Page 1

R44-2016 (Rev. E)

LM520 Scanner

Integration & Programming Manual

Page 2

R44-2016 i-1

Contents

The LM520 Bar Code Scanner

Overview .........................................................................................................................................................1

Unpacking the LM520................................................................................................................................ .... . 2

Scanner Care .................................................................................................................................................2

Mounting the LM520

General Considerations ..................................................................................................................................3

Mounting .........................................................................................................................................................3

Mounting the Scanner Stand-Alone............ ..... ..................................... ..... ..... ................................. ..... .... ..... . 4

Integrating the Scanner to Read at the Proper Distance ................................................................................4

Integrating the Scanner Behind a Window .....................................................................................................5

Electrical Interface ..........................................................................................................................................8

Interface Cable Schematic................................................................................................................. ..... . 9

LM520 Scanner Configuration

Configuration Management ..........................................................................................................................10

Programming Methods......................................................................... ..... ..... .............................................. 12

Programming through the Serial Interface .............................................................................................12

Programming with Bar Codes................................................................................................................ 13

Conventions ..................................................................................................................................................13

Setting Serial Communication Parameters................................................................................................... 14

Baud Rate ..............................................................................................................................................14

Data Format........................................................................................................................................... 15

Flow Control........................................................................................................................................... 16

Controlling Scanning Through Host Commands.......................................................................................... 17

Triggering Scanning Using Software Switch ..........................................................................................17

Triggering Scanning Using Hardware Switch ........................................................................................ 18

Continuous Scanning Mode ...................................................................................................................18

LaserSense Scanning Mode.................................................................................................................. 19

Canceling Software Triggered Scanning ...............................................................................................19

Setting Symbology Parameters.................................................................................................................... 20

Enabling All Symbologies ......................................................................................................................20

EAN ........................................................................................................................................................21

UPC .......................................................................................................................................................21

Code 128................................... ..... ..... ..... ..................................... ..... ..... ..... ......................................... 22

Code ISBT 128.................................... ..... .... ..... ...................................... ..... .... ..... ................................ 23

Code 93..................................... ..... ..... ..... ..................................... ..... ..... ..... ......................................... 25

Codabar .................................................................................................................................................25

Code 39 ......................................... ..... ..... ..................................... ..... ..... ..... ..........................................26

Interleaved 2 of 5................................................................................................................................... 27

Standard 2 of 5...................................................................................................................................... 28

Formatting Bar Code Data............................................................................................................................ 29

Preamble ................................................................................................................................................29

Postamble ..............................................................................................................................................29

Filters..................................................................................................................................................... 30

Field Descriptions ............................................................................................................................31

Pad Character ................ ...................................... .... ..... ..... ...................................... .... ...................33

Edit Function ...................................................................................................................................33

Page 3

R44-2016 i-2

Setting the Bar Code Format................................................................................................................. 34

Additional Commands........................... ..... ..... .... ...................................... ..... ..... .... ..................................... 35

Good Read Beeper Duration .................................................................................................................35

Laser Timeout ........................................................................................................................................35

Double Read Timeout............................................................................................................................ 36

Read Verification ...................................... .... ..... ...................................... ..... .... ..... .................................36

No Read Message................. .... ..... ...................................... ..... .... ..... ................................................... 37

No Read Output Signal ..........................................................................................................................37

No Read Output Signal Mode 1 ......................................................................................................37

No Read Output Signal Mode 2 ......................................................................................................37

Diagnostic Commands ...........................................................................................................................38

Good Read LED Duration ......................................................................................................................38

Appendix A:Technical Specifications ......................................................... ..................................................A-1

Appendix B: Mechanical Specifications .......................................................................................................B-1

Appendix C: Factory Default Configuration .................................................................................................C-1

Appendix D: LM520 Programming Labels ....................................................................................................D-1

Appendix E: ASCII Conversion Table ...........................................................................................................E-1

Page 4

R44-2016 i-3

List of Tables

Table 1. Electrical Interface Specifications ..........................................................................................8

Table 2. Configuration Commands .....................................................................................................10

Table 3. Baud Rate ..............................................................................................................................14

Table 4. Data Format ..........................................................................................................................15

Table 5. Flow Control .........................................................................................................................16

Table 6. Software Switch Control .......................................................................................................17

Table 7. Hardware Switch Control .....................................................................................................18

Table 8. Continuous Scanning Mode ..................................................................................................18

Table 9. LaserSense Mode ..................................................................................................................19

Table 10. Symbologies .......................................................................................................................20

Table 11. EAN ....................................................................................................................................21

Table 12. UPC .....................................................................................................................................21

Table 13. Code 128 .............................................................................................................................22

Table 14. ISBT Symbology ................................................................................................................23

Table 15. Concatenation Pairs ............................................................................................................24

Table 16. ISBT Commands ................................................................................................................24

Table 17. Code 93 ...............................................................................................................................25

Table 18. Codabar ...............................................................................................................................25

Table 19. Code 39 ...............................................................................................................................26

Table 20. Interleaved 2 of 5 ................................................................................................................27

Table 21. Standard 2 of 5 ....................................................................................................................28

Table 22. Preamble .............................................................................................................................29

Table 23. Postamble ............................................................................................................................29

Table 24. Filter Examples ...................................................................................................................30

Table 25. Symbology Identifiers ........................................................................................................32

Table 26. Pad Characters ....................................................................................................................33

Table 27. Edit Functions .....................................................................................................................33

Table 28. Bar Code Format .................................................................................................................34

Table 29. Beeper Duration ..................................................................................................................35

Table 30. Laser Timeouts ...................................................................................................................35

Table 31. Double Read Timeout .........................................................................................................36

Table 32. Read Verification ................................................................................................................36

Table 33. No Read Message ...............................................................................................................37

Table 34. No Read Output Mode ........................................................................................................38

Table 35. Diagnostic Commands ........................................................................................................38

Table 36. Good Read LED Duration ..................................................................................................38

Table A-1. Performance Specifications ...........................................................................................A-1

Table A-2. Power Requirements ...................................................................................................... A-2

Table A-3. Physical and Environmental Specifications .................................................................. A-2

Table A-4. Agency Approvals ......................................................................................................... A-2

Table C-1. Factory Default Configuration ........................................................................................C-1

Table D-1. Programming Labels .................................................................................................... D-1

Table E-1. ASCII Conversion Table .................................................................................................E-1

Page 5

R44-2016 1

Section 1

The LM520 Bar Code Scanner

Overview

The LM520 scanner is a compact, decoded, single-line scanner for fixed position or embedded applications, such as conveyor, library, document tracking, chemical analyzers, vending

machines, point-of-sale (POS) terminals, and other attended or unattended scanning applications. The LM520 is a complete scanning system, ready to plug in and scan. The LM520

presents a fast, easy and low-cost way to incorporate scanning into any application where

you need to read a bar code.

A typical system using the LM520 scanner consists of the scanner itself and a host system

such as a PC, POS system, or package sorting system. The host system controls the scanner

and receives the decoded bar code data produced by the scanner. The laser in the LM520

scanner emits coherent visible light. When a bar code passes through the scanner’s beam,

light is reflected off the bar code. The scanner collects this reflected light, processes it into a

digital signal and decodes it into data that can be used by the host system. In some cases the

data may be processed further by the scanner before being transmitted to the host.

The LM520 has four different operational modes which can be used to scan a bar code. The

four operational modes include:

• an external switch such as an output line from a Programmable Controller (also

known as a PLC) can be used to enable scanning

• software commands from the host system

• continuous scanning operations, and

• a unique PSC motion detection circuitry called LaserSense™. This circuitry allows

the LM520 to only scan when an object is passed in front of it.

The various modes are selected via host commands or special programming bar codes.

Page 6

The LM520 Bar Code Scanner Section 1

2 LM520 Scanner Integration & Programming Manual

Unpacking the LM520

The LM520 bar code scan scanner is shipped in custom packaging. Carefully open the

package, and remove the scanner from the packing material.

The LM520 standard configuration includes:

• LM520 scanner

• power supply

• mounting hardware (two bolt studs with nuts)

• interface cable - male DB9 (scanner side) [with optional beeper if ordered]

• diskette with this manual and other information

When you open the shipping cart on, visually inspect the pack age’s contents. If any parts ar e

damaged or you need additional hardware, please contact your reseller or the PSC

Customer Support Center at 1-800-547-2507.

Scanner Care

The LM520 bar code scanner contains sensitive components which require special

handling. PSC Inc. may not warrant damage due to improper handling.

• Do not open the scanner’s case. Doing so will void the warranty.

• Avoid touching the front window. Fingerprints will degrade the scanner’s

performance.

• Only clean the scan window when visual inspection reveals dirt or residue.

Remove lint or foreign material be present with filtered clean air. Remove

fingerprints or other residue using clean, cotton-tipped applicators dipped in

isopropyl alcohol, or with soft tissues dipped in high-quality lens or eyeglass

cleaner. Do not reuse cotton-tipped applicators or tissues.

• Do not scrub the window.

• Never wipe the window with a dry tissue or applicator.

Page 7

R44-2016 3

Section 2

Mounting the LM520

The LM520 bar code scanner is designed to be mounted to a stand in a fixed position. This

section describes the layout of the mounts for optimum scanner performance.

General Considerations

Although the LM520 bar code scanner has been designed to be impact-resistant, it is important to consider the effect of the environment on the scanner. In particular, the mounting

scheme should minimize the possibility of foreign objects contacting the window’s surface.

Such contact will damage the window over time and re duce the scann er’s performance. The

mounting design should also take into consideration the clearance needed for the power

supply and interface cables. These cables should be routed away from the operator’s working area in attended applications.

Mounting

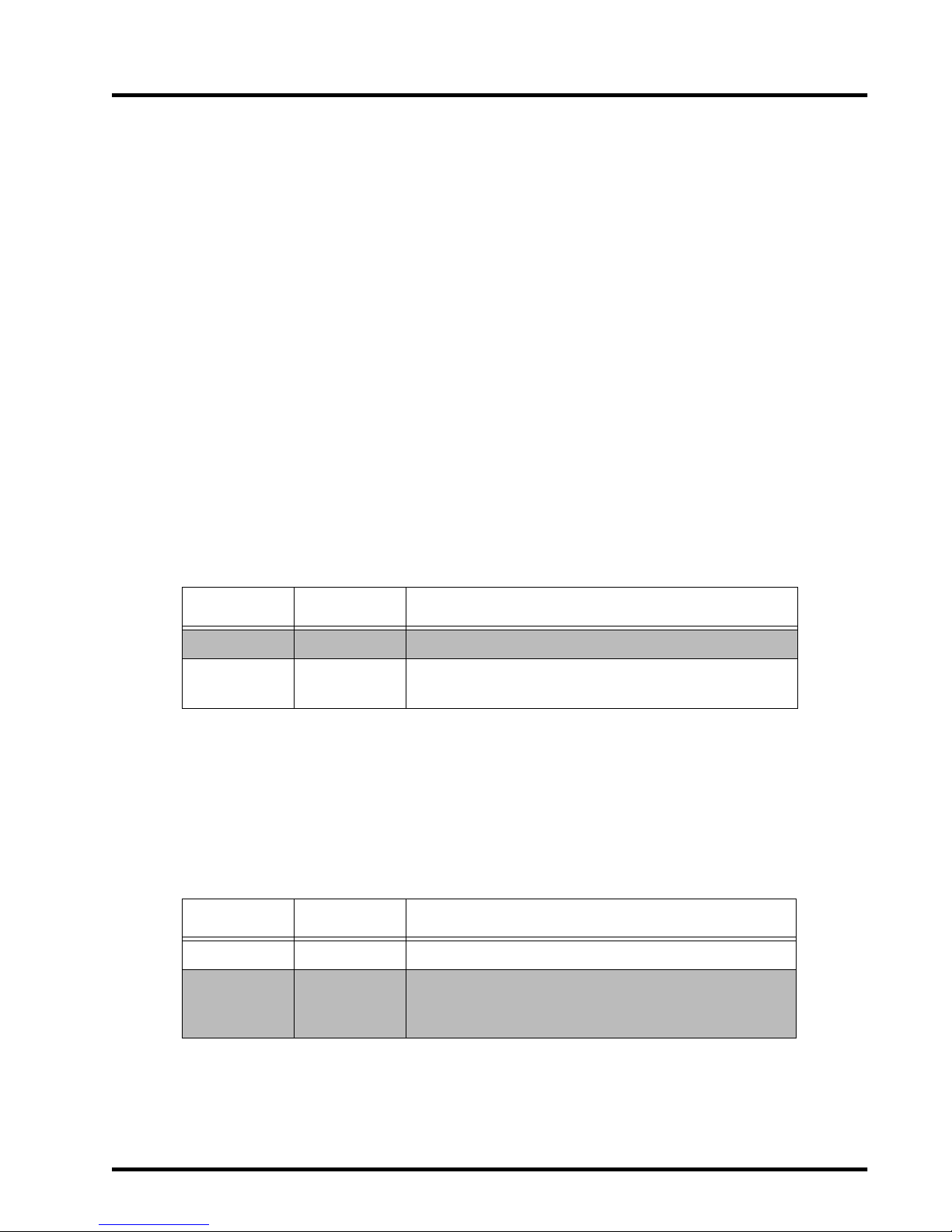

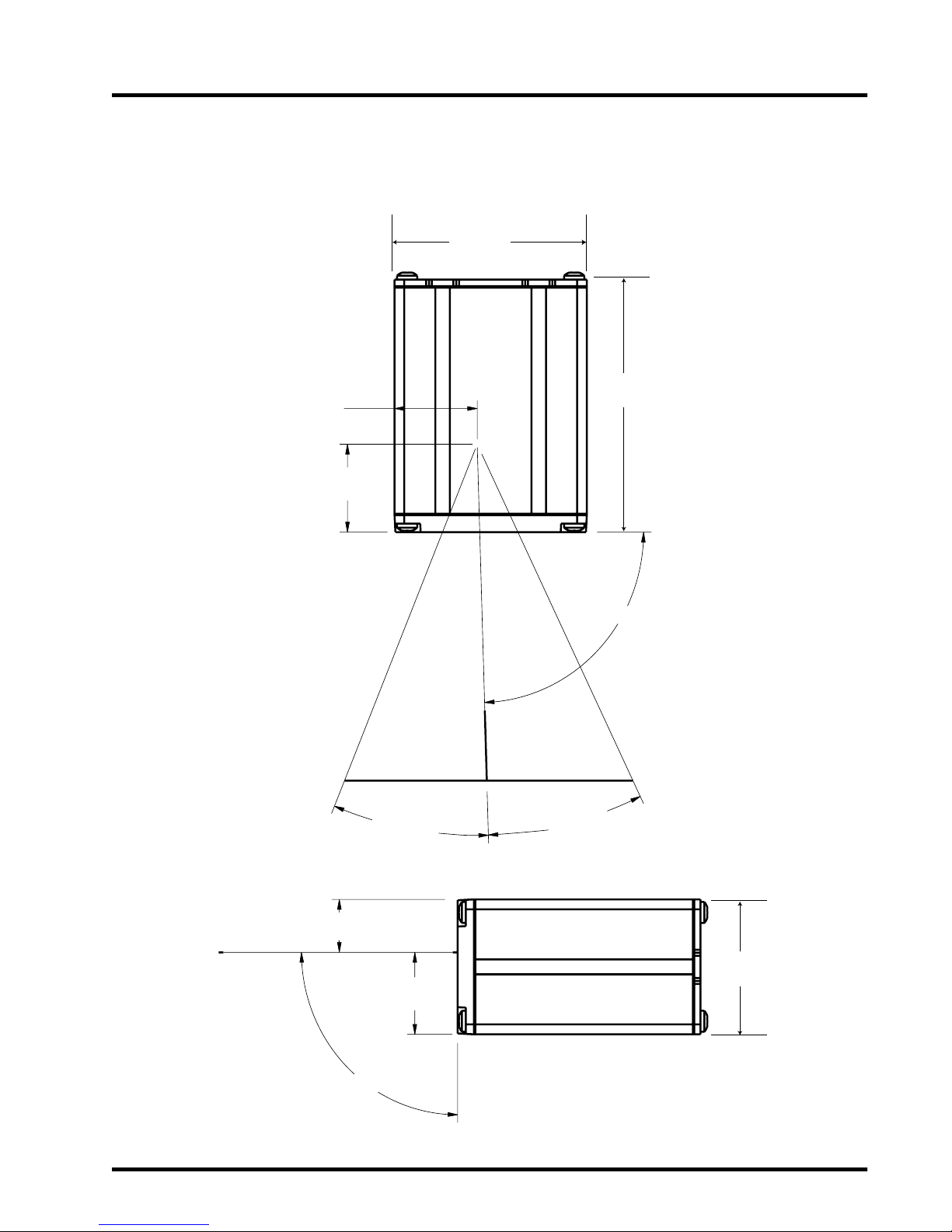

System integration is made easy with the LM520’s unique mounting design. Six mounting

grooves in the scanner’s sealed enclosure enable mounting on any one of four sides. When

looking at the back of the scanner, these slots are located as shown in Figure 1.

Figure 1. Mounting

Appendix B, Mechanical Specifications shows mechanical drawings of the precise position of

the mounting slots relative to the scanning laser beam.

6789

12345

Mounting Slots

Mounting Slots

1.00"

(2.54cm)

0.50"

(1.27cm)

0.50"

(1.27cm)

0.675"

(1.71cm)

0.675"

(1.71cm)

LM520 Scanner

Mounting Slots (6 total)

Page 8

Mounting the LM520 Section 2

4 LM520 Scanner Integration & Programming Manual

Mounting the Scanner Stand-Alone

For most instances using an adjustable mount is recommended. The position of the scan line

can be fine-tuned during actual installation and the scanner’s distance from the scanned

object can be easily changed. The location of the operator should also be considered for

attended applications. Care should be taken to position the scanner to minimize the possibility of the operator overturning the scanner, spilling liquid on the scanner, inadvertently

unplugging the cables, and so on.

Integrating the Scanner to Read at the Proper Distance

When deciding how to mount the LM520, there are many criteria that must be considered.

First, there are minimum and maximum distances that the bar code can be from the front of

the scanner to properly read, depending on the size of the bar code. These distances, or

depth of field, are specified in Appendix A, Technical Specifications.

Second, the scanner must be positioned so that the bar code to be read is not “square” or

parallel to the front of the scanner. The scanner must have at least 3 degrees skew angle to

operate properly. See Appendix B, Mechanical Specifications for such information as skew,

pitch, and the scanner’s mechanical parameters.

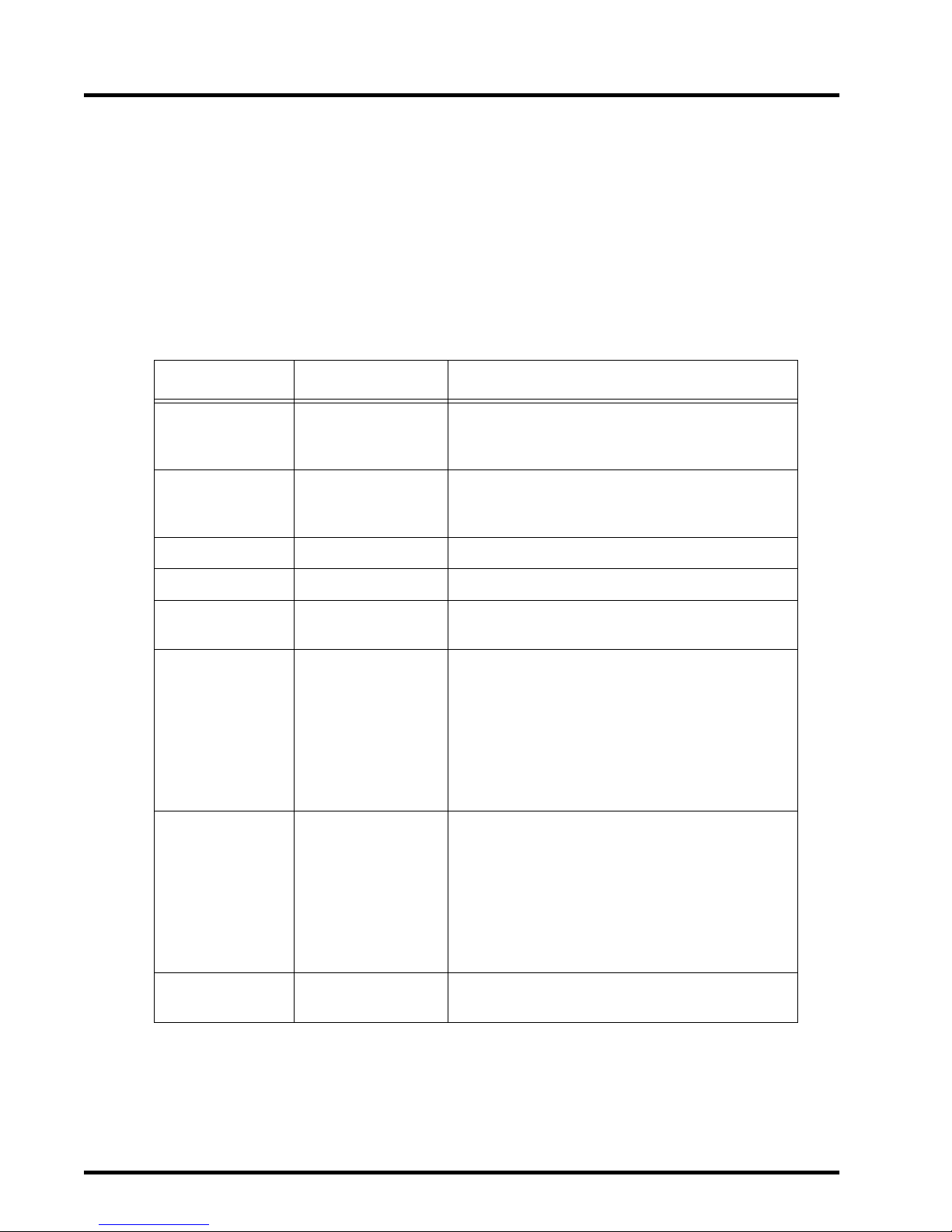

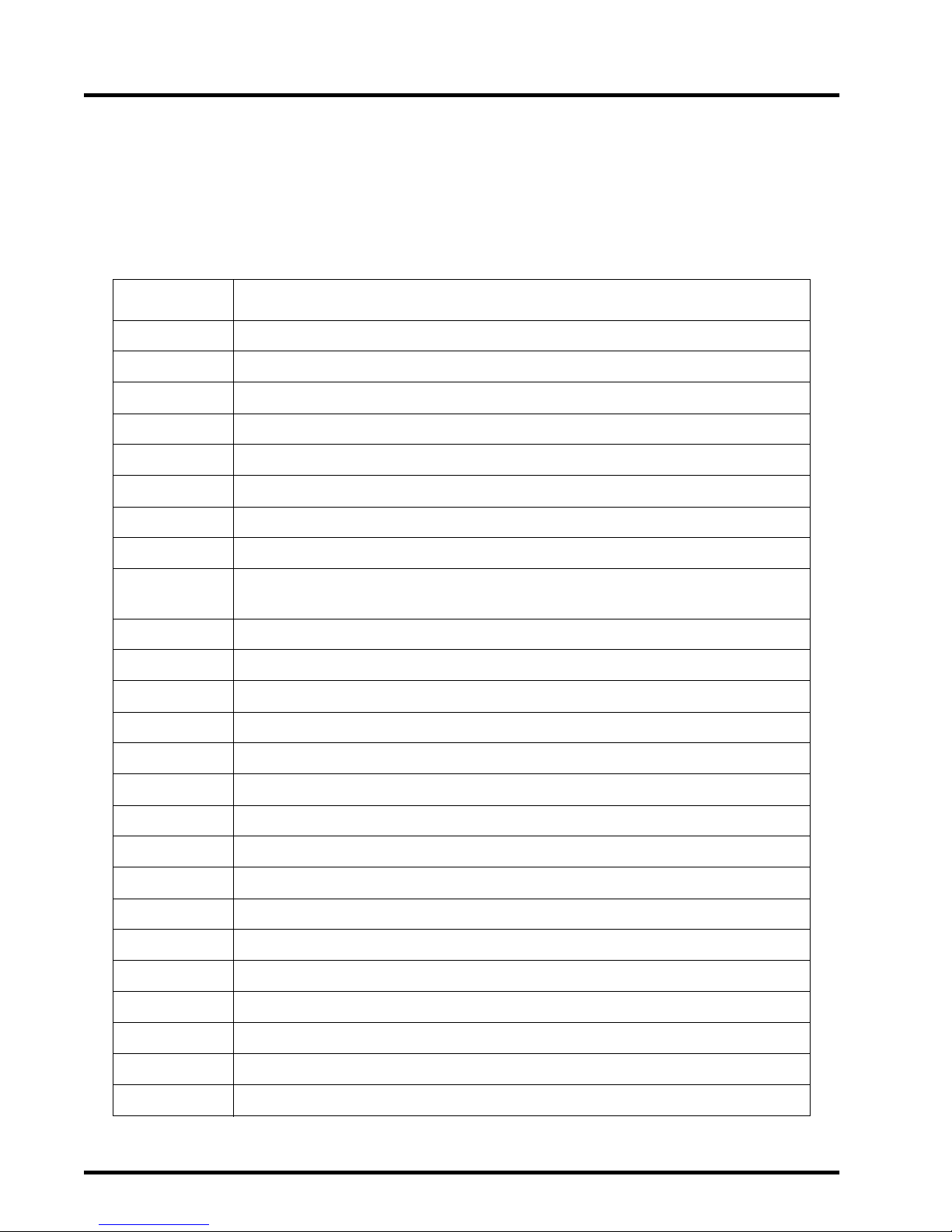

Third, the scanner must be positioned so that the scan line will be long enough to cover the

entire bar code. The scan line should exceed the width of the bar code since only about 80%

of the scan line is usable (see Figure 2). Use the following formula to calculate the expected

usable line length (l) at a given distance (d):

l = [(d+0.88in) x 2 x tan (q)] x 0.8 (if d is measured in inches)

or

l = [(d+2.34cm) x 2 x tan (q)] x 0.8 (if d is measured in centimeters)

where

l = usable line length

d = distance from the front of scanner

q = half of the scan angle, (23° ± 2.0°)

Page 9

Section 2 Mounting the LM520

R44-2016 5

Figure 2. Mounting the Scanner

Integrating the Scanner Behind a Window

When the LM520 scanner is integrated into a larger system, additional factors must be taken

into account. The most important of these is an additional window placed between the

LM520 and the bar code to be read. While an additional window provides protection for the

LM520, it will also degrade the scanner’s performance due to the need for the laser light to

traverse two additional optical surfaces passing through to the bar codes, and the reflected

light returning. Following the instructions in this section will help optimize the amount of

outgoing light that reaches the bar code and the amount of reflected light that is collected by

the scanner.

The LM520 scanner emits a laser beam in the form of a scan line. The beam’s light exits the

scanner’s window and reflects off the bar code symbol. The reflected light returns through

the window, and is collected with a photodiode. As in any optical system, any type of window causes a reduction in the amount of light that exits or enters the scanner since some of

the laser light is lost due to surface reflection.

LM520 scanner

l = 80%

of scan line

d

.88"

2.34cm

q=

Page 10

Mounting the LM520 Section 2

6 LM520 Scanner Integration & Programming Manual

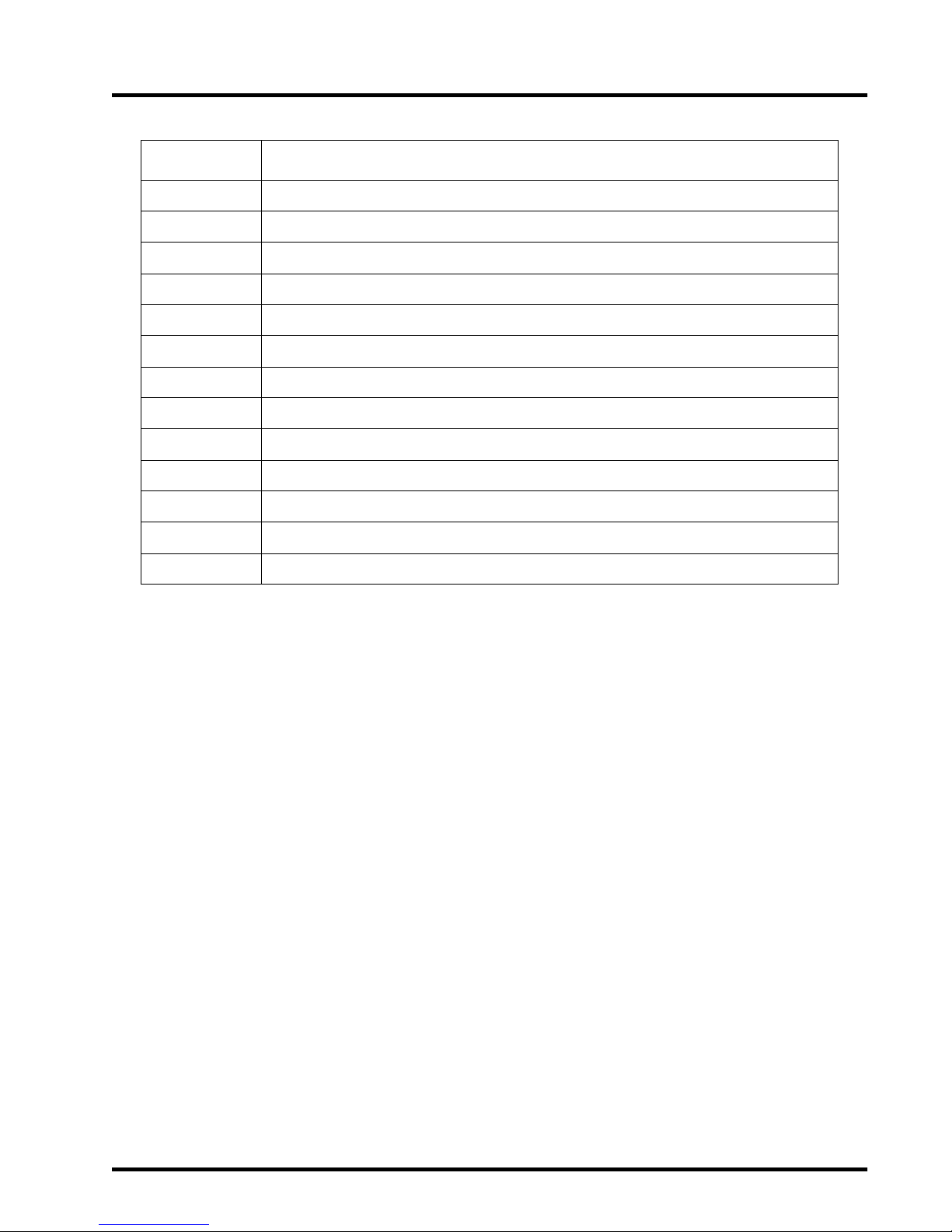

The design and placement of the window is critical for optimum system performance. The

following issues must be considered.

• The window must not block outgoing laser light.

• The window must not block laser light reflected from the bar code.

Figure 2 shows the minimum size and position of the window along the horizontal and vertical axes, respectively. The minimum window size must increase as

the distance between the scanner and the window increases. This is necessary

to accommodate the width of the scan line.

• Reflections of outgoing laser light caused by the window or other reflective surfaces should not reach the front window of the scanner.

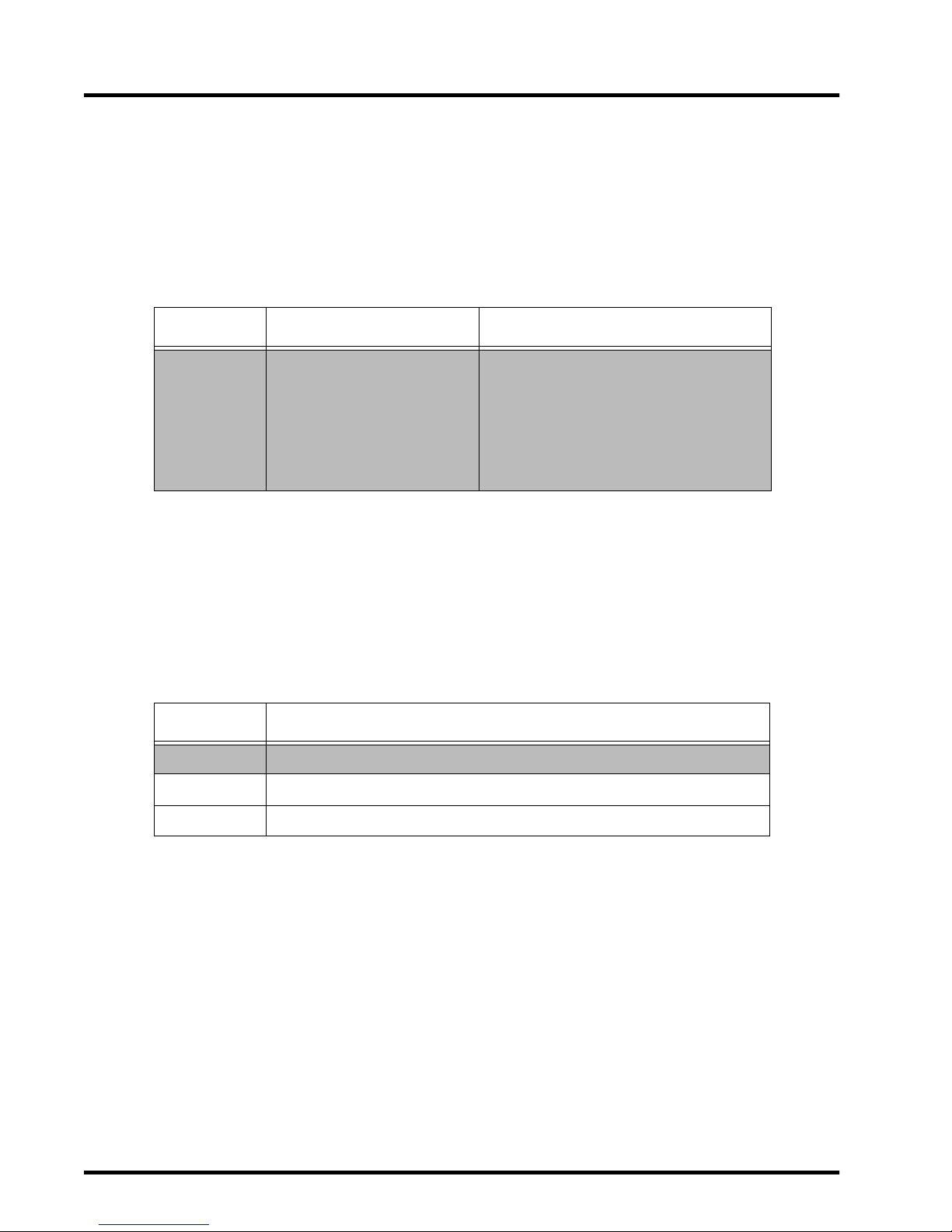

Determine the window tilt based on your application. The tilt angle of the window (that is,

its position relative to the optical axis or center-line) is important because a portion of the

emitted light will always be specularly reflected from each of the two window surfaces. This

reflected light must not reach the scanner’s window either directly or via multiple reflections from other parts of the system.

Figure 3. Tilt Angle

Nominal

Beam Path

d = 1.250"

31.74mm

0.880"

22.34mm

Angle = 103.7˚

0.125"

3.18mm

0.820"

20.83mm

Reflected light

Window

Angle

= 90 + 0.5 [ arctan (

)]

= 103.7

0.65

1.25

Page 11

Section 2 Mounting the LM520

R44-2016 7

An example of acceptable system window inclination is shown in Figure 2. As can be seen,

moving the system wind ow cl oser to the scanne r mak es it n eces sary to incr e ase the win dow

angle with respect to vertical. Less inclination is necessary if the reflection is directed below,

rather than above the scanner, since laser light is emitted near the bottom of the scanner’s

window and collected near the top of the scanner’s window. If the light reflected from the

window will be deflected above the scanner , the required window angle (fr om horizontal) is

given by:

If the light will be deflected below the scanner , the r equired window angle (from horizontal)

is given by:

The window material you select depends on the anticipated environment and your

scanner’s intended use. Appropriate window materials include glass, sapphire, and plastic.

Glass, and especially sapphire, have adequate surface hardness for most applications.

However , if you use any type of plastic, it should have a protective hard-coat on the exposed

surface. The hard-coat will protect the plastic surface from damage if the system window

needs to be cleaned.

In addition to hard-coating, some window applications may require special treatment such

as antistatic or antireflection coatings. In general, do not use antiglare coatings due to

undesirable polarization and diffusion effects.

Angle

= 90 + 0.5 [ arctan (

)]

if d is measured in inches

0.65

d

Angle

= 90 + 0.5 [ arctan (

)]

if d is measured in cm

1.65

d

Angle

= 90 - 0.5 [ arctan (

)]

if d is measured in inches

0.2

d

Angle

= 90 - 0.5 [ arctan (

)]

if d is measured in cm

0.51

d

Page 12

Mounting the LM520 Section 2

8 LM520 Scanner Integration & Programming Manual

Electrical Interface

The LM520 scanner communicates with the host over a standard DB-9 connector. The

pinouts for the connector are shown in Table 1.

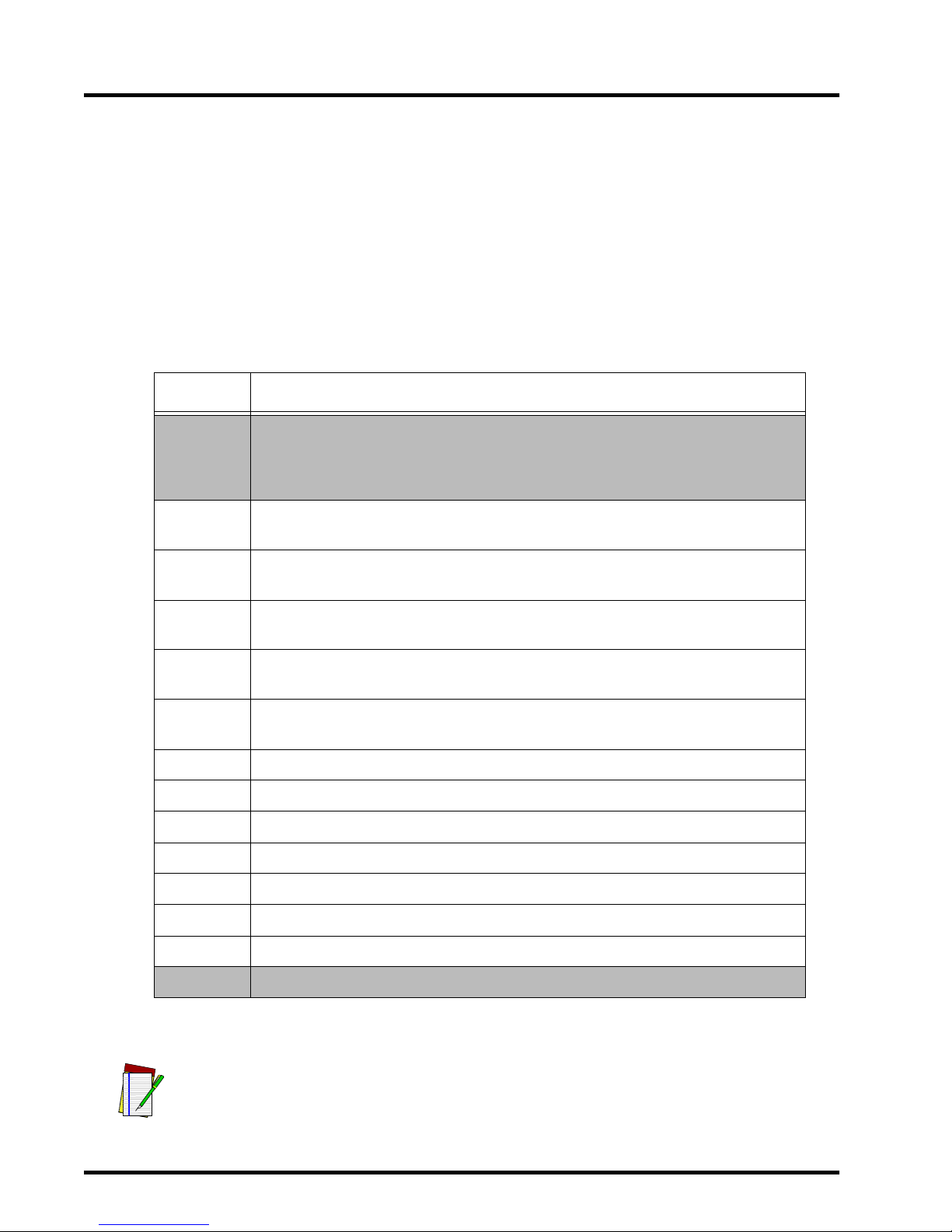

Table 1. Electrical Interface Specifications

Pin #

Direction

(relative to

LM520)

Signal Function

1 Output

Beeper/

Good Read

1

1

Beeper Drive/Good Read source current must be limited to 50mA with a maximum voltage of 5VDC.

5VDC output signal used to drive an audio indicator.

2 Output TX

Serial asynchronous RS232C le vel data transm itted to the host . NRZ f ormat

and user programmable f or wo rd fo rmat and baud rate. (Default: 9600 baud,

8 data bits, no parity, 1 stop bit).

3 Input RX

Serial asynchronous RS232C level data r eceived f r om th e ho st. NRZ format

and user programmable f or wo rd fo rmat and baud rate. (Default: 9600 baud,

8 data bits, no parity, 1 stop bit).

4 Output

No Read

2

2

No Read output will source 15mA @ 5VDC. The maximum sink current must be limited to 200mA with a maximum voltage of 14VDC.

This signal is asserted at the end of a scanning cycle if no label is decoded

and will remain asserted until:

1. A successful decode occurs, or

2. A user specified timeout period elapses.

This may be configured in 100ms increments from 100 ms to 9900 ms

(9.9 seconds). Refer to the section titled No Read Output.

NOTE: If the timeout is used, the signal will be immediately deasserted if a

software scan command, hardware scan trigger on pin 9 or a LaserSense

scan occurs before the user specified tim e elapses. Setting a timeout is not

available in Continuous Scan mode.

5 Input Gnd Power supply/signal ground.

6 Input Vcc Power supply input voltage (4.75 - 12.0VDC)

7 Input CTS RS232C Clear to send control line.

8 Output RTS RS232C Request to send control line.

9 Input

Scan Trigger

3

3

Scan trigger signal must be limited to a maximum input voltage of 5VDC with a maximum input current of 10mA.

Ground on this input initiates bar code scanning. Scanning will continue

until either: (a) this line returns to high (5VDC) level, or (b) this line is disconnected, or (c) the programmed time period expires, or (d) a bar code is

decoded.

Page 13

Section 2 Mounting the LM520

R44-2016 9

Interface Cable Schematic

The drawing in Figure 4 shows a schematic view of the electrical connection between the

scanner and the host.

Figure 4. Interface Cable Schematic

ORANGE

YELLOW

VIOLET

GREEN

RED

WHITE

BROWN

BLUE

1

2

3

4

5

6

7

8

9

3

2

7

4

5

1

2

3

DB25-S

DB9-P

HOST END

SCANNER END

Connector is a 2.5 mm stereo plug

for the scan trigger, no read signal

and power supply ground.

Power Supply

4.75 - 12VDC

Beeper

(if applicable)

BEEPER/GOOD READ

TXD

RXD

NO READ

GND

VCC IN

CTS

RTS

TRIGGER_IN

Page 14

R44-2016 10

Section 3

LM520 Scanner Configuration

The LM520 offers a command interface which allows a wide range of customization. Commands can be combined with standard programming bar codes to develop an active configuration and a saved or factory default configuration.

Configuration Management

The LM520 scanner always contains two configuration sets: the Active configuration and

the Factory Default configuration. Both configurations are stored in nonvolatile memory.

When the scanner receives a command changing the configuration, it changes the Active

configuration. If the scanner is reset to the Factory Default configuration, the factory

defaults are copied to the Active configuration. See Appendix C, Factory Default Configura-

tion for a concise list of the factory defaults.

The LM520 offers the ability to change and save a new Factory Default configuration. To

overwrite the Factory Default configuration as shipped from PSC, first make changes to the

Active Configuration, then store the Active Configuration as the Factory Default. The

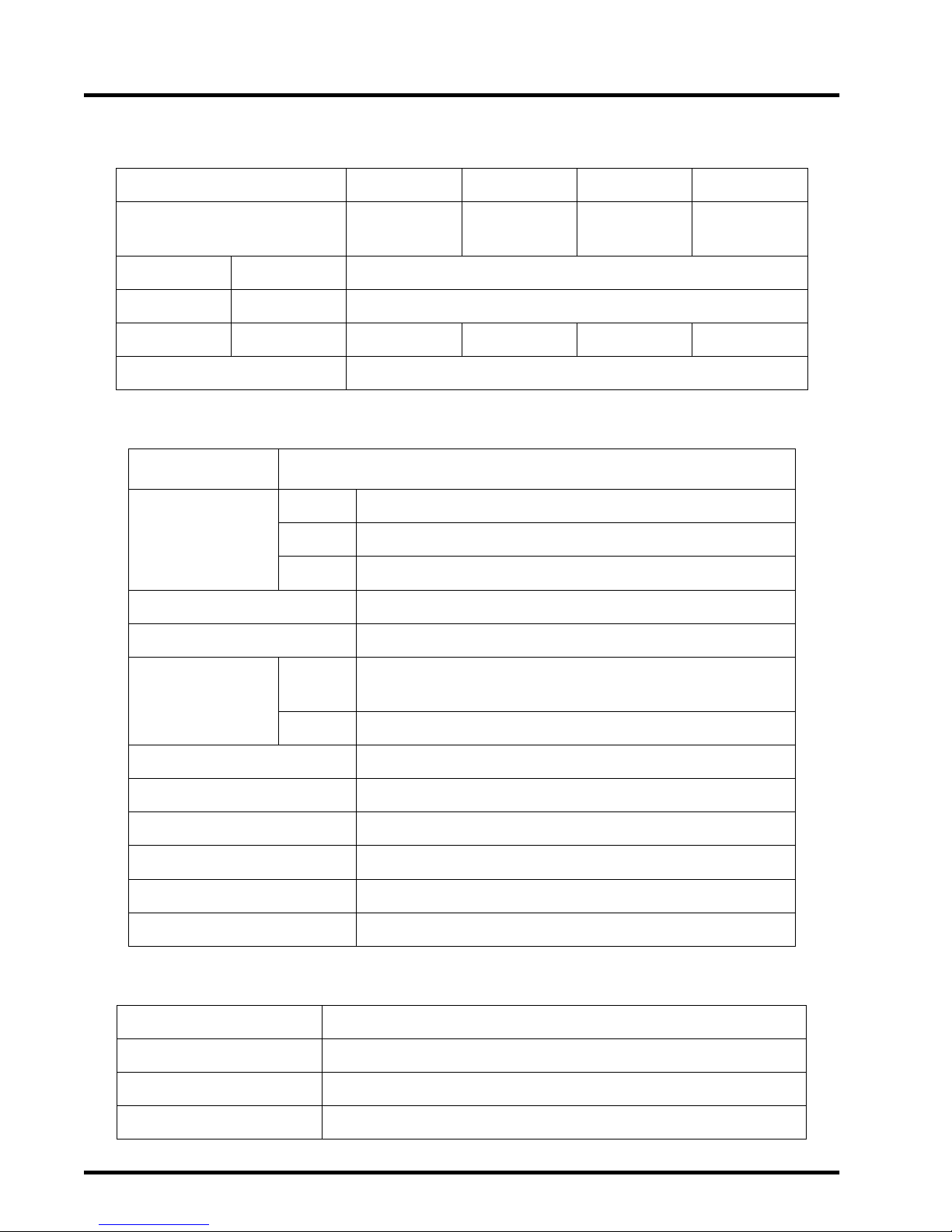

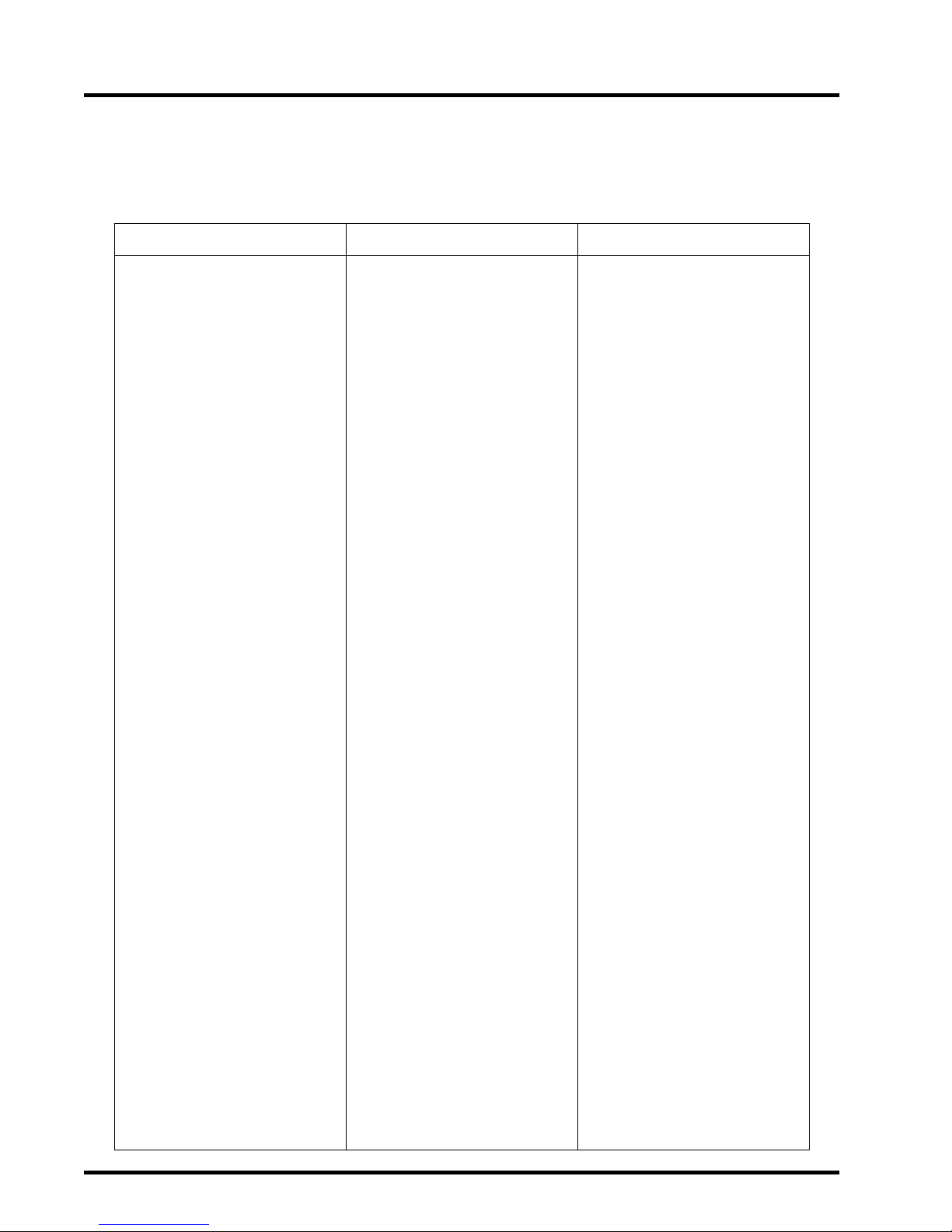

previous Factory Default will be overwritten. Figure 5 illustrates this process. Table 2

describes the commands for changing the default configuration.

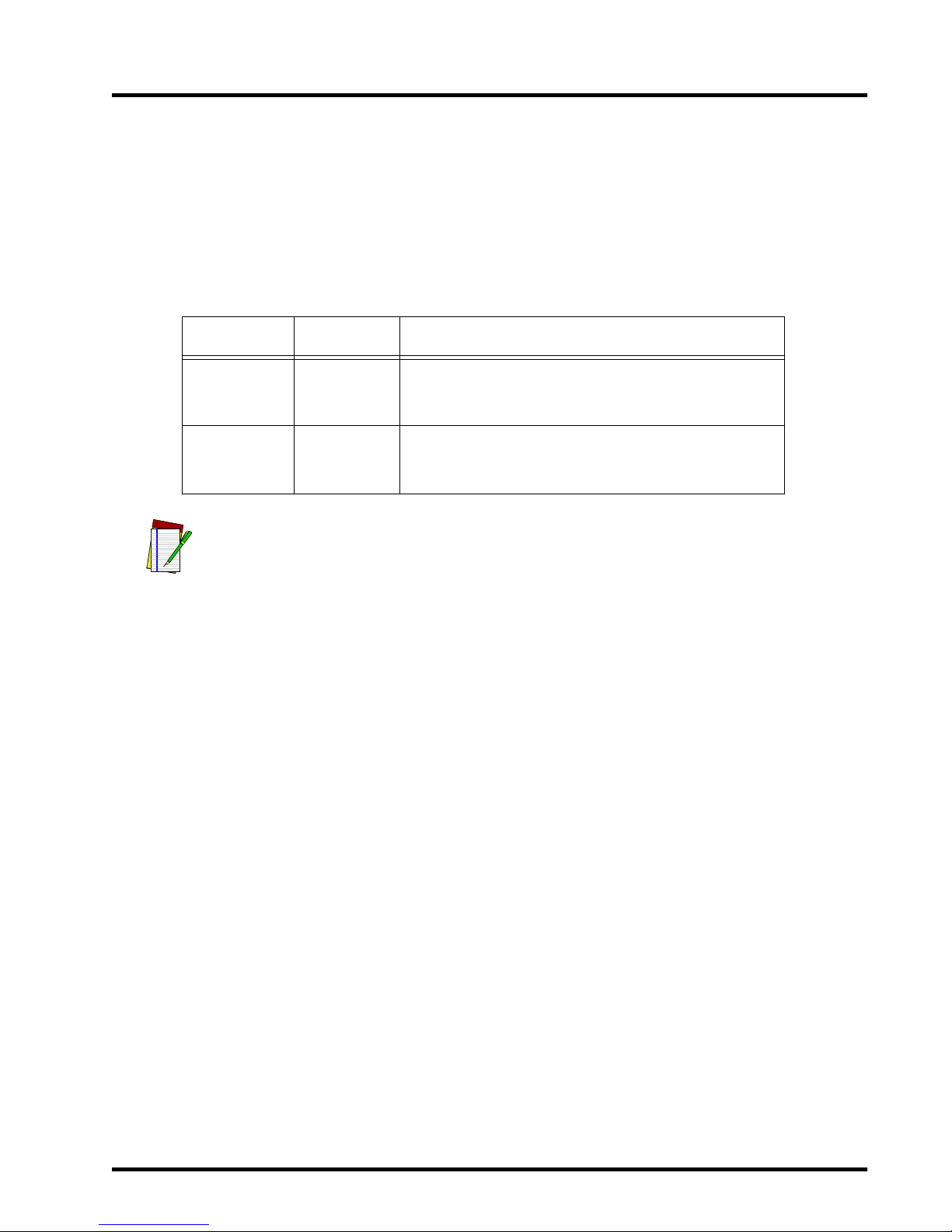

Table 2. Configuration Commands

Command Setting

Z1

Reset active configuration to factory defaults.

The active configuration will be overwritten.

Z2

Store the active configuration as Factory Default.

The contents of the Factory Default will be overwritten.

Page 15

Section 3 LM520 Scanner Configuration

R44-2016 11

Figure 5. Configuration Management

Factory Default

Configuration

Host Serial Command

or

Programming Label

Active

Configuration

Z2

Z1

Z1 - Copy vaulted configuration into active configuration.

Z2 - Copy configuration from active configuration to the factory default configuration.

Page 16

LM520 Scanner Configuration Section 3

12 LM520 Scanner Integration & Programming Manual

Programming Methods

The LM520 scanner may be programmed either by sending commands from a host over the

serial interface or by the using bar codes containing programmable commands. Typically,

the scanner is programmed over the serial interface when it is integrated into a system.

Appendix D, LM520 Programming Labels, contains a minimal set of programming

bar codes and the section titled, Programming with Bar Codes, on page13, describes how to

create programming bar codes.

Programming through the Serial Interface

The easiest and most common way to program the LM520 is by sending ASCII commands

through the serial interface. Each command transmission must begin with the STX (0x02

hex) and ESC (0x1B hex) characters. Next, the command itself is transmitted, followed by

any necessary parameters. The command transmission ends with an ETX (0x03 hex).

A complete serial command transmission, therefore, consists of:

STX-ESC-[command]-[parameters]-ETX

The scanner uses an ACK/NAK protocol to communicate with the host. The scanner does

not echo received data back to the host, and will not acknowledge transmissions which do

not begin with STX-ESC and end with ETX. Upon receipt of a valid command sequence,

the scanner responds in one of two ways:

• All commands that are valid (both commands and parameters) take the requested

action and then transmit an ACK to the host.

• If the command is invalid, the scanner responds with an ASCII NAK (0x15 hex).

All valid commands return an ACK. Otherwise, a NAK is returned if the command is not

valid. If the command is not formatted properly (missing the STX, ESC, or ETX), the scanner

does not respond. Each command recognized by the scanner consists of two ASCII characters, followed by any required parameters.

Page 17

Section 3 LM520 Scanner Configuration

R44-2016 13

Programming with Bar Codes

The LM520 scanner can also be programmed by scanning bar codes which contain commands. This method allows users to easily adjust scanner parameters.

Bar codes used for programming must be Code 128, with a Function Code 3 (FNC3) as the

first character. The command following the FNC3 character configures the scanner in

exactly the same way as if it had received the command over the serial line, except that the

scanner will not acknowledge the command on the serial line. Each bar code may contain

only one command. All parameters for the command must be included in the label with the

command characters. For example, the label to limit the minimum number of Code 39 to 5

characters would be.

<FNC3>OH05

The scanner can be programmed not to accept programming bar codes by using the Disable

Programming Bar Codes command (@Y). If you disable the programming with bar codes

feature, the scanner will still accept programming commands through the serial port. The

Enable Programming (@Z) bar code commands will always be accepted by the scanner, and

cannot be disabled.

If Disable Programming Bar Codes (@Y) is set, all programming bar codes except Enable

Programming Bar Codes (@Z) will be treated as standard Code 128 bar codes.

Conventions

The remainder of this manual presents the valid commands in a tabular format. These tables

contain two or three columns.

• First column

– Bar Code Command, contains the two-letter ASCII string which

the scanner accepts as programming commands through the serial port or in a

programming label. See Appendix D, LM520 Programming Labels, for instructions

on how to create bar code programming labels.

• Second co lumn

– Bar Code Parameters, may be present. If an entry appears in this

column, a parameter setting is required to complete the command.

• Last column

– Setting, describes the effect of the command and its associated

parameters.

• Default Entries – The factory default settings for the scanner are shaded and

denoted by asterisk.

A concise list of these defaults is presented in Appendix C, Factory Default Configuration.

³OH05

Page 18

LM520 Scanner Configuration Section 3

14 LM520 Scanner Integration & Programming Manual

Setting Serial Communication Parameters

The first step in the integration process is establishing communications between the scanner

and the host. This is done by matching the scanner’s communications parameters to the

serial communication requirements of the host. The Baud Rate, Data Format and Flow

Control communication settings of the scanner must match the serial communications

requirements of the host. For example, if the scanner is sending data at the wr ong baud rate,

the host will not be able to interpret the data that is being sent. The following section outlines the RS-232 communication settings.

Baud Rate

Use one of the commands shown in Table 3 to set the LM520 baud rate. Note that the scanner and the host must communicate at the same rate for communication to be successful. An

ACK command will be sent by the scanner at the new baud rate, indicating that the command has been received and understood.

* Asterisk and shading denotes the Factory Default Setting.

Table 3. Baud Rate

Command Setting

DA Baud = 300

DB Baud = 600

DC Baud = 1200

DD Baud = 2400

DE Baud = 4800

DF * Baud = 9600

DG Baud = 19200

DH Baud = 38400

Page 19

Section 3 LM520 Scanner Configuration

R44-2016 15

Data Format

These parameters control the data format in which the LM520 will communicate with the

host. Note that the scanner and host must

communicate in the same format for communication to be successful. An ACK command will be sent by the scanner in the new format indicating that the command has been received and understood. Table 4 lists the commands for

the data format options.

Table 4. Data Format

Command Setting

EC 7 data bits, 1 stop bit, even parity

ED 7 data bits, 1 stop bit, odd parity

EK 8 data bits, 1 stop bit, even parity

EL 8 data bits, 1 stop bit, odd parity

EM * 8 data bits, 1 stop bit, no parity

EN 8 data bits, 2 stop bits, no parity

Page 20

LM520 Scanner Configuration Section 3

16 LM520 Scanner Integration & Programming Manual

Flow Control

As shown in T able 5, the LM520 scanner supports standard flow contr ol protocols, including

XOn/XOff (software flow control) and CTS/RTS (hardware flow control). If CTS/RTS is

being used, first send the HA command before sending a new Flow Control command

(HB - HN). If the CTS and RTS lines are not used for flow control, they can be used to monitor and control the scanner. The default setting is no flow control: CTS = none; RTS = low

when scanning in process and Xon/Xoff disabled. To return to this configuration send the

HA command followed by the HN command.

Table 5. Flow Control

Command Setting

HA *

No Flow Control

Xon/Xoff disabled

CTS mode = none

RTS mode = RTS low when ready to receive

HB

Xon/Xoff Enabled

CTS mode = none

HC

CTS mode = Low to transmit

Xon/Xoff disabled

HD

CTS mode = High to transmit

Xon/Xoff disabled

HE

CTS mode = Low to begin scanning

Xon/Xoff state unchanged

HF

CTS mode = High to begin scanning

Xon/Xoff state unchanged

HG RTS = Always Low

HH RTS = Always High

HI RTS = Low when scanner is ready to receive commands

HJ RTS = High when scanner is ready to receive commands

HK RTS = High when scanner has data to send

HL RTS = Low when scanner has data to send

HM RTS = High when scanning is in progress

HN * RTS = Low when scanning is in progress

NOTE

If Xon/Xoff is enabled, then RTS = low when scanning and CTS = none

If Xon/Xoff is disabled, then RTS = low when ready to scan and CTS = none

Low = Mark signal (negative voltage)

High = Space signal (positive voltage)

Page 21

Section 3 LM520 Scanner Configuration

R44-2016 17

Controlling Scanning Through Host Commands

Triggering Scanning Using Software Switch

A host can instruct the scanner to begin scanning by sending the Scan Now command.

Table 6 shows that the number of scanning passes is user programmable.

Except for terminating after the requested number of scans if no bar code is read, scanning

initiated through this command performs identically to scanning initiated by pressing the

trigger (assertion on the Scan Trigger line, pin 9).

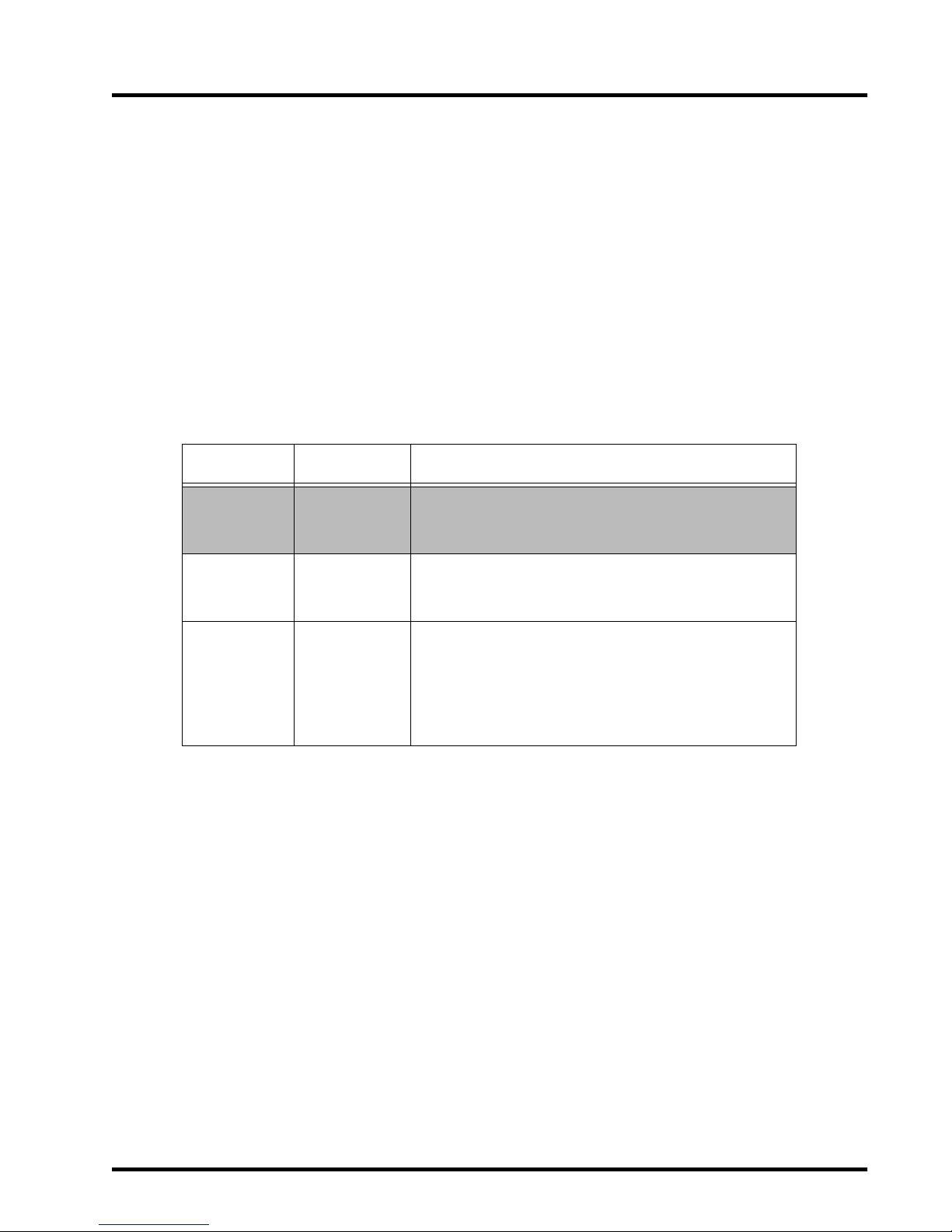

Table 6. Software Switch Control

Command Parameter Setting

ZD XX

(01-99)

Scan Now. Begin scanning immediately. Scan until a bar

code is decoded, or for a maximum of XX scans.

NOTE: The LM520 scans approximately 42 times per second.

ZD 00

Scan Now. Begin scanning immediately. Scan until a bar

code is decoded, or until the scanning timeout expires. See

BH command in Table 30.

NOTE

The ZD command returns ACK immediately followed by the bar code data when a bar code is decoded.

Page 22

LM520 Scanner Configuration Section 3

18 LM520 Scanner Integration & Programming Manual

Triggering Scanning Using Hardware Switc h

Using a hardware switch can also be configured to respond to the CTS line rather than the

Scan Trigger line using the commands below.

Scanning initiated in response to a CTS signal performs identically to scanning initiated by

pressing the trigger (assertion on the Scan Trigger line, pin 9). To disable scanning in

response to a CTS signal, set the CTS mode to a non-scanning mode (HA, HB, HC or HD) as

described in Setting Serial Communication Parameters on page 14.

Hardware scanning continues until either the Scan T rigger is deasserted or until the scanner

timeout expires. See BH command in Table 30.

Continuous Scannin g Mode

The LM520 may also be set for Continuous Scanning mode through host commands.

Table 7. Hardware Switch Control

Command Setting

HE

CTS mode = High signal triggers scanning

(Other serial options unchanged)

HF

CTS mode = Low signal triggers scanning

(Other serial options unchanged)

Table 8. Continuous Scanning Mode

Command Parameter Setting

NC Continuous scanning on.

ND*

Continuous scanning off – only for use when programming

with bar codes. (Also, see Canceling Software Triggered

Scanning.)

Page 23

Section 3 LM520 Scanner Configuration

R44-2016 19

LaserSense Scanning Mode

LaserSense is a significant technology breakthrough. LaserSense technology has two key

advantages over other automatic triggering methods.

• It detects movement at a user configurable range from the scanner. This eliminates false triggers from movement in the general area and clearly identifies

where the bar code should be placed with a stable marker point.

• It is integral to the scanner. There are no additional components to fail or add-on

components that are not well integrated.

Using a background color that contrasts with the object being detected will enhance

performance.

Default: NG60

Range = 45 - 70

NG45 = 4.5” (minimum)

NG60 = 10” (default)

NG70 = 23” (maximum)

Canceling Software Triggered Scanning

A scan triggered by software, such as software trigger (ZD), LaserSense scanning (NA), or

continuous scanning (NC) can be canceled using the ASCII DC4 command from the host, or

by scanning the ND or NB labels. The ASCII DC4 command is a single byte (0x14 hex) and

should not be sent with a STX-ESC preceding it. When the LM520 receives this single character, it will respond with an ACK, turn active scanning off and be ready to receive additional programming commands. Sending this DC4 command is sufficient and does not

require the host to send th e Continuous Scanning O f f (ND) or Disable Lase rS ense (NB) co mmands.

Table 9. LaserSense Mode

Command Parameter Setting

NA *

Enable LaserSense. When an object is detected, scanning

occurs until the scanning timeout expires.

See the BH command in Table 30.

NB

Disable LaserSense – only for use when programming with

bar codes.(Also see Canceling Software Triggered Scanning.)

NG

XX

(45 - 70)

Set range for LaserSense. Higher values increases the

effective range.

A value that is too large will result in false triggers and

continuous scanning.

A value too low will result in no triggering.

Tolerance = ±20%

Page 24

LM520 Scanner Configuration Section 3

20 LM520 Scanner Integration & Programming Manual

Setting Symbology Parameters

The LM520 is able to decode UPC-A, UPC-E, EAN-8, EAN-13, Code 39, Code 128, Code 93,

Codabar, Interleaved 2 of 5, and Standard 2 of 5 symbologies. The decoder will actively

attempt to match bar code data against all symbologies which are enabled. Thus, performance is enhanced by disabling symbologies which are not used in a particular environment. The possibility of misreads due to symbology overlap will also decrease by disabling

unused symbologies.

Enabling All Symbologies

It is possible to enable all symbologies at once. This command is typically used for diagnostic or demonstration purposes. For best performance in actual use, only those symbologies

which are needed should be enabled.

Table 10. Symbologies

Command Setting

QM Enable all symbologies.

NOTE

This command does not enable either ISBT 128 or UPC/EAN supplementals.

Page 25

Section 3 LM520 Scanner Configuration

R44-2016 21

EAN

UPC

Table 11. EAN

Command Parameter Setting

RA Disable EAN-13

RB Enable 2 and 5 digit supplementals for EAN-13 and EAN-8.

RC * Enable EAN-13

RN Disable EAN-8

RP * Enable EAN-8

RS

Disable all EAN 2 and 5 digit supplementals

(EAN-8, EAN-13).

QY

xx

(01-99)

Enable number of scans to try to build EAN/UPC 2 and 5

digit supplementals. Maximum number of scans is 99, the

default is 15

1

1

The higher the number of tries to build the supplemental portion of the code, the longer it takes EAN/UPC labels

without supplemental code to decode.

Table 12. UPC

Command Parameter Setting

QA

Disable UPC-A (If EAN-13 = enabled, UPC-A labels will

decode as EAN-13).

QB

Enable 2 and 5 digit supplementals for UPC-A and

UPC-E

QC * Enable UPC-A

QH * Disable expansion of UPC-E to UPC-A

QI Enable expansion of UPC-E to UPC-A

QL * Enable UPC-E

QV Disable UPC-E

QX Disable all UPC 2 and 5 digit supplementals (UPC-A UPC-E)

QY

xx

(01-99)

Enable number of scans to try to build EAN/UPC 2 and 5

digit supplementals. Maximum number of scans is 99, the

default is 15

1

1

The higher the number of tries to build the supplemental portion of the code, the longer it takes EAN/UPC labels

without supplemental code to decode.

Page 26

LM520 Scanner Configuration Section 3

22 LM520 Scanner Integration & Programming Manual

Code 128

Reads variable length bar codes 1 to 50 characters.

Table 13. Code 128

Command Setting

TA Disable Code 128

TC * Enable Code 128

TD Enable function code transmission

TE * Disable function code transmission

TF Enable UCC 128 Emulation

NOTE

Code 128 function codes are transmitted as follows:

FNC1 = 80h, FNC2 = 81h, FNC3 = 82, FNC4 = 83h

FNC3 = in the first data position of a Code 128 bar code is reserved for programming labels and

no data will be transmitted to the host from a programming label.

Page 27

Section 3 LM520 Scanner Configuration

R44-2016 23

Code ISBT 128

ISBT 128 is a bar code symbology for labeling of whole blood and blood components

adopted by the International Council for Commonality in Blood Banking Automation.

(ICCBBA). Implementation of ISBT 128 requires the payment of a registration fee and an

annual license fee thereafter. Contact the ICCBBA in Durham, NC USA. Their web address

is: (http://www.ICCBBA.inter.net

)

The ISBT 128 standard allows two bar codes to be read as if they were a single bar code,

known as concatenation. The physical placement of labels that can be concatenated is done

so that a laser beam can pass completely through both labels. The information for both bar

codes is transmitted to a host computer at the same time. There are 19 different code types

in the ISBT symbology.

Table 14. ISBT Symbology

ISBT 128 Single label codes

Donation Collection Date

Donation Collection Date and Time

Manufacturer’s Identity and Container Information

Manufacture’s Lot Number

Nationally-specified Special Testing

National use

Staff Member Identification Number

Date of Production

Date and Time of Production

Donor Identification Number

Special Concatenation Programming Label

ISBT 128 Concatenation label codes

1

1

Of these, 8 types may be concatenated together in seven legal ways (see the Concatention Pairs table on following page).

Blood Groups

Data ids are ‘=‘ and ‘%’, label length is 6 data

characters including data ids.

Nationally-specified Confidential Unit Exclusion

Status.

Data ids are ‘&’ and ‘!’, variable length, nationally defined

Donation Identification Number

Data ids are ‘=‘ and x (where x is A-Z or 0-9), label length is 16

data characters including data ids.

Nationally-specified Donor Identification Number Data ids are ‘&’ and ‘;’, variable length, nationally defined

Expiration Date

Data ids are ‘=‘ and ‘>‘, label length is 8 data

characters including data ids.

Expiration Date and Time

Data ids are ‘&‘ and ‘>‘, label length is 12 data

characters including data ids.

Product Code

Data ids are ‘=‘ and ‘<‘, label length is 10 data

characters including data ids.

Nationally-specified Product Code

Data ids are ‘&’ and ‘<’, label length is, label length is 10 data

characters including data ids).

Page 28

LM520 Scanner Configuration Section 3

24 LM520 Scanner Integration & Programming Manual

The other 11 types that are not normally concatenated may be specially programmed to be

concatenated. See the specification for ISBT 128 from ICCBBA for creating specially

programmed concatenated bar codes.

Table 15. Concatenation Pairs

Normal Concatenation Pairs

Donation Identification Number & Blood Groups

Donation Identification Number & Nationally-specified Donor Identification Number

Donation Identification Number & Nationally-specified Confidential Unit

Exclusion Status

Product Code & Expiration Date

Nationally-specified Product Code & Expiration Date

Product Code & Expiration Date and Time

Nationally-specified Product Code & Expiration Date and Time

Table 16. ISBT Commands

Command Setting

TQ

Enables single label mode ISBT 128, disables concatenated label mode ISBT 128. The single label mode

will read all 19 ISBT 128 labels as single labels only (no concatenation is done).

T o read single label ISBT 128, bo th Code 128 must be enabled (TC) and single ISBT 128 mu st b e enab led

(TQ). Standard Code 128 will not read while single ISBT 128 is enabled. To disable ISBT 128, use TA

command.

TR

Enables concatenated mode ISBT 128, disables single ISBT 128. The concatenation mode will only read

the 8 types of ISBT 128 labels that are used in concatenation. See Table 14 for the 8 types of concatenation labels and Table 15 for their legal combinations with other concatenation types. The other 11 types

of ISBT labels that are not normally used in concatenation will still read as single labels. However, with

the use of a special programming label, the ot her 11 types of ISBT128 labels that ar e not norm ally concatenated may be concatenated. If they are specially programmed, they will not read as single labels. Only

one special concatenation of these other 11 type labels can be programmed at a time.

T o read concat enated ISBT 128, both Code 128 m ust be enabled (TC) an d concatenat ed ISBT 128 m ust be

enabled (TR). Standard Code 128 will not read while concatenated ISBT 128 is enabled. To disable ISBT

128, use TA command.

TS

Disables the specially programmed concatenated ISBT 128 labels, if defined. To again read specially programmed concatenated ISBT 128 labels, use TR command followed by the special programming label.

See the specification for ISBT 128 from ICCBBA for creating specially programmed concatenated

bar codes.

Page 29

Section 3 LM520 Scanner Configuration

R44-2016 25

Code 93

When Code 93 is enabled, the bar code length defaults are set to zero which allows the scanner to read Code 93 bar codes of varying lengths up to 50 characters. If the scanner will be

used for specific fixed length bar codes, use the UE and UF commands to enable these fixed

lengths.

Codabar

When Codabar is enabled, the bar code length defaults is set to zero which allows the scanner to read Codabar bar codes of varying lengths up to 50 characters. If the scanner will be

used for specific fixed length bar codes, use the VE and VF commands to enable these fixed

lengths.

Table 17. Code 93

Command Parameter Setting

UA * Disable Code 93

UB Enabled Code 93

UE

XX

(00 - 50)

Set minimum length for Code 93 to XX.

If 00 is selected, the scanner ignores the min. and max

settings.

UF

XX

(00 -50)

Set maximum length for Code 93 to XX.

Table 18. Codabar

Command Parameter Setting

VA * Disable Codabar

VB Enable Codabar

VC * Disable transmission of start/stop characters

VD Enable transmission of start/stop as upper-case characters

VE

XX

(00 - 50)

Set minimum length for Codabar to XX characters. Includes

start/stop and check characters, if transmitted.

If 00 is selected, the scanner ignores the min. and max

settings.

VF

XX

(00 - 50)

Set maximum length for Codabar to XX characters. Includes

start/stop and check characters, if transmitted.

VG Enable transmission of start/stop as lower-case characters

Page 30

LM520 Scanner Configuration Section 3

26 LM520 Scanner Integration & Programming Manual

Code 39

When Code 39 is enabled, the bar code length defaults is set to zero which allows the scanner to read Code 39 bar codes of varying lengths up to 46 characters. If the scanner will be

used for specific fixed length bar codes, use the OH and OI commands to enable these fixed

lengths.

Table 19. Code 39

Command Parameters Setting

OA Disable Code 39

OB * Enable standard Code 39

OC Enable full ASCII Code 39

OD * Disable Modulo 43 check character

OE Enable Modulo 43 check character

OF * Disable transmission of the start/stop characters

OG Enable transmission of the start/stop characters

OH

XX

(00 - 46)

Set minimum data characters to XX characters.

Includes start/stop characters and check characters, if

transmitted. If set to 00, the scanner ignores the

min/max settings.

OI

XX

(00 -46)

Set maximum data characters to XX characters.

Includes start/stop characters and check characters, if

transmitted.

OJ Enable transmission of the check character

OK * Disable transmission of the check character

Page 31

Section 3 LM520 Scanner Configuration

R44-2016 27

Interleaved 2 of 5

When Interleaved 2 of 5 is enabled, the default bar code length is fixed at 14 characters

(PD14 & PE14).

Table 20. Interleaved 2 of 5

Command Parameters Setting

PA * Disable Interleaved 2 of 5.

PB Enable Interleaved 2 of 5 without a check digit.

PC Enable Interleaved 2 of 5 with a check digit.

PD

XX

(04 - 50)

Set minimum number of data characters for Interleaved

2 of 5 to XX characters. Add check digit, if transmitted.

PE

XX

(04 - 50)

Set maximum number of data characters for Interleaved 2

of 5 to XX characters. Add check digit, if transmitted.

PO *

Disable transmission of Interleaved 2 of 5

check digit.

PP

Enable transmission of Interleaved 2 of 5

check digit.

NOTE

The total number of characters must be even. If the Check Digit is included, the number of data

characters must be odd.

Page 32

LM520 Scanner Configuration Section 3

28 LM520 Scanner Integration & Programming Manual

Standard 2 of 5

When Standard 2 of 5 is enabled, the default bar code length is fixed at 14 characters

(PT14 & PU14).

Table 21. Standard 2 of 5

Command Parameter Setting

PQ * Disable Standard 2 of 5.

PR Enable Standard 2 of 5 without a check digit.

PS Enable Standard 2 of 5 with a check digit.

PT

XX

(04 - 48)

Set minimum length for Standard 2 of 5 to XX characters.

PU

XX

(04 - 48)

Set maximum length for Standard 2 of 5 to XX characters.

PV * Disable transmission of Standard 2 of 5 check digit.

PW Enable transmission of Standard 2 of 5 check digit.

Page 33

Section 3 LM520 Scanner Configuration

R44-2016 29

Formatting Bar Code Data

Bar code data can be returned to the host as raw bar code data or additional characters may

be appended before or after the bar code data, or the bar code data may be truncated and

reformatted to meet the needs of the host. Formatting can be set to occur regardless of the

symbology of the bar code scanned or it can be specific to the symbology by applying different filters to different types of bar codes. Formatting will occur on the bar code data if it is a

single bar code, if it is a bar code with additional supplementals added (UPC/EAN), or if it

is two codes concatenated together (ISBT=128). The data returned to the host can take the

form of a Preamble, Filtered Data, and Postamble. Both the Preamble and the Postamble

apply to all bar codes regardless of symbology, and one or both can be omitted if not

required by the host.

Preamble

A preamble may be added to the beginning of bar code data transmissions to provide a sta ndard start-of-transmission character. It may also be set for up to twenty ASCII characters.

Note that the characters set as the preamble will be added to every bar code transmission for

all symbologies.

Postamble

A Postamble may be added to the end of bar code data transmissions. This is commonly

used to provide a standard end-of-transmission character, but may be set to up to twenty

ASCII characters. Note that the characters set as the Postamble will be added to every bar

code transmission for all symbologies.

Table 22. Preamble

Command Parameter Setting

KA * No preamble

KB

(Up to 20

characters)

Add the characters specified to the beginning of every data

transmission.

Table 23. Postamble

Command Parameter Setting

LA No postamble

LB *

(Up to 20

characters)

Add the characters specified to the end of every data transmission.

The default is CR, LF (0x0D hex, 0x0A hex)

Page 34

LM520 Scanner Configuration Section 3

30 LM520 Scanner Integration & Programming Manual

Filters

After the bar code is decoded, the LM520 scanner may apply a filter on the decoded data

before transmitting the data to the host. A filter is maintained for each symbology the scanner supports. All bar codes using a given symbology are processed using the filter for that

symbology. Table 24 shows examples of filters that include fill characters, edit functions and

two types of “literals,” pre-literals and post-literals.

In the following examples the bar code data contain five numeric characters: “12345.”

Table 24. Filter Examples

Filter Output Comment

%DZL7% ‘12345000’

Return left-most seven character s. Zeroes are added to

to the right of the label data to bring the total number

of characters to seven.

%DSR7% ‘ 12345’

Return right-most seven character s. Spaces are added

to the left of the label data to bring the total number of

characters to seven.

%DL3% ‘123’ Return left-most three characters of the label.

%DR4% ‘2345’ Return right-most four characters of the label.

%DM2,3% ‘234’

Return three characters of the label, starting at the

second character.

%DZLM2,3,7% ‘2340000’

1. Inner-most edit functions (M2,3): return three char-

acters of the label, starting at the second character.

Provide this data (‘234’) as in put to the ne xt inner -most

edit function.

2. Outer-most edit functions (L7): return the left-most

seven characters of the input string (‘234’). Zeroes are

added to the right of the label data to bring the total

number of characters to seven.

%DSRM2,3,7% ‘ 234’

1. Inner-most edit functions (M2,3): return three char-

acters of the label, starting at the second character.

Provide this data (‘234’) as in put to the ne xt inner -most

edit function.

2. Outer-most edit functions (R7): return the rig ht-most

seven characters of the input string (‘234’). Spaces are

added to the left of the label data to bring the total

number of characters to seven.

SCAN%D%END ‘SCAN12345END’

Return the pre-literal ‘SCAN’, the label data, and the

post-literal ‘END’.

Page 35

Section 3 LM520 Scanner Configuration

R44-2016 31

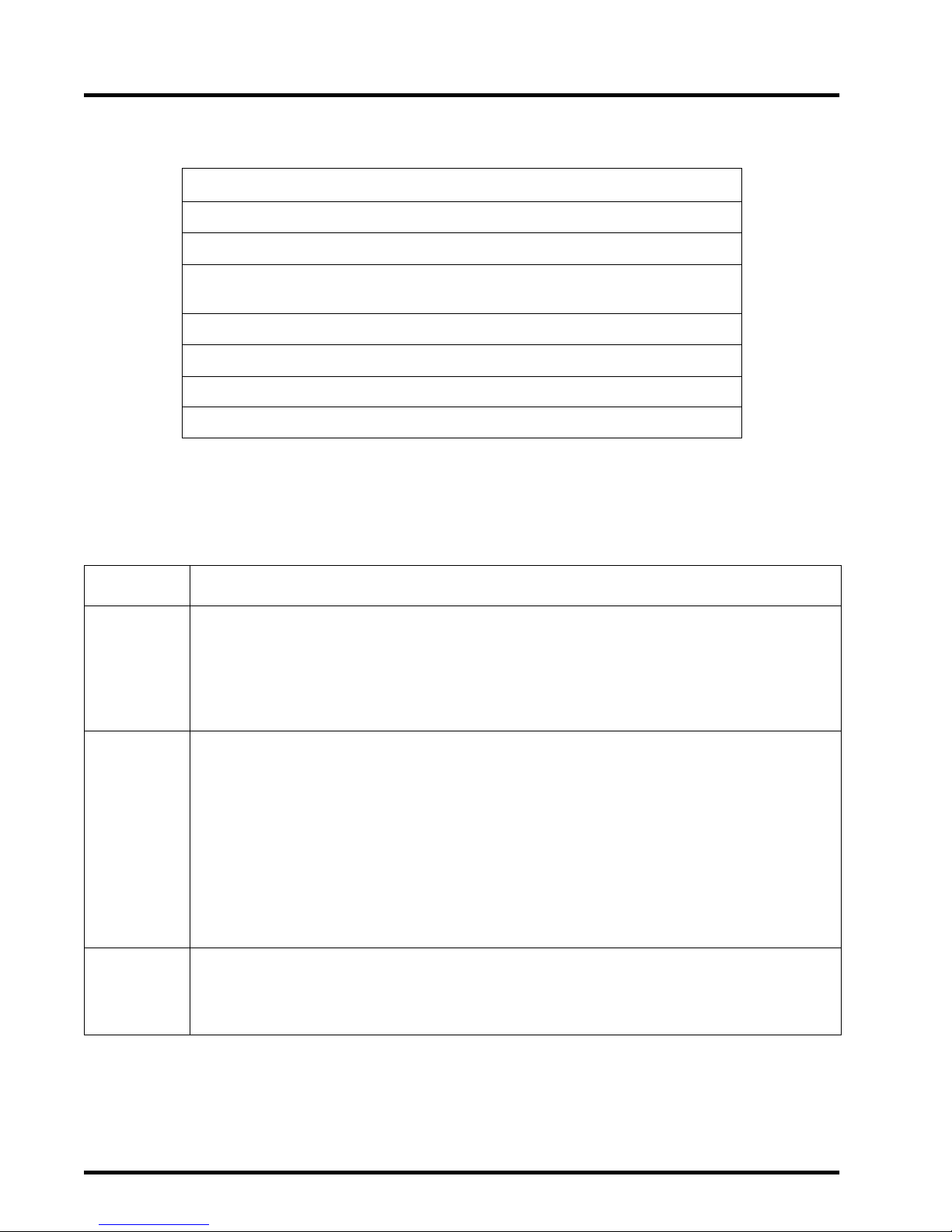

Figure 6 shows an example of fully appended bar code data that would be sent from the

scanner to the host. To set a filter for a particular symbology, use the command below. Note

that the filter must be provided as a parameter. If no filter is provided, the scanner will

return no data. To return only the bar code data a filter of %D% may be set. Reference

Table 25 for Symbology Identifiers.

Figure 6. Formatting Example

Field Descriptions

[Pre-literal] and [Post-literal] - Optional fields that specify literal characters before and after

the bar code data. These are different from a Preamble or Postamble in that they only apply

to the symbology that the filter is defined. When a filter is applied to all symbologies, preand post-literals serve the same function as a Preamble and Postamble. For example, if the

following was defined: Preamble = “123”, Postamble = “789”, Pre-literal = “ABC”, and Postliteral = “XYZ” the data returned to the host would take the format of “123ABC[bar code

data]789XYZ”.

NOTE

Filters must be bracketed by the ‘%’ character as shown in this example:

%[id]D[Pad Character][Edit Function]%

PREAMBLE | PRE-LITERAL | BARCODE DATA | POST-LITERAL | POST-AMBLE

[PRE-LITERAL]%[SYMBOLOGY ID][D][PAD CHARACTERS][EDIT FUNCTIONS]%[POST-LITERAL]

0 - 20

CHARACTERS

0 - 20

CHARACTERS

Symbology specific

filter data

[PRE-LITERAL] and [POST-LITERAL] - optional fields that specify literal characters before and after the bar code data.

[SYMBOLOGY ID] - optional field that identifies the type of bar code symbology the scanner read. When provided, the filter

contains an entry from, Symbology Identifiers Table.

[D] - optional field. If present, contains bar code data.

[PAD CHARACTERS] - optional field used to add padding characters when justifying the bar code data.

[EDIT FUNCTIONS] - optional field used to include part of the bar code data as part of the output data.

Page 36

LM520 Scanner Configuration Section 3

32 LM520 Scanner Integration & Programming Manual

The [D] parameter is an optional field containing the ASCII character D (0x44 hex). If the D

is present, bar code data (including supplemental and concatenated bar code data) will be

returned in it’s place (edited or unedited – see Edit Functions below.) If a ‘D’ is not present

in the filter, no bar code data will be sent, but any pre- or post-literal data will be sent for

that symbology.

The [symbology id] parameter is optional. When provided, the filter will output a single

character indicating the symbology of the bar code. When a symbology identifier is used, it

precedes the bar code data and informs the host of the data type that follows. For example:

If the filter for Code 39 is set to ‘%idD%’, a Code 39 bar code containing the data ‘12345’ will

be transmitted to the host as ‘a12345’. The following table lists the symbology

identifiers.

The [pad character] field is optional. It designates a character to be used as padding when

justifying the code data.

The [edit functions] parameter is an optional field that can divide the bar code data into

pieces by taking the right-most characters, left-most characters, or middle characters.

Table 25. Symbology Id ent if iers

Symbology Identifier

UPC-A ‘d’

UPC-E ‘d’

EAN-13 ‘d’

EAN-8 ‘d’

Code 39 ‘a’

ITF ‘b’

STF ‘c’

Codabar ‘h’

Code 93 ‘g’

Code 128 ‘f’

Code ISBT128 ‘f’

Page 37

Section 3 LM520 Scanner Configuration

R44-2016 33

Pad Character

Valid pad characters are N, S and Z as shown below.

Edit Function

Edit functions may be one of:

If n is larger than the number of characters in the bar code, then pad characters ar e added to

the output. The bar code data will be justified in the same position in which it appeared in

the bar code.

Edit functions may also be nested. When nested, the innermost function is processed first,

taking the bar code data as input. The ou tput of the in nerm ost functio n is passed to th e next

most-embedded function as input. However, only the outermost function will pad data

using the pad character(s).

Examples of edit strings, including nesting and the use of pad characters, are shown in

Table 26.

Table 26. Pad Characters

N Do not fill

S Pad with spaces

Z Pad with zeroes

Table 27. Edit Functions

R[s,](n)

Include the last ‘n’ characters of the output from filter ‘s’ or the

label if ‘s’ is not present.

L[s,](n)

Include the first ‘n’ characters of the output from filter ‘s’, or the

label if ‘s’ is not present.

M[s,](p,n)

Include ‘n’ characters starting at position ‘p’ of the output from

filter ‘s’ or the label if ‘s’ is not present.

Page 38

LM520 Scanner Configuration Section 3

34 LM520 Scanner Integration & Programming Manual

Setting the Bar Code Format

To set the bar code format for a particular symbology, use the following commands. Note

that the filter must be provided as a parameter. If no filter is provided, the scanner will

return no data. To return only the bar code data (including supplemental and concatenated

bar code data), a filter of %D% may be set.

For example, a complete command to set the bar code filter to return the literal ‘12’, the bar

code data, then the literal ‘34’ for UPC-A bar codes is:

FC12%D%34

The command to set the same filter for UPC-E bar codes is:

FD12%D%34

Table 28. Bar Code Format

Command Parameter Setting

FA *

Set filters for all symbologies to %D%

(bar code data only)

FB

Set filters for all symbologies that have not been specifically

set with a filter to %idD%

(symbology identifier and bar code data)

FC Filter Set filter for UPC-A bar codes

FD Filter Set filter for UPC-E bar codes

FE Filter Set filter for EAN-13 bar codes

FF Filter Set filter for EAN-8 bar codes

FG Filter Set filter for Code 39 bar codes

FH Filter Set filter for Interleaved 2 of 5 bar codes

FI Filter Set filter for Codabar bar codes

FJ Filter Set filter for Code 93 bar codes

FK Filter Set filter for Code 128 and ISBT 128 bar codes

FM Filter Set filter for Standard 2 of 5 bar codes

Page 39

Section 3 LM520 Scanner Configuration

R44-2016 35

Additional Commands

The commands in this section customize the scanner’s operation to meet your specific

system requirements.

Good Read Beeper Duration

This command controls the length of time the scanner will produce a signal on the

Beeper/Good Read line (pin 1) when a bar code is successfully decoded.

Laser Timeout

If a bar code is not read and decoded successfully within a certain period of time, the LM520

will stop scanning. The length of time the scanner remains active before timing out can be

set to between 0.1 and 9.9 seconds. This command affects hardware, software and

LaserSense triggering modes.

Table 29. Beeper Duration

Command Parameter Setting

AE

XX

(00 - 99)

Set Beeper duration to (XX * 45)ms.

The default is 135ms (XX = 03).

NOTE

Setting AE = 00 disables the Good Read Beeper.

Table 30. Laser Timeouts

Command Parameter Setting

BH

XX

(00 - 99)

Set scanning timeout to (XX * 100)ms.

+/-10%. (Default is 6 seconds XX = 60)

NOTE

A duration of zero implies infinite duration. The scanner continues to scan until:

a. a bar code is decoded

b. cancel command, DC4 (0x14 hex) is sent if using software or LaserSense triggering

c. hardware triggering is released or deasserted on the scan trigger line using hardware trig ger.

Page 40

LM520 Scanner Configuration Section 3

36 LM520 Scanner Integration & Programming Manual

Double Read Timeout

After a bar code has been successfully read, the scanner will wait for the amount of time set

using this command before it will read a bar code that contains the same bar code data.

Setting this parameter effects the scanner’s internal timing and produces no external I/O

response.

Read Verification

When the Read Verification feature is used, the LM520 will not consider a bar code to be successfully decoded until it has obtained the same results from scanning the bar code on multiple attempts. This feature is particularly useful for reading poorly printed bar codes. Since

there is a small performance penalty when this feature is enabled, it should be left disabled

unless it is needed to prevent misreads of poorly printed bar codes.

Table 31. Double Read Timeout

Command Parameter Setting

NH *

XX

(00-99)

Default is NH24 (timeout = 600ms).

Set double read prevention to XX * 25ms.

After a successful decode, the scanner will

ignore a label containing identical data for

XX * 25ms.

If set to 00, scanner returns to default

timeout = 600 ms.

Table 32. Read Verification

Command Setting

BC * Read verification disabled

BD Read verification set to two decodes

BE Read verification set to four decodes

Page 41

Section 3 LM520 Scanner Configuration

R44-2016 37

No Read Message

When no read message is enabled, the ASCII character string ‘No Read’ will be transmitted

to the host when scanning is completed without a bar code being successfully decoded.

No Read Output Signal

The LM520 No Read signal is output on pin 4 of the 9 pin DSUB connector. This signal is an

active low signal (0 V) input to a PLC (Programmable Logic Controller). The normal signal

is high (5VDC). Care must be taken no to exceed the electrical limits of this output (see

Electrical Interface). The signal is asserted (0V) when a scan results in no bar code being

decoded. There are two modes of operation available.

No Read Output Signal Mode 1

When a scanning timeout occurs or the trigger is released and no bar code was decoded, the

signal is set active (0V) and remains active until a label is successfully decoded.

No Read Output Signal Mode 2

When a scanning timeout occurs or the trigger is released and no bar code was decoded, the

signal is set active (0V) and remains active until a duration set by the timeout argument of

the enable command NKxx. After the timeout, the signal returns to 5V.

The two digit argument for NK has a valid range of 1-99 (0.1 – 9.9 sec.) In the event of

another scanning timeout occurring during the active period of the signal, the timer is reset

to 0, which extends the active period of the No Read Output Signal for the period xx.

Table 33. No Read Messa ge

Command Setting

NX No read message enabled.

NY * No read message disabled.

NOTE

The No Read message is not available if Continuous Scanning mode is enabled.

NOTE

The No Read Output Signal is deactivated and remains at 5VDC when the command is given to

disable this function.

This Function is not available in Continuous Scan mode.

Page 42

LM520 Scanner Configuration Section 3

38 LM520 Scanner Integration & Programming Manual

Diagnosti c C ommands

The LM520 scanner provides commands which allow testing of the scanner, and provide

information about the firmware in the scanner.

Good Read LED Duration

This command controls the length of time the scanner will light the Good Read LED when a

bar code is successfully decoded.

Table 34. No Read Output Mode

Command Parameter Setting

NI

Enable No Read Timeout Mode 1 and forces disable of

No Read Timeout Mode 2 [if a laser timeout occurs, the

No Read Timeout signal (pin 4) is asserted (0.0VDC)

until a decode occurs].

NJ *

Disable No Read Timeout Mode 1.

Returns signal to +5VDC.

NKxx XX = 01 - 99

Enables No Read Timeout Mode 2 and for ces disab le of

No Read Timeout Mode 1. The XX arguments following

the command characters are the length of time in

approximately 100 ms that the No Read Timeout signal

will remain 0.0VDC.

NL *

Disable No Read Timeout Mode 2.

Returns signal to +5VDC

Table 35. Diagnostic Commands

Command Settings

ZC

Display operational software version.

Scanner sends ACK followed by the data.

AG

Activate the Beeper/Good Read line (pin 1) for a single Good Read beep (as configured by B eeper Duration: AE command).

AH

Activate the internal Good Read LED for the amount of time specified by Good

Read LED duration (AF command).

Table 36. Good Read LED Duration

Command Parameter Setting

AF

XX

(00-99)

Set Good Read LED duration to XX * 45ms.

The default is 135ms (XX = 03).

Page 43

R44-2016 A-1

Appendix A:Technical Specifications

Table A-1. Performance Specifications

Parameter Specification

Scan Rate 42 scans/second ± 10% (bi-directional)

Scan Angle 46° nominal, ±2.0°

Vertical Beam Pointing 0° nominal, ±2.0° (relative to mounting surface)

Horizontal Beam Pointing

88.3° nominal, ±4° (toward right from engine perspective, relative to

engine front face)

Vertical Beam Exit Position See Appendix B

Horizontal Beam Exit Position See Appendix B

Usable Scan Line Length

l = [(d+0.88 inches) x 2 x tan q]0.8

or

l = [(d+2.34 cm) x 2 x tan q]0.8

where

l = usable line length

d = distance from the front of scanner

q = half of the scan angle, (23° +/- 2°)

Depth of Field

The minimum depth of field ov er which a print quality UPCA label (10 mil,

13 mil) or C39 label (all others) with given minimum element width can

be read.

Code Size Depth of Field

5 mils 2.5 – 4.25“

7.5 mils 2.0 – 7.25“

10 mils 1.5 – 10.25“

13 mils 1.5 – 14.25“

20 mils* * -- 20.0“

55 mils* * -- 36.0“

Start-Up Time 100ms from power on (mirror at rest) to >90% of full deflection scanning.

Skew Tolerance

< ± 55° from normal. Measured 7” (127 mm) from the front of the module

on 20 mil paper code.

Pitch Angle