Page 1

ProxxonTools.com

90

8

0

70

60

5

0

4

0

30

20

1

0

0

1

0

20

30

4

0

5

0

60

70

8

0

9

0

m

a

x

.

Z

ustell

u

ng

mm

B

r

ei

t

e

B

u

c

he

E

r

le

Pa

ppel

Ba

l

s

a

20

0

,

5

0

,

8

0

,

8

0

,

8

4

0

0

,

3

0

,

6

0

,

8

0

,

8

60

0

,

2

0

,

2

0

,

3

0

,

8

8

0

0

,

1

0

,

1

0

,

2

0

,

6

U

=

230

V~

5

0/60

H

z

P

=

200

W

KB

15

n

M

e

ss

e

rw

elle

=

6

.

000/

min

B

r

ei

t

e

m

a

x

=

8

0

mm

MT

300

MICRO Shaper MT 300

Manual

Page 2

- 3 -

9

0

8

0

70

60

5

0

4

0

30

20

1

0

0

1

0

20

30

4

0

5

0

60

70

8

0

9

0

4

7

3

9

1

5

13

2

12

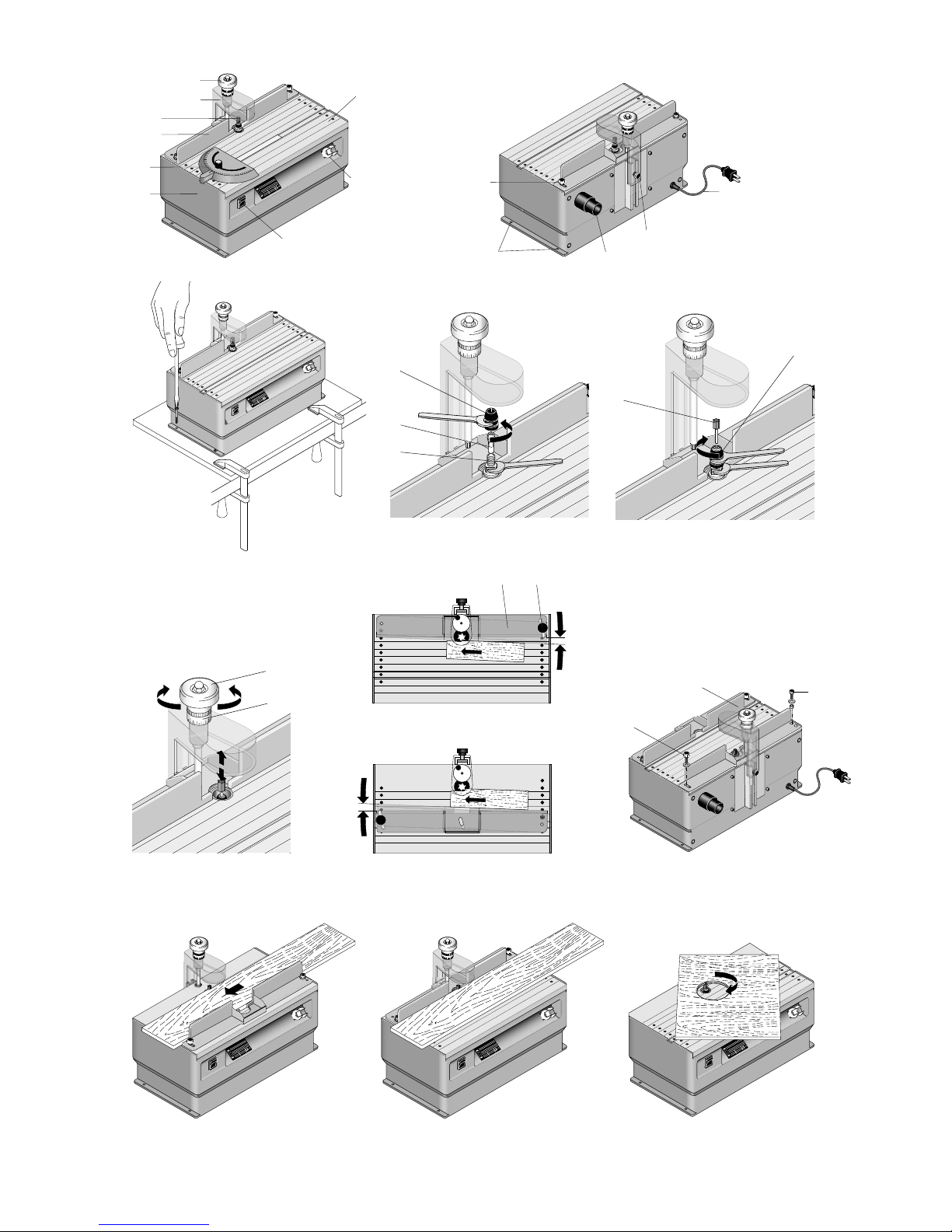

Fig 1

m

a

x

.

Z

ust

ell

u

ng

mm

B

r

ei

t

e

B

u

c

he

E

r

le

Pa

ppel

Ba

l

s

a

20

0

,

5

0

,

8

0

,

8

0

,

8

4

0

0

,

3

0

,

6

0

,

8

0

,

8

60

0

,

2

0

,

2

0

,

3

0

,

8

8

0

0

,

1

0

,

1

0

,

2

0

,

6

U=

230

V~

5

0/60

H

z

P

=

200

W

KB

15

n

M

e

ss

e

rw

elle

=

6

.

000/

min

B

r

ei

t

e

m

a

x

=

8

0

mm

MT

300

6

14

8

11

10

m

a

x

.

Z

ust

ell

u

ng

mm

B

r

ei

t

e

B

u

c

he

E

r

le

Pa

ppel

Ba

l

s

a

20

0

,

5

0

,

8

0

,

8

0

,

8

4

0

0

,

3

0

,

6

0

,

8

0

,

8

60

0

,

2

0

,

2

0

,

3

0

,

8

8

0

0

,

1

0

,

1

0

,

2

0

,

6

U=

230

V~

5

0/60

H

z

P

=

200

W

KB

15

n

M

e

ss

e

rw

elle

=

6

.

000/

min

B

r

ei

t

e

m

a

x

=

8

0

mm

MT

300

3

2

1

2

4

1

2

m

a

x

.

Z

ust

ell

u

ng

mm

B

r

ei

t

e

B

u

c

he

E

r

le

Pa

ppel

Ba

l

s

a

20

0

,

5

0

,

8

0

,

8

0

,

8

4

0

0

,

3

0

,

6

0

,

8

0

,

8

60

0

,

2

0

,

2

0

,

3

0

,

8

8

0

0

,

1

0

,

1

0

,

2

0

,

6

U=

230

V~

5

0/60

H

z

P

=

200

W

KB

15

n

M

e

ss

e

rw

elle

=

6

.

000/

min

B

r

ei

t

e

m

a

x

=

8

0

mm

MT

300

m

a

x

.

Z

ust

ell

u

ng

mm

B

r

ei

t

e

B

u

c

he

E

r

le

Pa

ppel

Ba

l

s

a

20

0

,

5

0

,

8

0

,

8

0

,

8

4

0

0

,

3

0

,

6

0

,

8

0

,

8

60

0

,

2

0

,

2

0

,

3

0

,

8

8

0

0

,

1

0

,

1

0

,

2

0

,

6

U=

230

V~

5

0/60

H

z

P

=

200

W

KB

15

n

M

e

ss

e

rw

elle

=

6

.

000/

min

B

r

ei

t

e

m

a

x

=

8

0

mm

MT

300

m

a

x

.

Z

ust

ell

u

ng

mm

B

r

ei

t

e

B

u

c

he

E

r

le

Pa

ppel

Ba

l

s

a

20

0

,

5

0

,

8

0

,

8

0

,

8

4

0

0

,

3

0

,

6

0

,

8

0

,

8

60

0

,

2

0

,

2

0

,

3

0

,

8

8

0

0

,

1

0

,

1

0

,

2

0

,

6

U=

230

V~

5

0/60

H

z

P

=

200

W

KB

15

n

M

e

ss

e

rw

elle

=

6

.

000/

min

B

r

ei

t

e

m

a

x

=

8

0

mm

MT

300

1

2

3

Fig. 1 Fig. 1

Fig. 2

Fig. 4

Fig. 7a Fig. 7b Fig. 7c

Fig. 6

Fig. 3a Fig. 3b

Fig 5a

2 1

Fig. 5b

Fig. 5a

Page 3

- 4 -

Operating Instructions

MT 300

Instructions for the use of the MICRO Shaper

MT 300:

Dear Customer,

In order to be able to operate the shaper safely and

correctly, please carefully read the following safety and

operating instructions prior to use.

This instruction manual covers:

• safety regulations

• operation and maintenance

• spare parts list

Please read carefully and become familiar with this

entire instructions manual. Learn the tool´s applications,

limitations and possible hazards.

Using this instruction manual will

• make it easier for you to get used to the machine,

• help prevent faults occurring due to improper use and

• increase the service life of your machine.

Keep this instruction manual in an easily accessible

place. Only operate this machine if you are qualified to

do so and follow the guidelines in this instruction

manual.

PROXXON does not accept responsibility for the safe

functioning of the machine

• if it is handled in a manner which constitutes improper

use,

• if it is used for other purposes which are not specified

in the instruction manual,

• if the safety regulations are not observed.

Warranty claims are invalid if

• the machine is incorrectly operated,

• the machine has not been sufficiently maintained.

In the interests of your safety, please always observe

the safety regulations.

Only use genuine PROXXON spare parts.

We reserve the right to make further alterations for the

purpose of technical progress.

We wish you every success with your machine.

Safety instructions

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

3. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations, or

expose them to rain. Keep work area well lighted.

5. KEEP CHILDREN AWAY. All visitors should be kept

safe distance from work area.

6. MAKE WORKSHOP KID PROOF with padlocks,

master switches, or by removing starter keys.

7. DON’T FORCE TOOL. It will do the job better and

safer at the rate for which it was designed.

8. USE RIGHT TOOL. Don’t force tool or attachment

to do a job for which it was not designed.

9. USE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When

using an extension cord, be sure to use one heavy

enough to carry the current your product will draw.

An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table 1

shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt,

use the next heavier gage. The smaller the gage

number, the heavier the cord.

10. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

Exception: The reference to gloves may be omitted

from the instructions for a grinder.

11. ALWAYS USE SAFETY GLASSES. Also use face or

dust mask if cutting operation is dusty. Everyday

eyeglasses only have impact resistant lenses, they

are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to hold work

when practical. It’s safer than using your hand and it

frees both hands to operate tool.

13. DON’T OVERREACH. Keep proper footing and

balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing

accessories.

15. DISCONNECT TOOLS before servicing; when

changing accessories, such as blades, bits, cutters,

and the like.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in off position

before plugging in.

17. USE RECOMMENDED ACCESSORIES. Consult

the owner’s manual for recommended accessories.

The use of improper accessories may cause risk of

injury to persons.

18. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

Page 4

- 5 -

19. CHECK DAMAGED PARTS. Before further use of

the tool, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function –

check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced.

20. DIRECTION OF FEED. Feed work into a blade or

cutter against the direction of rotation of the blade or

cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Don’t leave tool until it comes

to a complete stop.

22. WHEN SERVICING USE ONLY IDENTICAL

REPLACEMENT PARTS.

23. TO REDUCE THE RISK OF ELECTRIC SHOCK,

THIS EQUIPMENT HAS A POLARIZED PLUG.

(One blade is wider than the other). This plug will fit

in a polarized outlet only one way. If the plug does

not fit fully in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician to install

the proper outlet. Do not change the plug in any

way.

Table 1:

Minimum gage for cord:

Total length of

cord in feet 25 ft 50 ft 100 ft 150 ft

AWG: 18 16 16 14

Additional safety instructions:

• Ensure the workplace is tidy.

• Check the unit for damage before use (connection

cable, protective devices, etc.), have defective parts

replaced by qualified personnel.

• This unit corresponds to the pertinent safety

regulations. Repairs (e.g., replacement of the power

supply lead) may only be performed by a qualified

electrician

• Never work without the safety equipment fitted.

• Do not use electrical power tools in the rain, in damp

surroundings or in the vicinity of flammable liquids or

gases.

• Only use the tool when the handle is dry and free from

grease.

• Avoid contact with earthed components, e.g., pipes,

radiators, ovens and refrigerators.

• Protect the connection lead from heat and sharp

edges and route it so it cannot be damaged.

• Do not remove the plug from the socket by pulling on

the cable.

• Do not pick up the unit by the cable.

• Keep children and third parties away from the

workplace.

• Keep tools in childsafe locations when not in use.

• Do not overload the tool.

• Do not use the tool to perform operations for which it is

not suitable.

• Replace blunt tools in good time.

• Visually inspect application tools to ensure they are in

good working order and suitable for the task prior to

setting up the job.

• Fasten tools securely.

• Clean the unit thoroughly following all work.

• Disconnect the plug from the power supply when the

unit is not in use, before performing maintenance, tool

replacement or repair work.

• Only plug the unit in when the unit is switched off.

• Always wear protective goggles (danger of tool

breakage).

• If necessary, wear a protective dust mask.

• Only use appropriate working clothes (no loose

sleeves, ties, jewelry).

• Wear a hair net if you have long hair.

• Only use accessories and spare parts recommended

by PROXXON.

• Observe the max. permitted rotational speed.

• If necessary, use dust extract equipment.

• Do not use the tool when you are tired or under the

influence of alcohol.

• Keep fingers away from rotating or fast moving tools

(saws, etc.).

• Keep the operation instructions in a safe place.

Additional safety instructions for shapers:

WARNING

For Your Own Safety Read Instruction Manual Before

Operating Shaper!

• Always wear eye protection.

• Feed workpiece against rotation of cutter.

• Do not use awkward hand positions.

• Keep fingers away from revolving cutter – use fixtures

when necessary.

• Use overhead guard when adjustable fence is not in

place.

• Fix the machine to a solid base.

• Always wear ear protection.

Page 5

- 6 -

Description of the machine

The MT 300 table milling machine is ideal for shaping,

grooving, chamfering, edging and taking out. With the

milling cutter running at 30,000 rpm, clean and precise

results with rapid waste removal are guaranteed. The

cutter height can be adjusted for a wide range of tasks.

Overall view (fig. 1):

1. Housing

2. Table

3. Fence

4. Hand wheel for milling cutter height adjustment

5. On-Off switch

6. Fence clamping screw

7. Cutter shield (Guard)

8. Clamping screw for cutter shield

9. Milling cutter

10. Fixing holes

11. Vacuum cleaner connection

12. Spanner holder

13. Angle stop

14. Supply cable

Included in delivery:

1 pc. MICRO Shaper

2 pc. Spanners

1 pc. Extractor connection

1 pc. Angle stop

3 pc. Collets

Technical data:

Voltage: 110-120 V, 50/60 Hz, ~

Power: 1/8 hp (100 W) 10 min

Cutter speed: 30000 rpm

Table Size: 111/2” x 6” (293 x 150 mm)

Weight: approx. 4,4 lb (2.0 kg)

Milling cutter

shaft diameter: up to 1/8” (3.2 mm)

Noise level: 91 dB(A)

Work piece

height/thickness: 1,5” (40 mm)

Double Insulated

For indoor use

Operation

Before milling

Fixing the shaper

(see also fig. 2)

Before starting work, fasten the shaper to a solid

wooden base with suitable screws. Fixing holes are

provided for this purpose in the base of the housing.

The wooden base can then, for example, be fixed to a

bench by means of screw clamps.

Fitting and changing the milling cutter:

Note!

When carrying out any of the work described below, it is

appropriate to raise the adjustable cutter shield (see fig.

1, item 7) to its maximum height. Disconnect by pulling

the plug!

Fitting the milling cutter:

Note!

Ensure that the cutter is suitable for running speeds up

to 30,000 rpm.

1. With one of the C-spanners provided, block the

cutter shaft 1 (see fig. 3a). With the other, unscrew

and remove the clamping nut, 2.

2. Insert a collet of the correct size in the mouth of the

shaft and screw the clamping nut back on but do not

tighten it.

3. Insert the selected milling cutter, 4, (fig. 3b).

4. Tighten the clamping nut, as shown in fig. 3b.

Changing the milling cutter:

1. As shown in fig. 3b, loosen but do not remove the

clamping nut.

2. Remove the milling cutter, 4.

3. Insert a new milling cutter.

4. Re-tighten the clamping nut.

Note!

The diameter of the cutter shaft and the inner diameter

of the collet must match! If this requires that to change

the collet, proceed as described under “Fitting the

milling cutter” above.

Cutter height adjustment

Before milling, the cutter height must be set. To this

end, turn the hand wheel, 1, (fig. 4). Turn clockwise to

raise the cutter, turn anti-clockwise to lower. Note that

one full turn of the hand wheel corresponds to an

adjustment of 1 mm (0,04 inch). With the adjustable

dial, 2, the required cutter height can be set exactly.

Adjusting the fence (figs. 5 and 6)

As shown in fig. 5a, the fence is suitably positioned for

bevelling or grooving the edges of boards.

1. Loosen the knurled screw, 1.

2. Swing the fence, 2, to obtain the desired cutting

depth.

3. Re-tighten the knurled screw.

If grooves are to be cut in the surface of boards or

similar items, the fence can be positioned as shown in

fig. 5b).

Page 6

- 7 -

Proceed as follows:

Note!

For this purpose, it is necessary to remove the cutter

shield (fig. 1, item 7). In this case, loosen the knurled

screw, 8, (fig. 1) and lift off the shield. When re-

mounting the shield, ensure that the hexagonal tip on

the shield engages correctly with the hexagonal socket

of the milling cutter carriage.

1. Completely remove the knurled screw and the Allen

screw, 1 and 2, (fig. 6), including the corresponding

washers and sleeves.

2. Roughly estimate the distance from the milling

cutter. The fence can then be fixed in the position

shown as item 3 by inserting the screws in the

appropriate threaded holes in the milling table. Do

not forget the sleeves and washers. Do not

immediately tighten the knurled screw.

3. The fine setting can now be carried out as

described under “Adjusting the fence” above.

Angle stop (fig. 1, item 13)

This can be fitted in the groove provided and slid to the

desired position. To adjust, loosen the knurled nut and

rotate the plastic part

Milling

Fig. 7 shows some applications for the use with our

MICRO-shaper.

Note!

Wear ear defenders!

Danger of injury:

Always work with the the milling cutter shield!

If you have to dismount the cutter protection for an

application like shown in Fig. 7 c, be extremely careful!

Danger of injury!

Note!

For use in schools (children over 14 years age) the

knurled screw of the milling cutter shield must be

replaced by a screw requiring a tool and the cutter

shield must be set at 5 mm (0,2 inch).

The cutter shield must be set so that it covers the cutter

immediately above the work piece. Exercise particular care

when milling workpieces over 5 mm (0,2 inch) thickness.

Keep your fingers clear of the rotating cutter. The

workpiece may only be so long and wide as can be

properly supported and fed on the milling table. The

cutting depth should never exceed 0.04 inch. For

milling, the work piece is slid along the fence. It must be

ensured that the cutting depth and feed rate are not

excessive! Cutting too deeply and too high a feed rate

lead to poor results and load the mechanism

unnecessarily. It is preferable to make a number of

milling passes with small adjustments of the fence and/

or the cutter height.

Note!

It is recommended that the dust extraction should

always be used. A rubber extractor connection is

located on the rear of the machine. Vacuum cleaner can

be readily connected here.

Care and maintenance

Note!

Defective parts should be changed by a qualified

technician.

Note!

Before carrying out repairs, pull the electrical plug. The

shaper requires little maintenance. To prolong its life,

you should clean the machine after each use with

compressed air or a soft cloth. Always use the dust

extractor.

Maintenance

Important

Pull out the mains plug prior to commencing all

maintenance and repair work.

Warning!

Turn switch OFF and always remove plug from power

source before making any adjustments or repairs.

If any part is missing or damaged, do not plug the tool in

until the missing or damaged part is replaced, and

assembly is complete. To avoid electrical shock, use

only identical replacement parts when servicing the tool.

Warning!

To avoid fire or toxic reaction, never use gasoline,

naphtha, acetone, lacquer thinner, or similar highly

volatile solvents to clean the MICRO Shaper.

Do not allow brake fluids, gasoline, or penetrating oils to

come in contact with the plastic parts. They contain

chemicals that can damage or destroy plastics!

All electrical or mechanical repairs should be done only

by qualified service technicians.

When servicing use only PROXXON replacement parts.

Use of any other parts may create a hazard or cause

product damage.

Any attempt to repair or replace electrical parts on this

tool may create a hazard unless repair is done by a

qualified service technician.

Repair service is available at your PROXXON service

center

(You find the address at address at the back of this

manual).

Loading...

Loading...