Page 1

START-UP OF STEAM AND BOILER WATER HEATERS

**FOR DETAILED INFORMATION SEE INSTALLATION & MAINTENANCE MANUAL **

WARNING: These startup instructions are prepared for a qualified service installer,

service agency or gas supplier and require and rely on the experience and training of

these qualified gas appliance technicians to be safely completed. Attempting to follow

these instructions without such training and experience can result in property damage,

exposure to hazardous materials, personal injury or death.

1. When placing a unit into operation, open relief valve to purge air from top of tank and begin to fill the tank with

cold water. Check for plumbing leaks. Be sure the tank is completely filled before closing the relief valve.

2. Push control switch, located on the control box, to “ON” to activate the control valves (steam or boiler water)

and thermostats. Check the valves for proper operation.

3. Check operating thermostat settings. The operating thermostat is set at the factory at approximately 120°F and

the upper operating thermostat (if supplied) is set at approximately 125°F. Adjustment may be made by turning

the thermostat’s dial to the desired temperature. The temperature limiting device is factory set at 200°F.

4. Push the operating switch to “OFF” before opening manual main steam or boiler water supply valve. The

heating supply should be introduced gradually until all passages of the heat exchanger are filled

5. Start operation gradually. Do not admit steam or boiler water to the unit suddenly when empty or cold. Do not

shock unit with cold fluid when unit is hot. . Slowly bring the unit up to temperature.

6. Do not operate unit under conditions in excess of those specified on nameplate.

7. Open nearby hot water tap to maintain a flow of water through the tank when starting up units. Regulate flow

of water through the tank to allow the control valve to cycle off and on, and check operation of all safety and

operating controls.

8. In all installations there should be no pulsation or water hammer since this causes vibration and strain with

resulting leaks.

9. Retighten bolting on all gasketed joints after the heat exchanger has reached temperature to prevent leaks

and gasket failures. Retightening should be done uniformly and in a diametrically staggered pattern

10. Complete the attached startup report.

Important – Contact PVI Customer Service, 800-433-5654, if any recommended setpoint or analysis

reading falls outside of the recommended ranges before completing startup.

PV 19A 8/05

Page 2

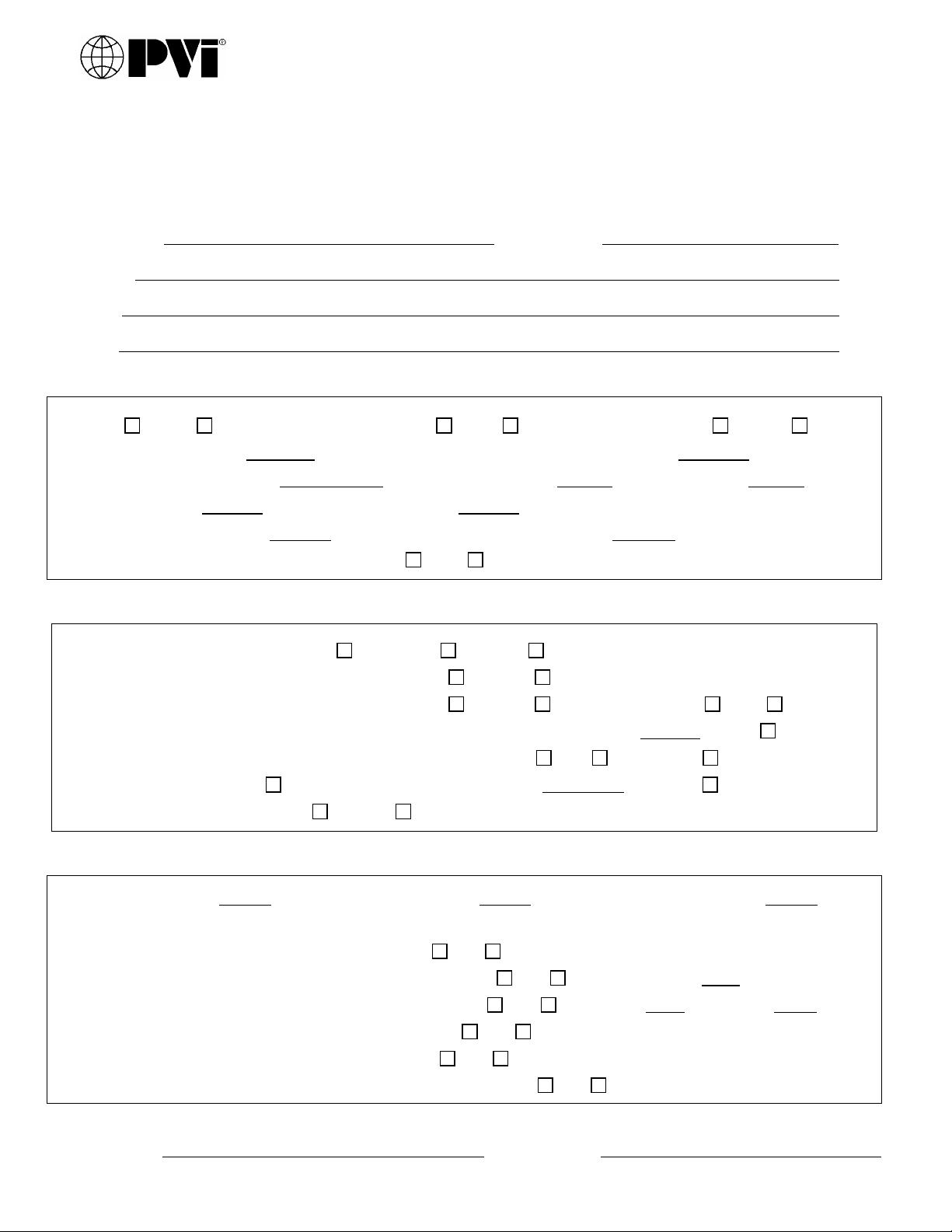

START-UP REPORT

STEAM/WATER - TO - WATER HEATERS

QUICKDRAW® - CSX - ISX

Warning: Startup must be performed by a qualified service installer, service agency or the gas supplier.

Model Number:

Job Name:

Address:

GENERAL INFORMATION

Serial Number:

Restart? Yes No Installation is: New Replacement/Renovation Indoor Outdoor

Primary operating voltage: VAC Voltage from neutral to earth ground: (should be zero)

Thermostat Set Points: Hi-Limit °F Upper Operating: °F Operating °F

Operating (optional): °F Operating (optional): °F

Cold Water Inlet Temperature: °F Hot Water Outlet Temperature: °F

T & P Relief Valve(s) plumbed to a suitable drain? Yes No

WATER HEATER INSTALLATION

Type of piping connected to heater: Copper Brass Galvanized

Is there a check valve in the supply water piping? Yes No

Is there a water softener on the cold water supply? Yes No Operational? Yes No

Is there a mixing valve on the hot water supply? If yes; temperature setting: °F No

Is there expansion relief in the cold water supply? If yes, what type: tank valve No

Is there a recirculation loop? Yes Circulating pump horsepower: No

Is there a floor drain in the room? Yes No

STEAM SYSTEM

Static Steam Pressure: PSI Flow Steam Pressure: PSI Operating Steam Pressure: PSI

Is steam supplied from utility company or installed boilers?

Is there a condensate trap in the steam supply main? Yes No

Is there lift in the condensate return line? (Before receiver tank) Yes No Lift in feet: FT

Is there a steam strainer ahead of the appliance steam valve? Yes No Size: in. Mesh:

Is there a steam trap ahead of the appliance steam valve? Yes No

Is there a steam trap in the appliance condensate line? Yes No

Does steam flow stop completely when steam valve is de-energized? Yes No

Model Number:

Serial Number:

PV 19 8/05 817-335-9531 ● 800-433-5654 ● FAX 800-880-2019 ● www.pvi.com Page 2 of 3

Page 3

HEATING WATER SUPPLY

Is heating water supplied from boiler? Yes No

If No, describe:

Heating water pump flow rate: GPM Pump Horsepower: HP

Supply water temperature: °F Return Water temperature: °F

Comments:

Service Company Name:

Service Company Address:

Start-up Performed By:

Customer Representative:

Phone:

Date:

Date:

Important: You must submit the original copy of the completed form to your PVI representative before the

warranty will become effective on this product. Contact Customer Service for assistance at 1-800-433-5654.

PV 19 8/05 817-335-9531 ● 800-433-5654 ● FAX 800-880-2019 ● www.pvi.com Page 3 of 3

Loading...

Loading...