Page 1

INSTALLATION & MAINTENANCE MANUAL FOR

QuickDraw

INSTANTANEOUS

ENERGY: WATER TO WATER

U-TUBE SINGLE-WALL & DOUBLE-WALL HEAT EXCHANGERS

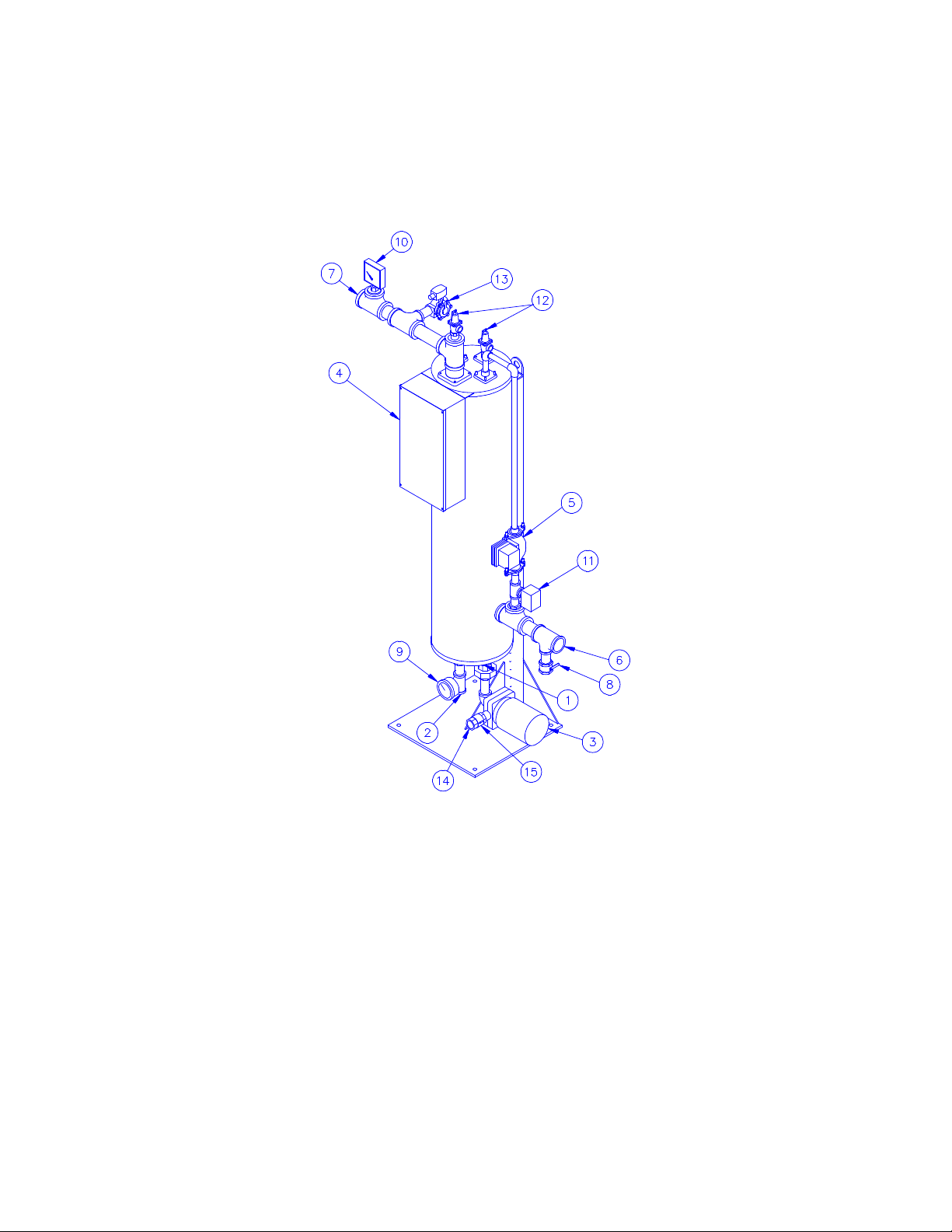

TYPICAL CONSTRUCTION

FIGURE 24-1

1. U-tube Heat Exchanger 9. Boiler Water Temperature Gauge *

2. Boiler Water Inlet 10. Tridicator *

3. Boiler Water Pump 11. Flow Switch *

4. Control Enclosure 12. Relief Valve (AGA optional)

5. Intratank Circulator 13. Tank Purge Valve *

6. Potable Water Inlet 14. Boiler Water Outlet

7. Potable Water Outlet 15. Check Valve

8. Tank Drain * Optional

CAUTION: TEMPERATURES HIGHER THAN 125°F. INCREASE THE RISK OF SCALD INJURY!

IMPORTANT: Clearances for servicing and inspection are 18” at top, sides and rear and a

minimum of one tank diameter in front.

PV500-24 03-99 Section 24 1

Page 2

QuickDraw

WATER WITH SINGLE-WALL / DOUBLE-WALL

START-UP OPERATION

1. The boiler water circulating pump has

been selected to provide optimum flow

through the heat exchanger tubes to

meet demand with the available boiler

water. The pump is controlled by the

thermostat and draws from the

operating boiler water loop. When the

demand is satisfied, the pump stops,

causing the boiler water to bypass the

CAUTION: Temperatures higher than 125°F. increase the risk of scald injury.

unit. In addition, the water heater maybe

equipped with a continuous operation

tank circulation pump. The boiler water

circulation pump is sized to satisfy all of

the head resistance of the heat

exchanger, therefore no pressure drop

need be considered for this unit in sizing

primary loop pumps.

START-UP PROCEDURE

1. Fill the tank with water; open the relief

valve or a nearby hot water outlet to

purge air from the top of tank. Check for

plumbing leaks.

2. Push the control switch to “on” position.

Check boiler water pump operation. The

tank circulating pump should also

operate. Check thermostats for proper

setting. The thermostats are labeled as

to their function. The temperature

limiting device is set at 200°F.

Temperature Setting: The thermostats

are set at the factory to 120°F on the

operating control. Upon startup, the

factory preset operating temperature is

visible on the LED indicator of the digital

controller. Adjust the temperature using

the appropriate up and down arrow keys

on the face of the controller. A slight

variance in temperature control may be

noticed as the digital control tunes,

allow time for the temperature to

stabilize.

3. Open nearby hot water tap to maintain a

flow of water through the tank when

starting up units. Regulate flow of water

through the tank to allow the boiler

water pump to cycle off and on, and

check operation of unit.

PV500-24 03-99 Section 24 2

Page 3

QuickDraw

WATER WITH SINGLE-WALL / DOUBLE-WALL (con't)

ELECTRICAL

The heater is wired for 120 volts and must be electrically grounded in accordance with local

codes, or in the absence of local codes, with the latest edition of the National Electrical Code

ANSI/NFPA. When unit is installed in Canada, it must conform to the CSA C22.1, Canadian

Electrical Code, Part 1 and/or local electrical codes.

1. Water must be pumped continuously

through the boiler when it is being fired.

2. Do not energize water heater or pumps

until tank is full of water. Serious

damage may result.

NOTE: Use only copper wire of proper sizing for incoming service. Damage

resulting from use of aluminum wiring will be excluded from coverage under

the warranty of this unit.

RELIEF VALVE PIPING

The water heater is supplied with a

pressure and temperature relief valve, sized

in accordance with ASME requirements.

Each relief valve should be piped to a

MAINTENANCE

1. A preventive maintenance program

should be established to assure a long,

trouble-free life for the water heater.

2. Scale will normally form in the tank

during operation and will accumulate on

the bottom of the tank. The scale is

formed from the natural chemicals in the

water that precipitate out during the

heating cycles. Some water supplies

contain more of these chemicals than

others, and the scale buildup will occur

3. All wiring must be in accordance with all

local, state, or federal codes.

4. Provide proper overload protection for

the system's circulating pumps.

suitable floor drain. No reducing coupling or

other restriction can be installed in the

discharge line.

more rapidly. Other factors affecting the

scale buildup are the amount of hot

water used and the temperature of the

water. The more hot water used, the

more fresh water containing the scaleforming chemicals is brought into the

tank. As the temperature of the water

increases, the rate of scale deposited

will be increased. The unit should be

inspected and cleaned as required by

local water conditions.

PV500-24 03-99 Section 24 3

Page 4

QuickDraw

WATER WITH SINGLE-WALL / DOUBLE-WALL (con't)

WARNING: Make sure valve is piped to a

proper drain per instructions. Scalding

injury and/or water damage can occur

from either the manual lifting of the lever

or the normal operation of valve if it is

not piped to a proper drain. Insure that

the safety relief valve piping is of the

proper material and rating for the

temperature and pressure of the system

and that it is secured to prevent possible

injury. If valve fails to flow water or

reseat, consult the factory.

CAUTION: The relief valve is a primary

safety device.

Since PVI cannot control the use of the water heater, water conditions, or maintenance,

the warranty on the water heater does not cover poor performance, structural failure, or

leaking due to an excessive accumulation of scale.

3. The temperature limiting device and

thermostat sensors that extend into the

water in the tank may become coated

with scale, depending on the type of

water in your area. This coating will

affect the accuracy of the sensors and

can allow the water temperature to

exceed the desired limits. They should

be removed from the tank and inspected

at intervals. Remove scale if present.

CAUTION: On control systems using 120

volt external power, be certain switch

is off, and power disconnected to

avoid electrical shock before work is

performed on this heater.

PV500-24 03-99 Section 24 4

Loading...

Loading...