Page 1

I

O

1

2

3

4

5

6

TG125/E

Manual

Page 2

1

2

3

4

5

6

12

I

O

8

7

13

10

1

2

3

4

5

6

I

O

1

2

3

4

5

6

I

O

Fig. 1

Fig. 2

Fig. 3

-4-

5

1

2

3

4

5

6

I

O

Fig. 4

Page 3

-5-

1

2

3

4

5

6

I

O

1

2

I

O

1

2

3

4

5

6

1

2

3

4

5

6

I

O

31

45°

40°

35°

30°

25°

20°

15°

10°

5°

0°

2

4

Fig. 5

Fig. 7

2

1

3

4

Fig. 6

Page 4

-11-

Translation of the Original Operating

Instructions TG 125/E disc grinding

machine

Contents:

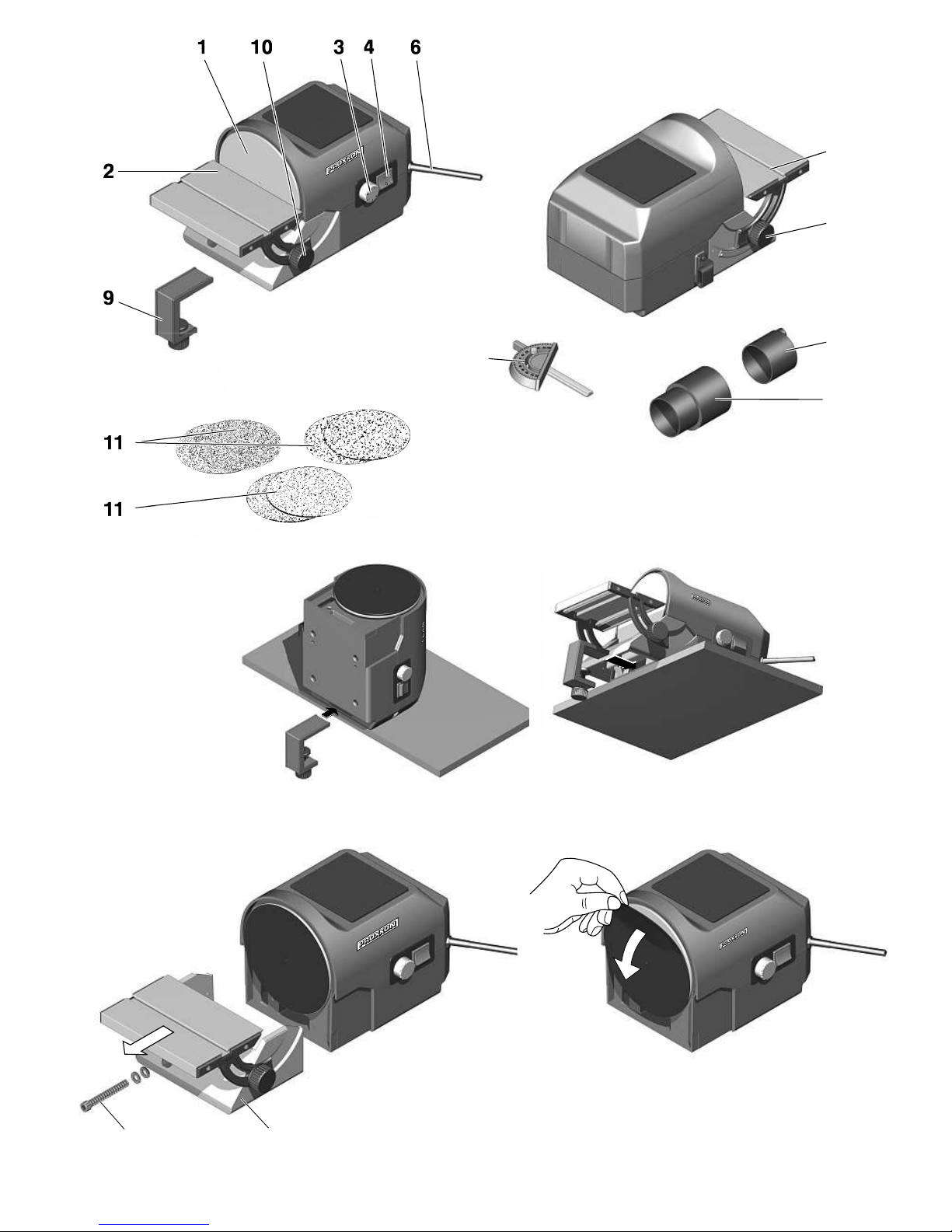

1General view (fig. 1) 11

2Description of the machine 12

3Scope of delivery 12

4Technical data 12

5Beforework 12

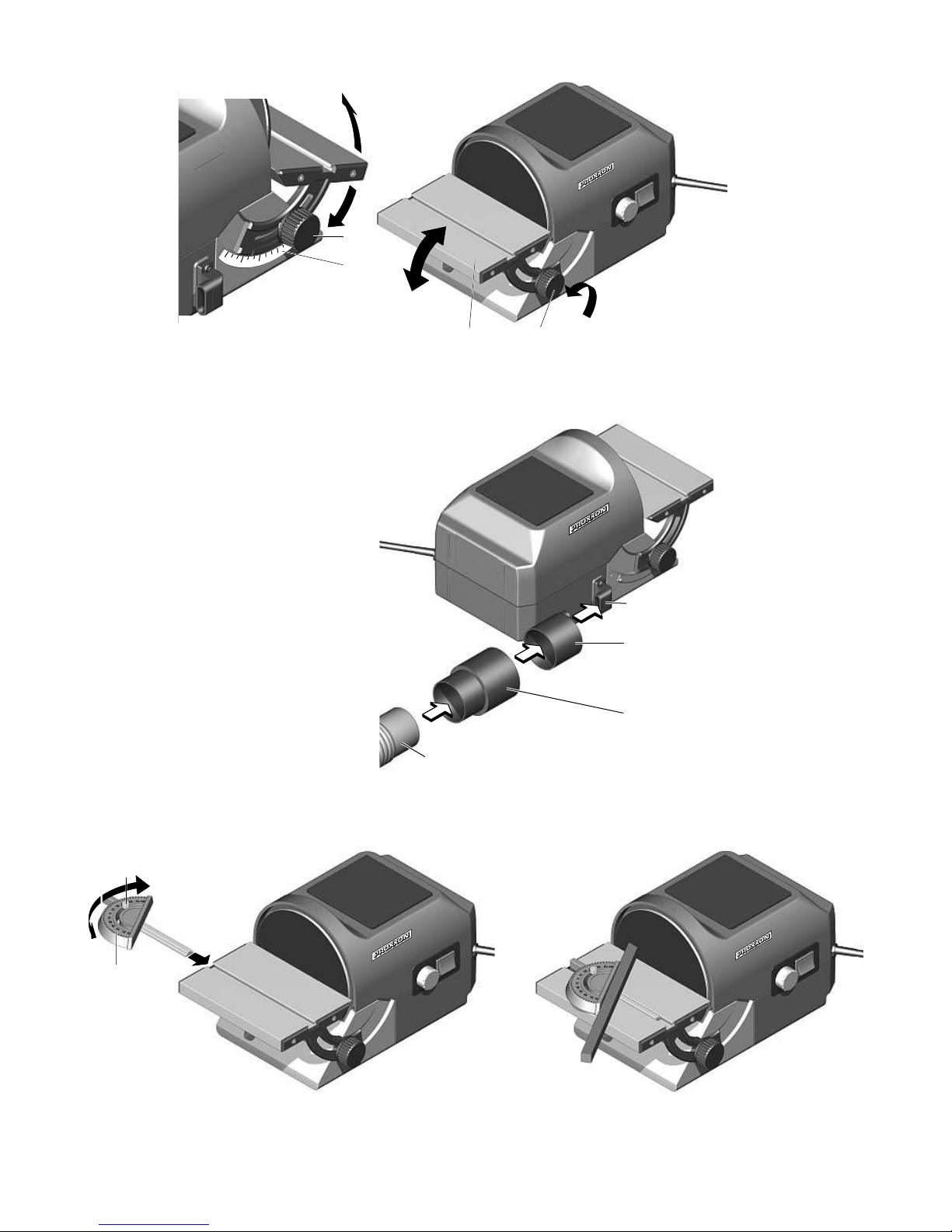

5.1 Setting up your disc grinding machine

(fig. 2): 12

5.2 Removing and inserting the grinding

table (fig.3): 13

5.3 Affixing and replacing grinding wheels

(fig. 4): 13

5.4 Adjusting the grinding table angle

(fig. 5): 13

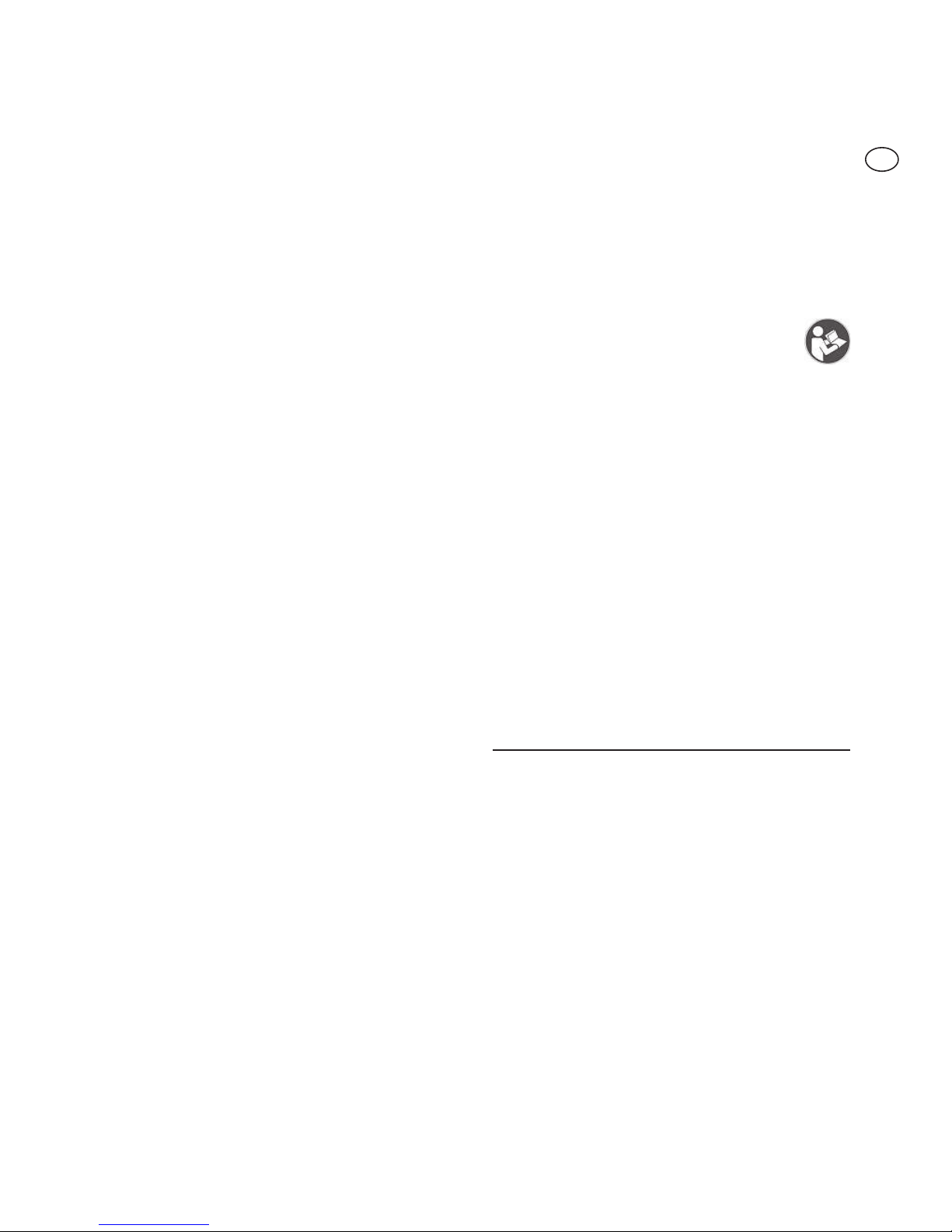

5.5 Connecting the dust exhaust

(fig. 6): 14

6Working with the TG 125/E disc

grinding machine 14

6.1 Working with the angle stop (fig. 7): 14

6.2 Notes on grinding speed 14

7Careand maintenance 15

8Disposal 15

9CEconformity declaration 15

Dear customer!

Using these instructions

•makes it easier to get familiar with the device

•prevents malfunctions caused by improper

handling, and

•lengthens the service life of your device.

Please keep these instructions readily accessible at all times.

Use the device only when you have understood

it exactly and always adheretothe instructions.

PROXXON is not liable for the safe functioning

of the device in cases of:

•handling that does not conform to the usual

usage,

•purposes of use not designated in the

instructions,

•disregardofthe safety instructions.

Youare not entitled to guarantee claims in

cases of:

•operator errors,

•inadequate maintenance.

For your own safety,please follow the safety

instructions exactly.

Use only genuine PROXXON replacement parts.

We reserve the right to make improvements in

the sense of technical progress. We wish you

much success with the device.

WARNING!

Read all safety warnings and

instructions. Failuretofollow all safety

warnings and instructions listed below may

result in electric shock, fireand/or serious injury.

KEEP ALL SAFETY WARNINGS AND

INSTRUCTIONS FOR THE FUTURE!

Do not use damaged bits and cutters.Before

each use, inspect bits and cutters such as

sanding discs for chips and cracks, grinding

discs for cracks, strong wear or tear.After

you have inspected and installed the bits and

cutters, keep yourself and any other persons

in the vicinity away from the plane of the

rotating bits and cutters and run the device

at maximum rotational speed for one minute.

Damaged bits and cutters usually break during

this test time.

1General view (fig. 1)

1. Grinding disc

2. Swivel-mountedgrinding table

3. Rotary knob for speed control

4. On-offswitch

5. Angle stop

6. Mains cable

7. Connecting piece

8. Guide slot for angle stop

9. Clamp

10. Locking button for angle adjustment

11. Grinding discs

13. Rubber connector

GB

Page 5

2Description of the machine

Thank you for purchasing the TG 125/E disc

grinding machine. Younow own ahigh-precision machine to use in grinding work for which

complete accuracy is required.

Ahigh-precision manufactured and carefully

balanced grinding disc with double ball-bearing

direct drive guarantees excellent smoothness,

precision concentricity and minimum wear.

In this way,soft and hardwoods, plates, nonferrous metal or steel, even plastic, cork, rubber

and many further materials can be processed

with high precision at grinding speeds of

approx. 250-800 m/min (adjustable).

The various fixing possibilities ensureparticular

flexibility: Your TG 125/E can be operated both

in "normal position" and in standing, with the

grinding table removed. To this end, it is fixed

with the enclosed clamp.

The grinding table is made of high-grade aluminium and can be adjusted upwards by 10°

and downwards by 50°. This also includes the

guide slot for the angle stop that is also

included in the scope of delivery.

Twogrinding wheels in each of the grain sizes

offered of 80, 150 and 240 areincluded in the

scope of delivery.

In order that the swarf goes directly whereit

should, namely into the vacuum cleaner,thereis

aconnecting piece to which the vacuum cleaner

can be connected. So you areoptimally

equipped for the grinding work.

3Scope of delivery

1x TG 125/E disc grinding machine

1x Angle stop

1x Connecting piece

1x Rubber connector

2x Grinding wheels grain 80

2x Grinding wheels grain 150

2x Grinding wheels grain 240

1x Operating instructions

1x Brochurewith safety instructions

1x Vice

4Technical data

Dimensions and weights:

Length: approx. 300 mm

Width: approx. 140 mm

Height: approx. 160 mm

Weight: approx. 3kg

ØGrinding disc: 125 mm

Dimensionsgrinding table: 98 x140 mm

Motor:

Voltage: 230 volt,

50/60 Hz

Power input: 140 watt

KB 15 min

Speed: max. 3600 rpm

Grinding speed: approx. 250-800 rpm

Noise development: <55dB(A)

Vibration: ≤ 2,5 m/ s

2

Only in dry rooms

Please do not dispose of this electrical

machine in the household refuse!

Wear safety glasses!

5Beforework

5.1 Setting up your disc grinding

machine (fig. 2):

Note:

When setting up the machine,make surethat

the ground below it is level and secure! Asecure

stand is indispensable for working with the

machine!

Note:

When setting up and fixing the machine, always

disconnect the mains plug to prevent the disc

being started up accidentally. Risk of injury!

Caution:

During all adjusting and assemblywork, such as

when adjusting the angle stop or when attaching or removing the grinding table, disconnect

the mains plug to prevent the device from starting up unintentionally!

-12-

Page 6

-13-

The disc grinding machine can be operated in

two different positions: Once in the normal horizontal position or standing vertically (for sharpening tools and blades for example).

In both positions, the machine should be

securely clamped with the enclosed vice, as

shown in fig. 2.

5.2 Removing and inserting the grinding

table (fig.3):

Caution:

Before removingand inserting the grinding table,

always disconnect the mains plug to prevent the

disc being started up accidentally.Risk of injury!

Normally,your TG 125/E is operated with the

attached grinding table (as in delivery condition). Additionally,thereisalso the possibility,

whererequired, of removing the grinding table,

if this is necessary for certain tasks or for

changing the grinding wheels.

Caution:

Please note that when working particularly in

the operating mode without the grinding table,

always make suretocontrol the work piece by

holding it firmly and securely in order to prevent

it from being flung about.

Use the machine in the horizontal position with

attached grinding table, if possible!

1. Remove Allen head screw 1

2. Remove the grinding table with grinding

table holder 2bypulling out from the front

3. To insert, simply push into the normal

position

4. Turn in Allen head screw 1again

Caution:

If the grinding disc is blocked due to awork

piece that is jammed between the grinding disc

and the grinding table, immediatelyshut offthe

device using the On/Offswitch and disconnect

the mains plug. Only put the device back into

operation after the jammed work piece has

been removed!

5.3 Affixing and replacing grinding

wheels (fig. 4):

Note:

Beforeaffixing or replacing the grinding wheels,

always disconnect the mains plug to prevent the

disc being started up accidentally.Risk of injury!

Twogrinding wheels in each of the grain sizes

80, 150 and 240 aresupplied as initial equipment with your disc grinding machine; these

can also be easily obtained as spareparts. It is

thereforenoproblem to change wheels,

whether because of wear or because discs with

various grain sizes arerequired when working.

Caution:

When replacing the wheels, it is advisable to

remove the grinding table as described in the

previous section!

1. Remove the rear protective foil above the

adhesive surface from the desired wheel,

2. Push the wheel evenly and bubble-free onto

the grinding disc.

3. To replace, simply remove the grinding wheel

again and push on the new wheel.

5.4 Adjusting the grinding table angle

(fig. 5):

Caution:

Beforeadjusting the grinding table, always disconnect the mains plug to prevent the disc

being started up accidentally.Risk of injury!

1. Loosen rotary knob 1Atthe same hold rotary

knob 2

2. Swing grinding table 3into the desired angle

position and check the set value on angle

scale 4.

3. Tighten rotary knob 1. At the same hold

rotary knob 2

Page 7

5.5 Connecting the dust exhaust

(fig. 6):

Caution:

Beforeconnecting the dust exhaust, always disconnect the mains plug to prevent the disc

being started up accidentally.Risk of injury!

It is recommended to always work with the dust

exhaust! This not only guarantees clean working, it also reduces the hazardous effect of

some dusts!

1. Push adapter piece 1onto connecting piece

2ofthe machine

2. Push rubber adapter 3onto adapter piece 1

3. Insert vacuum cleaner nozzle 4into rubber

adapter 3

4. Switch on vacuum cleaner when working

Another small tip:

When using the Proxxon CW-matic vacuum

cleaner,manual switching on and offisno

longer necessary.The CW-matic is fitted with

an automatic control device; it automatically

switches on and offwhen the power tool is

switched on and off. The same effect can be

obtained with traditional vacuum cleaners by

using our vacuum control device.

6Working with the TG 125/E disc

grinding machine

Caution:

Please note that the grinding disc turns to the

left! If you use the left side when working with

the attached grinding table, the work piece can

be guided easily and securely,thus effectively

preventing it from being hurled away!

Caution:

When grinding metallic work pieces, such as

when grinding knife blades for example, or

when grinding stone or ceramics the material to

be ground can become very hot! Do not hold

the material to be ground near the grinding surface in order to avoid burns!

Caution:

Wear suitable gloves to avoid abrasions especially when working with coarse sandpaper and

when processing smaller work pieces!

1. If mitres aretobeground, adjust the grinding

angle as described above

2. Insert the mains plug

3. Switch on the machine at On-Off-Switch

4. Set the required speed on the speed control

button (pos. 3, fig. 1)

Please adjust the size of the work piece to the

size of the machine! Awork piece that is too

large and too heavy can overburden the drive or

the construction of the machine and cause

damage or injuries!

6.1 Working with the angle stop (fig. 7):

If, for example, the ends of somewhat thinner

strips areground for mitre, it is advantageous to

use the angle stop included in the scope of

delivery.

1. Loosen knurled screw 1

2. Set the desired angle on scale 2

3. Turn the knurled screw tightly and insert into

the intended table groove

4. Guide the desired workpiece up to the stop

against the grinding wheel as shown in the

illustration

6.2 Notes on grinding speed

The grinding speed of your TG 125/E is infinitely

adjustable from approx. 250 –800 m/min. In

this way,optimal adaptation to various material

conditions is possible. Please note that the circumferential speed of the grinding disc is greatest at the edge and reduces towards the middle.

General recommendations on the selection of

the grinding speed aredifficult; it may be necessary to experiment somewhat to find out the

correct grinding speed for "its" material and

workpiece.

Based on experience, non-ferrous metals and

plastic requirelower grinding speeds than soft

and hardwood; this also applies for ceramics

and glass.

-14-

Page 8

-15-

But as stated: Recommendations aredifficult,

the correct speed depends on the material, contact pressureand friction and grain size of the

grinding wheels.

7Careand maintenance

Caution:

Beforecleaning, adjusting, service or repair,disconnect the mains plug!

Note:

The machine is largely maintenance free. To

ensurealong service life, however,the machine

should be cleaned with asoft cloth, handbrush

or paintbrush after each time it is used. Avacuum cleaner is also recommended here. Avacuum cleaner should always be used during

work!

The outside of the housing can be cleaned with

asoft, possibly damp cloth. In this process, mild

soap or another suitable cleaning agent can be

used. Solvents or cleaning agents containing

alcohol (e.g. petrol, cleaning alcohols etc.)

should be avoided, since these can attack the

plastic cases.

8Disposal

Please do not dispose of this machine in household refuse! The machine contains materials

that can be recycled. If you have any questions

about his, please contact your local recycling

company or other relevant communal facilities.

9ECDeclaration of Conformity

Name and address:

PROXXON S.A.

6-10, Härebierg

L-6868 Wecker

Product designation: TG 125/E

Article No.: 27060

In sole responsibility,wedeclarethat this

product conforms to the following directives

and normative documents:

EU EMC Directive 2014/30/EC

DIN EN 55014-1/05.2012

DIN EN 55014-2/02.2016

DIN EN 61000-3-2/03.2015

DIN EN 61000-3-3/03.2014

EU Machinery Directive 2006/42/EC

DIN EN 62841-1/07.2016

DIN EN 62841-3-4/12.2016

Date: 07.12.2016

Dipl.-Ing. JörgWagner

PROXXON S.A.

Machine Safety Department

The CE document authorized agent is identical

with the signatory.

Page 9

-66-

G 125/E Art. 27060

27060 - 0

27060 - 0

27060 - 0

27060 - 0

27060 - 0

27060 - 0

27060 - 0

27060 - 0

27060 - 1

27060 - 1

27060 - 1

27060 - 1

27060 - 1

27060 - 1

27060 - 1

27060 - 1

27060 - 1

27060 - 1

27060 - 2

27060 - 2

27060 - 2

27060 - 2

27060 - 2

27060 - 2

27060 - 2

27060 - 2

27060 - 3

27060 - 3

27060 - 3

27060 - 3

27060 - 3

27060 - 3

27060 - 3

27060 - 3

27060 - 3

27060 - 4

27060 - 4

27060 - 4

27060 - 4

27060 - 4

27060 - 4

27060 - 4

27060 - 4

27060 - 4

27060 - 9

Page 10

-67-

Page 11

GB Service note

All PROXXON products are thoroughly inspected after production.Should adefect

occur nevertheless, please contact the dealer from whom you purchased the

product. Only the dealer is responsible for handling all legal warranty claims

which refer exclusively to material and manufacturer error.

Improper use, such as capacityoverload, damage due to outside influences

and normal wear are excluded from the warranty.

You will find further notes regarding "Service and Spare Parts Management" at

www.proxxon.com.

Art. Nr.27060-99 PR 712716706 J

Loading...

Loading...