Page 1

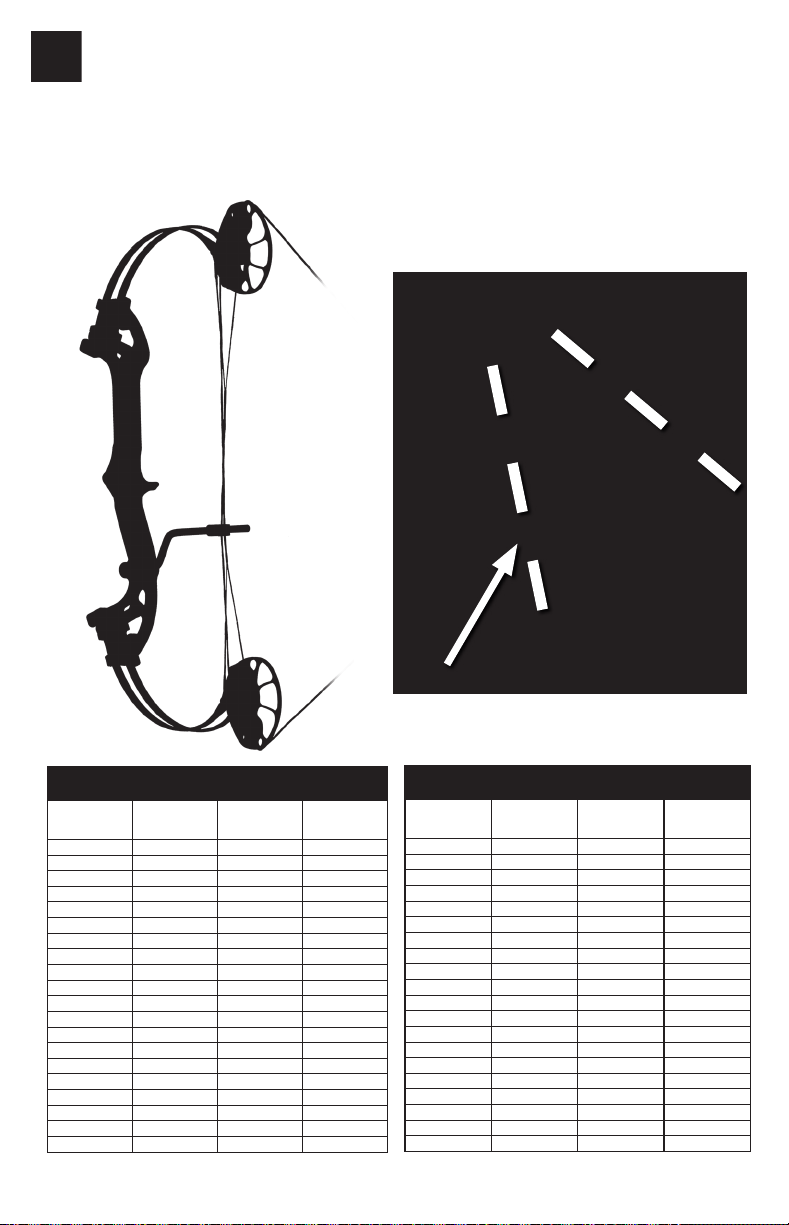

Compound Bow

USER’S GUIDE

compound bow user’s guide

PAGE

1

Page 2

Thank You!

Thank you from the entire PSE family for purchasing a PSE bow!

Your bow was manufactured from the finest materials available and

handcrafted with pride in the USA. With proper care you will enjoy the

use of this product for years to come.

Please read this entire booklet before shooting or adjusting your bow.

Remember, many adjustments to a compound bow require the use of a

bow press. Whenever shooting a bow, be certain of your target as well as

what else lies down range.

NOTE: IMPORTANT WARRANTY REGISTRATION INFORMATION IS ON PAGE 43

pse compound bow owner’s information

Fill in the following information for your personal records.

Bow Model

Bow Serial Number:

See page 43 for the serial number location on your bow.

Purchased From:

Purchase Date:

Draw Length Draw Weight

PAGE

2

Page 3

Compound Bow

USER’S GUIDE

index

SUBJECT PAGE

Welcome to PSE and general product information

C

ompound bow terminology ............................................................................ 5

PSE cable configurations

PSE X-Tech bow press info ............................................................................. 7-9

Installation of accessories .................................................................................10

Other adjustments

Setting up your bow

Flexslide™ installation and adjustments .......................................................... 12

BackStop™ 2 installation and adjustments ..................................................... 12

Sting Stop™ installation and adjustments

Limb bands and cable guard dampers

C

hanging the FlexSlide rod .............................................................................15

PSE asymmetric idler ........................................................................................15

Cam adjustments .............................................................................................16

Draw stop information

Limb stop adjustments

PSE Pro Series bows- draw setting charts

PSE Mainline bows- draw setting charts

PSE Morph™cam information .........................................................................21

PSE Surge™with Morph™cam settings charts ...........................................22-23

PSE Fever™One with Morph cam settings charts ..................................... 24-25

PSE Vision™cam information

PSE Vision™ with Vision™ “performance” cam setting charts

PSE Vision™ with Vision™ “grow with you” cam setting charts ............... 30-31

PSE Fever™ with Vision™ “performance” cam setting charts .................. 32-33

PSE Fever™ with Vision™ “grow with you” cam setting charts ................ 34-35

PSE Mini Burner™ XT with Vision™ “performance” setting charts ........... 36-37

PSE Mini Burner™ XT with Vision™ “grow with you” setting charts

PSE limited lifetime warranty information

PSE warranty registration

.................................................................................... 6

...........................................................................................10

.........................................................................................11

....................................................... 13

......................................................... 14

.....................................................................................17

.................................................................................... 17

.......................................................18

.........................................................19

...........................................................................27

................................................... 42

.............................................................................43

.......................................... 4

.................28-29

.........38-39

PAGE

3

Page 4

Compound Bow

USER’S GUIDE

General operatinG instructions

• Always inspect your bow thoroughly before each shooting session to insure that it is in good

working order. Check for worn, loose or missing components and have them replaced at an

authorized PSE dealer as required, i.e. bushings, spacers, etc.

•

Inspect your arrows to insure that they are straight, undamaged and that each nock is in good

condition. A cracked nock can break when fired from the bow and cause the bow to “dry fire”

resulting in possible injury to the archer and damage to the bow. Dry-firing is drawing and

releasing the bowstring without an arrow on the string.

•

When purchasing arrows for your bow, consult the selection chart from the arrow manufacturer

and select the correct arrow for your application. Always use an arrow that is at least 5 grains per

pound of peak bow weight. Failure to do so could cause personal injury and damage to your bow.

bow maintenance

Your PSE bow will give you many years of use if maintained and cared for properly.

It is a mechanical device that is subject to wear and therefore must be inspected periodically and

given the proper adjustments and service. It is recommended that this service be performed at least

once a year by an authorized PSE dealer. All components, including string, cables, axles, e-clips,

limbs and riser should be carefully inspected for damage or wear.

STRINGS AND CABLES

Apply a light coat of high quality bowstring wax to your string and cable each time you shoot your

bow. It is especially important NOT to wax the area of the string that wraps around the idler wheel.

This area of the string should be treated with a cam lubricant. This will help reduce wear on your

string and cables. Inspect the string and cables regularly and replace them when there is evidence of

wear, every 5000 shots or every 12 months.

I

MPORTANT: Before servicing any PSE bow in a bow press, back out each limb

bolt the maximum number of turns from bottom.

• Keep synthetic cables and strings waxed. Apply bow string wax to your synthetic cables and string

before each shooting session.

•

Strings and cables must be replaced periodically. A worn cable or string can suddenly break

causing serious injury to the archer and damage to the bow. It is recommended that the string

and cables be replaced at least every 5,000 shots or 12 months.

PSE recommends that this work be performed by an authorized PSE dealer.

•

Always store your bow in a cool dry place. High temperatures, such as those that can occur in

the interior of a vehicle, can cause serious damage to your bow.

•

After use in high humidity or damp conditions, wipe metal components of your bow

with a light oil.

safety

As with any weapon, safe operation of your PSE bow must always be the highest priority.

ALWAYS WEAR SAFETY GLASSES WHEN HANDLING A BOW.

Do not attempt to use your bow without proper instruction.

Doing so can result in serious injury.

a.

NEVER DRY-FIRE YOUR BOW. Dry-firing is drawing and releasing the bowstring without an

arrow on the string. Dry-firing will likely cause damage to the bow and serious injury to the

archer. In the event of a dry-fire, have an authorized PSE dealer inspect the bow

for damage.

Always be sure of your intended target as well as what lies behind the target area. An arrow can travel

b.

a considerable distance, so it is important to have a safe and sound backstop.

c.

If you draw a bow and need to let it down, do so in a slow and careful manner. Keep your

support arm straight and prepare for a rapid and violent let-down. Avoid hitting your hand on

protruding accessories such as the cable guard or quiver. Keep your head and face back and

out of danger during let-down. Never draw a bow with a peak weight above your comfort level.

Always use a wrist sling when drawing a bow.

d.

Never modify any part of the bow or its components by drilling extra holes or removing material.

This voids the warranty and presents safety problems.

e. It is not recommended to time the bow using a draw board unless the draw board is operated by

a winch or other mechanical pulling device.

PAGE

4

Page 5

TOP

LIMB

BOLT

Compound Bow

USER’S GUIDE

compound bow terminoloGy

(HYBRID DUAL CAM MODELS)

TOP

LIMB

BAND

TOP CAM

or IDLER WHEEL

(SINGLE CAM MODEL- SHOWN)

AXLE

TOP LIMB

POCKET

BOW QUIVER

HOOD AND FOAM

QUIVER BRACKET

AND QUICK-MOUNT*

TUNING

ALIGNMENT MARK

ARROW CLIP

ARROW SHELF

STABILIZER

BOTTOM

LIMB BOLT

BOTTOM

LIMB

POCKET

SIGHT

SIGHT

PINS

BOTTOM

LIMB

VANE

OR

FLETCHING

ARROW

GRIP

LIMB

PEEP

SIGHT

TUBE

CABLE GUARD

DAMPER

CABLE

SLIDE

CABLE

GUARD ROD

CABLE GUARD

ADJUSTMENT SCREW

ARROW

REST

BACKSTOP

OR STINGSTOP

BACKSTOP™*

ADJUSTMENT

SCREWS

RISER

DRAW STOP

MODULE

POSITION HOLES

AXLE

BOTTOM CAM

BOTTOM

LIMB BAND

NOCK

* = DEPENDS ON BOW MODEL

BOW

SLING

™

2* (SHOWN)

™

*

PAGE

5

Page 6

Compound Bow

USER’S GUIDE

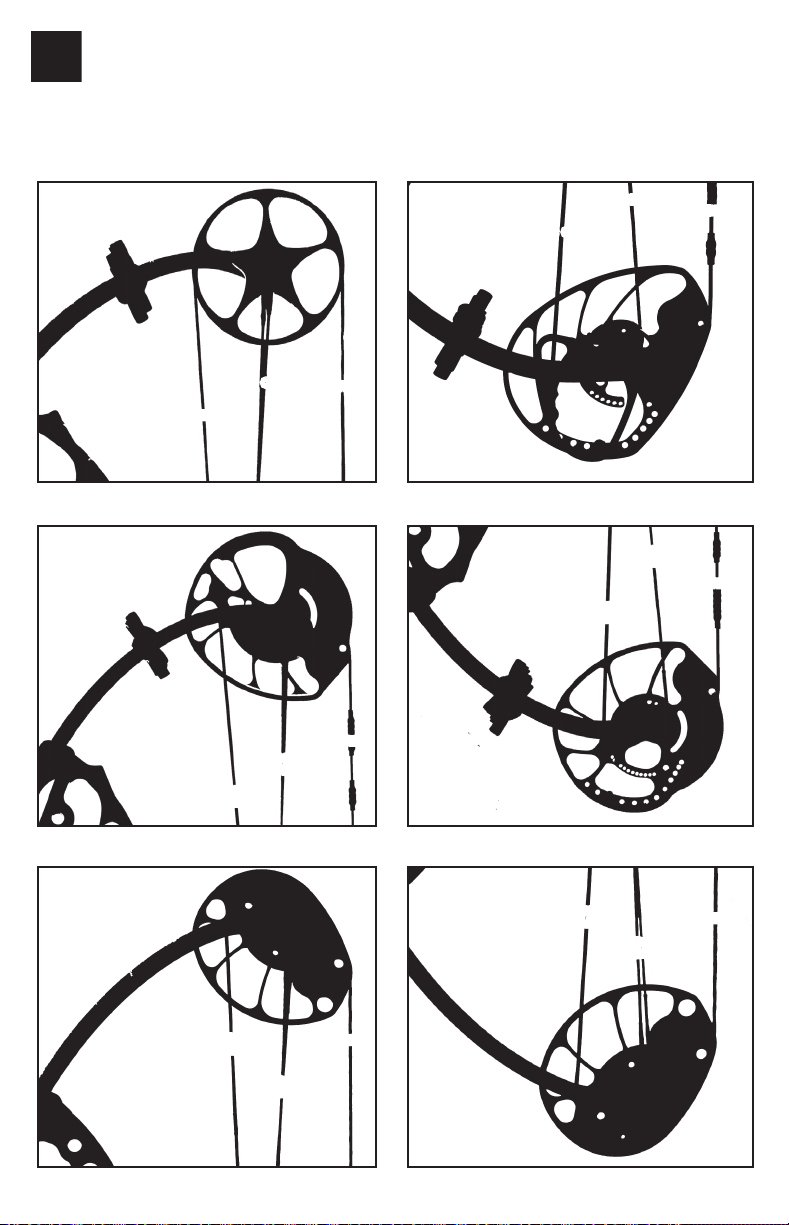

cable confiGurations

idler wheel

one cam bow

BUSS CABLE

STRING

STRING

top cam

top cam

STRING

BUSS CABLE

CONTROL

CABLE

STRING

hybrid cam bow

BUSS

CABLE

STRING

two cam bow

bottom cam

bottom cam

BUSS

CABLE

BUSS

CABLE

CONTROL

CABLE

BUSS

CABLE

STRING

STRING

PAGE

6

BUSS

CABLE

BUSS

CABLE

STRING

bottom cam

Page 7

Compound Bow

USER’S GUIDE

pse x technoloGy

PSE X Technology bows come with many unique features that will enhance your

archery experience.

USING A BOW PRESS WITH X TECHNOLOGY BOWS

ALL PSE X Technology bows MUST be serviced in an approved bow press and require special

consideration. Do not attempt to service these bows in any bow press without reviewing the

procedures described herein.

Use of a non-approved bow press or improper use of an approved bow press WILL result

in damage to the bow and possible personal injury. Damages incurred by improper use

or maintenance will not be covered under the warranty. See the PSE website at

www.pse-archery.com for a list of approved bow presses.

There are two basic types of approved presses available: compression-type

and pull-type. (Pg8)

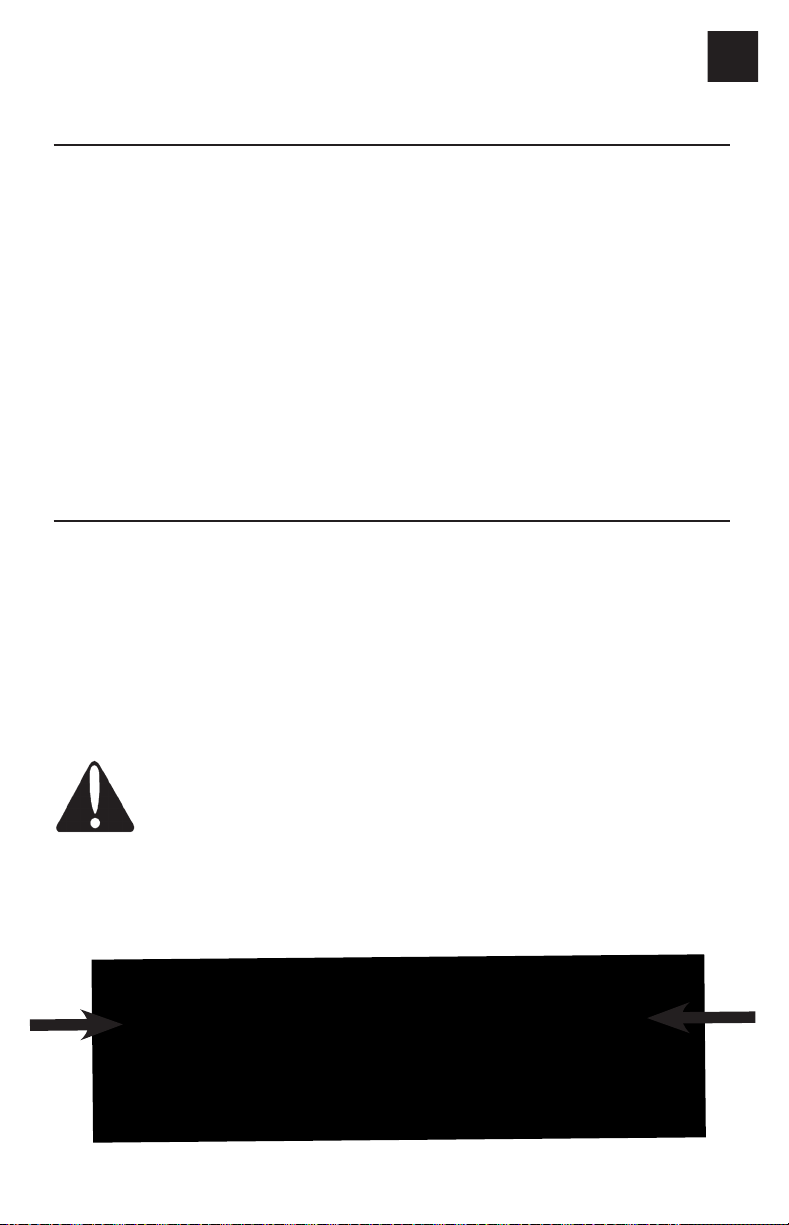

COMPRESSION-TYPE BOW PRESS:

This type of press pushes in a horizontal direction against the tips of the limbs.

No other support for the bow is required.

When using a press of this type, back each limb bolt out the maximum number of turns

indicated on your bow’s hang tag. Position the bow in the press and crank press inward to

apply a compression force against the limb tips as shown below.

COMPRESS ONLY FAR ENOUGH TO LOOSEN THE STRING AND CABLES.

OVER COMPRESSING COULD BREAK THE LIMBS AND CAUSE PERSONAL

INJURY.

ANY DAMAGES INCURRED FROM OVER-COMPRESSING WILL NOT BE

COVERED UNDER WARRANTY.

COMPRESSION-TYPE BOW PRESS

X Technology continued on next page

PAGE

7

Page 8

Compound Bow

USER’S GUIDE

pse x technoloGy USING A BOW PRESS

PULL-TYPE BOW PRESS

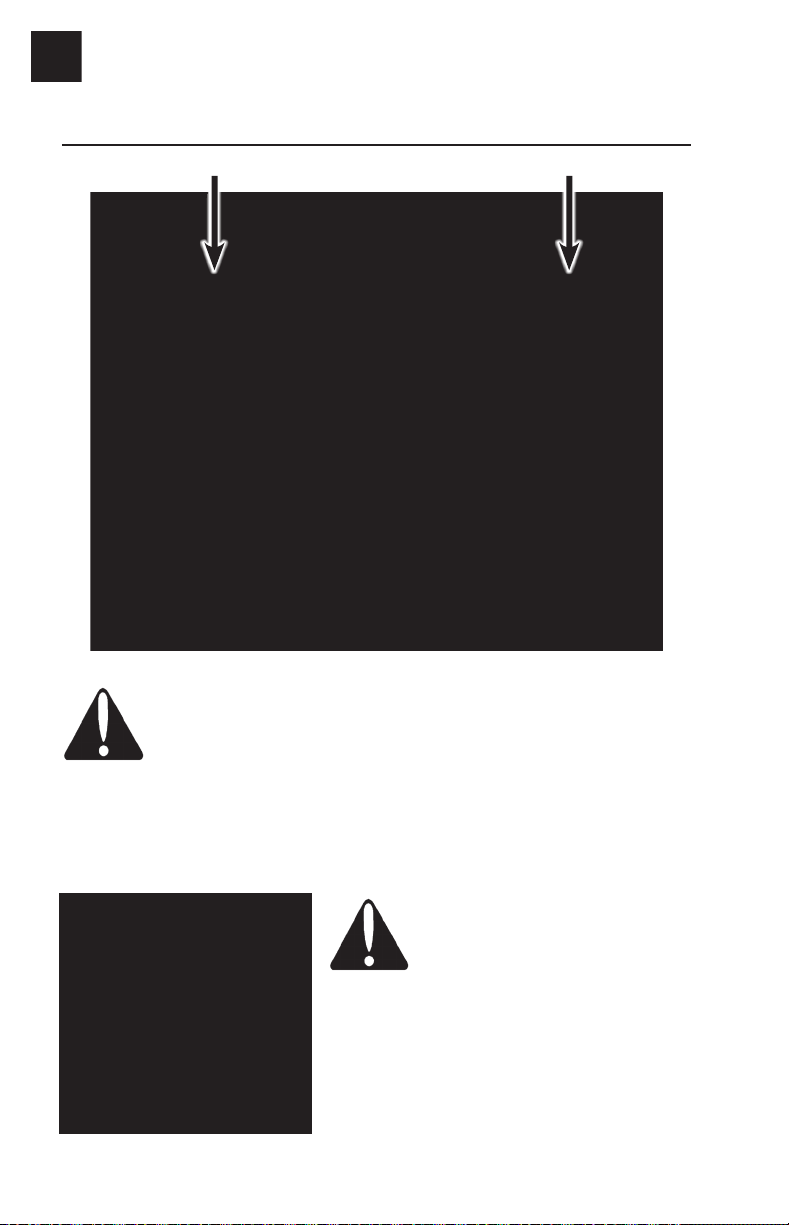

PULL-TYPE BOW PRESS:

This type of press pulls the riser of the bow in a vertical direction between

rollers that compress the limbs.

When using this type press it is very important to position the rollers and

pressure points correctly! See illustration above.

Back each limb bolt out the maximum number of turns indicated on your bow’s hang tag

and position the pressure points on the riser as close to the limbs as possible WITHOUT

making contact with the limbs as shown in the photo below.

THE PRESSURE POINTS MUST NOT CONTACT THE

LIMBS AT ANY TIME DURING SERVICING.

PULL-TYPE BOW PRESS

PAGE

8

X Technology continued on next page

Page 9

Compound Bow

USER’S GUIDE

pse x technoloGy USING A BOW PRESS (Continued)

Position the limb rollers outward on the limbs so that when the riser is pulled down

the bow does not slip through/between the rollers before releasing tension on the

string and cables. The rollers must be at least 4” from the limb pockets or the limbs

will break. While placing tension on the limbs, BE VERY CAREFUL NOT TO PULL THE RISER

DOWN TOO FAR. DEFLECT THE LIMBS JUST ENOUGH TO REMOVE THE STRING AND

CABLES. Never allow the rollers to go past the end of the limb belly (thinnest part).

Service such as peep and string mounted vibration damper installation and string replacement

can be performed with a “Pocket Press” portable bow press available from your local PSE

dealer. These pocket presses are available for alternate axle-to-axle lengths and cam types.

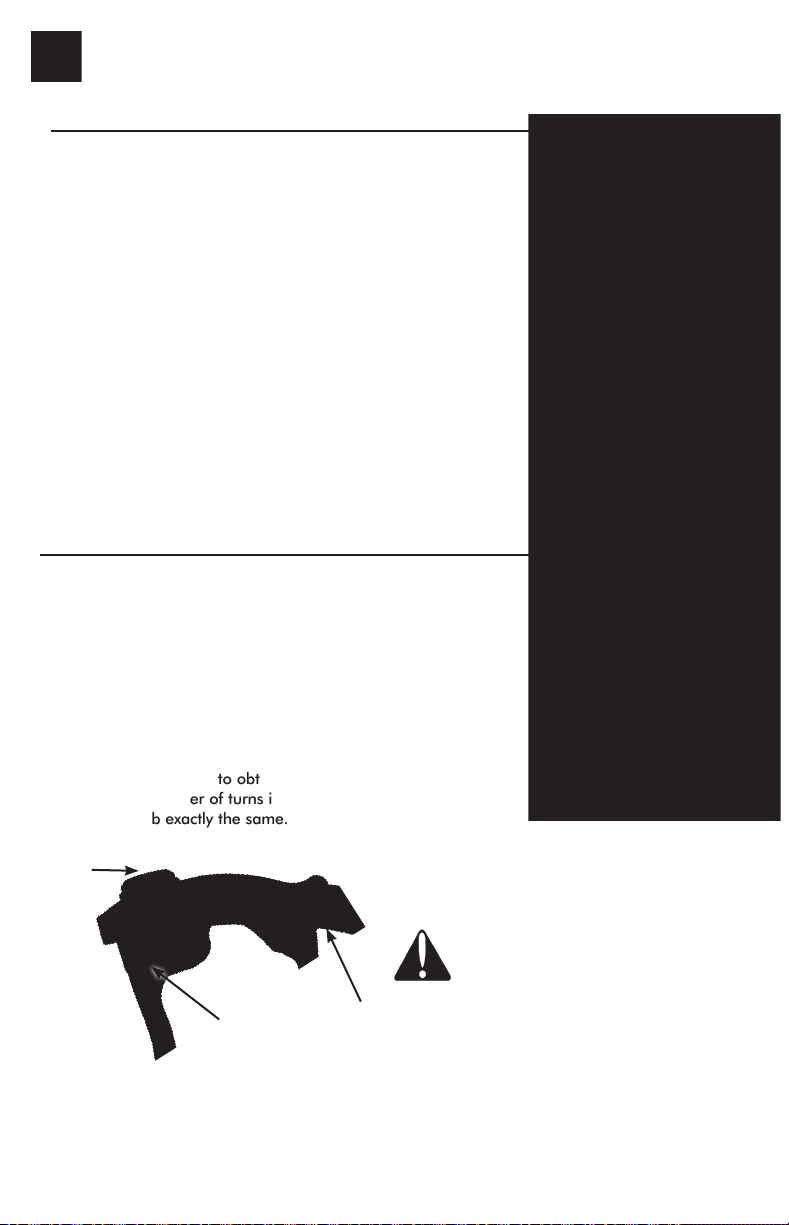

SERVICING BOWS WITH PSE FT CAMS (PSE FULL THROTTLE™)

CAUTION • CAUTION • CAUTION!

When servicing bows with PSE FT cams, such as the

Full Throttle™, it is important to use a bow press

that has enough clearance for the cams.

On some bow presses the cams may make

contact with the area shown in Figure 1 when

compressing the limbs. Watch very carefully as the

bow is compressed. If either cam comes in contact

with the bow press, STOP IMMEDIATELY

or permanent damage to bow

components may occur.

Contact the bow press manufacturer for

further information.

Figure 1

Cam may

hit here

PAGE

9

Page 10

Compound Bow

USER’S GUIDE

installation of accessories

Arrowrest/Overdraw: The arrowrest or overdraw should be

installed according to the instructions received with the product.

It is usually mounted to the riser in the threaded hole on the

side opposite the shelf (Hole “A”) using the hardware provided

with the arrowrest or overdraw.

Sight: The sight should be installed according to the instructions

received with the product. It is usually mounted to the riser in

the threaded holes (Holes “B”) on the side opposite the shelf

using the hardware provided with the sight. Some bows are

equipped with multiple sight mounting holes which allow the

sight to be moved up or down.

Stabilizer: The stabilizer should be mounted according to the

manufacturer’s recommendation. It is usually mounted in the

threaded hole on the front of the riser (Hole “C”).

Bow Sling: The bow sling attaches to the riser of the bow

generally with the stabilizer. If a stabilizer is not used, attach the

sling to the riser with the correct sized bolt (5/16” - 24) using

the hole provided for the stabilizer (Hole “C”).

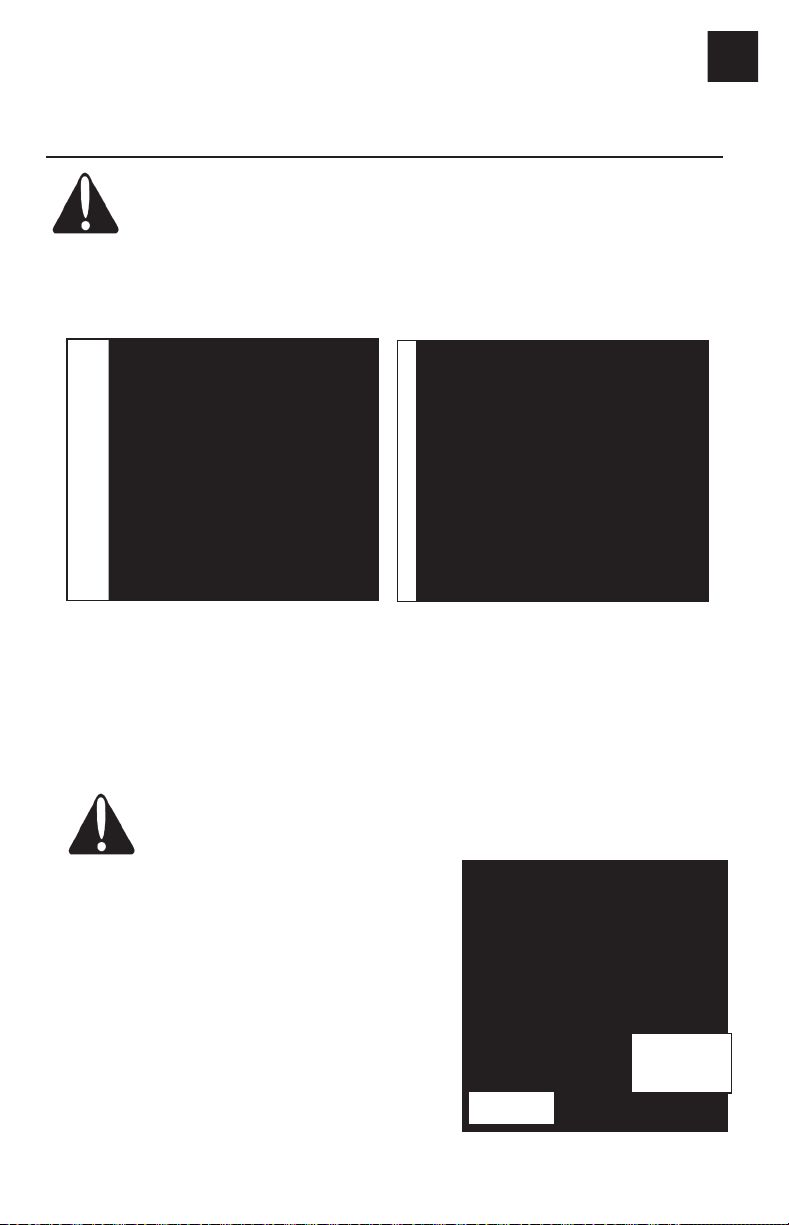

other adjustments

Draw Weight: Your bow is factory-set to within 2 lbs.

of the peak draw weight indicated on the bow hang tag and the

last 2 digits of the serial number. Changes in draw weight can

be made by turning the limb bolt in or out. Before making any

changes in weight, turn the limb bolt clockwise to the bottom

position. Never use extreme torque when turning the bolt or

damage to the limb may occur. The limb bolt may then be

turned counterclockwise to obtain the desired weight, but NEVER

more than the number of turns indicated on the hang tag.

Adjust each limb exactly the same. (See note and Fig. A below)

Limb

bolt

Holes

B

Hole

A

Hole

C

CAUTION: On some bow models,

the limb bolt locking screw, limb

Fig. A

Limb

Pocket tang

locking screw

Your Authorized PSE Dealer is supplied with technical information on PSE bows

and cams. Please see your Dealer for assistance when making these adjustments.

PAGE

10

support

screw

support screws or pocket tang

locking screw MUST be loosened

BEFORE adjusting.

Page 11

Compound Bow

settinG-up your bow

Tuning

nockinG point placement:

Finger shooters: Install the nocking point so that the arrow

passes the center of the arrow rest mounting hole and

runs slightly point-down relative to the tuning mark on the

window of the bow.

Release Aid shooters: Install the nocking point so that the

arrow passes the center of the arrow rest mounting hole

and runs parallel to the alignment mark on the window of

the bow.

arrow rest adjustment:

When shooting with a release aid, the in/out position

of the arrow rest should be adjusted so that the arrow

runs parallel with the tuning mark on the shelf when

viewed from above. When shooting with fingers the

arrow should point slightly outside the tuning alignment

mark on the shelf.

NOTE: Tuning alignment marks are for reference only.

Adjustments will likely be necessary to nocking point

and in/out position during tuning

Mark

USER’S GUIDE

Arrow rest mounting hole

Tuning

Mark

Alignment

Mark

siGht adjustment:

When adjusting the sight pin locations, always remember

to “follow the group”. That is, if the shot group is to the

left of the target, move the sight pins to the left. If the shot

group is low, move the sight pins down.

cable Guard adjustment

and installation:

Install the cable guard as shown in

Figure A. Adjust the cable guard so the

cables just clear the arrow vanes. On bows

using an offset cable guard rod, adjustments

must be done with the rod in the up position

(approximately 2 o’clock) as shown in

Figure B (10 o’clock for left handed bows).

Over-rotating an adjustable cable guard

creates excessive arrow clearance and may

cause the cable to track incorrectly on the

wheels and cause personal injury and/or

damage to the bow.

••

•

Figure A

Figure B

PAGE

11

Page 12

Compound Bow

USER’S GUIDE

flexslide™installation and adjustment

The PSE FlexSlide™ cable guard system is based on the same advanced

design and analysis used to create PSE Limbs. The flex-tuned design

and adjustable offset are engineered to create more consistent lateral

loads through the draw cycle and improve bow accuracy.

1. The standard factory setting adjusts the

FlexSlide

arrow clearance.

2. To adjust the lateral position, turn the

adjustment screw counterclockwise to

reduce arrow clearance or clockwise to

increase arrow clearance.

3. After making adjustments to your

FlexSlide

and BackStop

the bow, the buss cable should never

contact the arrow shaft or any part of

the Backstop

4. If any contact exists, tighten the

adjustment screw to create adequate

clearance. One full turn on the adjustment

screw will move the slide approximately 1/8”.

™

to its bottom position for maximum

™

, check both arrow clearance

™

clearance. When drawing

™

.

FlexSlide

Pivot with

Alignment

Tabs

FlexSlide

Limb

Low Friction

FlexSlide Rod

FlexSlide

Washer with

Alignment Tabs

Lateral

Adjustment

Screw

NOTE: Lateral adjustments to the FlexSlide

™

may affect arrow tuning.

backstop™2 instructions

At rest At full-draw

Note: Many PSE bow models come from the factory with the Backstop™ 2 installed.

These instructions refer to reinstallation or adjustment if needed after making adjustments

to your PSE bow.

1. Remove the set screws from the base using a T8 Torx wrench.

2. Install the Backstop™ 2 into the threaded hole below the

grip on the string-facing side of the bow.

3. Extend the Backstop™ 2 until it makes contact with the string. Mark the string ¼”

above and ¼” below where it makes contact with the string. Remove the Backstop™ 2

and add serving to that area of the string. Reinstall the Backstop™ 2.

4. Securely tighten the base to the bow handle.

6. Extend rod from base. Install the set screws to secure rod in this position.

Tighten set screws. It is desired to have some clearance (approximately 1/16”) between

the bumper and the bowstring at brace.

7. Rotation instructions- Adjust the Backstop™ 2 to the desired position and tighten the

rotator screw. The Backstop™ 2 design allows for the bumper to be positioned so the

string strikes the center of the bumper. It is desired to have some clearance

(approximately 1/16”) between the bumper and the bowstring at brace.

Serve string

in this area.

PAGE

12

Alignment

holes

Set screws

Page 13

Compound Bow

USER’S GUIDE

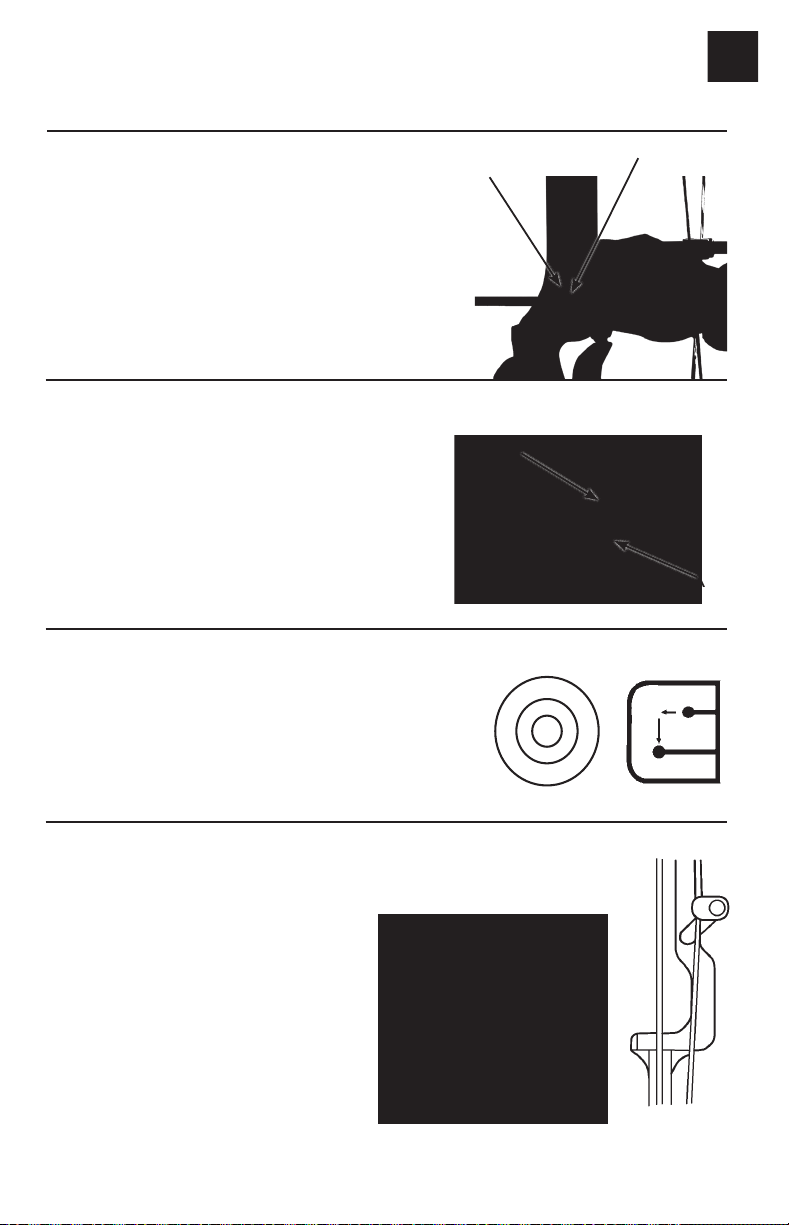

stinG stop™ instructions

Note: Some PSE bow models come from the factory with the PSE Sting Stop™

Backstop installed. These instructions refer to reinstallation or adjustment if

needed after making adjustments to your PSE bow.

1. Thread the Sting Stop™nut all the way up toward the bumper of

the Sting Stop™ rod.

2. Thread the Sting Stop™rod into the threaded hole below the grip on the

riser. The bowstring will need to be displaced slightly to one side to thread

the rod into the bow.

3. Unscrew the Sting Stop™until the rubber bumper approaches the bowstring.

Mark the string 1/4” above the rubber bumper in its highest position and

1/4” below the bumper in its lowest position. Remove the Sting Stop™ and

add serving to the marked area of the string. Reinstall the Sting Stop™.

4. Adjust the Sting Stop™to the desired position and tighten the Sting Stop™

nut against the riser. The Sting Stop™ design allows for the bumper to

be positioned so the string strikes the center of the bumper. It is desired

to have some clearance (approximately 1/16”) between the bumper and

the bowstring at brace. It is preferred to have the Sting Stop™rod in the

up position if possible, but may not be possible in order to achieve the

necessary clearance and contact point.

Serve string

in this area.

PAGE

13

Page 14

Compound Bow

USER’S GUIDE

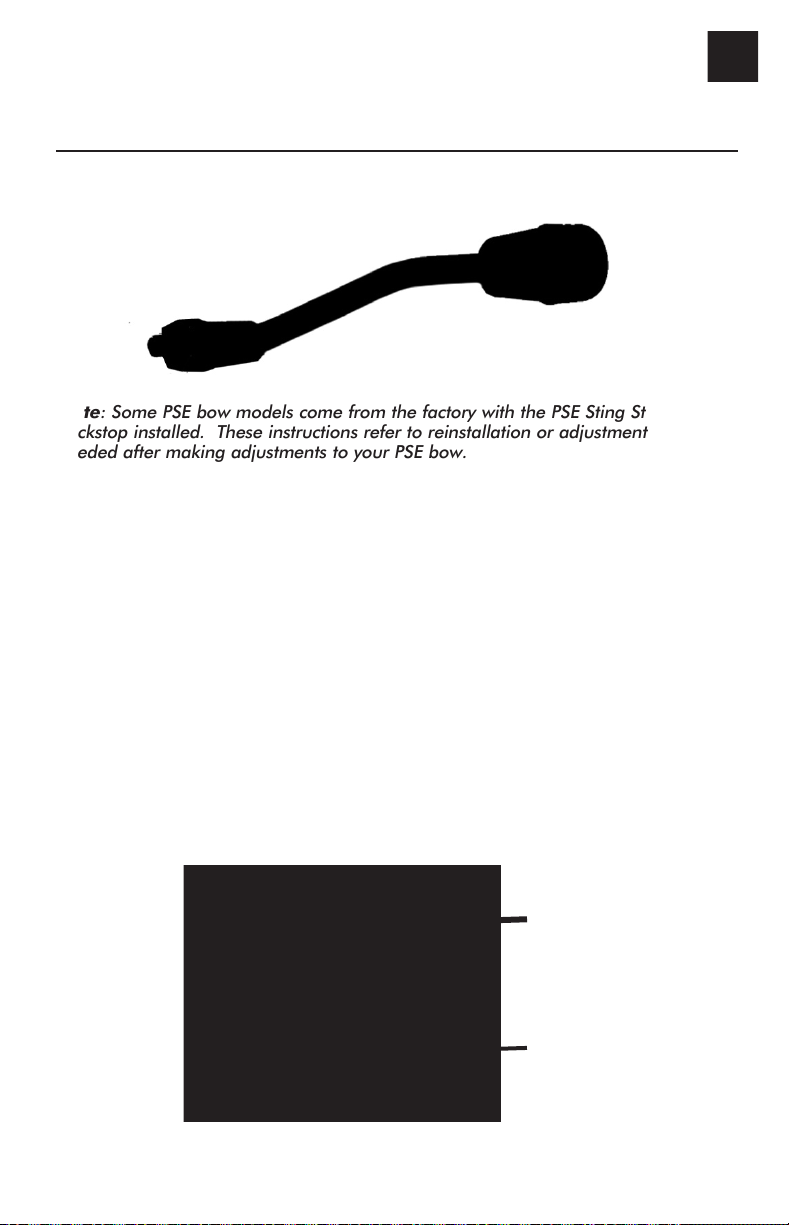

installinG limb bands and cable Guard damper

If your bow is equipped with a Cable Guard Damper it should be even with

the cable slide when the bow is at rest. More than one Cable Guard Damper

can be used.

If your solid limb bow is equipped with limb bands, the proper placement of the

bands is approximately 1/8” beyond the limb fork.

If your split limb bow is equipped with limb bands, the proper placement of the

bands is at least 1/4” away from the cam (align the band with the end of

the limb graphic).

Cable Guard Damper

Limb Band on

Solid Limb

Limb Band Damper Cable Guard Damper

Limb Bands across

Split Limb

Limb Bands on

Split Limb (one per limb)

check out our line of briGht colored rubber

Your PSE dealer carries a full line of colored rubber

add-ons for your PSE bow. Choose from pink,

orange, yellow, blue, purple, black, red and

lime green.

PAGE

14

Page 15

Compound Bow

chanGinG the flex slide rod

If you are replacing a PSE Flex slide rod or changing

to a different color follow these instructions.

FIGURE 1:

Unsnap the two strings from the cable slide- noting

the orientation of the two different clips (shorter clip

closest to the riser)

FIGURE 2:

Slide the cable slide off the Flex slide

FIGURE 3:

Using a T9 torx wrench remove the two screws.

Replace with the new Flex slide rod and tighten

the screws.

Re-assembly is the reverse of the

instructions above.

USER’S GUIDE

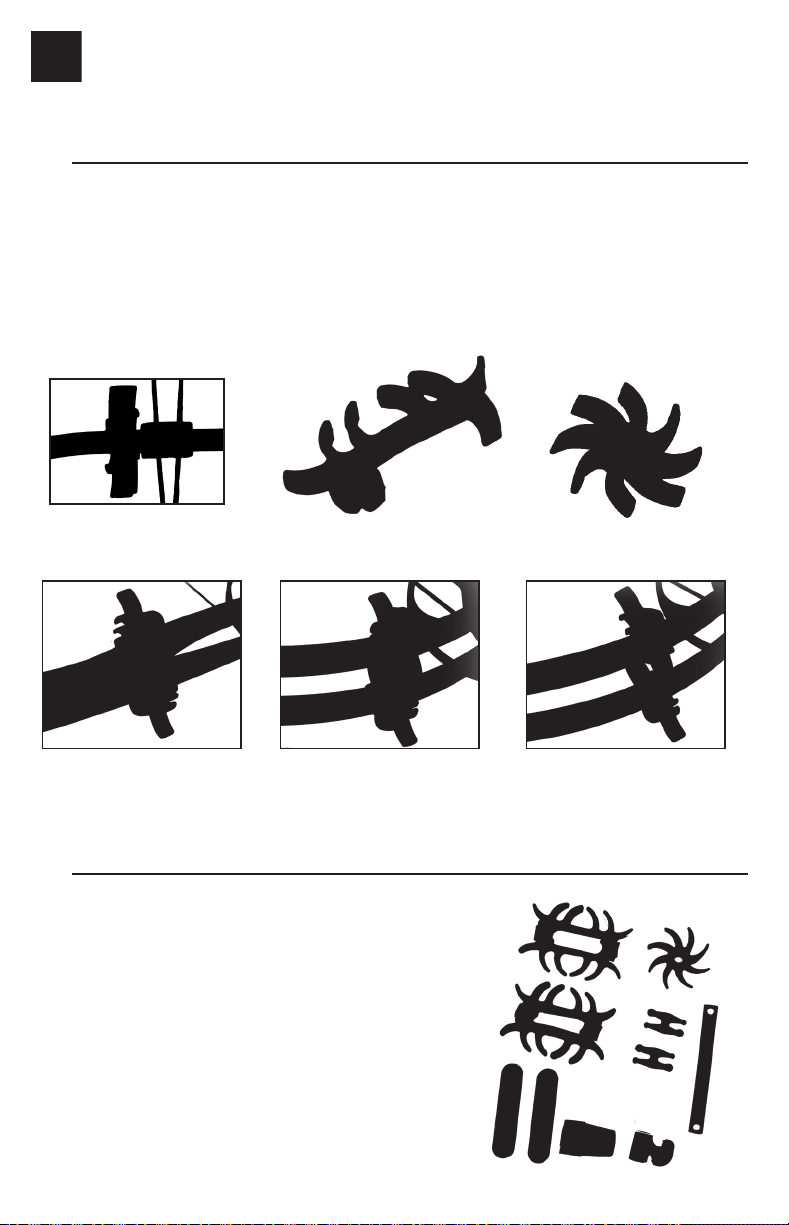

pse asymmetric idler

PSE single cam bows are equipped with a special

asymmetric idler wheel, which is assembled on the

top limb. It is essential that the idler be

oriented properly.

The wide edge of the idler always goes to the

cable guard side of the bow.

The illustration shows the proper orientation of

the idler for a right-handed bow when viewed while

holding the bow as it is shot.

Wide edge

PAGE

15

Page 16

Compound Bow

USER’S GUIDE

cam adjustments

WHEELS/CAMS: Many PSE wheels and cams have adjustable features. Each one comes from

the factory set up and ready to use but there may be occasions that you need to adjust the

characteristics of your bow. In some cases you will need a PSE Tune Chart to determine what

to adjust, and you may need to see a PSE Dealer for information. If you are not sure of the

adjustment you are making, stop and see your PSE Dealer for assistance. In some cases, an

appropriate bow press will be needed to make adjustments to cams and wheels. If you do not

have an appropriate press, see your PSE Dealer.

CAM ORIENTATION:

On cams with orientation marks, a reference mark is found to indicate an approximate

orientation. This line is for reference only and is meant to give approximate orientation

only and may vary between bow models. The orientation of the cams may be changed slightly

by twisting or untwisting the string or cables.

ALL

INNER-CAMS:

The inner-cam system allows draw length adjustments over a prescribed range usually without

putting the bow in a bow press. There are two types of inner-cam systems: discrete setting

inner-cams and Posi-Lock inner-cams.

Discrete setting inner-cams have the adjustment screws going through a specific hole in the

inner-cam and threading into the cam. The screws need to be completely removed to make

adjustments. The “A” setting is the longest draw length for that bow and draw lengths get

shorter as you progress through the alphabet (A to B, B to C, etc.)

Posi-lock adjustable inner-cams are adjustable in ½” draw length increments. The “A” setting is

the longest setting for the cam. Draw lengths get shorter as you progress through the alphabet

(“A” to “B”, “B” to “C”, etc.) by roughly ½” per letter.

Second and third generation Posi-lock inner-cams

allow for draw length adjustments in ½” increments

without changing inner-cams. To adjust draw length,

loosen the two 8-32 button head screws two full

turns. This will allow the inner-cam to be lifted far

enough to disengage the positioning pin and allow

the inner-cam to rotate to a new position. Some

cams may require the 8-32 button head screws to

move to alternate locations to reach the new draw

length adjustment position. Some draw length

adjustment positions may not be accessible without

putting the bow in a bow press. When the new

draw length adjustment position has been achieved

with the inner-cam, tighten the two 8-32 button

head screws and move the draw stop to the

matching setting (“A” and “A”, “B” and “B”).

In cases where there is an inner-cam on both the top and bottom cam, both cams must be

set in the same letter position for the bow to tune and shoot properly. In cases where there

is a separate draw stop, the draw stop must be moved to the hole marked with the letter

corresponding to the inner-cam setting.

PAGE

16

Positioning Pin

8-32 Button Head Screw

Page 17

Compound Bow

USER’S GUIDE

INFORMATION ON DRAW STOP ADJUSTMENTS:

The position of the draw stop must match the setting on the inner-cam. For example, if the cam is set on “E”, the draw

stop must be placed in one of the draw stop holes marked with an “E”. If the inner-cam is in the “B” setting, the stop

must be in the “B” position. Certain hybrid cams have top and bottom stops. They can be shot with both stops for a

harder “wall” or with only the top stop for a softer “wall”. Never shoot hybrid cams with the two stop option with only the

bottom stop. In either case, the stops need to be in the holes marked with the same marking as the inner-cam setting.

Draw Stop

Draw Stop

Screw

limb stop adjustments

On bows equipped with a limb stop and cable stop, use of the limb stop is optional. If

choosing not to use the limb stop it may be removed or set in the longest “A” position so

that it does not contact the limb before the cable stop. Engraving for limb stop positions is

approximate and for reference only. Many factors will cause changes to the optimum limb

stop position.

OPTION 1: (If a safe method of holding the bow at full draw is available) Set Limb Stop to

the Longest “A” Location and time bow to cable stops at desired draw length as shown in

Figure 1. Using a safe method to hold the bow at full draw adjust limb stop so it contacts

the limb as shown in Figure 2.

FIGURE 2FIGURE 1

OPTION 2: Set Limb Stop to the Longest “A” Postition. Time bow to cable stops at desired

draw length.Set Limb stop to the corresponding stop position. Draw bow with an arrow and

observe whether the cable stop or Limb Stop contacts first. Make small adjustments to the

Limb Stop position and recheck until it contacts at

the same time as the cable stop.

PAGE

17

Page 18

Compound Bow

USER’S GUIDE

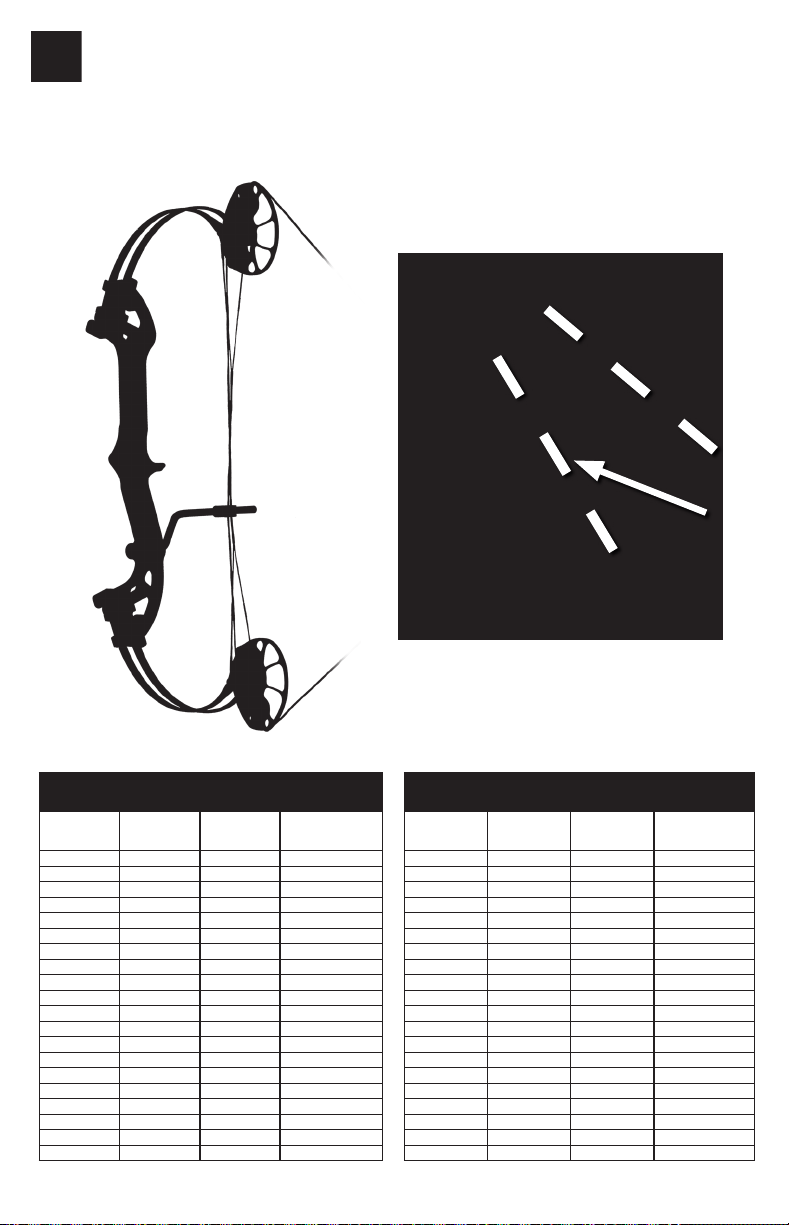

PSE PRO SERIES BOWS: DRAW SETTING CHART

NOTE: The PSE Full Throttle™ has cam-specific draw lengths from 26-1/2” to 30” in 1/2” increments.

SETTING

A 30 30 31-1/2 30 27 33 31

B 29-1/2 29-1/2 31 29-1/2 26-1/2 32-1/2 30-1/2

C 29 29 30-1/2 29 26 32 30

D 28-1/2 28-1/2 30 28-1/2 25-1/2 31-1/2 29-1/2

E 28 28 29-1/2 28 25-1/8 31 29

F 27-1/2 27-1/2 29 27-1/2 24-5/8 30-1/2 28-1/2

G 27 27 28-1/2 27 24-1/4 30 28

H 26-1/2 26-1/2 28 26-1/2 23-3/4 29-1/2 27-1/2

I 26 26 27-1/2 26 23-3/8 29 27

J - 25-1/2 27 25-1/2 22-7/8 28-1/2 26-1/2

K - 25 26-1/2 25 22-1/2 28 26

L - 24-1/2 26 24-1/2 22 27-1/2 25-1/2

DREAM

SEASON DNA

DNA SP SOURCE PREMONITION

VERGE

& STILETTO

FREAK SP DRIVE LT

SETTING

A 31-1/2 30-1/2 30 30 28-1/2

B 31 30 29-1/2 29-1/2 28

C 30-1/2 29-1/2 29 29 27-1/2

D 30 29 28-1/2 28-1/2 27

E 29-1/2 28-1/2 28 28 26-1/2

F 29 28 27-1/2 27-1/2 26

G 28-1/2 27-1/2 27 27 25-1/2

H 28 27 26-1/2 26-1/2 25

I 27-1/2 26-1/2 26 26 24-1/2

J 27 26 25-1/2 25-1/2 24

K - - - - 23-1/2

L - - - - 23

PAGE

18

DOMINATOR

MAX

DOMINATOR

3D MAX

SUPRA MAX PHENOM PHENOM SD

Page 19

Compound Bow

USER’S GUIDE

PSE MAIN LINE BOWS: DRAW SETTING CHART

Setting ProPhecy

A 30 30 31

B 29-1/2 29-1/2 30-1/2

C 29 29 30

D 28-1/2 28-1/2 29-1/2

E 28 28 29

F 27-1/2 27-1/2 28-1/2

G 27 27 28

H 26-1/2 26-1/2 27-1/2

I 26 26 27

J 25-1/2 25-1/2 26-1/2

K 25 25 26

Bow

MadneSS xP

MoMentuM

PSE Mainline bows with highly adjustable cams continued on page 20

PAGE

19

Page 20

Compound Bow

USER’S GUIDE

PSE HIGHLY ADJUSTABLE

CAM INFORMATION

The following pages of information apply to the

following PSE Main Line models:

™

• PSE SURGE

™

• PSE FEVER

• PSE VISION

ONE

™

• PSE FEVER™

• PSE MINI BURNER

PAGE

20

™

XT

Page 21

Compound Bow

USER’S GUIDE

PSE MORPH™ CAM INFORMATION

BOWS: PSE SURGE™ AND PSE FEVER

ADJUSTING THE MORPH™ CAM:

Select the “PERFORMANCE” or “GROW WITH YOU” cable position based on the

desired draw characteristics and peak weight range.

Rotate the inner-cam position (A thru Q) to match the desired draw length. To adjust,

loosen each #8-32 button head screw approx. 2 full turns. Rotate into position and

tighten screws. NOTE: the 3rd tapped hole position in the inner-cam may be used if

the screw becomes hidden behind the limb.

The “R” position is a unique guide and hub track design for minimum draw weight

and draw length. Remove the inner-cam and stop from the cam, align with the “R”

holes and install the screws.

™

ONE

PAGE

21

Page 22

Compound Bow

USER’S GUIDE

PSE SURGE™: MORPH™ CAM DRAW SETTING CHARTS

PSE SURGE 70#

PERFORMANCE

CABLE SETTINGS

Inner

Cam

Stop

Setting

A 30” 70 49

B 29½” 70 49

C 29” 70 49

D 28½” 70 49

E 28” 70 49

F 27½” 70 49

G 27” 70 49

H 26½” 70 49

I 26” 70 49

J 25½” 70 49

K 25” 70 49

L 24½” 70 49

M 24” 70 49

N 23½” 70 49

O 23” 70 49

P 22½” 70 49

Q 22” 70 49

R* N/A N/A N/A

Draw

Length

Setting

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

PSE SURGE 70#

GROW WITH YOU

CABLE SETTINGS

Inner

Cam

Stop

Setting

A 29½” 62½ 43¾

B 29” 61¾ 43½

C 28½” 61¼ 43¼

D 28” 60¾ 42½

E 27½” 60 42

F 27” 59½ 41½

G 26½” 59 40¾

H 26” 58¼ 40¼

I 25½” 57¾ 39¾

J 24⅞” 57 39

K 24¼” 56 38½

L 23⅝” 54¾ 37¾

M 23” 53½ 36½

N 22⅜” 51¼ 35

O 21¾” 48¾ 33½

P 21⅛” 45¾ 31¾

Q 20½” 42½ 30

R 19½” 32¾ N23A

Draw

Length

Setting

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

PAGE

22

*CAUTION: The “R” inner-cam and stop settings may ONLY

be used with the cable in the “GROW WITH YOU” position.

Page 23

PSE SURGE 60#

PERFORMANCE

CABLE SETTINGS

Inner

Cam

Stop

Setting

Draw

Length

Setting

A 30” 60 42

B 29½” 60 42

C 29” 60 42

D 28½” 60 42

E 28” 60 42

F 27½” 60 42

G 27” 60 42

H 26½” 60 42

I 26” 60 42

J 25½” 60 42

K 25” 60 42

L 24½” 60 42

M 24” 60 42

N 23½” 60 42

O 23” 60 42

P 22½” 60 42

Q 22” 60 42

R* N/A N/A N/A

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

Compound Bow

USER’S GUIDE

PSE SURGE 60#

GROW WITH YOU

CABLE SETTINGS

Inner

Cam

Stop

Setting

Draw

Length

Setting

A 29½” 53½ 37½

B 29” 53 37¼

C 28½” 52½ 37

D 28” 52 36½

E 27½” 51½ 36

F 27” 51 35½

G 26½” 50½ 35

H 26” 50 34½

I 25½” 49½ 34

J 24⅞” 48¾ 33½

K 24¼” 48 33

L 23⅝” 47 32¼

M 23” 45¾ 31¼

N 22⅜” 44 30

O 21¾” 41¾ 28¾

P 21⅛” 39¼ 27¼

Q 20½” 36½ 25¾

R 19½” 28 20

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

PSE SURGE 50#

PERFORMANCE

CABLE SETTINGS

Inner

Cam

Stop

Setting

Draw

Length

Setting

A 30” 50 35

B 29½” 50 35

C 29” 50 35

D 28½” 50 35

E 28” 50 35

F 27½” 50 35

G 27” 50 35

H 26½” 50 35

I 26” 50 35

J 25½” 50 35

K 25” 50 35

L 24½” 50 35

M 24” 50 35

N 23½” 50 35

O 23” 50 35

P 22½” 50 35

Q 22” 50 35

R* N/A N/A N/A

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

PSE SURGE 70#

GROW WITH YOU

CABLE SETTINGS

Inner

Cam

Stop

Setting

Draw

Length

Setting

A 29½” 44¾ 31

B 29” 44½ 30¾

C 28½” 44¼ 30½

D 28” 44 30¼

E 27½” 43½ 30

F 27” 43 29¾

G 26½” 42½ 29¼

H 26” 42 28¾

I 25½” 41½ 28¼

J 24⅞” 40¾ 27¾

K 24¼” 39¾ 27¼

L 23⅝” 38¾ 26½

M 23” 37¾ 25¾

N 22⅜” 36½ 24¾

O 21¾” 35 23¾

P 21⅛” 33½ 22¾

Q 20½” 31½ 21½

R 19½” 23½ 16½

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

PAGE

23

Page 24

Compound Bow

USER’S GUIDE

PSE FEVER™ ONE:

MORPH™ CAM DRAW SETTING CHARTS

PSE FEVER ONE 60#

PERFORMANCE

CABLE SETTINGS

Inner

Cam

Stop

Setting

A 29” 60 42

B 28½” 60 42

C 28” 60 42

D 27½” 60 42

E 27” 60 42

F 26½” 60 42

G 26” 60 42

H 25½” 60 42

J 24½” 60 42

K 24” 60 42

L 23½” 60 42

M 23” 60 42

N 22½” 60 42

O 22” 60 42

P 21½” 60 42

Q 21” 60 42

R* N/A N/A N/A

Draw

Length

Setting

I 25” 60 42

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

PSE FEVER ONE 60#

GROW WITH YOU

CABLE SETTINGS

Inner

Cam

Stop

Setting

A 28½” 53½ 37½

B 28” 53 37¼

C 27½” 52½ 37

D 27” 52 36½

E 26½” 51½ 36

F 26” 51 35½

G 25½” 50½ 35

H 25” 50 34½

J 24” 48¾ 33½

K 23½” 48 33

L 22⅞” 47 32¼

M 22¼” 45¾ 31¼

N 21⅝” 44 30

O 21” 41¾ 28¾

P 20¼” 39¼ 27¼

Q 19½” 36½ 25¾

R 18½” 28 20

Draw

Length

Setting

I 24½” 49½ 34

Draw

Weight

Bottom

*CAUTION: The “R” inner-cam and stop settings may ONLY

be used with the cable in the “GROW WITH YOU” position.

Draw

at

Weight

12 Turns

Off

PAGE

24

Page 25

Compound Bow

USER’S GUIDE

PSE FEVER ONE 50#

PERFORMANCE

CABLE SETTINGS

Inner

Cam

Stop

Setting

Draw

Length

Setting

A 29” 50 35

B 28½” 50 35

C 28” 50 35

D 27½” 50 35

E 27” 50 35

F 26½” 50 35

G 26” 50 35

H 25½” 50 35

I 25” 50 35

J 24½” 50 35

K 24” 50 35

L 23½” 50 35

M 23” 50 35

N 22½” 50 35

O 22” 50 35

P 21½” 50 35

Q 21” 50 35

R* N/A N/A N/A

Draw

Weight

at

Bottom

PSE FEVER ONE 40#

PERFORMANCE

CABLE SETTINGS

Inner

Cam

Stop

Setting

Draw

Length

Setting

A 29” 40 28

B 28½” 40 28

C 28” 40 28

D 27½” 40 28

E 27” 40 28

F 26½” 40 28

G 26” 40 28

H 25½” 40 28

I 25” 40 28

J 24½” 40 28

K 24” 40 28

L 23½” 40 28

M 23” 40 28

N 22½” 40 28

O 22” 40 28

P 21½” 40 28

Q 21” 40 28

R* N/A N/A N/A

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

Draw

Weight

12 Turns

Off

PSE FEVER ONE 50#

GROW WITH YOU

CABLE SETTINGS

Inner

Cam

Stop

Setting

Draw

Length

Setting

A 28½” 44¾ 31

B 28” 44½ 30¾

C 27½” 44¼ 30½

D 27” 44 30¼

E 26½” 43½ 30

F 26” 43 29¾

G 25½” 42½ 29¼

H 25” 42 28¾

I 24½” 41½ 28¼

J 24” 40¾ 27¾

K 23½” 39¾ 27¼

L 22⅞” 38¾ 26½

M 22¼” 37¾ 25¾

N 21⅝” 36½ 24¾

O 21” 35 23¾

P 20¼” 33½ 22¾

Q 19½” 31½ 21½

R 18½” 23½ 16½

Draw

Weight

at

Bottom

PSE FEVER ONE 40#

GROW WITH YOU

CABLE SETTINGS

Inner

Cam

Stop

Setting

Draw

Length

Setting

A 28½” 35¾ 24¾

B 28” 35½ 24½

C 27½” 35½ 24½

D 27” 35¼ 24¼

E 26½” 34¾ 24

F 26” 34½ 23¾

G 25½” 34 23½

H 25” 33½ 23

I 24½” 33¼ 22½

J 24” 32½ 22¼

K 23½” 31¾ 21¾

L 22⅞” 31 21¼

M 22¼” 30¼ 20½

N 21⅝” 29¼ 19¾

O 21” 28 19

P 20¼” 26¾ 18¼

Q 19½” 25¼ 17¼

R 18½” 18¾ 13

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

Draw

Weight

12 Turns

Off

PAGE

25

Page 26

Compound Bow

USER’S GUIDE

THE PSE WEBSITE IS YOUR RESOURCE

FOR EVERYTHING WE HAVE TO OFFER!

PAGE

26

www.pse-archery.com

Page 27

Compound Bow

USER’S GUIDE

PSE VISION™ CAM INFORMATION

BOWS: PSE VISION™, PSE FEVER™ AND

PSE MINI BURNER™ XT

ADJUSTING THE VISION

DRAW LENGTH:

STRING POST ADJUSTMENTS

PSE Vision cams have a string post adjustment for draw length as well as inner cam

adjustments and “Flexible Cam” adjustments. To make a string post adjustment,

compress the bow in a suitable bow press and relieve tension from the string and

cables. See the draw length adjustment chart for your bow for details.

Select the draw length and the “PERFORMANCE” or “GROW WITH YOU” cable position

based on the desired draw characteristics and peak weight range. If your desired draw

length lies in the short post category, an approved bow press will be required to make this

adjustment.Once the string is positioned onto the posts of your choice, adjust the inner-cam

to the desired location.

The inner-cam has holes marked “A” through “J” for adjusting draw length as well as a set of

threaded holes marked “S” and “L”. The “L” holes are used for longer draw lengths and the

“S” holes are used for shorter draw lengths. See the following tables for the setting required

to achieve different draw lengths and weight for bows using this cam.

™

CAM:

To make the necessary adjustment, remove the screw holding the inner-cam in place and

rotate the inner-cam so the letter setting desired lines up with the threaded “L” or “S” hole

in the cam. Replace and tighten the screw. IT IS IMPORTANT THAT BOTH TOP AND

BOTTOM CAMS BE ADJUSTED THE SAME. These adjustments can be made either with or

without a bow press.

PAGE

27

Page 28

Compound Bow

USER’S GUIDE

PSE VISION™: PERFORMANCE DRAW SETTINGS

PSE VISION 70#

CABLE SETTINGS-LONG POST

Inner

Cam

Stop

Setting

A-L 30” 70 48

B-L 29¾” 70 48

C-L 28½” 70 48

D-L 28¼” 70 48

E-L 26¾” 70 48

F-L 26½” 70 48

G-L 25¼” 70 48

H-L 24¾” 70 48

J-L 23” 70 48

A-S 22¼” 70 48

B-S 21” 70 48

C-S 20¼” 70 48

D-S 19¼” 70 48

E-S 18¾” 70 48

F-S 18¾” 70 48

G-S 18¼” 70 48

H-S 18” 70 48

J-S 17¾” 70 48

PAGE

28

PERFORMANCE

Draw

Length

Setting

I-L 23¾” 70 48

I-S 18” 70 48

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

PSE VISION 70#

CABLE SETTINGS-SHORT POST

Inner

Cam

Stop

Setting

A-L 29” 60 42

B-L 28½” 60 42

C-L 27” 60 42

D-L 26½” 60 42

E-L 25½” 60 42

F-L 25” 60 42

G-L 24” 58 41

H-L 23½” 58 41

I-L 22½” 56 40

J-L 21½” 56 39

A-S 20½” 56 37

B-S 19½” 56 37

C-S 19” 56 37

D-S 18” 56 37

E-S 17½” 56 37

F-S 17¼” 56 37

G-S 17¼” 56 37

H-S 17” 56 37

I-S 16¾” 56 37

J-S 16¼” 56 37

PERFORMANCE

Draw

Length

Setting

Draw

Weight

Bottom

at

Draw

Weight

12 Turns

Off

Page 29

PSE VISION 60#

PERFORMANCE

CABLE SETTINGS-LONG POST

Inner

Cam

Stop

Setting

Draw

Length

Setting

Draw

Weight

at

Bottom

A-L 30” 60 41

B-L 29¾” 60 41

C-L 28½” 60 41

D-L 28¼” 60 41

E-L 26¾” 60 41

F-L 26½” 60 41

G-L 25¼” 60 41

H-L 24¾” 60 41

I-L 23¾” 60 41

J-L 23” 60 41

A-S 22¼” 60 41

B-S 21” 60 41

C-S 20¼” 60 41

D-S 19¼” 60 41

E-S 18¾” 60 41

F-S 18¾” 60 41

G-S 18¼” 60 41

H-S 18” 60 41

I-S 18” 60 41

J-S 17¾” 60 41

Draw

Weight

12 Turns

Off

Compound Bow

PERFORMANCE CABLE

SETTINGS-SHORT POST

Inner

Cam

Stop

Setting

A-L 29” 51 36

B-L 28½” 51 36

C-L 27” 51 36

D-L 26½” 51 36

E-L 25½” 51 36

F-L 25” 51 36

G-L 24” 50 35

H-L 23½” 50 35

I-L 22½” 48 34

J-L 21½” 48 33

A-S 20½” 48 32

B-S 19½” 48 32

C-S 19” 48 32

D-S 18” 48 32

E-S 17½” 48 32

F-S 17¼” 48 32

G-S 17¼” 48 32

H-S 17” 48 32

I-S 16¾” 48 32

J-S 16¾” 48 32

USER’S GUIDE

PSE VISION 60#

Draw

Length

Setting

Draw

Weight

at Bottom

Draw

Weight

12 Turns

Off

PSE VISION 50#

PERFORMANCE

CABLE SETTINGS-LONG POST

Inner

Cam

Stop

Setting

Draw

Length

Setting

Draw

Weight

at

Bottom

A-L 30” 50 34

B-L 29¾” 50 34

C-L 28½” 50 34

D-L 28¼” 50 34

E-L 26¾” 50 34

F-L 26½” 50 34

G-L 25¼” 50 34

H-L 24¾” 50 34

I-L 23¾” 50 34

J-L 23” 50 34

A-S 22¼” 50 34

B-S 21” 50 34

C-S 20¼” 50 34

D-S 19¼” 50 34

E-S 18¾” 50 34

F-S 18¾” 50 34

G-S 18¼” 50 34

H-S 18” 50 34

I-S 18” 50 34

J-S 17¾” 50 34

Draw

Weight

12 Turns

Off

PSE VISION 50#

CABLE SETTINGS-SHORT POST

Inner

Cam

Stop

Setting

PERFORMANCE

Draw

Length

Setting

Draw

Weight

Bottom

at

A-L 29” 43 30

B-L 28½” 43 30

C-L 27” 43 30

D-L 26½” 43 30

E-L 25½” 43 30

F-L 25” 43 30

G-L 24” 42 29

H-L 23½” 42 29

I-L 22½” 40 28

J-L 21½” 40 28

A-S 20½” 40 27

B-S 19½” 40 27

C-S 19” 40 27

D-S 18” 40 27

E-S 17½” 40 27

F-S 17¼” 40 27

G-S 17¼” 40 27

H-S 17” 40 27

I-S 16¾” 40 27

J-S 16¼” 40 27

Draw

Weight

12 Turns

Off

PAGE

29

Page 30

Compound Bow

USER’S GUIDE

PSE VISION™: GROW WITH YOU DRAW SETTINGS

PSE VISION 70#

GROW WITH YOU

CABLE SETTINGS-LONG POST

Inner

Cam

Stop

Setting

A-L 29¾” 64¼ 43¼

B-L 29½” 64¼ 43¼

C-L 28½” 64¼ 43¼

D-L 27¾” 64¼ 43¼

E-L 26½” 64¼ 43¼

F-L 26” 64¼ 43¼

G-L 24¾” 64¼ 43¼

H-L 24” 64¼ 43¼

I-L 23½” 64¼ 42

J-L 22½” 64¼ 42

A-S 22” 60¾ 42

B-S 20½” 58¼ 39¾

C-S 19¾” 56 37¼

D-S 18½” 51¼ 33¾

E-S 18” 49 31½

F-S 16½” 43¼ 29¼

G-S 16” 40¾ 28

H-S 15¼” 35 26¾

I-S 15” 35 25¾

J-S 14½” 35 24

PAGE

30

Draw

Length

Setting

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

PSE VISION 70#

GROW WITH YOU

CABLE SETTINGS-SHORT POST

Inner

Cam

Stop

Setting

A-L 28½” 56 39¾

B-L 28” 56 39¾

C-L 26½” 56 38½

D-L 26” 56 38½

E-L 25” 56 38½

F-L 24½” 56 38½

G-L 23½” 53¾ 37¼

H-L 23” 53¾ 37¼

I-L 22” 52½ 36¼

J-L 21” 50¼ 35

A-S 20” 49 31½

B-S 18½” 45½ 31½

C-S 18” 42 29¼

D-S 16½” 37¼ 25¾

E-S 16” 33¾ 23¼

F-S 15” 29¼ 19¾

G-S 14¼” 25¾ 17½

H-S 13½” 19¾ 14

I-S 13” 17½ 12¾

J-S 12¼” 17½ 11¾

Draw

Length

Setting

Draw

Weight

at

Bottom

12 Turns

Draw

Weight

Off

Page 31

Compound Bow

USER’S GUIDE

PSE VISION 60#

GROW WITH YOU

CABLE SETTINGS-LONG POST

Inner

Cam

Stop

Setting

Draw

Length

Setting

Draw

Weight

at

Bottom

12 Turns

A-L 29¾” 55 37

B-L 29½” 55 37

C-L 28½” 55 37

D-L 27¾” 55 37

E-L 26½” 55 37

F-L 26” 55 37

G-L 24¾” 55 37

H-L 24” 55 37

I-L 23½” 55 36

J-L 22½” 55 36

A-S 22” 52 36

B-S 20½” 50 34

C-S 19¾” 48 32

D-S 18½” 44 29

E-S 18” 42 27

F-S 16½” 37 25

G-S 16” 35 24

H-S 15¼” 30 23

I-S 15” 30 22

J-S 14½” 30 20½

PSE VISION 50#

GROW WITH YOU

CABLE SETTINGS-LONG POST

Inner

Cam

Stop

Setting

Draw

Length

Setting

Draw

Weight

at

Bottom

12 Turns

A-L 29¾” 45¾ 30¾

B-L 29½” 45¾ 30¾

C-L 28½” 45¾ 30¾

D-L 27¾” 45¾ 30¾

E-L 26½” 45¾ 30¾

F-L 26” 45¾ 30¾

G-L 24¾” 45¾ 30¾

H-L 24” 45¾ 30¾

I-L 23½” 45¾ 30

J-L 22½” 45¾ 30

A-S 22” 43¼ 30

B-S 20½” 41¾ 28¼

C-S 19¾” 40 26¾

D-S 18½” 36¾ 24¼

E-S 18” 35 22½

F-S 16½” 30¾ 20¾

G-S 16” 29¼ 20

H-S 15¼” 25 19¼

I-S 15” 25 18¼

J-S 14½” 25 17

Draw

Weight

Off

Draw

Weight

Off

PSE VISION 60#

GROW WITH YOU

CABLE SETTINGS-SHORT POST

Inner

Cam

Stop

Setting

Draw

Length

Setting

Draw

Weight

at

Bottom

Weight

12 Turns

A-L 28½” 48 34

B-L 28” 48 34

C-L 26½” 48 33

D-L 26” 48 33

E-L 25” 48 33

F-L 24½” 48 33

G-L 23½” 46 32

H-L 23” 46 32

I-L 22” 45 31

J-L 21” 43 30

A-S 20” 42 27

B-S 18½” 39 27

C-S 18” 36 25

D-S 16½” 32 22

E-S 16” 29 20

F-S 15” 25 17

G-S 14¼” 22 15

H-S 13½” 17 12

I-S 13” 15 11

J-S 12¼” 15 10

PSE VISION 50#

GROW WITH YOU

CABLE SETTINGS-SHORT POST

Inner

Cam

Stop

Setting

Draw

Length

Setting

Draw

Weight

at

Bottom

Weight

12 Turns

A-L 28½” 40 28¼

B-L 28” 40 28¼

C-L 26½” 40 27½

D-L 26” 40 27½

E-L 25” 40 27½

F-L 24½” 40 27½

G-L 23½” 38¼ 26¾

H-L 23” 38¼ 26¾

I-L 22” 37½ 25¾

J-L 21” 35¾ 25

A-S 20” 35 22½

B-S 18½” 32½ 22½

C-S 18” 30 20¾

D-S 16½” 26¾ 18¼

E-S 16” 24¼ 16¾

F-S 15” 20¾ 14¼

G-S 14¼” 18¼ 12½

H-S 13½” 14¼ 10

I-S 13” 12½ 9¼

J-S 12¼” 12½ 8¼

Draw

Off

Draw

Off

PAGE

31

Page 32

Compound Bow

USER’S GUIDE

PSE FEVER™: PERFORMANCE DRAW SETTINGS

PSE FEVER 60# PERFORMANCE

CABLE SETTINGS-LONG POST

Inner Cam

Stop

Setting

A-L 29” 60 40

B-L 28¾” 60 40

C-L 27½” 60 40

D-L 27” 60 40

E-L 25¾” 60 40

F-L 25¼” 60 40

G-L 24¼” 60 40

H-L 24” 60 40

I-L 22½” 60 40

J-L 21¾” 60 40

A-S 21¼” 60 40

B-S 20” 60 40

C-S 19¼” 60 40

D-S 18½” 60 40

E-S 18” 60 40

F-S 17¾” 60 40

G-S 17½” 60 40

H-S 17¼” 60 40

I-S 17¼” 60 40

J-S 17” 60 40

PAGE

32

Draw

Length

Setting

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

PSE FEVER 60# PERFORMANCE

CABLE SETTINGS-SHORT POST

Inner Cam

Stop

Setting

A-L 28” 52 36

B-L 27½” 52 36

C-L 26½” 52 36

D-L 26” 52 36

E-L 24¾” 52 36

F-L 24½” 52 36

G-L 23” 52 36

H-L 22½” 52 35

I-L 21¼” 48 33

J-L 20¼” 48 31

A-S 19¾” 47 31

B-S 18½” 47 31

C-S 18” 47 31

D-S 17” 47 31

E-S 16½” 47 31

F-S 16¼” 47 31

G-S 16” 47 31

H-S 16” 47 31

I-S 15¾” 47 31

J-S 15½” 47 31

Draw

Length

Setting

Draw

Weight

at

Bottom

Draw

Weight

12 Turns

Off

Page 33

PSE FEVER 50# PERFORMANCE

Inner Cam

CABLE SETTINGS-LONG POST

Stop

Setting

A-L 29” 50 33

B-L 28¾” 50 33

C-L 27½” 50 33

D-L 27” 50 33

E-L 25¾” 50 33

F-L 25¼” 50 33

G-L 24¼” 50 33

H-L 24” 50 33

I-L 22½” 50 33

J-L 21¾” 50 33

A-S 21¼” 50 33

B-S 20” 50 33

C-S 19¼” 50 33

D-S 18½” 50 33

E-S 18” 50 33

F-S 17¾” 50 33

G-S 17½” 50 33

H-S 17¼” 50 33

I-S 17¼” 50 33

J-S 17” 50 33

Draw

Length

Setting

Draw Weight

at

Bottom

PSE FEVER 40# PERFORMANCE

Inner Cam

CABLE SETTINGS-LONG POST

Stop

Setting

A-L 29” 40 26

B-L 28¾” 40 26

C-L 27½” 40 26

D-L 27” 40 26

E-L 25¾” 40 26

F-L 25¼” 40 26

G-L 24¼” 40 26

H-L 24” 40 26

I-L 22½” 40 26

J-L 21¾” 40 26

A-S 21¼” 40 26

B-S 20” 40 26

C-S 19¼” 40 26

D-S 18½” 40 26

E-S 18” 40 26

F-S 17¾” 40 26

G-S 17½” 40 26

H-S 17¼” 40 26

I-S 17¼” 40 26

J-S 17” 40 26

Draw

Length

Setting

Draw Weight

at

Bottom

PSE FEVER 29# PERFORMANCE

Inner Cam

CABLE SETTINGS-LONG POST

Stop

Setting

A-L 29” 29 19

B-L 28¾” 29 19

C-L 27½” 29 19

D-L 27” 29 19

E-L 25¾” 29 19

F-L 25¼” 29 19

G-L 24¼” 29 19

H-L 24” 29 19

I-L 22½” 29 19

J-L 21¾” 29 19

A-S 21¼” 29 19

B-S 20” 29 19

C-S 19¼” 29 19

D-S 18½” 29 19

E-S 18” 29 19

F-S 17¾” 29 19

G-S 17½” 29 19

H-S 17¼” 29 19

I-S 17¼” 29 19

J-S 17” 29 19

Draw

Length

Setting

Draw Weight

at

Bottom

Draw

Weight

12 Turns Off

Draw

Weight

12 Turns Off

Draw

Weight

12 Turns Off

PSE FEVER 50# PERFORMANCE

CABLE SETTINGS-SHORT POST

Inner Cam

Stop

Setting

A-L 28” 43 30

B-L 27½” 43 30

C-L 26½” 43 30

D-L 26” 43 30

E-L 24¾” 43 30

F-L 24½” 43 30

G-L 23” 43 30

H-L 22½” 43 29

I-L 21¼” 40 27

J-L 20¼” 40 26

A-S 19¾” 39 26

B-S 18½” 39 26

C-S 18” 39 26

D-S 17” 39 26

E-S 16½” 39 26

F-S 16¼” 39 26

G-S 16” 39 26

H-S 16” 39 26

I-S 15¾” 39 26

J-S 15½” 39 26

Draw

Length

Setting

DrawWeight

at

Bottom

PSE FEVER 40# PERFORMANCE

CABLE SETTINGS-SHORT POST

Inner Cam

Stop

Setting

A-L 28” 35 24

B-L 27½” 35 24

C-L 26½” 35 24

D-L 26” 35 24

E-L 24¾” 35 24

F-L 24½” 35 24

G-L 23” 35 24

H-L 22½” 35 23

I-L 21¼” 32 22

J-L 20¼” 32 21

A-S 19¾” 31 21

B-S 18½” 31 21

C-S 18” 31 21

D-S 17” 31 21

E-S 16½” 31 21

F-S 16¼” 31 21

G-S 16” 31 21

H-S 16” 31 21

I-S 15¾” 31 21

J-S 15½” 31 21

Draw

Length

Setting

DrawWeight

at

Bottom

PSE FEVER 29# PERFORMANCE

CABLE SETTINGS-SHORT POST

Inner Cam

Stop

Setting

A-L 28” 25 18

B-L 27½” 25 18

C-L 26½” 25 18

D-L 26” 25 18

E-L 24¾” 25 18

F-L 24½” 25 18

G-L 23” 25 18

H-L 22½” 25 17

I-L 21¼” 23 16

J-L 20¼” 23 15

A-S 19¾” 23 15

B-S 18½” 23 15

C-S 18” 23 15

D-S 17” 23 15

E-S 16½” 23 15

F-S 16¼” 23 15

G-S 16” 23 15

H-S 16” 23 15

I-S 15¾” 23 15

J-S 15½” 23 15

Draw

Length

Setting

Draw Weight

at

Bottom

Draw

Weight

12 Turns Off

Draw

Weight

12 Turns Off

Draw

Weight

12 Turns Off

PAGE

33

Page 34

Compound Bow

USER’S GUIDE

PSE FEVER™: GROW WITH YOU DRAW SETTINGS

PSE FEVER 60# GROW WITH YOU

CABLE SETTINGS-LONG POST

Inner Cam

Stop

Setting

A-L 28¾” 54 37¼

B-L 28½” 54 37¼

C-L 27¼” 54 37¼

D-L 26¾” 54 37¼

E-L 25½” 54 37¼

F-L 25” 54 37¼

G-L 24” 54 37¼

H-L 23¼” 54 37¼

I-L 22” 54 36

J-L 21½” 52¾ 34¾

A-S 21” 51½ 33½

B-S 19½” 49¼ 32½

C-S 18¾” 48 31¼

D-S 17½” 43¼ 28¾

E-S 17” 40¾ 26½

F-S 16” 36 24

G-S 15½” 33½ 21½

H-S 14½” 28¾ 19¼

I-S 14¼” 28¾ 19¼

J-S 13½” 28¾ 19¼

PAGE

34

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight

12 Turns Off

PSE FEVER 60# GROW WITH YOU

CABLE SETTINGS-SHORT POST

Inner Cam

Stop

Setting

A-L 27¾” 49¼ 33½

B-L 27¼” 49¼ 33½

C-L 26” 49¼ 33½

D-L 25½” 49¼ 33½

E-L 24½” 49¼ 33½

F-L 24” 48 32½

G-L 22¾” 46¾ 31¼

H-L 22¼” 45½ 31¼

I-L 21” 43¼ 28¾

J-L 20” 42 28¾

A-S 19½” 40¾ 31¼

B-S 18” 37¼ 25¼

C-S 17½” 34¾ 22¾

D-S 16” 30 20½

E-S 15¼” 27½ 18

F-S 14” 22¾ 14½

G-S 13½” 20½ 13¼

H-S 12½” 15½ 10¾

I-S 12” 13¼ 9½

J-S 11” 13¼ 8½

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight

12 Turns Off

Page 35

PSE FEVER 50# GROW WITH YOU

CABLE SETTINGS-LONG POST

Inner Cam

Stop

Setting

A-L 28¾” 45 31

B-L 28½” 45 31

C-L 27¼” 45 31

D-L 26¾” 45 31

E-L 25½” 45 31

F-L 25” 45 31

G-L 24” 45 31

H-L 23¼” 45 31

I-L 22” 45 30

J-L 21½” 44 29

A-S 21” 43 28

B-S 19½” 41 27

C-S 18¾” 40 26

D-S 17½” 36 24

E-S 17” 34 22

F-S 16” 30 20

G-S 15½” 28 18

H-S 14½” 24 16

I-S 14¼” 24 16

J-S 13½” 24 16

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight

12 Turns Off

PSE FEVER 50# GROW WITH YOU

CABLE SETTINGS-SHORT POST

Inner Cam

Stop

Setting

A-L 27¾” 41 28

B-L 27¼” 41 28

C-L 26” 41 28

D-L 25½” 41 28

E-L 24½” 41 28

F-L 24” 40 27

G-L 22¾” 39 26

H-L 22¼” 38 26

I-L 21” 36 24

J-L 20” 35 24

A-S 19½” 34 26

B-S 18” 31 21

C-S 17½” 29 19

D-S 16” 25 17

E-S 15¼” 23 15

F-S 14” 19 12

G-S 13½” 17 11

H-S 12½” 13 9

I-S 12” 11 8

J-S 11” 11 7

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight

12 Turns Off

PSE FEVER 40# GROW WITH YOU

CABLE SETTINGS-LONG POST

Inner Cam

Stop

Setting

A-L 28¾” 36 24¾

B-L 28½” 36 24¾

C-L 27¼” 36 24¾

D-L 26¾” 36 24¾

E-L 25½” 36 24¾

F-L 25” 36 24¾

G-L 24” 36 24¾

H-L 23¼” 36 24¾

I-L 22” 36 24

J-L 21½” 35¼ 23¼

A-S 21” 34½ 22½

B-S 19½” 32¾ 21½

C-S 18¾” 32 20¾

D-S 17½” 28¾ 19¼

E-S 17” 27¼ 17½

F-S 16” 24 16

G-S 15½” 22½ 14½

H-S 14½” 19¼ 12¾

I-S 14¼” 19¼ 12¾

J-S 13½” 19¼ 12¾

Inner Cam

Stop

Setting

A-L 28¾” 26 18

B-L 28½” 26 18

C-L 27¼” 26 18

D-L 26¾” 26 18

E-L 25½” 26 18

F-L 25” 26 18

G-L 24” 26 18

H-L 23¼” 26 18

I-L 22” 26 17½

J-L 21½” 25½ 16¾

A-S 21” 25 16¼

B-S 19½” 23¾ 15¾

C-S 18¾” 23¼ 15

D-S 17½” 21 14

E-S 17” 19¾ 12¾

F-S 16” 17½ 11½

G-S 15½” 16¼ 10½

H-S 14½” 14 9¼

I-S 14¼” 14 9¼

J-S 13½” 14 9¼

Draw

Length

Setting

PSE FEVER 29# GROW WITH YOU

CABLE SETTINGS-LONG POST

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight at

Bottom

Draw

Weight

12 Turns Off

Draw

Weight

12 Turns Off

PSE FEVER 40# GROW WITH YOU

CABLE SETTINGS-SHORT POST

Inner Cam

Stop

Setting

A-L 27¾” 32¾ 21½

B-L 27¼” 32¾ 21½

C-L 26” 32¾ 21½

D-L 25½” 32¾ 21½

E-L 24½” 32¾ 21½

F-L 24” 32 21½

G-L 22¾” 31¼ 20¾

H-L 22¼” 30½ 20¾

I-L 21” 28¾ 19¼

J-L 20” 28 19¼

A-S 19½” 27¼ 20¾

B-S 18” 24¾ 16¾

C-S 17½” 23¼ 15¼

D-S 16” 20 13½

E-S 15¼” 18½ 12

F-S 14” 15¼ 9½

G-S 13½” 13½ 8¾

H-S 12½” 10½ 7¼

I-S 12” 8¾ 6½

J-S 11” 8¾ 5½

Inner Cam

Stop

Setting

A-L 27¾” 23¾ 16¼

B-L 27¼” 23¾ 16¼

C-L 26” 23¾ 16¼

D-L 25½” 23¾ 16¼

E-L 24½” 23¾ 16¼

F-L 24” 23¼ 15¾

G-L 22¾” 22½ 15

H-L 22¼” 22 15

I-L 21” 21 14

J-L 20” 20¼ 14

A-S 19½” 19¾ 15

B-S 18” 18 12¼

C-S 17½” 16¾ 11

D-S 16” 14½ 9¾

E-S 15¼” 13¼ 8¾

F-S 14” 11 7

G-S 13½” 9¾ 6½

H-S 12½” 7½ 5¼

I-S 12” 6½ 4¾

J-S 11” 6½ 4

Draw

Length

Setting

PSE FEVER 29# GROW WITH YOU

CABLE SETTINGS-SHORT POST

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight at

Bottom

Draw

Weight

12 Turns Off

Draw

Weight

12 Turns Off

Page 36

Compound Bow

USER’S GUIDE

MINI BURNER™ XT: PERFORMANCE DRAW SETTINGS

PSE MINI BURNER XT- 50# PERFORMANCE

CABLE SETTINGS-LONG POST

Inner Cam

Stop

Setting

A-L 28¼” 50 37

B-L 28” 50 37

C-L 27” 50 37

D-L 26½” 50 35

E-L 25¼” 50 35

F-L 25” 50 35

G-L 23¾” 50 35

H-L 23½” 50 35

I-L 22½” 50 35

J-L 21½” 50 35

A-S 21” 50 34

B-S 20” 50 34

C-S 19¼” 50 34

D-S 18¼” 50 34

E-S 18” 50 34

F-S 17¾” 50 34

G-S 17½” 50 34

H-S 17¼” 50 34

I-S 17” 50 34

J-S 16¾” 50 34

PAGE

36

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight

6 Turns Off

PSE MINI BURNER XT- 50# PERFORMANCE

CABLE SETTINGS-SHORT POST

Inner Cam

Stop

Setting

A-L 27½” 43 33

B-L 27¼” 43 33

C-L 26” 43 33

D-L 25¾” 43 32

E-L 24½” 43 32

F-L 24” 43 32

G-L 22¾” 42 32

H-L 22½” 42 31

I-L 21¼” 40 29

J-L 20¾” 40 29

A-S 20” 40 29

B-S 18¾” 40 29

C-S 18” 40 29

D-S 17¼” 40 29

E-S 16¾” 40 29

F-S 16½” 40 29

G-S 16¼” 40 29

H-S 16” 40 29

I-S 15¾” 40 28

J-S 15½” 40 28

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight

6 Turns Off

Page 37

PSE MINI BURNER XT- 40# PERFORMANCE

Inner Cam

CABLE SETTINGS-LONG POST

Stop

Setting

A-L 28¼” 40 30

B-L 28” 40 30

C-L 27” 40 30

D-L 26½” 40 28

E-L 25¼” 40 28

F-L 25” 40 28

G-L 23¾” 40 28

H-L 23½” 40 28

I-L 22½” 40 28

J-L 21½” 40 28

A-S 21” 40 28

B-S 20” 40 27

C-S 19¼” 40 27

D-S 18¼” 40 27

E-S 18” 40 27

F-S 17¾” 40 27

G-S 17½” 40 27

H-S 17¼” 40 27

I-S 17” 40 27

J-S 16¾” 40 27

PSE MINI BURNER XT- 29# PERFORMANCE

Inner Cam

Stop

Setting

A-L 28¼” 29 21

B-L 28” 29 21

C-L 27” 29 21

D-L 26½” 29 20

E-L 25¼” 29 20

F-L 25” 29 20

G-L 23¾” 29 20

H-L 23½” 29 20

I-L 22½” 29 20

J-L 21½” 29 20

A-S 21” 29 20

B-S 20” 29 20

C-S 19¼” 29 20

D-S 18¼” 29 20

E-S 18” 29 20

F-S 17¾” 29 20

G-S 17½” 29 20

H-S 17¼” 29 20

I-S 17” 29 20

J-S 16¾” 29 20

PSE MINI BURNER XT- 20# PERFORMANCE

Inner Cam

Stop

Setting

A-L 28¼” 20 15

B-L 28” 20 15

C-L 27” 20 15

D-L 26½” 20 14

E-L 25¼” 20 14

F-L 25” 20 14

G-L 23¾” 20 14

H-L 23½” 20 14

I-L 22½” 20 14

J-L 21½” 20 14

A-S 21” 20 14

B-S 20” 20 14

C-S 19¼” 20 14

D-S 18¼” 20 14

E-S 18” 20 14

F-S 17¾” 20 14

G-S 17½” 20 14

H-S 17¼” 20 14

I-S 17” 20 14

J-S 16¾” 20 14

Draw

Length

Setting

CABLE SETTINGS-LONG POST

Draw

Length

Setting

CABLE SETTINGS-LONG POST

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight at

Bottom

Draw

Weight at

Bottom

6 Turns Off

6 Turns Off

6 Turns Off

Draw

Weight

Draw

Weight

Draw

Weight

PSE MINI BURNER XT- 40# PERFORMANCE

Inner Cam

CABLE SETTINGS-SHORT POST

Stop

Setting

A-L 27½” 35 27

B-L 27¼” 35 27

C-L 26” 35 27

D-L 25¾” 35 26

E-L 24½” 35 26

F-L 24” 35 26

G-L 22¾” 34 26

H-L 22½” 34 25

I-L 21¼” 32 23

J-L 20¾” 32 23

A-S 20” 32 23

B-S 18¾” 32 23

C-S 18” 32 23

D-S 17¼” 32 23

E-S 16¾” 32 23

F-S 16½” 32 23

G-S 16¼” 32 23

H-S 16” 32 23

I-S 15¾” 32 23

J-S 15½” 32 23

PSE MINI BURNER XT- 29# PERFORMANCE

Inner Cam

Stop

Setting

A-L 27½” 25 19

B-L 27¼” 25 19

C-L 26” 25 19

D-L 25¾” 25 19

E-L 24½” 25 19

F-L 24” 25 19

G-L 22¾” 24 19

H-L 22½” 24 18

I-L 21¼” 23 17

J-L 20¾” 23 17

A-S 20” 23 17

B-S 18¾” 23 17

C-S 18” 23 17

D-S 17¼” 23 17

E-S 16¾” 23 17

F-S 16½” 23 17

G-S 16¼” 23 17

H-S 16” 23 17

I-S 15¾” 23 16

J-S 15½” 23 16

PSE MINI BURNER XT- 20# PERFORMANCE

Inner Cam

Stop

Setting

A-L 27½” 17 13

B-L 27¼” 17 13

C-L 26” 17 13

D-L 25¾” 17 13

E-L 24½” 17 13

F-L 24” 17 13

G-L 22¾” 17 13

H-L 22½” 17 13

I-L 21¼” 16 12

J-L 20¾” 16 12

A-S 20” 16 12

B-S 18¾” 16 12

C-S 18” 16 12

D-S 17¼” 16 12

E-S 16¾” 16 12

F-S 16½” 16 12

G-S 16¼” 16 12

H-S 16” 16 12

I-S 15¾” 16 11

J-S 15½” 16 11

Draw

Length

Setting

CABLE SETTINGS-SHORT POST

Draw

Length

Setting

CABLE SETTINGS-SHORT POST

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

eight at

W

Bottom

Draw

eight at

W

Bottom

Weight

6 Turns Off

Weight

6 Turns Off

Weight

6 Turns Off

Draw

Draw

Draw

Page 38

Compound Bow

USER’S GUIDE

MINI BURNER™ XT: GROW WITH YOU DRAW SETTINGS

PSE MINI BURNER XT- 50# GROW WITH YOU

CABLE SETTINGS-LONG POST

Inner Cam

Stop

Setting

A-L 28” 45 33

B-L 27¾” 45 33

C-L 26¾” 45 33

D-L 26¼” 45 32

E-L 25” 45 32

F-L 24¾” 45 32

G-L 23½” 45 32

H-L 23¼” 45 32

I-L 22” 45 32

J-L 21” 45 32

A-S 20¾” 44 31

B-S 19½” 40 30

C-S 19” 40 30

D-S 17¾” 37 27

E-S 17¼” 36 25

F-S 16” 30 23

G-S 15¾” 29 22

H-S 15” 26 20

I-S 14¾” 25 19

J-S 14” 25 19

PAGE

38

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight

6 Turns Off

PSE MINI BURNER XT- 50# GROW WITH YOU

CABLE SETTINGS-SHORT POST

Inner Cam

Stop

Setting

A-L 27¼” 40 30

B-L 27” 40 30

C-L 25¾” 40 30

D-L 25½” 39 30

E-L 24” 39 29

F-L 23¾” 39 29

G-L 22½” 38 29

H-L 22½” 38 28

I-L 21” 36 27

J-L 20½” 36 26

A-S 19¾” 34 26

B-S 18½” 32 24

C-S 17¾” 29 22

D-S 16½” 27 19

E-S 15½” 25 17

F-S 14¾” 21 15

G-S 14” 19 11

H-S 13” 16 11

I-S 12¾” 14 10

J-S 11½” 14 9

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight

6 Turns Off

Page 39

PSE MINI BURNER XT- 40# GROW WITH YOU

CABLE SETTINGS-LONG POST

Inner Cam

Stop

Setting

A-L 28” 36 26½

B-L 27¾” 36 26½

C-L 26¾” 36 26½

D-L 26¼” 36 25½

E-L 25” 36 25½

F-L 24¾” 36 25½

G-L 23½” 36 25½

H-L 23¼” 36 25½

I-L 22” 36 25½

J-L 21” 36 25½

A-S 20¾” 35¼ 24¾

B-S 19½” 32 24

C-S 19” 32 24

D-S 17¾” 29½ 21½

E-S 17¼” 28¾ 20

F-S 16” 24 18½

G-S 15¾” 23¼ 17½

H-S 15” 20¾ 16

I-S 14¾” 20 15¼

J-S 14” 20 15¼

PSE MINI BURNER XT- 29# GROW WITH YOU

Inner Cam

Stop

Setting

A-L 28” 26 19¼

B-L 27¾” 26 19¼

C-L 26¾” 26 19¼

D-L 26¼” 26 18½

E-L 25” 26 18½

F-L 24¾” 26 18½

G-L 23½” 26 18½

H-L 23¼” 26 18½

I-L 22” 26 18½

J-L 21” 26 18½

A-S 20¾” 25½ 18

B-S 19½” 23¼ 17½

C-S 19” 23¼ 17½

D-S 17¾” 21½ 15¾

E-S 17¼” 21 14½

F-S 16” 17½ 13¼

G-S 15¾” 16¾ 12¾

H-S 15” 15 11½

I-S 14¾” 14½ 11

J-S 14” 14½ 11

PSE MINI BURNER XT- 20# GROW WITH YOU

Inner Cam

Stop

Setting

A-L 28” 18 13¼

B-L 27¾” 18 13¼

C-L 26¾” 18 13¼

D-L 26¼” 18 12¾

E-L 25” 18 12¾

F-L 24¾” 18 12¾

G-L 23½” 18 12¾

H-L 23¼” 18 12¾

I-L 22” 18 12¾

J-L 21” 18 12¾

A-S 20¾” 17½ 12½

B-S 19½” 16 12

C-S 19” 16 12

D-S 17¾” 14¾ 10¾

E-S 17¼” 14½ 10

F-S 16” 12 9¼

G-S 15¾” 11½ 8¾

H-S 15” 10½ 8

I-S 14¾” 10 7½

J-S 14” 10 7½

Draw

Length

Setting

CABLE SETTINGS-LONG POST

Draw

Length

Setting

CABLE SETTINGS-LONG POST

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight at

Bottom

Draw

Weight at

Bottom

6 Turns Off

6 Turns Off

Draw

Weight

Draw

Weight

Draw

Weight

6 Turns Off

PSE MINI BURNER XT- 40# GROW WITH YOU

Inner Cam

Inner Cam

Inner Cam

CABLE SETTINGS-SHORT POST

Stop

Setting

A-L 27¼” 32 24

B-L 27” 32 24

C-L 25¾” 32 24

D-L 25½” 31¼ 24

E-L 24” 31¼ 23¼

F-L 23¾” 31¼ 23¼

G-L 22½” 30½ 23¼

H-L 22½” 30½ 22½

I-L 21” 28¾ 21½

J-L 20½” 28¾ 20¾

A-S 19¾” 27¼ 20¾

B-S 18½” 25½ 19¼

C-S 17¾” 23¼ 17½

D-S 16½” 21½ 15¼

E-S 15½” 20 13½

F-S 14¾” 16¾ 12

G-S 14” 15¼ 8¾

H-S 13” 12¾ 8¾

I-S 12¾” 11¼ 8

J-S 11½” 11¼ 7¼

PSE MINI BURNER XT- 29# GROW WITH YOU

Stop

Setting

A-L 27¼” 23¼ 17½

B-L 27” 23¼ 17½

C-L 25¾” 23¼ 17½

D-L 25½” 22½ 17½

E-L 24” 22½ 16¾

F-L 23¾” 22½ 16¾

G-L 22½” 22 16¾

H-L 22½” 22 16¼

I-L 21” 21 15¾

J-L 20½” 21 15

A-S 19¾” 19¾ 15

B-S 18½” 18½ 14

C-S 17¾” 16¾ 12¾

D-S 16½” 15¾ 11

E-S 15½” 14½ 9¾

F-S 14¾” 12¼ 8¾

G-S 14” 11 6½

H-S 13” 9¼ 6½

I-S 12¾” 8 5¾

J-S 11½” 8 5¼

PSE MINI BURNER XT- 20# GROW WITH YOU

Stop

Setting

A-L 27¼” 16 12

B-L 27” 16 12

C-L 25¾” 16 12

D-L 25½” 15½ 12

E-L 24” 15½ 11½

F-L 23¾” 15½ 11½

G-L 22½” 15¼ 11½

H-L 22½” 15¼ 11¼

I-L 21” 14½ 10¾

J-L 20½” 14½ 10½

A-S 19¾” 13½ 10½

B-S 18½” 12¾ 9½

C-S 17¾” 11½ 8¾

D-S 16½” 10¾ 7½

E-S 15½” 10 6¾

F-S 14¾” 8½ 6

G-S 14” 7½ 4½

H-S 13” 6½ 4½

I-S 12¾” 5½ 4

J-S 11½” 5½ 3½

Draw

Length

Setting

CABLE SETTINGS-SHORT POST

Draw

Length

Setting

CABLE SETTINGS-SHORT POST

Draw

Length

Setting

Draw

Weight at

Bottom

Draw

Weight at

Bottom

Draw

Weight at

Bottom

Draw

Weight

6 Turns Off

Draw

Weight

6 Turns Off

Draw

Weight

6 Turns Off

Page 40

Compound Bow

USER’S GUIDE

notes:

PAGE

40

Page 41

lookinG for the latest information

on pse products and serVices?

pse-archery.com

The PSE website has

numerous resources for

the PSE owner:

• The latest PSE products

• Product feature videos

• Serial number search

• Online product

registration

• Tune charts on PSE bows

from 1991 to present

• Purchase bows,

accessories,

PSE Signature Items

and more!

Compound Bow

USER’S GUIDE

pse patent information

Manufactured Under Patents:

5,365,650

5,469,834

5,487,373

5,507,270

5,657,739

5,678,529

5,762,060

5,960,778

6,112,732

6,176,231

6,360,735

6,792,930

6,889,683

6,968,837

7,347,196 B1

RE36,942

D429,309

D503,958

D528,625

7,699,045

ExpEriEncE. pErformancE.

7,721,721

7,784,452

7,832,388

7,891,349

7,918,218

7,980,236

7,980,237

Licensed Under Patents:

5,501,208

5,505,185

5,749,351

5,894,835

5,921,227

6,142,132

6,237,584

6,588,411

6,966,314

PAGE

41

Page 42

Compound Bow

USER’S GUIDE

®

limited lifetime warranty

Each PSE Bow is backed by a PSE Limited Lifetime Warranty to the

original owner for the life of the product. Product will be replaced

or repaired to restore it to its original performance.

or wearable items are not covered by this warranty.

Evidence of abuse, mishandling, misuse, or alteration to any

PSE product voids any claim to warranty.

PSE specifications on strings and harnesses must be adhered to.

Cables, strings,

PSE cannot be held responsible for injury or product failure resulting

from improper use or neglect of maintenance.

All bows must undergo string and cable changes every 5,000 shots

or every 12 months to maintain PSE warranty coverage. Total arrow

weight must be in accordance with the guidelines published by

the Archery Trade Association (ATA) for minimum arrow weight/

bow peak weight. Overstressing PSE compound bows by using

arrows lighter than ATA guideline will void warranty and may cause

damage to the bow or injury to the shooter.

PSE makes no other claims either expressed or implied. In the

interest of product improvement and consumer safety, PSE reserves

the right to make changes in product design, color,

and specifications without notice.

PAGE

42

Page 43

IMPORTANT

WARRANTY REGISTRATION

TO ACTIVATE YOUR BOW WARRANTY, PSE BOW REGISTRATION

MUST BE RECEIVED BY PSE WITHIN 30 DAYS OF PURCHASE.

REGISTER YOUR BOW ONLINE OR COMPLETE THE INFORMATION

AND MAIL-IN THE WARRANTY CARD INSERT.

ONLINE WARRANTY REGISTRATION

Log on at: www.pse-archery.com/registration

The PSE serial number is laser

etched into your riser- opposite

the shelf area.

NOTE: IF THE CARD IS NOT PRESENT, PLEASE USE THE FORM BELOW.

MAIL-IN WARRANTY REGISTRATION

Fill out the form below completely, remove it, place in a stamped envelope and mail to:

PSE WARRANTY REGISTRATION

P.O. Box 5487 Tucson, AZ 85703

SERIAL # OF BOW

BOW MODEL

#

DEALER NAME OR WHERE PURCHASED

YOUR NAME

YOUR ADDRESS

CITY

COUNTRY EMAIL ADDRESS

DATE PURCHASED

STATE

/ / PHONE ( )

APT #

POSTAL/ZIP CODE

Page 44

Thank you for choosing pse!

PRECISION SHOOTING EQUIPMENT INC.

2727 N. FAIRVIEW AVE. TUCSON, AZ 85705 •

PN: 80699

PSE-ARCHERy.COM

Loading...

Loading...