Page 1

INSTALLATION & MAINTENANCE MANUAL FOR

MAXIM

INTEGRATED WATER HEATING SYSTEM

IMPORTANT: READ AND FOLLOW THE INFORMATION IN THIS MANUAL, THE GENERAL

INSTALLATION & MAINTENANCE MANUAL, AND ALL OTHER PROVIDED INSTRUCTIONS,

LABELS AND MARKINGS BEFORE INSTALLING, OPERATING OR SERVICING THIS UNIT.

TABLE OF CONTENTS

Typical Construction 2

Introduction 3

Start-up Procedures & Warnings 4 – 5

Electrical 5

Maintenance & Safety Inspections 5 – 7

MX Burner Manual, Start-up & Troubleshooting Guide 8 – 14

MXG Burner Manual Refer to PV500-21A

MXO Burner Manual Refer to PV500-22A

MXL Burner Manual Refer to Heat Wise SU-3

WARNING: If the information on the appliance and in the supplied manual(s) is not followed

exactly, a fire, explosion or exposure to hazardous materials may result causing

property damage, personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or the gas

supplier.

This product contains, or may come to contain, materials that have been identified as carcinogenic,

or possibly carcinogenic, to humans. Before installing, servicing, or removing this product, read and

follow the supplied instructions.

PV500-17 07/13 Section 17

PVI INDUSTRIES, LLC

3209 Galvez Ave.

Fort Worth, TX 76111

(800) 433-5654

www.pvi.com

1

Page 2

MAXIM

INTEGRATED WATER HEATING SYSTEM

TYPICAL CONSTRUCTION - MX MODEL

FIGURE 17-1

1. VENT STACK * 8. HANDHOLE CLEANOUT

2. TEMPERATURE LIMITING DEVICE (set at 200°F) 9. UPPER OPERATING THERMOSTAT (set at 130°F)

3. OPERATING THERMOSTAT (set at 120°F) 10. COLD WATER INLET & RETURN CONNECTION

4. CONTROL SWITCH(es) AND FUSE(s) 11. DRAIN

5. GAS VALVE 12. RELIEF VALVE

6. GAS INLET 13. PRIMARY SAFETY CONTROL

7. BURNER (MX model shown) 14. DIFFERENTIAL AIR PROVING SWITCH

(* NOT FURNISHED BY PVI)

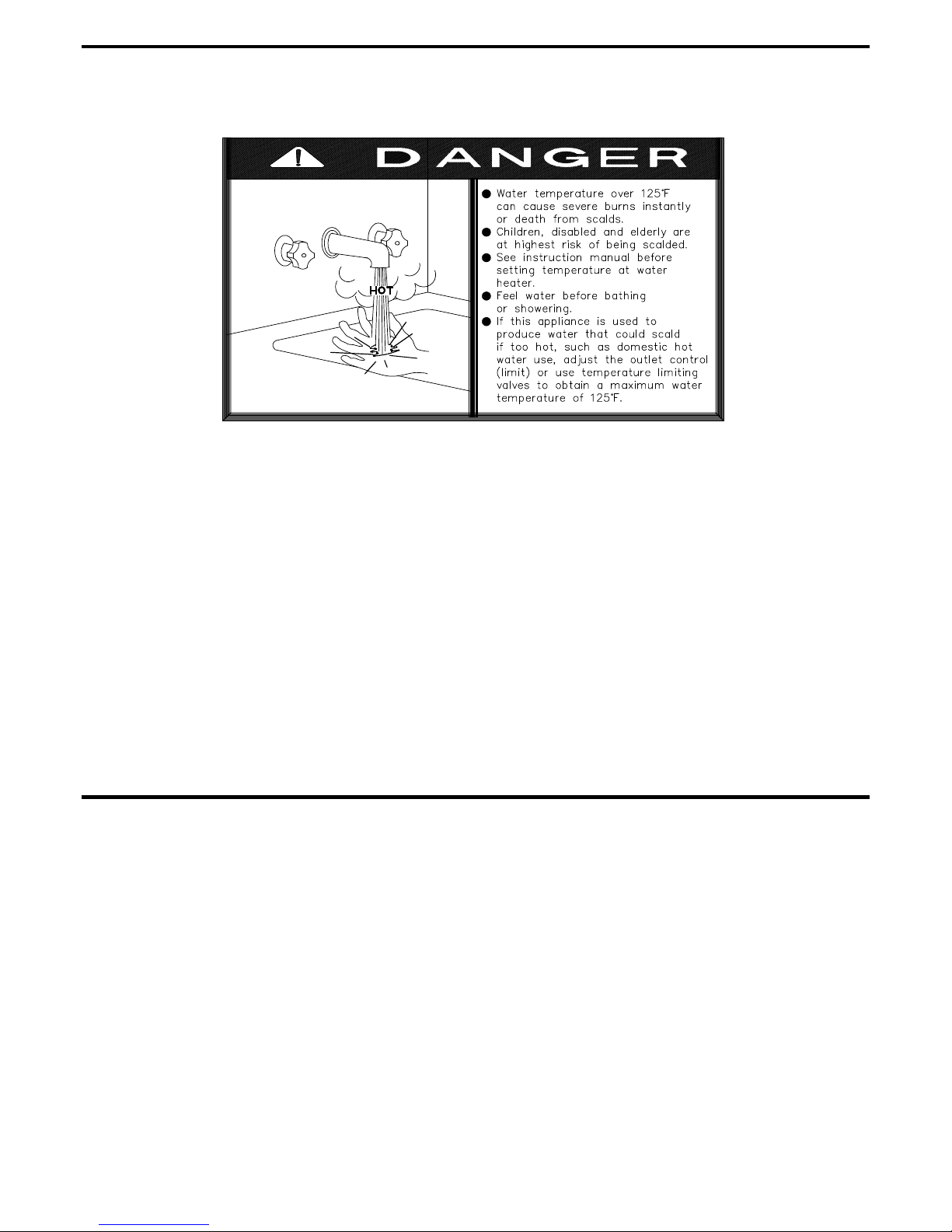

WARNING! Temperatures higher than 125°F increase the risk of scald injury!

IMPORTANT! Clearance to unprotected combustible material must be 8"min. at top, sides and rear, and

24" min. in front.

PV500-17 07/13 Section 17

2

Page 3

MAXIM

PRODUCT SAFETY INFORMATION

REFRACTORY CERAMIC FIBER PRODUCT

WITH CRYSTALLINE SILICA

WARNING: This product contains crystalline silica which has been identified by the International Agency

for Research on Cancer (IARC) as carcinogenic to humans. This product also contains refractory ceramic

fibers which have been identified by the IARC as possibly carcinogenic to humans.

RISKS:

Airborne fibrous insulation is a possible cancer hazard by inhalation.

Airborne crystalline silica may cause silicosis (lung disease) by inhalation.

May cause temporary irritation to eyes, skin, and respiratory tract.

PRECAUTIONARY MEASURES:

Minimize airborne fibers with engineering controls.

Use NIOSH/MSHA approved respirators as required (see MSDS).

Wear long sleeved, loose-fitting clothing, eye protection, and gloves.

FIRST AID MEASURES:

Eyes: Flush with water.

Skin: Wash with soap and warm water.

Ingestion: Do not induce vomiting. Get medical attention if gastrointestinal symptoms develop.

Inhalation: Remove to fresh clean air.

If any of the above irritations persists, seek medical attention.

WARNING! If you are unfamiliar with the safe handling of Refractory Ceramic Fiber

products, or if you wish additional information prior to beginning any disassembly of the

water heater that might expose refractory ceramic fiber materials, contact: Unifrax

Corporation, 2351 Whirlpool Street, Niagara Falls, NY 14305-2413, 1-800-322-2293.

This manual covers installation, operation and maintenance on all PVI commercial water heaters and storage tanks. Read all

instructions thoroughly before attempting to start any unit.

CAUTION: Factory authorized start-up may be required on this equipment. Labeling on

the unit will indicate this requirement.

City, state and national codes governing installation of commercial water heaters and storage tanks must

be followed and take precedence over recommendations in this manual.

CODES FOR WATER HEATERS & BOILERS INSTALLATIONS

ANSI Z223.1 National Fuel Gas Code

ANSI Z83.1 Installation of Gas Piping & Gas Equipment

on Industrial & Certain other premises

American Gas Association

NFPA No.31 Installation of Oil Burning Equipment

ANSI Z95.1 National Fire Protection Association

NFPA No.54 Installation of Gas Appliances & Gas

Piping

Avoid breathing fiber particulates and dust.

INTRODUCTION

CSA B149 Natural Gas & Propane Installation Code

CSA B139 Installation Code for Oil Burning Equipment

National Electrical Code National Fire Protection

Association

Canadian Electrical Code Part 1

All Provincial Ordinances

All State & Local Codes

PV500-17 07/13 Section 17

3

Page 4

MAXIM

START-UP PROCEDURES

WARNING!

This water heater is equipped with an

adjustable thermostat to control water

temperature. Hot water temperatures

required for automatic dishwasher and

laundry use could cause scald burns

resulting in serious personal injury and/or

death. The temperature at which injury

occurs varies with the person’s age and

time of exposure. The slower response

time of disabled persons increases the

hazards to them. Never allow small

children to use a hot water tap or to draw

their own bath water. Never leave a child

or disabled person unattended in a

WARNING!

Failure to follow these instructions can

result in serious person injury or death.

Do not relight pilot or start burner with

combustion chamber full of gas or oil

vapor, or with very hot combustion

chamber.

1. Study the burner start-up information included

in this manual carefully.

2. Fill the water heater tank with water. Open the

relief valve or a nearby hot water faucet to

allow air in the tank to escape.

PV500-17 12-2004 Section 17

bathtub or shower. Since the thermostat

temperature setting could be set too high,

adjust the thermostat temperature setting

to 125°F or lower. Lower settings help

reduce risk of scald injury. Remember, no

water heater system will provide exact

temperature at all times. Allow a few days

of operation at this setting to determine

the correct temperature setting consistent

with your needs and remember, “Hotter

water increases the risk of scald injury.”

Also, the water heater should be located

in an area where the general public does

not have access to set temperatures.

Be sure all connections into the tank are tight

as leaks at tank fittings will damage the

insulation.

3. The top thermostat is a temperature limiting

safety device set at 200°F. The thermostats

are set at the factory at 130°F on the upper

operating thermostat and 120°F on the lower

operating thermostat. The lower operating

thermostat should be set 10° lower than the

upper operating thermostat setting. Adjustment

may be made by turning the thermostat dial to

the desired temperature.

4

Page 5

MAXIM

START-UP PROCEDURES (con't)

CAUTION!

Conduct the following gas train leakage test before start-up, at annual intervals and

prior to investigating the cause of any reported occurrences of delayed ignition.

1. Using an appropriate bubble detection

solution, thoroughly coat all gas train pipe

connections. If any bubbles are detected, the

leaking connection must be tightened,

recoated and rechecked to assure stoppage

of the leak.

2. Attach a manometer, to measure gas

pressure, at the manual gas shutoff valve

located just upstream of the gas train. Adjust

gas train inlet pressure to the specified value

(e.g. 14 in. W.C.), and tightly close the gas

train manual shutoff valve closest to burner.

ELECTRICAL

1. Wiring to the unit should conform to the

National Electrical Code or the code legally

authorized in your locality. A fused disconnect

switch should be used for water heater

control. Service wiring connections of 120V, 1

phase, 60 Hz. are located in the enclosure on

the water heater.

MAINTENANCE AND SAFETY INSPECTIONS

1. Establish a preventive maintenance program

to assure a longer water heater life.

2. The tank should be flushed at two- or threemonth intervals depending on water conditions

in your location. To flush, turn off electrical

disconnect switch to prevent the burner from

operating. Open drain valve and allow water to

flow through the tank until it runs clear. Close

the drain valve and turn the electrical switch

back on. Draining two or three gallons from the

bottom of the tank on a weekly basis will also

help prevent the accumulation of sediment.

Water impurities consist of fine particles of soil

or sand that will settle out and form a layer of

sediment on the bottom of the tank.

3. Reattach the manometer to the gas train

manual shutoff valve at the burner and record

the measured gas pressure in inches of water

column (in W.C.). Measure gas pressure

again after 15 minutes. If gas pressure has

increased 0.5" W.C. or more, the gas leak

must be isolated to one or more of the

operating gas valves, for example, a solenoid

actuated gas shutoff valve. After any leaking

valve is replaced, the reassembled gas train

must be leak tested again before start-up is

attempted. (NOTE: All gas valves removed

because of suspected leakage must be

returned to PVI Customer Service for

disposition.)

IMPORTANT

Use only copper wire of proper sizing for

incoming service. Damage resulting from

use of aluminum wiring will be excluded

from coverage under the warranty of this

unit.

3. A scale of lime will normally form during

operation and will accumulate on the bottom of

the tank. Lime is formed from the natural

chemicals in the water that precipitate out

during heating cycles. Some water supplies

contain more of these chemicals than others

and scale buildup will occur more rapidly.

Other factors affecting scale buildup are the

amount of hot water used and temperature of

the water. The more hot water used, the more

fresh water containing scale-forming chemicals

is brought into the tank. As the temperature of

water increases, the rate of scale deposition

will be increased.

PV500-17 07/13 Section 17

5

Page 6

MAXIM

MAINTENANCE AND SAFETY INSPECTIONS (con't)

4. The tank will have a handhole for inspection

and cleaning. (See Figure 17-1, page 2.) To

inspect tank for scale buildup, remove the

handhole cover. If scale is present, it can be

loosened with a high pressure stream of water.

The smaller pieces can be flushed through the

drain and the larger pieces removed by hand

through the handhole. The frequency of

inspections will be determined by the rate of

scale buildup. Intervals of 30-60 days are

recommended.

5. If a firetube leaks for any reason, consult

factory for instructions.

CARBON MONOXIDE WARNING!

CAUTION: IMPROPER COMBUSTION MAY CAUSE SERIOUS INJURY.

PVI recommends a seasonal or annual combustion check-out be performed by a

qualified service agency to ensure safe and efficient operation.

Periodic Inspection of Operational Components

Periodic inspection and check-out of the burner ignition, control system, and fuel valve operation (for tight

close-off) should be made. Refer to the burner installation instruction for recommendations.

1. Examine the venting system at least once each

year for proper connections, alignment and

corrosion. The blower inlet will collect dust from

the air during operation. Disconnect the power to

the heater and clean the blower wheel when

necessary. Inspect all parts and make

replacements when necessary. Check wiring for

loose connections and burned wires.

CAUTION!

The relief valve is a primary safety device.

2. The temperature and pressure relief valve may

be checked by slowly lifting the seat lever on top

of the valve to determine its condition for safe

operation. The openings inside the valve may

become restricted by a buildup of scale and

become inoperative. If the valve does not open

and close properly when tested, it must be

replaced. Replace the relief valve with like kin d or

one meeting the requirements stated on the

rating decal located adjacent to the relief valve.

IMPORTANT

Condensate coming from the tubes on a cold

start is normal and does not indicate a leaking

tube.

6. Regularly inspect the bottom tubesheet.

Inspect the SCALEGUARD

tubesheet

insulator for holes or areas that may have

pulled away from tubesheet. Repair or replace

as required.

3. A table of periodic safety inspections is an

attachment of this manual for ease of

reference by the building service technician or

licensed equipment operator. Since water

heater designs vary, only some o f these listed

inspections may be appropriate for your

particular model.

4. PVI strongly recommends the recording of

significant events, such as maintenance or

repair actions and safety inspections, and

encourage the preparation of an event log for

this purpose. All recorded events should be

dated, fully described, and signed by the

individual performing the service, repair, or

inspection. (See Table 17-1, page 7 for

sample of Inspection Record.)

Call your PVI Customer Service Representative

if you have any questions. (1-800-433-5654)

PV500-17 07/13 Section 17

6

Page 7

MAXIM

MAINTENANCE AND SAFETY INSPECTIONS (con’t)

Instructions for Taking Water Heater Out of Service

Extended shutdown of the appliance and

restarting are as follows:

A. Turn off all power and fuel supplies.

B. Drain and flush tank as previously discussed.

MAINTENANCE & SAFETY INSPECTION REPORT

DATE

BURNER

INSPECTION

COMBUSTION

ANALYSIS

TANK

INSPECTION

TANK FLUSH

& CLEANOUT

C. Tag power switch(es) that fuel is off and tank

is empty.

D. Refill tank with water and turn fuel and power

switch(es) on to restart. Reset all controls and

conduct start-up of the appliance as

discussed in the previous pages.

TANK FITTING

INSPECTION

VENT

INSPECTION

THERMOSTAT

INSPECTION

GAS TRAIN

LEAK TEST

Recommended

Inspection

Intervals

YEARLY 6 MONTHS 6 MONTHS 3 MONTHS 6 MONTHS YEARLY YEARLY YEARLY

NOTE: Burner Inspection and Combustion Analysis should be done by a factory-authorized service person.

PV500-17 07/13 Section 17

TABLE 17-1

7

Page 8

MAXIM

AXIAL FLOW GAS BURNER

CARBON MONOXIDE WARNING!

CAUTION: IMPROPER COMBUSTION MAY CAUSE SERIOUS INJURY.

PVI recommends a seasonal or annual combustion check-out be performed by a

qualified service agency to ensure safe and efficient operation.

1. FAN HOUSING 9. AIR PROVING SWITCH

2. AIR DAMPER 10. DAMPER ADJUSTMENT KNOB

3. GAS NOZZLE ASSEMBLY 11. MANUAL SHUTOFF VALVE(s)

4. PRESSURE PLATE 12. GAS PRESSURE REGULATOR

5. BLAST TUBE & BURNER HOUSING JUNCTION 13. GAS VALVE

6. IGNITION TRANSFORMER 14. AUXILIARY GAS VALVE

7. IGNITION ELECTRODE 15. MAIN GAS TRAIN

8. FLAME SENSING ROD 16. ELECTRODE CLAMP

PV500-17 07/13 Section 17

TYPICAL CONSTRUCTION

MX MODEL APPLICATION

FIGURE 17-2

8

Page 9

MAXIM

AXIAL FLOW GAS BURNER START-UP

(Refer to Figure 17-2, page 8 to identify burner parts)

1. Remove the enclosure panel cover on the

water heater or boiler to expose the contro l

circuit. A wiring diagram, included in this

packet, will show the controls used in our

circuitry.

2. Visually check that all components are

intact and no damage has occurred during

transit.

3. Check all connections within the control

cabinet. A loose connection could cause

intermittent shutdowns.

4. Some burners will use direct spark ignition.

They may use a single gas pressure

regulator and gas valve or multiple valves

and regulators. On a call for heat, the

motor starts, the gas primary control is

energized, and after a short delay (prepurge) the gas valve(s) opens and ignition

should occur.

IMPORTANT

Do not tamper with or readjust program

dipswitch settings. This will cause the

control to become inoperable. Damage

resulting from tampering will be

excluded from coverage under the

warranty of this unit.

5. Remove the flame safeguard control from

its base. Check the connections in control

mounting base; loose connections can

cause nuisance shutdowns. Check the

time card or programmer, when applicable,

for good connection.

IMPORTANT

Always secure gas lines and tag "Out of

Service" before servicing burner nozzle

or electrodes.

6. Pull the nozzle assembly to check the

flame and ignition electrodes. This is done

by first disconnecting the gas train by

breaking at the unions. Then removing the

nozzle assembly which will have the

electrodes and pressure plate attached.

Disconnect the electrode wires and take

care not to damage the insulation on the

electrodes.

PV500-17 07/13 Section 17

9

7. With the electrodes exposed, check them

for the proper settings as called for in

Figure 17-3, page 10. Check for any hairline

cracks in the insulators. Should

replacement of burner electrodes be

required, certain procedures must be

followed. In all cases, removal of the

electrodes is accomplished by loosening

the electrode mounting clamps. Draw the

electrodes out of the nozzle assembly

through the holes in the pressure plate.

8. Inspect the electrodes for cracked ceramic

or loose retaining studs that hold the wire

within the ceramic. Select the proper

pressure plate hole to place each electrode

and insert the electrode through the hole,

retaining stud end first.

9. Tighten electrode mounting clamp slightly

until electrode ceramics are seated firmly

and completely in the mounting bracket

without gaps between ceramics and

mounting bracket at the bearing faces.

10. Measure and set electrodes according to

Figure 17-3, page 10. After the gaps and

setting are complete, fully tighten the

electrode mounting clamp. Do not

overtighten or the insulation may crack.

11. Replace nozzle assembly; be sure to

connect the flame and spark rod wires

before installing nozzle assembly fully into

blast tube. Check connectors on the ends of

the flame and spark rod wires for good

contact. Look for properly stripped wire

ends. Be sure connectors are firmly

attached to the flame and ignition rod ends.

Insulating boots can give a false feeling of

proper seating. DO NOT MOVE

ELECTRODES. Be careful not to bump

electrodes. Check fan wheel for free

rotation.

12. Reinstall orifices in unions (if required).

Reinstall gas nozzle assembly.

Page 10

MAXIM

AXIAL FLOW GAS BURNER START-UP (continued)

PRESSURE PLATE

Set up and Tolerances

Figure 17-3

13. Connect a test meter to the control for

reading the flame response signal.

IMPORTANT

Some controls read the flame signal in

micro amps and some in volts DC. The TFM

or MEC120 series control has two terminals

marked for reading volts DC. The S89

control uses a micro amp signal for

measuring flame strength. For this control, a

meter must be hooked in series with the

flame rod wire. Disconnect the leadwire at

the S89 sensor terminal. Connect the

positive lead of the meter to the quickconnect sensor terminal on the S89 and the

negative lead to the free end of the sensor

leadwire.

14. Be sure the tank is filled with water. Once

the burner is reassembled, two devices will

be needed to read gas pressures,

preferably U-tube manometers. Connect

one to read the inlet pressure of the burner.

This is the pressure measured before all

components in the gas train. The

Record static pressure; it must not exceed

14" W.C. Pressures above this could cause

damage to the diaphragm in the gas valve or

pressure regulator.

15. Burners with pilot; inputs over 400,000

Btu/h (See wiring diagram.)

16. Connect a manometer to the manifold test

port at the shutoff valve closest to the

burner. Turn off the main gas shutoff valve.

Set the air shutter as shown on the tag

attached to gas train. This may not be the

exact setting you end up with, but it is a

good starting point. Turn the unit on using

the rocker switch on the side of the control

enclosure assembly. If the operating control

switches are closed, the burner blower

should come on and pre-purge begin.

If nothing happens, check the control to be

sure it is not in the tripped position and

reset it by pushing the flame safeguard

reset button. The burner should pre-purge

for no longer than thirty seconds.

manometer must stay connected

throughout the testing as the inlet pressure

must be monitored during the firing of the

burner.

PV500-17 07/13 Section 17

10

Page 11

MAXIM

AXIAL FLOW GAS BURNER START-UP (continued)

This section pertains to MEC120 control only.

When the blower motor starts, the air proving

light on the MEC120 should be on. This

indicates a positive airflow condition. If the air

proving light is not on, turn air proving switch

adjustment screw counter-clockwise until the

air proving light comes on, then turn screw one

turn counter-clockwise. If the gas valves open

and close intermittently during normal

operation, turn screw one half turn counterclockwise until this condition ceases. This

procedure should be followed with every

burner.

After purging is complete, terminal 3 energizes

the pilot valve and terminal 4 energizes the

ignition transformer on the control. The pilot is

then established. The VDC reading on the

meter should read a steady 14-17 VDC. Each

different control will have the required flame

response signal stamped on it. This is the

minimum for it to properly operate. If the pilot

fails to light during the initial period, it is

probably due to air in the line. The control will

lock out. Wait one minute and push the flame

safeguard reset button to restart burner and

begin the purge cycle again.

Once the flame is established, set the pilot

pressure (measured downstream of gas valve)

at pressure shown on the tag attached to gas

train. Next, open the main gas valve slowly.

Set manifold pressure at pressure shown on

the tag attached to gas train. Do not screw the

adjusting nut of the regulator in past the point

where no further increase in manifold pressure

is noted. Check the incoming pressure with the

burner running. This is recorded as inlet flow

pressure.

Our standard flow pressure requirement on

these burners is 8" W.C. flow. If the required

manifold cannot be reached, check the inlet

pressure. It should be a minimum of that

shown on the heater decal with the burner

running on full input. It is important that the

incoming pressure does not fall below these

minimums or nuisance control lockouts could

occur.

IMPORTANT

Where low gas pressure is a problem, special

arrangements may have been made to fire the

burner with reduced pressure. The appliance

data decal will reflect this information.

17. Direct Spark Ignition - (DSI) Burners - No

pilot. (See wiring diagram.)

Connect manometer to the manifold test port.

Set the air shutter as shown on the tag

attached to gas train. This may not be the

exact setting you end up with, but it is a good

starting point.

Turn the unit on, using the rocker switch on the

side of the control enclosure assembly. The

burner should come on and ignition occur. If

the burner fails to ignite, there may have been

air in the line. To reset the control, turn the

switch off for 60 seconds (S89 controls only)

and it should automatically reset, or push the

reset button on the control. If after the

appropriate prepurge, ignition does not occur,

turn air proving switch adjustment screw

counter-clockwise until TFI (try for ignition)

occurs. Now in order to more precisely adjust

the air failure set point, slowly turn screw

clockwise until the burner shuts off. Then turn

screw counter-clockwise one turn. If the gas

valves open and close intermittently during

normal operation, turn screw one half turn

counter-clockwise until this condition ceases.

Once the burner fires, set manifold pr essure at

pressure shown on the tag attached to gas

train. There will be a tap on the downstream

side of the valve to measure pressure. The

manifold pressure must be taken downstream

of the gas valve. Check the incoming pressure

with the burner running. This recorded flow

pressure must be the minimum specified on

the heater decal.

PV500-17 07/13 Section 17

11

Page 12

MAXIM

AXIAL FLOW GAS BURNER START-UP (continued)

18. Check flue gases with a flue analyzer to

make final settings of the air shutter.

a. The readings need to be taken from a

hole in the vent several inches above the

heater vent connection, but before draft

regulator.

b. Insert draft gauge into the 1/4" test

opening in the stack. Draft in stack should

read -.02" to -.06" W.C. Adjust draft

regulator, if installed.

c. When water in the tank is above 120°F,

insert analyzer or O

opening and take O

percentage.

d. Gradually close air shutter, taking O

reading at each adjustment of air shutter

until optimum O

O

% decreases, open air shutter to last

2

reading where the greatest reading is

achieved.

e. Insert CO tester in 1/4" test opening and

take CO reading. CO should not exceed

.03%. A reading greater than .03%

indicates lack of air. Open air shutter

slightly and take readings until CO is

within proper range. Optimum reading is

no CO.

f. If air shutter was changed during CO test,

take a final O

reading.

2

g. Insert CO

tester in 1/4" test opening;

2

record in percentage.

h. Insert stack temperature gauge in 1/4"

test opening and read gross stack

temperature; maximum gross stack is to

be 450°F, minimum net stack is to be

300°F. (NOTE: net temperature is the

total stack temperature, less room

temperature.) If an excessively high

gross stack temperature is recorded,

check the flue tubes for turbulators.

tester in 1/4" test

2

reading in

2

% (4-6%) is reached. If

2

2

i. Make sure the air shutter is locked

securely in place.

19. On burners with pilots, recheck pilot to make

sure its operation has not deteriorated if

adjustments are made to the air shutter. To

do this, shut off the main valve, check the

flame response signal by cycling the burner

through several lightoffs.

20. Check each operating and limit control to be

sure they function properly by lowering and

raising the temperature setting on each

control, causing the burner to cycle on and

off.

IMPORTANT

During the initial firing of the burner, smoke

that is not related to the burner will be

emitted from the heater. This is normal during

"burn in" and could possibly continue for

several hours.

21. Record the following information for future

use:

A. Air shutter position________________

B. Manifold gas pressure________"W.C.

C. Stack draft_________________"W.C.

D. O

reading_______________%(4-6%)

2

E. CO

reading______________%(8-9%)

2

F. CO reading________%(less than .03%)

G. Stack temperature:

Gross _______________________°F.

Less ambient__________________°F.

Net__________________________°F.

H. Combustion efficiency___________%

PV500-17 07/13 Section 17

12

Page 13

MAXIM

TROUBLESHOOTING SUGGESTIONS

AXIAL FLOW GAS BURNER

1. BURNER FAILS TO START

Defective On/Off switch. Replace switch.

A. Control circuit has an open control contact.

Check limits, low water cutoff, proof of closure

switch and others as applicable.

B. Bad fuse or switch open on incoming power

source. Correct as required.

C. Flame safeguard control safety switch

tripped out. Reset and determine cause for

apparent flame failure.

D. Loose connections or faulty wiring. Tighten all

terminals screws and consult wiring diagram

furnished with the burner.

E. Flame safeguard control starting circuit

blocked due to flame relay being energized.

Possible defective scanner or flame rod replace. Possible defective amplifier - replace.

Scanner actually sighting flame due to leaking

fuel valve - correct unwanted flame cause.

Defective flame safeguard control - replace.

F. Defective blower motor. Check for free rotation

of fan wheel. Repair or replace.

G. Air proving switch is not properly adjusted.

Adjust per instructions; page 11 of this manual.

2. OCCASIONAL LOCKOUTS FOR NO APPARENT

REASON

A. Gas pilot ignition failure. Check to see that

ignition is instant and that flame signal readings

are stable and above minimum values. Use a

manometer or 0 to 10" W.C. gas pressure gauge

to make certain that pressure is as

recommended.

B. Loose or broken wires. Check all wire nut

connections and tighten all terminal screw

connections in panel and elsewhere as

appropriate.

C. With flame safeguard controls that

incorporate the air flow switch in the nonrecycling circuit, ensure that when main flame

lights, the air flow switch is not so critically set as

to allow occasional momentary opening of the air

switch contacts.

D. Occasional low voltage supply. Have local

utility correct. Make certain the burner control

circuit transformer (if supplied) is correct for the

voltage and power (VAC) being supplied.

E. Occasional low gas supply pressure. Have

local utility correct.

3. BURNER MOTOR RUNS, BUT PILOT DOES NOT

LIGHT

A. Gas supply to burner shut off. Make sure all

manual gas supply valves are open. Automatic

high pressure valve at meter such as "Sentry"

type tripped shut due to high gas pressure.

Reset valve and correct cause for trip out.

B. Pilot solenoid valve not opening. Listen and

feel for valve actuation. Solenoid valve not

being powered. Check electrical circuitry.

Replace coil or entire valve if coil is burned out.

C. Defective gas pilot regulator. Replace.

D.

Gas pressure too high or too low at pilot

orifice (if supplied). Check orifice size in gas

pilot assembly. Replace if incorrect. Readjust

pressure as required.

E. Defective ignition transformer. Replace.

Incorrect ignition electrode settings.

Readjust as required.

F. Defective flame safeguard control or plug in

purge timing card. Replace as required.

G. Air flow switch not making circuit. Check out

electrically. Defective air flow switch- replace.

Air switch negative pressure sensing tube out

of position-reposition as necessary.

4. BURNER MOTOR RUNS & PILOT LIGHTS, BUT

MAIN GAS FLAME IS NOT ESTABLISHED.

A. Main shut off or test cock closed. Check to

make certain fully open.

B. Pilot flame signal reading too low to pull in

flame safeguard relay. Readjust as required.

PV500-17 07/13 Section 17

13

Page 14

MAXIM

TROUBLESHOOTING SUGGESTIONS

AXIAL FLOW GAS BURNER (continued)

C. Defective automatic main or auxiliary gas shut

off valves. Check electrical circuitry to valves.

Replace valves or correct circuitry as required.

D. Main diaphragm shut off valve opening too

slowly. Adjust bleed on valve.

E. Defective flame safeguard control or plug on

amplifier. Check and replace as required.

F. Main gas pressure regulator atmospheric vent

line obstructed. Correct.

G. Defective main gas pressure regulator. Replace.

Misadjusted main gas pressure regulator.

Readjust to meet required operational values.

H. Polarity reversed on incoming power. (S89 control

only)

5. CARBON MONOXIDE READINGS ON GAS FIRING

A. Flame impingement on "cold" heat transfer

surfaces caused by excessive firing rate. Reduce

firing rate to correct input volume.

B. Incorrect gas/air ratios. Readjust burner to correct

CO

6. GAS HIGH FIRE INPUT CANNOT BE ACHIEVED

A. Gas company pressure regulator or meter

operating incorrectly, not allowing required gas

pressure at burner train inlet. Contact gas

company to correct.

B. Gas cock upstream of train inlet not fully open.

Check and correct.

Additional troubleshooting information can be found in the Flame Safeguard bulletin supplied with the burner.

levels, eliminated all CO formation.

2/O2

C. Gas line obstructed. Check and correct.

D. Gas train main and/or lead test cocks not fully

open. Check and correct.

E. Gas supply line between gas company

regulator and burner inlet too small. Check

supply pressure at meter, determine pressure drop

and increase line size as required, or raise supply

pressure to compensate for small line. Do not raise

pressure so high that under static (no flow)

conditions the pressure exceeds the maximum

allowable pressure to the gas train components on

the burner.

F. Burner gas train components sized too small

for supply pressure. Increase component size as

appropriate or consult factory.

G. Automatic gas valve not opening fully due to

defective operation. Replace gas valve.

H. Orifice (if supplied) too small. Replace with

correct size.

I. Defective main gas pressure regulator. Replace.

J. Incorrect spring in main gas pressure regulator.

Replace as required.

K. Main gas pressure regulator vent line

obstructed. Check and correct.

L. Normally open vent valve (if supplied) not

closing when automatic gas valves open. Check

to see if valve is fully closed when automatic valves

are open. Replace vent valve, if not closing fully.

PV500-17 07/13 Section 17

14

Loading...

Loading...