Page 1

Leopard

User and Installation

Instructions

24 BTV / v.17

24 BOV / v.17

XXXX

Wallhung gas boiler

DHW preparation

Power 9 - 24kW

Page 2

1

Mandatory warning for CEE countries

Warning: This appliance is designed, approved and inspected to meet the

requirements of the market. The identificationplate located on the inside of the

appliance certifies the origin where the product was manufactured and the country

for which it is intended.

If you see any exception to this rule, please contact your nearest dealer.

Thank you in advance for your assistance.

CE Mark

This boiler meets the requirements of Statutory Instrument No. 3083 The boiler

(Efficiency) Regulations, and therefore is deemed to meet the requirements of Directive

92/42/EEC on the efficiency requirements for new hotwater boilers fired with liquid or

gaseous fuels.

Type test for purposes of Regulation 5 certified by: Notified body 1015.

Product/production certified by: Notified body 1015.

The CE mark on this appliance shows compliance with:

1. Directive 90/396/EEC on the approximation of the laws of the Member States

relating to appliances burning gaseous fuels.

2. Directive 73/23/EEC on the harmonization of the Laws of the Member States relating

to the electrical equipment designed for use within certain voltage limits.

3. Directive 89/336/EEC on the approximation of the Laws of the Member States

relating to electromagnetic compatibility.

24 BTV/BOV

Table of contents

Introduction ...........................................2

Important notes ......................................2

Safety of life and property ......................3

User instruction

Control and signaling .............................4

Boiler indication ......................................5

Water temperature setting ......................5

Fault messages ......................................6

Boiler Start and Switch-Off .....................7

Boiler Regulation ....................................7

Protective features of the boiler ..............8

Servicing and maintenance ....................9

Note: The boiler serial number is marked on the data label attached to the fascia

behind the front panel. Refer to the ‘Introduction’ section for a description of the basic

functions of the boiler. The ‘User’ section describes how to safely operate the boiler.

The "Installation " is meant for workers of specialized companies..

Warranty conditions .............................10

Technical parameters ...........................11

Boiler schematic ...................................13

Dimensions and pressure available .....14

Installation instruction

Introduction ..........................................15

Boiler installation ..................................18

Flue gas and air ducts ..........................22

Example of horizontal duct flue ............25

Example of vertical duct flue ................22

Electrical part .......................................27

Electrical diagrams ...............................28

Conversion to LPG ...............................30

Page 3

2

workshops, of fic es, etc. and as a flow

heater of domestic hot water (DHW).

We believe it will serve you to your

full satisfaction – certain minimum

requirements must be fulfilled to that end.

That is why we are asking you to study and

follow these instructions carefully.

You have become an owner of a wallhung combination boiler, for natural gas

or LPG. The boiler 24BTV 17 with forced

flue gas removal and 24BOV 17 with flue

gas removal by means open chimney

draught are designed for heating up

the heating circuit water (CH) in central

heating systems in flats, family houses,

Please, keep the following rules in

mind:

• The boiler and all accessories must be

installed and used in compliance with

the design, the applicable laws, technical

regulations and the manufacturer’s

instructions.

• The boiler can only be installed in the type

of environment for which it is designed.

• Only service centers authorized by the

manufacturer are allowed to put the boiler

into operation after in stal la tion.

• In case of defects, call a service

centre authorised by the manufacturer

– incompetent intervention can damage

the boiler (and/or the accessories)!

• The service centre’s employee who initiates

the boiler operation after installation shall

instruct the user about the boiler, its parts

and operation.

• Check completeness of the delivery.

• Check to make sure the supplied boiler

type complies with the expected manner

of use.

• If you feel uncertain about any activities

related to the boiler operation, look up

and study all relevant information in these

instructions, and follow the recommended

procedure.

• Do not remove or damage any labels or

markings on the boiler.

• It is not allowed to tamper with inner fitting

and wiring or make changes. In case of

reparation, all parts must be approved by

producer of boiler.

• If the boiler is going to be switched off

for a longer time, it is recommended to

disconnect boiler from the electricity source

and close gas valve. This recommendation

is valid with reference to condition in these

Instruction (e.g. the anti-freeze protection

is inactivated then)

• When the life cycle of the boiler, or its parts,

has expired, they should be disposed of in

an environmentally friendly manner.

• Producer do not provide warranty

and do not answer for damage due to

infringement of:

- conditions mentioned in these

Instructions

- valid Regulations and Standards

- correct installation and use

- conditions mentioned in Guarantee

Certificate and Service Booklet

Dear Customer

Important notes

Page 4

3

• Boilers as products are checked for

compliance with the following documents:

EN 483, EN 437, EN 625, EN 50 165, EN

60 335-1:1997.

• The installation of this boiler must be

carried out by a competent person in

accordance with the relevant requirements

of the current issue of:

- the Gas Safety (Installation and Use)

Regulations,

- the Building Regulations,

- the local water company Bylaws,

- the Building Standards Regulation,

- the Health and Safety at Work Act

• Besides the requirements as expressed

in the above-cited documents, these

Instructions for Use and the boiler

documentation provided by the

manufacturer are to be followed. During

use, no children, drug-intoxicated or

legally irresponsible persons should be

allowed to tamper with the boiler.

Abbreviations used:

CH – heating circuit water,

DHW – domestic hot water.

Safety of life and property

In practice, situations may occur

in which the users must apply

necessary precautions:

• Preventing the boiler from switching on

(also accidental) when inspecting the

chimney, flue-gas duct, water and gas

piping – i.e., electricity supply to the boiler

must be stopped (e.g., by unplugging) in

addition to using the boiler switch;

• Stopping the boiler whenever flammable

or explosive vapours appear (even if

temporarily) – such as vapours of flooring

glue, paints when surface finishing, gas

leaks, etc.);

• If it is necessary to discharge water

from the heating system, it must not be

dangerously hot;

• If water has leaked from the boiler

exchanger, or if the exchanger is filled

with ice, no attempts to start the boiler

should be made until normal operating

conditions prevail.

• If there is a (whether confirmed or

suspected) gas leak or stoppage in the gas

supply, switching off the boiler, shutting

down the gas supply and calling gasworks

or a specialised service centre

Page 5

4

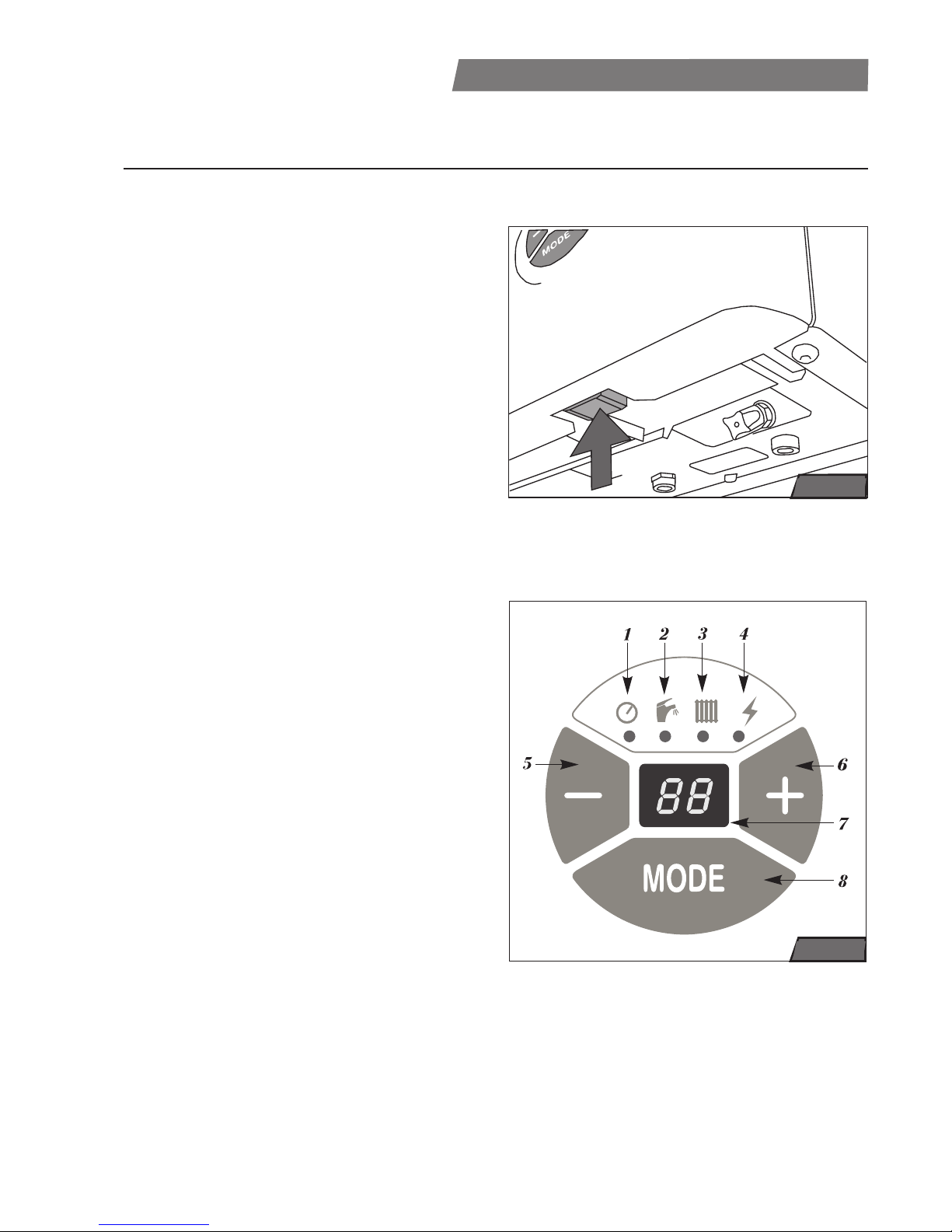

Main on/of switch

The main on/off switch (see fig.1) is on

the bottom of the boiler, below the control

panel.

Caution: Commencing and first start of the

boiler operation may only be carried out by

a specialised service centre! Only turned on

boiler has activated all protective function

(e.g. anti-freeze protection).

Control panel

It serves for indication of actual parameters

and for setting or changing required values

this parameters.

1 - heating system pressure LED

(indication of the heating water

pressure)

2 - domestic hot water LED

(indication DHW taking or domestic hot

water temperature setting)

3 - central heating LED

(indication of the heat requirement or

heating temperature setting

4 - fault message LED

(indication of faults in boiler operation)

5 - decrease button (-)

(decrease the setting value of

parameters)

6 - increasing button (+)

(increase the setting value of

parameters)

7 - display

(showing of pressure, temperatures,

service parameters and fault

messages)

8 - MODE button

(switches between setting modes and

corfirms setting value of parameters)

Control and Signaling

USER INSTRUCTONS

fig. 1

fig. 2

Page 6

5

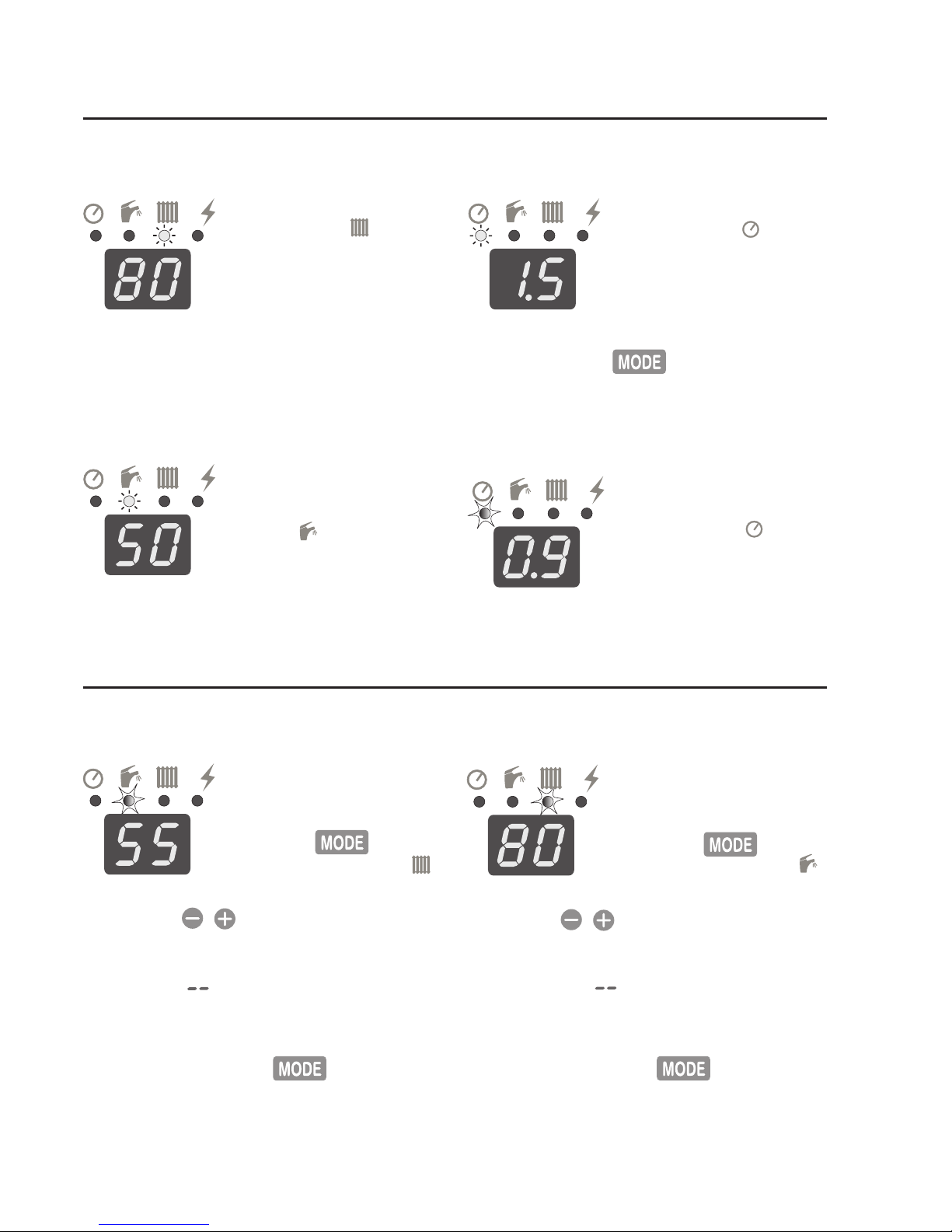

Actual circuit heating water temperature indication in °C.

LED 3 under symbol

lights continuously. The

actual temperature of heating water flowing from

boiler is displayed.

Domestic hot water temperature

indication in °C (required value).

Domestic hot water tap is

open. LED 2 under symbol lights continuously. DHW temperature corresponds with required

value in certain DHW flow

range.

Water pressure in central heating

system in Bar.

LED 1 under symbol

lights continuously. Recommended range is

1 - 2 Bar. Pressure is

displayed for 30 sec.

after one pressing

button.

Domestic hot water temperature

setting in °C.

Temperature is displayed

for 30 second after two

pressing button,

LED 2 under symbol

flash.

Buttons set domestic water temperature to following values: 35, 37, 38,

39, 40, 41, 44, 47, 50, 55, 60°C. Setting

symbol means no preparation domestic hot water.

Setting value are saved into memory

after next pressing button (if it's

not confirmed until 30 sec., the previous

setting is saved again)

Circuit heating water temperature

setting in °C.

Temperature is displayed for 30 sec. after three

pressing button,

LED 3 under symbol

flash.

Buttons set central heating water

temperature to following values: 38, 40,

42, 45, 50, 55, 60, 65, 70, 75, 80°C. Setting symbol switches central heating

off (SUMMER adjustment).

Setting value are saved into memory

after next pressing button (if it's

not confirmed until 30 sec., the previous

setting is saved again).

Boiler indication during ordinary operation (display mode)

Water temperature setting

Warning on wrong pressure in heating system under value 1 Bar (or

over 2,5 Bar).

Boiler still works. LED 1

under symbol flash. It

is necessary to fill up (or

drain) the heating system to pressure 1- 2 Bar

soon.

Page 7

6

Equithermal mode - curve slope

Press the button letter E with the characters

(0) through to (9) attached

will appear on the display.

By pressing the

buttons, select the required

equithermal curve. The cur-

ve´s slope grows with the growing number

(E0 < E9) - see fig. 3.

By pressing the

.button, the selecti-

on is saved in the memory.

Note: Equithermal control requires an external sensor to be connected to the boiler, which must not be set to the SUMMER

mode.

Attention: Boiler does heating with maximal power on one hour after installation of

the outdoor sensor. All settings are ignored in this time except room thermostat (if

is connected).

Equithermal mode – paralel curve

shift

If previous parameter E

was confirmed by pressing the button

- letter P with the characters (0) through to (9)

attached will apear on

display. By pressing the

buttons, select the required shift

(see fig. 3, table 1). For beginning setting

choose the parameter P5, which respond

to outdoor temperature 15 °C (see table

1, fig. 3).

Note: If boiler reaches the reference temperature, then heats system by minimal

temperature (38 °C) till outdoor temperature increase at 3 °C, then is heating

switched-off (see table 1 - switch-off temperature).

fig. 3

Equithermal curves

„P“ parameter 0 1 2 3 4 5 6 7 8 9

Reference temp. °C 6 7 9 11131517192123

Switch-off temp. °C 9 10 12 14 16 18 20 22 24 26

Table 1

Page 8

7

Operation diagram

Page 9

8

No flame - F1

Boiler is switched off, for

example by reason of gas

supply failure. LED 4 under symbol

flash. Boiler can be restarted by

switching off and on (

from

position „I” to position „0“ and again to position „I“

by mains on/off switch). If fault is

frequent, call service centre.

Loss of circuit heating water - F0

Pressure is under 0,7

Bar. Boiler is switched off,

LED 1 and LED 4 under

symbols

and flashes.

After filling system up to 12 Bar the boiler automatically starts. For filling can

be used refilling valve at the bottom of

boiler (see fig. 4). If fault is frequent, call

service centre.

Other boiler faults (from F2 to F8)

Boiler switched off itself.

LED 4 under symbol

flash. It is necessary to

call service centre.

Fault messages

Boiler memory fault - F9

Boiler works, but possibility changes in setting

exists. LED 3 under symbol

lights continuously.

Switch the boiler off and

on (

from position „I” to

position „0“ and again to position „I“

by

mains on/off switch). Then check boiler

parameters (see Water temperature setting). Let check the boiler setting by service centre occasionally.

Note: The preparation for and commencing

of the boiler operation may only be carried

out by a specialised service centre!

Before starting the boiler when it

has been put into operation, check

the following facts:

• The power cord must be plugged into the

socket.

• The gas valve that feeds the boiler must

be open.

• The water pressure in the heating system

should be between 1 and 2 bar

Now the boiler is ready to be started.

Boiler start

Set the mains on/off switch to the “on” position (“I”). Display light up.

Note: In case of safety switch-off due to

extinction of flame or the flue thermostat

reaction (version 24 BOV) LED 4 under

symbol

starts flash.

Boiler can be un-

blocking by switching the boiler off and on

Boiler Start and Switch-Off

(

from position „I” to position „0“ and again

to position „I“

by mains on/off switch).

In case of

safety switch-off due to overheat

thermostat Led 4 under symbol

flash

too, but boiler can be unblocking only by

service centre and this act is not guarantee

repair.

Warning: The boiler must not be operated if the safety elements (e.g. overheat

thermostat, flue termostat) are dis abled or

re placed with elements different from those

specified by the manufacturer.

Boiler switch-off

Set the mains on/off switch to the “off”

position (“0”).

If the boiler is going to be switched off for

a longer time, it is recommended to disconnect boiler from the electricity source

and close gas valve. This must be done

with reference to ambient temperature,

because there is the risk of freezing boiler

and system in frost weather.

Page 10

9

Setting SUMMER mode (only DHW)

• Start the boiler;

• Select “– –” for CH temperature as described under Control and Signalling (CH

temperature setting);

• Activate the basic state by MODE button.

Operation without a room thermostat

Boiler keeps CH temperature on setting

value. The room thermostat is not connected; its contacts must be interconnected

(by utilizing a jumper).

• Set the desired temperature value as described under Control and Signalling (CH

temperature setting);

Operation with a room thermostat

Boiler keeps CH temperature on setting

value, with breaks in operation dependent

upon the temperature in the room in which

the thermostat is installed. The radiator in

that room must not be equipped with a

thermostatic valve head. The settings are

the same as the operation without the room

thermostat, but the jumper is removed and

the room thermostat is connected to the

contacts.

Running the Boiler with Equithermal

Control

The boiler changes heating water (HeW)

temperature according to the changing

outdoor temperature.

Important: The boiler must have an outdoor temperature sensor connected! The

outdoor temperature sensor is installed

on the coldest wall of the building (north of north-west), about 2.5 – 3 m above

ground. The sensor must not be exposed

to any external sources of heat such as

open windows or ventilation shafts or sunshine.

When selecting a heating curve, a rule

applies that curves of a lower number are

suitable for buildings with good thermal

insulation and steeper thermal gradient,

and vice versa.

The heating curve diagram provided is

used as a primary guideline. More accurate setting is achieved by monitoring both

outdoor and indoor temperatures for several days.

In the first setting select the E5 curve.

When doing the setting, all radiator valves

must be completely opened, thermostatic

valves must be set to maximum temperature and doors and windows must be

closed.

Change the curve gradient or reference

temperature in small steps, and after each

new setting wait about 2 hours and then

assess the change. When trying to find

the right setting, it is better to do so when

the outdoor temperature fluctuations are

greater, and the final setting should be

done when the outdoor temperature is below the freezing point.

The boiler is set in the following procedure: 1. Select the “HeW temperature” mode

and make sure that the function “SUMMER” is not activated. (symbol --). Set the

temperature to a concrete value (it will

have no effect on the equithermal mode).

2. Select “Equithermal mode – curve gradient” and set it to symbol E5 – see page

7.

3. Select “Equithermal mode –reference

temperature shift “ and set it to (P5). 4. Put

the boiler into the ready state. After several days of operation (when the premises

have been heated up), change the curve

gradient as necessary.

5. If the indoor temperature does not noticeably change with a changing outdoor

temperature, the selected curve is the correct one. The temperature can be set to

Boiler Regulation

Setting WINTER mode (CH + DHW)

• Start the boiler;

• Select the CH temperature instead of “– –”

as described under Control and Signalling

(CH temperature setting);

• Activate the basic state by MODE button

Page 11

10

Anti-freeze protection of the system

The boiler has build-in protection against

freezing water in boiler (no in whole heating

system or DHW pipes). The boiler is always

started if the CH temperature is below 4°C

and works until CH temperature reaches

8°C. This protection is independent on

room thermostat or SUMMER mode (CH

water temperature setting – – )

Pump protection

The pump is automatically switched on for

a short time (approximately 30 sec.) if it

has not been operated for 24 hours – thus

clogging by sludge sedimentation in the

pump’s bearings is prevented.

Anti-cycling function

This function restrict too repeated starts

of boiler to heating system and it is useful especially in smaller heating system,

when required heating power is smaller

than minimal boiler's thermal power output.

Next start is delayed in range from 1min 30

sec to 5 min.

Overheating protection

If the CH temperature is higher than the

pre-set value of 80°C, the pump is always

switched on and continuously operated. If

temperature further increases, safety thermostat shut boiler down, and thermostat

must be unblocked by service centre.

In case water loss the boiler shut down too,

but it will be reactivated automatically when

the pressure increases again.

Disconnected boiler from el. source

Should the boiler be disconnected from the

electricity source for a long time (continuously for one month or longer), it should be

regularly reconnected and switched on (at

least once a month). If the pump is blocked,

always call a specialised service centre.

Repairs of the pump caused by impurities

in the heating system are not covered by

Protective features of the boiler

a higher or a lower value by shifting the

reference temperature – see the section

“Controls and signals – equithermal mode

– reference temperature shift”.

Please note: If with a decreasing outdoor

temperature the indoor temperature noticeably increases, select a heating curve

of a lower number, and if it decreases,

with a higher number.

Running the Boiler with Equithermal

Control and Room Control Unit

The room control units augments the equithermal control, allowing time setting and

economy heating mode (e.g. at night).

How to set the boiler: • set the equithermal

control as explained above;

• connect the room control unit to the boiler (remove the terminal jumper) and then

set the required temperature during the

comfort period on the control unit to a value about 5°C higher then the temperature

reached with equithermal control. Set the

required temperature during the economy

period (at night, when absent) on the control unit to the actually required value – it

must always be at least 3°C lower than

the actual comfort temperature.

Please note: Room control unit must be

installed by a specialist service organisation.

Example: Select curve E5. With the outdoor temperature -10°C, the boiler supplies water to the heating system of about

70°C. If you at the same time select the

P5 reference temperature shift parameter, when the outdoor temperature rises

by 15°C, the boiler should supply water

to the heating system of 38°C. When the

outdoor temperature rises to 18°C, the

heating water heating is turned off.

Heating power setting

Boiler's power factory setting is 15 kW to

heating system. The maximal power 23 kW

is always available for preparing DHW. Only

service centre authorized by manufacturer

can change heating power in accordance

with requirement of heating system.

Page 12

11

Servicing and maintenance

Refilling water to heating system

Caution: The boiler is installed as part

of a sealed system which must only be

drained and filled by a com pe tent person.

Common user can fill and drain boiler in

order to keep the heating water pressure

in recommended range 1-2 bar.

When refilling, follow these conditions:

• The pressure of the water source must be

higher than that of the water in the heating

system;

•

The temperature in CH has to be lower

than 30°C.

• Recommended water pressure in cold boil-

the boiler’s warranty.

Warning: The protective functions are

only active if the boiler is plugged into the

electrical grid socket and the main switch

is on (in the “I” position).

Stoppage and recovery of electricity

supply

If there is a stoppage in electricity supply,

the boiler is switched off. When the electricity supply is recovered, the boiler will switch

on, without a loss of the parameters.

If the F1 fault message is shown on the

display after the electricity supply recovery,

turn mains on/off switch from position „I” to

position „0“ and again to position „I“ (see

Control and Signalling).

If the boiler does not restart, the overheat

de vice may need resetting by a

specialised

service centre

.

Pump after-running

The pump after-running is standardly set

from factory on 45 sec after shutdown

of boiler by room termostat. If no room

thermostat is used, the pump runs contuniously.

Above-mentioned adjustment can be

changed on the 45 second pump running

after burner stop. This is recommended in

case regulation without room thermostat

Caution: The chages of the pump affter-

running can makes only competent person

autorised by the manufacturer.

Safety valve

The boiler is equipped with a safety valve.

DO NOT TOUCH THE SAFETY VALVE! If

water is leaking from the valve, switch the

boiler off, unplug it and call a specialised

service centre. Only qualified persons

are allowed to fill the boiler with water or

discharge water from the boiler. If there is

a repeated drop of pressure, discuss the

defect with your service centre.

Air flow rate safety device (for version

24BTV with forced flue gas removal)

If an obstruction, even partial, of the flue

occurs, the built in safety sys tem of the

boiler will turn the boiler off. The boiler will

be ready to op er ate when the fault has

been cleared.

Chimney draft control system (for version 24BOV with flue gas removal by

means open chimney draught)

If the chimney draught is impaired or

blocked, gas supply is stopped and the

boiler is automatically shut down and it

will light up fault F1 display on the control

panel. The boiler can be start after cooling

up the flue-gas safety thermostat by turning

the mains on/off switch from position „I” to

position „0“ and again to position „I“.

er (to 30

°C) is in range from 1 to 2 bar.

Note: If the pressure in the water mains

were the same or lower than that in the

heating system, there would be a risk of

heating water entering the water mains,

which must not be allowed. The risk is

lowered by installing a backflow valve on

the water-supply pipe in boiler.

The manufacturer is not liable for any

damages caused by tampering with the

refilling or draining valve or failures to

adhere to the above conditions. No damages or defects so caused are covered

by the boiler’s war ran ty.

Page 13

12

The warranty on boilers is provided as

specified in the Guarantee Certificate,

Service Booklet and under conditions

specified in these Instructions for Use

and Instructions for Installation (in chapters

Introduction, Boiler installation).

Warranty conditions

Too high pressure in central heating system:

If it's necessary to reduce pressure in CH

or drain the boiler, can be used the tap at

the bottom of boiler (see fig. 12 in Installation instruction) Water in CH has to be

cold (max. 30°C), DHW setting and heating

setting have to be ´– –´. Be careful during

draining to prevent damages caused by

water flowing from boiler.

Caution: The frequent water loss indicates

the water escape from system. Too small

pressure in cold system together with too

high pressure in warm system indicates

too much water in system or little air in

expansion vessel. Call service centre

soon.

Cleaning

The boiler can be cleaned with a wet

cloth and then dried and polished with

a dry cloth. Never use any abrasives or

thinners.

Caution: Before cleaning switch the boiler

off by mains on/off switch (to position „0“)

Maintenance and inspections

Checks and maintenance on the boiler

should be regular, at least once a year.

Such inspections are not covered by the

warranty. The Service Booklet contains a

checklist for such inspections, that can

provide only service centre authorised by

manufacturer.

Refilling procedure:

• Check if the power cord is plugged into the

socket and the gas valve that feeds the

boiler is open. The main on/of switch is in

position

„I“.

• Press MODE button to display pressure in

heating system. If the pressure is under 0,7

bar, LED under symbol flash.

• Slowly open the refilling valve and

simultaneously watch the pressure increase

on the display. Pressure is displayed only

30 second after pressing MODE button.

The valve is opened counter-clockwise,

closed clockwise.

• Fill the system to pressure 1 - 2 bar.

• When the desired pressure is achieved,

shut the valve (without applying excessive

force) and check that the water pressure is

not growing (which would occur if the valve

were not closed properly).

fig. 4

Refilling valve

Page 14

13

Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II

2H3P

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

11BS

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . electronic

Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G20 . . . . . . . . . . . . . G31

Max. thermal power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.5 . . . . . . . . . . . . .25.5

Min thermal power input . . . . . . . . . . . . . . . . . . . . .kW . . . . . 10.0 . . . . . . . . . . . . .10.0

Max. thermal power output . . . . . . . . . . . . . . . . . . .kW . . . . . 23,0 . . . . . . . . . . . . .23.0

Min. thermal power output . . . . . . . . . . . . . . . . . . .kW . . . . . .8.5 . . . . . . . . . . . . . 8.5

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . % . . . . . . . . . . . . . . . 90

Gas consumption (Q max / Q min) . . . . . . . . . . . . . . . . 2,72/1,08 m

3

/h . . . . .2,11/0.89 kg/h

Noise level (1m from boiler, at a height of 1.5 m) .dB(A) . . . . . . . . . . .up to 55

Nox class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Gas pressure

Input pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . mbar . . . . . . 20 . . . . . . . . . . . . . . 37

Pressure on burner max/min . . . . . . . . . . . . . . . . . mbar. . . . 12/2,2 . . . . . . . . . . 35,5/6,9

Nozzle diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . mm . . . . . .1,2 . . . . . . . . . . . . . 0,7

Heating

Max. working pressure. . . . . . . . . . . . . . . . . . . . . . .bar . . . . . . . . . . . . . . 3

Min. working pressure . . . . . . . . . . . . . . . . . . . . . . .bar . . . . . . . . . . . . . .0,8

Recommended working pressure . . . . . . . . . . . . . .bar . . . . . . . . . . . . . 1 - 2

Temperature range . . . . . . . . . . . . . . . . . . . . . . . . . °C . . . . . . . . . . . . . 38 – 80

Expansion vessel. . . . . . . . . . . . . . . . . . . . . . . . . . litre . . . . . . . . . . . . . . 5

Max. quantity of water in heating circuit. . . . . . . . . litre . . . . . . . . . . . . . . 70

Max. pressure in expansion vessel . . . . . . . . . . . . .bar . . . . . . . . . . . . . . 3

Domestic hot water (DHW)

Max. input pressure . . . . . . . . . . . . . . . . . . . . . . . . .bar . . . . . . . . . . . . . . 6

Min. input pressure . . . . . . . . . . . . . . . . . . . . . . . . .bar . . . . . . . . . . . . . . 1

Min. water flowrate. . . . . . . . . . . . . . . . . . . . . . litre per min . . . . . . . . . . .2.7

Adjustable temperature range . . . . . . . . . . . . . . . . °C. . . . . . . . . . . . . 35 – 60

Flowrate at 25°C temperature increase . . . . . litre per min . . . . . . . . . . 12.5

30°C temperature increase . . . . . litre per min . . . . . . . . . . 10.8

35°C temperature increase . . . . . litre per min . . . . . . . . . . . 8.8

Electrical data

El. voltage / frequency . . . . . . . . . . . . . . . . . . . . . . V/Hz . . . . . . . . . . . .230 / 50

El. power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . W . . . . . . . . . . . . . . . 95

El. protection class. . . . . . . . . . . . . . . . . . . . . . . . . . IP . . . . . . . . . . . . . . . 45

El. current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A . . . . . . . . . . . . . . . 0.5

Connections

Heating water in/out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G 3/4"

DHW in/out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G 1/2"

Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G 1/2"

Flue

Flue diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . mm . . . . . . . . . . . . . 125

Flue gas temperature . . . . . . . . . . . . . . . . . . . . . . . °C . . . . . . . . . . . . . 95-120

Required chimney draft . . . . . . . . . . . . . . . . . . . . . . Pa. . . . . . . . . . . . . . . 2

Weight flowrate – flue gas . . . . . . . . . . . . . . . . . . . .g/s . . . . . . . . . . . . . . 20

Dimensions

Height / Width / Depth . . . . . . . . . . . . . . . . . . . . . . mm . . . . . . . . . 740 /410 / 320

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . kg . . . . . . . . . . . . . . . 33

fig. 6

Technical parameters 24 BOV

Page 15

14

fig. 5

Technical parameters 24 BTV

Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II

2H3P

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C12 , C32, C42, C52, C62, C

82

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . electronic

Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G20 . . . . . . . . . . . . . G31

Max. thermal power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.0 . . . . . . . . . . . . .25.0

Min thermal power input . . . . . . . . . . . . . . . . . . . . .kW . . . . . 10.5 . . . . . . . . . . . . .10.5

Max. thermal power output . . . . . . . . . . . . . . . . . . .kW . . . . . 23,0 . . . . . . . . . . . . .23.0

Min. thermal power output . . . . . . . . . . . . . . . . . . .kW . . . . . .8.5 . . . . . . . . . . . . . 8.5

Efficiency Qnom . . . . . . . . . . . . . . . . . . . . . . . . . . . % . . . . . . . . . . . . . . . 91

Gas consumption (Q max / Q min) . . . . . . . . . . . . . . . . .2,64/1,1 m3/h . . . . . 2,1/0.89 kg/h

Noise level (1m from boiler, at a height of 1.5 m) .dB(A) . . . . . . . . . . .up to 55

Nox class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Gas pressure

Input pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . mbar . . . . . . 20 . . . . . . . . . . . . . . 37

Pressure on burner max/min . . . . . . . . . . . . . . . . . mbar. . . . 12/2,2 . . . . . . . . . . 35,5/6,9

Nozzle diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . mm . . . . . .1,2 . . . . . . . . . . . . . 0,7

Heating

Max. working pressure. . . . . . . . . . . . . . . . . . . . . . .bar . . . . . . . . . . . . . . 3

Min. working pressure . . . . . . . . . . . . . . . . . . . . . . .bar . . . . . . . . . . . . . .0,8

Recommended working pressure . . . . . . . . . . . . . .bar . . . . . . . . . . . . . 1 - 2

Temperature range . . . . . . . . . . . . . . . . . . . . . . . . . °C . . . . . . . . . . . . . 38 – 80

Expansion vessel. . . . . . . . . . . . . . . . . . . . . . . . . . litre . . . . . . . . . . . . . . 5

Max. quantity of water in heating circuit. . . . . . . . . litre . . . . . . . . . . . . . . 70

Max. pressure in expansion vessel . . . . . . . . . . . . .bar . . . . . . . . . . . . . . 3

Domestic hot water (DHW)

Max. input pressure . . . . . . . . . . . . . . . . . . . . . . . . .bar . . . . . . . . . . . . . . 6

Min. input pressure . . . . . . . . . . . . . . . . . . . . . . . . .bar . . . . . . . . . . . . . . 1

Min. water flowrate. . . . . . . . . . . . . . . . . . . . . . litre per min . . . . . . . . . . .2.7

Adjustable temperature range . . . . . . . . . . . . . . . . °C. . . . . . . . . . . . . 35 – 60

Flowrate at 25°C temperature increase . . . . . litre per min . . . . . . . . . . 12.5

30°C temperature increase . . . . . litre per min . . . . . . . . . . 10.8

35°C temperature increase . . . . . litre per min . . . . . . . . . . . 8.8

Electrical data

El. voltage / frequency . . . . . . . . . . . . . . . . . . . . . . V/Hz . . . . . . . . . . . .230 / 50

El. power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . W . . . . . . . . . . . . . . 135

El. protection class. . . . . . . . . . . . . . . . . . . . . . . . . . IP . . . . . . . . . . . . . . . 45

El. current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A . . . . . . . . . . . . . . . 0.6

Connections

Heating water in/out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G 3/4"

DHW in/out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G 1/2"

Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G 1/2"

Flue gas and air ducts

Flue duct / air inlet . . . . . . . . . . . . . . . . . . . . . . . . . mm . . . . . . . . . 100/60 (80/80)

Max length of coaxial ducts 100/60 . . . . . . . . . equivalent m. . . . . . . . . . . 4

Max length of separate ducts 80/80 . . . . . . . .equivalent m. . . . . . . . . . . 10

Flue gas temperature . . . . . . . . . . . . . . . . . . . . . . . °C . . . . . . . . . . . . .115-145

Weight flowrate – flue gas . . . . . . . . . . . . . . . . . . . .g/s . . . . . . . . . . . . . . 18

Dimensions

Height / Width / Depth . . . . . . . . . . . . . . . . . . . . . . mm . . . . . . . . . 740 /410 / 320

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . kg . . . . . . . . . . . . . . . 37

Page 16

15

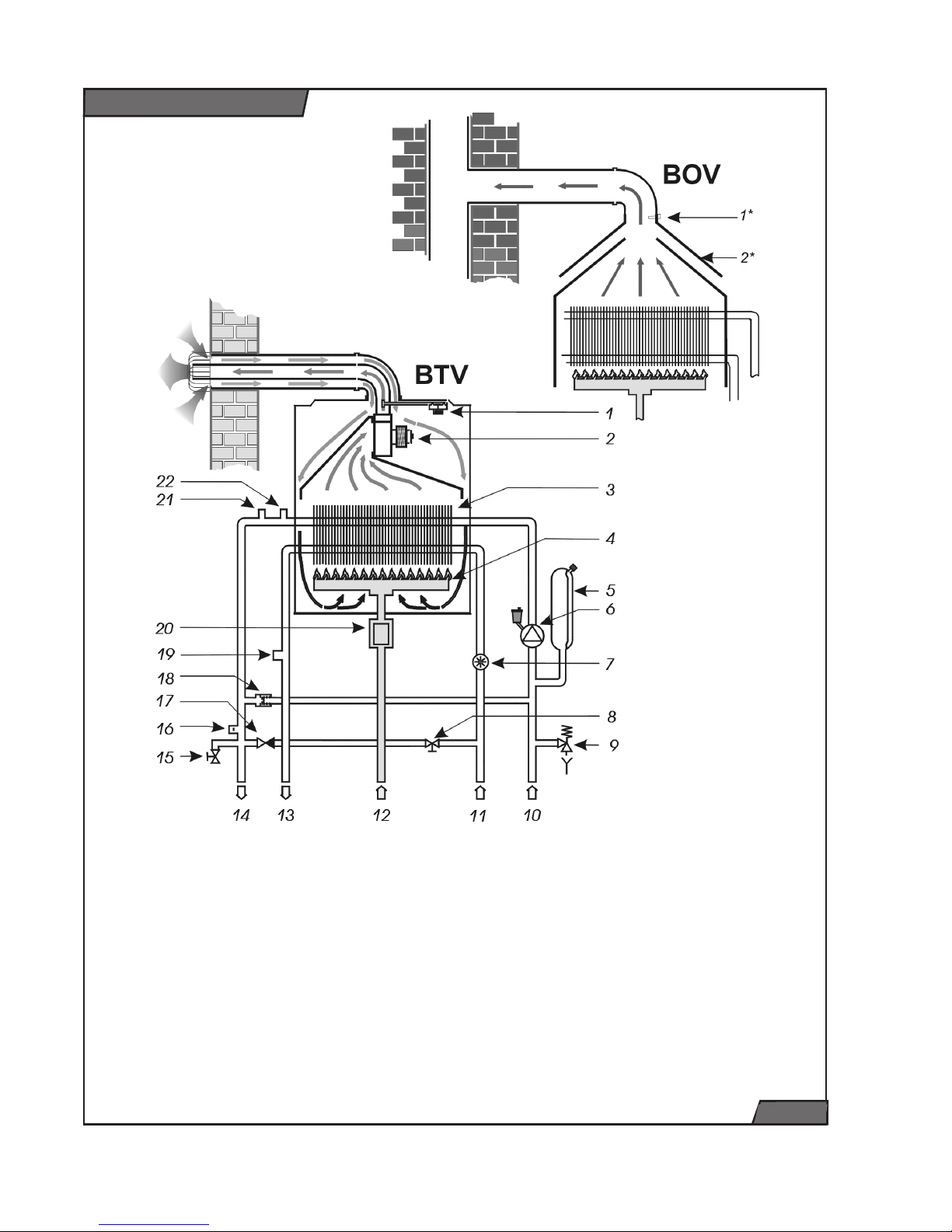

1. manostat

1* chimney draft control system

(flue thermostat)

2. fan

2* draught damper

3. heat exchanger

4. burner

5. expansion vessel

6. pump

7. DHW flow rate sensor

8. water refilling valve

9. safety valve

10. CH inlet

11. DHW inlet

12. gas inlet

13. DHW outlet

14. CH outlet

15. drain valve

16. pressure sensor

17. backflow valve

18. By-pass

19. DHW temperature sensor

20. Gas valve

21. CH temperature sensor

22. overheat thermostat

fig. 7

Boiler schematic

Page 17

16

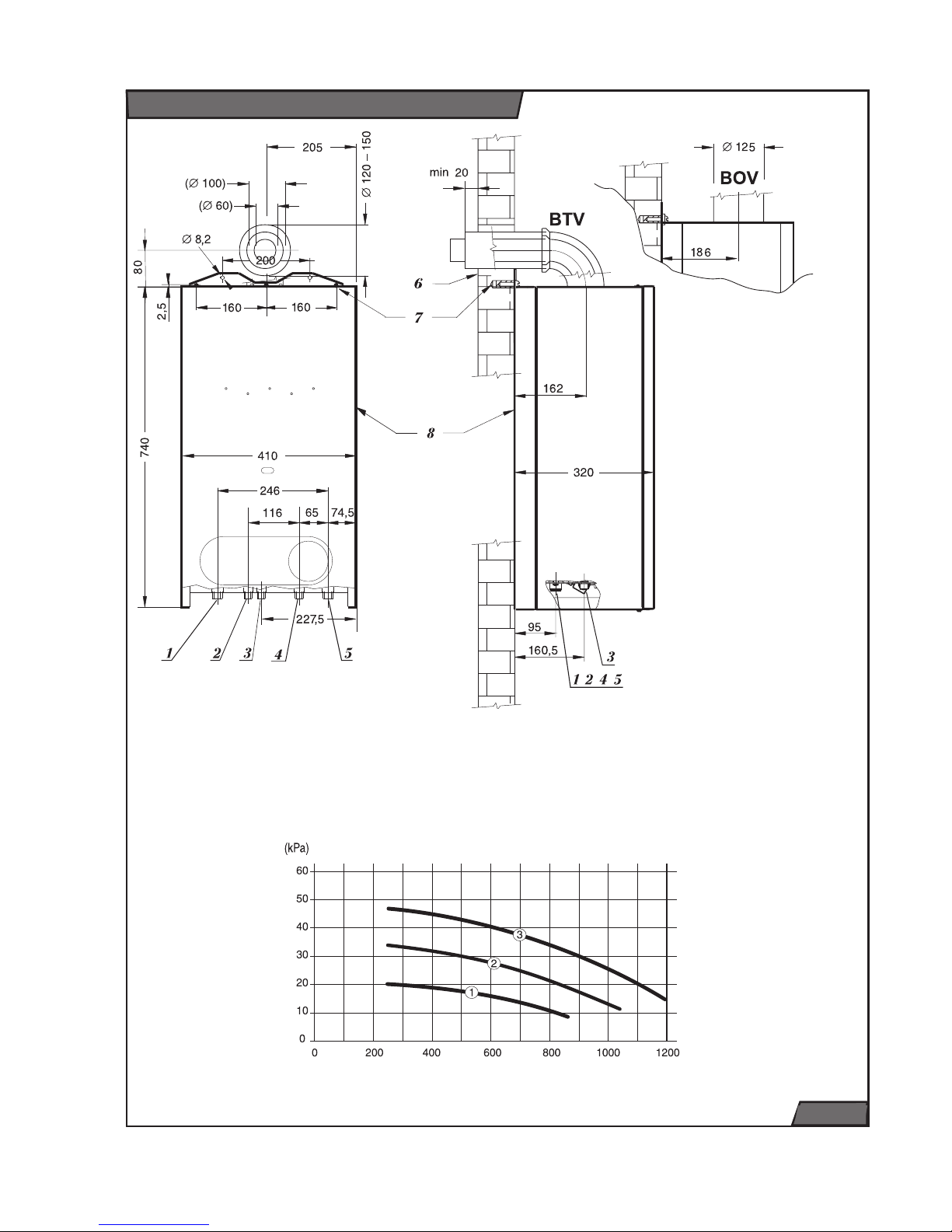

1. CH outlet (outer thread G 3/4")

2. DHW outlet (outer thread G 1/2")

3. Gas in (outer thread G 1/2")

4. DHW inlet (outer thread G 1/2")

5. CH inlet (outer thread G 3/4")

6. Wall

7. Wall-fixing bracket

8. Casing

Dimensions and pressure available

fig. 8

Flow rate through heating system (l/h)

Available pressure (kPa) between

heating supply and return

(10 kPa = 1 m WG)

Page 18

17

24 BTV/BOV is compatible with all

common types of heating water systems

and radiators.

24 BTV/BOV boiler can be put into operation only by an authorised installer in compliance with valid regulations. A network

of the manufacturer’s con trac tu al service

centres provides installation, maintenance

and repairs.

The boiler is designed for operation in a

normal environment (temperatures between +5 and +40°C, humidity up to 85%,

depending on the tem per a ture).

The boiler is suitable for installations in

residential and social rooms as regards

the noise level.

The heating-circuit water must comply

with the relevant Standard (it must not be

acidic, i.e., its pH must be above 7, and

the carbonate hardness must be as low

as possible).

Use of anti-freeze mixtures is not recommended, since they have properties unsuitable for boiler operation. These specifically

include: reduction of heat transmission to

the heating circuit, high thermal expansion of volume, ag ing, de te ri o ra tion of

rubber parts. Even if no other solution for

preventing the system from freezing has

been found, con se quent failures to meet

the operational parameters and/or defects

caused by the use of the anti-freeze mixtures will not be covered by the warranty.

Prior to the final assembly, the heating-circuit pipes should be flushed by pressure

water, several times. For old er cir cuits (that

have already been in use) the flushing

stream direction must be opposite to that

of the heating wa ter.

Installation of a sludge separator is recom-

mended in the incoming branch of heating

water. The design of the sep a ra tor should

enable regular removal of sludge without

necessity to discharge large quantities of

heating wa ter. The sludge separator can

be combined with a filter; however, a filter

itself is not sufficient protection. Both the

filter and the sep a ra tor should be regularly

checked and cleaned.

The relevant standards provide require ments for the water quality: if the sum

of calcium and magnesium concentrations

is above 1.8 mmol/litre, other “non-chem i cal” measures should be taken against

scaling (such as protection by magnetic or

electrostatic field).

The warranty does not cover mechanical

defects caused by foreign bodies and

impurities (e.g., a clogged ex chang er or

pump).

Working temperature of the upper parts

of the boiler (especially the top and side

panels) may be up to 50°C high er than the

ambient temperature. The clearance from

flammable materials (such as chipboard,

polyurethane, polystyrene, polyethylene,

ex pand ed PVC, synthetic fibre, cellulose,

asphalt board, rubber, etc.) must secure

temperature these materials under 80°C.

The minimum handling space around the

boiler should be such that easy and safe

work with bare hands and/or with tools be

possible.

Introduction

INSTALLATION INSTRUCTONS

Page 19

18

For the 24 BTV flue-gas is removed and

combustion air is brought in by a special

double duct. Double-duct routes can be

completed from the standard parts supplied by the manufacturer for virtually any

sit u a tion. The route must be designed to

enable removal of condensed flue vapours

out of the duct. Special con den sate-discharge elements can be used for that

purpose. If any defects are caused by the

condensation, they will not be cov ered by

the warranty. Due to the variability of local

conditions, the double duct elements are

not in clud ed in the de liv ery or in the boiler’s price. Principles for completion of the

routes – see. chapter “Air and flue ducts.”

For the 24 BOV flue-gas is removed by

means open chimney draught. Minimal

required chimney draught in steady stage

is 2 Pa. Connection to the chimney is via

a connecting flue pipe with diameter corresponding to flue outlet on the boiler (125

mm). Installation of both the boiler and the

connecting flue pipes with chimney must

comply with valid standards. The standard's requirements prevent appearance of

adversary effects, such as excessive cooling of the flue gases, penetration of the

chimney wall by humidity, and variability

of chimney draught which would affect the

boiler operation in an undesirable manner.

The connecting flue pipes are not included

in the boiler delivery.

Caution: Elements reducing the chimney

draught (such as various exchangers for

using the residual heat) are prohibited

from being inserted in the connecting

flue pipe.

The 24 BOV takes combustion air from the

space around it. There must be possibility

of direct space ventilation and sufficient

combustion air supplies comply with valid

standards.

Delivery completeness

BTV /BOV boiler is delivered in assembled

state and functionally tested.

Delivery contains (see fig. 9):

1. Boiler

2. User and installation instruction

3. Service book

4. List of Service centres

5. Certificate of Warranty

6. Template

7.

Drawbar for hanging of boiler

Additional accessories

Following accessories can be ordered

according to various requirements;

1. Connecting set, supply number XXXX

(see fig. 10)

2. Flue gas and air ducts 100/60 for BTV

version e.g.:

- S5D-1000 Horizontal set (elbow with flange 90°, 1m horizontal terminal), supply

number 7194

- K1D Elbow 90°, supply number 2842

- T1D-1000 Extension 1m, supply number

2825

- S3 Vertical terminal, supply n. 2805

- Z1 Condensate retainer, supply n. 2857

3. Flue gas and air ducts 80/80 for BTV

version e.g.:

- S2 Air-flue duct set (separator, 2x elbow

90°, 2x 1m horizontal terminal) , supply

n. 2803

- K2A Elbow 90°, supply n.

- T2 Extension 1m, supply n. 2819

- S4 Vertical terminal, supply n. 2809

- Z2 Condensate retainer, suply n. 2858

Page 20

19

Delivery contents

1

Záruční list

Seznam servisních

středisek

Servisní kniha

Návod k obsluze

a instalaci

2

3

4

5

6

7

fig. 9

Connecting set

fig. 10

Connection set contain:

1x assembly platform

2x CH stop valve G 3/4" including gasket

2x Heating system connections - pipe

diameter 22 mm

2x DHW stop valve G 1/2" including

gasket

1x gas stop valve G 1/2" including gasket

1x template

1x drawbar for hanging of boiler

3x bolts including wall plug

Page 21

20

Heating system

Rated diameters of pipes are determined

in the usual manner, depending on the

pump characteristic curve. The piping is

determined by the requirements for the

system in question, not by the boiler’s

maximum power output. Nevertheless, the

piping must provide for a 20°C temperature

difference between the incoming and

outgoing CH and the minimum flow rate

500 litres per hour.

The pipes’ layout must be such that no

bubbles form in the system and purging

is facilitated. Purging valves should be

situated at all high points of the system and

on each radiator. It is absolutely necessary

to flush the system before the new boiler

installation and remove impurities from

heating system.

The heating system’s hydraulic pressure

(measured at the boiler) should be at least

1 bar (corresponding to 10 m of water

column). The recommended pressure

range is from 1 to 2 bar. The expansion

vessel is suitable for max.70 litres of

heating water (for temperature 80°C).

Thermostatic valve heads can be used on

the radiators. If the boiler is controlled by

a room thermostat, the ther mo stat ic valve

heads should not be installed in the room

where the room thermostat is.

The boiler may be connected to the heating

circuit by flexible elements (hoses) during

reconstructions, if necessary because of

the layout, etc. Such hoses must have

parameters suitable for the purpose,

should be as short as possible, protected

from damages caused by mechanical load

and chemical agents, and replacement

must always be arranged prior to the

end of the life-cycle and/or deterioration

of their parameters (according to their

manufacturer’s instructions).

Note: after connecting of boiler to heating

system remove plastic stoppers which are

placed in boiler outlets.

DHW system

The DHW pressure should be between 1

an 6 bars; if it is higher, a reduction valve

must be installed. In areas with very hard

water, suitable measures for softening

should be applied.

It is recommended to install CH, DHW

and gas stop valves on the pipes near

the boiler.

For easy connecting of boiler is used the

special connecting set with stop valves

(see Fig. 10).

Boiler installation

Page 22

21

Boiler hanging

The boiler is hung on the wall on two bolts,

with minimum diameter of 6 mm. Suitable

washers must be placed under the bolt

heads. The connecting fittings have outer

threads. All necessary distances are shown

in the figure of connecting dimensions

(fig.8).

Boiler connecting

It is recommended to install CH, DHW

and gas stop valves on the pipes near

the boiler.

The connection fittings on the boiler

must not be affected by any pressures or

forces from the piping – in other words,

all dimensions and distances of the

connected pipes must be accurate, both

mutually and from the wall and floor. For

this end is supplied special connecting set

(see Fig. 10).

On the hydraulic set at the boiler’s bottom,

the following elements are situated: safety

valve, relief valve and discharge valve.

The boiler should be connected to the

heating system such that it is possible to

discharge water only from the boiler if it is

necessary for repairs.

Boiler hanging

fig. 11

Page 23

22

Boiler filling and draining

Water filling into / draining from the heating

system and the related steps (purging,

setting the expansion vessel) are not

covered by the warranty.

Small quantities of water can be refilled into

the boiler by the refilling valve.

The drain valve is designed to reduce water

pressure in the boiler before repairs. Only

partial discharge of water from the boiler

can be achieved via the drain valve.

Filling/draining valves should be installed at

suitable points of the system for complete

discharge of water from the boiler or the

entire heating system.

Basic conditions and procedure of filling

and draining are described in User

instructions. In additional must be open the

little cap on deaerating valve (on pump),

checked pressure in expansion vessel and

deaerated whole heating system.

Safety valve

On the hydraulic set at the boiler’s bottom

is situated safety valve (see fig. 13), The

safety valve outlet may release hot water

or steam (if the safety pressure limit is exceed ed).

Gas connection

The 24 BTV/BOV - G20 model is designed

for natural gas, with 2.0 kPa rated pressure

in the network and the calorific value of 9

to 10 kWh/m3. The internal gas piping and

the gas meter must be dimensioned for

all gas appliances of the respective user.

The boiler’s connection branch’s rated

inner diameter should be at least DN

1/2", but one degree higher (DN 3/4") is

recommended.

The 24 BTV/BOV - G30 model is designed

for LPG, whose calorific value is between

12.3 and 13.0 kWh per kg. Operation using

portable cylinders would be problematic,

due to both sufficient volume and han dling

of the cylinders; hence a prerequisite for

the operation is installation of an LPG tank

near the heated premises and filling of the

tank by an organisation authorised for such

activities.

Sufficient supply of LPG from the tank to

the boiler (and other gas appliances, if any)

is part of the design and delivery of the

LPG tank . For LPG boilers, a pressurecontrol (reduction) valve should provide the

pressure of exactly 3.7 kPa (37 mbar).

Gas piping in buildings must fulfill the valid

requirements.

Note: for connecting of gas valve must

be always used union nut and gasket

directly placed on gas valve !!!.

Drain valve

Safety valve

fig. 12 fig. 13

Page 24

23

Boiler template

fig. 14

Page 25

24

For 24 BTV, the air input and flue gas

output goes through a special double

duct. The sufficient distance must be

ensured betveen the flue gas duct and

the flammable materials to prevent the

increasing temperature of these materials

over 80°C. Horizontal segments of the duct

are laid with a slope, so that condensate

flows into an opening to the outside (or to

special condensate discharge elements).

it is possible to slightly deviate from the

direction at the elbow-to-straight-piece

connection. Vertical segments of the flue

duct must always be equipped with special

condensate discharge elements.

Maximum length and kinds of flue

design

The maximum length of a concentric and

separate double duct route is in table.

Warning: if the length of the contrentric

double duct is more than 2 Em (separate

ducts more than 4 Em), the flue diffuser

must be taken out of the fan mouth.

Flue gas and air ducts

obr. 15

Em

obr. 16

∅

80

∅

80

L2

L1

Em

obr. 17

obr. 18

flue duct diameter min. length max. length with

diffusor

max. length without diffusor

100 / 60 1,5 Em 2 Em 4 Em

80 / 80 2 Em 6 Em 18 Em

C52 Design

C32 Design

C12 Design

Diffusor

Page 26

25

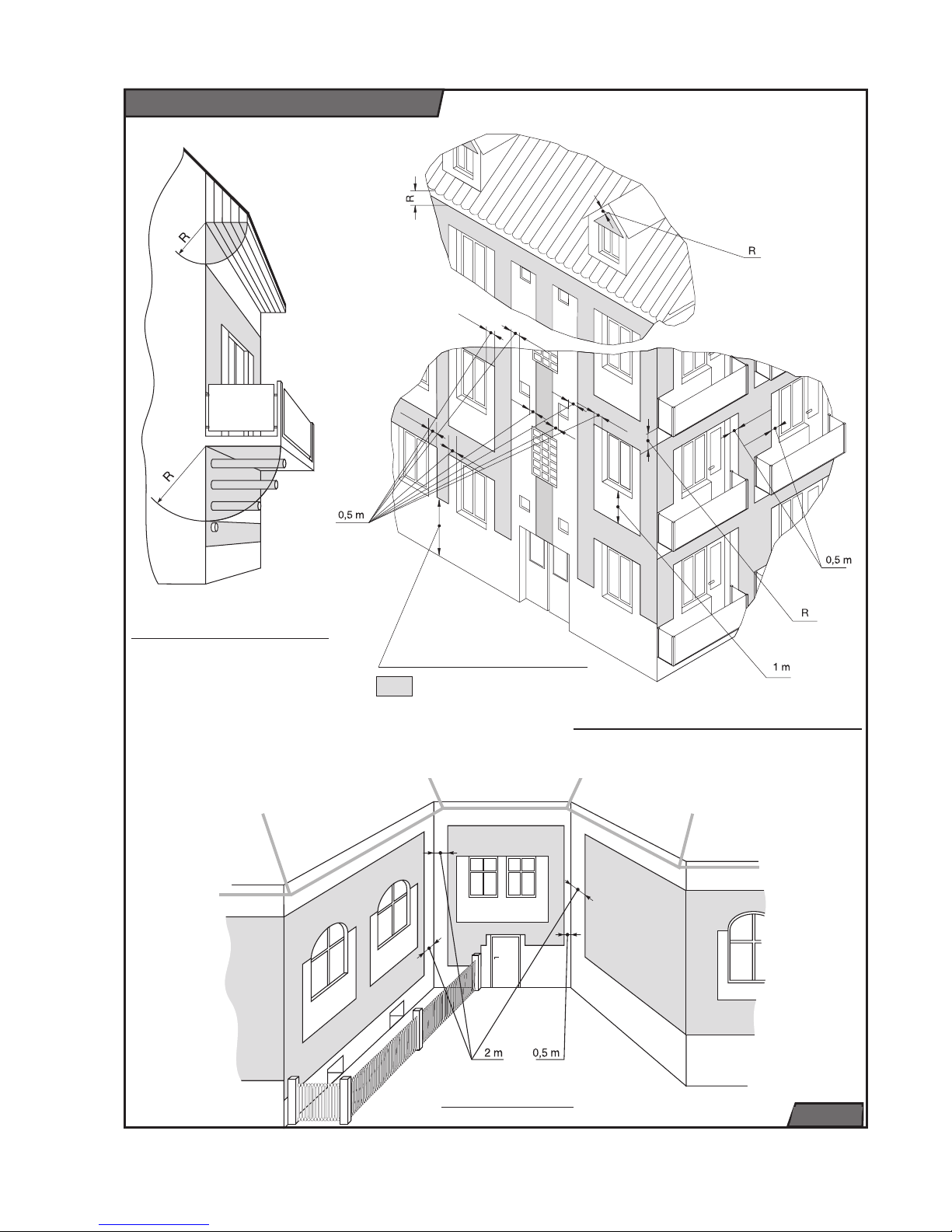

The most frequent kinds of flue design are

illustrated on fig. 16, 17 and 18. The boiler

24 BTV can be used for next following

designs:

• C42 design - connecting to common

chimney

• C62 design - connecting to separately

approved and sold ducts.

• C82 design - air duct leads combustion air

from outdoor environment and flue gas duct

are connected to chimney.

External vent of horizontal ducts on

the façade should be at least:

• 2 m above ground level at publicly

accessible places (0.4 m at other places);

• 0.5 m from sides of windows and other

ventilation openings (grilles) or doors;

• above the top edge of windows, grilles

and doors;

• 1 m below window level, never below

grilles;

• at depth of R (see Fig.19) below

overhanging parts (e.g., roofs, balconies).

Minimum span between external vents:

• 1 m horizontal

• 2 m vertical

The external vent should always be

oriented to the open space (not to doors,

windows or grilles). If this re quire ment

cannot be met, the minimum distances

must be preserved as follows:

a) opposite – between the façade with the

external vent and a façade parallel to it:

• 2 m – if the opposite façade has no windows

or grilles;

• 1 m – if neither façade has any windows

or grilles in it;

• 4 m – if there are windows or grilles (or

external vents) in both façades

b) in corners – between the external vent axis

and the façade parallel to it:

• 2 m – if there are any windows, grilles or

doors in the façade;

• 0.5 m – if there are none.

• Corners smaller than 0.5 m are ignored.

All the distances are understood from the

external vent axis to the outer edge of the

respective window, grille or door.

Special instances

The external vent may also be closer

below an overhanging part, provided it is

equipped with a protruding part of the duct,

whose length at least reaches to the circle

of radius “R” – see. fig 19. .

External vent into a shaft leading to the

open space is possible, if the cross-section

area of the shaft is at least 1.25 m

2

along

its length and there are no doors, windows,

grilles or other flue ducts into the shaft

Vertical external vent – to the roof

Roof vents must be at least 0.4 m from

each other and from air-conditioning

outlets/intakes. Its protruding part must

reach above a snow layer 40 cm thick (if it

were lying on the roof).

Safety precautions

Flue ducts must not be vented into

spaces:

• with a risk of explosion;

• internal (attic, corridor, stairwell, etc.);

• that can be closed, such as passages,

etc.

• below ground level (even if open) such as

tunnels, subways, etc.

If an air intake is separately installed, its

location must be assessed similar to the

above rules.

The opening for the duct passage through

a wall should be bored with sufficient extra

clearance (approx. 120 to 150 mm) and the

duct must be sealed inside of it the sealing

flame proof materials – such as mortar,

gypsum, etc. Passages through walls or

ceilings made of flammable materials must

comply with the valid standard.

Page 27

26

Overhanging parts

Installation in a façade

External vents - Illustration

Corners

fig. 19

2m - in public places

0,4m - in other places

- zone where external vents

can be instaled

Page 28

27

Standard set

Coaxial

elbow 90°

Coaxial duct

Standard set

A Outside casing – air part

B Inside casing – flue gas part

C Collar and clip

D Elbow with flange

E Sealing

F Bolts

G Outer sealing ring (rubber)

I Inner sealing ring (plastic)

J O-ring

• Apply the seal (E) to the bottom part of

the elbow (D);

• Carefully insert the O-rings (J) into the

upper and lower parts inside the elbow;

• Attach the elbow to the boiler – be careful

to con nect the inside part to the boiler’s

outlet properly;

• Put the rubber sealing ring (G) on the air

duct (A);

• Push the completed duct section through

the wall opening so that the (G) ring is

aligned with the outside surface of the

wall;

• Place the collar and clip onto the duct and

elbow; check proper sealing of both inside

and outside sections of the duct;

Note: The maximum horizontal length is 1

elbow plus 3 m (4 equivalent metres) – if

the horizontal route’s equivalent length is

more than 2 m, the diffuser (R) must be

removed from the fan (see Fig. 15 ).

• Secure the elbow’s flange using the

bolts;

Note: If you have to shorten the straight

part, always cut the same length from

both the outside and inside elements.

Always cut at the end opposite to the

external vent.

Example accessories:

Horizontal set 1 m

Horizontal set 0.75 m

Coaxial extension duct (1 m)

Coaxial elbow 90°

Example of horizontal double-duct flue

fig. 20

Horizontal flue - Illustration

Page 29

28

Example of a vertical duct route

• Apply the seal to the coaxial vertical

adaptor (O);

• Carefully insert the O- ring (J) into the

inside part of the vertical adaptor;

• Put the vertical adaptor on the boiler’s and

fan’s outlets;

• Insert the coaxial extension (M) into the

vertical adaptor;

• For passage through the roof cover,

use either special roof tiles (so-called

“ventilation tiles”) or a roof flashing

custom-made by a tinsmith;

• The coaxial extension duct protruding

above the roof should be terminated with

a coaxial (“Meindinger”) head. Instead of

the extension duct and head, a vertical

terminal (L) is better to use as the nicer

top part.

• Attach a condensate-drainage part (tube,

hose, etc. – not included in the delivery)

to the condensate outlet of the vertical

adaptor;

Example accessories:

Coaxial vertical element (O)

Coaxial extension duct (1 m) (M)

Vertical terminal (L)

Example of a vertical double-duct flue

Vertical flue - Illustration

fig. 21

Vertical terminal (L)

Extension duct (M)

Vertical adaptor (O)

Vertical adaptor (O)

Boiler

O-Ring (J)

Groove

Page 30

29

Electrical connection of the boiler to the

power grid is by three-wire cord without

plug. The socket for the plug must comply

with the relevant standard and have the

grounding pin connected to a PE or PEN

cable (yellow-green).

The boiler must be connected to the protective grounding wire; the electrical plug in the

socket must always be accessible without

obstacles. Use of adaptor plugs, extension cords, etc. is prohibited. The boiler

is protected by tube fuse 125 mA/250V

placed on PCB.

Only a person with adequate electricalengineering qualifications can be allowed

to install the socket and the thermostat

(thermostat installation requires utilization

of the boiler’s internal electric cabling); the

same requirements apply to servicing the

electric part. Before any work commences

on the electrical part, the boiler’s cord must

be unplugged.

Only no-voltage thermostats or regulators

can be used for regulating the boiler, i.e.,

they must not bring in any foreign voltage.

The minimum requirements for the regulator’s contacts: 24 V / 0.1 A, A.C.

The room thermostat is connected to the

boiler with a two-wire cable, with copper

wires of a recommended cross-section

between 0.5 and 1.5 mm

2

The connecting cables of the room thermostat should not be led parallel to

other cables or through premises with highpower electric motors (or electric welding

machines., etc.)

The terminal board for connections of the

room thermostat is inside the boiler, on

the bottom. It is accessible after removing

the front cover panel and tilting the control

panel out.

The outdoor temperature sensor is connected to the boiler with a two-core cable

of 0.75 sq.mm cross-section. Maximum

permissible cable resistance may not exceed 10 Ohms, and the total cable length

10 m.

The terminal box for connecting an outdoor sensor and a room control unit is situated next to the terminal box for connecting

a room control unit.

Electrical part

Electrical connection

fig. 22

Page 31

30

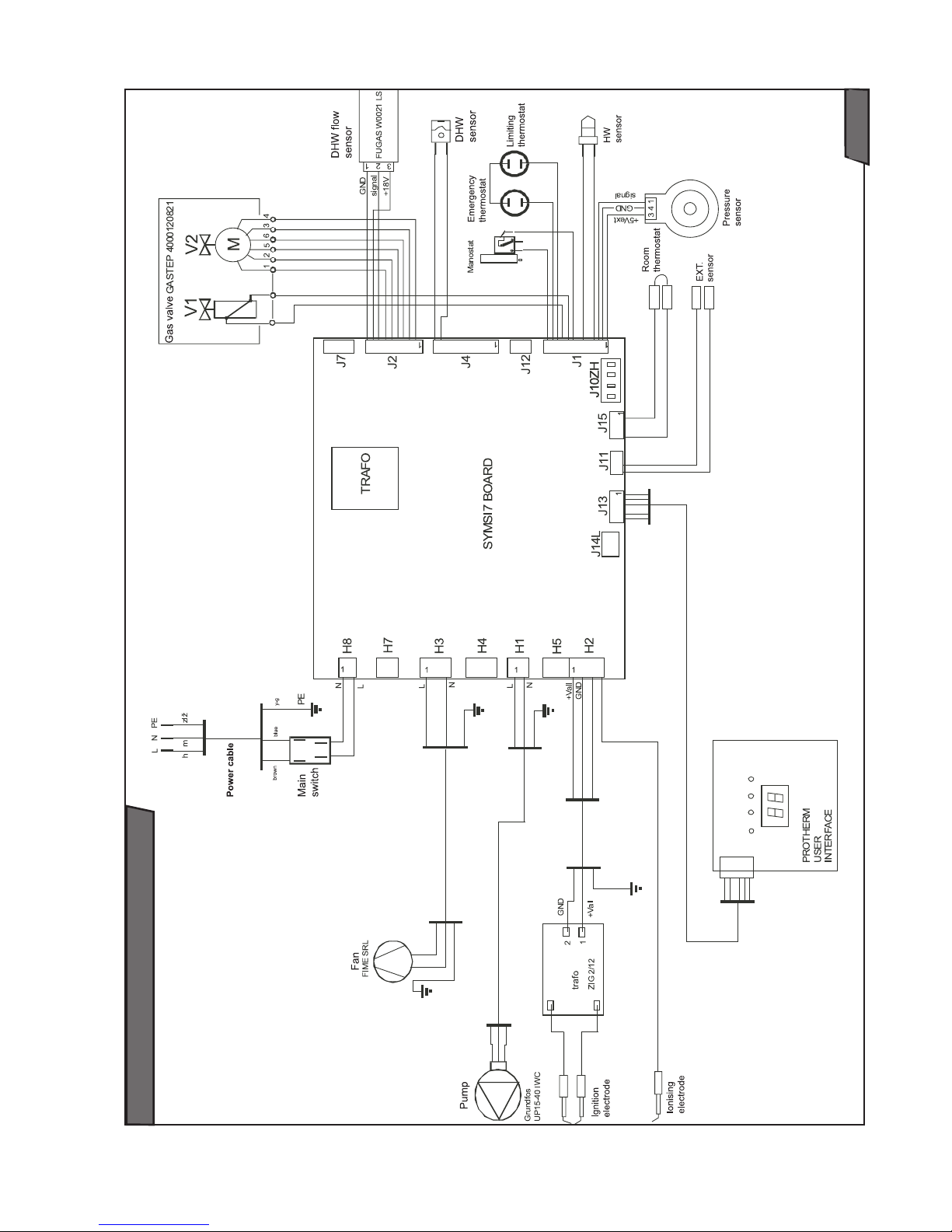

24 BTV - Electrical diagram

fig. 23

Page 32

31

24 BOV - Electrical diagram

fig. 24

Page 33

32

Conversion to LPG

Boiler 24 BTV/BOV is standardly supplied

in the version for the combustion of natural

gas. If the combustion LPG is required, it

is necessary replace gas valve and burner

platform and then set the boiler to specified

parameters. Conversion must only be carried out by a competent person, authorised

by the manufacturer. Gas valve and burner

platform are part of Conversion set. This set

contains all needful parts and Instructions

for conversion.

Page 34

Loading...

Loading...