Page 1

IBS/A

Manual

Page 2

- 3 -

3

2

4

1

1

3

1

2

Fig. 2

Fig. 3 Fig. 4

Fig. 5

5

2

1

4

7

639

8

Fig. 6

Fig. 1

Page 3

- 14 -

Translation of the Original

Operating Instructions

PROXXON - IBS/A

Dear customer!

Always keep these operating instructions and the

enclosed safety guidelines within reach.

Only use this device with exact knowledge of it and

comply with the instructions and safety guidelines!

This is necessary to ensure safe operation and, secondly, it simplifi es familiarisation with the device

and its functions.

Proxxon assumes no liability for the safe function of

the device in the case of:

• handling that does not comply with normal

intended use,

• use for other purposes not mentioned in the

manual,

• incorrectly executed repairs,

• failure to heed safety instructions,

• external infl uences for which the manufacturer

is not responsible

We recommend using PROXXON original spare

parts for all repair and maintenance work.

Repairs should only be performed by qualifi ed

skilled personnel!

Please note: All information contained in these operating instructions - especially the technical data

- corresponds to the status at the time of printing.

We reserve the right to make further developments

in the interest of technical progress. We wish you

every success with the device.

WARNING!

Read all safety warnings and instructions. Failure to follow all safety

warnings and instructions listed below

may result in electric shock, fi re and/or serious

injury.

KEEP ALL SAFETY WARNINGS AND INSTRUCTIONS FOR THE FUTURE !

Battery tool use and care

Recharge only with the charger specifi ed by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of fi re

when used with another battery pack.

Use power tools only with specifi cally designated battery packs. Use of any other battery

packs may create a risk of injury and fi re.

When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal objects, that can make a connection from

one terminal to another. Shorting the battery

terminals together may cause burns or a fi re.

Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentally occurs, fl ush with water. If liquid

contacts eyes, additionally seek medical

help. Liquid ejected from the battery may cause

irritation or burns.

Service

Have your power tool serviced by a qualifi ed

repair per- son using only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

Safety warnings common for grinding, sanding, wire brushing, polishing, carving or

abrasive cutting-off operations:

a) This power tool is intended to function as a

grinder, sander, wire brush, polisher, carving

or cut-off tool. Read all safety warnings, inst-

ructions, illustrations and specifi cations provided

with this power tool. Failure to follow all instructions listed below may result in electric shock,

fi re and/or serious injury.

GB

Page 4

- 15 -

b) Do not use accessories which are not specifi cally designed and recommended by the

tool manufacturer. Just because the accessory

can be attached to your power tool, it does not

assure safe operation.

c) The rated speed of the grinding accessories must be at least equal to the maximum

speed marked on the power tool. Grinding ac-

cessories running faster than their rated speed

can break and fl y apart.

d) The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized ac-

cessories cannot be adequately controlled.

e) The arbour size of wheels, sanding drums

or any other accessory must properly fi t the

spindle or collet of the power tool. Accessories

that do not match the mounting hardware of the

power tool will run out of balance, vibrate excessively and may cause loss of control.

f) Mandrel mounted wheels, sanding drums,

cutters or other accessories must be fully inserted into the collet or chuck. If the mandrel

is insuffi ciently held and/or the overhang of the

wheel is too long, the mounted wheel may become loose and be ejected at high velocity.

g) Do not use a damaged accessory. Before

each use inspect the accessory such as abrasive wheels for chips and cracks, sanding

drum for cracks, tear or excess wear, wire

brush for loose or cracked wires. If power

tool or accessory is dropped, inspect for

damage or install an undamaged accessory.

After inspecting and installing an accessory,

position yourself and bystanders away from

the plane of the rotating accessory and run

the power tool at maximum no-load speed

for one minute. Damaged accessories will nor-

mally break apart during this test time.

h) Wear personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses. As appropriate,

wear dust mask, hearing protectors, gloves

and workshop apron capable of stopping

small abrasive or workpiece fragments. The

eye protection must be capable of stopping fl ying

debris generated by various operations. The dust

mask or respirator must be capable of fi ltrating

particles generated by your operation. Prolonged

exposure to high intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken accessory

may fl y away and cause injury beyond immediate

area of operation.

j) Hold power tool by insulated gripping surfaces only, when performing an operation

where the cutting accessory may contact

hidden wiring or its own cord. Cutting acces-

sory contacting a "live" wire may make exposed

metal parts of the power tool "live" and could

give the operator an electric shock.

k) Always hold the tool fi rmly in your hand(s)

during the start-up. The reaction torque of the

motor, as it accelerates to full speed, can cause the

tool to twist.

l) Use clamps to support workpiece whenever practical. Never hold a small workpiece in

one hand and the tool in the other hand while

in use. Clamping a small workpiece allows you

to use your hand(s) to control the tool. Round

material such as dowel rods, pipes or tubing

have a tendency to roll while being cut, and may

cause the bit to bind or jump toward you.

m) Position the cord clear of the spinning accessory. If you lose control, the cord may be cut

or snagged and your hand or arm may be pulled

into the spinning accessory.

Page 5

- 16 -

n) Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grab the surface and

pull the power tool out of your control.

o) After changing the bits or making any adjustments, make sure the collet nut, chuck or

any other adjustment devices are securely

tightened. Loose adjustment devices can un-

expectedly shift, causing loss of control, loose

rotating components will be violently thrown.

p) Do not run the power tool while carrying it

at your side. Accidental contact with the spin-

ning accessory could snag your clothing, pulling

the accessory into your body.

q) Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the

housing and excessive accumulation of powdered metal may cause electrical hazards.

r) Do not operate the power tool near fl ammable materials. Sparks could ignite these

materials.

s) Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Kickback and related warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, sanding band, brush

or any other accessory. Pinching or snagging

causes rapid stalling of the rotating accessory

which in turn causes the uncontrolled power

tool to be forced in the direction opposite of the

accessory’s rotation.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into

the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump

toward or away from the operator, depending on

direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under

these conditions.

Kickback is the result of power tool misuse and/

or incorrect operating procedures or conditions

and can be avoided by taking proper precautions

as given below.

a) Maintain a fi rm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. The operator can con-

trol kickback forces, if proper precautions are

taken.

b) Use special care when working corners,

sharp edges etc. Avoid bouncing and snagging the accessory. Corners, sharp edges or

bouncing have a tendency to snag the rotating

accessory and cause loss of control or kickback.

c) Do not attach a toothed saw blade. Such

blades create frequent kickback and loss of

control.

d) Always feed the bit into the material in the

same direction as the cutting edge is exiting

from the material (which is the same direction as the chips are thrown). Feeding the tool

in the wrong direction causes the cutting edge of

the bit to climb out of the work and pull the tool

in the direction of this feed.

e) When using rotary fi les, cut-off wheels,

high-speed cutters or tungsten carbide cutters, always have the work securely clamped.

These wheels will grab if they become slightly

canted in the groove, and can kickback. When

a cut-off wheel grabs, the wheel itself usually

breaks. When a rotary fi le, high-speed cutter or

tungsten carbide cutter grabs, it may jump from

the groove and you could lose control of the tool.

Safety warnings specifi c for grinding and abrasive cutting-off operations:

a) Use only wheel types that are recommended for your power tool and only for recommended applications. For example: do not

grind with the side of a cut-off wheel. Abra-

sive cut-off wheels are intended for peripheral

grinding, side forces applied to these wheels

may cause them to shatter.

Page 6

- 17 -

b) For threaded abrasive cones and plugs

use only undamaged wheel mandrels with an

unrelieved shoulder fl ange that are of correct

size and length. Proper mandrels will reduce

the possibility of breakage.

c) Do not “jam” a cut-off wheel or apply excessive pressure. Do not attempt to make

an excessive depth of cut. Overstressing the

wheel increases the loading and susceptibility to

twisting or snagging of the wheel in the cut and

the possibility of kickback or wheel breakage.

d) Do not position your hand in line with and

behind the rotating wheel. When the wheel, at

the point of operation, is moving away from your

hand, the possible kickback may propel the spinning wheel and the power tool directly at you.

e) When wheel is pinched, snagged or when

interrupting a cut for any reason, switch off

the power tool and hold the power tool motionless until the wheel comes to a complete

stop. Never attempt to remove the cut-off

wheel from the cut while the wheel is in motion otherwise kickback may occur. Investigate

and take corrective action to eliminate the cause

of wheel pinching or snagging.

f) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed

and carefully re-enter the cut. The wheel may

bind, walk up or kickback if the power tool is restarted in the workpiece.

g) Support panels or any oversized workpiece to minimize the risk of wheel pinching and

kickback. Large workpieces tend to sag under

their own weight. Supports must be placed under

the workpiece near the line of cut and near the

edge of the workpiece on both sides of the wheel.

h) Use extra caution when making a “pocket

cut” into existing walls or other blind areas.

The protruding wheel may cut gas or water pipes,

electrical wiring or objects that can cause kickback.

Safety warnings specifi c for wire brushing

operations:

a) Be aware that wire bristles are thrown by

the brush even during ordinary operation. Do

not overstress the wires by applying excessive load to the brush. The wire bristles can easily

penetrate light clothing and/or skin.

b) Allow brushes to run at operating speed

for at least one minute before using them.

During this time no one is to stand in front

or in line with the brush. Loose bristles or wires

will be discharged during the run-in time.

c) Direct the discharge of the spinning wire

brush away from you. Small particles and tiny

wire fragments may be discharged at high velocity during the use of these brushes and may

become imbedded in your skin.

Only for use in dry rooms

Charger LG/A

Protection class II device

WARNING

Always wear protective goggles

Do not dispose of the device charger and

battery with household rubbish!

Description of the machine

The PROXXON IBS/A industrial drill/grinder is the

ideal device for micro drilling, milling, grinding,

polishing, brushing, removing rust, engraving,

chasing and separating. You can work on any

type of material such as steel, non-ferrous metals, glass, wood, minerals and ceramics: You will

fi nd the matching tool for any task in our comprehensive range of accessories. 34 bits and

cutters (with 2.35 mm shaft) are included in the

scope of delivery.

The precision drill spindle is supported free from

play through two precision ball bearings in the

aluminium die-cast head: This guarantees a long

service life and accurate concentricity.

Page 7

- 18 -

A quiet, permanently excited special motor with

electronic speed control ensures maximum performance at minimum size, the speed range of

7,000 to 23,000 revolutions per minute permits

great fl exibility while working. The compact

high-strength housing is made of glass-fi bre

reinforced polyamide.

With the 20 mm fi t at the front device end, the

device can be clamped into e.g. drill stand or

other device holders from our range.

The fl at end cap of the battery enables the tool to

stand upright as well.

The supplied steel collet chuck makes it easy to

change tools and offers a signifi cantly greater

concentric accuracy than a drill chuck.

Powerful batteries in lithium-ion technology and

2.6 Ah capacity guarantee continuous, high performance work. To charge the battery, it is simply

inserted into the charger and is ready for operation again within approx. 1 hour. For your safety

the process is thermally monitored.

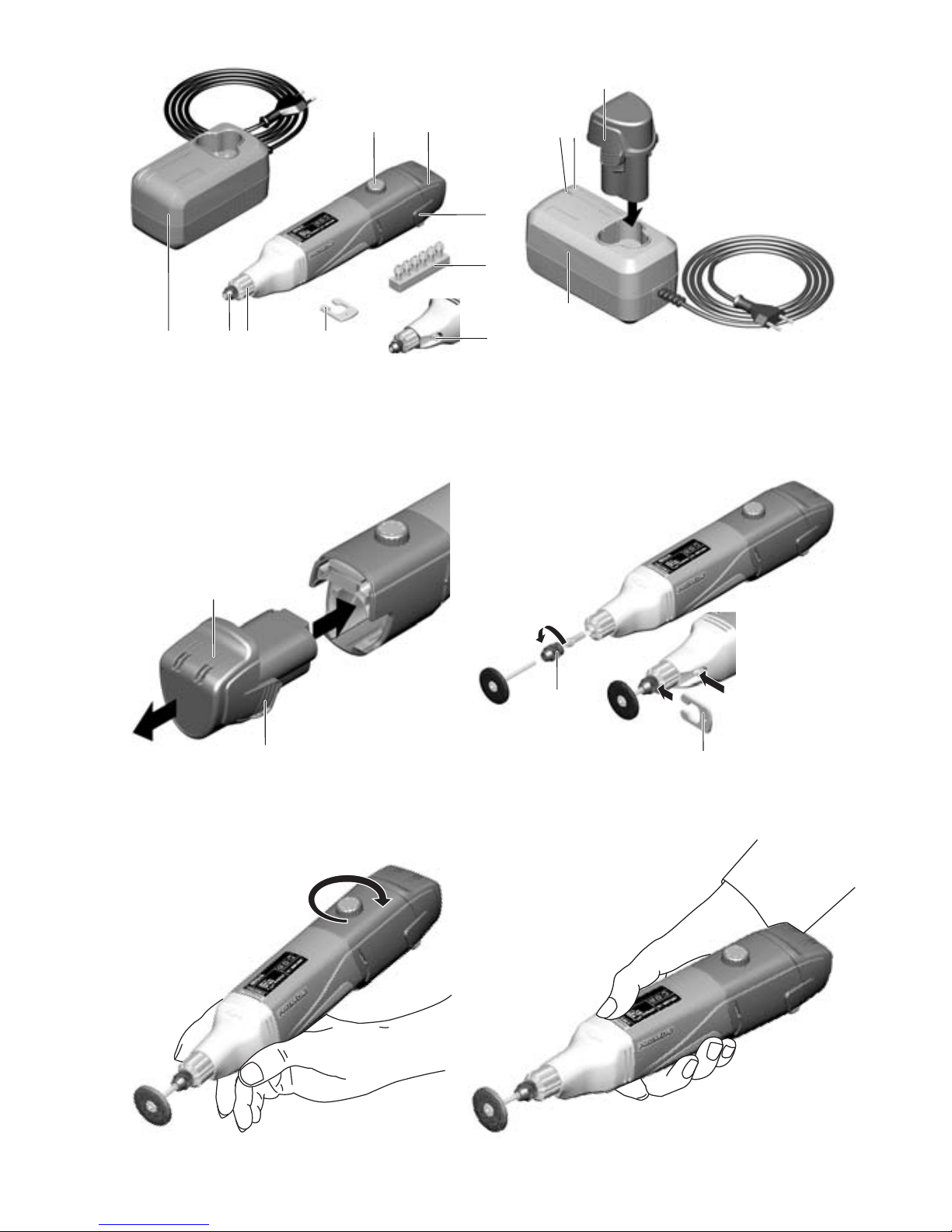

1 Key (Fig. 1)

1. Rotational speed regulating knob with On/Off

switch

2. Lock button

3. Sleeve nut for steel collet

4. Fit for drill stand (ø 20 mm)

5. Steel collet chucks

6. Key for chucks

7. Battery

8. Battery release button

9. Charger

2 Technical data

Device:

Length: approx. 270 mm (with battery)

approx. 235 mm (without battery)

Weight: approx. 700 g (with battery)

approx. 520 g (without battery)

Fit: ø 20 mm

Voltage: 10.8 V

Rotational speed: 7,000 – 23,000/min

Noise generation: < 70 dB(A)

Grip vibration: < 2.5 m/s2

Charger:

Mains voltage: 100-240 V~, 50/60Hz

Output voltage: 12.6 V

Charging current: 1 A

Battery:

Rechargeable lithium-ion battery

Nominal/charging voltage: 10.8V/12.6V

Energy/Capacity: 28.19Wh/2.61Ah

3 INR 19/66

Please note that the sound and vibration measurements in particular have been performed with

Proxxon bits and cutters. When using third-party

brands we cannot guarantee compliance with

the statements given here!

3 Scope of delivery

IBS/A (29800)

1 pc. IBS/A industrial drill/grinder

1 pc. Charger

1 pc. Battery

1 pc. Storage case

1 pc. Operating instructions

1 pc. Safety guidelines

1 pc. Key

6 pcs. Collets (1.0-1.5-2.0-2.4-3.0 and 3.2 mm)

1 pc. Round grinding pin Ø 5mm

1 pc. Cylinder grinding pin Ø 6mm

1 pc. Cylinder grinding pin Ø 2.5 mm

1 pc. Cup grinding pin Ø 7mm

1 pc. Tungsten carbide micro drill Ø 0.5 mm

1 pc. Tungsten carbide micro drill Ø 1 mm

1 pc. Diamond-coated grinding pin Ø 1.8 mm

1 pc. Finishing miller, ball shaped Ø 2.3 mm

2 pcs. Sanding disc Ø 22mm (pink colour) of

high-grade corundum, for steel, cast iron,

HSS steels

2 pcs. Sanding disc Ø 22mm (grey) For

engraving and frosting of glass, ceramic

and stellites, also for grinding of hard

metal, white cast iron and high-alloy steels

Page 8

- 19 -

1 pc. Polishing disc for acrylic glass and Plexiglas

1 pc. Brass brush for machining brass, brass

alloys, copper, precious metals,

semi-precious stones, plastic and wood.

For cleaning electronic components and

printed circuit boards.

10 pcs. Corundum cutting discs for cutting

alloyed and non-alloyed steel, stainless

steels and non-ferrous metals. Can also

be used to cut wood and plastic.

1 pc. Clamping arbour shaft diameter Ø 3.2 mm

IBS/A (29802)

1 pc. IBS/A industrial drill/grinder

1 pc. Operating instructions

1 pc. Safety guidelines

1 pc. Key

6 pcs. Collets (1.0-1.5-2.0-2.4-3.0 and 3.2 mm)

4 Commissioning and operation

Charging the battery (Fig. 2 and 3)

Caution:

Before starting up, read the warning instructions and the labels attached to the charger

and the battery!

• Do not disassemble the battery or break the

housing! Electrolytes could leak out and

cause injuries! If electrolyte gets into your

eyes, rinse them with clean water and seek

medical attention immediately!

• Protect battery from overheating! Defects

could be the result.

• Never short-circuit the battery! Strong

currents could overheat the battery. Burns

or a defect could be the possible result.

When storing the batteries, ensure that the

electric contacts cannot establish a conduc tive connection.

• Do not put the battery in open fi re! The bat tery can explode.

• Never subject the battery to liquids!

Caution:

Please note that your Proxxon power tool may

only be operated with the appropriate Proxxon

battery and that the charger is to be used exclusively for the charging of these batteries.

Furthermore, no other charger may be used

to charge the Proxxon battery: The respective

Proxxon components are optimally coordinated.

Please note: The device, battery and charge are

also separately available at retailers!

When delivered, the battery is partially charged

and must be charged completely before commissioning the device. To do so, proceed as

follows:

1. Insert the plug of the charger.

2. Insert battery 1 in the charger 2 as shown in

Fig. 2.

3. The yellow light-emitting diode 3 signals the

charging process. When completed, the green

light-emitting diode 4 lights up.

4. Remove the completely charged battery from

the charger.

5. Insert battery 1 as shown in Fig. 3 in the

housing opening of the device until it engages.

To protect the battery from harmful total discharge while in operation, the charge status is permanently monitored electronically and the device will switch off before it reaches the critical

discharge condition. The battery will now need

to be recharged. Do not attempt to put the device

back into operation with a discharged battery!

6. To charge, press the release buttons 2, pull out

the battery to the rear and carry out steps 1-5.

The charging process can be interrupted at any

time and continued without damage to the battery.

Page 9

- 20 -

Caution:

Drastically reduced operating times after the

charging process indicates that the battery

needs to be replaced!

If after inserting the battery into its designated

opening the light-emitting diode fl ashes instead

of glowing yellow continuously, the cause may

be a too high temperature, a defect, or the total

discharge of the battery.

• If the battery is too hot, the charging process

will start automatically after it cools down.

• If, on the other hand, the battery has a

normal temperature but is totally discharged,

the charger will check if it still draws power or

it if is already defective.

• If the battery can be recovered, the yellow

light-emitting diode will glow continuously after

some time, signalling the successful charging

process.

• If the yellow light-emitting diode fl ashes, the

battery is defective and needs to be disposed

of; see also "Note on disposal within the EU"

later on in these instructions.

General handling of the device:

Caution:

• Wear a protective mask if large amounts of

dust or harmful dusts accumulate.

• A correct and consistent speed achieves a high

grinding performance, not excessive contact

pressure!

• By tendency: Bits and cutters with smaller

diameters require higher speeds than those

with a larger diameter.

• Caution: You absolutely must observe the

permissible maximum speed of the bits and

cutters! The tool can break when the maximum

permissible speed is exceeded. Flying parts

can cause damage and severe injuries!

• Never press the lock button while the device

is operating.

• A collet chuck is inserted in the spindle of the

device ex works!

• Depending on the collet size, bits and cutters

may have a shaft diameter of max. 3.2 mm.

• Insert the tools are far as possible when clam ping. Ensure that the shaft of the tool does

not stand out more than 30 mm from the collet.

Protruding shafts bend easily and cause rough

running.

• Do not in any case use bits and cutters with an

arbour length of more than 55 mm!

• When using collets, always make sure that the

collet chuck and the utilised tool have the

same shaft diameter! The arbour of the tool

must be seated fi rmly and securely in the collet!

• Do not work with damaged or worn bits and

cutters! Make sure the tools are in perfect

condition. Damaged or worn tools can break

and cause injuries!

• When storing the bits and cutters, make sure

they are reliably protected from damage!

Clamping and changing the tool (Fig. 4):

Caution:

Always remove the battery before exchanging

tools!

1. Turn sleeve nut 1 slightly whilst simultaneously

pressing the lock button until it engages.

2. Release the nut for a few rotations and

exchange the tool.

3. If the collet chuck needs to be replaced as well,

screw off the nut entirely, exchange the collet

and screw on the nut lightly by hand.

4. Insert the bits and cutters and tighten with the

supplied wrench 3.

The IBS/A industrial drill/grinder was ergonomically designed to make it easy to handle and guide

precisely. The thread of the collet chuck nut is

countersunk in the machine housing. Using a

drill chuck is not possible for this reason.

Page 10

- 21 -

Working with the device

1. To activate, operate the rotary button 1 (Fig. 1)

and set the right speed for the work. Applicable

in principle, tools with smaller diameters must

be operated at higher speeds, and tools with

greater diameters at lower speeds in order to

achieve optimal results.

2. If you would like to guide the device by hand

while working, hold it like a ballpoint pen whilst

milling or engraving. Do not cover the ventilati

on slots (Fig. 5). For coarser work, hold the de

vice like the shaft of a hammer (Fig. 6).

An ideal working environment is achieved if the

device is clamped by its 20 mm fi t in a drill stand

or in one of the universal holders from the Proxxon range.

A diversity of additional fi elds of application develop when combining your professional grinder

IBS/A with other machines and devices!

5 Maintenance, cleaning and care

Caution:

Remove the battery from device before any assembly, adjustment, maintenance measure or

repair!

Note:

Every device is dirtied by dust when working

with wood. Cleaning is therefore essential. To

ensure a long service life, however, the machine

should be cleaned with a soft cloth or brush after

each use.

Mild soap or other suitable cleaning agent may

be used in this context. Solvents or cleaning

agents containing alcohol (e.g. petrol, cleaning

alcohols etc.) should be avoided, since these can

attack plastic casings.

Always keep the apertures required for cooling

the motor free of dust and dirt.

Service note

Please note: The mains power input for the charger may only be replaced by our Proxxon Service

Department or a qualifi ed specialist!

6 Accessories

For more detailed information on accessories,

please request our device catalogue from the

address specifi ed on the last page in the warranty information.

Please note in general:

Proxxon bits and cutters have been designed

to work with our machines, which makes them

optimal for their use.

We will not assume any liability whatsoever

for the safe and proper function of our devices

when using third-party bits and cutters!

7 Disposal:

Please do not dispose of this machine in

household waste! The device contains valuable

materials which can be recycled. If you have

questions concerning this topic, please contact

your municipal disposal company or other appropriate municipal institutions.

Note on disposal within the EU:

Please note that in accordance with the EU directive 2012/19/EU and the EU directive 2006/66/

EC, defective or consumed accumulators and

no longer operational electrical devices must be

disposed of separately from household waste

and must be sent for reuse in an environmentally

responsible manner!

Page 11

- 22 -

8 CE Declaration of conformity

Name and address of the manufacturer:

PROXXON S.A.

6-10, Härebierg

L-6868 Wecker

Product designation: IBS/A

Article No.: 29800/29802

On our sole responsibility, we declare that

this product conforms to the following directives and normative documents:

EU EMC Directive 2016/30/EU

DIN EN 55014-1 / 05.2012

DIN EN 55014-2 / 01.2016

DIN EN 61000-3-2 / 03.2015

DIN EN 61000-3-3 / 03.2014

DIN EN 61000-4-2/12.2009

DIN EN 61000-4-3/04.2011

DIN EN 61000-4-4/04.2013

DIN EN 61000-4-5/03.2015

DIN EN 61000-4-6/08.2014

DIN EN 61000-4-11/02.2005

EU Machinery Directive 2006/42/EC

DIN EN 60745-1 / 01.2010

DIN EN 60745-2-23 / 11.2013

Date: 24/10/2016

Dipl.-Ing. Jörg Wagner

PROXXON S.A.

Appliance Safety Division

The CE document authorized agent is identical with the signatory.

Page 12

- 122 -

Spare Parts List

PROXXON IBS/A

:

Page 13

- 123 -

8 10 11 12 13

1514

9

17

16

18

19 20 21 22 23

12 35

5 74

6

24

230 V

3 VA

3 VA

döjfkdgj sdgbjdsgj döfjdkgfjk

dlfida dlg,dlg d dgfdl fg

12 VA

12 VA

12 VA

Page 14

Service note

All PROXXON products are thoroughly inspected after

production. Should a defect occur nevertheless, please

contact the dealer from whom you purchased the product. Only the dealer is responsible for handling all

legal warranty claims which refer exclusively to material

and manufacturer error.

Improper use, such as capacity overload, damage due to

outside infl uences and normal wear are excluded from

the warranty.

You will fi nd further notes regarding „Service and Spare

Parts Management“ at www.proxxon.com.

GB

Loading...

Loading...