Page 1

D-54518 Niersbach

BBS/S

230V~

50/60 Hz

100 Wa

tt

V

Band

=

2

75/min

MICRO-Belt Sander

BBS/S

Manual

Page 2

Notes:

2

Page 3

3

D-54518Niersbach

B

B

S/S

2

3

0

V

~

5

0

/6

0

H

z

1

0

0W

a

tt V

Band

=2

7

5

/m

i

n

7

1

2

3

4

6

8

5

1

D-54518Niersbach

BBS/S

23

0V

~

50/60H

z

10

0

W

att

V

B

an

d

=

2

75

/m

in

D-54518Niersbach

BBS/S

2

3

0

V

~

5

0

/6

0

H

z

1

0

0

W

a

tt V

B

an

d

=2

7

5

/m

i

n

1

2

3

D

-5

4

5

1

8

N

ie

rs

b

a

c

h

B

B

S

/S

230V~

50/60Hz

100Watt V

Band

=275/min

1

34

2

5

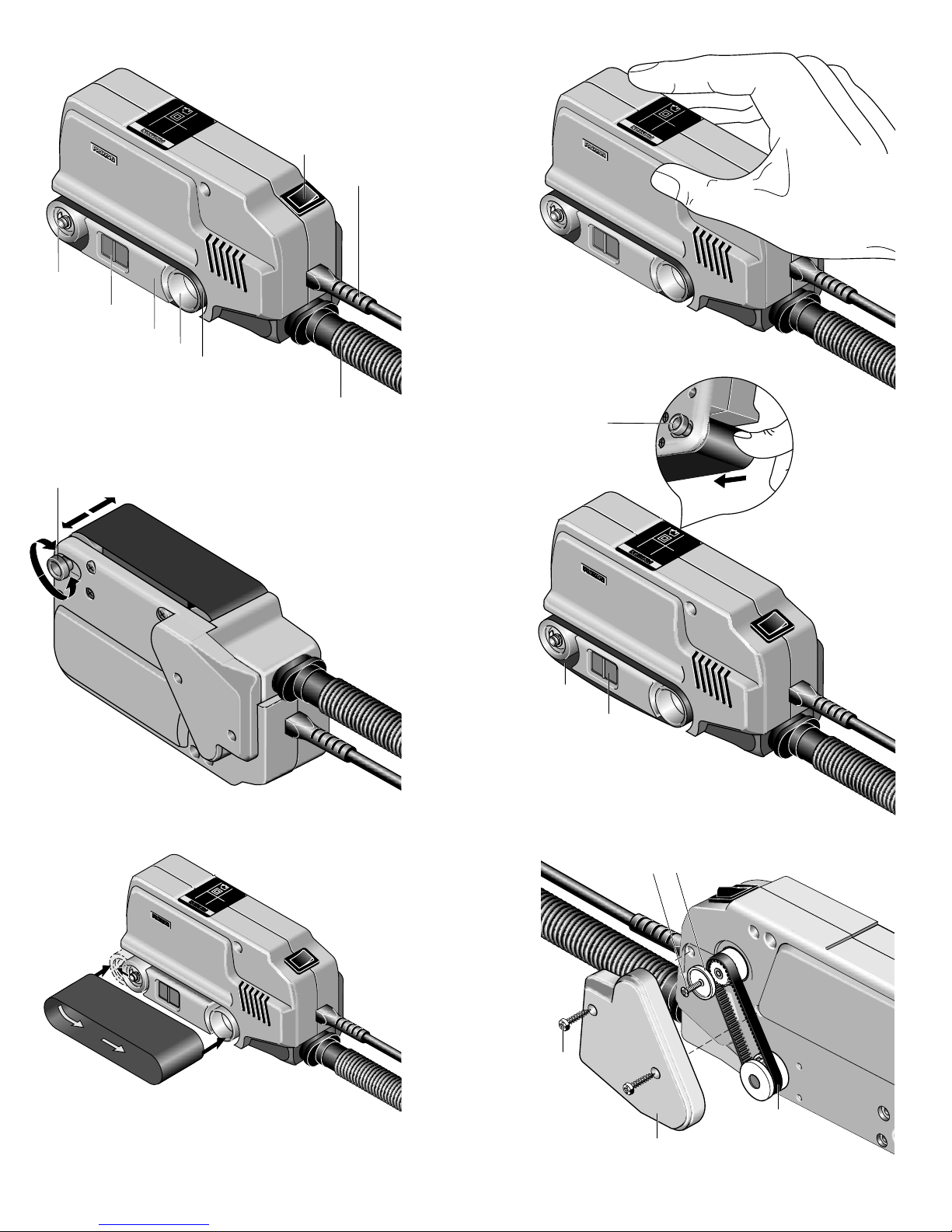

Fig. 1

Fig. 3

Fig. 4b Fig. 5

Fig. 2

Fig. 4a

Page 4

Operating instructions

BBS/S MICRO-Belt Sander

Contents:

1 General safety instructions …………………………………………………………… 5

2 Specific safety rules …………………………………………………………………… 7

3 Symbols ………………………………………………………………………………… 8

4 Legend (fig. 1) ………………………………………………………………………… 9

5 Technical data ………………………………………………………………………… 9

5.1 Motor:………………………………………………………………………………… 9

5.2 Unit: ………………………………………………………………………………… 9

6 Description of the machine …………………………………………………………… 9

7 Operation ……………………………………………………………………………… 9

7.1 Adjusting the belt run …………………………………………………………… 10

7.2 Fitting or replacing the sanding belt …………………………………………… 10

8 Accessories …………………………………………………………………………… 10

8.1 Accessories recommended and actually provided by PROXXON ………… 11

9 Care and maintenance ……………………………………………………………… 11

9.1 After use ……………………………………………………………………………… 11

9.2 Changing the drive belt (Fig. 5) …………………………………………………… 11

9.3 Disposal ……………………………………………………………………………… 11

10 Spare parts list ……………………………………………………………………… 12

11 LIMITED WARRANTY OF PROXXON POWER TOOLS FOR HOME USE … 12

12 Explosion drawing …………………………………………………………………… 13

4

Dear Customer,

In order to be able to operate your

Sander safely and correctly, please carefully read the following safety and operating instructions prior to use.

The use of these instructions makes it

easier to get familiar with the device, prevents malfunctions caused by improper

operation, and lengthens the service life

of your device.

This instruction manual covers:

• safety regulations

• operation and maintenance

• spare parts list

Please read carefully!

Using this instruction manual will

• make it easier for you to get used to

the machine,

• help prevent faults occurring due to

improper use and

Page 5

5

• increase the service life of your

machine.

Keep this instruction manual in an easily

accessible place.

Only operate this machine if you are

qualified to do so and follow the guidelines in this instruction manual.

PROXXON does not accept responsibility for the safe functioning of the machine

• if it is handled in a manner which constitutes improper use,

• if it is used for other purposes which

are not specified in the instruction manual,

• if the safety regulations are not

observed.

Warranty claims are invalid if

• the machine is incorrectly operated,

• the machine has not been sufficiently

maintained.

In the interests of your safety, please

always observe the safety regulations.

Only use genuine PROXXON spare

parts.

We reserve the right to make further alterations for the purpose of technical

progress.

We wish you every success with your

machine.

1 General safety instructions

Warning!

Read and understand all instructions.

Failure to follow all instructions listed below, may result in electric shock, fire

and/or serious personal injury.

Save these instructions!

Work Area

1. Keep your work area clean and

well lit. Cluttered benches and dark

areas invite accidents.

2. Do not operate power tools in ex-

plosive atmospheres, such as in

the presence of flammable liquids,

gases, or dust. Power tools create

sparks which may ignite the dust or

fumes.

3. Keep bystanders, children, and

visitors away while operating a

power tool. Distractions can cause

you to lose control.

Electrical Safety

4. Double Insulated tools are

equipped with a polarized plug (one

blade is wider than the other.) This

plug will fit in a polarized outlet only one way. If the plug does not fit

fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change the plug

in any way. Double Insulation

Class II Equipment eliminates the

need for the three wire grounded

power cord and grounded power

supply system.

5. Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges and refrigeratorsand refrigerators. There is an increased risk of

electric shock if your body is grounded.

Page 6

6

6. Do not expose power tools to rain

or wet conditions. Water entering a

power tool will increase the risk of

electric shock.

7. Do not abuse the cord. Never use

the cord to carry the tools or pull

the plug from an outlet. Keep cord

away from heat, oil, sharp edges

or moving parts. Replace damaged

cords immediately. Damaged cords

increase the risk of electric shock.

8. When operating a power tool out-

side, use an outdoor extension

cord marked „W-A“ or „W.“ These

cords are rated for outdoor use and

reduce the risk of electric shock.

Personal Safety

9. Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use

tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while

operating power tools may result in

serious personal injury.

10. Dress properly. Do not wear loose

clothing or jewelry. Contain long

hair. Keep your hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts.

11. Avoid accidental starting. Be sure

switch is off before plugging in.

Carrying tools with your finger on the

switch or plugging in tools that have

the switch on invites accidents.

12. Remove adjusting keys or wrench-

es before turning the tool on. A

wrench or a key that is left attached

to a rotating part of the tool may result in personal injury.

13. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables

better control of the tool in unexpected situations.

14. Use safety equipment. Always

wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or

hearing protection must be used for

appropriate conditions.

Tool Use and Care

15. Use clamps or other practical way

to secure and support the workpiece to a stable platformstable

platform. Holding the work by hand

or against your body is unstable and

may lead to loss of control.

16. Do not force tool. Use the correct

tool for your application. The correct tool will do the job better and

safer at the rate for which it is designed.

17. Do not use tool if switch does not

turn it on or off. Any tool that cannot

be controlled with the switch is dangerous and must be repaired.

18. Disconnect the plug from the pow-

er source before making any adjustments, changing accessories,

or storing the tool. Such preventive

Page 7

7

safety measures reduce the risk of

starting the tool accidentally.

19. Store idle tools out of reach of

children and other untrained persons. Tools are dangerous in the

hands of untrained users.

20. Maintain tools with care. Keep cut-

ting tools sharp and clean. Properly

maintained tools, with sharp cutting

edges are less likely to bind and are

easier to control.

21. Check for misalignment or binding

of moving parts, breakage of parts,

and any other condition that may

affect the tools operation. If damaged, have the tool serviced before using. Many accidents are

caused by poorly maintained tools.

22. Use only accessories that are rec-

ommended by the manufacturer

for your model. Accessories model.

Accessories that may be suitable for

one tool, may become hazardous

when used on another tool.

SERVICE

23. Tool service must be performed

only by qualified repair personnel.

Service or maintenance performed by

unqualified personnel could result in

a risk of injury.

24. When servicing a tool, use only

identical replacement parts. Follow

instructions in the Maintenance

section of this manual. Use of

unauthorized parts or failure to follow

Maintenance Instructions may create

a risk of electric shock or injury. Certain cleaning agents such as gasoline, carbon tetrachloride, ammonia

etc. may damage plastic parts.

2 Specific safety rules

1. Accessories must be rated for at

least the speed recommended on

the tool warning label. Some mate-

rial may produce harmful or toxic

dust (i. e. lead containing paint, some

kinds of wood or metal). Accessories

running over rated speed can fly

apart and cause injury.

2. Hold tool by insulated gripping

surfaces when performing an operation where the cutting tool may

contact hidden wiring or its own

cord. Contact with a "live" wire will

make exposed metal parts of the tool

"live" and shock the operator.

3. Always disconnect tool from pow-

er source before making adjustments or changing accessories.

4. Make sure that the cord will not get

hung up during sanding.

5. Let the motor come to a complete

stop before putting the tool down.

6. Do not leave the tool running. Operate the tool only when hand-held.

7. Check the abrassive belt carefully

for damage before operation. Replace damaged belt immediately.

8. Always keep hands away from ro-

tating and moving parts to prevent

personal injury.

9. Wear hearing protection during ex-

tended period of operation.

Page 8

8

10. Some material contains chemicals

which may be toxic. Take caution to

prevent dust inhalation and skin contact. Follow material supplier safety

data.

11. Keep cutting pressure constant.

You could overload the motor.

12. Make sure the belt is not contacting

the workpiece before the switch is

turned on.

SAVE THESE INSTRUCTIONS!

WARNING!

Some dust created by power sanding,

sawing, grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause

cancer, birth defects or other reproduc-

tive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

arsenic and

• chromium from chemically-treated

lumber.

Your risk from these exposures varies,

depending on how often you do this type

of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks

that are specially designed to filter out

microscopic particles.

3 Symbols

Important: Some of the following symbols may be used on your tool. Please study them and learn their

meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Ø Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

…/min Revolutions or reciprocation Revolutions, strokes, surface speed, orbits etc.

per minute per minute

1, 2, 3, … Selector settings Speed, torque or position settings. Higher number

means greater speed

Infinitely variable selector Speed is increasing from narrow end

➞ Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Class II construction Designates Double Insulated Construction tools.

Page 9

4 Legend (fig. 1)

1. On/Off switch

2. Connecting cable with mains plug

3. Belt support

4. Tensioning slider

5. Drive roller

6. Tension roller

7. Grinding belt

8. Suction hose

Caution:

Use your belt Sander only in well-ventilated areas.

Pay attention to the dust concentration in

the air. Do not use the BBS/S if the surrounding air becomes dusty or wear a

mask.

5 Technical data

5.1 Motor:

Voltage: 110 - 120 V ~, 50/60 Hz

Power: 150 Watt (1,3 A)

5.2 Unit:

Grinding speed: 525 ft/min (160 m/min)

Dimensions:

(LxWxH): 6.9"x2.5"x 3.5"

(175x63x90 mm)

Dimensions of

sanding belt: 10 7/16" x 1 37/36"

(265x40mm)

Grinding area: 2 37/64" x 1 37/64"

(60x40mm)

Weight: ca. 2.42 lbs (1,1 kg)

Noise: ≤ 83 dB (A)

Vibration: ≤ 2.5 m/s

2

Protection class II device

Please do not dispose off the machine!

Caution:

Always use ear protection when working!

6 Description of the machine

The PROXXON BBS/S block belt Sander

is an ideal tool for building models, tools

and moulds but is also suitable for small

car repair jobs, such as on the bodywork

for example. The sanding belt is located

flush on the left side to allow surfaces to

be sanded "right down to the corner".

A fine adjustment for the rollers prevents

running off on the side. Spring clamping

system for easy replacement of belts

without tool:

The BBS/S can be used for de-burring,

roughing, fine sanding, edging, paintstripping, rust removal and sharpening

tools.

For machining steel, non-ferrous metals,

wood and plastics. Included with the

machine are 2 x 5 grinding belts with

different grit sizes (120/240).

7 Operation

The belt Sander is easily guided over the

surface to be sanded with the right hand.

Hold the BBS/S as shown in Fig. 2.

Make sure you do not obstruct the cooling slots for the motor. Take care not to

apply too much pressure when working.

This causes the belt to wear quickly and,

furthermore, will put excessive strain on

the mechanics.

9

Page 10

The best results are obtained by using

moderate pressure.

Caution:

Ensure that no poisonous dusts can be

produced, for example, when sanding

paints which contain lead, some types of

wood and some metals.

Always use a dust mask when working.

Caution:

The belt sander is not suitable for wet

sanding.

7.1 Adjusting the belt run

Caution! Risk of injury!

Please proceed with particular care when

tracking the belt.

If the belt does not run sufficiently

straight or if the belt runs inwards or outwards, the position of the front roller can

be adjusted by turning the knurled screw

1 (Fig. 3). Turning the knurled screw

clockwise will make the belt run further

towards the inside; turning counterclockwise will make the belt run further towards the outside.

7.2 Fitting or replacing the grinding

belt

In use, the sanding material will wear

and the effectiveness of sanding will reduce due to the belt becoming clogged

with sanding dust or the abrasive grits

becoming worn. With its rapid tensioning

mechanism, the BBS/S provides a very

quick and convenient way of changing

sanding belts.

Caution! Risk of injury!

Unplug from electrical outlet before

changing the sanding belt.

Please use only genuine PROXXON

spare parts.

1. Slacken the knurled screw 1 (Fig. 4a).

2. Then push in the belt roller until the

slide 2 of the tensioning mechanism

clicks into place.

3. Remove the worn sanding belt 3.

4. Fit new sanding belt. Make sure to

place the belt in accordance to the

arrow for the direction of running

(Fig. 4b).

5. Press in the slider slightly to release

the catch. The fork will spring back to

its original position. The belt is now

automatically preset to the correct

tension by spring pressure.

6. The belt run may possibly have to be

re-adjusted using the knurled screw 1.

8 Accessories

WARNING!

Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable

for one tool, may become hazardous

when used on another tool.

Replace damaged or worn abrasive belts

immediately. They represent a safety risk

and worsen the work result.

Please use PROXXON accessories.

NOTE: The use of improper accessories

may cause hazards.

10

Page 11

8.1 Accessories recommended and

actually provided by PROXXON

(Current and available at the time this

manual was printed):

Standard corundum sanding belts for

BBS/S block belt sander, various grits of

high density, on a powerful backing, cover a wide range of applications. Used on

metals, non-ferrous metals, wood and

plastic. Size 10

7

/16” x 137/36” mm. 5 pc.

each package

9 Care and maintenance

Caution!

Unplug tool from electrical outlet before

carrying out any maintenance and cleaning work. Apart from occasional cleaning,

the unit is essentially maintenance-free.

When cleaning, please pay attention to

the following:

9.1 After use

Thoroughly clean the unit of all sanding

dust with a brush or soft cloth. In particular, the dust which collects in the belt

drive must be removed. Cleaning with

compressed air, if available, is suitable

for this. However, care must be taken to

avoid inhaling the dust. Always wear a

dust mask when performing this process.

Otherwise, no special maintenance is required.

9.2 Changing the drive belt (Fig. 5)

In very rare cases, it may be necessary

to replace the drive belt inside the unit

due to wear or breakage. In this case,

proceed as follows:

Caution! Risk of injury!

Unplug from electrical outlet.

1. Remove cover 1 after unscrewing

both screws 2.

2. Unscrew, screw 3 and remove collar

disc 4 of the upper timing belt pulley.

3. Remove old drive belt 5 and fit the

new sprocket belt.

4. Reassembly occurs in reverse order.

9.3 Disposal

Please do not dispose of the device in

domestic waste! The device contains

valuable substances that can be recycled. If you have any questions about

this, please contact your local waste

management enterprise or other corresponding municipal facilities.

11

NO 28 922 grit 80

NO 28 924 grit 120

NO 28 926 grit 180

NO 28 928 grit 240

Page 12

12

10 Spare parts list

MICRO-Sander BBS/S, Article No. 38526

Please order spare parts in writing from PROXXON Service center (Address on back

of instruction manual)

Part no.: Designation Part no.: Designation

28526- 01 Casing half, gear side

28526- 02 Casing half, ventilation slots

28526- 03 Cover for driving belt

28526- 04 Dust port

28526- 05 Support for abrasive belt

28526- 06 Support

28526- 07 Mounting plate for motor

28526- 08 Forked lever

28526- 09 Drive pulley

28526- 10 Front pulley

28526- 11 Shaft for front pulley

28526- 12 Shaft for drive pulley

28526- 13 Shaft for gear

28526- 14 Gear wheel, motor side

28526- 15 Ring gear

28526- 16 Pulley 14 teeth

28526- 17 Washer disk

28526- 18 Pulley 20 teeth

28526- 19 Roller bearing

28526- 20 Bearing bush

28526- 21 Washer

28526- 22 Shim

28526- 24 Circlips

28526- 25 Knurled screw

28526- 26 Screw

28526- 27 Screw

28526- 28 Screw

28526- 29 Screw

28526- 30 Set screw

28526- 31 Spring

28526- 32 Spring for front pulley

38526- 33 Motor

28526- 34 Driving belt

28526- 35 Switch

28526- 36 Board

28526- 37 Insulating plate

38526- 38 Power cord with bend

protection

28526- 39 Plate

28526- 41 Spring

28526- 43 Hose

28526- 44 Adaptor

28526- 45 Connection hose

28526- 46 Abrasive belt

28526- 99 Manual

11 LIMITED WARRANTY OF PROXXON POWER TOOLS FOR HOME USE

Prox-Tech, Inc., ("Seller") warrants to the original purchaser only, that all PROXXON consumer power tools will be free from defects in

material or workmanship for a period of two years from the date of purchase. Seller's sole obligation and your exclusive remedy under

this limited warranty and, to the extent permitted by law, any warranty or condition implied by law, shall be the repair or replacement of parts,

without charge, which are defective in material or workmanship and which have not been misused, carelessly handled, or misrepaired by

persons other than Seller or Authorized Service Station. In the event of a failure of a product to conform to this written warranty, please

refer to the Service and Repair section on the back of this manual and take action accordingly. This Limited Warranty does not apply to

accessory items such as circular saw blades, drill bits, router bits, jigsaw blades, sanding belts, grinding wheels and other related items.

Damage to the product resulting from tampering, accident, abuse, negligence, unauthorized repairs or alterations, unapproved attachments or other causes unrelated to problems with material or workmanship are not covered by this warranty. Any implied warranties shall

be limited in duration to two years from date of purchase. Some states in the U.S. and some Canadian provinces do not allow limitations

on how long an implied warranty lasts, so the above limitation may not apply to you. In no event shall seller be liable for any incidental or

consequential damages (including but not limited to liability for loss of profits) arising from the sale or use of this product. Some states

in the U.S. and some Canadian provinces do not allow the exclusion or limitation of incidental or consequential damages; so the above

limitation or exclusion may not apply to you. This limited warranty gives you specific legal rights, and you may also have other rights,

which vary from state to state in the U.S., province to province in Canada and from country to country. This limited warranty applies only

to PROXXON power tools sold within the United States of America, Canada, the commonwealth of Puerto Rico and Mexico. For warranty

coverage within other countries contact your local PROXXON Importer.

Page 13

13

25

1629 261314 29 1 39 26 19 34 17 35 28 3 26

38

19

32

6

30

19

18

27

21

822 11 22 12 931 2420

4

15

5

24

20

2

10

36

7

37

26

19

33

41

43

44

46

45

22

22

Page 14

Art. Nr. 28526-99 PR710707701J

SERVICE AND REPAIR

Your device does not work properly? Please read the operating

instructions again carefully. If the unit is in fact defective, please

send it to:

Prox-Tech, Inc.

Attn.: PROXXON Service Center

2555 Tate Blvd. S.E.

PO Box 1909

Hickory, NC 28603-1909

Please make sure, that your tool is carefully packaged and

include a copy of your dated proof of purchase. You will help us

to react even quicker, if you describe the problem in short and

please don’t forget to include your name, address and day-

time telephone number. We will respond in a prompt and reliable

manner.

Spare Parts

You can also order any necessary spare parts from our Service

Center at the above address. Please check the article-number of

the tool concerned on the nameplate of the tool and define the

part needed by using the explosion drawing in the manual that

came with the tool. Every part has a specific number (5 digitXX). Please provide us with this number when ordering.

For any further information call us toll free at 1-877-PROXXON

(1-877-776 9966) or visit us on the web at www.proxxon.com/us.

Made in China

Distributed in the U. S. by Prox-Tech, Inc

Loading...

Loading...