Page 1

INSTALLATION & MAINTENANCE MANUAL

PVI DURAWATT® ELECTRIC WATER HEATERS

Installation and service must be performed by a qualified service installer, service agency or utility supplier.

IMPORTANT: THIS MANUAL CONTAINS INFORMATION REQUIRED FOR INSTALLATION, OPERATION AND

MAINTENANCE OF THIS EQUIPMENT. READ AND FOLLOW THE INFORMATION IN THIS MANUAL AND ALL

OTHER PROVIDED INSTRUCTIONS, LABELS AND MARKINGS BEFORE INSTALLING, OPERATING OR

SERVICING THIS UNIT.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage,

personal injury, exposure to hazardous materials or loss of life. Refer to the information contained in this

manual. A qualified installer, service agency or the utility supplier, who must read and follow the supplied

instructions before installing, servicing or removing this appliance, must perform installation and service.

WARNING: Do not use this appliance if any part has been under water. Immediately call a qualified service

technician to inspect the unit and to replace any part of the control system, and any other items affecting safe

appliance operation. Failure to follow these instructions can cause property damage, personal injury, or loss of

life.

TOPIC PAGE

Typical Construction 2

Important Safety Notice 3

Location and Installation 4

Clearances and Electrical Connections 5

Start-up Procedures and Operation 6

Maintenance 7

Replacing Electric Elements 8

Cleaning Electric Elements 9

Element Continuity Checks 10

Contactor to Element Wiring 11

Typical Current Measurement 12

Bolted Head Removal 13

Troubleshooting 14

CONTENTS

TO THE INSTALLER: After installation, these instructions must be given to the equipment user or left near the appliance.

SPECIAL INSTRUCTIONS TO THE OWNER: Retain this manual for future reference. These instructions contain

important information that will help you in maintaining and operating this appliance.

PV 500-6 09/07

Page 2

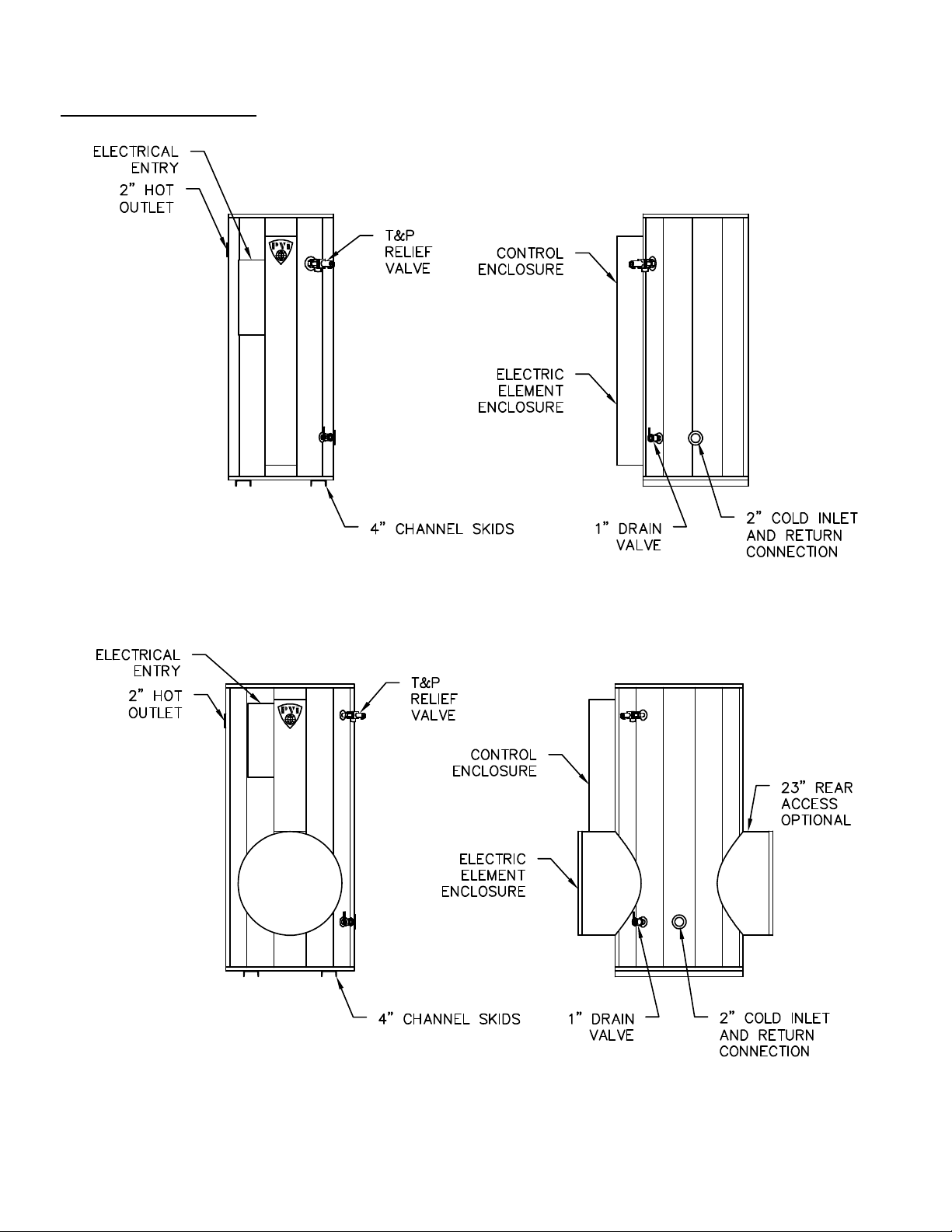

TYPICAL CONSTRUCTION

DURAWATT® ELECTRIC WATER HEATER

FIGURE 1

Without 23” Diameter Tank Access

FIGURE 2

With 23” Diameter Tank Access

PV500-6 09/07 2

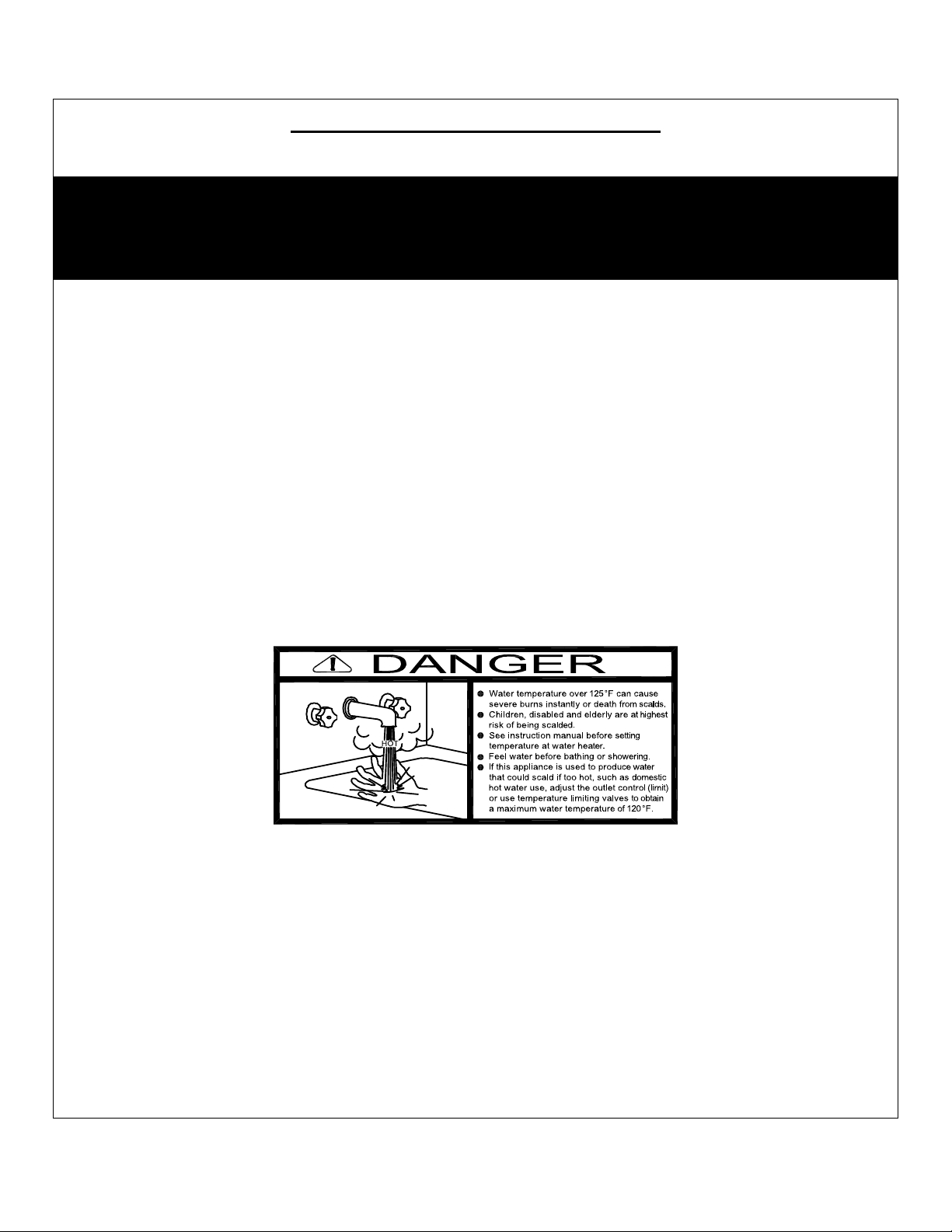

Page 3

DURAWATT® ELECTRIC WATER HEATER

IMPORTANT SAFETY NOTE

It takes only 5 seconds of skin contact with 140°F water to cause a

second degree burn! You must protect against high water temperatures at all

lavatories, tubs, showers and other points of hot water contact.

Accidental scalding from high water temperatures is a greater

risk in some types of installations. Some examples are:

HOMES FOR THE MENTALLY HANDICAPPED

HOMES FOR THE PHYSICALLY HANDICAPPED

HOSPITALS AND NURSING HOMES

ELDER CARE FACILITIES AND REST HOMES

ORPHANAGES AND CHILD CARE FACILITIES

OTHER INSTALLATIONS - WHERE RESPONSE TO CONTACT WITH HOT WATER

MAY BE SLOWER OR WHERE THE DANGER OF HOT WATER CONTACT IS

GREATER

Thermostatically controlled mixing valves must be used in the

design of the potable hot water system.

Potable hot water should be tempered to no more than

110°F when used for bathing or other personal uses.

Good engineering practice mandates the use of thermostatically controlled

mixing valves set at 120°F or less to keep the delivered water temperature below

scalding temperatures.

PV500-6 09/07 3

Page 4

DURAWATT® ELECTRIC WATER HEATER

CHECKING EQUIPMENT BEFORE YOU INSTALL

Inspect the unit completely upon receipt from the freight carrier before signing the bill of lading. Inspect the appliance and

all accompanying parts for signs of impact or mishandling. Verify the total number of pieces shown on packing slips with

those actually received. Contact the freight carrier immediately if any damage or shortage is detected.

WARRANTY

Factory warranty does not cover improper installation or operation. (See warra nty for complete details).

Warranty exclusions include but are not limited to failure or malfunctions resulting from:

1. Failures to properly apply, install, operate, or maintain the appliance in accordance to printed instructions.

2. Abuse, alteration, accident, fire, flood and the like.

3. Sediment or lime buildup, freezing or any other conditions causing inadequate circulation.

4. Corrosive or contaminated atmosphere.

CODES

The equipment shall be installed in accordance with those installation regulations in force in the local area where the

installation is to be made. These shall be carefully followed in all cases. Authorities having jurisdiction shall be consulted

before installation is made. In the absence of such requirements, the installation shall conform to the latest edition of the

National Electrical Code.

LOCATION

1. Locate the unit in a clean and dry area as close as possible to the greatest hot water usage and as near to electrical

power as practical.

2. Install the unit on a firm, level foundation.

3. Locate the foundation on a pitched floor near a suitable drain, or make other provisions to prevent contact to areas

of the building subject to water damage should the boiler or a water connection leak. The drain must be sufficient to

contain water in excess of 210°F.

INSTALLATION

WARNING: Use industry standard safe rigging methods when attempting to lift or move this product. Failure to

follow these instructions could result in property damage, serious injury or death. One common method includes

the use of straps and spreader bars, lifting from the water heater base skid assembly.

1. Check the data decal on the heater. Be sure the electrical supply is adequate for the installation.

2. Carefully remove all shipping supports and bracing. (Float type devices have shipping plugs blocking the float).

3. Install shut-off valves and unions on the inlet and outlet water piping for servicing. Use caution when threading pipe

nipples into tank connections to prevent cross threading, or over-tightening. Always use a back-up wrench on tank

nipples when tightening unions, valves, etc.

4. Insulate hot water and return circulation lines. Insulate cold water supply lines if subject to freezing during shutdown

periods. IMPORTANT: Do not use the plumbing connected to the appliance as a ground for welding or any

other purpose.

5. The water heater is equipped with a temperature and pressure relief valve(s) rated for the input. Pipe the relief valve

discharge to a suitable open drain. The drain pipe may not be smaller than the relief valve opening and must be

secured to prevent it from lifting out of the drain under discharge pressure. Do not install valves or restrictions in the

discharge line.

6. Pipe the drain valve to a suitable open drain.

PV500-6 09/07 4

Page 5

DURAWATT® ELECTRIC WATER HEATER

SERVICE CLEARANCES

Allow sufficient space to provide adequate clearances on all sides for service and inspection. Recommended clearance is

24” at the top and front, 18” at left and right sides of the appliance. Optional equipment may increase the clearance

requirements. Allow sufficient space for installing and servicing connections such as water, electrical, pump and other

auxiliary equipment.

CLEARANCES TO COMBUSTIBLE SURFACES

The appliance must not be installed on a combustible floor, or on a non-combustible floor covering combustible material.

Clearance to unprotected combustible material must be 6” minimum at top, sides and rear, and 24” minimum in front.

Recommended access for service is 18” at sides and rear and 42” in front.

ELECTRICAL CONNECTIONS

Check rating plate on front for correct voltage, phase and amperage. Refer to wiring diagram for control components

mounted on heater.

Use proper wire size and branch circuit protection as required by National Electrical Code and state and local codes. The

PVI electric water heater specification sheets show number and size of power connectors furnished with the heater for

minimum 90°C copper connecting wire.

Use correct size ground wire, attach to pressure connector provided and marked with decal “GR.”

Connect supply feeders to distribution block (or circuit interrupter if furnished) inside electrical enclosure on the heater

IMPORTANT: Check all wiring connections in heater and element enclosure to assure tightness prior to energizing.

NOTE: Use only copper wire of proper sizing for incoming service. Damage resulting from use of aluminum

wiring is excluded from coverage under the warranty of this unit.

ELECTRONIC LOW WATER CUTOFF

The device consists of a probe in the tank that acts as a switch, closed when submerged in water and open when the

water level is below the probe, preventing heating elements from energizing. The probe should be kept free of scale

buildup to insure operation.

OPTIONAL EQUIPMENT

Shunt Trip Circuit Interrupter (optional on all models): The shunt trip, wired in the non-automatic circuit interrupter, is a

safety device designed to open the circuit interrupter and prevent the elements from energizing if the control panel door is

opened.

Time Sequencer (optional on all models):

Time sequencing is optional and used in lieu of the proportional sequencer. It is a series of time delay relays wired to the

contactors which allows approximately a 40 second delay in energizing each succeeding heating element when the

controls call for heat. This prevents all heating elements from energizing at the same time.

Proportional Sequencer (optional on all models): Progressive sequencing (orbital) equalizes the on time for each

contactor and heating element. The heating elements are staged-on based on the demand on the water heater. The

control gives visual, indication of stages that are on. In the event of power interruption, all contactors are turned off. When

power is resumed, the control will re-stage the elements beginning with number one.

PV500-6 09/07 5

Page 6

DURAWATT® ELECTRIC WATER HEATER

START-UP PROCEDURES AND OPERATION

1. The tank must be full of water before turning on electricity. If elements are energized without water in the tank, they

will burn out immediately. Warranty is void on dry starts. Use multimeter to check resistance to ground between all

element terminals and the element mounting flange. (See table 1, page 10)

Fill the heater with water. Open the relief valve to allow air in the tank to escape. Be sure all connections into the tank

are tight as leaks at tank fittings or heating elements can cause damage.

Check inside of electrical enclosure for leaks with tank full of water at water line pressure. Heating element gaskets

are pressure tested at factory but may leak if unit has been in dry storage for a long period of time.

If leaks are present, tighten all four nuts uniformly on the element mounting flange in a criss-cross pattern. Tighten

one nut, then the nut on the diagonal from the first nut. Next, tighten the nut adjacent to the second nut, and then the

nut diagonal from the third nut. Repeat this sequence until all nuts are tight. Each nut should be tightened to 15 foot

pounds of torque. To avoid warping the flange, do not over tighten.

IMPORTANT: All leaks must be corrected prior to turning on electricity to avoid damage to electrical components

within the enclosure.

Electric element (design may vary): 3 phase elements have 3 terminals; 1 phase elements hav e 6 terminals

FIGURE 3

2. Check all electrical connections for tightness before turning the unit on.

3. Energize manual disconnect switch. Check for proper voltage (with voltmeter) on power circuit. Voltage should not

vary more than 5% from voltage shown on data plate. If voltage exceeds these limits, immediately turn off main

disconnect and contact utility company.

4. Energize control circuit switch. Check for proper voltage.

5. Check for proper amperage with ammeter on power circuit. Amperage should not vary more than 5%, when under full

load, from amperage shown on data plate. (Element Continuity Checks, page 10). If amperage exceeds these limits,

immediately turn off main manual disconnect and refer to Electric Water Heater Trouble Sho oting Guid e (page 14).

6. Check magnetic contactors for noise. If noisy, i.e., buzzing or chattering, turn off main power disconnect, disassemble

contactor and blow out foreign particles. Drill filings, dirt or other particles can cause pitting of points which will in turn

burn out contactor and/or wire. Extra care has been taken during fabrication and inspection for cleanliness; however,

field installation is often responsible for debris collecting on the contactor points.

7. The top thermostat is a temperature limiting safety device set at 200°F. The upper operating thermostat is factory set

at 130°F. The lower operating thermostat is set at 120°F Adjust stored water temperature by turning the Operating

thermostat dial to the desired temperature. The Upper Operating and Operating thermostats should be set minimum

10°F higher.

PV500-6 09/07 6

Page 7

DURAWATT® ELECTRIC WATER HEATER

8. If an optional proportional sequencer is furnished, adjust set point to desired water temperature. (All other temperature

controls must be set above the sequencer’s set point.) Refer to manufacturer’s product literature for servicing,

operation and maintenance of proportional sequencer.

9. After startup and with the water heater operating, allow the water in the tank to reach the desired temperature and deenergize the heating elements. Draw hot water from a nearby faucet or outlet until the heating elements come back

on. This will check for proper operation of the thermostats and other operating controls.

IMPORTANT: After approximately 30 minutes of operation, turn off all power to the unit. With main disconnect

off, check each wire connection and fuse clip for elevated temperature. If an elevated temperature is noted, there

is a loose connection at the point of greatest heat. All connections must be tight for proper performance.

MAINTENANCE

A preventative maintenance program is required to ensure a long trouble-free life of the water heater.

Flushing

1. Turn off the heater electrical disconnect switch.

2. Open the drain valve and allow water to flow until it runs clean.

3. Close the drain valve when finished flushing.

4. Turn on the heater electrical disconnect switch.

Draining the Tank

The heater must be drained if it is to be shut down and exposed to freezing temperature. Maintenance and service

procedures may also require draining the heater.

1. Turn off the heater electrical disconnect switch.

2. Close the cold water inlet and hot water outlet valve to heater.

3. Open a relief valve to vent the tank pressure.

4. Open the heater drain valve.

5. If the heater is being drained for an extended shutdown, it is suggested the drain valve be left open during this peri od.

Maintenance Schedule

COMPONENT OPERATION INTERVAL REQUIRED

Tank Sediment Removal Every 3 Months Flushing

Relief Valve Inspect Every 6 Months Test

Electrical Connections Inspect Monthly Inspect for wire discoloration

Electric Elements Check Every 6 Months Amp Draw

Electric Elements Remove & Clean See Page 9

PV500-6 09/07 7

Page 8

DURAWATT® ELECTRIC WATER HEATER

Sediment / Lime Scale Removal

Waterborne impurities consist of the particles of soil and sand which settle out and form a layer of sediment on the bottom

of the tank and adheres to heat exchange surfaces. The amount of calcium carbonate (lime) released from water is in

direct proportion to water temperature and usage. The higher the water temperature or water usage, the more lime

deposits are dropped out of the water. Lime accumulation not only reduces the life of the equipment but also reduces

efficiency of the heater.

T & P Relief Valve

The pressure relief valve should be checked at regular intervals by manually opening the valve. The openings inside the

valve may become restricted by a buildup of scale and become inoperative. If the valve does not open and close properly

and does not blow off internal pressure when tested, it must be replaced. Shut down heater, relieve internal pressure and

replace relief valve with a like kind or one meeting the requirements stated on the rating decal located adjacent to the

relief valve mounting location.

Low Water Cut-Off

The standard low water control is electronic. Inspection should be made of the electrode on water heaters equipped with

electronic low water devices.

Electrical Connections

Check all electrical connections approximately one to two weeks after initial start-up to assure tightness. Heating and

cooling from operation can loosen connections. Visually inspect wire terminal points for any discoloration on a monthly

basis. Discoloration is likely due to a loose connection at the point nearest discoloration. Check Contactors periodically

and clean if necessary and repair or replace pitted points caused by foreign particles. Check Fuses periodically for

continuity and replace if necessary with the same dual-element type.

REPLACING ELECTRIC ELEMENTS

Some electric heating elements installed in dished heads may be factory bent to allow clearance from adjacent elements.

Replacement elements must be identical to the original equipment installed. The Bend Angle Stamp # is required for all

replacement electric element requests. Important

: Install the element facing away from the center of the head.

Typical Electric Element

FIGURE 4

BEND ANGLE STAMP

25° #1

18° #2

FIGURE 4

Note: No stamp on element flange means that element is not bent.

PV500-6 09/07 8

Page 9

DURAWATT® ELECTRIC WATER HEATER

CLEANING ELECTRIC ELEMENTS

Electric immersion INCOLOY® sheath elements are wound at high wattage ratings and must be completely covered by

water while in operation. Otherwise, they overheat and burn out. Scale from the water will collect on the sheathing of the

element over a period of time and must be removed periodically to extend the life of the element. Water in some areas will

produce the scale buildup more rapidly than other areas. The rapidity of the scale buildup is also determined by the watt

density of the element.

It is good maintenance practice to remove and clean 80 W/in² (18kW) density elements on a monthly basis. The interval

between removal and cleaning can usually be extended to six months when 40 W/in² (9kW) density elements are

installed. Most installations where 20 W/in² (4 1/2kW) density elements are used, require only annual cleaning. Elements

are cleaned by soaking in a scale dissolving solution. A 30” piece of four or six inch PVC pipe with a cap on one end

makes an ideal container for element cleaning. (See figure 5.) Contact a chemical supply house for advice on the proper

cleaning solution for your area.

Element Cleaner

FIGURE 5

PV500-6 09/07 9

Page 10

DURAWATT® ELECTRIC WATER HEATER

ELEMENT CONTINUITY CHECKS

I. II III. IV. V.

I. II. III. IV.

V.

ELEMENT RATING

kW VOLT

18 480 A-B 26 78

B-C 26 39 39

C-A 26 39

18 240 A-B 7 20

B-C 7 10 10

C-A 7 10

18 208 A-B 5 15

B-C 5 7.5 7.5

9 480 A-B 51 153

B-C 51 76.5 76.5

C-A 51 76.5

9 240 A-B 13 39

B-C 13 19.5 19.5

C-A 13 19.5

9 208 A-B 10 30

B-C 10 15 15

C-A 10 15

4.5 480 A-B 102 306

B-C 102 153 153

C-A 102 153

4.5 240 A-B 26 78

CHECK OPEN

COILS

C-A 5 7.5

OHM

READING

NORMAL

OHM READING 1

LEG OPEN

OHM READING

2 LEGS OPEN

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

OHM READING 3

LEGS OPEN

∞

∞

∞

∞

∞

∞

∞

OHM READING

TERMINAL TO

FLANGE

DEPENDING ON

THE SEVERITY

OF THE SHORT,

THE OHM

READING MAY

VARY FROM

ZERO, (DIRECT

SHORT) TO

SEVERAL

HUNDRED

OHMS (PARTIAL

SHORT). IN

ANY CASE

WHERE THE

OHM READING

IS NOT INFINITY,

THE ELEMENT

SHOULD BE

REPLACED

B-C 26 39 39

C-A 26 39

4.5 208 A-B 19 58

B-C 19 29 29

C-A

19

29

TABLE 1

∞ ∞

∞ ∞

∞ ∞

∞

∞

PV500-6 09/07 10

Page 11

DURAWATT® ELECTRIC WATER HEATER

TYPICAL SINGLE PHASE WIRING TYPICAL THREE PHASE WIRING

FIGURE 6

TYPICAL WIRE TERMINATIONS

FIGURE 7

FIGURE 8

FIGURE 9

FIGURE 10

PV500-6 09/07 11

Page 12

DURAWATT® ELECTRIC WATER HEATER

TYPICAL CURRENT MEASUREMENT

FIGURE 11 FIGURE 12

KW-VOLTAGE

*14 kW-600V 13 1/2 13 1/2 — —

*7 kW-600V 7 7 — —

18 kW-480V 22 22 — —

9 kW-480V 11 11 — —

4.5 kW-480V 5 1/2 5 1/2 — —

18 kW-240V 44 44 25 75

9 kW-240V 22 22 13 38

4.5 kW-240V 11 11 6 18

18 kW-208V 50 50 29 87

9 kW-208V 25 25 15 44

4.5 kW-208V 12 1/2 12 1/2 7 22

3 Ø AMPS PER ELEMENT 1 Ø AMPS PER ELEMENT

AMPS PER LEG AMPS TOTAL AMPS PER LEG AMPS TOTAL

TABLE 2

NOTE: Elements are usually wired to contactors in groups, in order to maintain an amperage draw of close to, but not more

than, 50 amps per contactor.

*Applications for 600V use a re-rated 480V element. Therefore, the 40W/in.2 is rated for 14 kW instead of 9 kW.

PV500-6 09/07 12

Page 13

DURAWATT® ELECTRIC WATER HEATER

SUPERTANK™ BOLTED HEAD REMOVAL

SUPERTANK™ water heaters and storage tanks will have one or more removable heads or bolted tank sections. The

heads are used to mount an energy module (i.e. TURBOPOWER

water heat exchanger heating elements) or bolted head for access to the tank. If a head or module is removed during the

course of maintenance, replace the O-ring and all special

high quality 9/16”-12 NC, grade 8 bolts, washers and nuts with

identical parts available from your PVI representative or directly from PVI. Do not reuse or substitute these special

fasteners with similar grade 8 bolts, washers and nuts. Install the flange bolts and nuts with a flat washer under each bolt

head and nut. First, snug them in an alternating star pattern. Then, using a calibrated torque wrench, and in an alternating

star pattern, tighten the bolts in 2 increments: 95 ft lbs and 145 ft lbs. Use a small amount of silicone RTV to hold the oring in place while positioning the flanged head or heat exchanger. Apply adhesive sparingly!

Contact PVI at 1-800-433-5654 for replacement Fastener Kits and O-Ring Replacement Instructions.

IMPORTANT: Mark one hole on head and on tank flange for reference when removing head. Be certain to align these

holes during reassembly to insure the original gasket or O-ring mating surfaces will be correctly positioned.

Typical Vertical SUPERTANK™ Bolted Head Attachment

FIGURE 13

®

module, electric elements, QUICKDRAW® or steam or

PV500-6 09/07 13

Page 14

DURAWATT® ELECTRIC WATER HEATER

ELECTRIC WATER HEATER TROUBLESHOOTING GUIDE

TROUBLE PROBABLE CAUSE REMEDY

Thermostat(s) Check to assure proper thermostat setting.

No hot water

Insufficient hot

water

Contractors will not pull in

Control circuit switch is in OFF position Close switch. (Turn to ON position)

Control circuit fuse blown Isolate cause for failure and replace fuse.

Contractor(s) coil open Check continuity. Replace coil if not a complete circuit.

Time delay sequencer not operating

Proportional sequencer not operating

Low water cutoff open

Heating elements Check for open legs. (See table 2).

Heater not large enough to satisfy peak

demands

Hot water lines not insulated

Power fuse(s) blown

Contractor(s) not closing Check coil for continuity. If defective, replace.

Check continuity between all three thermostats or pressure

controls. Complete circuit. If one is open, it must be replaced.

Check for 120 volts to coil on first sequencer step. Allow ample

time for additional steps to energize. If steps do not energize in

reasonable time, replace only the defective relay step. See

wiring diagram.

Check for 120 volts to line connection (L) on sequencer. Check

fuse for continuity. See wiring diagram. Consult factory.

Check for open circuit. Check water level in tank. Replace low

water cutoff if defective.

Add booster or additional kw input. Consult local PVI

representative.

Add insulation; it will protect against heat loss and save on cost

of operation.

Check fuses for continuity. Replace if blown. If blown, determine

cause of break before replacing with same type fuse.

Burned or

discolored wires

Blown fuses

High or low

voltage

High or low

amperage

Wire burned

or melted at

element

Thermostat(s) not correctly set Check to assure proper thermostat control setting.

Check for proper amperage draw. Check for proper ohm

Element(s) not heating

Loose connections

Dirty or pitted contactor points

Loose connection. Defective element

Local utility Check with local utility.

High or low voltage. Defective element

Loose connections. Water leaking on elements

resistance. Replace if defective. Consult factory.

(See table 1)

Tighten all connections. If charred, replace wire with wire of

same type and size.

Remove contactor points and inspect. If dirty, clean with emery

paper. CAUTION: Point must remain flat. If pitted or burned,

contractor points must be replaced.

Check all connections for tightness. Check ohm resistance in

electric elements. Replace.

Check with local utility. Low amperage, check fuses, tighten

connections. Check ohm resistance on elements.

Tighten connection and replace wire. Isolate leaking water and

repair. Replace wire with same type and size.

PV500-6 09/07 14

Loading...

Loading...