Page 1

Magellan SL™

Programming Kit

®

Magellan

Page 2

PSC Scanning, Inc.

959 Terry Street

Eugene, Oregon 97402-9120

Telephone: (541) 683-5700

Toll Free: (800) 547-2507

Telefax: (541) 686-1702

PSC and the PSC logo are registered trademarks of PSC INC.

Magellan is a registered trademark owned by PSC INC. Magellan

SL is a trademark owned by PSC INC.

This manual and its contents are copyrighted, with all rights

reserved. Under copyright law, this manual may not be copied

in whole or in part without the prior written consent of PSC.

The same proprietary and copyright notices must appear on

any permitted copies as appear on the original. This exception

does not permit copies to be made for others, whether or not

sold. Under the law, copying includes translating into another

language or format.

The information and specifications contained in this manual

are subject to change without notice. PSC shall not be held

liable for damages resulting from the use or misuse of the

information contained herein.

Page 3

Table of Contents

ABOUT PROGRAMMING ......................................................... 1

SCANNER PROGRAMMING

(HOW IT WORKS)........................................................ 5

PROGRAMMING YOUR SCANNER ...................................... 7

PROGRAMMING CONVENTIONS ......................................... 9

SPECIAL LABELS ............................................................... 11

INCREMENT VOLUME ................................................... 12

SWITCH LABEL .......................................................... 13

RETURN TO FACTORY DEFAULT ...................................... 14

PROGRAMMABLE SPEAKER FEATURES ..................................... 15

SPEAKER VOLUME PROGRAMMING .................................. 20

UPC/EAN PRICE/WEIGHT

CHECK DIGIT SELECTIONS ................................................... 24

TIMEOUTS ....................................................................... 30

SETTING LASER TIMEOUT ............................................. 31

SETTING MOTOR TIMEOUT ........................................... 35

SETTING DOUBLE READ TIMEOUT ................................... 40

PERIPHERAL PORT ............................................................. 44

HANDHELD LED ........................................................ 52

Page 4

CHANGING BARCODE TYPES ................................................. 54

UPC/EAN EXPANSION ............................................... 57

UPC CHECK DIGIT TRANSMISSION ................................. 63

CODE 39 ................................................................. 72

CODE 128 ............................................................... 82

INTERLEAVED 2 OF 5................................................... 88

INTERFACE SELECTIONS ..................................................... 130

RS-232 INTERFACE SPECIFICATIONS ............................ 130

SINGLE CABLE RS-232............................................ 132

OCIA INTERFACE SELECTION ...................................... 154

MULTIDROP SCANNER ADDRESSING .............................. 162

SCALE FEATURES ............................................................ 167

BARCODE INDEX .............................................................. 185

SWITCH LABEL .................................... INSIDE BACK COVER

Page 5

®

MAGELLAN

PROGRAMMING

/BARCODES

W

This programming guide contains the procedures

and barcode programming labels necessary to set

Magellan's programmable features.

ABOUT PROGRAMMING

The following list shows an overview of this

manual’s organization.

• About Programming

• Special Labels (Switch label and

Increment Volume)

• Return to Factory Default

• Operational Settings (Speaker, Laser &

Motor Timeouts)

• RS-232 Parameters (Baud Rate, etc.)

• Symbology Selection

• Interleaved 2 of 5 Label Length

1

Page 6

We have divided the contents into groups of

features that are usually changed together. For

example, all of the RS-232 parameters (baud rate,

parity, stop bits, etc.) are grouped together. Check

the Index for the location of specific programming

labels.

This introduction describes the programming and

configuration procedures for the Magellan scanner

and scanner/scale.

Scanner Programming: describes how

to put the scanner in Programming

Mode and how to use the programming barcodes to set the scanner’s

parameters.

Special Labels: includes a set of labels

which perform unique functions and

cannot be duplicated by standard label

definition and printing equipment.

Each special label affects the scanner

when in normal operating mode.

These include:

• Switch Label - puts the scanner in

Programming Mode and exits from

Programming Mode.

2

Page 7

• Increment Volume Label - changes the

speaker volume setting in volatile

(temporary) memory. If power to the

scanner is interrupted, the volume will

revert to the default setting.

Return to Factory Settings: resets all

scanner programmable options to the

original factory settings. Any special

features or options programmed prior

to scanning this label in Programming

Mode must be reselected.

User Features: allow selection of On/Off

Switch, Laser Timeout, Motor Timeout,

Peripheral Port, Speaker Volume,

Double Read Timeout interval, and

Price/Weight Check Digit read and

transmission.

When the speaker's volume is programmed with these labels, the setting

is stored in default memory. If power

to the scanner is interrupted, the

volume setting is retained.

3

Page 8

RS-232 Communication Format: settings

are used only with scanners which

have an RS-232 interface. Options

include Data Bits, Baud Rate, Parity,

Handshake, Stop Bit, Prefixes and Host

Echo.

OCIA Communication Format: is used

only with scanners that have an OCIA

communication interface. The labels in

this manual allow you to change OCIA

interface types and enable or disable

an Intercharacter Delay.

Symbology Selection: allow selection of

the types of barcode (symbologies) the

scanner can read. These features also

include UPC/EAN Expansion, control

the calculation and transmission of

check digits for Code 39. If Interleaved 2 of 5 symbologies is selected,

label lengths settings are required.

4

Page 9

SCANNER PROGRAMMING

(HOW IT WORKS)

Magellan features advanced programming capabilities which lets you change the scanner’s configuration and functional behavior by using the EAN-13

programming labels contained in this manual.

The scanner’s operating parameters are held in

three different portions of memory.

• RAM (Random Access Memory) holds

the current operational settings while

the scanner is powered-up. These

settings are lost when power to the

scanner is removed. For example, the

Increment Volume label changes the

volume setting held in RAM, but is lost

when power to the scanner is interrupted. RAM is temporary or ‘volatile’

memory.

• Default Memory is stored in the

EEPROM (non-volitile memory) and

holds the operational settings that are

loaded to RAM each time the scanner is

powered-up. This portion of memory is

5

Page 10

preserved even if the scanner is powered

down. All settings made through the

Programming Mode are stored in default

memory.

• Permanent Memory is also stored in

the EEPROM and holds the factory

programmed settings for all of the

scanner’s operational parameters. The

contents of permanent memory are

loaded into default memory when the

Return to Factory Settings label is

scanned. The contents of permanent

memory can only be modified at the

factory.

By entering the ‘Programming Mode’

the desired characteristics can be set in

default memory by scanning programming barcode labels. These settings

are saved even if the scanner is

powered down.

6

Page 11

PROGRAMMING YOUR SCANNER

To program your scanner:

1. Power-up the scanner to be programmed by plugging the power cord

into the scanner and an electrical outlet

of the appropriate voltage. Wait for

the scanner to complete the selftest

routine and emit a tone. The green

lamp will light steadily, indicating that

the scanner is in normal Operating

Mode.

2. Put the scanner into Programming

Mode by scanning the Switch Label

(located on page 13 and on the inside

of the back cover).

The green LED flashes continuously

indicating that the scanner is in

Programming Mode.

7

Page 12

3. Scan a programming label(s) for the

feature you want to change. The

scanner will emit a 'good read' tone to

indicate that the label has been read

and the setting has been stored in the

scanner’s memory. Scan the remaining

programming labels as required.

If a label scanned is not a valid

programming label, the scanner will

emit a low rejection tone.

4. After all the desired programming

labels have been successfully scanned,

exit Programming Mode by pressing

the Operator switch or scanning the

Switch Label. The green lamp will

light dimly, indicating that the scanner

is ready for normal operation.

8

Page 13

PROGRAMMING CONVENTIONS

• All options set while in Programming

Mode are stored in default memory,

and will be retained even if the

scanner is powered-down.

• Settings are stored on a first-in, first-out

basis. The last programming label

scanned for a given option is the

setting stored in memory. For example, if a programming label which

sets the baud rate at 9600 is scanned,

followed by a label which sets the

baud rate at 19,200, the scanner will be

programmed with a baud rate of

19,200.

• Only labels included in this manual

will be accepted as valid programming

labels. Labels which attempt to set

features not implemented in a

scanner’s software revision will be

rejected as invalid. Programming

labels which are not printed in accordance with industry standards may also

be rejected.

9

Page 14

• If an invalid label is scanned when in

Programming Mode, the scanner will

emit a low tone to indicate that the

label is either not a programming label

or that it contains values outside of the

acceptable programming range.

• After five minutes of inactivity in

Programming Mode, the scanner will

revert to normal Operating Mode. Any

options set during the programming

session will be stored and activated.

• If confusion arises as to which options

have been set during a programming

session, scanning the Return to Factory

Settings label will reset the scanner to

the original factory defaults for all

options, regardless of interface type.

We recommend that you use the table

provided in the back of this manual to

record all changes that you make. This

will help to ensure that you can record

all modifications that you have made

to the factory default configuration.

This will be very helpful if you must

return Magellan to the factory default

settings.

10

Page 15

PROGRAMMABLE FEATURES

The remainder of this manual includes programming labels for all Magellan's scanner and scanner/

scale programmable features. Refer to the detailed

features listing shown in the index at the back of

this manual to find the individual features that you

wish to change.

SPECIAL LABELS

There are two programming labels in this manual

that work differently from all the other labels

included in this Programming Guide; the Increment

Volume label and the Switch label.

Increment Volume works without

entering Programming Mode, but its

volume selection is lost when power is

removed from the scanner.

The Switch label is the key that allows

you to enter and exit Programming

Mode.

11

Page 16

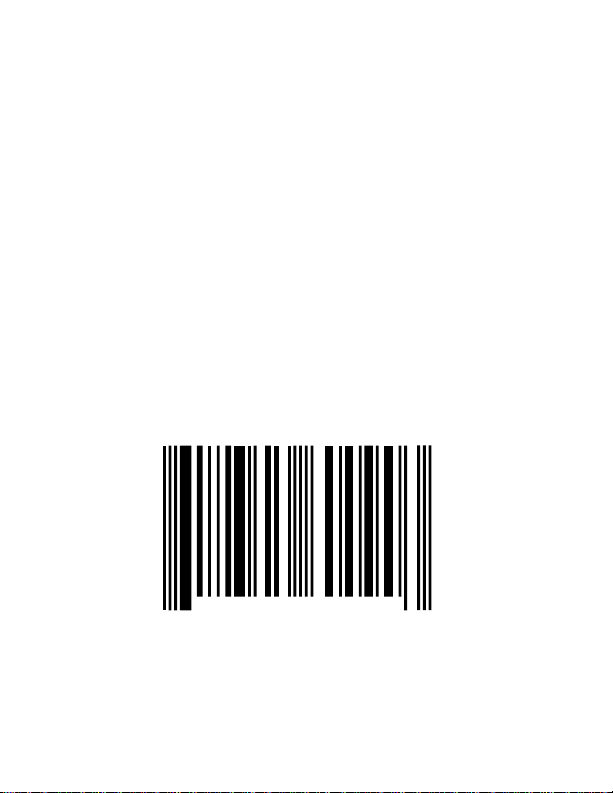

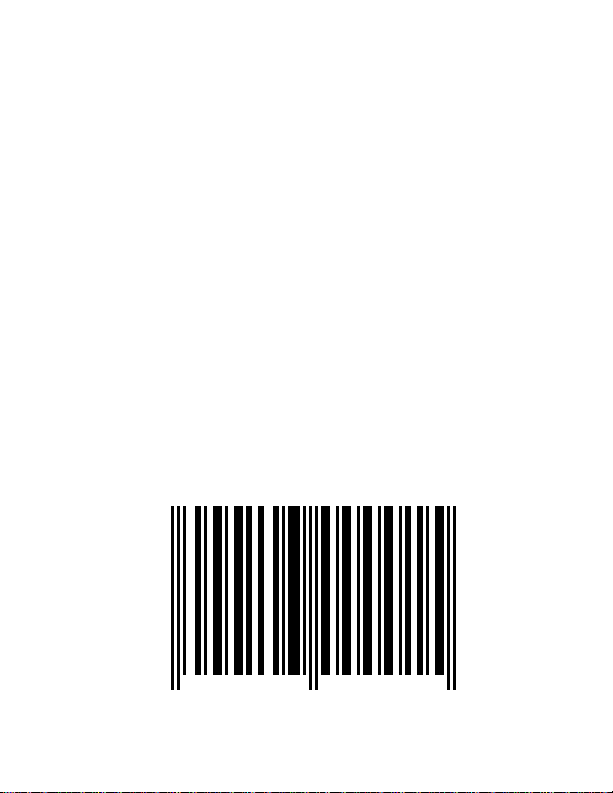

INCREMENT VOLUME

The Increment Volume label affects the scanner

when in normal Operating Mode. Each pass of the

label increments the speaker volume to the next

loudest available level. When the highest of the

three available levels is reached, the sequence starts

again at the quietest level. If speaker volume is set

using this label, the scanner reverts to the default

volume setting when power to the scanner is

interrupted. To permanently store changes to the

speaker’s default volume use the labels titled,

Speaker Volume, later in this manual.

Increment Volume

12

Page 17

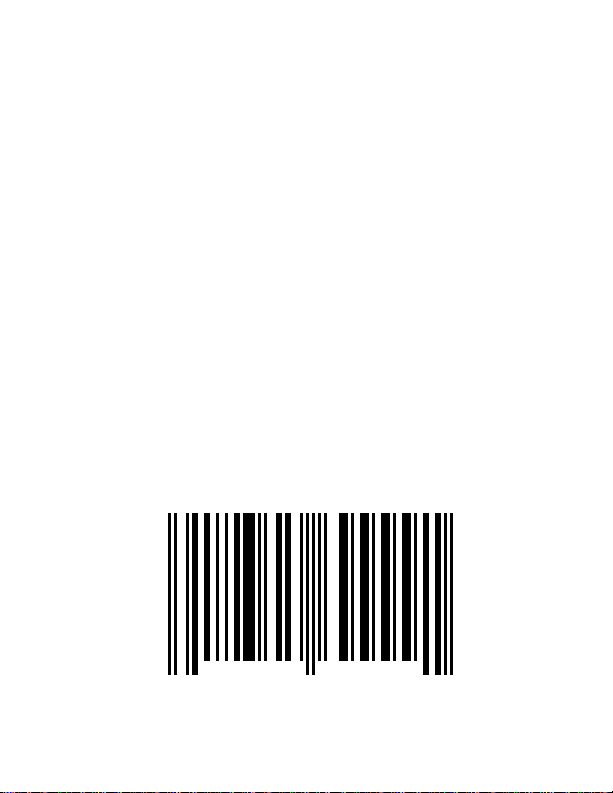

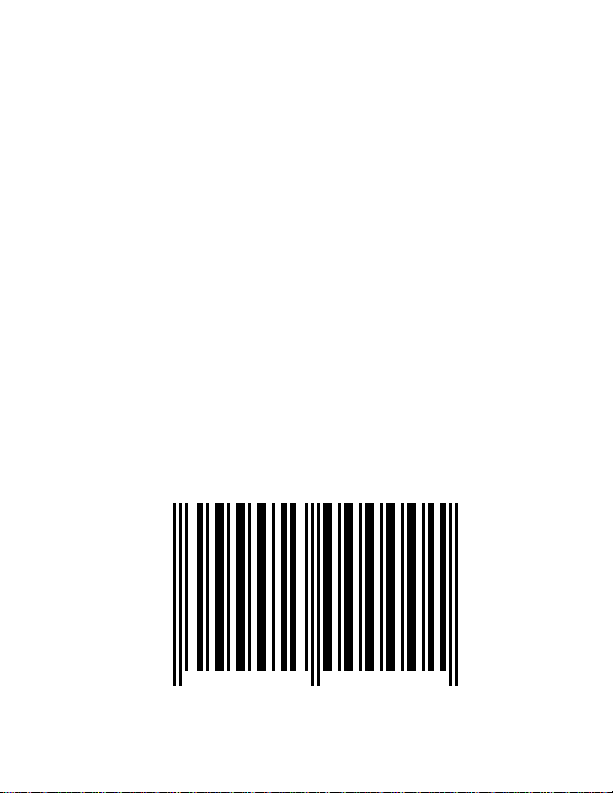

SWITCH LABEL

Like the Increment Volume label, the Switch label

affects the scanner when in normal Operating

Mode. Scanning the Switch label in normal Operating Mode causes the scanner to enter Programming

Mode. Scanning the Switch label while in Programming Mode instructs the scanner to save all

changes made while in Programming Mode, exit

Programming Mode, reset the scanner to implement

the changes you made, and return to normal

Operating Mode. All programming sessions must

begin with the Switch label in order for the scanner

to recognize them as programming labels and end

with the Switch label for the scanner to store the

changes you have made.

It is a good practice to cover the label on the

opposite page to prevent Magellan from reading

both labels when changing a feature.

Switch Label

13

Page 18

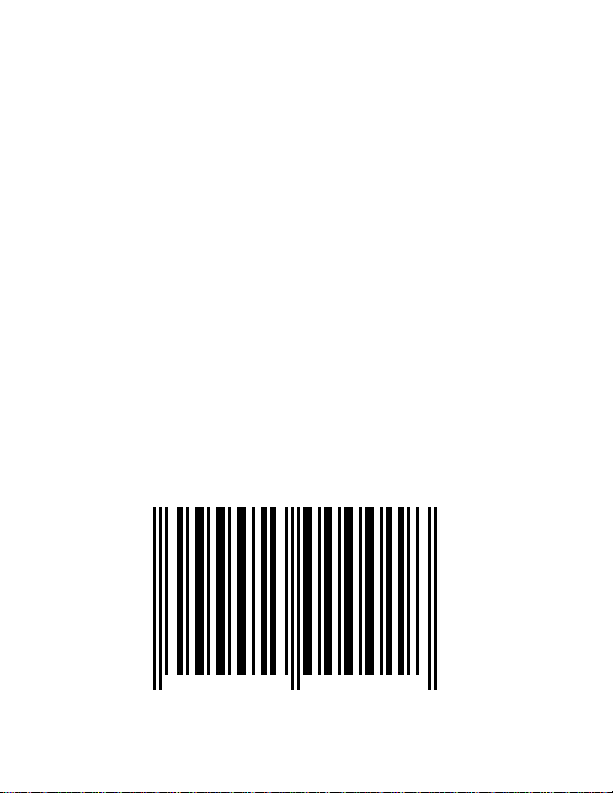

RETURN TO FACTORY DEFAULT

Use this label to return the scanner

or scanner/scale to the factory

default settings.

6 500000 000009

14

Page 19

PROGRAMMABLE SPEAKER FEATURES

The speaker has three programmable features:

• Good Read indicator can be turned on

or off.

• Good Read volume can be set to one

of three levels. The volume can either

be changed temporarily using the

switch on the top of the scanner,

Increment Volume label, or its default

can be reprogrammed using the

programming labels on the following

pages.

15

Page 20

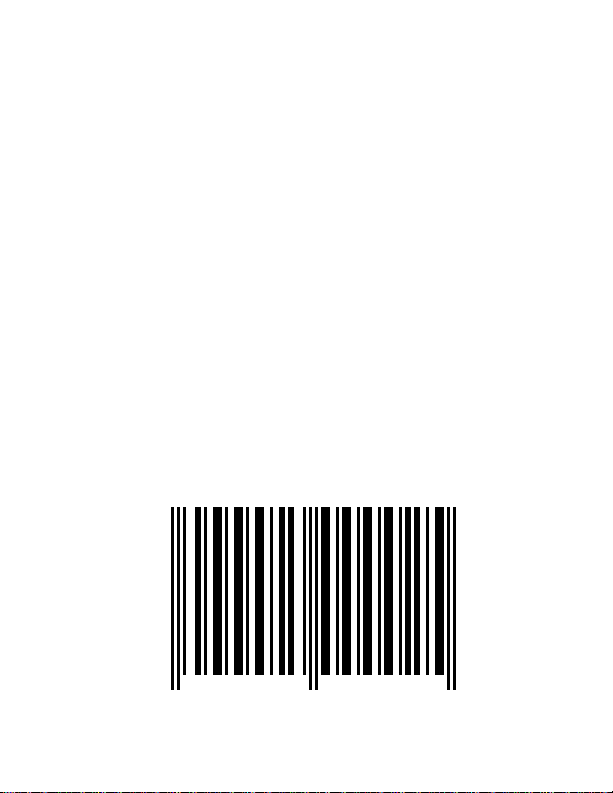

VOLUME SWITCH: DISABLE

Use this label to disable Magellan's

volume selection switch.

6 401024 000016

16

Page 21

VOLUME SWITCH: ENABLE

Use this label to enable Magellan's

volume selection switch.

6 401024 000009

17

Page 22

SPEAKER: ON

Use this label to enable the

speaker.

6 400103 000008

18

Page 23

SPEAKER: OFF

Use this label to disable the

speaker.

6 400103 000015

19

Page 24

SPEAKER VOLUME PROGRAMMING

The Magellan scanner and scanner/scale allows you

to change the speaker's volume without entering

Programming Mode or using programming labels.

To change the speaker's volume press and release

the speaker switch.

NOTE

Keeping the switch depressed for longer

than three seconds will initiate a scanner reset.

The scanner sounds the next volume setting three

times. There are three volume options available.

Continue pressing and releasing the switch until the

volume level you want is sounded.

If you wish to change the speaker's active default

setting, use the labels on the following pages to

change the speaker volume setting.

NOTE

If this feature appears not to work, the

switch may be disabled. Follow the

normal programming sequence and use

the label on page 17 to enable the

switch and try again.

20

Page 25

SPEAKER VOLUME = LOW

Use this label to set the speaker

volume to low.

6 400025 000001

21

Page 26

SPEAKER VOLUME = MEDIUM

Use this label to set the speaker

volume to medium.

6 400025 000018

22

Page 27

SPEAKER VOLUME = HIGH

Use this label to set the speaker

volume to high.

6 400025 000025

23

Page 28

UPC/EAN PRICE/WEIGHT CHECK DIGIT SELECTIONS

The Price/Weight Check Digit selections allow you

to specify whether the scanner should calculate an

extra check digit based on a four or five-digit price/

weight block, and compare it with the price/weight

check digit contained in the barcode.

If the calculated check digit does not match the

value of the check digit contained in the barcode,

the label will be rejected as invalid.

24

Page 29

PRICE/WEIGHT CHECK DIGIT = 4 DIGIT

Use this label to enable the

calculation and comparison of four

digit Price/Weight Check Digit

for UPC/EAN.

6 400092 000010

25

Page 30

PRICE/WEIGHT CHECK DIGIT = 5 DIGITS

Use this label to enable the

calculation and comparison of five

digit Price/Weight Check Digit

for UPC/EAN.

6 400092 000027

26

Page 31

PRICE/WEIGHT CHECK DIGIT = 4 DIGITS (EUROPE)

Use this label to enable the

calculation and comparison of four

digit Price/Weight Check Digit

for UPC/EAN.

6 400092 000034

27

Page 32

PRICE/WEIGHT CHECK DIGIT = 5 DIGITS (EUROPE)

Use this label to enable the

calculation and comparison of five

digit Price/Weight Check Digit

for UPC/EAN.

6 400092 000041

28

Page 33

PRICE/WEIGHT CHECK DIGIT: DISABLE

Use this label to disable Price/

Weight Check Digit calculation and

comparison.

6 400092 000003

29

Page 34

TIMEOUTS

Timeouts allow you to shut off the scanner's laser

and/or motor if the scanner isn't used for a

predetermined period of time. This feature is

included to prolong the life of the motor and

Visible Laser Diode (VLD).

NOTE

Laser safety requires that the laser

switch off before the motor. If you set

the motor timeout shorter than the laser timeout, the motor will remain on

until the laser shuts off.

If you want to maximize both productivity and

scanner life, set laser to timeout in five minutes, but

leave the motor on for fifteen minutes. The

scanner will be ready to scan, and you will prolong

the life of the VLD.

30

Page 35

SETTING LASER TIMEOUT

The laser timeout programming labels set the time

for switching the visible laser diode (VLD) off if the

scanner isn't used. Using this feature can prolong

the life of the VLD.

The selections are:

• Set timeout = 5 minutes

• Set timeout = 10 minutes

• Set timeout = 15 minutes

31

Page 36

LASER TIMEOUT = 5 MINUTES

Use this label to set the laser

timeout to 5 minutes.

6 400079 000200

32

Page 37

LASER TIMEOUT = 10 MINUTES

Use this label to set the laser

timeout to 10 minutes.

6 400079 000408

33

Page 38

LASER TIMEOUT = 15 MINUTES

Use this label to set the laser

timeout to 15 minutes.

6 400079 000606

34

Page 39

SETTING MOTOR TIMEOUT

The Motor Timeout programming labels set the

time for switching the motor off if the scanner isn't

used. At no time will the motor timeout before the

laser.

The selections are:

• Motor timeout = 5 minutes

• Motor timeout = 15 minutes

• Motor timeout = 30 minutes

• Motor timeout = 60 minutes

35

Page 40

MOTOR TIMEOUT = 5 MINUTES

Use this label to set the motor

timeout to 5 minutes.

6 400078 000201

36

Page 41

MOTOR TIMEOUT = 15 MINUTES

Use this label to set the motor

timeout to 15 minutes.

6 400078 000607

37

Page 42

MOTOR TIMEOUT = 30 MINUTES

Use this label to set the motor

timeout to 30 minutes.

6 400078 001208

38

Page 43

MOTOR TIMEOUT = 60 MINUTES

Use this label to set the motor

timeout to 60 minutes.

6 400078 002403

39

Page 44

SETTING DOUBLE READ TIMEOUT

The double read timeout sets a time limit that determines how much time must pass before reading the

same label again (e.g. two identical items in succession).

The selections are:

• Set timeout = 400 milliseconds

• Set timeout = 600 milliseconds

• Set timeout = 800 milliseconds

• Set timeout = 1 second

DOUBLE READ TIMEOUT = 400MS

Sets the time you must wait between reading the same

label again to 400ms. This is the recommended setting.

NOTE

If the incidence of multiple reads is not

acceptable, increase the Double Read

Timeout setting to the next higher level.

6 400077 000400

40

Page 45

DOUBLE READ TIMEOUT = 600MS

Sets the time you must wait

between reading the same label

again to 600ms.

6 400077 000608

41

Page 46

DOUBLE READ TIMEOUT = 800MS

Sets the time you must wait

between reading the same label

again to 800ms.

6 400077 000806

42

Page 47

DOUBLE READ TIMEOUT = 1 SECOND

Sets the time you must wait

between reading the same label

again to one second.

6 400077 001001

43

Page 48

PERIPHERAL PORT

Magellan's peripheral port can be configured to

accept input from an undecoded handheld scanner.

The labels on the following pages allow you to

enable/disable the port, change the communication

speed and enable/disable the handheld scanner's

LED.

HANDHELD PORT: ENABLE

Use this label to enable the

peripheral port to accept input

from a handheld (HHLC) scanner.

6 401035 000005

44

Page 49

HANDHELD PORT: DISABLE

Use this label to disable the

peripheral port to accept input

from a handheld (HHLC) scanner.

6 401035 000012

45

Page 50

HANDHELD PERIPHERIAL PORT SPEED

Since the communication speed of handheld

scanners vary greatly, it is necessary to select a

speed that tells Magellan how long to wait to

receive a complete barcode data. This selection

process is rather unscientific (trial and error) since

industry standards do not exist. We have included

references for known and tested models of other

manufacturers handheld scanners, but these should

be considerer as guidelines since newer and older

models from the same manufacturer may be

different.

The selectable options are named speeds five

through nine with five being used for scanners that

communicate at a slow rate and nine for scanners

that communicate at a faster rate.

46

Page 51

HANDHELD PERIPHERAL PORT: SPEED = 5

This label sets the communication

speed to five. Use Peripherial Port

Speed settings to tell Magellan

how long to wait to receive a

complete barcode data. This

setting works best when connecting a Symbol Technology

undecoded scanner to the

peripherial port.

6 401067 000059

47

Page 52

HANDHELD PERIPHERAL PORT: SPEED = 6

This label sets the communication

speed to six. Use Peripherial Port

Speed settings to tell Magellan

how long to wait to receive a

complete barcode data.

6 401067 000066

48

Page 53

HANDHELD PERIPHERAL PORT: SPEED = 7

This label sets the communication

speed to seven. Use Peripherial

Port Speed settings to tell Magellan

how long to wait to receive a

complete barcode data.

This is the default setting. Use this

setting when connecting a SP400,

Caere or PSC undecoded scanner.

6 401067 000073

49

Page 54

HANDHELD PERIPHERAL PORT: SPEED = 8

This label sets the communication

speed to eight. Use Peripherial

Port Speed settings to tell Magellan

how long to wait to receive a

complete barcode data.

6 401067 000080

50

Page 55

HANDHELD PERIPHERAL PORT: SPEED = 9

This label sets the communication

speed to nine. Use Peripherial Port

Speed settings to tell Magellan

how long to wait to receive a

complete barcode data.

6 401067 000097

51

Page 56

HANDHELD LED

When the scanner and POS system both indicate

that a label has been read, it is helpful to disable

the handheld devises good read indicator. The

labels on the next two pages allow you to enable

and disable the handheld's LED.

HANDHELD LED: ON

Scan this label and the handheld

device LED will light when a label

is successfully scanned.

6 401136 000003

52

Page 57

HANDHELD LED: OFF

Scan this label to disable the

handheld scanner's LED. This

prevents the LED from lighting

when a barcode label is scanned

successfully.

Use this feature when the POS

system sounds a tone to indicate

that the label has been read.

6 401136 000010

53

Page 58

CHANGING BARCODE TYPES

One of Magellan's features is the ability to autodiscriminate between the UPC/EAN symbology

family and three industrial codes; Code 39, Interleaved 2 of 5 and Code 128. The following

barcodes allow you to change the types of barcode

symbologies that your scanner recognizes. Be sure

that your POS terminal interface can recognize the

barcodes you wish to enable before you change

these settings.

To change symbologies:

1. Select the symbology you wish to

enable. (e.g. Code 39)

2. Scan the appropriate programming

barcode label that enables the selected

symbology.

3. Enable all additional parameters that

are required by your POS terminal (e.g.

check digits, start/stop characters, etc).

All of the symbology selection features on the

following pages can be used to customize the

Magellan scanner or scanner/scale.

54

Page 59

UPC-D: ENABLE

Scanning this barcode label adds

UPC-D to other UPC/EAN symbologies that are enabled.

6 400066 000015

55

Page 60

UPC-D: DISABLE

Scanning this barcode label disable

UPC-D only while leaving other

UPC/EAN symbologies uneffected.

6 400066 000008

56

Page 61

UPC/EAN EXPANSION

The labels on the following pages

allow you to change the UPC/EAN

label transmission format.

UPC-E TO UPC-A EXPANSION – ENABLE

Use this label to enable the expansion of UPC-E labels to UPC-A

format before transmission to the

host terminal. Enabling this

feature will automatically disable

the 'Expand UPC-E to EAN-13'

feature. The scanner will now

translate UPC-E label data into

UPC-A format before sending it to

the host.

6 400065 000016

57

Page 62

UPC-E TO UPC-A EXPANSION – DISABLE

Use this label to disable the expansion of UPC-E labels to UPC-A

format before transmission to the

host terminal. The scanner now

sends UPC-E label data to the host.

6 400065 000009

58

Page 63

UPC-E TO EAN-13 EXPANSION – ENABLE

Use this label to enable the expansion of UPC-E labels to EAN-13

format before transmission to the

host terminal. Enabling this

feature will automatically disable

the 'Expand UPC-E to UPC-A'

feature.

The scanner will now translate

UPC-E label data into EAN-13

format before sending it to the

host.

6 401026 000014

59

Page 64

UPC-E TO EAN-13 EXPANSION – DISABLE

Use this label to disable the expansion of UPC-E labels to EAN-13

format before transmission to the

host terminal. The scanner will

now send UPC-E label data to the

host.

6 401026 000007

60

Page 65

UPC-A TO EAN-13 EXPANSION – ENABLE

Use this label to enable the expansion of UPC-A labels to EAN-13

format before transmission to the

host terminal.

The scanner will now translate

UPC-A label data into EAN-13

format before sending it to the

host.

6 400067 000014

61

Page 66

UPC-A TO EAN-13 EXPANSION – DISABLE

Use this label to disable the expansion of UPC-A labels to EAN-13

format before transmission to the

host terminal. The scanner will

now send UPC-A label data to the

host.

6 400067 000007

62

Page 67

UPC CHECK DIGIT TRANSMISSION

The following pages contain the programming

labels for enabling and disabling the transmission

of UPC and EAN check digits.

They are:

• UPC-A Check Digit Transmission

• UPC-E Check Digit Transmission

• EAN-8 Check Digit Transmission

• EAN-13 Check Digit Transmission

63

Page 68

UPC-A CHECK DIGIT TRANSMISSION: ENABLE

Use this label to enable sending

the UPC-A check digit to the host.

6 400183 000011

64

Page 69

UPC-A CHECK DIGIT TRANSMISSION: DISABLE

Use this label to disable sending

the UPC-A check digit to the host.

6 400183 000004

65

Page 70

UPC-E CHECK DIGIT TRANSMISSION: ENABLE

Use this label to enable sending

the UPC-E check digit to the host.

6 400064 000017

66

Page 71

UPC-E CHECK DIGIT TRANSMISSION: DISABLE

Use this label to disable sending

the UPC-E check digit to the host.

6 400064 000000

67

Page 72

EAN-8 CHECK DIGIT TRANSMISSION: ENABLE

Use this label to enable sending

the EAN-8 check digit to the host.

6 400184 000010

68

Page 73

EAN-8 CHECK DIGIT TRANSMISSION: DISABLE

Use this label to disable sending

the EAN-8 check digit to the host.

6 400184 000003

69

Page 74

EAN-13 CHECK DIGIT TRANSMISSION: ENABLE

Use this label to enable sending

the EAN-13 check digit to the host.

6 400185 000019

70

Page 75

EAN-13 CHECK DIGIT TRANSMISSION: DISABLE

Use this label to disable sending

the EAN-13 check digit to the host.

6 400185 000002

71

Page 76

CODE 39

The labels on the following pages allow you to

enable or disable Code 39, select barcode content

verification, choose whether or not to send the

check digit to the host and set the minimum

number of good reads required before the label

data is sent to the host.

CODE 39: ENABLE

Use this barcode to select Code 39

as an active symbology.

6 400142 000014

72

Page 77

CODE 39: DISABLE

Use this barcode to disable

Code 39 as an active symbology.

6 400142 000007

73

Page 78

CODE 39: CHECK DIGIT – VERIFY

Use this barcode to enable Verify

Code 39 check digit. Scanning this

label tells the scanner to calculate

the check digit and verify that it

matches the barcodes internal

check digit. The check digit will

not be sent to the host unless you

also enable Code 39: Check Digit -

Send.

Check your system interface

communications requirements

before changing this setting.

6 400085 000010

74

Page 79

CODE 39: CHECK DIGIT – DON'T VERIFY

Using this barcode disables

verification of the Code 39 check

digit. If you disable this feature,

you should also scan the label that

disables sending the Code 39

Check Digit.

Check your system interface

communications requirements

before changing this setting.

6 400085 000003

75

Page 80

CODE 39: CHECK DIGIT – SEND

Use this barcode to instruct the

scanner to send the Code 39 check

digit (if present). This feature

should not be set unless Code 39:

Check Digit - Verify is also enabled.

Check your system interface

communications requirements

before changing this setting.

6 400138 000011

76

Page 81

CODE 39: CHECK DIGIT – DON'T SEND

Use this barcode to disable Send

Code 39 check digit.

Check your system interface

communications requirements

before changing this setting.

6 400138 000004

77

Page 82

CODE 39: MINIMUM READ = 1

Minimum read settings are useful

when poorly printed barcodes

causes the scanner to misread

labels and send incorrect data to

the host.

Scanning this label sets the number

of times the barcode must be read

to one. Use this setting when you

do not experience misreads.

6 400107 000011

78

Page 83

CODE 39: MINIMUM READ = 2

Minimum read settings are useful

when poorly printed barcodes

causes the scanner to misread

labels and send incorrect data to

the host.

Scanning this label sets the number

of times the barcode must be read

to two. Use this setting when you

occasionally experience misreads.

6 400107 000028

79

Page 84

CODE 39: MINIMUM READ = 3

Minimum read settings are useful

when poorly printed barcodes

causes the scanner to misread

labels and send incorrect data to

the host.

Scanning this label sets the number

of times the barcode must be read

to three. Use this setting when

you regularly experience misreads.

If you must use this setting, you

should examine your barcode

production methods.

6 400107 000035

80

Page 85

CODE 39: MINIMUM READ = 4

Minimum read settings are useful

when poorly printed barcodes

causes the scanner to misread

labels and send incorrect data to

the host.

Scanning this label sets the number

of times the barcode must be read

to four. Use this setting when

misreads are a common problem.

If you must use this setting, you

should examine your barcode

production methods.

6 400107 000042

81

Page 86

CODE 128

The labels on the following pages allow you to

enable or disable Code 128 and set the minimum

number of good reads required before the label

data is sent to the host.

CODE 128: ENABLE

Use this barcode to select Code

128 as an active symbology.

6 400146 000010

82

Page 87

CODE 128: DISABLE

Use this barcode to select Code

128 as an active symbology.

6 400146 000003

83

Page 88

CODE 128: MINIMUM READ = 1

Minimum read settings are useful

when poorly printed barcodes

causes the scanner to misread

labels and send incorrect data to

the host.

Scanning this label sets the number

of times the barcode must be read

to one. Use this setting when you

do not experience misreads.

6 400111 000014

84

Page 89

CODE 128: MINIMUM READ = 2

Minimum read settings are useful

when poorly printed barcodes

causes the scanner to misread

labels and send incorrect data to

the host.

Scanning this label sets the number

of times the barcode must be read

to two. Use this setting when you

occasionally experience misreads.

6 400111 000021

85

Page 90

CODE 128: MINIMUM READ = 3

Minimum read settings are useful

when poorly printed barcodes

causes the scanner to misread

labels and send incorrect data to

the host.

Scanning this label sets the number

of times the barcode must be read

to three. Use this setting when

you regularly experience misreads.

If you must use this setting, you

should examine your barcode

production methods.

6 400111 000038

86

Page 91

CODE 128: MINIMUM READ = 4

Minimum read settings are useful

when poorly printed barcodes

causes the scanner to misread

labels and send incorrect data to

the host.

Scanning this label sets the number

of times the barcode must be read

to two. Use this setting when you

regularly experience misreads.

If you must use this setting, you

should examine your barcode

production methods.

6 400111 000045

87

Page 92

INTERLEAVED 2 OF 5

If you select Interleaved 2 of 5 (I 2of 5) as an active

symbology, you must select fixed label length(s)

using the programming labels on the following

pages.

You have the option of selecting either one or two

lengths. If you only wish to enable one fixed label

length, select that length using the first set of label

length programming labels and then use the label

on page 114 to set the second label length to none.

This instructs the scanner to only recognize the first

label length.

88

Page 93

I 2 OF 5: ENABLE

Use this barcode to select

Interleaved 2 of 5 as an active

symbology.

6 400144 000012

89

Page 94

I 2 OF 5: DISABLE

Use this barcode to disable Interleaved 2 of 5 as an active

symbology.

6 400144 000005

90

Page 95

I 2 OF 5: CHECK DIGIT – VERIFY

Use this barcode to enable Verify

Interleaved 2 of 5 check digit.

Scanning this label tells the

scanner to calculate the check digit

and verify that it matches the

barcodes internal check digit. The

check digit will not be sent to the

host unless you also enable

Interleaved 2 of 5: Check Digit Send.

Check your system interface

communications requirements

before changing this setting.

6 400112 000013

91

Page 96

I 2 OF 5: CHECK DIGIT – DON'T VERIFY

Using this barcode disables

verification of the Interleaved 2 of

5 check digit. If you disable this

feature, you should also scan the

label that disables sending the

Interleaved 2 of 5 Check Digit.

Check your system interface

communications requirements

before changing this setting.

6 400112 000006

92

Page 97

I 2 OF 5: CHECK DIGIT – SEND

Use this barcode to instruct the

scanner to send the Interleaved 2

of 5 check digit (if present). This

feature should not be set unless

Interleaved 2 of 5: Check Digit Verify is also enabled.

Check your system interface

communications requirements

before changing this setting.

6 400139 000010

93

Page 98

I 2 OF 5: CHECK DIGIT – DON'T SEND

Use this barcode to disable sending the Interleaved 2 of 5 check

digit to the host. This feature is

only required for some host

interfaces. Check your system

interface communications requirements before changing this setting.

6 400139 000003

94

Page 99

I 2 OF 5: MINIMUM READ = 1

Minimum read settings are useful

when poorly printed barcodes

causes the scanner to misread

labels and send incorrect data to

the host.

Scanning this label sets the number

of times the barcode must be read

to one. Use this setting when you

do not experience misreads.

6 400109 000019

95

Page 100

I 2 OF 5: MINIMUM READ = 2

Minimum read settings are useful

when poorly printed barcodes

causes the scanner to misread

labels and send incorrect data to

the host.

Scanning this label sets the number

of times the barcode must be read

to two. Use this setting when you

occasionally experience misreads.

6 400109 000026

96

Loading...

Loading...