Page 1

PVI ATMOSPHERIC GAS WATER HEATERS

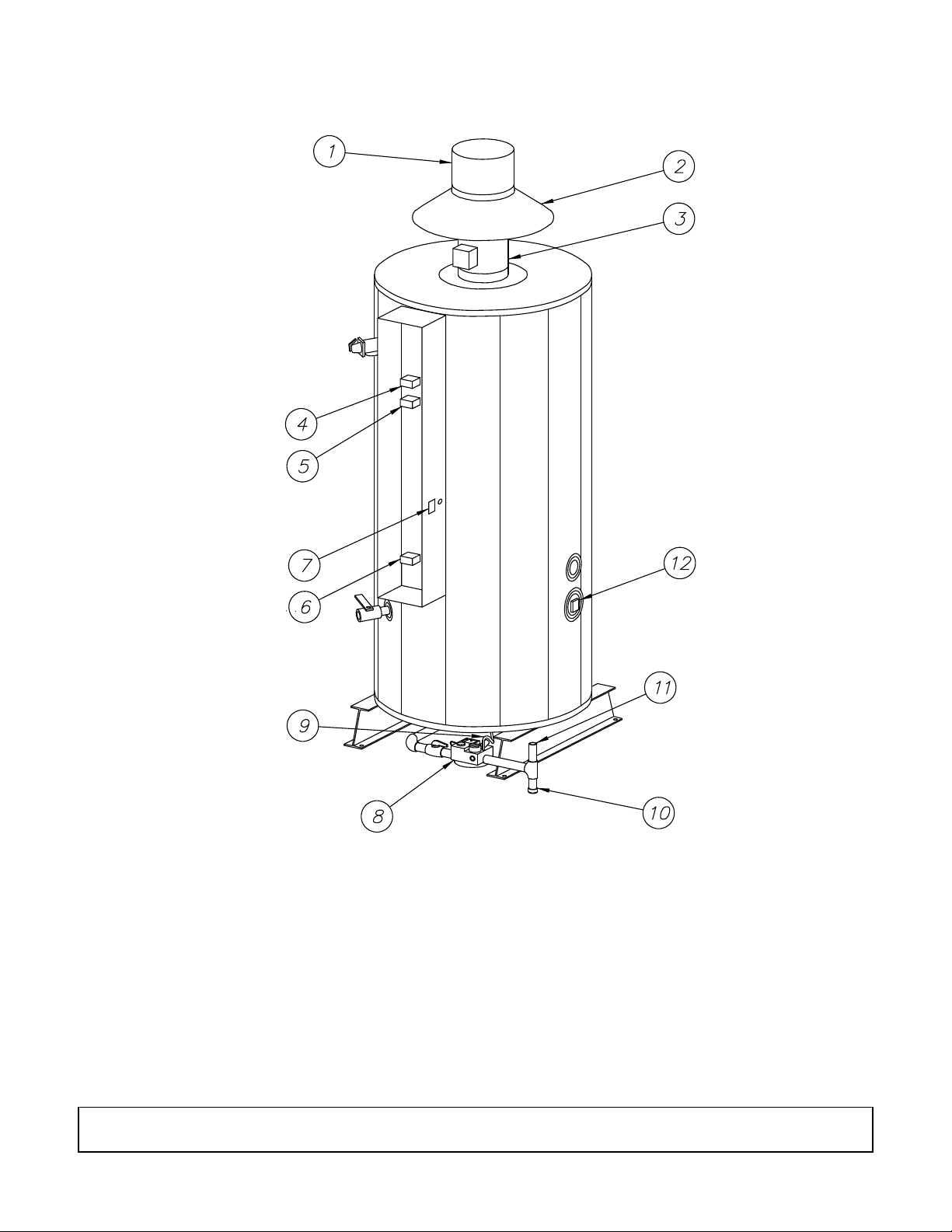

TYPICAL CONSTRUCTION

MANUFACTURED AFTER JANUARY 1, 1994

Figure 2-1

1. Vent stack * 7. Control switch(es) and fuse(s)

2. Draft diverter (hood) 8. Gas valve

3. Flue damper (on some models) 9. Pilot line

4. Temperature limiting device 10. Drip leg *

(set at 200°F) 11. Gas supply line *

5. Upper operating thermostat 12. Handhole cleanout

(set at 130°F)

6. Operating thermostat

(set at 120°F) (* Not furnished by PVI)

CAUTION: TEMPERATURES HIGHER THAN 125°F INCREASE THE RISK OF SCALD INJURY!

IMPORTANT: Clearances to unprotected combustible material must be 8" minimum at top, sides and rear, and 24" in front.

Clearances for servicing and inspection must be 18" minimum at sides and rear and 24" minimum in front.

PV500-2 06/10 1 Section 2

Page 2

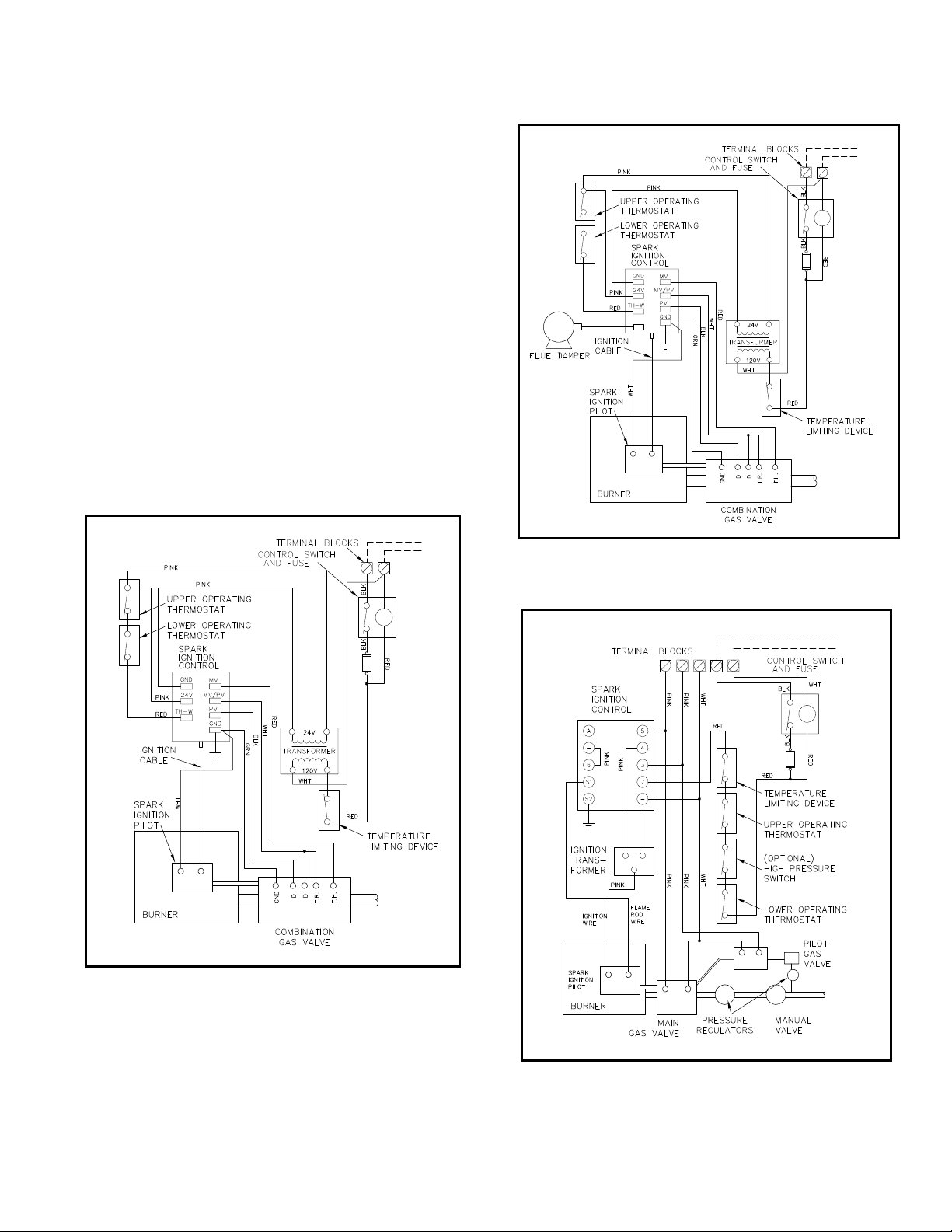

ELECTRICAL

1. Wiring to the unit should conform to the National

Electrical Code or the code legally authorized in your

locality. A fused disconnect switch should be used for

the water heater control. 120V, 1ph, 60 Hz service

wiring is brought to the terminal block in the lower part

of the enclosure on the water heater. See Figures 22, 2-3 and 2-4.

FOR YOUR SAFETY

USE ONLY COPPER WIRE OF PROPER SIZING

FOR INCOMING SERVICE. DAMAGE RESULTING

FROM USE OF ALUMINUM WIRING WILL BE

EXCLUDED FROM COVERAGE UNDER THE

WARRANTY OF THIS UNIT.

Typical 24 Volt Control System

Typical 24 Volt Control System

with Damper

Figure 2-3

Typical 120 Volt Control System

Figure 2-2

Figure 2-4

PV500-2 06/10 2 Section 2

Page 3

START-UP PROCEDURES AND OPERATION

V

V

1. Some PVI atmospheric gas-fired water heaters are

designed to operate with a flue damper that is

shipped with the water heater for installation in the

field. If your water heater was shipped with a flue

damper, it must be attached to the flue collector and

interconnected to the ignition control module before

proceeding with start-up.

Flue Damper Installation

a. Set the flue damper over the flue collector opening

and align the damper drive housing to the front of

the heater.

b. Secure the flue damper to the flue collector at three

locations using the fasteners provided.

c. Remove the damper drive housing cover, feed the

damper interconnect cable through the access hole

and attach the female connector to the four-pin

receptacle. Secure the access hole cover, check to

make sure the test switch is in the "NORMAL"

position, and reattach the damper driver housing

cover.

CAUTION: BE SURE THERE IS NO FOREIGN MATTER

IN THE DAMPER HOUSING BEFORE ATTACHING

THE DRAFT DIVERTER.

Draft Diverter Installation

The draft diverter (provided) is designed to mount on top

of the flue damper. Set the draft diverter on top of the flue

damper and secure in three locations using the fasteners

provided.

Venting

Type B galvanized vent pipe, of the same diameter as the

draft diverter outlet, must be installed to route combustion

products either to existing overhead breeching or to an

appropriate outside location.

1. The control manufacturer's installation and service

manual and start-up procedures for the control

system on your water heater are shipped with the

unit. Study the information carefully and follow the

manufacturer's recommendations.

2. Fill the water heater tank with water. Open the relief

valve or a nearby hot water faucet to allow air in the

tank to escape. Be sure all connections into the tank

are tight as leaks at tank fittings will damage the

insulation.

3. Remove the control box cover to access the control

thermostats and other electrical devices needed to

operate the water heater. The thermostats are labeled

as to their function. The temperature limiting device is

set at 200°F. The thermostats are factory set at

130°F. (the upper operating thermostat) and 120°F

(the operating thermostat). Adjustment may be made

by turning the thermostat dial to the desired

temperature.

CAUTION: BE SURE TO REATTACH THE

CONTROL BOX COVER TO HELP PREVENT

UNAUTHORIZED ACCESS TO CONTROLS.

CAUTION: DO NOT OVERTIGHTEN

COMPRESSION FITTINGS ON THERMOSTAT

BULBS AS CALIBRATION WILL BE CHANGED.

CAUTION: TEMPERATURES HIGHER THAN 125°F

INCREASE THE RISK OF SCALD INJURY!

Gas Train Safety Inspection

CAUTION: ALL VENTED GAS CONTROLS MUST

BE VENTED TO THE OUTSIDE USING TUBING

SIZED IN ACCORDANCE WITH THE

FOLLOWING TABLE:

ENT LINE SIZING

Fuel Line Size,

Nominal Pipe Size,

Inches

Up to 1 1/2 3/4

21

2 1/2 1 1/4

31 1/4

42

52

62 1/2

83

ent Line Size,

Nominal Pipe Size,

Inches

PV500-2 06/10 3 Section 2

Page 4

START-UP PROCEDURES AND OPERATION (con't)

CAUTION: CONDUCT THE FOLLOWING GAS TRAIN

LEAKAGE TESTS BEFORE START-UP, AT

ANNUAL INTERVALS AND PRIOR TO

INVESTIGATING THE CAUSE OF ANY REPORTED

OCCURENCES OF DELAYED IGNITION.

1. Using an appropriate bubble detection solution,

thoroughly coat all gas train pipe connections. If any

bubbles are detected, the leaking connection must be

tightened and tested to assure stoppage of the leak.

2. Attach a manometer. to measure gas pressure, at the

manual gas shutoff valve located just upstream of the

gas train. Adjust gas train inlet pressure to the

specified value (e.g. 14"W.C.), and tightly close the

gas train outlet manual shutoff valve.

3. Reattach the manometer to the gas train outlet

manual shutoff valve and record the measured gas

pressure in inches of water column (in W.C.).

Measure gas pressure again after 15 minutes. If gas

pressure has increased 00.5"W.C. or more, the gas

leak must be isolated to one or more of the operating

gas valves, for example a solenoid actuated gas

shutoff valve. After any leaking valve is replaced, the

reassembled gas train must be leak tested again

before start-up is attempted. (NOTE: All gas valves

removed because of suspected leakage must be

returned to PVI Customer Service for disposition.)

Spark Ignition Systems

These systems use 120 VAC power from an external

source and are equipped with transformers to reduce the

voltage to 24 volts to actuate the gas valve.

At start-up or during operation when the thermostat calls

for heat, the spark ignition system performs the following

basic steps:

1. Opens the flue damper.

2. Activates a high voltage transformer to supply a

sparking action to the pilot.

3. Opens the pilot gas valve. The pilot gas ignites from

the sparking.

4. A sensor located in the pilot flame signals the control

module to open the main burner gas valve. The pilot

flame ignites the main burner gas. An adequate pilot

flame must be present before the main burner gas

valve can open.

5. When the water temperature reaches the operating

thermostat setting, the control circuit opens which

closes both the pilot and main burner gas valves

terminating burner operation.

PV500-2 06/10 4 Section 2

6. The flue damper is closed.

NOTE: The spark ignition system provides additional

safety functions to close the pilot valve if the pilot

flame is not established and to close the main burner

valve if the pilot flame is extinguished while the

burner is in operation.

WATER HEATER START-UP

NOTE: The following test equipment is required:

a. Vent temperature gauge

b. Manometer for checking gas pressure

c. Draft gauge for checking draft in vent

d. CO (carbon monoxide) tester

e. CO

(carbon dioxide) or O2 (oxygen) tester

2

f. Drill and ¼" drill bit for ¼" hole drilled in vent

approximately 12" above draft hood outlet

NOTE: Emergency shutoff can be made by turning off

the fuel inlet shutoff valve.

CAUTION: DO NOT START BURNER WITH

COMBUSTION CHAMBER FULL OF GAS OR WITH

VERY HOT COMBUSTION CHAMBER.

The following steps must be performed to assure

that the water heater is operating safely and

efficiently.

1. Read the enclosed control manufacturer's instruction

sheet for start-up procedure. Allowing the pilot to

ignite with the main burner gas valve turned to "off"

position is required at initial start-up. The pilot flame

can be visually checked for size and position. Check

inlet gas pressure. It must not exceed 14"W.C. Press

the control circuit switch on the front panel to "on"

position. The control system will open the pilot valve

allowing the pilot to ignite. Observe pilot flame. If

satisfactory, open the main burner valve and main

burner should ignite.

Pilot and main burner flames can be observed during

adjustment and under operating conditions by using

the stainless steel hand-held inspection mirror that is

enclosed in the information packet that was shipped

with this water heater.

If the spark ignition fails to ignite the pilot flame, refer

to the control manufacturer's manual supplied with

the unit.

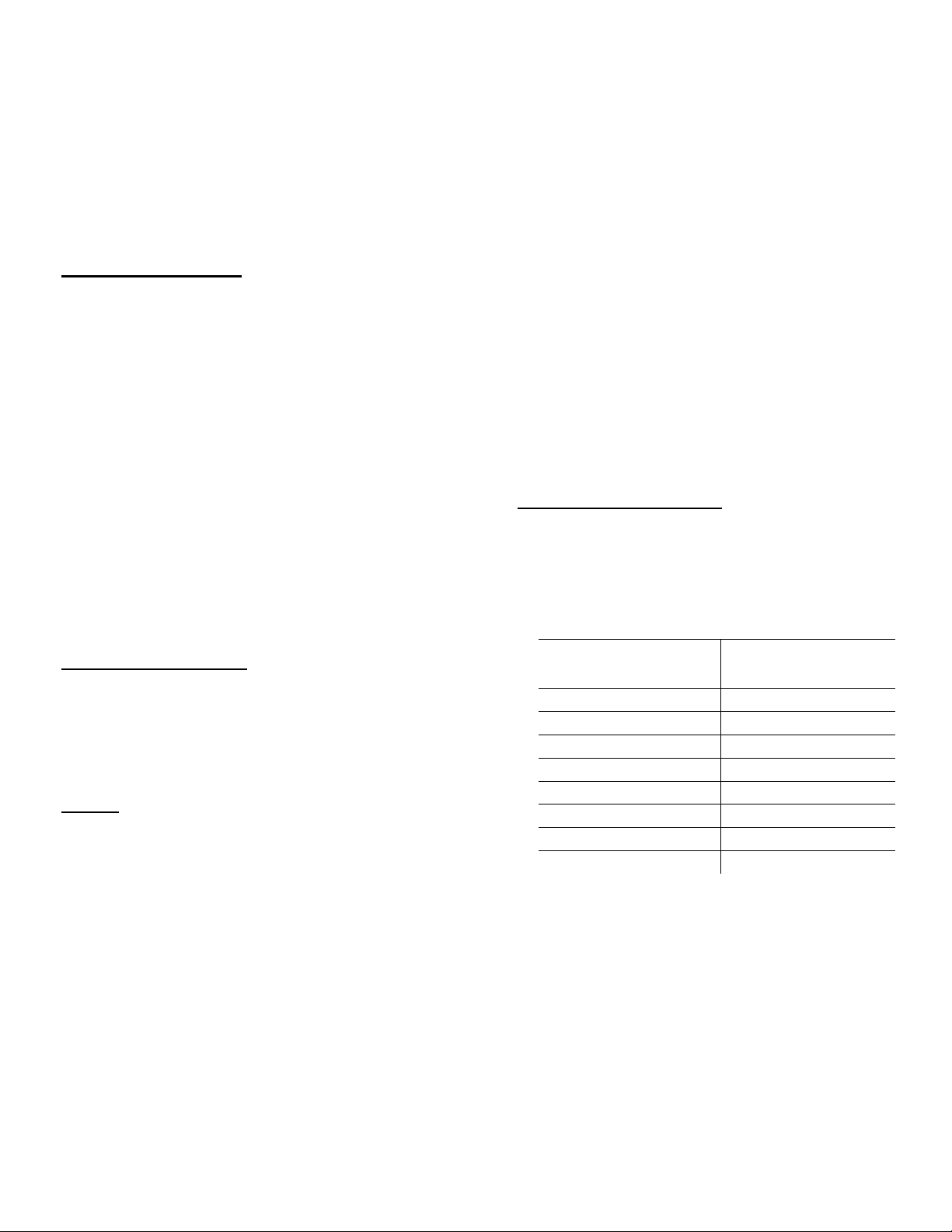

2. Check gas pressure at the gas valve with a

manometer. (See Figure 2-5.) Most gas valves have

pressure taps for this purpose. Adjust gas pressure to

the value shown on rating plate of the water heater.

3. Drill ¼" diameter hole in vent about 12" above draft

diverter. Insert draft gauge in drilled ¼" hole. Draft in

vent should be -.02" -.06" W.C.

Page 5

4. After 20 to 30 minutes of operation or when water in

the tank is above 120°F, insert CO (carbon monoxide)

tester in flue damper opening under the draft diverter

(125 gallon models) or in the flue collector opening

(250 gallon models). CO reading must be less than

.02% (or 200 ppm).

5. Insert CO

(carbon dioxide) tester in the flue damper

2

opening under the draft diverter (125 gallon models)

or in the flue collector opening (250 gallon models)

and take reading. CO

should be 6 to 8%.

2

NOTE: Monitoring CO and CO

readings in vent after the

2

draft diverter will give erroneous readings. These

measurements must be taken as flue gases exit the

heater flue collector under the draft diverter as

dilution with ambient air from the draft diverter occurs

in the vent.

6. Insert temperature gauge in ¼" hole and read vent

temperature. Temperature should be at least 300°F

but less than the room temperature plus 400°F when

the water temperature is approximately 130°F.

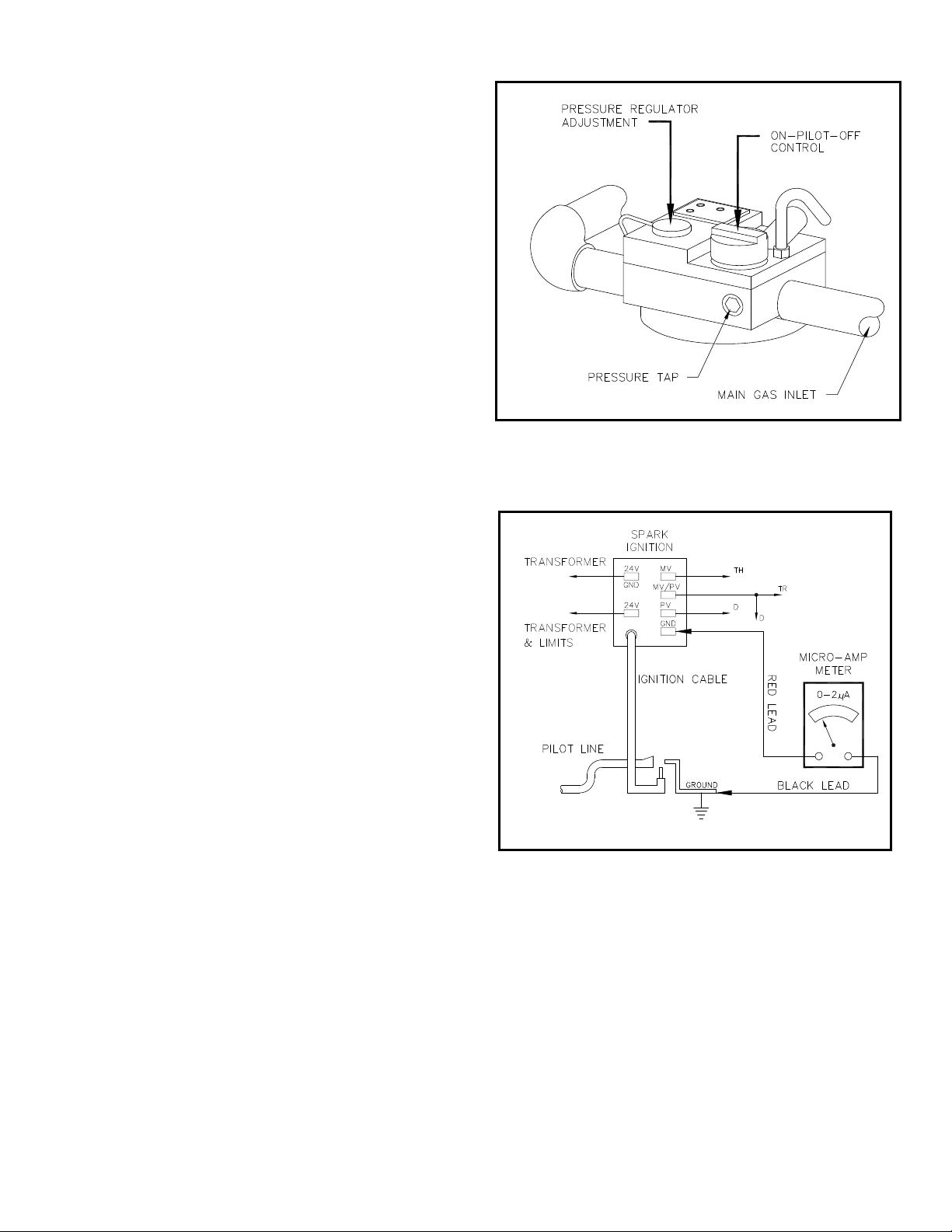

7. Connect micro-amp meter as shown in Figure 2-6 and

check micro-amps. A minimum of two micro-amps is

required for proper operation.

8. Record the following information for future use:

A. Inlet gas pressure ________________"W.C.

B. Gas pressure, manifold (step 2) _____ "W.C.

C. Vent draft (step 3) ______ __________"W.C.

(should be mi nimum of 1 in. W.C.)

D. CO reading (step 4) ______% (less than .02%)

E. CO

reading (step 5) __________% (6-8%)

2

F. Vent gas temperature (step 6)

Gross__________________F.

Less Ambient____________°F.

Net____________________°F.

G. Micro-amps reading (step 7)______________.

COMBINATION GAS VALVE

Figure 2-5

MICRO-AMP METER HOOK-UP

Figure 2-6

PV500-2 06/10 5 Section 2

Page 6

MAINTENANCE AND SAFETY INSPECTIONS

To Minimize Scale Accumulation in Tank

1. A preventative maintenance program should be

established to assure a long, trouble-free life of the

water heater.

2. The tank should be flushed at two or three month

intervals depending on water conditions in your

location. To flush, turn off the electrical disconnect

switch to prevent the burner from operating. Open the

drain valve and allow water to flow through the tank

until it runs clear. Close the drain valve and turn the

electrical switch back on. Draining two or three

gallons from the bottom of the tank on a weekly basis

will also help prevent an accumulation of sediment.

Water impurities can consist of fine particles of soil or

sand which will settle out and form a layer of

sediment on the bottom of the tank.

A scale of lime will normally form in the tank during

operation and will accumulate on the bottom of the

tank. Lime is formed from the natural chemicals in the

water which precipitate out during the heating cycles.

Some water supplies contain more of these elements

than others, and the scale buildup will occur more

rapidly. Other factors affecting the scale buildup are

the amount of hot water used and the water

temperature. As more hot water is used, the more

fresh water containing the scale-forming elements is

brought into the tank. As the temperature of the water

increases, the rate of scale deposition will be

increased.

Sediment and scale accumulations in the tank will

greatly reduce the water heating ability of the heater

by reducing effectiveness of heat transfer surfaces.

When heating energy from the burner cannot be

effectively transferred to the water in the tank, the

metal can overheat causing it to lose structural

strength.

3. Should a firetube leak for any reason, consult the

factory for instructions. Inspect bottom tubesheet on a

regular basis to determine if insulation may have

pulled away from the tubesheet. Repair or replace as

required.

NOTE: Condensate coming from the tubes on a cold start

is normal and does not indicate a leaking tube.

4. The tank may have a handhole for inspection and

cleaning use. The handhole cover should be

periodically removed and the tank inspected for scale

buildup. If scale is present, it can be loosened with a

high-pressure stream of water. The smaller pieces

can be flushed through the drain and the larger

pieces removed by hand through the handhole. The

frequency of inspections should be determined by the

rate of scale buildup. We recommend 30-60 day

intervals.

PV500-2 06/10 6 Section 2

Periodic Inspection of Operational Components

Periodic inspections and check-out of the burner

ignition system, control system and gas valve

operation should be made and recorded for future

reference.

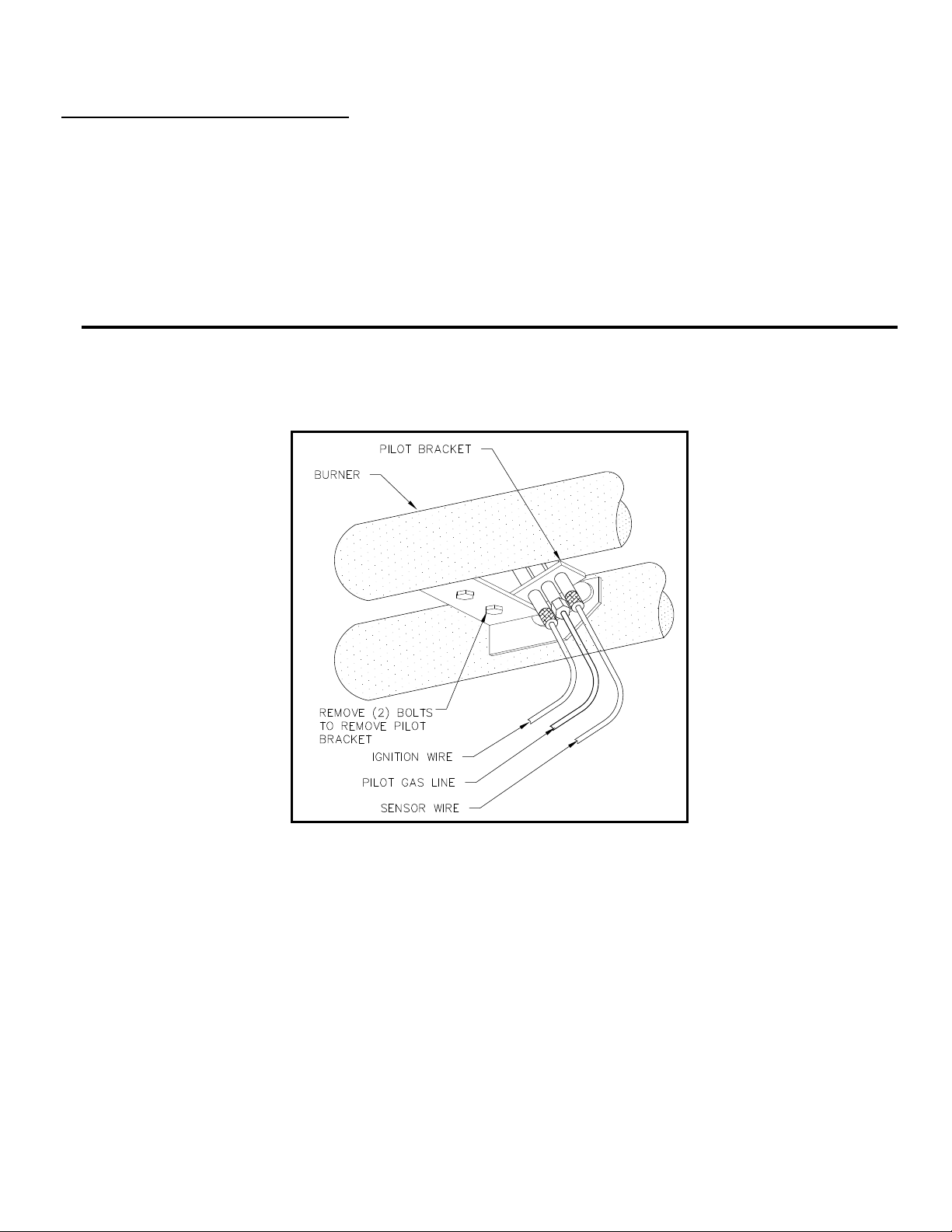

1. Pilot assemblies should be checked by a qualified

serviceman using control manufacturer's instructions.

Wiring connections on the ignition high voltage wire

and flame sensor wire must be tight. Clearance

between these wires and metal parts of the water

heater or burner must be maintained to avoid possible

shorting out. Positions of the electrode, flame sensor

and pilot flames are very important and have been set

by the manufacturer. If they are loose or if ceramic

insulators are cracked or broken, replace the pilot

assembly. To replace, remove pilot bracket from

bottom of burner, disconnect the pilot gas line and

replace pilot assembly on pilot bracket. Replace in

reverse order. Do not bend or distort pilot bracket as

this determines pilot flame position relative to burner

orifices. (See Figure 2-7). Inspect individual burner

jets for evidence of overheating. Replace burner jets

as necessary.

2. Examine the venting system at least quarterly for

proper connections, alignment and the presence of

corrosion. Any corroded vent section should be

immediately replaced to prevent CO leakage. Recheck vent temperature (step 6, page 5) and correct if

necessary.

CAUTION: THE RELIEF VALVE IS A PRIMARY

SAFETY DEVICE.

3. The temperature and pressure relief valve should be

removed and inspected at regular intervals to

determine its condition for safe operation. The

openings inside the valve may become restricted by a

buildup of scale and become inoperative. If the valve

does not open and close properly when tested, it

must be replaced with a like kind or one meeting the

requirements stated on the rating tag located on the

relief valve.

4. Spark ignition system operation should be checked as

follows:

Flame failure – Close downstream gas train shutoff

valve and determine safety shutdown timing.

Flame signal – Determine flame signal strength in

accordance with step 7 on page 5.

Page 7

MAINTENANCE AND SAFETY INSPECTIONS (con't)

Taking the Water Heater Out of Service

Extended shutdown of the appliance and restarting

instructions are as follows:

a. Turn off all power and fuel supplies.

b. Drain and flush tank as previously discussed.

PILOT LOCATION & REMOVAL

SPARK IGNITION SYSTEMS

c. Tag power switch(es) indicating that fuel is off

and tank is empty.

d. To restart, refill tank with water and turn fuel

and power switch(es) on. Reset all controls

and conduct start-up of the appliance as

discussed on preceding pages.

Figure 2-7

PV500-2 06/10 7 Section 2

Loading...

Loading...