Page 1

Manual

BBS/S

Page 2

- 3 -

D-54518Niersbach

B

B

S

/S

230V~

50/60

Hz

100

Wa

tt

V

Band

=

2

75/m

i

n

7

1

2

3

4

6

8

5

D-54518Niersbach

B

B

S

/S

230V~

50/60Hz

100

W

a

tt

V

Band

=

2

75/min

1

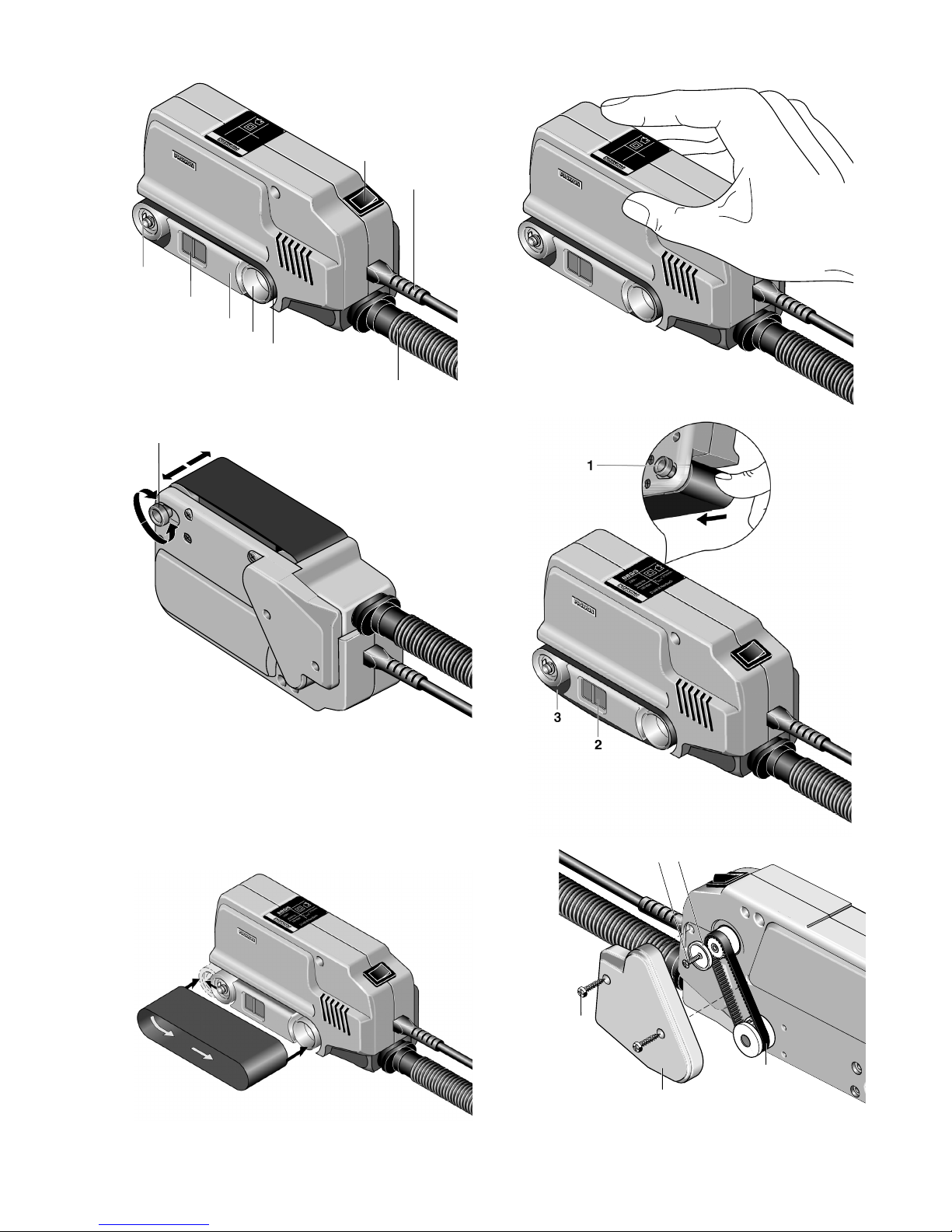

Fig.1

Fig.3 Fig.4a

Fig.4b

1

34

2

5

Fig.5

Fig.2

Page 3

Translation of the Original Operating

Instructions BBS/S

Dear Customer,

Please read the attached safety and operating instructions carefully before using the unit.

Key (Fig. 1)

1. On/Off switch

2. Connecting cable with mains plug

3. Belt support

4. Tensioning slider

5. Drive roller

6. Tension roller

7. Grinding belt

8. Suction hose

Description of the machine

The PROXXON BBS/S block belt grinder is an

ideal unit for modelmaking, toolmaking and

mould making but is also suitable for small car

repair jobs, such as on the bodywork for example. Can be used for de-burring, roughing, fine

grinding, edging, paint-stripping, rust removal

and sharpening tools.

For machining steel, non-ferrous metals, wood

and plastics. Included with the machine are 2 x 5

grinding belts with different grain sizes.

Caution:

Use your belt grinder only in well-ventilated areas. Pay attention to the dust concentration in

the air. Do not use the BBS/S if the surrounding

air becomes dusty.

We recommend you always work with the vacuum cleaner! This not only guarantees clean work

but also reduces the harmful effect of some

dusts!

Caution:

Hold the device by the insulated gripping

surfaces as the grinding band could hit its own

mains cable!

Technical data

Motor:

Voltage: 220-240 V, 50/60 Hz

Power: 150 Watt

Unit:

Grinding speed: 160 m/min

Dimensions of unit: (LxWxH): 175x63x90

Dimensions of grinding belt: 265x40 mm

Grinding area: 60x40 mm

Weight: ca. 1,1 kg

Noise: ≤ 83 dB (A)

Vibration: ≤ 2.5 m/s2

Protection class II device

Please do not dispose off the machine!

Caution:

Always use ear defenders when working.

Operation

The belt grinder is easily guided over the surface

to be ground with the right hand. Hold the BBS/S

as shown in Fig. 2. Make sure you do not obstruct the cooling slots for the motor. Take care

not to apply too much pressure when working.

This causes the belt to wear quickly and, furthermore, will put excessive strain on the mechanics.

The best results are obtained by using moderate

pressure.

Caution:

Ensure that no poisonous dusts can be produced,

for example, when grinding paints which contain

lead, some types of wood and some metals.

Always use a dust mask when working.

Caution:

The belt grinder is not suitable for wet grinding.

Adjusting the belt run

Caution! Risk of injury!

Please proceed with particular care when adjusting the belt run.

If the belt does not run sufficiently straight or if

the belt runs inwards or outwards, the position of

the front roller and thus the run of the belt can be

adjusted by means of the knurled screw 1 (Fig.

3). Turning the knurled screw clockwise will make

the belt run further towards the inside; turning anticlockwise will make the belt run further towards

the outside.

Fitting or replacing the grinding belt

In use, the grinding media will wear and the effectiveness of grinding will reduce due to the belt

becoming clogged with grinding dust or the abrasive grits becoming worn. With its rapid tensioning mechanism, the BBS/S provides a very quick

and convenient way of changing grinding belts.

- 6 -

Page 4

Caution! Risk of injury!

Unplug from the mains before changing the

grinding belt.

Please use only genuine PROXXON spare parts.

1. Slacken the knurled screw (Fig. 4a).

2. Then push in the belt roller until the slide 2 of

the tensioning mechanism clicks into place.

3. Remove the worn grinding belt 3.

4. Fit new grinding belt taking note of the arrow

for the direction of running (Fig. 4b).

5. Press in the slider slightly to release the

catch. The fork will spring back to its original

position. The belt is now automatically pre-set

to the correct tension by spring pressure.

6. The belt run may possibly have to be re-adjusted using the knurled screw 1.

Care and maintenance

Caution!

Remove the mains plug before carrying out any

maintenance and cleaning work.

Apart from occasional cleaning, the unit is essentially maintenance-free. When cleaning, please

pay attention to the following:

After use

Thoroughly clean the unit of all grinding dust with

a brush or soft cloth. In particular, the dust which

collects in the belt drive must be removed. Cleaning with compressed air, if available, is suitable

for this. However, care must be taken to avoid inhaling the dust. Wear a dust mask if necessary.

Otherwise, no special maintenance actions are

required.

Changing the toothed belt (Fig. 5)

In very rare cases, it may be necessary to replace the drive belt inside the unit due to wear or

breakage. In this case, proceed as follows:

Caution! Risk of injury!

Unplug from the mains in all cases.

1. Remove cover 1 after unscrewing

both screws 2.

2. Unscrew screw 3 and remove collar disc 4

of the upper timing belt pulley.

3. Remove old toothed belt 5 and

fit the new sprocket belt.

4. Reassembly occurs in reverse order.

Disposal

Please do not dispose of the device in domestic

waste! The device contains valuable substances

that can be recycled. If you have any questions

about this, please contact your local waste management enterprise or other corresponding municipal facilities.

EC Declaration of Conformity

Name and address of the manufacturer:

PROXXON S.A.

6-10, Härebierg

L-6868 Wecker

Product designation: BBS/S

Article No.: 28526

In sole responsibility, we declare that this product conforms to the following directives and

normative documents:

EU EMC Directive 2004/108/EC

DIN EN 55014-1 / 09.2003

DIN EN 55014-2 / 08.2002

DIN EN 61000-3-2 / 09.2005

DIN EN 61000-3-3 / 06 2006

EU Machinery Directive 2006/42/EC

DIN EN 60745-1 / 2010-01

DIN EN 60745-2-4 / 05.2010

Date: 28.02.12

Dipl.-Ing. Jörg Wagner

PROXXON S.A.

Machine Safety Department

The CE document authorized agent is identical

with the signatory.

- 7 -

GB

Page 5

- 28 -

Spare Parts List

BBS/S - Art-No. 28526

Page 6

29

25

1640 29 261314 29 1 39 26 19 34 17 35 28 3 26

38

21

19

32

6

30

19

18

27

42

822 11 22 12 931 2420

4

15

5

24

20

2

10

36

7

37

26

19

33

41

Page 7

Loading...

Loading...