MODEL NO. ______________

SERIAL NO. ______________

GENERAL INSTRUCTIONS

For the

INSTALLATION,

OPERATION and MAINTENANCE

of

DURAWATT EXR

WATER HEATERS

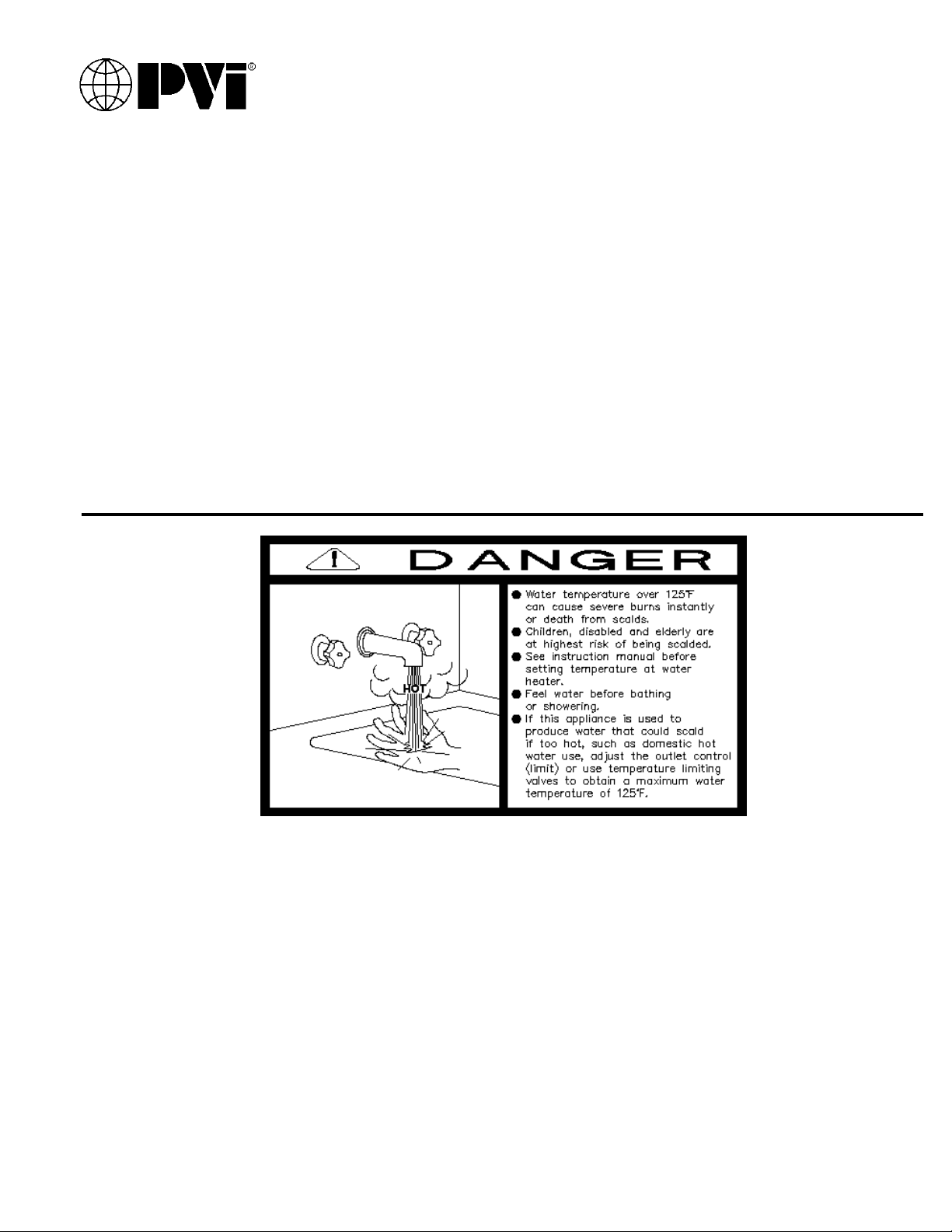

This water heater is equipped with an

adjustable thermostat to control water

temperature. Hot water temperatures

required for automatic dishwasher and

laundry use could cause scald burns

resulting in serious personal injury and/or

death. The temperature at which injury

occurs varies with the person’s age and

time of exposure. The slower response time

of disabled persons increases the hazards

to them. Never allow small children to use a

hot water tap or to draw their own bath

water. Never leave a child or disabled

person unattended in a bathtub or shower.

PV500-33 05-2002 1 Section 33

Since the thermostat temperature setting

could be set too high, adjust the thermostat

temperature setting to 125°F or lower.

Lower settings help reduce risk of scald

injury. Remember, no water heater system

will provide exact temperature at all times.

Allow a few days of operation at this setting

to determine the correct temperature

setting consistent with your needs and

remember, “Hotter water increases the risk

of scald injury.” Also, the water heater

should be located in an area where the

general public does not have access to set

temperatures.

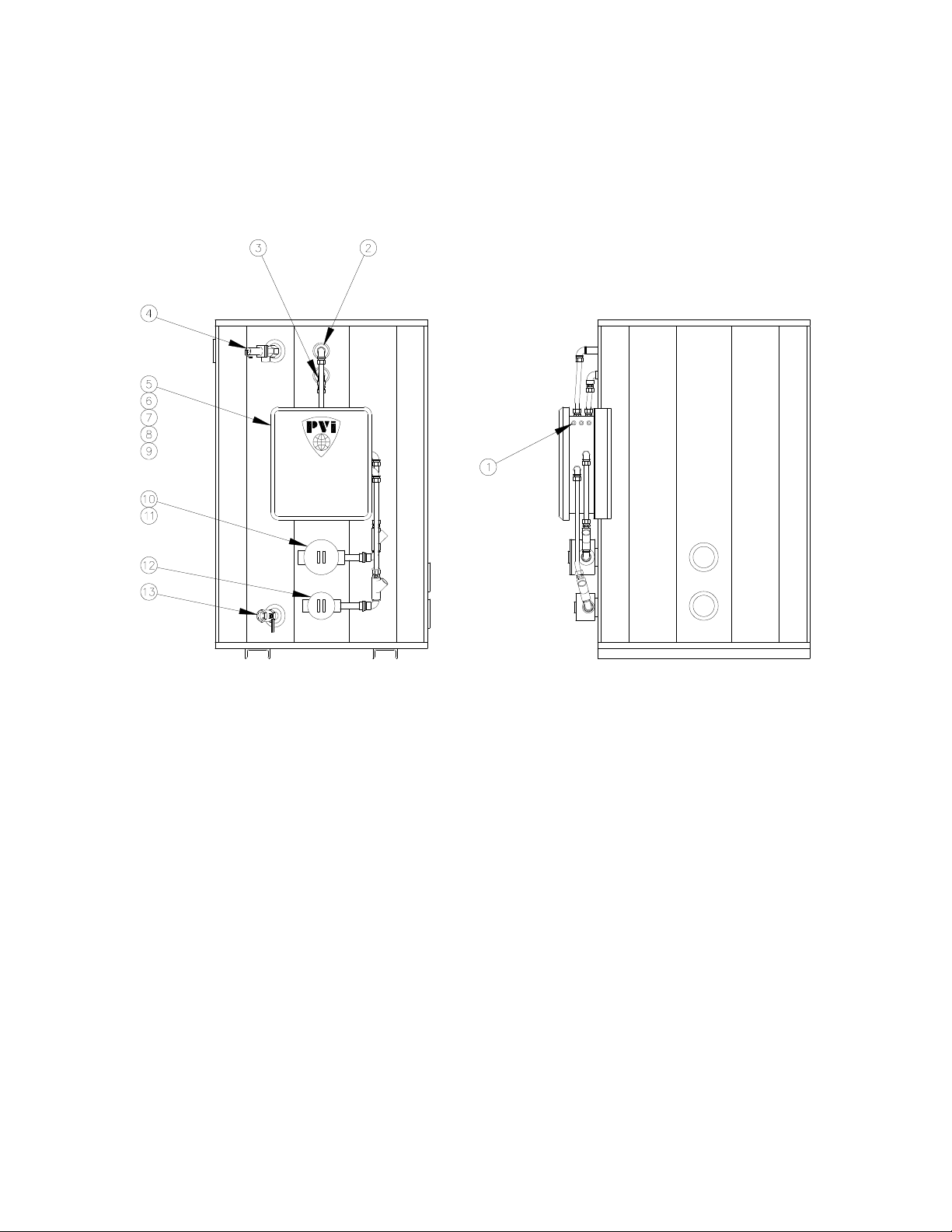

DURAWATT EXR WATER HEATER

TYPICAL CONSTRUCTION

Figure 33-1

1. Status lights 7. Fuses

(GRN-Power on; YEL-Elements on; 8. Contactors

RED-Over temp or low water 9. Step-down transformer (optional)

2. Float low water cutoff 10. Primary heating element (NEMA 7)

3. Temperature limiting device 11. Operating thermostat

(Set at 190°F) (Set at 120°F, adjustable from 80°F to 185°F)

4. Temperature & pressure relief valve 12. Secondary heating element (NEMA 7)

5. Control enclosure 13. Drain

6. Supply & remote signal connections

PV500-33 05-2002 2 Section 33

DURAWATT EXR WATER HEATER

ELECTRICAL CONNECTIONS

1. Check rating plate on water heater for correct voltage, phase and amperage. Refer to wiring

diagram for control component identification.

2. Use a proper wire size and branch circuit protection as required by the National Electrical Code

and state/local codes. PVI electric water heater specification sheets show number and size of

power connectors furnished with the heater for a minimum 90°C copper connecting wire.

3. Use correct size ground wire; attach to pressure connector marked “GR” inside the control

enclosure.

4. Connect supply feeders to distribution block inside the control enclosure. Conduit openings

have been provided for electrical connection and remote alarm circuitry as required. All holes

should be sealed with appropriate threaded hole plug if not used.

5. A float type low water cut-off switch has been provided to de-energize the heating circuit when

a low water volume is present.

STARTUP

1. Secure and lock-out electrical feed power circuit to water heater.

2. Check components to assure secure fit during transport and installation. Check wiring

connections in junction box for full contact and tight connection.

3. Inspect conduit seals between the control enclosure and heating element junction boxes to

ensure that they have been sealed.

4. Plumb water connections with appropriate shutoff valves, expansion tanks and check valves per

local plumbing codes.

5. With water outlet valve closed, open relief valve and water inlet valve, and fill tank with water

before turning on electricity. Dry energizing water heater immersion elements will burn out

elements rapidly and void the element warranty. When water exits relief valve, close relief valve

and continue to fill until tank is full.

6. Energize the main power circuit. Check power distribution to circuits with electrical meter to

assure proper power supply and operation. If improper readings are indicated, de-energize the

unit, disconnect the power lines to the unit and review wiring diagram for proper connection.

Check fuses to assure tight connection or any signs of failure.

7. To set the operating thermostat, remove the heating element junction box screw cover. (The

thermostat is located in one element housing only - check upper element first for thermostat

location.) A dial type thermostat has been selected for ease of use. Align desired temperature

(°F) with element temperature indicator mark and secure cover.

NOTE: The mercury displacement contactors are activated by a magnetic field and will make

some noise and vibration. This is normal.

PV500-33 05-2002 3 Section 33

DURAWATT EXR WATER HEATER

8. Open water outlet valve. Water heater is ready for operation. Heat up time will be dependent on

input and tank capacity.

9. After startup and with the water heater operating, allow the water in the tank to reach desired

temperature and the heating elements shut off. Draw hot water from a nearby outlet valve until

the heating elements energize. This will assure proper operation of the heating elements,

thermostat and other operating controls.

MAINTENANCE

1. A preventative maintenance program should be established to assure a long, trouble free life of

the water heater.

2. Flushing of the tank is recommended every two or three months, depending on water

conditions. To flush, disconnect (lockout) power to the unit. Open the drain valve and allow

water to flow through the tank until it runs clear. Close the drain valve. Draining two or three

gallons of water from the bottom of the tank on a weekly basis will also help prevent the

accumulation of sediment. A scale of lime will normally form on the heating elements and the

surface of the tank during heating cycles. The more hot water used, the more fresh water

containing the scale-forming elements are brought into the tank. As the temperature increases,

the rate of scale deposited will also increase. Sediment and scale accumulations in the tank will

greatly reduce the heating ability of the heater by reducing the effectiveness of the heat transfer

surfaces and can result in element failure.

3. Since PVI cannot control the use of the water heater, the water conditions or maintenance, the

warranty on the heating elements does not cover poor performance, structural failure or leaking

due to an excessive accumulation of scale.

4. The temperature and pressure relief valve should be checked at regular intervals. Open and

close the valve to insure proper operation. If the valve does not open or close properly when

tested, it must be replaced. Replace the relief valve with a like kind or one meeting the

requirements stated on the rating decal located on the valve.

WARNING: THE RELIEF VALVE IS A SAFETY DEVICE. DO NOT PLUG VALVE.

5. All electrical connections must be checked two weeks after startup to assure tightness. Heating

and cooling from operation can loosen connections. Every month, connections should be

inspected for any discoloration of wire terminal points.

6. The contactors are sealed and require no periodic maintenance other than checking wire

connections. These contactors contain MERCURY and must be returned directly to the

manufacturer for proper disposal. To return contactors, please call WATLOW CUSTOMER

SERVICE @507-454-5300 for a “Return Material Authorization” number. Mail the contactor

directly to the address provided by WATLOW CUSTOMER SERVICE for proper disposal.

Contact PVI @800-433-5654 to purchase the new contactor. Please have the water heater serial

number when ordering replacement contactors and the printed rating of the contactor to be

replaced.

7. Fuses for the load circuits are fast acting to prevent the contactor from rupturing in the event of

a heater short circuit. Replace with same type and rating.

PV500-33 05-2002 4 Section 33

Loading...

Loading...