Page 1

ProxxonTools.com

230 V

3 V

A

3 V

A

döjfk

dgj

sdgbjd

sg

j döfjdk

gfjk

d

lfida dlg

,dl

g

d

dgfd

l fg

12 V

A

12 V

A

12 V

A

- 2 -

Manual

DELTA SANDER OZI 115/E

Page 2

- 2 -

Page 3

PROXXON - OZI 115/E

Dear Customer,

Before putting the machine into ope-

ration, read the enclosed safety rules

and operating instructions.

GENERAL SAFETY RULES

Warning! Read and understand all

instructions. Failure to follow all

instructions listed below, may result

in electric shock, fire and/or serious

personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and

well lit. Cluttered benches and dark

areas invite accidents.

Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases, or dust. Power tools create

sparks which may ignite the dust or

fumes.

Keep bystanders, children, and

visitors away while operating a

power tool. Distractions can cause

you to lose control.

Electrical Safety

Double Insulated tools are equip-

ped with a polarized plug (one

blade is wider than the other.) This

plug will fit in a polarized outlet

only one way. If the plug does not

fit fully in the outlet, reverse the

plug. If it still does not fit, contact

a qualified electrician to install a

polarized outlet. Do not change the

plug in any way.

- 3 -

- 4 - 9

230 V

3 VA

3 VA

döjfk

dgj

sdgbjd

sg

j dö

fjdkgfjk

dl

fida

dlg,d

lg d

dgfdl

fg

12 VA

12 VA

12 VA

2

1

3

4

6

7

5

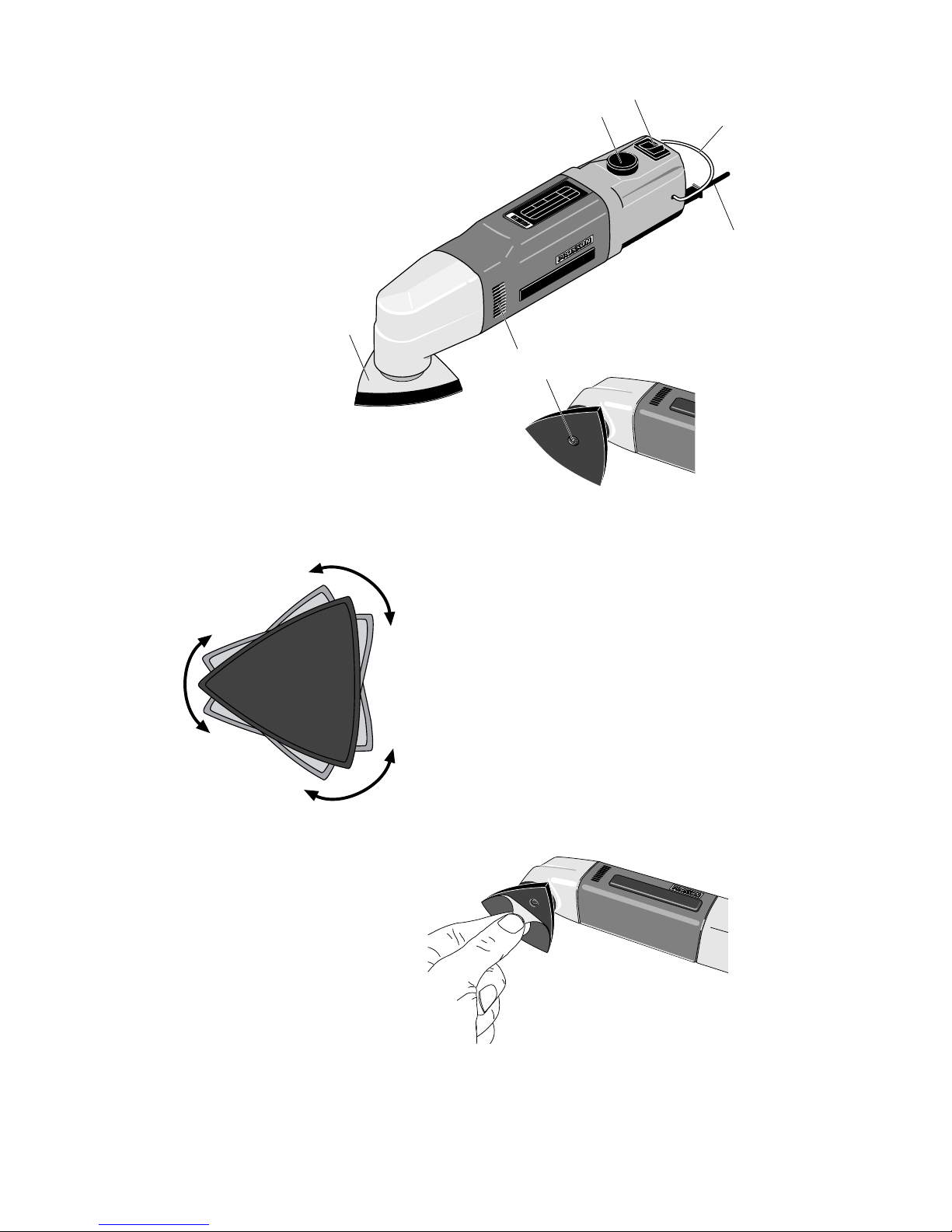

Fig. 3

Fig. 2

Fig. 1

Page 4

PROXXON - OZI 115/E

Dear Customer,

Before putting the machine into operation, read the enclosed safety rules

and operating instructions.

GENERAL SAFETY RULES

Warning! Read and understand all

instructions. Failure to follow all

instructions listed below, may result

in electric shock, fire and/or serious

personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and

well lit. Cluttered benches and dark

areas invite accidents.

Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases, or dust. Power tools create

sparks which may ignite the dust or

fumes.

Keep bystanders, children, and

visitors away while operating a

power tool. Distractions can cause

you to lose control.

Electrical Safety

Double Insulated tools are equip-

ped with a polarized plug (one

blade is wider than the other.) This

plug will fit in a polarized outlet

only one way. If the plug does not

fit fully in the outlet, reverse the

plug. If it still does not fit, contact

a qualified electrician to install a

polarized outlet. Do not change the

plug in any way.

Double Insulation eliminates the

need for the three wire grounded

power cord and grounded power

supply system.

Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges and refrigerators. There is

an increased risk of electric shock if

your body is grounded.

Do not expose power tools to rain

or wet conditions. Water entering a

power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use

the cord to carry the tools or pull

the plug from an outlet. Keep cord

away from heat, oil, sharp edges

or moving parts. Replace damaged

cords immediately. Damaged cords

increase the risk of electric shock.

When operating a power tool outside, use an outdoor extension

cord marked "W-A" or "W." These

cords are rated for outdoor use and

reduce the risk of electric shock.

Personal Safety

Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use tool while tired or under

the influence of drugs, alcohol, or

medication. A moment of inattention

while operating power tools may

result in serious personal injury.

- 4 - 9

1

2

3

4

5

6

7

8

9

10

11

Schematics for OZI 115/E

Page 5

- 5 -

Dress properly. Do not wear loose

clothing or jewelry. Contain long

hair. Keep your hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts.

Avoid accidental starting. Be sure

switch is off before plugging in.

Carrying tools with your finger on the

switch or plugging in tools that have

the switch on invites accidents.

Remove adjusting keys or

wrenches before turning the tool

on. A wrench or a key that is left

attached to a rotating part of the tool

may result in personal injury.

Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables

better control of the tool in unexpected situations.

Use safety equipment. Always wear

eye protection. Dust mask, non-skid

safety shoes, hard hat, or hearing protection must be used for appropriate

conditions.

Tool Use and Care

Use clamps or other practical way

to secure and support the workpiece to a stable platform. Holding

the work by hand or against your

body is unstable and may lead to loss

of control.

Do not force tool. Use the correct

tool for your application. The correct

tool will do the job better and safer at

the rate for which it is designed.

Do not use tool, if switch does not

turn it on or off. Any tool that cannot

be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power

source before making any adjustments, changing accessories, or

storing the tool. Such preventive

safety measures reduce the risk of

starting the tool accidentally.

Store idle tools out of reach of

children and other untrained

persons. Tools are dangerous in the

hands of untrained users.

Maintain tools with care. Keep

cutting tools sharp and clean.

Properly maintained tools, with sharp

cutting edges are less likely to bind

and are easier to control.

Check for misalignment or binding

of moving parts, breakage of parts,

and any other condition that may

affect the tools operation. If damaged, have the tool serviced before

using. Many accidents are caused by

poorly maintained tools.

Use only accessories that are

recommended by the manufacturer

for your model.

Accessories that may be suitable for

one tool, may become hazardous

when used on another tool.

SERVICE

Tool service must be performed

only by qualified repair personnel.

Service or maintenance performed by

unqualified personnel could result in a

risk of injury.

When servicing a tool, use only

identical replacement parts. Follow

instructions in the Maintenance

section of this manual. Use of

unauthorized parts or failure to follow

Maintenance Instructions may create

a risk of electric shock or injury.

SPECIFIC SAFETY RULES

Hold tool by insulated gripping

surfaces when performing an

operation where the cutting tool

may contact hidden wiring or its

own cord. Contact with a „live“ wire

will make exposed metal parts of the

tool „live“ and shock the operator.

Some material may produce harmful

or toxic dust (i. e. lead containing

paint,some kinds of wood or metal)

Page 6

Symbols

Important: Some of the following symbols may be used on your tool. Please study

them and learn their meaning. Proper interpretation of these symbols will allow you

to operate the tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Ø Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

…/min Revolutions or reciprocation Revolutions, strokes, surface

per minute speed, orbits etc. per minute

1, 2, 3, … Selector settings Speed, torque or position settings.

Higher number means greater speed

Infinitely variable selector Speed is increasing from narrow end

➞ Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

- 6 -

Operating Instructions

Legend

1. Grinding shoe

2. Screw

3. Speed control button

4. ON/OFF switch

5. Hoop

6. Mains supply cable

7. Ventilation slots

Machine description

The PROXXON Detail Sander

MICROMOT OZI 115/E is ideal for

grinding difficult-to-reach areas, such

as corners, edges, joints and cavities.

Thanks to the oscillating grinding plate

(Fig. 2), better grinding results are

achieved than are possible using

Detail Sanders that operate with

eccentric action. Additional attach-

ments can be fitted, such as circular

saw blades or diamond cutting blades

to disaggregate the most disparate

materials in inaccessible areas.

This machine features:

• Housing crown made of diecast

aluminium for precision ball bearing

fit and increased durability under

extreme loads.

• Quiet-running, enclosed ventilated

full-wave electronic motor.

• Grinding shoe with velcro facing for

quick replacement of grinding pads.

Technical data

Motor:

Voltage ~ 115 V

Power:

1

/8 hp (100 Watt)

Speed 3,000 to 10,000/min

Page 7

- 7 -

Weight approx. 1,7 lb (780 g)

Characteristic noise

emission 74 dB(A)

Noise level may exceed

85 dB(A) during operation.

Ear protection must be worn!

Vibration at handle < 2.5 m/s

2

Double insulated tool

Proper handling of the machine

Replacing grinding pads

1. Hold grinding pad at one corner

(Fig. 3) to remove.

2. Place new grinding pad on grinding

shoe to fit, and then press on firmly.

Note:

Replace dull grinding pads promptly.

To make optimal use of individual

grinding pads, offset pads at 120°

after each use.

Removing, installing and rotating

grinding shoe

It may be necessary to rotate the

grinding shoe to access hard to-reach

areas.

Impor

tant:

Unplug machine before replacing or

turning shoe!

1. Remove grinding pad (Fig. 3)

2. Detach screw 2 (Fig. 1) using Allen

wrench. In the event that screw is

jammed, exert load moment

against grinding shoe to avoid

unnecessary mechanical stress.

3. Replace grinding shoe, or rotate to

desired position.

4. Re-tighten screw without exceeding

tightening torque of 5 Nm.

Impor

tant!

Always ensure that only suitable

attachments are used. Always

observe the relevant safety

precautions.

Operating the machine

Important!

Always wear protective goggles when

operating the machine.

1. Switch on machine at switch 4

(Fig. 1) and set the appropriate

speed at button 3.

Note:

For optimal grinding, apply requisite

uniform speed. Applying excessive

pressure does not achieve improved

grinding results and increases heat

build-up.

2. When holding machine, do not

cover ventilation slots 7 (Fig. 1).

Note:

In the event that machine overheats,

switch it off immediately and allow to

cool.

Care and maintenance

Impor

tant!

Unplug machine prior to maintenance!

Always ensure that ventilation slots

remain unobstructed.

Check power supply cable at regular

intervals for damage. In the event that

cable is damaged, have a qualified

technician replace it.

The power cord shall be replaced by

part no. 38520-32 only, if the cord is

damaged.

Accessoires

For safe operation, it is recommended

that only PROXXON-accessories be

used with this product, i. e. the

following:

Sanding pads 28880: (80grit-5sheets)

Sanding pads 28882: (150grit-5sheets

Sanding pads 28886: (280grit-5sheets)

Polishing set: 28888

Loading...

Loading...