instructions for Models

FAL / AUS / MIL / TAN

Remote Switching Specications

Ducting Pieces

Operation Details, Rangehood Cleaning, Filter Cleaning

Guarantee & Exclusions

Warranty

6

13

19

21

23

24

26

Condor Rangehood Installation Instructions

3

Page 4

IMPORTANT INFORMATION

CONDARI PTY LTD makes over 120 different models of QASAIR and CONDOR Rangehoods plus many

specials designed by architects and interior designers.

It is important to follow the installation instructions for each model.

The following is general advice for the installation of CONDOR Rangehoods.

Gas regulations require different heights for different brands of hoods. CONDOR hoods can be tted between

1000 mm to 1400 mm above the barbecue. This is due to the fact they do not have plastic motors.

1. The installation of CONDOR Rangehoods must comply with the information in this booklet. CONDOR

Rangehoods are designed and made to work efciently over all domestic barbecues available on the

Australian market.

2. Every CONDOR Rangehood must be ducted to the outside atmosphere by the use of zinc-alume duct or

non-porous and non-ammable materials. We do not recommend the use of any type of exible ducting

or plastic PVC piping (barbecue heat output will affect exible ducting and cause it to desintegrate).

Rangehoods must not be vented into a wall cavity or a ceiling space. This prevents a build up of grease,

which can be a re risk. Ensure the external outlet vent does not restrict the airow in any way, as this may

result in reduced performance.

3. CONDOR Rangehoods must be ducted in duct work equivalent to the outlet of the rangehood

ie: The cross sectional area of the rangehood outlet and the duct work must be equal. Do not reduce the

duct size or have sharp bends. Enlarge the duct size if the duct is to run 6 metres or longer. Advice from

CONDOR is available to ensure optimum performance. Always use nonammable materials to minimise the

risk of re in the duct at a later date.

4. Ensure all ducting pieces are correctly tted and sealed with either duct tape or silicone to ensure that fumes

do not escape into the ceiling space and seep into living areas through vents or light ttings. The installation

and tting of the rangehood should be done in such a way that will allow the unit to be removed if service is

required. Additional costs incurred in the removal of wall tiles, damage to walls or bench tops are not covered

by warranty.

5. Always adequately ventilate the room when the rangehood is in use at the same time as appliances burning

gas or other fuels.

6. WARNING: Incorrect venting will result in additional noise and a reduction in efciency. Exhaust air must not

be discharged into any chimney or ue, which may carry combustible products from other sources.

a) Do not discharge the air-ow from the rangehood into a ue used for exhausting fumes

from burning gas or fuel;

b) A reduction in ducting size will result in the motors eventually failing and will need replacement.

c) For cleaning purposes please refer to page 23 of installation instructions for stainless steel;

d) If cleaning is not carried out in accordance with the instructions as listed on page 23, you

may have an increased risk of re;

e) Accessible parts of the rangehood may become hot when used with cooking appliances;

f) This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

4

Condor Rangehood Installation Instructions

Page 5

7. If the supply cord is damaged, an authorised service centre or licensed electrician must replace it.

8. NOTE: CONDARI recommend minimum air movement of 2000 cubic metres per hour and recommend up

to 2700 cubic metres per hour over a barbecue, depending on the length of the duct run. Barbecues should

be positioned under the centre of the hood where the fans are mounted and not near the outer edges where

leakage may occur. Please also note barbecue lid position, as if it does not open to a 90 degree angle the

smoke and by-products can be diverted forward and away from the rangehood catchment area.

9. The lights in the rangehoods are LED.

10. To reduce the risk of xing screws coming in contact with live parts, do not drill or screw into the rangehood.

Live wires are encapsulated where possible to prevent user contact. If necessary drill from the inside out and

only through single sheet material.

11. CONDARI can manufacture rangehoods to be used over commercial cookers in domestic applications.

NOTE: Installation must comply with local State & Council regulations.

Condor Rangehood Installation Instructions

5

Page 6

INSTALLATION INSTRUCTIONS CONDOR RANGE

To suit wall mounted models:

• Boston

• Eyre

• Baltimore

1. Determine hood position on wall 1000mm to 1400mm above the cooking surface. The installer should check

for state and local regulations in case additional requirements may apply.

2. Mark centre line on wall.

3. Mark base line on wall.

4. Mark the outlet hole in the ceiling or wall for the outlet and cut out, removing any obstructions.

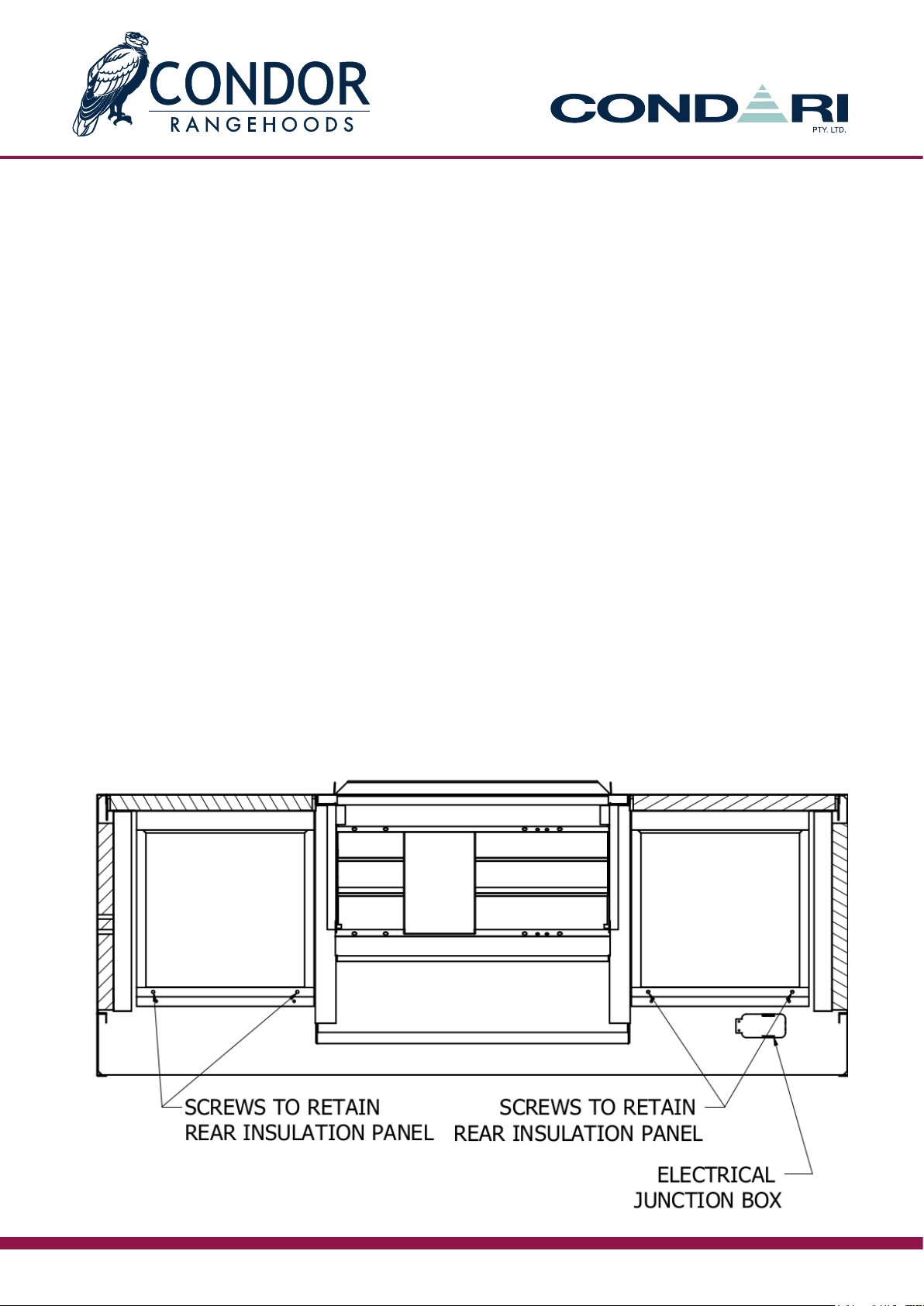

5. Remove the rear insulation panels in hood by removing the lower screws for each panel. slide panel

upwards, pull lower part of insulation panel to clear lower bracket then slide downwards. For the Eyre model

similar insulation panels can be removed from top to access area above the inner fanbox.

6. Locate drill mounting holes in wall as high and wide as possible to suit Rangehood to avoid sagging from

wall.

7. Drill xing holes in rear of hood to suit mounting holes on wall.

8. Remove protective lm from wall mounting bracket and x to wall at base height of hood making sure this is

level and exactly central.

9. Locate position and cut hole for power cable. Consult your electrician for his preferred location.

10. If tting optional Condor ue (CFL-XXX refer pg.11) to suit Baltimore & Boston models, t the ue to top of

Rangehood and secure by bending the 4 tabs over from inside the Rangehood.

11. Remove fans if needed and lift hood up onto wall mounting bracket carefully locating outlet through hole in

ceiling/wall and bringing power cable into hood during this process. Take care when lifting ranghood into

position and ensure you have enough people to lift safely.

6

Condor Rangehood Installation Instructions

Page 7

12. Using appropriate xing method to safely support Rangehood, secure Rangehood to wall making sure

Rangehood is level and sitting properly on the wall mounting bracket. If required, for the Eyre model t 8mm

all thread (threaded rod) through holes in top of Rangehood and secure to roof structure, secure Rangehood

with washers and nuts. Level Rangehood by tensioning the 8mm nuts, do not over tighten. It is advisable to

use props or portable stands when attaching the Rangehood to the wall or ceiling.

13. Ret insulation panel in the rear/top of the Rangehood and ret fans if they have been removed.

14. Electrical connection can now be made by a licensed electrician to the junction box inside bottom right side

of Rangehood.

15. Extend ducting through to exterior and t roof cowl or wall vent. Making sure to seal roof/wall penetration with

preferred ashing material, consult your plumber for the best product to suit.

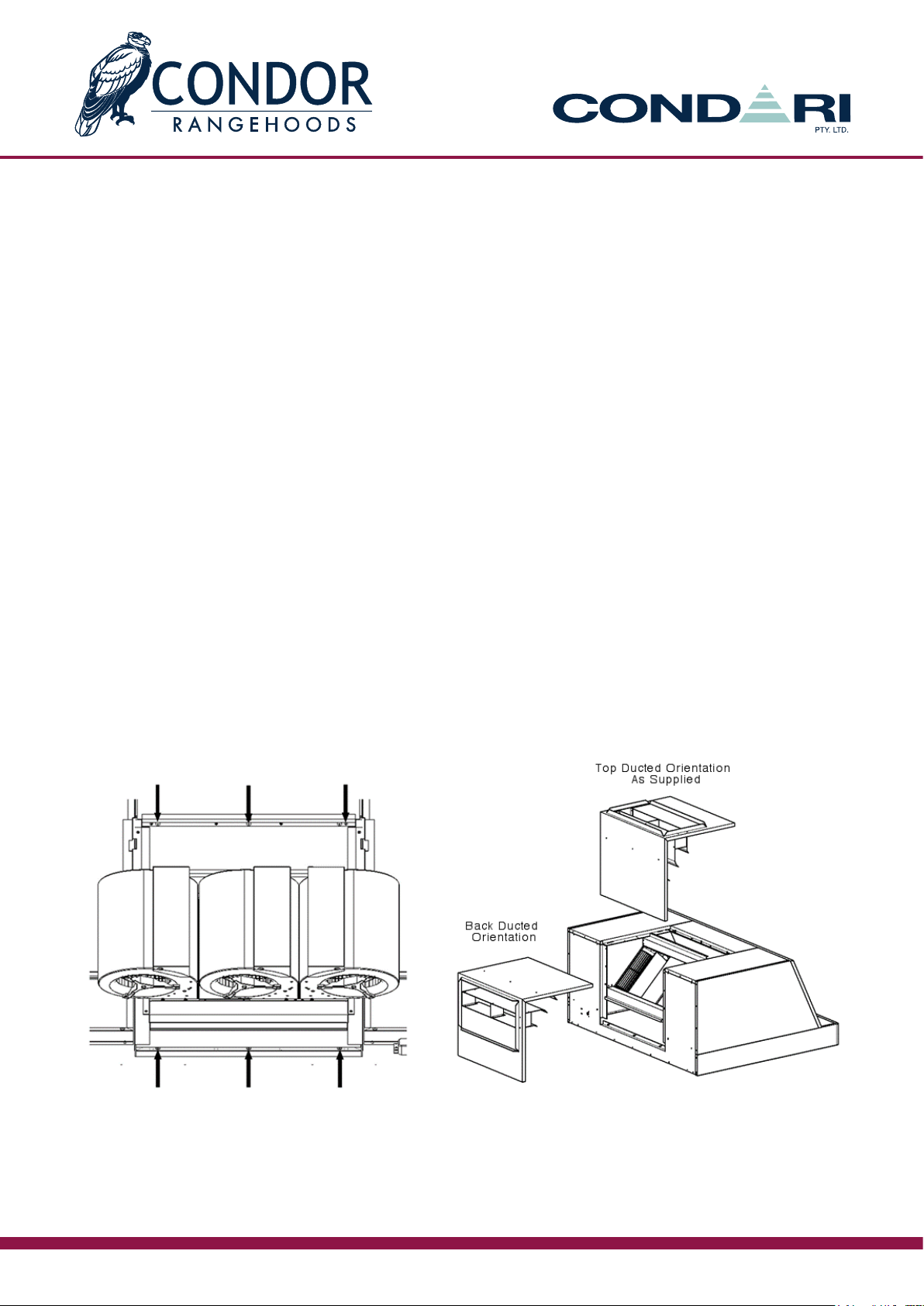

INSTRUCTIONS TO CHANGE THE ORIENTATION OF THE

RANGEHOOD OUTLET PLATE

1. Locate and remove 6x M4 Phillips head screws as shown below.

2. Once all screws are removed, push rangehood outlet plate from the inside of the rangehood outwards. Do

not push the fans as they are xed.

3. Reorient rangehood outlet plate from top to back ducted or vice versa, relocate back into range hood and

replace 6x Phillips head screws removed previously.

Condor Rangehood Installation Instructions

7

Page 8

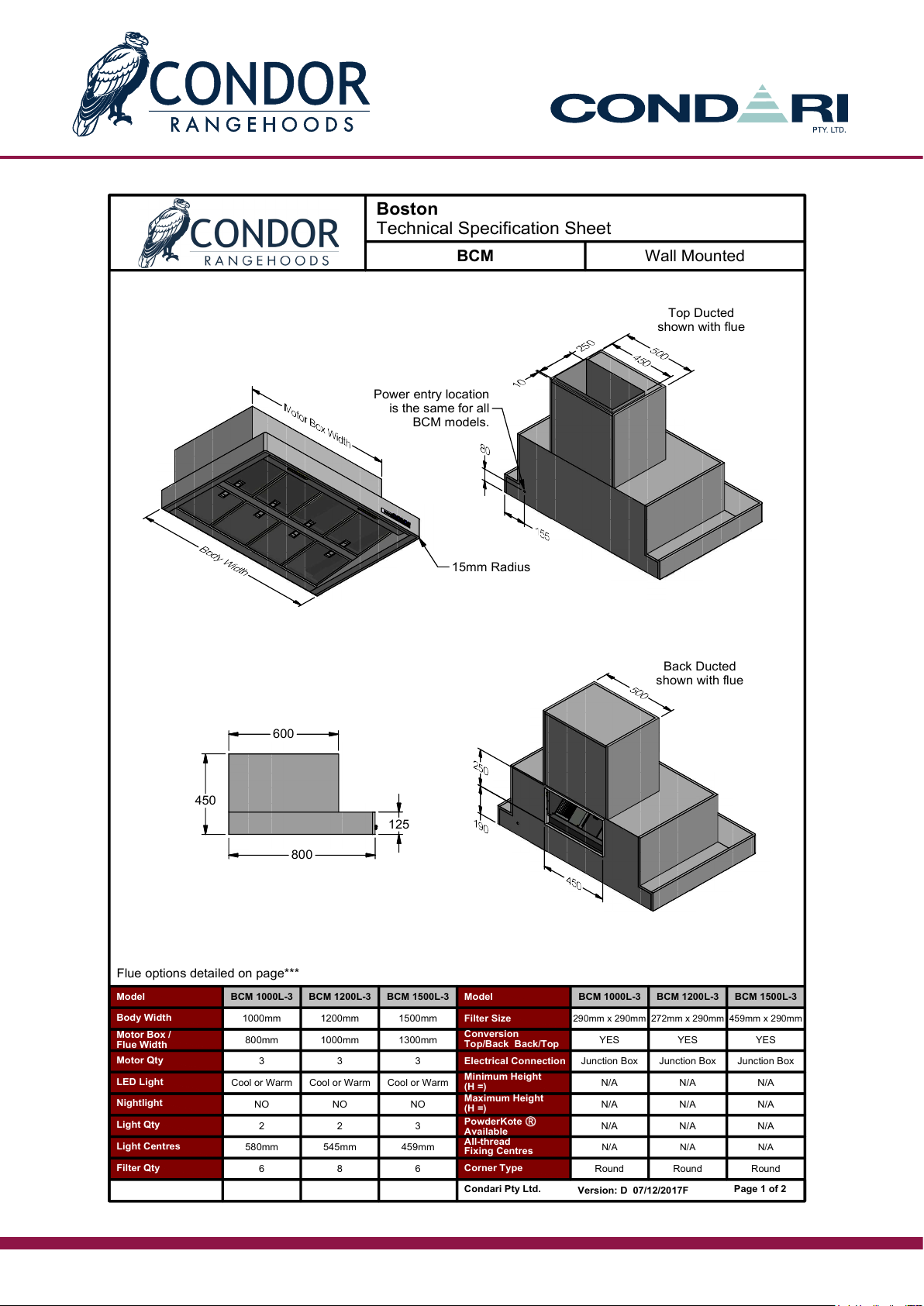

Motor Box /

Flue Width

Condari Pty Ltd. Page 1 of 2

Version: D 07/12/2017F

Body Width

Model

Motor Qty

Light Centres

Light Qty

Nightlight

LED Light

Filter Qty

Model

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

}

Available

All-thread

Fixing Centres

Corner Type

BCM 1000L-3 BCM 1500L-3BCM 1200L-3BCM 1000L-3BCM 1500L-3BCM 1200L-3

1000mm

580mm

6

800mm

3

Cool or Warm

NO

2

290mm x 290mm

YES

Junction Box

N/A

N/A

N/A

N/A

Round

1200mm

1000mm

3

Cool or Warm

NO

2

545mm

8

1500mm

1300mm

3

Cool or Warm

NO

3

459mm

6

272mm x 290mm

YES

Junction Box

N/A

N/A

N/A

N/A

Round

459mm x 290mm

YES

Junction Box

N/A

N/A

N/A

N/A

Round

Boston

Technical Specification Sheet

BCM Wall Mounted

Power entry location

is the same for all

BCM models.

800

125

450

600

15mm Radius

Top Ducted

shown with flue

Back Ducted

shown with flue

Flue options detailed on page***

8

Condor Rangehood Installation Instructions

Page 9

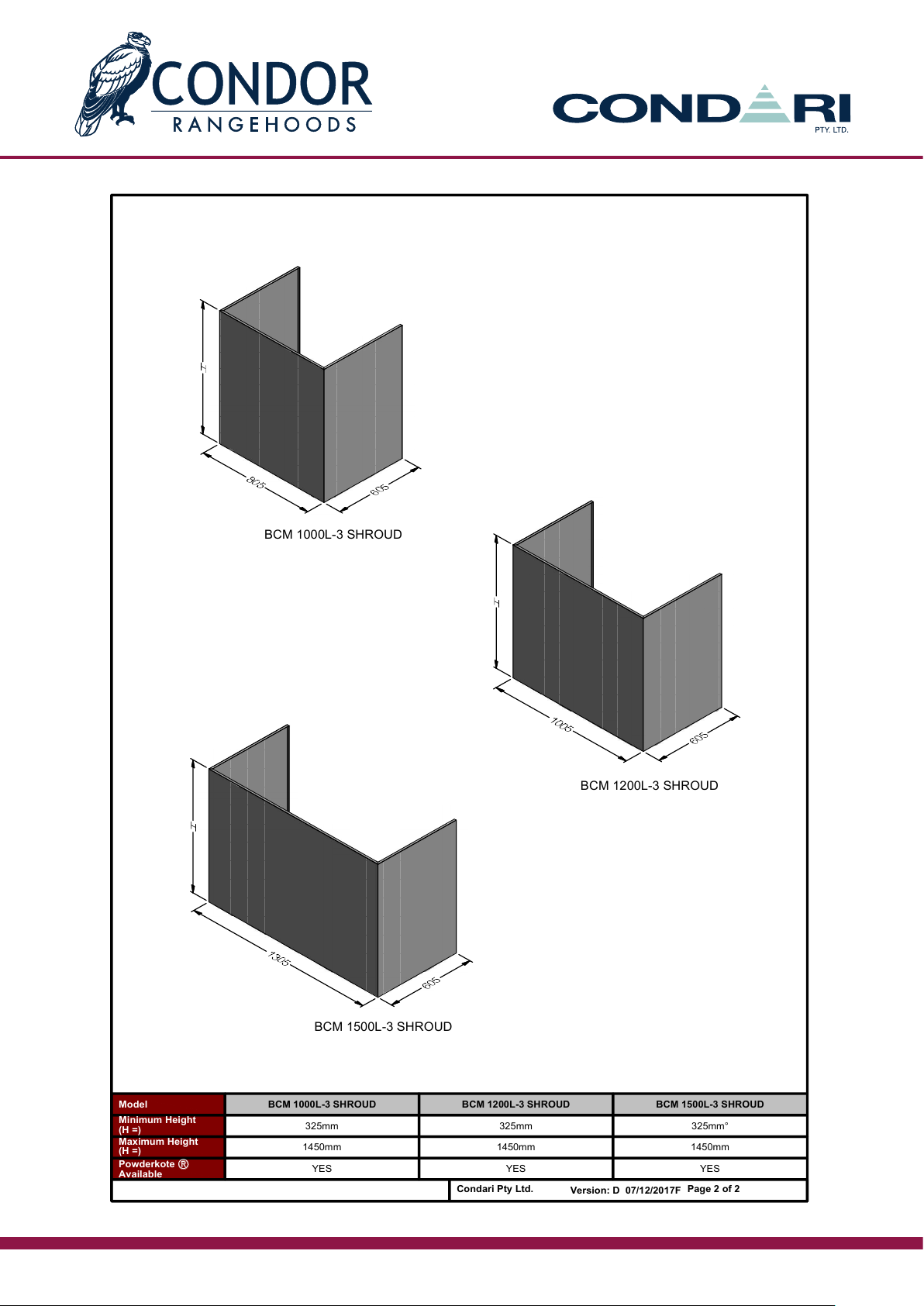

BCM 1000L-3 SHROUD

325mm

°

BCM 1500L-3 SHROUDBCM 1200L-3 SHROUD

325mm

1450mm

YES

325mm

1450mm

YES

Powderkote

}

Available

Maximum Height

(H =)

Model

Minimum Height

(H =)

Condari Pty Ltd.

YES

1450mm

Page 2 of 2

Version: D 07/12/2017F

BCM 1000L-3 SHROUD

BCM 1200L-3 SHROUD

BCM 1500L-3 SHROUD

Condor Rangehood Installation Instructions

9

Page 10

Motor Box /

Flue Width

Condari Pty Ltd. Page 1 of 1

Version: C 07/12/2017F

Body Width

Model

Motor Qty

Light Centres

Light Qty

Nightlight

LED Light

Filter Qty

Model

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

}

Available

All-thread

Fixing Centres

Corner Type

BAL 1000L-3 BAL 1500L-3BAL 1200L-3BAL 1000L-3BAL 1500L-3BAL 1200L-3

1000mm

580mm

6

500mm

3

Cool or Warm

NO

2

290mm x 290mm

YES

Junction Box

N/A

N/A

N/A

N/A

Round

1200mm

500mm

3

Cool or Warm

NO

2

545mm

8

1500mm

500mm

3

Cool or Warm

NO

3

459mm

6

272mm x 290mm

YES

Junction Box

N/A

N/A

N/A

N/A

Round

459mm x 290mm

YES

Junction Box

N/A

N/A

N/A

N/A

Round

Baltimore

Technical Specification Sheet

BAL Wall Mounted

Power entry location

is the same for all

BAL models.

15mm Radius

Top Ducted

shown with flue

Back Ducted

shown with flue

700

800

100

450

540

Flue options detailed on page ***

10

Condor Rangehood Installation Instructions

Page 11

Condari Pty Ltd. Page 1 of 1

Version: A 08/02/2016F

Condor Flues

Technical Specification Sheet

FLUE Wall Mounted

FLUES T

O SUI

T BCM AND BAL MODELS.

CFL 600 T

CFL 900 T

CFL 120

0 T

CFL 600 B

CFL 900 B

CFL 120

0 B

Top

D

ucted

F

lue

s

Bac

k

D

ucted

F

lue

s

Condor Rangehood Installation Instructions

11

Page 12

Back Ducted

Top Ducted

Motor Box /

Flue Width

Condari Pty Ltd. Page 1 of 1

Version: A 21/11/2016F

Body Width

Model

Motor Qty

Light Centres

Light Qty

Nightlight

LED Light

Filter Qty

Model

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

}

Available

All-thread

Fixing Centres

Corner Type

EYR 1000L-3 EYR 1500L-3EYR 1200L-3EYR 1000L-3EYR 1500L-3EYR 1200L-3

1000mm

580mm

6

N/A

3

Cool or Warm

NO

2

290mm x 290mm

NO

Junction Box

500mm

1160mm

N/A

800mm

Square

1200mm

N/A

3

Cool or Warm

NO

2

545mm

8

1500mm

N/A

3

Cool or Warm

NO

3

459mm

6

272mm x 290mm

NO

Junction Box

500mm

1160mm

N/A

1000mm

Square

459mm x 290mm

NO

Junction Box

500mm

1160mm

N/A

1300mm

Square

Eyre

Technical Specification Sheet

EYR Wall Mounted

Power entry location

is the same for all

EYR models.

12

Condor Rangehood Installation Instructions

Page 13

INSTALLATION INSTRUCTIONS CONDOR RANGE

To suit island models:

• Falcon

• Millington (Island)

• Austin (Undercupboard)

• Tanami

It is recommended that the rangehood be mounted 100mm back from the edge of the benchtop.

1. The rangehood can be installed between 1000mm and 1400mm above the cooking surface. The installer

should check for state and local regulations in case additional requirements may apply.

2. It is advisable to remove fans for easier handling of unit by removing retaining bolts or clips and unplugging

electrical connector.

3. Measure hole centres and duct size on top of the rangehood. This will vary with the hood size, model and

number of fans tted and will determine the ducting required.

4. Using a plumb line, mark the ceiling before making the cut out. Check for obstructions like electrical cables

etc.

5. Ensure roof structure has the strength to support the weight of Rangehood. Fit 8mm all thread (threaded rod)

to roof structure 4 places.

6. Guide allthread throught top of Rangehood and lift into position, bringing power cable into hood during this

process.. Take care when lifting ranghood into position and ensure you have enough people to lift safely. It is

advisable to use props or portable stands when attaching the Rangehood hood to the ceiling.

7. In the rangehood install washers and nuts to secure the Ranghood. Level Rangehood by tensioning the 8mm

nuts, do not over tighten.

8. Ret fans if they have been removed and the electrical connection can now be made by a licensed

electrician to the junction box inside bottom right side of Rangehood.

9. Extend ducting through to exterior and t roof cowl or wall vent. making sure to seal roof penetration with

preferred ashing material, consult your plumber for the best product to suit.

Condor Rangehood Installation Instructions

13

Page 14

ISLAND CONDOR INSTALLATION DETAILS

8mm NUT

CEILING JOISTS

8mm WASHER

8mm

ALLTHREAD

14

POWER

ENTRY

Condor Rangehood Installation Instructions

Page 15

Falcon

Technical Specification Sheet

FAL

Ceiling Mounted

1200mm x 500mm

Round

Page 1 of 1

1275mm

900mm x 500mm

Round

1275mm

N/A

272mm x 355mm

10 Amp Lead

NO

FAL 1500L-3

Minimum Height

(H =)

PowderKote

}

Available

Electrical Connection

Corner Type

All-thread

Fixing Centres

Maximum Height

(H =)

Condari Pty Ltd.

Version: B 03/02/2016F

480mm

N/A

Cool or Warm

8

545mm 409mm

10

3

FAL 1500L-3

1500mm

Cool or Warm

NO

2

Conversion

Top/Back Back/Top

Filter Size

1300mm

NO

1000mm

3

1200mm

FAL 1200L-3

Body Width

Model

Light Qty

Nightlight

480mm

NO

FAL 1200L-3Model

10 Amp Lead

Filter Qty

Light Centres

LED Light

Motor Qty

Motor Box /

Flue Width

3

272mm x 355mm

Power entry location

is the same for all

FAL models.

15mm Radius

900

125

H

175 250 175

600

25

Condor Rangehood Installation Instructions

15

Page 16

Millington

Technical Specification Sheet

MIL

Ceiling Mounted

1300mm x 700mm

Square

Page 1 of 1

1160mm

1000mm x 700mm

Square

1160mm

N/A

272mm x 355mm

10 Amp Lead

NO

MIL 1500L-3

Minimum Height

(H =)

PowderKote

}

Available

Electrical Connection

Corner Type

All-thread

Fixing Centres

Maximum Height

(H =)

Condari Pty Ltd.

Version: A 21/11/2016F

500mm

N/A

Cool or Warm

8

545mm 409mm

10

3

MIL 1500L-3

1500mm

Cool or Warm

NO

2

Conversion

Top/Back Back/Top

Filter Size

N/A

NO

N/A

3

1200mm

MIL 1200L-3

Body Width

Model

Light Qty

Nightlight

500mm

NO

MIL 1200L-3Model

10 Amp Lead

Filter Qty

Light Centres

LED Light

Motor Qty

Motor Box /

Flue Width

3

272mm x 355mm

900

325 250 325

20

Power entry location

is the same for all

MIL models.

H

16

Condor Rangehood Installation Instructions

Page 17

Motor Box /

Flue Width

Condari Pty Ltd. Page 1 of 1

Version: B 07/12/2017F

Body Width

Model

Motor Qty

Light Centres

Light Qty

Nightlight

LED Light

Filter Qty

Model

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

}

Available

All-thread

Fixing Centres

Corner Type

AUS 1000L-3 AUS 1500L-3AUS 1200L-3AUS 1000L-3AUS 1500L-3AUS 1200L-3

1000mm

580mm

6

950mm

3

Cool or Warm

NO

2

290mm x 290mm

NO

Junction Box

N/A

N/A

N/A

360mm x 665mm

Square

1200mm

1150mm

3

Cool or Warm

NO

2

545mm

8

1500mm

1450mm

3

Cool or Warm

NO

3

459mm

6

272mm x 290mm

NO

Junction Box

N/A

N/A

N/A

460mm x 665mm

Square

459mm x 290mm

NO

Junction Box

N/A

N/A

N/A

610mm x 665mm

Square

Austin Undercupboard

Technical Specification Sheet

AUS

Undercupboard

Power entry location

is the same for all

AUS models.

800

50

450

250 250 250

125

250

75

Top Ducted

Back Ducted

Condor Rangehood Installation Instructions

17

Page 18

Tanami

Technical Specification Sheet

TAN

Ceiling Cavity Mounted

N/A

Square

Page 1 of 1

N/A

N/A

Square

N/A

N/A

422mm x 355mm

Remote Switching

YES

TAN 1800L-4

Minimum Height

(H =)

PowderKote

}

Available

Electrical Connection

Corner Type

All-thread

Fixing Centres

Maximum Height

(H =)

Condari Pty Ltd.

Version: A 26/08/2016F

N/A

N/A

NO

10

N/A N/A

8

N/A

TAN 1800L-4

1800mm

NO

NO

N/A

Conversion

Top/Back Back/Top

Filter Size

N/A

NO

N/A

4

1500mm

TAN 1500L-4

Body Width

Model

Light Qty

Nightlight

N/A

YES

TAN 1500L-4Model

Remote Switching

Filter Qty

Light Centres

LED Light

Motor Qty

Motor Box /

Flue Width

4

290mm x 355mm

Power entry location

is the same for all

Tanami models.

Showing as Top Ducted

Showing as

Back Ducted

900

300

20

110

20

110

Tanami comes top ducted and can be converted to back ducting on site by the installer.

18

Condor Rangehood Installation Instructions

Page 19

REMOTE SWITCHING SPECIFICATIONS

3 FAN (no lights)

1. Wiring to the appliance must comply with State and local regulations.

2. Switching is not provided with this unit. - The order was for the controls to be separate from the unit.

3. You may use any switching to connect the rangehood (e.g. Clipsal switches).

4. All fans must be controlled by at least one ON/OFF and one HI/LO switch.

(i.e. single or twin motor models).

5. Please refer to Wiring Diagram below for detailed wiring information.

BROWN

BLUE

BLUE

BLACK

BROWN

BLACK

BLUE

BLUE

BROWN BROWN

WHITE

GREEN

WHITE

GREEN

JUNCTION

BOXES

-------------------- CABLES TO REMOTE SWITCHES --------------------

NOTES:-

1. IT IS NECESSARY TO PROVIDE

AN ON/OFF AND A HIGH/LOW

SWITCH FOR EACH FAN.

2. THE WIRING FOR THE FANS ARE 4 CORE -

LOW SPEED - BROWN

HIGH SPEED - WHITE

NEUTRAL - BLUE

EARTH - GREEN

BROWN

BLUE

BROWN

BLACK

BLUE

WHITE

GREEN

JUNCTION

BOXES

WIRING DIAGRAM

NOTE: This diagram is for reference only. A qualied elecrician must connect remote

switching to rangehood.

Reected in this drawing is the most common method of connecting the rangehood.

Be aware that Active voltage must NOT be applied to both the ‘White- High’ or

‘Brown-Low’ wires at the same time. This will cause the fan to fail.

ALL FANS MUST BE CONTROLLED

BY AT LEAST ONE ON/OFF AND

ONE HI/LO SWITCH.

Condor Rangehood Installation Instructions

19

Page 20

REMOTE SWITCHING SPECIFICATIONS

3 FAN with LED

1. Wiring to the appliance must comply with State and local regulations.

2. Switching is not provided with this unit. - The order was for the controls to be separate from the unit.

3. You may use any switching to connect the rangehood (e.g. Clipsal switches).

4. All fans must be controlled by at least one ON/OFF and one HI/LO switch.

(i.e. single or twin motor models).

5. Please refer to Wiring Diagram below for detailed wiring information.

AC1 AC2

LED

AC2

AC1

LED

BLUE

BLUE

BROWN

BLUE

BROWN

BLUE

BROWN

CIRCUIT DIAGRAM

DESIGNER

CHECKED

M. Malesevic REVISION

CONDARI PTY LTD

DATE

8 Argent Place, Ringwood VIC 3134

Ph: (03) 9873 5877 / Fx: (03) 9873 5748

A

22/08/2013

BROWN

BLUE

BLUE

BLACK

BROWN

M. Brewin

BLACK

BLUE

BLUE

BROWN

BROWN

WHITE

GREEN

WHITE

GREEN

JUNCTION

BOXES

-------------------- CABLES TO REMOTE SWITCHES --------------------

NOTES:-

1. IT IS NECESSARY TO PROVIDE

AN ON/OFF AND A HIGH/LOW

SWITCH FOR EACH FAN.

2. THE WIRING FOR THE FANS ARE 4 CORE -

LOW SPEED - BROWN

HIGH SPEED - WHITE

NEUTRAL - BLUE

EARTH - GREEN

3. THE WIRING FOR THE LIGHTS IS 2 CORE -

ACTIVE - BROWN

NEUTRAL - BLUE

BROWN

BLUE

BROWN

BLUE

JUNCTION

BOXES

BLUE

BROWN

WHITE

GREEN

BLACK

BLUE

BROWN

JUNCTION

BOXES

WIRING DIAGRAM

NOTE: This diagram is for reference only. A qualied elecrician must connect remote

switching to rangehood.

Reected in this drawing is the most common method of connecting the rangehood.

Be aware that Active voltage must NOT be applied to both the ‘White- High’ or

‘Brown-Low’ wires at the same time. This will cause the fan to fail.

ALL FANS MUST BE CONTROLLED BY

AT LEAST ONE ON/OFF AND ONE

HI/LO SWITCH.

20

Condor Rangehood Installation Instructions

Page 21

CONDOR DUCTING

All Condor ducting pieces are available in zincalume, stainless steel,

colourbond material or powderkote colour.

400. DL-4

DL-4 SS

DL-4 C/P

402. VB-450X250

VB-450X250 SS

VB-450X250 C/P

401. HB-450X250

HB-450X250 SS

HB-450X250 C/P

403. HB-450X250/45

HB-450X250/45 SS

HB-450X250/45 C/P

404. VB-450X250/45

VB-450X250/45 SS

VB-450X250/45 C/P

Condor Rangehood Installation Instructions

405. BD/WV-H-450X250

BD/WV-H-450X250 SS

BD/WV-H-450X250 C/P

21

Page 22

CONDOR DUCTING

All Condor ducting pieces are available in zincalume, stainless steel,

colourbond material or powderkote colour.

406. BD/WV-V-450X250

BD/WV-V-450X250 SS

BD/WV-V-450X250 C/P

408. RCBA

RCBA SS

RCBA C/P

407. RCB

RCB SS

RCB C/P

409. WVC-H-450X250

WVC-H-450X250 SS

WVC-H-450X250 C/P

410. WVC-V-450X250

WVC-V-450X250 SS

WVC-V-450X250 C/P

22

411. BD RC-4

BD RC-4 SS

BD RC-4 C/P

Condor Rangehood Installation Instructions

Page 23

OPERATION DETAILS

Fan Left Side ON and OFF

Light ON and OFF

Fan Left Side High and Low

Right Side Fan/s ON and OFF

Right Side Fan/s High and Low

RANGEHOOD CLEANING

CONDOR Rangehoods are made from stainless steel, either type 304 or type 316.

* Type 304 is classied as 18/8 stainless steel

* Type 316 is classied as 18/10 stainless steel

This means that the stainless steel is made of 18% nickel and either 8% or 10% of chromium respectively.

Stainless steel gets its protective coating from the chromium oxidising in the air to form a protective surface

of chromium oxide. This can be attacked by different substances, such as salt water or sea air. The stainless

steel will start to show pit marks which are referred to in the industry as tea staining. This will happen to

marine grade stainless steel type 316 in the same way it will happen to stainless steel type 304, it will just

take longer to happen.

The way to overcome this is to clean the stainless steel with warm soapy water and then polish it with a cloth

so that the chromium will oxidise again.

When exposed to sea water or sea side conditions this is only a stop gap measure as the attack will start

again.

With stainless steel rangehoods exposed in Alfresco areas we recommend spraying the hood with vegetable

oil and rubbing it all over the rangehood, if it is going to be unused over a period of time.

FILTER CLEANING

For the best results, please clean filters regularly.

Condari recommends cleaning filters once per month, or immediately after heavy use.

You can do this by hand washing in warm soapy water, or by placing filters in the top rack of the

dishwasher using a detergent of pH 8 or less.

Note: Washing the filters in the dishwasher may cause discolouration of the filters.

We recommend washing filters in the dishwasher without detergent or use one of the powder

detergents.

Ensure the filters are completely dry before placing them back.

Do not operate the rangehood without the filters installed.

Condari does not recommend the use of corrosive, caustic or acidic products, particulary industrial

or citric products.

Condari has experienced problems with many of the dishwashing detergents now on the market.

Particularly with the tablet type detergents as many come from overseas, which are made for a hard

water environment. We have found that these detergents have a deleterious effect on the filters and

the result is that the filters last for about 50 to 60 washes.

This is equivalent to about 5 to 6 years life.

Condor Rangehood Installation Instructions

23

Page 24

CONDARI PTY LTD APPLIANCE GUARANTEE

The benefits conferred by this warranty are in addition to all other rights and remedies in respect of the product

which the consumer has under the Competition and Consumer Act 2010 and similar state and territory laws.

Condari P/L in Melbourne (and by their agency in Country Areas and other States) warrants that the appliance

will be free from defects in materials and workmanship for a period of 36 months from the date of purchase of

the appliance to the consumer.

If there is a breach of this warranty, Condari will rectify, free of charge, at it’s nearest service centre or

authorised service agency any fault caused by faulty workmanship or material at the time of manufacture

occurring in the appliance within 36 months from the date of purchase of the appliance to the customer.

This warranty is conditional upon the appliance being used only for personal, domestic and household purposes

and installed and operated in accordance with CONDOR Instructions and does not apply to articles which by

their nature are consumable.

If a defect is caused by neglect, misuse, or failure to follow operating instructions where special precautions are

detailed for user attention then a charge shall be made for the service call.

For example:

With the filters the user is specifically requested:

• To clean filter regularly by handwashing or placing in a dishwasher at least once a month.

• To turn rangehood off after each use.

• Note: Warranty under filter cleaning on page 23.

Where a claim is made under warranty, CONDARI reserves the right to determine whether or not the fault is

caused by faulty workmanship or material or that the part is defective.

The consumer shall be fully responsible for all expenses whatsoever incidental to the removal of parts from

the unit or to their replacement. Amongst other things, such responsibility shall extend to damaged walls, tiles,

fixtures and fittings whether or not the unit has been built into a cupboard and irrespective of the stage either of

its installation or the fitting of any other item whatsoever in its vicinity.

No other person, or firm or corporation is authorised by Condari to offer or give on its behalf any other greater

warranty than that given by Condari under this warranty.

Condari Pty Ltd provides to all CONDOR Rangehoods a 10 year motor replacement warranty. This is a change

over warranty.

The installation of the rangehood must comply with the information in this guide. Failure to adhere to the

instructions may result in loss of the Condari warranty.

We do point out that incorrect installation such as the ducting being the incorrect size or the duct run being too

long will result in the motor failing and possible burning out.

Replacement of the Fan Motors will need to be carried out by a authorized Condari technician and will be

charged at the rates applicable at time of replacement.

24

Condor Rangehood Installation Instructions

Page 25

EXCLUSIONS

There are some exclusions from the Condari Pty Ltd Guarantee. (on previous page)

CONDOR Rangehoods are designed to be used over all domestic barbecues available

in AUSTRALIA.

QASAIR Rangehoods are not to be used over barbecues approved for outdoor use only.

Outdoor barbecues will have a rating plate on them specifying that they are approved for outdoor use only.

If none of our Standard Condor Rangehoods suit your requirements, Condari can manufacture a special

rangehood to suit your Alfresco Area.

Condor Rangehood Installation Instructions

25

Page 26

STANDARD

WARRANTY

Date purchased

Purchased from

Model

Serial No

The purchaser must fill in the above information and keep this with the original purchase document.

This form must be produced if and when

a claim is made under this warranty.

CONDOR Rangehoods are made in Ringwood, Australia.

Tel: +61 3 9482 7088

Fax: +61 3 9482 7011

Email: sales@condari.com.au

Please Note that the Standard Warranty is from the date of purchase. Proof of purchase date is required to

obtain service under this warranty.

If no proof of purchase date can be provided at the time of the service call, then the service call will be charged

at the standard rate.

If proof of purchase date can be provided at a later date, reimbersement of the service cost will be made.

26

Condor Rangehood Installation Instructions

Page 27

EXTENDED

WARRANTY

Condari Pty Ltd provides an extended warranty from 36 months to 72 months if installed by an authorised

Condari installer and the below form is completed.

The authorised installer also offers a warranty on their workmanship for the same period of 72 months with a

guarantee that the installation is in compliance with

‘Condor installation instructions’.

Customer Name:

Model Number: Serial Number:

Purchased from:

Purchased Date: Installed Date:

Installer Name:

Installer Signature:

Condari Pty Ltd authorised installer stamp:

(This is required for validity of extended warranty)

Pleae note: The installation warranty does not cover the ageing process in a building or any problems due to

storm damage.

Condor Rangehood Installation Instructions

27

Page 28

rev. 071217F

DISTRIBUTED IN AUSTRALIA BY CONDARI PTY LTD

Tel: 1300 360 563

HEAD OFFICE

VIC Tel: 03 9482 7088 Fax: 03 9482 7011

Email: sales@condari.com.au

Website: www.condari.com.au

YOUR DISTRIBUTORS

NSW/ACT Tel: 02 9316 4599 Fax: 02 9316 9299 Email: salesnsw@qasair.com.au

QLD Tel: 07 3423 3503 Fax: 07 3282 9122 Email: salesqld@qasair.com.au

WA Tel: 08 9242 5387 Fax: 08 9201 0887 Email: saleswa@qasair.com.au

SA/NT Tel: 1300 360 563 Fax: 03 9482 7011 Email: sales@qasair.com.au

TAS Tel: 03 9482 7088 Fax: 03 9482 7011 Email: sales@qasair.com.au

CONDARI RESERVES THE RIGHT TO CHANGE SPECIFICATION WITHOUT NOTICE

CONDOR RANGEHOODS MADE IN RINGWOOD 3134

New Zealand

Kouzina Appliances

155 The Strand, Parnell

Auckland New Zealand

Tel: +64 9 377 7822 Fax: +64 9 377 7824

Email: sales@kouzina.co.nz

Singapore

Eldric Marketing Pte Ltd

176 Orchard Road

#05-03 Centrepoint Singapore 238843

Tel: +65 6369 1168 Fax: +65 6733 8133

Loading...

Loading...