Page 1

Operation & Maintenance Manual

AquaSolve

®

Anti-Scale Systems

Chemical-Free, Salt-Free

Scale Prevention

M8414TM-COM (50 GPM)

M8416TM-COM (75 GPM)

Important: Read this Manual BEFORE using this equipment. Failure

to read and follow all safety and use information can result in death,

serious personal injury, property damage, or damage to the

equipment. Keep this Manual for future reference.

IOM-ASM1465TM_M1665TM

Manufacturing ASME Commercial Water Heaters Since 1961

PVI Industries • 3209 Galvez Avenue • Fort Worth, TX 76111

USA: T: (817) 335-9531 • Toll Free: (800) 784-8326 • PVI.com

Technical Support • (800) 433-5654 • Mon-Fri, 8 am - 5 pm EST

© 2019 PVI

Page 2

Operation & Maintenance Manual

AquaSolve

®

INTRODUCTION

The PVI AquaSolve Anti-Scale System provides protection from scale formation on internal plumbing

surfaces. The AquaSolve system can be installed

at the point of entry to a building to treat both hot

and cold water, or it can be located directly before a

water heater, boiler, or other water using device that

requires protection from hard water.

AquaSolve prevents scale by transforming the normal

dissolved hardness minerals into undissolved crystal microparticles. These crystals stay suspended in

the water and have a greatly reduced ability to react

and attach to surfaces like dissolved hardness does.

Therefore the problem of internal buildup of scale

in pipes, water heaters and on fixtures and glass is

greatly reduced.

AquaSolve is not a water softener or a chemical

additive (like antiscalants or sequestrants). It is a

scale prevention device with proven third party laboratory test data and years of successful residential

and commercial installation. AquaSolve is the one

water treatment device that effectively provides scale

protection and is a great saltfree alternative to water

softening (ion exchange) or scale sequestering chemicals. Laundry and warewashing chemistry will likewise require adjustments.

• Compatible with all on-site and community

wastewater treatment systems

• Perfect system for towns or communities where

water softeners are banned or restricted

• For high-flow applications, install multiple tanks

in parallel

• AquaSolve does not remove minerals or add

sodium to the water supply

• AquaSolve can be installed as pre-treatment to

commercial reverse osmosis systems (contact

your PVI representative for further details)

**For hot water applications where feed water

temperature is 100° - 140°F (38° - 60°C), please

contact PVI Technical Support at 1-800-433-5654.

WARNING

Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after the

system.

Systems are certied through WQA against NSF/

ANSI Standard 372 for Lead Free compliance.

AquaSolve Benefits

• Chemical-free scale prevention and protection –

converts hardness minerals to harmless, inactive

microscopic crystals making AquaSolve an effective alternative technology to a water softener for

the prevention of scale due to water hard-ness

• Virtually maintenance free – no control valve

• Uses environmentally friendly technology by

using no salt or other chemicals to constantly

add, no electricity and no wastewater

• Improves efficiency of all water using appliances

– both hot** and cold

• Simple sizing and installation – all you need to

know is pipe size and the peak flow rate

• Safe for landscaping and lawn watering, no need

for costly bypass plumbing.

IOM-ASM1465TM_M1665TM Page 2 of 7Technical Support • (800) 433-5654 • Mon-Fri, 8 am - 5 pm EST

Page 3

Operation & Maintenance Manual

AquaSolve

®

Specifications

AquaSolve scale prevention system shall be installed

on the main water service pipe just after it enters the

building, but after other whole building water safety

devices (backflow preventers or pressure reducing

valves), to effectively address water hardness concerns. A system may also be installed further downstream to protect specific equipment or areas within

a plumbing system. The system shall be plumbed

with a bypass valve to allow isolation of tank(s) and

to allow the bypass of untreated water in the event

that service or media replacement be necessary. The

installation area should be suitable in size for the

tank(s) to be serviced without encumbrance and sit

upright on a flat level surface.

The system must operate in an upflow manner and

does not require additional water to backwash, flush,

or regenerate once put into service. The system does

not require any chemical additives and does not

require electricity for operation.

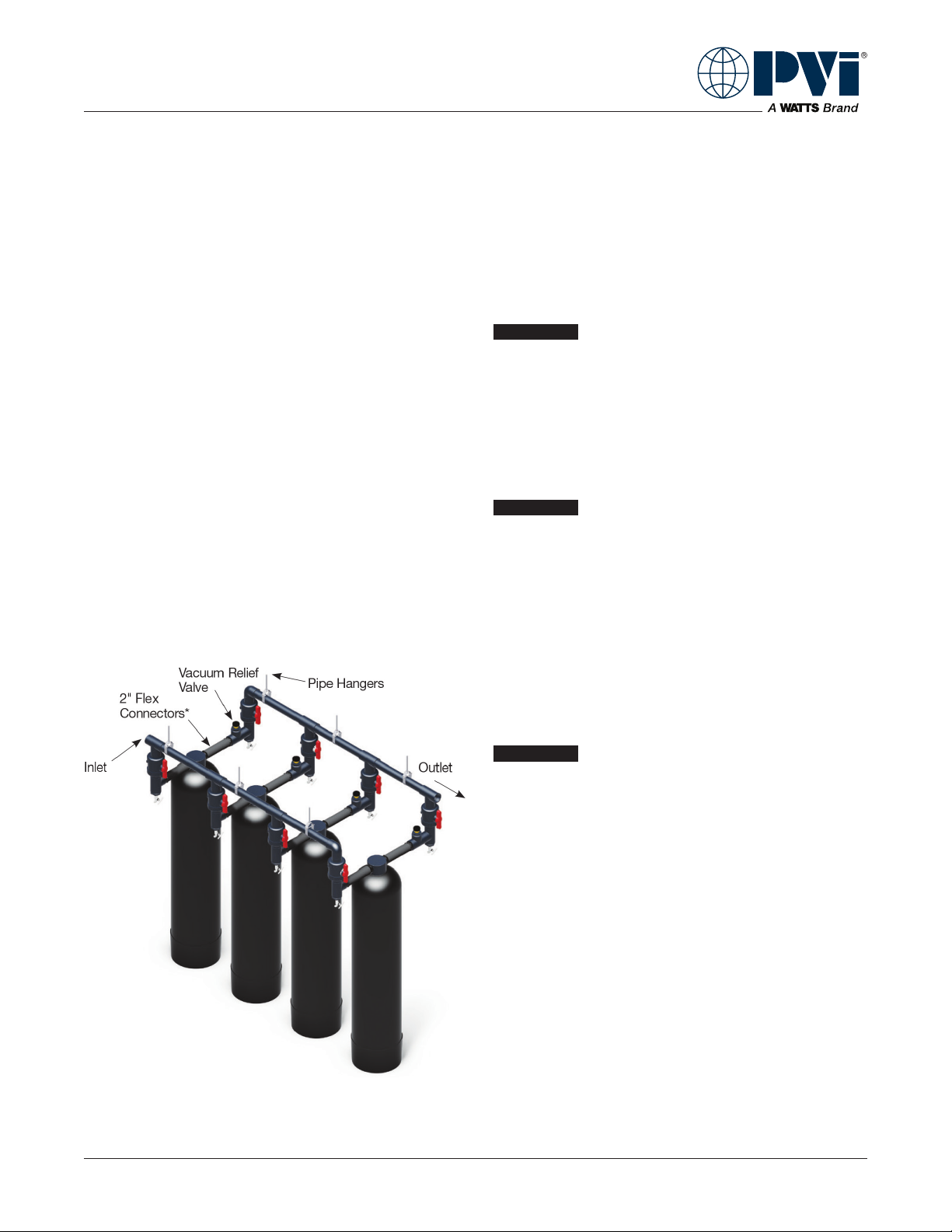

Multi-tank systems shall be installed in parallel with

PVC/CPVC manifold to meet peak flow rate requirements – see image below.

Standards

Independent scientific testing has confirmed

Template Assisted Crystallization (TAC) technology

provides scale reduction of over 95+%. Testing was

conducted under protocol based on DVGW W512

test to access control of scale formation.

NOTICE

Spotting may occur on external plumbing surfaces.

AquaSolve media systems perform best in single pass potable water applications with NO additional chemical additives.

Depending on hardness, soft scale spotting may occur. Soft scale

spots in most cases can be easily wiped down with a damp cloth

and will not form hard scale deposits. A Point of Use (POU) Water

Softener should be used on mandatory spot-free applications (e.g.

glass stemware, dishware).

CAUTION

• Not for use on closed loop systems.

• Do not let the system freeze. Damage to the tank may result.

• System must be operated in a vertical position. Do not lay

it down during operation. The system may be placed in any

position for shipping and installation but must be operated in

the vertical position.

• Place the system on a smooth, level surface. Because the system operates in an upflow, fluidized bed mode, having a level

surface is more important than with a softener or media filter.

• A bypass valve should be installed on every system to facilitate installation and service.

• Observe all local plumbing and building codes when installing

the system.

WARNING

Using AquaSolve with other water treatment equipment.

Due to the unique properties of AquaSolve, there are some unique

requirements for using AquaSolve in conjunction with other forms

of water treatment:

1. AquaSolve must be the last stage in the treatment chain. Do

not install any filters after AquaSolve or before any devices for

which scale prevention is required. POU filters, e.g. carbon,

RO or Ultraviolet (UV) are exempt from this requirement.

2. Do not apply phosphate or any other antiscalant before or

after AquaSolve.

3. The addition of soaps, chemicals, or cleaners, before or after

AquaSolve treatment, may reverse its anti-scale treatment

effects and/or create water with a heavy residue or spotting

potential. Any adverse conditions caused by the addition of

soaps, chemicals, or cleaners are the sole responsibility of the

end user.

4. AquaSolve is not a water softener and does not softener the

water - water treatment chemistry (e.g. antiscalants, seque

trants, soaps, chemicals or cleaners etc.) will most likely have

to be changed to be compatible with AquaSolve treated water.

Laundry and ware-washing chemistry will likewise require

adjustments.

IOM-ASM1465TM_M1665TM Page 3 of 7Technical Support • (800) 433-5654 • Mon-Fri, 8 am - 5 pm EST

Page 4

Operation & Maintenance Manual

AquaSolve

®

Equipment Specifications

AquaSolve systems are complete, selfcontained,

loaded with media, and ready to use. A simple

inlet and outlet connection is all that is required for

installation. Please review operating pressures, temperatures and water chemistry limitations to ensure

compatibility.

Feed Water Chemistry Requirements

pH 6.5 to 8.5

Hardness (max.) 30 grains

Water Pressure 15 psi to 150 psi

Temperature 40ºF to 100ºF (5ºC to 38ºC)

Chlorine <2 ppm

Iron (max.) 0.3 mg/l*

Manganese (max.) 0.05 mg/l**

Copper (max.) 1.3 ppm**

Oil & H2S Remove prior to AquaSolve

Phosphates Remove prior to AquaSolve

Silica (max.) 20 ppm***

TDS 1500 mg/l****

NOTICE

*Iron and Manganese

Just as with conventional water softening media, AquaSolve needs

to be protected from excess levels of certain metals that can easily coat the active surface, reducing its effectiveness over time.

Public water supplies rarely, if ever, present a problem, but if the

water supply is from a private well, confirm that the levels of iron

(Fe) and manganese (Mn) are less than 0.3 mg/L and 0.05 mg/L

respectively.

**Copper

Pursuant to the EPA drinking water standards, the copper concentration permitted is up to 1.3 ppm. Typically originating from new

copper plumbing, high levels of copper can foul AquaSolve media.

For applications with copper concentration greater than 1.3 ppm,

please contact PVI Technical Support at 1-800-433-5654.

To further minimize any problem with excess

copper, avoid applying excessive flux on the

inner surfaces of the pipe and use a lowcorrosivity water soluble flux listed under the

ASTM B813 standard.

***Silica

AquaSolve media does not reduce silica scaling.

While silica tends to have a less significant effect

on scale formation than other minerals, it can

act as a binder that makes water spots and

scale residue outside the plumbing system

difficult to remove. This 20 ppm limitation is for

aesthetic purposes.

****All other contaminants must meet the requirements of the

USEPA Safe Drinking Water Act. Specific Mineral and Metal

MCLs, identified in Watts’ published Feed Water Chemistry

Requirements, supersede the USEPA SDWA.

NOTICE

Water known to have heavy loads of dirt and debris may require

prefiltration prior to AquaSolve.

*See note about iron, manganese and copper (bottom left).

Systems using AquaSolve technology prevent hard water scale

formation inside the plumbing system at influent hardness levels

of 30 grains per gallon of calcium carbonate and less. Due to variances in water chemistry, certain aesthetic conditions external of

the plumbing system may not be attained. AquaSolve is designed

for the treatment of potable water that meets the requirements of

the current USEPA Safe Drinking Water Act.

Mechanical Specifications

Model M8414TM-COM M8416TM-COM

Dry Weight

lbs/kg

Service Weight

lbs/kg

Inlet/Outlet

Connection

124 / 56 145 / 66

458 / 208 550 / 250

2” FNPT 2” FNPT

Replacement Media

M8414-COM-RM Replace media every 3 years

M8416-COM-RM Replace media every 3 years

Dimensions (nominal - inches)

Model M8414TM-COM M8416TM-COM

a 14 16

b 73.1 73.1

Max. Service Flow (gpm) vs. Water Temp. (ºF)

System 40º 45º 50º 55º 60º 65º 70º

M8414TM 40 44 48 50 50 50 50

M8416TM 45 51 56 59 63 69 75

Intermittent Duty Systems

M8414TM-COM 50 gpm at all temperatures

M8416TM-COM 75 gpm at all temperatures

Max. Flow Rate***

M8414TM-COM 50 gpm 189 lpm

M8416TM-COM 75 gpm 284 lpm

***Exceeding maximum flow can reduce effectiveness and void

warranty.

Pressure drop at peak flow rate is less than 22 psi.

Pressure drop reading taken with inlet and outlet gauges installed

at a common elevation and 80 degree feed water.

IOM-ASM1465TM_M1665TM Page 4 of 7Technical Support • (800) 433-5654 • Mon-Fri, 8 am - 5 pm EST

Page 5

Operation & Maintenance Manual

AquaSolve

®

Installation

Tighten the tank head

NOTICE

Check the head on top of the tank. It’s common for it to loosen

during shipment. Tighten the head with a strap wrench as needed.

NOTICE

*It is very important to use flexible connections on the inlet and

outlet plumbing in the horizontal orientation as shown in the

images on this page. The tanks expand and contract with water

pressure fluctuations. Flexible connectors will prevent plumbing

and tank leaks. The EDP code for the suggested PVI 2” Flexible

Connectors is C515285 (Two are included and required for installation).

Anytime AquaSolve systems are installed above the ground floor

of a building it is recommended that a vacuum relief valve also be

installed to protect against tank collapse in the event the plumbing system is drained. If a vacuum relief valve is not used then the

system should be placed in bypass anytime the plumbing system

is drained. The EDP code for the suggested vacuum relief valve is

0556031 (not included). The vacuum relief valve should be

installed on the outlet of the system.

NOTICE

• We recommend the installation of a dual-union ball-valve on

the inlet and outlet to isolate the tank for servicing.

• A full bypass should be installed so that the full service flow

can be routed around the system as needed for servicing.

steady stream of water appears at the drain, close

the supply valve and hose bibb.

Open the inlet and outlet valves on the system.

Transfer the bypass valves from Bypass to the

Service position. Open a nearby faucet downstream

from the AquaSolve system to relieve any air.

Check for leaks. Repair as needed.

NOTICE

Fill in install date and rebed due date on product label located

on front of each tank as reminder to replace AquaSolve media

every 3 years. The system is now ready for service.

Typical Installation for Single and

Multi-Bank Systems

Install Piping

Connect the inlet and outlet plumbing according to

your preferences and any applicable local codes.

Include sample/drain ports with hose-bibb connections on the inlet and outlet piping to facilitate startup

and service.

WARNING

Support the Piping

2 inch Flex Connectors must be installed horizontally not vertically

in the water pipe line. The full weight of the piping and valves must

be supported by uni-strut, pipe hangers or other means. The tank

connections cannot support the weight of the piping. The image

below for a multi-tank system installation shows properly supported piping.

Start-Up

Connect a hose to the hose bibb on the outlet of

the tank. Run the hose to a drain and open the hose

bibb.

Slowly/partially open the supply water ball valve.

Allow the tank to slowly fill with water. When a

IOM-ASM1465TM_M1665TM Page 5 of 7Technical Support • (800) 433-5654 • Mon-Fri, 8 am - 5 pm EST

Page 6

Operation & Maintenance Manual

AquaSolve

®

NOTICE

Your AquaSolve media should be replaced every 3 years.

Replacing the Media

1. Shut off the primary feed supply going to the

AquaSolve tank.

2. Open up a downstream spigot or faucet to release

pressure in the tank and in the distribution lines

before and after the system.

3. Shut the isolation valves immediately before and

after the tank.

4. Disconnect the unions on the inlet and outlet of

the tank, and then disconnect flex connectors from

head.

5. Using a step ladder and strap wrench, remove

the threaded head assembly connection (turning

counter-clockwise) and remove the complete upper

assembly including grey-colored PVC strainer.

Rinse these parts in a nearby sink or bucket of

water. Do not drain the tank.

6. Remove the distributor tube with the bottom strainer. Rinse these parts in a nearby sink or bucket of

water.

7. Get a 6ft length of 3/4” sch. 40 PCV and a length

of 1” polyvinyl hose. The length of hose depends

on the distance to the nearest floor drain. (Both of

these can be acquired at Home Depot or Lowes.)

8. Insert one end of the pipe inside the hose and put

the other end of the pipe into the top of the tank

and down into the media. Put the other end of the

hose inside a rice bag and put the rice bag on the

floor drain.

9. Get a garden hose and put it on the open end of

the poly hose to fill the hose and pipe with water.

Air will bubble out of the tank. Once all the air is

out of the hose and pipe, you can start a siphon to

remove the media. Put the garden hose in the top

of the tank and turn it on to keep the tank full of

water. Push the pipe up and down in the media to

get it all out. The rice bag will catch the media and

allow the water to go down the drain.

10. Try not to be too aggressive when extracting the

media. You need to take it out in small bites. If you

let the whole pipe/ hose fill with media it will plug

up. You need to let slugs of water flush out the pipe

as you go.

11. When all the old media is removed turn off the garden hose and continue to siphon until the tank is

about half full with water.

12. Using the step ladder again, reinstall the distributer tube with bottom strainer that was removed in

step #6. Center the distributor tube in the bottom

of the tank. Keeping any and all media from entering the distributor tube, carefully pour-in a new

bag(s) of media that specifically meets the replacement requirement of the tank. For example, an

M8416-TM-COM system requires (x1) OF1665RM

Replacement Media.

13. Inspect the threaded connection on the top of the

tank to ensure no loose beads of media are stuck

to the internal threads. If visible, wipe away the

beads with a damp cloth.

14. Re-attach the head assembly onto the distributor

tube and thread the head assembly back onto the

tank. Hand-tighten until the final turn when a strap

wrench can help tighten the connection.

15. Reconnect the flex connectors and union connections.

16. Open the feed water inlet (slowly) to fill the tank.

17. Purge the air at a downstream faucet close to the

system.

18. Once the tank is full, wait 4 hours for media to

“hydrate”.

19. Put the tank in service.

Alternative Method for Replacing Media

Follow steps 1 – 6 then,

• Remove center distributor tube and lower basket

and siphon all water from tank

• Lay tank down on its side

and tip upside down while

using hose to flush

media out

• When all the old media is

removed, stand tank back

up and install in original

position. Fill the tank so

that it is about half full

with water.

Then continue with

steps 12 – 19.

IOM-ASM1465TM_M1665TM Page 6 of 7Technical Support • (800) 433-5654 • Mon-Fri, 8 am - 5 pm EST

Page 7

Operation & Maintenance Manual

AquaSolve

®

Parts List

Item Qty. PVI Part # Description

1 1 149692

Tank head only basket

assembly is separate basket

2 2 144065 Flex hose 2” x 12”

3 1 144066

Riser and bottom

distributor assembly

4a 1 144067 14” X 65” tank 4” top

4b 1 144068 16” X 65” tank 4” top

Limited Warranty

PVI warrants its AquaSolve tank system as follows:

• AquaSolve tank system is warranted to be free of defects in materials and workmanship for 5 years from the date of original shipment.

• The AquaSolve media is warranted for performance for a period of

2 years from the date of the original installation when installed and

oper-ated in accordance with the instructions in the corresponding

Installation and Operation Manual. PVI warrants its AquaSolve cartridge systems as follows:

• The AquaSolve cartridge system is warranted to be free of defects

in materials and workmanship for 1 year from the date of original

shipment.

• AquaSolve cartridges are warranted for performance for a period

of one year from the date of original installation when installed and

operated in accordance with the instructions in the corresponding

Installation and Operation Manual.

• Carbon replacement filter cartridges are not warranted to perform for

any period of time because the service life of replacement carbon

filter cartridges varies significantly with local water conditions and

volume.

1. AquaSolve system must be installed in applications with municipally

supplied water adhering to EPA guidelines with the exception of

oil and grease, copper, phosphate, silca and chlorine. See copper

warnings on page 2 and condition number 5 below.

2. Any component failure must not result from abuse, fire, freezing or

other acts of nature, violence, or improper installation.

3. Equipment must be installed and operated in compliance with the

local plumbing codes and on an approved water supply.

4. Equipment is limited to use at water pressures and temperatures that

do not exceed our published specifications.

5. Water supply must not exceed 2.0 PPM chlorine. For water supply

exceeding 2.0 PPM chlorine, pretreatment is required. (Please contact your water treatment specialist.)

6. Information, including model number, serial number, and date of

installation, must be provided for any claims pertaining to equipment

in warranty.

7. Defective parts are subject to inspection by either PVI or any authorized representative before final commitment of warranty adjustment

is made.

8. PVI reserves the right to make changes or substitutions in parts or

equipment with material of equal quality or value and of then current

production.

Limitations

Our obligation under this warranty with respect to the tank or valve is

limited to furnishing a replacement for, or at our option, repairing any

part or parts to our satisfaction that prove defective within the warranty

period stated above. Such replacement parts will be delivered to the

owner F.O.B. nearest factory, at no cost, excluding freight and local

labor charges, if any. Our obligation under this warranty with respect to

the AquaSolve media will be limited to furnishing a replacement for the

media within two years from date of original installation. Such replacement media will be delivered to the owner F.O.B. nearest factory, at no

cost, excluding freight and local labor charges, if any. Damage to the

media due to chlorine, other oxidizers or fouling caused by local water

conditions or any other operation outside of the limits shown under

Specifications, is not covered by this warranty.

The warranty set forth herein is given expressly and is the only warranty

given by PVI company with respect to the product. PVI company makes

no other warranties, express or implied. PVI company hereny specifically

disclaims all other warranties, express or implied, including but not limited to the implied warranties of merchantablity and fitness for a particular

purpose.

The remedy described under this warranty shall constitute the sole and

exclusive remedy for breach of warranty, and PVI company shall not

be responsible for any incidental, special or consequential damages,

including without limitation, freight, handling, lost profits or the cost of

repairing or replacing other property which is damaged if this product

does not work properly, other costs resulting from labor charges, delays,

vandalism, negligence, fouling caused by foreign material, damage from

adverse water conditions, chemical, or any other circumstances over

which PVI company has no control. This warranty shall be invalidated

by any abuse, misuse, misap-plication or improper installation of the

product.

Some states do not allow limitations on how long an implied warranty

lasts, and some states do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above limitations may not

apply to you. This warranty gives you specific legal rights, and you may

have other rights that vary from state to state. You should consult applicable state laws to determine your rights. So far as is consistent with

applicable state law, any implied warranties that may not be disclaimed,

including the implied warrantied of merchanability and fitness for a particular purpose, are limited in duration to the applicable warranty periods

stated above.

IOM-ASM1465TM_M1665TM Page 7 of 7Technical Support • (800) 433-5654 • Mon-Fri, 8 am - 5 pm EST

Loading...

Loading...