Page 1

START-UP OF POWER VT

®

WATER HEATERS OR BOILERS

**FOR DETAILED INFORMATION SEE INSTALLATION & MAINTENANCE MANUAL **

WARNING: These startup instructions are prepared for a qualified service installer, service

agency or gas supplier and require and rely on the experience and training of these

qualified gas appliance technicians to be safely completed. Attempting to follow these

instructions without such training and experience can result in property damage, exposure

to hazardous materials, personal injury or death.

1. Check the water heater tank to make sure it is full of water. (Remove air through T&P valve)

2. Remove enclosure panel cover on the water heater to expose control circuit. A wiring diagram, included in this

packet, will show the controls used in our circuitry.

3. Visually check that all components are intact and no damage has occurred during transit.

4. Check all connections within the control cabinet. A loose connection could cause intermittent shutdowns.

5. Check flue gases with an electronic flue analyzer to make final settings of gas pressure regulator.

6. The readings need to be taken from a hole in the vent several inches downstream of the fan outlet connection.

7. Insert 0-6" W.C. manometer into the test opening in the vent. Pressure in stack should not exceed 2" W.C.

8. When water in tank is above 120°F, insert analyzer or O

9. Increase manifold gas pressure at the main gas pressure regulator taking O

regulator until optimum O

where the greatest reading is achieved.

10. CO should not exceed 200 ppm. A reading greater than 200 ppm indicates lack of air. Reduce manifold gas

pressure slightly and take readings until CO is within proper range. Optimum reading is no CO.

11. If manifold pressure was changed during startup, take a final CO and O

12. Record CO

13. Insert vent temperature gauge in test opening and read gross vent temperature; maximum gross stack is to be

250°F. If an excessively high gross vent temperature is recorded, consult the factory.

14. Check each operating and limit control to be sure they function properly by lowering and raising the temperature

setting on each of the controls, causing burner to cycle on and off.

15. NOTE: During the initial firing of the burner, smoke that is not related to the burner will be emitted from the

heater. This is normal during "burn in" and could possibly continue for several hours.

16. Complete the attached startup report.

and NOx if applicable. (See I&M if NOx measurement is required).

2

% (5-7%) is reached. If O2% decreases, reduce the gas pressure to last reading

2

testing in test opening; take O2 reading in percentage.

2

reading at each adjustment of gas

2

reading.

2

Important – Contact PVI Customer Service, 800-433-5654, if any recommended setpoint or analysis

reading falls outside of the recommended ranges before completing startup.

PV 413A 8/05

Page 2

START-UP REPORT

POWER VT

Warning: Startup must be performed by a qualified service installer, service agency or the gas supplier.

Model Number:

®

WATER HEATERS OR BOILERS

Serial Number:

Job Name:

Address:

GENERAL INFORMATION

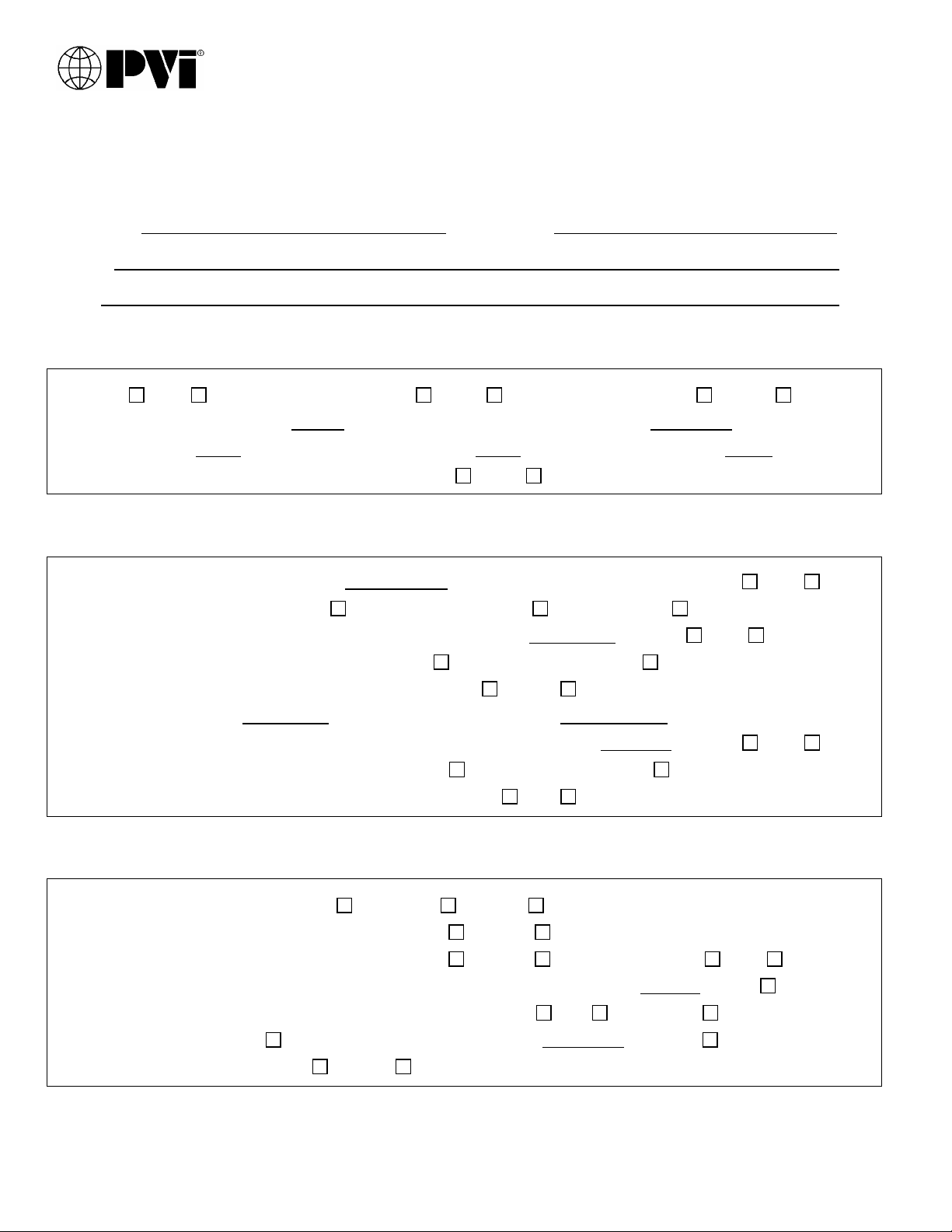

Restart? Yes No Installation is: New Replacement/Renovation Indoor Outdoor

Primary operating voltage supply: VAC Voltage from neutral to earth ground: (should be zero)

Thermostat Setting: °F Thermostat Setting: °F Hi-Limit Setting °F

Is the T & P Relief Valve plumbed to a suitable drain? Yes No

BOILER INSTALLATIONS (Closed Loop Heating System)

Boiler water supply and return piping size Is there a Primary (boiler bypass) loop? Yes No

Primary (boiler bypass) loop contains: Modulating 3-way valve Manual valve No valve

What is the horsepower of the primary (boiler loop) circulator pump? VFD? Yes No

What is the location of the primary circulator pump? Downstream from boiler Upstream from boiler

Is there a balancing valve (circuit setter) in the primary loop? Yes No

Supply water temperature: °F Return water temperature: °F

What is the horsepower of the secondary (main heating loop) circulator pump? VFD? Yes No

What is the location of the secondary circulator pump? Downstream from boiler Upstream from boiler

Is there a balancing valve (circuit setter) in the secondary loop? Yes No

WATER HEATER INSTALLATIONS

Type of piping connected to heater: Copper Brass Galvanized

Is there a check valve in the supply water piping? Yes No

Is there a water softener on the cold water supply? Yes No Operational? Yes No

Is there a mixing valve on the hot water supply? If yes; temperature setting: °F No

Is there expansion relief in the cold water supply? If yes, what type: tank valve No

Is there a recirculation loop? Yes Circulating pump horsepower: No

Is there a floor drain in the room? Yes No

PV 413 8/05 817-335-9531 ● 800-433-5654 ● FAX 800-880-2019 ● www.pvi.com

Page 1 of 2

Page 3

Model Number: Serial Number:

VENTING and COMBUSTION AIR

Vent Material: (CPVC – Water Heaters Only; AL29-4C Stainless Steel – Boilers or Water Heaters)

Vent Diameter: inches; Vent Length: feet Vent Type: Through-the-roof Through Sidewall

Does vent have condensate drain? Yes No Does vent have elbows? Yes; Qty No

Does vent contain any of these devices? Power Vent Draft Inducer Draft Regulator Flue Damper

Combustion air louvers or openings? Yes; Qty: Size: No Interlocked? Yes No

Have direct-ducted combustion air? Yes; duct diameter inches, length feet. No

Duct Material: Does duct have elbows? Yes; Qty No

GAS SUPPLY

Type of Gas: Natural LP Inlet Static Gas Pressure: “W.C. (14”W.C. maximum)

Gas Supply Pipe Size: Inlet Flow Gas Pressure: “W.C. (see data label)

Combination Gas Pressure Switch Setting: High “W.C. Low “W.C.

COMBUSTION ANALYSIS

Heaters

Pilot Gas Pressure

Manifold Gas Pressure

Boilers

st

Stage 2nd Stage

1

Carbon Dioxide CO2 (8-9%)

Oxygen O2 (5-7%)

Carbon Monoxide CO (less than 200 ppm)

Nitrogen Oxide NOX (if available)

Vent Pressure (+.25” to + 2.0” W.C.)

Gross Vent Temperature (maximum 230°F)

less Room Temperature °F

= Net Vent Temperature °F

Important: You must submit the original copy of the completed form to your PVI representative before the

warranty will become effective on this product. Contact Customer Service for assistance at 1-800-433-5654.

Service Company Name: Phone:

Service Co. Address:

Start-up Performed By:

Customer:

Phone No.: Date:

Date:

PV 413 8/05 817-335-9531 ● 800-433-5654 ● FAX 800-880-2019 ● www.pvi.com

Page 2 of 2

Loading...

Loading...