Page 1

Floorstanding cast iron boiler

Cascade conection possible

Output up to 150 kW

Grizzly

EN

verzion

XXXX - v.2 4/2005

Manual for instruction

and use of boiler

65, 85, 100, 130, 150 KLO

Protherm spol. s r.o.

Jurkovičova 45

909 01 Skalica

Tel.: 034 6966 101

Fax: 043 6644 017

www.protherm.sk

Page 2

2

3

Dear Client,

You have just become an owner of a KLO /

KLO EKO (Grizzly) natural gas or propane gas fired cast iron boiler. We are confident that you will be satisfied with the

service this boiler will give you. However, you’ll have to comply with at least

minimum requirements when running

the equipment. Therefore please read

these Operating Instructions carefully

and comply with their guidelines.

Please pay careful attention to the following

important information:

1. The boiler with all its accessories must

be installed and used in accordance

with an installation design, all applicable

legal regulations, technical standards

and manufacturer’s instructions.

2. The boiler may be installed only in the

environment for which it has been designed and only in a correctly ventilated

room.

3. After installation, the boiler must be put

into operation by a service organisation

authorised by the manufacturer.

4. Please also contact authorised service

if you are experiencing any problems

with the equipment – unauthorised repairs may damage the boiler (as well as

the connected equipment!).

5. The service technician when putting

the boiler into operation for the fist time

must demonstrate its controls and show

you its various parts and how to control

them.

6. Check whether the boiler is complete.

7. Check whether it is the model you have

ordered.

8. Whenever you have any doubts how to

operate the boiler, find and study the

relevant information in these Operating

Instructions and proceed in accordance

with them.

In practice, situations might occur when the

following essential measures have to be

taken:

– prevent the boiler from being (even

accidentally) switched on while inspecting the fumes exhaust and gas

and water distribution routes, by disconnecting the boiler from power

supply by another means than just

with the boiler’s switch (e.g. by pulling the power cord plug out of the

socket),

– shut the boiler down every time when

flammable or explosive vapours are

present (even temporarily) inside

the premises from which combustion air is supplied to the boiler,

– if it is inevitable to drain water from

the boiler or the heating system, the

water must not be dangerously hot,

– when water leaks from the boiler’s

heat exchanger or when the exchanger is clogged with ice, do not try to

switch the boiler on until normal running conditions have been restored,

– during (even suspected) gas leaks or

after gas supply failure, switch the

boiler and the gas supply off and call

the gas company or authorised service.

Regulations and Directives

The PROTHERM KLO boiler may be

put into operation only by an authorised

service organisation in accordance with

UBP SR Notice No. 74/1996. Installations,

putting the boiler into operation, warranty

and post-warranty service are performed

by a network of the manufacturer’s contractual service organisations, which meet

the above-specified requirements. Installations must be carried out in accordance

with a design prepared in compliance with

applicable regulations detailed below.

9. When repairing the boiler, only original

parts must be always used. Internal wiring and factory settings must not be

changed or interfered with.

10. Do not remove or damage any signs

and labels on the boiler.

11. The boiler meets regulations applicable

in Slovakia. For use in other countries,

any potential differences must be identified and resolved.

12. At the end of life of the boiler’s parts and

components (or of the entire boiler), their disposal must be carried out ecologically – metal parts must be delivered to

a metal scrap yard, plastics, seals, and

insulation materials must be sorted out

as required, or a special disposal technology used, engaging the services of

companies authorised for such operations.

13. Before a protracted shutdown we recommend to turn off the gas supply and

disconnect the boiler from power supply.

This recommendation is part of general

conditions defined in this Operating Instructions.

15. The manufacturer shall not be held liable for any damages caused by the

user’s failure to:

– abide by the conditions defined in

these Operating Instructions,

– abide by applicable regulations and

standards,

– abide by installation and operating in-

structions.

– abide by the regulations specified in

the Warranty Certificate and Service

Book.

Such damages are not covered by the pro-

duct warranty.

a ) Heating systems:

STN 06 0310 – Central heating, design

and installations

STN 06 0830 – Safety equipment for central heating and hot water heating systems.

STN 07 7401 – Water and steam for heat

energy equipment of operating pressure

up to 8 MPa

b ) Gas distribution systems:

STN 38 6420 – Industrial gas pipelines.

STN EN 1775 – Gas supply – Gas pipelines in buildings – Maximum operating

pressure below 5 bar

STN 38 6413 – Steel gas pipelines and

connections

STN 07 0703 – Gas-fired boilers

STN 38 6405 – Gas equipment. Operating

principles.

Act No. 222/94 Coll. on business conditions and public service supervision in

the energy industry and on state energy

inspection.

c ) Electrical installation:

STN 33 2180 – Wiring of electrical instruments and appliances.

STN 33 2000-3 – Electrical installation in

buildings. Part 3: Definition of basic characteristics.

STN 33 2000-7-701 – Electrical installation in buildings. Part 7: Requirements on

special installations or premises. Section

701. Rooms with a bath-tub…

STN 33 2130 – Electrical engineering regulations. Interior electrical installations.

STN 33 0160 – Electrical engineering

regulations. Labelling terminals of electrical objects.

Execution regulations.

STN 33 0165 – Electrical engineering

regulations. Colour marking or numbering

of wires.

Execution regulations.

STN 33 2350 – Regulations for electrical

equipment in difficult climatic conditions.

Page 3

4

5

STN 34 0350 – STN electrical engineering regulations. Regulations for loose cables and cords.

STN 33 1500 – Instructions for electrical

equipment.

STN EN 60 335-1 – Safety of household

and similar electrical appliances. Part 1

– General requirements.

d ) Chimney:

STN 73 4210 – Construction of chimneys

and fume exhausts and connecting fuel

appliances to them.

STN 73 4201 – Designing chimneys and

fume exhaust flues.

STN 06 1610 – Fume exhaust parts of

household appliances.

STN EN 297 – Gas-fired central heating

boilers. Boilers Type B11 and B11BS with

atmospheric burners and nominal thermal

output up to 70 KW.

e ) Fire protection regulations:

STN 92 0300 – Fire safety of local appliances and sources of heat.

STN 73 0823 – Fire technical properties

of materials. Degrees of flammability of

building materials.

f ) Utility hot water heating systems:

STN 06 0320 – Heating of utility hot water.

STN 06 0830 – Safety devices for central

heating and utility hot water heating systems.

STN 73 6660 – Internal water distribution

systems.

STN 83 0616 – Utility hot water quality.

Safety of Persons and Equipment

As products, boilers are verified for compliance with the following documents:

STN EN 437, STN EN 50165, STN EN

60335-1+A11, Act No. 513/1991 Commercial Code, Act No. 634/1992 and Ministry

of Health Public Notice No. 13/1977.

Boiler Features

The PROTHERM KLO / KLO EKO stationary, cast iron boiler is designed for heating

water for heating purposes and, if combined with an indirectly heated reservoir,

also for heating utility hot water. It is available in the following series of size:

a) 65, 85, 100, 130, 150 KLO

b) 65, 85, 100, 130, 150 KLO EKO

The boilers use as fuel natural gas and

both series have a dual-stage design (low

and high output).

Models 65 – 85 KLO/KLO EKO are single-stage and designed to run on propane

gas.

Both model series can be fitted with a Siemens Albatros RVA 43.222 equithermal

control unit. By combining it with other

RVA 43.222 control units, a cascade system can be created with multiple sources

of heat.

The central heating system water pump is

controlled by a thermostat and turned on

only when the heating water temperature

reaches a set value. This reduces the time

required to heat the water inside the boiler after a protracted break in the boiler’s

function. The heating water pump is part

of the delivery.

The boiler can work in conjunction with

an indirectly heated utility water tank. The

standard boiler configuration allows the

tank to be connected easily to the boiler’s

terminal box.

To guarantee correct functioning of the

system, we recommend using a PROTHERM reservoir heater of 95- to 200-litre

volume, equipped with a thermostat and a

switching contact. Using the RVA 43.222

control unit will allow water in the reservoir

to be topped up by a pump.

Important: For combined heaters (with

water heated also by electricity), it is essential to prevent the supply of alien volt-

The boiler (as well as its accessories)

complies with the type which has been

tested and certified by the Technical Testing Institute in Piešťany, SKTC-104, authorised to verify the compliance with the

requirements of the Slovak Bureau for

Standardisation, Metrology and Testing,

and the compliance with the technical requirements specified by Government Decrees Nos. 392/99, 393/99 and 393/99 as

set forth in Act No. 264/1999.

Hence the boilers (and their accessories)

meet the requirements of applicable technical and legal standards, a fact confirmed

in a “Certificate of Compliance” issued by

the manufacturer. Pursuant to applicable legislation, the Certificate is kept for

inspection and supervision authorities,

and for distribution purposes sufficient is

a written confirmation that the Certificate

has been issued.

When installing and using the boilers and

their accessories, other generally applicable documents must taken into account,

which also define requirements in addition

to those on the product itself, namely:

– in the areas of design and installation

(and maintenance and repairs): STN

06 0310, STN 06 0830, STN 07 0703,

STN EN 1775, STN 38 6413 and STN

38 6460, STN 73 4201and STN 73

4210, and Public Notice No. 48/1982

(in the wording of later regulations)

and binding work safety and health at

work regulations;

– . during transportation and operation:

STN 38 6405, Public Notice No. 718/

2002.

In addition to abiding with the requirements of these documents, it is necessary to proceed when using the boiler in

accordance with these Operating Instructions and other manufacturer’s documentation supplied with the boiler.

age to the boiler – i.e. the thermostat contacts must be separated from the heater’s

internal electrical wiring!!!

Utility hot water heating has priority before

heating water. This means that water in

the central heating (CH) system is heated

only after the utility hot water (UHW) has

been heated to the required temperature.

Setting this value above usual temperature (50-60°C) will result in longer heating

times and hence longer breaks in heating the building. The heating time will be

longer also when the boiler is set to low

output, or when the CH water temperature

is set too low.

Important: The boiler must not be used for

any other purposes than those described

in these Operating Instructions.

Page 4

6

7

The PROTHERM KLO boiler consists of

the following components:

1. cast iron body of the boiler with thermal

insulation and water connection pipe section;

2. burner plate with gas connection route

and ignition device;

3. collector of combustion fumes with a

chimney thrust detector and SKKT thermostat.

4. boiler covers with control panel and

boiler terminal box;

5. boiler base.

The cast iron boiler body is made of seg-

ments and serves as a combustion chamber (including combustion fumes routes),

and also as a water reservoir (including

water routes). The segments are lateral

(right and left) and central (one kind). The

boiler body of the required size (including

combustion chamber and water reservoir)

is constructed by assembling and joining

together the segments. The assembled

boiler body is fitted with pipe sections for

water connection and is insulated against

heat loss and heat radiation. It also has

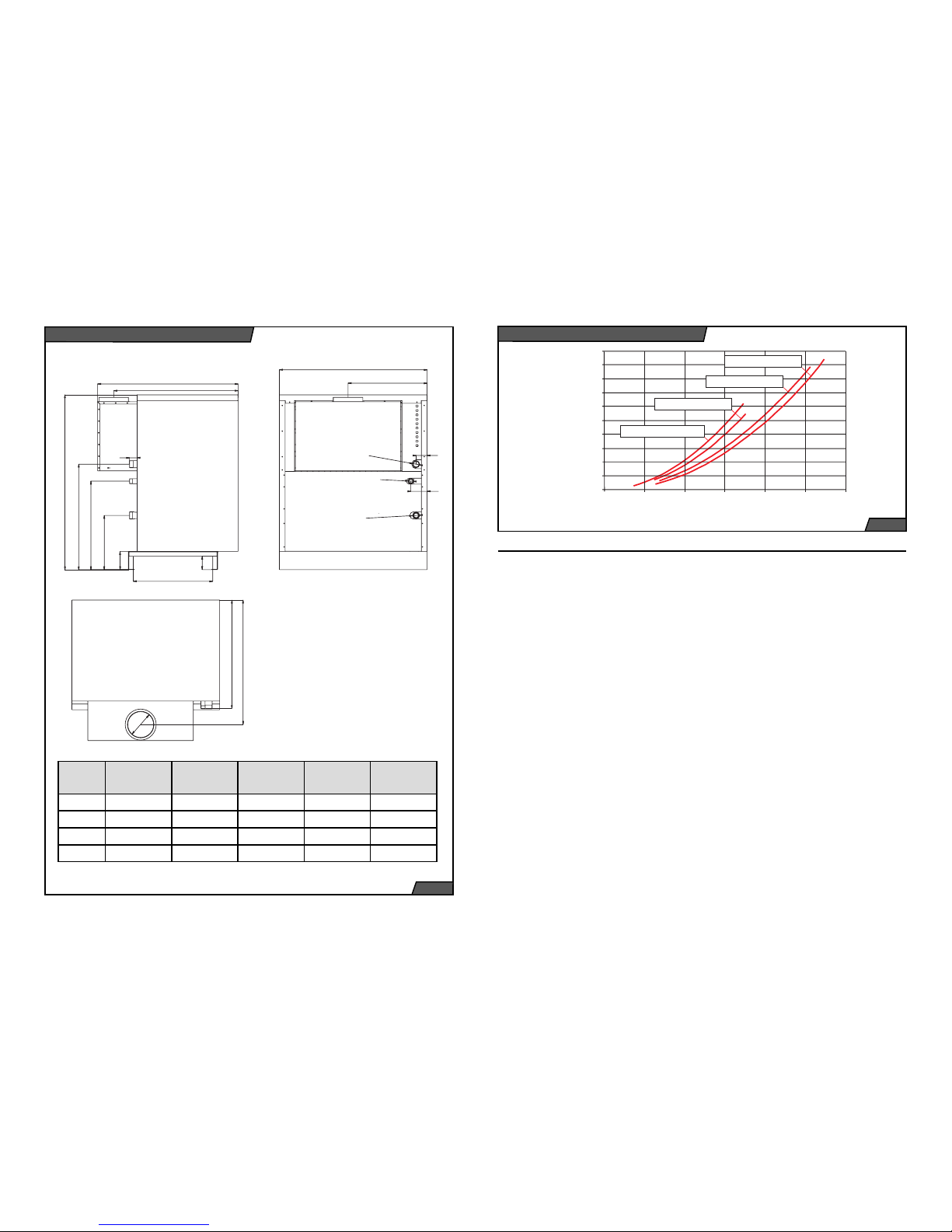

960

850

52

544

92

125

370

605

720

1195

A

B

75

111

Æ G 6/4"

G

1"

Æ G 6/4"

C

Æ D

770

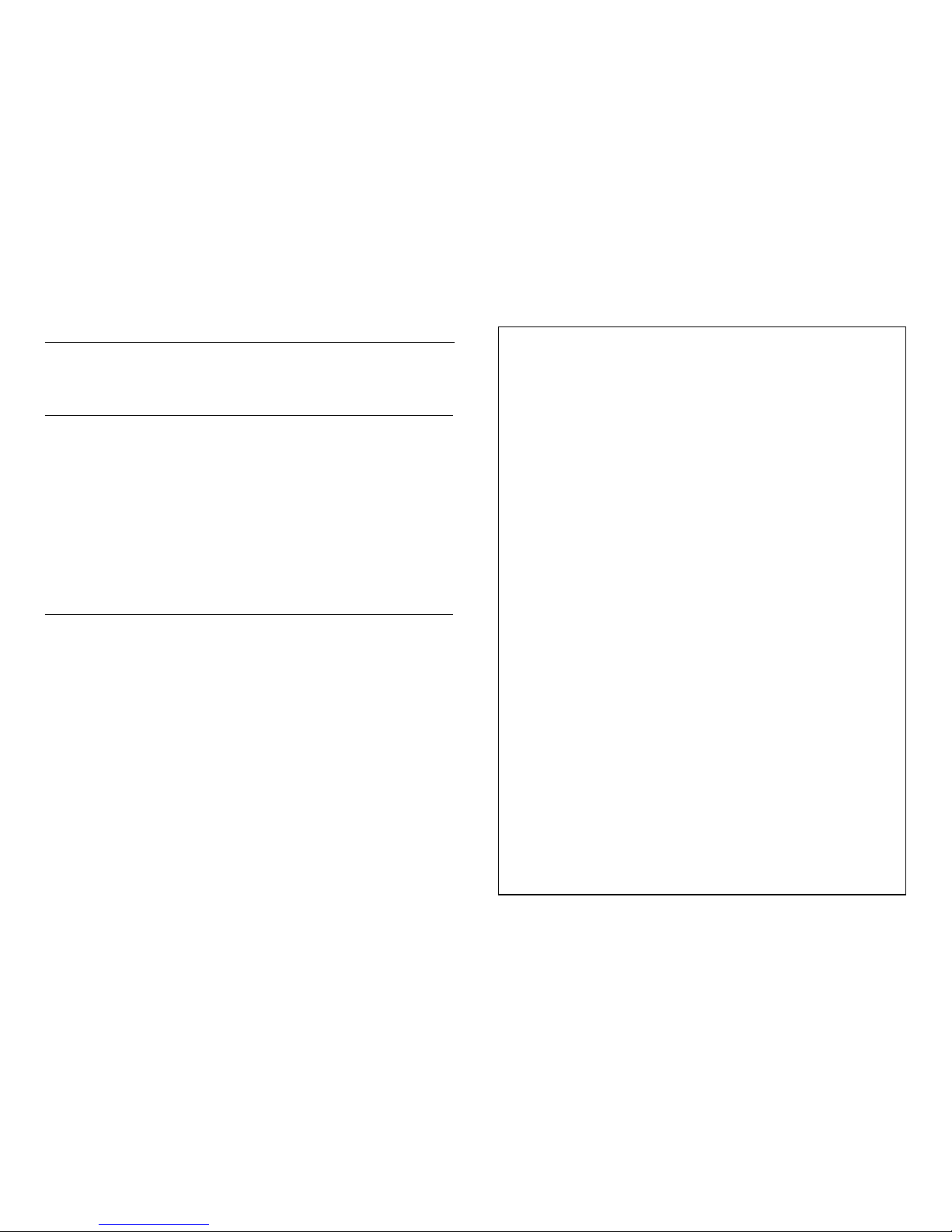

objemový prùtok vody V (m /h)

3

tlaková ztráta p (Pa)

20000

18000

20

0

4681012

16000

14000

12000

10000

8000

6000

4000

2000

65, 85 KLO / KLO EKO

100 KLO / KLO EKO

130 KLO / KLO EKO

150 KLO / KLO EKO

Model 65 KLO /

KLO EKO

85 KLO /

KLO EKO

100 KLO /

KLO EKO

130 KLO /

KLO EKO

150 KLO /

KLO EKO

A 850 1010 1170 1410 1570

B 460,5 540,5 620,5 740, 5 820,5

C 860,3 850,3 840,3 825,3 825,3

D 180 200 220 250 250

brackets for fitting thermostat sensors and

a thermometer, and lugs on feet for connecting the body to the boiler base. The

KLO EKO series boilers use low-emission

burner tubes, the KLO series boilers use

standard tubes. Depending on the output,

the boiler has 7 to 16 burner tubes and a

complete gas route.

The burner plate is fitted with a gas distribution section, the actual burner tubes

and an ignition device. The gas route

consists of a gas supply pipe section terminated with a combined gas valve. The

combined gas valve controls the supply

of gas into the boiler depending on the

required and reached operating states of

the whole system (i.e. the boiler combined

with the heating system); its outlet is already the gas distribution section of the of

the burner plate, terminated with 7 to 15

jets (one for each burner tube).

Igniting the burner and watching that it is

running is done by a Polidoro low-emission ignition burner. When a request is

sent to ignite the main burner, after waiting

time T

w

= 10 seconds, the ignition burner

Accessories

Pressure loss (Pa)

Fig. 1

Basic and Connecting Dimensions

Pressure loss of the boiler´s body

Fig. 2

Flow of water volume V (m3/h)

Page 5

8

9

is automatically ignited. It is ignited by an

ignition spark and its flame is detected by

an ionisation electrode. After the ignition

burner has steadied up and the ionisation

circuit closed, the main gas supply valve

to the main burner opens. If the ignition

burner does not ignite within a safety time

T

s

= 25 seconds, the gas supply to the

main burner and to the ignition burner is

automatically shut off. If the flame during

normal boiler operation goes out, the automatic ignition system will repeat the ignition cycle of the ignition burner. If the loss

of ionisation prevails, the boiler will switch

to a fault status (the light of the “Unlock

automatic fault signalling system” button

on the control panel lights up). After a

waiting time of approximately 10 seconds,

the fault status can be manually cancelled

by pressing the RESET button.

The ignition burner remains on while the

main burner is on.

In the event of power supply failure, the

gas supply to the burner is automatically

shut off. When power supply is restored,

the boiler will automatically restart itself.

KLO

1

2

3

4

5

6

7

8

10

9

11131415

16

18

22

20

21

19

2

3

4

5

6

7

8

10

9

12131415

16

18

19

20

1

21

22

11

17

17

1. Main control panel

2. Chimney thrust detector system cover

3. Fume exhaust

4. Chimney thrust detector

5. Fume thermostat

6. Heating water outlet

7. Gas supply

8. Cast iron body segments

9. Heating water inlet

10. Combustion chamber

11. Secondary air supply

12. Supply burning air

13. Burner

14. Supply burning air

15. Jet

16. Combining pipeline gas

17. Operator burner

18. Gas armatures*

19. Boiler covering

20. Case for sensors

21. Main control panel

22. Automotive ignition

automatics

* For models 130-150 KLO / KLO EKO is used only 1 gas armature.

KLO EKO

KLO

The combustion fumes collector is connected to a chimney thrust detector and

behind it is terminated in a boiler exhaust

outlet (on a fumes flue connection). The

collector is equipped with a removable

cleaning lid, which is accessible after removing the top boiler’s cover.

The chimney thrust detector system

(SKKT) works on the principle of monitoring the combustion fumes temperature

inside the collector. A thermostat situated

inside the collector reacts to an increase

of the combustion fumes temperature

caused by a reduced chimney effect will

shut the boiler down (by shutting off gas

supply to the burner).

The boiler has covers, which are rigidly

fixed to the rear and side-wall, a removable wall and a removable top cover. The

boiler’s control panel is located in the top

section.

The boiler body base is a single steelbase on which the body of the boiler and

the covers are mounted.

Boiler Installation Guidelines

The PROTHERM KLO / KLO EKO boilers can be put into operation only by an

authorised service organisation in accordance with UBP SR Public Notice No. 74/

1996. Installations, putting into operation,

warranty and post-warranty service are

done by a network of manufacturer’s contractual service organisations, which meet

the requirements specified above.

Connecting the boiler to gas supply

The PROTHERM Series KLO - ZP / KLO

EKO – ZP boilers are designed to run on

natural gas with nominal pressure in the

distribution network 1.8 kPa (18 mbar) and

a calorific value usually claimed between

9 and 10 kWh/cum. The internal gas distribution system as well as the gas meter

must be of sufficient size, taking into account also other user’s gas appliances.

The gas supply pipe must have an internal

diameter of at least the same size as the

gas connection pipe on the boiler (which

depends on the boiler size), but preferably

one size bigger.

The PROTHERM Series 65 – 85 KLO - P /

65 - 85 KLO EKO - P boilers are designed

to run on propane gas. Propane gas calorific value is given between 12.8 and 13

kWh/kg. Because supplying boilers from

pressure cylinders is problematic, particularly from the capacity and handling point

Fig. 3

Schematic operation diagram

Page 6

10

11

of view, it is recommended that a reservoir

is installed near the building to be heated,

and refilled by an authorised organisation.

Adequately sized propane supply from

the reservoir to the boiler and to other gas

appliances will then be part of the design

and delivery of the reservoir. When installing a propane gas-fired boiler, an accurate

nominal pressure of 3.0 kPa (30 mbar)

must be secured by installing a reduction

valve (station) before the boiler.

Supply of combustion air

Ventilation must guarantee that sufficient

quantity of combustion air is supplied to

the boiler and that the maximum permissible concentrations of harmful gases

in the boiler’s vicinity are not exceeded

and that an acceptable temperature is

maintained there (all in accordance with

Ministry of Environment Public Notice No.

706/2002).

The stationary cast iron PROTHERM

KLO/KLO EKO boilers draw combustion

air from the space in which they are installed. The combustion air supplied to the

boiler must be free of dust and corrosive

and flammable substances (vapours, solvents, paints, adhesives, etc.). The supply of adequate quantity of combustion

air must meet the requirements of STN

070703 “Gas-fired boiler rooms”. Gas appliances connected to combustion fumes

flue must not be located in places where

negative pressure can be created by ventilation fans.

Combustion fumes exhaust

The boiler is designed for combustion

fumes to be removed into a chimney (via

a chimney connection point) with a stabilised thrust of at least 2 Pa. The boiler is

connected to the chimney by a flue of a

diameter corresponding to the flue diam-

quired by the water composition. Depending on the anticipated amount of sludge

trapped; is recommended to desludge the

boiler approximately a week after it has

been put into operation. Functional defects

caused by mechanical dirt are not covered

by the manufacturer’s overall warranty (refer to Warranty Terms and Conditions).

Important: When filling the boiler with

water, all air in the boiler as well as in

the heating system has to be thoroughly

bled.

Using antifreeze liquid

KLO and KLO EKO boilers may be filled

with an antifreeze liquid, namely product

called ALYCOL TERMO, produced by

Slovnaft Moravia. Using other antifreeze

products will invalidate the manufacturer’s

warranty on parts and related costs.

Properties of the heating system

and filling the system with water

The boiler must be connected to the heating system distribution pipes (G6/4”) and

to the gas supply pipe (G 1”) in such a way

that the connection end pieces are not

stressed by forces imposed by the heating system distribution pipes or by the gas

supply pipe. The connection end pieces

have an external thread.

We recommend equipping the connection

eter of the flue connection point (depends

on the boiler size). The flue is part of the

delivery.

It is forbidden to put inside the flue objects

obstructing the flow of combustion fumes

(e.g. various types of heat exchangers to

increase utilisation of the heat).

Construction of the flue and the chimney

must comply with STN 06 1610, STN 73

420 and STN 73 4201 standards.

By complying with requirements of these

standards, we prevent undesirable phenomena from occurring, such as excessive cooling of the fumes, penetration of

dampness into walls, fluctuations in the

chimney effect (thrust) and thus undesirable effects on the boiler’s functioning.

Requirements on heating water

quality

The PROTHERM KLO / KLO EKO boilers

are designed for heating water of up to

400 kPa (4 bar) gauge pressure, which is

in compliance with STN 07 7401.

The first fill as well as top up water must

be clear and colourless, and be free of

suspended substances; oil and chemically corrosive additives, under no circumstances may be acidic (i.e. have pH factor

greater than 7) and must have minimal

carbonate hardness.

For softening the first fill water can be used

trisodium phosphate or a one-off dose of

chelating agent.

It is recommended to install before the

boiler (i.e. to the return heating water pipe)

a sludge trap. Its design should allow the

device to be emptied in regular intervals

without draining a great deal of heating

water in the process. The sludge trap can

be combined with a filter, but the filter itself

would not provide adequate protection.

Both the filter and the sludge trap must

be checked regularly and cleaned, as re-

pipes with isolation valves, so that when

repairing the boiler it is not necessary to

drain water from the heating system.

The heating system should be designed

in such a way that a permanent circulation

of the heating water is possible at least

through some radiators.

The boiler does not have an expansion

vessel or a safety valve built in, therefore

these devices can be connected only to

an external system, designed in accordance with STN 06 0310 and safety features compliant with STN 06 0830.

The boiler can work in systems with both

an open and closed (pressurised) expansion vessel. However, when using the

boiler in systems with an open expansion

vessel, it is necessary to harmonise the

temperature setting of the emergency

thermostat (98°C) and limit the operation

range on the heating controls. This setting

must be done by authorised service only.

In open expansion vessels, correct water

level must be maintained (between the operating minimum and maximum). Closed

expansion vessels when being filled up

must be set according to the heating system.

For filling and draining purposes, the boiler

is equipped with a filling (draining) valve.

After being filled up, the system must be

thoroughly bled.

After reconstructions, in unsuitable building disposition, etc., the boiler may be

connected to the heating system and to

the gas supply by flexible hoses, but only

those designed for this purpose. When using flexible connections, these should be

as short as possible, protected against

mechanical and chemical stress and damage, and be always replaced before the

end of their life or before their parameters

deteriorate with new ones (as determined

by their manufacturer).

Fig. 4

Page 7

12

13

Before final installation of the boiler, the

heating system distribution pipes must be

flushed several times by pressurised water. In old, already used systems, this is

done in the opposite direction to the heating water flow.

Boiler’s location

If there are special requirement on manipulation with the boiler (e.g. in order to

prevent its covers from getting damaged,

to reduce its width, etc.), the boiler, delivered assembled, can be partially disassembled.

Enough manipulation space should be

left around the boiler and the connected

devices, to allow adequate access and

works using tools to be performed.

Leaving adequate free space around the

boiler will also satisfy the requirements for

the so-called safe (fire) distance.

Prevention against freezing

Unless the boiler is protected against

freezing by implementing technical and

organisational measures around the boiler (controls, operator), it will necessary to

shut it down possibly together with some

other equipment in the boiler’s vicinity (the

boiler room), such as for instance a water

treatment plant, water top-up equipment,

etc., or the entire heating system will have

to be shut down, i.e. the water drained,

and the supply of water, gas and electricity to the boiler shut off.

Connecting the boiler to power

supply

The boiler is designed to be hardwired to

power supply. The electric boiler’s hardwired connection must have a disconnection device built in – a main switch, with

the distance between open contacts at

least 3 mm in all poles, with all regulations

for switching the boiler being abided by.

The boiler is connected to power supply

by means of a terminal box which has

terminals for a three-wire connection. The

boiler must be wired to power supply in

accordance with STN 33 2000-4-46

[Slovak

Technical Standard Specifications]

. Its protective contact

(peg) must be always connected to the PE

or PEN wire (green and yellow).

It is prohibited to use any type of adapters,

extension cables, etc. The boiler is protected against overloading and short circuit by a T 4A / 250 V fuse, located on the

control panel. The fuse must be replaced

by authorised service only.

Boilers controlled by a room thermostat

must use only thermostats which have a

potential-free output, i.e. those which do

not feed any alien voltage into the boiler. It

is recommended that a suitable room thermostat is selected by authorised service.

The boiler must be placed on a building

base, i.e. floor (or on a pedestal). The

floor must have at least normal load-bearing capacity and must not be slippery.

The space around the boiler may be only

cleaned in a dry way (e.g. by vacuuming).

The boiler must be positioned on an inflammable mat. If the floor is constructed

of a flammable material, it must be put on

an inflammable, thermally insulating mat,

exceeding the boiler’s footprint by at least

100 mm.

When transporting the boiler with the covers on, doors must be at least 100 cm

wide.

Important: Unauthorised persons must

not interfere with the boiler’s setting (particularly those with an impact on the combustion process), to prevent an increased

generation of harmful substances in the

combustion fumes, operation noise, reduced heat utilisation or heat generation,

etc.).

Table 1: Flammability classes of building materials and products

Flammability classes

of building materials

and products

Building materials and products classified by flammability

class (selection from STN 73 0823)

A – non-flammable granite, sandstone, bricks, ceramic tiles, mortars, fire pro-

tection plasters

B – very low flammability

aluminium, Izumin, Heraklit (hardboard), Lignos, basalt felt

boards, fibre glass boards

C1 – low flammability beech wood, oak wood, Hobrex boards, plywood, Werzalit,

Umakart, Sirkolit

C2 - stredne horľavé pine wood, spruce wood, spruce boards, chipboards and

cork boards, rubber

C3 – highly flammable

tar paper, wood fibre boards, cellulose materials, polyurethane, polystyrene, polyethylene, PVC

The boiler must not be installed in an environment in which the burner tubes can get

clogged up by dirt or biological agents (small living creatures).

The boiler has an outlet for connecting

a room thermostat, located on a printed

circuit board. As an option, the boiler can

be supplied with the so called switching

kit, used to interconnect with boiler an

equithermal control unit. For a specific

control unit type must be ordered a specific kit. These switching kits support as

standard Siemens Albatros control units

RVA43.222, RVA63.242 and RVA63.280,

Important: If a different control unit is used,

it must not restrict of disable the boiler’s

safety functions.

Siemens control units

Albatros RVA43.222 is an equithermal

control unit designed for standalone boilers or cascaded boilers.

It is suitable for serial connection to the

source of heat with:

• one or two-stage burner

• hot water supply pump or bypass valve

• boiler pump, supply pump, or heating

circuit pump

Heating circuit is controlled equithermally,

hot utility water heating is controlled by

temperature in the tank and a time programme.

By combining more RVA43.222 control

units, you can create a stepped up cascades of multiple (maximum 16) sources

of heat.

Albatros RVA63.242 is an equithermal

control unit designed for serial connection

to the source of heat with:

• one or two-stage burner, 1BMU

• hot water supply pump or hot water heating bypass valve

• three-point blender drive with circulation

pump

• various multi-function outlet applications

Page 8

14

15

123 4 5 6 7

891011121314

Albatros RVA63.242 is an equithermal

control unit designed for serial connection

to the source of heat with:

• one or two-stage burner, 1BMU

• hot water supply pump or hot water heating bypass valve

• one or two heating circuits with a three-

-point blender drive and circulation

pump, or with a circulation pump only

All the above equithermal control units

can be mutually combined, allowing more

complex heating systems to be built. More

detailed documentation is supplied with

the equithermal control units, or can be

viewed on website www.siemens.cz.

Connecting room control unit

The boiler has a special terminal box for

connecting a room control unit, located

underneath the control panel. The zeropotential contact control unit is connected

by an electrical wire. If a unit requiring

230 V power supply is used (bimetal, with

heating resistor), it has to be connected

to the terminal box by a three-core cable.

The boiler’s manufacturer supplies suitable room control units as an option.

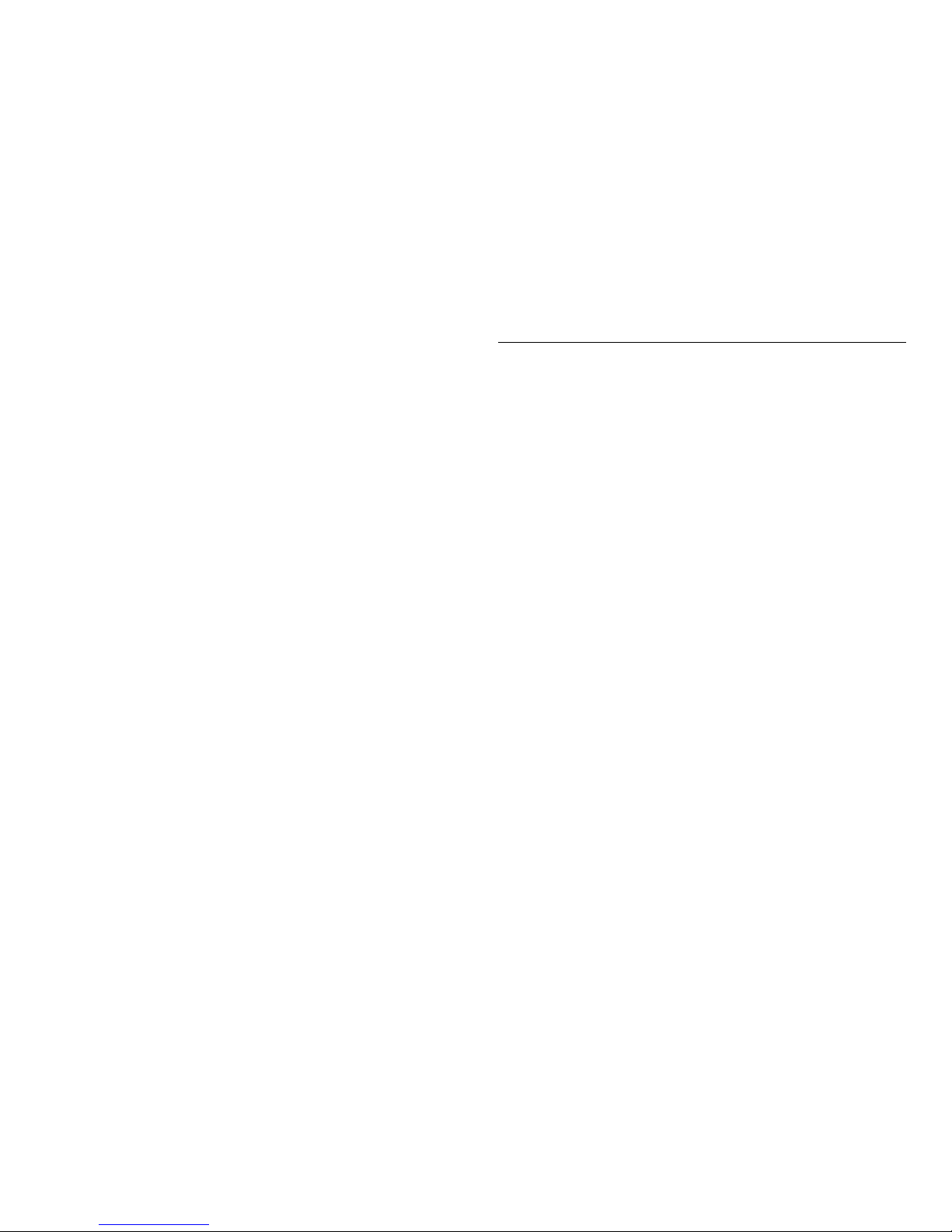

Fig. 5

1. Main boiler switch

2. “Flame out” control light

3. “Boiler overheated” control light

4. Thermometer

5. Pressure gauge

6. Equithermal control unit

1)

7. Gas leakage detection device

2)

8. Boiler output control switch

9. Pump thermostat

10. Operation heating control

11. Emergency thermostat

12. Combustion gases thermostat

13. RESET button

14. Power mains fuse (4 A)

Control panel and signallization

Locations of the boiler’s control and signalling elements are illustrated in the picture of the

boiler’s control panel (Fig. X).

The boiler has two control panels:

– Main control panel, with basic control elements for the user

– Service control panel (located under the front cover), used for service settings.

Description of control elements

Main switch – used to cut off power supply

to the boiler.

“Flame out” control light – a red light signalling a fault caused by the flame going

out. The fault may be caused by gas supply interruption during start up or while the

boiler is running.

“Boiler overheated” control light – and orange light signalling a fault triggered by:

– the combustion fumes thermostat af-

ter drop or loss of chimney effect,

– the emergency thermostat when the

heating water temperature exceeds

105°C (98°C in open systems).

Thermometer, pressure gauge – show

temperature and pressure, respectively, of

the heating water in the boiler.

Boiler output switch (two flames – one

flame) – used to switch between two op-

eration stages (LOW/HIGH).

Pump thermostat – used to protect the

cast iron body of the boiler against condensation. After igniting the burner, the

boiler pump runs until the temperature

exceeds 60°C (factory setting). This temperature setting may be changed by authorised service only.

Heating operation controls – used to set

the heating water temperature.

Important: The selected temperature

must be always higher than the temperature set on the pump thermostat. If not, the

pump will stay permanently switched off.

Emergency thermostat – used to protect

the boiler against overheating. If overheated, the thermostat will shut the boiler

down. The boiler can be restarted after

the heating water in the boiler has cooled

off by pressing an unlocking button (11),

which is sometimes located under a plastic plug.

Combustion fumes thermostat – used to

shut the boiler down when the chimney effect has been reduced or lost. The boiler

can be unlocked only after the combustion fumes thermostat has cooled off, by

pressing an unlocking button (12).

Important: The boiler must never be run

with the above described safety elements

(combustion fumes and emergency thermostat) disabled or replaced by devises

other than those specified by the manufacturer! Under no circumstances may the

user manipulate with these elements.

RESET button – by pressing this button,

the fault signalled by the “Flame out” red

control light can be fixed. If the fault is signalled repeatedly, call authorised service.

For fault statuses triggered by the combustion fumes of emergency thermostat,

using the RESET button is ineffective.

In such cases it is necessary to call authorised service, which will diagnose the

problem and after repairing the fault put

the boiler back into operation.

Power mains fuse – protects the boiler’s

electrical wiring against overloading and

short circuit.

Model KLO / KLO EKO Max. power / Low power (kW)

NATURAL GAS

Max. power (kW) PROPAN

65 65 / 49 55 / -

85 85 / 59

100 99 / 70 -

130 130 / 91 -

150 150 / 105 -

Table 2 :

Maximum and Low power of the boiler.

Fig. 5

Control panel

1)

Not a standard boiler accessory

2) Optional accessory, available with 130 - 150 KLO and KLO EKO boilers only

Page 9

16

17

Operator’s duties

In addition to setting the control elements

(including control unit), the operator must:

1) comply with the Local Operating Mode

– LOM (or, if one has not been devised

yet, proceed in accordance with operating instructions for each device and its

components (for the boiler, control unit,

pumps, expansion vessel…) – refer to the

section General Requirements,

2) maintain the area around the clean

and neat,

3) make sure that no works unrelated to

running and maintaining the boiler are

performed in its vicinity,

4) enforce and secure (e.g. by warning

signs or locking the entrance door, etc.)

that no unauthorised persons are present

near the boiler (i.e. persons without necessary knowledge, younger than 18, certified, etc.); the presence of such persons

in the boiler’s vicinity is permissible only

when accompanied by authorised persons,

5) keep passages around the boiler and

entrance door free,

6) keep important operation records (the

so called Operation Diary – OD) as laid

down in LOM.

In addition to the measures taken in practical situations – see section General Requirements – the operator must always

shut the boiler down whenever it becomes

impossible to control the boiler reliably,

even manually. Supplies must always be

shut off in the event of leaks of any media

(in particular gas, but also heating water

and electricity) and an authorised service

called.

The operator must also shut the boiler

down and close all supplies (if necessary

not only in the boiler’s vicinity but also sup-

plies to the building or at least its relevant

part) even if undesirable situations have

not occurred yet, but there is a danger that

they might occur (e.g. when fire breaks in

the building).

Preparing and starting the boiler

Preparing and starting the boiler up is part

of the process of putting the boiler into operation, which must be performed by authorised service.

First live test run

The first live test run is a short live run of

the boiler to make the last check whether

the boiler has been installed correctly and

the heating system functions properly. It

is part of the process of putting the boiler

into operation, which must be performed

by authorised service.

The actual operation

The boiler runs automatically according to

the setting of control elements, the user

performs only the following operations,

which have to demonstrated to the user

by the authorised service technician who

put the boiler into operation:

1. Switching the boiler on or off using the

power mains switch on the boiler’s control

panel.

2. Controlling the boiler’s operation using

selected control unit, which are always

supplied with separate operating instructions.

3. Setting and checking the required heating water temperature within a 0 to 85°C

range on the boiler’s thermostat.

4. Switching between nominal or reduced

output (HIGH/LOW).

5. When a fault is detected, a fault control

light will switch on. In the event of power

Running the Boiler

failure, the burner will be shut down, and

when power supply is restored, the burner

will be automatically re-ignited. The fault

state can be unlocked by pressing the RESET button in the service section of the

control panel. If the fault reoccurs, call authorised service.

6. Unlocking the emergency thermostat. If

the emergency thermostat shuts down the

boiler, the orange light on the boiler’s control panel will light up, signalling, “Boiler

overheated”. The thermostat is unlocked

by pressing button 11, situated in the

service section of the control panel. If the

fault reoccurs, call authorised service.

7. Unlocking combustion fumes thermostat (reverse fumes flow safety cut-out).

When this detector shuts down the boiler,

the orange control light on the main control panel will light up, signalling, “Boiler

overheated”. The cutout device (TS) is

unlocked by pressing button 12, situated

in the service section of the control panel.

Important: If the fault reoccurs, disconnect

the boiler from power supply and call authorised service.

Important guidelines

1. The boiler room must have a permanent

supply of air.

2. The boiler operator must be at least 18

years old.

3. The boiler must be connected to 230

V/50 Hz power supply mains with appropriate circuit breaker.

4. When putting the boiler out of operation

for a longer period of time, disconnect it

from power mains.

5. If a defect occurs in the combustion

fumes exhaust system and is triggered

by the chimney thrust detector (reverse

thrust, blocked chimney), the reverse

fumes flow cutout device will shut off the

supply of fuel into the boiler.

6. The boiler room must be kept clean

and free of dust. All sources of dirt must

be removed from the boiler room and during works, which generate dust (insulation

works, cleaning), the boiler must be shut

down. Even partially blocked burner by

dirt degrades the combustion process and

endangers economic and reliable running

of the boiler. We do not recommend keeping in the boiler room any pets (dogs, cats,

etc.).

7. Before commencing any works, which

generate flammable vapours or gases that

might penetrate the boiler room, or works

with temporary fire or explosion hazard

(gluing on floor covering material, painting

with flammable paints), the boiler must be

shut down beforehand.

8. No objects made of flammable material

may be placed on the boiler or within a

distance less than a safe distance from it.

9. Getting close to or touching the flame

checking-window may cause burns.

10. The user must have the installation,

putting into operation, regular maintenance and repairs done by a PROTHERM

authorised service. Failing to abide by this

condition will result in invalidating the warranty provided by the boiler’s manufacturer. The Certificate of Quality and Completeness of the PROTHERM KLO Boiler,

after being filled in and signed by an authorised service organisation, serves as a

Warranty Certificate.

11. The boilers must once year undergo

regular maintenance as laid down in

Chapter X.

12. The boiler must be run in accordance

with these Operating Instructions and oth-

Page 10

18

19

er applicable regulations. Incorrect use of

the boiler might result in reducing its life,

but also in damages to health and property.

Starting the boiler up

The boiler the functioning of which has already been verified by the first live test is

started up as follows:

– Set the heating water operating tempe-

rature control to approximately 2/3 of its

full range. You will set it to the required

temperature later. The heating water

temperature has an impact on the heating speed of the UHW reservoir.

– . If the boiler works in conjunction with

an indirectly heated UHW reservoir, set

the reservoir temperature to approximately ½ or its full range.

– . Check the water pressure on the boi-

ler’s pressure gauge. When the water is

cold, the pressure must not be lower

than indicated (by the pressure gauge

red hand – set by authorised service during the first live test run).

– If the boiler is controlled by either an

equithermal or room heating control

unit, set it in accordance with the device’s operating instructions.

– Set the power mains switch to the ON

position (I). The boiler will ignite itself

and start heating the water in the UHW

reservoir (if one is installed). When it

has been heated up, the boiler starts

heating the heating system water. If your

boiler is equipped with an RVA 43.222

equithermal control unit, this function is

achieved by selecting the WINTER

mode.

The boiler switches off:

– when heating the UHW, always when

the UHW temperature reaches the value set on the UHW reservoir thermostat,

– when the heating system water tempe-

rature in the boiler reaches the values

set on the operating heating water thermostat,

– when the required temperature set on

the room or equithermal control unit has

been reached.

If the boiler fails to start up and the emergency state control light is not on, it is

an operating shutdown described above.

After the heating water and UHW have

cooled down and the temperature in the

room dropped, the boiler will automatically

start up.

If the boiler does not start up even after a

longer period of time and does not react to

increasing the set values on the operating

controls or other control elements (room

and equithermal control unit), the problem

is in the boiler, and it is necessary to call

authorised service.

If the boiler has not started up and the

emergency state control light is on, proceed in accordance with the instructions

in Description and Functions of Control

Elements.

Boiler shutdown

If you wish to shut the boiler down for a

short while, use the power mains switch. If

you want to shut the boiler for longer, pull

out the power cord plug out of the socket

and shut off gas supply to the boiler. If

there is no danger of the boiler freezing,

leave the water in, otherwise drain the water from the boiler, from the UHW reservoir and from the system.

Provided the heating system configuration

allows it, when dismantling the boiler drain

the water from the boiler only and leave

it in the heating system to prevent it from

corroding.

We recommend that once a year, preferably before the start of a new heating season, you have the boiler inspected by an

authorised service. This inspection is not

part of warranty. Things to be inspected

are specified in the Service Book.

Mostly it is checking the functions and

condition of the burner, checking and adjusting the output, checking for leaks in the

flue joints (and if necessary sealing them)

and then – if necessary – also cleaning

the burner jets (caution – their interior

must not be damaged!) and cleaning the

boiler’s heat exchanger.

Particularly important is to check the functioning of the emergency and combustion

fumes thermostat. This inspection is also

carried out whenever these components

are serviced.

Maintenance performed by the user

a) Clean the boiler covers as needed,

without removing the top cover. Before

you start cleaning the boiler, disconnect if

from power mains and pull the power cord

plug from the socket. If the boiler surface

is wet, wait until it dries before reconnecting it.

b) Once a week check water pressure in

the heating system and if necessary top up

the water. Water in the heating system can

be topped up only after the temperature of

the water in the boiler has dropped below

40°C (measured on the boiler’s thermometer). Failing to abide by this requirement

may result in damaging the boiler’s block.

c) Check the combustion fumes ducting

for leaks.

d) When discovering any gas leak, shut

the boiler down, shut the gas valve off and

call authorised service.

e) Check and clean the filter and the

sludge trap:

– straight after the first live test run,

– after the first week of operation,

– regularly once a week or at least

once a quarter, depending on the degree of clogging.

Maintenance

Compliance with the requirements on boilers

Compliance of the boiler’s properties are

guaranteed and checked during the manufacturing process by a Quality Control

System which, as confirmed by Certificate

BVQI No. 69097 dated 17 May 2000, meet

the BSN EN ISO 9001:1994 quality standard.

Services of a sustained standard for installations and putting the boilers into

operation, warranty and post-warranty

service, are provided through authorised

contracted service organisations of necessary technical qualification and knowhow (see point X).

The boiler must be used exclusively in

accordance with these Operating Instructions and the accompanying documentation. Whenever you have any doubts or

insufficient information, or if you feel you

didn’t fully understand the instructions, or

if you suspect any unauthorised interference with the configuration and functioning of the boiler, always contact authorised service.

Page 11

20

21

The PROTHERM KLO/KLO EKO gas-fired

boilers are covered by a warranty specified in the Warranty Certificate, Service

Book and the conditions defined in these

Operating Instructions.

Warranty and Warranty Terms and Conditions

Completeness of the Delivery

Delivery of the actual boiler

The PROTHERM KLO/KLO EKO boilers

are delivered completely assembled and

with their functions tested.

Part of the delivery is the following documentation:

– Operating Instructions,

– Product Quality and Completeness

Certificate,

– Warranty Cer tificate,

– Service Book,

– Directory of Service Centres.

Customised delivery

The following optional accessories can be

supplied with the boiler:

– room control unit,

– RVA 43.222 equithermal control unit,

– gas leak detection system,

– UHW heating reservoir,

– three-way distribution valve.

Transportation and Storage

The manufacturer suppliers the boiler

standing on a palette, to which it is secured against moving (by screws). When

manipulating and storing the boiler, do not

apply force on the boiler’s covers! Boilers

without a palette are manipulated on the

boiler’s body base (see Chapter X).

Boilers must be stored in a room, which

meets at least the basic environmental

conditions (non-corrosive, maximum humidity 75%, temperature between 5°C

and 55°C, low dust, no biological agents).

Technical specifications of KLO Series boilers

Boiler type . . . . . . . . . . . . . . . . . . 65 KLO . . . . . . . 85 KLO . . . . 100 KLO . . . . .130 KLO . . . . . 150 KLO

Number of elements . . . . . . . . . . . . . 8 . . . . . . . . . . . 10 . . . . . . . . . . 12 . . . . . . . . . .15 . . . . . . . . . . .17

Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B11BS

Appliance category . . . . . . . . . . . . II2H3P I2H . . . . . . . . . I2H . . . . . . . . I2H . . . . . . . . . . I2H

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . by electric spark

Fuel/ inlet gauge pressure . . . . . . . . . . . . . . . . . . natural gas / 2 kPa, propane / 3.7 kPa

Output stage I / II - ZP (kW) . . . . .49 / 65 . . . . . . . 59 / 85 70 / 99 91 / 130 105 / 150

Output stage I / II - P(kW) . . . . . . . - / 55 . . . . . . . . . . - . . . . . . . . . . - . . . . . . . . . . - . . . . . . . . . . . . -

Input stage I / II - ZP (kW) . . . . 53,5 / 70,6 . . . . 64,7 / 92,4 . . .76,8 / 107,6 . . 98,4 / 141,3 . . . 115,3 / 163

Input stage I / II – P (kW) . . . . . . . - / 60,1 . . . . . . . . . - . . . . . . . . . . - . . . . . . . . . . - . . . . . . . . . . . . -

Efficiency ZP / P (%) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 / 91

Consumption

Natural gas (cu.m / h) . . . . . . . . . 5,7 / 9,5 . . . . . . 6,8 / 9,8 . . . . . 8,1 / 11,3 . . . 10,4 / 14,9 . . . . 12,2 / 17,2

Propane (kg/h) . . . . . . . . . . . . . . . . 6,1 . . . . . . . . . . . - . . . . . . . . . . . - . . . . . . . . . . - . . . . . . . . . . . . -

Burner jet diameter (mm)

Natural gas / Propane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,7 / 1,55

Number of burner tubes (pieces) . . . 7 . . . . . . . . . . . . 9 . . . . . . . . . 11 . . . . . . . . . 14 . . . . . . . . . . . 16

Volume of water in the heating body (l)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .27,7 . . . . . . . . . 34,3 . . . . . . . . 40,9 . . . . . . . . 50,8 . . . . . . . . . 57,4

Max. operating temperature (°C) . . . . . . . . . . . . . . . . . . 85 (80°C for open systems)

Max. operating gauge pressure VV (bar) . . . . . . . . . . . . . . . . . . . . . . 4

Min. operating gauge pressure (bar) . . . . . . . . . . . . . . . . . . . . . . . . . 0,3

Test water gauge pressure (bar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/N/PE AC 230 V, 50 Hz/TN-S

Electric input (W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Electric protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP 41

Noise level (dB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . do 55

Removal of combustion gases

Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .through chimney

Flue diameter (mm) . . . . . . . . . . . . 180 . . . . . . . . . . 200 . . . . . . . . .220 . . . . . . . . . 220 . . . . . . . . . . 250

Minimum chimney thrust (mbar) . . . . . . . . . . . . . . . . . . . . . . . .0,025 / 2,5 Pa

TTemperature of combustion fumes at max. output ZP / P(°C) . 129 / 115

NOX class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class III

Combustion fumes flow in weight terms at min./max. output

Natural gas (g/s) . . . . . . . . . . . . . 44 / 46,3 . . . . . .53 / 60,5 . . . . .63 / 70,5 . . . . . 81 / 92,6 . . . . . . 95 / 107

Propane (g/s) . . . . . . . . . . . . . . . . - / 45,7 . . . . . . . . . - . . . . . . . . . . . - . . . . . . . . . . . .- . . . . . . . . . . . . -

Connection dimensions

Gas / heating water connection . . . . . G1" / G6/4"

Boiler width (mm) . . . . . . . . . . . . . . 850 . . . . . . . . . 1010 . . . . . . . 1170 . . . . . . . .1410 . . . . . . . . . 1570

Boiler height / depth (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1195 / 960

Boiler weight (kg) . . . . . . . . . . . . . . 258 . . . . . . . . . .332 . . . . . . . . 395 . . . . . . . . . 482 . . . . . . . . . 546

Page 12

22

23

Assembling the boiler after delivery

The boilers Series KLO / KLO EKO are

for transportation reasons delivered with

the thrust breaker installed in a horizontal

position. After the boiler has been delivered to the point of installation, the thrust

breaker must be installed in the operating

position. The installation procedure is as

follows:

1. Remove the top boiler cover which is

fastened with two self-cutting screws.

2. After having removed the top cover, dismantle the thrust breaker. The thrust

breaker is attached with three self-cutting screws to the internal boiler bulkhead (Fig. 6).

3. Pull out part of the thrust breaker and

rotate it so that the combustion fumes

neck is pointing vertically upwards. Insert this part into the counter-part and

secure it with ten self-cutting screws.

The line in Fig. 7 indicates the joining of

the two thrust breaker parts.

4. After assembling the thrust breaker, you

must install a sensor (capillary) of the

combustion fumes thermostat, which is

located inside the boiler, next to the

thrust breaker. Insert the sensor in the

hole at the back of the thrust breaker

and fasten it with the clip and the self-

-cutting screw provided for this purpose

(Fig. 8).

Boiler covers

The front cover is removable. It is held

by spring clips which are attached in the

top corners. When removing the cover,

the pressure of the spring clips gripping

the holding pins must be overcome. After

dropping it down first, the cover can be

completely removed.

Technical specifications of KLO EKO Series boilers

Boiler type . . . . . . . . . . . . . . . . 65 KLO EKO . . .85 KLO EKO 100 KLO EKO 130 KLO EKO 150 KLO EKO

Number of elements . . . . . . . . . . . . . 8 . . . . . . . . . . . 10 . . . . . . . . . . 12 . . . . . . . . . .15 . . . . . . . . . . .17

Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B11BS

Appliance category . . . . . . . . . . . . II2H3P I2H . . . . . . . . . I2H . . . . . . . . I2H . . . . . . . . . . I2H

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . by electric spark

Fuel/ inlet gauge pressure . . . . . . . . . . . . . . . . . . natural gas / 2 kPa, propane / 3.7 kPa

Output stage I / II - ZP (kW) . . . . .49 / 65 . . . . . . . 59 / 85 70 / 99 91 / 130 105 / 150

Output stage I / II - P(kW) . . . . . . . - / 55 . . . . . . . . . . - . . . . . . . . . . - . . . . . . . . . . - . . . . . . . . . . . . -

Input stage I / II - ZP (kW) . . . . 53,5 / 70,6 . . . . . 64 / 92,4 . . .75,5 / 107,6 . . .98,4 / 141 . . . . 113,5 / 163

Input stage I / II – P (kW) . . . . . . . - / 59,8 . . . . . . . . . - . . . . . . . . . . - . . . . . . . . . . - . . . . . . . . . . . . -

Efficiency ZP / P (%) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 / 92

Consumption

Natural gas (cu.m / h) . . . . . . . . . 5,6 / 7,5 . . . . . . 6,8 / 9,8 . . . . . 8,1 / 11,3 . . . . 10,4 / 15 . . . . 12,2 / 17,2

Propane (kg/h) . . . . . . . . . . . . . . . . 6,1 . . . . . . . . . . . - . . . . . . . . . . . - . . . . . . . . . . - . . . . . . . . . . . . -

Burner jet diameter (mm)

Natural gas / Propane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,6 / 1,6

Number of burner tubes (pieces) . . . 7 . . . . . . . . . . . . 9 . . . . . . . . . 11 . . . . . . . . . 14 . . . . . . . . . . . 16

Volume of water in the heating body (l)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .27,7 . . . . . . . . . 34,3 . . . . . . . . 40,9 . . . . . . . . 50,8 . . . . . . . . . 57,4

Max. operating temperature (°C) . . . . . . . . . . . . . . . . . . 85 (80°C for open systems)

Max. operating gauge pressure VV (bar) . . . . . . . . . . . . . . . . . . . . . . 4

Min. operating gauge pressure (bar) . . . . . . . . . . . . . . . . . . . . . . . . . 0,3

Test water gauge pressure (bar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/N/PE AC 230 V, 50 Hz/TN-S

Electric input (W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Electric protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP 41

Noise level (dB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . do 55

Removal of combustion gases

Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .through chimney

Flue diameter (mm) . . . . . . . . . . . . 180 . . . . . . . . . . 200 . . . . . . . . .220 . . . . . . . . . 250 . . . . . . . . . . 250

Minimum chimney thrust (mbar) . . . . . . . . . . . . . . . . . . . . . . . .0,025 / 2,5 Pa

TTemperature of combustion fumes at max. output ZP / P(°C) . 125 / 100

NO

X

class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class V

Combustion fumes flow in weight terms at min./max. output

Natural gas (g/s) . . . . . . . . . . . . . 44 / 46,3 . . . . . .53 / 60,5 . . . . .63 / 70,5 . . . . . 81 / 92,6 . . . . . . 95 / 107

Propane (g/s) . . . . . . . . . . . . . . . . - / 45,7 . . . . . . . . . - . . . . . . . . . . . - . . . . . . . . . . . .- . . . . . . . . . . . . -

Connection dimensions

Gas / heating water connection . . . . . . . . . . . . . . . . . . . . . . . . . G1" / G6/4"

Boiler width (mm) . . . . . . . . . . . . . . 850 . . . . . . . . . 1010 . . . . . . . 1170 . . . . . . . .1410 . . . . . . . . . 1570

Boiler height / depth (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1195 / 960

Boiler weight (kg) . . . . . . . . . . . . . . 317 . . . . . . . . . .369 . . . . . . . . 421 . . . . . . . . . 499 . . . . . . . . . 550

These instructions are intended for specialised service only, and together

with Operating Instructions and Service Book provide technical guidelines

for installing, setting up and maintaining the boiler.

Installing the Boiler

a

b

c

Fig. 6

Fig. 7

Fig. 8

Page 13

24

25

The top cover can be removed after the

two self-cutting screws located at the back

of the boiler have been removed. When

the screws have been removed, lift the

cover upwards.

The boiler’s control panel front can be

dismantled after removing the two selfcutting screws in the panel’s top corners.

The remaining covers (side and rear) are

attached by three lugs and self-cutting

screws to the boiler’s chassis. The covers

are connected by protective wires to the

boiler’s electrical wiring.

Heating system pump

Select the heating system pump according to the design. Problems (e.g. insufficient heating water circulation) caused by

using a different than prescribed pump are

not covered by the manufacturer’s warranty. In addition to other aspects, the pump

delivery pressure rating must be designed

taking into account overall losses in the

heating system and in the boiler.

Properties of the heating system

and filling it with water

The emergency thermostat temperature

must be set depending on the expansion

vessel type (closed or open). The emergency thermostat is located under the

boiler’s front cover (see Fig. X). For open

systems, set the emergency temperature

to 98°C, for closed systems to 105°C.

In open systems it is also necessary to

limit the range of the operating heating

water control unit to not more than 85°C,

to prevent overlapping of their ranges due

to tolerances, and undesirable reactions

of the emergency thermostat.

The operating control unit limiting is done

with an arresting wire clip situated inside

the control button. The clip can be accesses after pulling the button off the thermostat shaft. The setting must be checked in

an operation test.

After filling the heating system with water,

bleeding it and adjusting the expansion

pressure vessel (if one is installed), mark

the resultant pressure of the heating water

in cold state by pointing the red (adjustable) hand of the boiler’s pressure gauge

at it.

Instructions for installing closed

expansion pressure vessels

Expansion vessels and safety pipes (connecting the boiler with the pressure vessel)

must be protected against freezing. The

maximum operating pressure in closed

expansion vessels must mot be lower than

the opening pressure of the safety valve,

and this must not be higher than the permissible operating pressure of the boiler’s

body; hence it is not recommended that

the operating pressure of the expansion

vessel exceed the operating pressure of

the boiler’s body. Closed heating systems

(with a closed expansion vessel) must be

equipped with a low water level detector; if

the water drops below the minimum level,

the boiler must be shut down in such a

way that it can be restarted only after operator intervention.

The heating water system pipes, its joints

and embedded elements (shutting valves,

meter connectors and meters, etc.) must

not be causes of leaks, i.e. they must be

able to withstand the maximum operating

pressure and temperature with a sufficient

reserve.

The boiler’s electrical compartment as

well as the service section of the control

panel is accessible after folding the top

boiler cover. After dropping the cover forward, the terminal box becomes accessible for connecting accessories. The panel

remains connected with the electrical

compartment by wires and capillaries of

meters and thermostats.

Important: the boiler must be earthed.

If the boiler is run with a room control unit,

before it can be connected, the jumper in

the terminal box must be removed. Otherwise the jumper is left in.

The room control unit’s power supply wires

are connected to terminals Pr1 and Pr2,

positions 4 and 5. Recommended wire

cross-section is 0.5 to 1.5 sq. mm.

The principle of the room control unit outlet’s zero-potential must be respected.

If a bimetal control unit, which requires

230 V power supply is used, then the

phase (L) and neutral (N) unit’s terminals

are connected to terminals Pr1 (position

4) and N of the boiler side, respectively.

The control unit’s outlet terminal is connected to terminal Pr2 (position 5) on the

boiler side. Minimum rating of the control

unit outlet terminals should be 230 VAC/2

A (induction load).

Pump wiring – if the pump’s input exceeds

the boiler’s power supply circuit breaker

rating, an additional switching element

(contactor) must be installed.

Interconnecting the boiler with an

indirectly heated reservoir

The boiler’s internal wiring allows several

ways how to interconnect the boiler with

an indirectly heated reservoir.

a) Topping-up pump.

b) A three-way, actuator-controlled valve

and the boiler thermostat using an RVA

43.222 equithermal regulator.

Connecting equithermal control unit

The boiler’s standard wiring allows the

boiler control to be extended. The so called

switching kit can be ordered, by means of

which the boilers can be connected to one

of Siemens Albatross equithermal control

units, RVA 43.222, 63.242 or 63.280. Basic properties or these equithermal control

units are detailed on page 13.

For connecting an equithermal control

unit, the printed circuit board (behind the

control panel) is equipped with a connector, “J1”, which is as standard fitted with

jumpers. The installation is performed as

follows:

1. Take out of the switching kit box the

connector which is already fitted with

wires. Connect lose ends of the wires to

relevant terminal boxes which are also

part of the switching kit, depending on

the control unit type.

Schematic wiring diagrams are shown on

pages 37 - 39.

2. Part of the RVA 63.242 and RVA 63.280

switching kit is an auxiliary printed circuit board which can be used for instance for connecting pumps and valves for

blending circuits. If you are using one of

these, connect the “J1” wire as indicated in the wiring diagram.

Important: each of these control units

requires specific wiring, and hence it is

not possible to use the ready made wiring

for a different type of equithermal control

unit.

3. Disconnect the boiler from power supply.

4. Pull the jumper off the boiler printed circuit board connector and replace it with

the connector supplied with the swit-

Electrical wiring

Page 14

26

27

ching kit of the equithermal control unit.

Check the connector and make sure

that it has not interconnected for instance also an additional opposite pin.

5. Insert the remaining terminal boxes into

the equithermal control unit as shown in

the relevant schematic diagram (pages

37 – 39).

6. Insert the equithermal control unit into

the cut-out in the boiler’s control panel

and secure it against falling out with the

lugs provided. The fixing lugs are located in the equithermal control unit’s corners.

7. If you have used the auxiliary printed

circuit board for the RVA 63.242 and

63.280 control units, connect the auxiliary device leads to corresponding terminals (see the wiring diagram on pages 37 - 39).

8. Depending on the application, connect

temperature sensors to the control unit.

9. Remove from the boiler sump (Fig. 9)

the pump thermostat capillary and replace it with the heating water temperature sensor from the equithermal control

unit.

– The boiler may be restarted only after

the sensor of the reverse fumes flow safety device has cooled off, i.e. after 10

minutes.

The heating water pump thermostat is factory-set to 60°C (recommended temperature) and secured against changes by a

wire clip.

The power mains switch serves as a protection of the boiler’s internal wiring against

overloading and short-circuiting. The boiler’s power mains fuse labelled T1.6A can

be replaced after unscrewing the fuse box

cover, located on the left-hand side of the

service panel.

Important: The fuse may not be repaired

or substituted by a different object.

“Flame out” control light – lighting up of

the red control light signals a fault caused

by unwanted outage of the flame. It can be

unlocked by pressing the RESET button.

If the light comes on repeatedly, the fault

might be caused, besides other, by the following problems:

1. gas mains supply failure,

2. blocked or damaged house gas pres-

sure regulator,

3. insufficient supply of combustion air,

4. insufficient gas jet pressure,

5. defective gas valve,

6. defective automatic ignition system,

7. broken ignition or ionisation cable,

8. defective pre-ignition burner,

9. defective ionisation electrode,

10. clogged up burner tubes.

“Boiler overheated” – lighting up of the

orange control light, signalling one of the

following faults:

1. shutdown by the fumes thermostat after loss or drop of the chimney thrust,

the fault might be caused, among other,

by the following problems:

a) ncorrect temperature setting of the fu-

mes thermostat,

b) obstacle in the chimney route,

c) chimney thrust dropping below 2 Pa,

d) faulty fumes thermostat.

2. shutdown by the emergency thermostat due to overheating which might be

caused, among other, by the following

problems:

a) shut heating water outlet and boiler

outlet valves,

b) incorrect temperature setting of the

emergency thermostat,

c) heating water pump of incorrect rating,

d) clogged up heating water filter,

e) clogged up desludging device,

f) obstacle in the heating system,

g) clogged up fumes/water heat exchan-

ger.

Description of Safety Elements

Important: The pump thermostat will

remain unused. The heating system protection function must be provided by the

equithermal control unit. With the equithermal control unit set to an appropriate mode, set the heating water system

protection temperature to 60°C.

10. Connect the boiler to power supply.

11. Set the equithermal control unit as de-

tailed in this Instruction Guide, in the

enclosed equithermal control unit documentation and in the design documen-

tation for the given application

With an approval by an authorised measurements and control technician, it is possible to use the switching kit also for other

types of control units.

Important: When using any control unit,

the boiler’s operating and safety functions

must not be disabled or by-passed.

The emergency thermostat sensor, the

operating controls sensor and the heating

water temperature pump sensor are located in an indent in the boiler’s body next

to the heating water outlet. The combustion fumes thermostat sensor is located

in the chimney thrust detector device. The

emergency thermostat, the combustion

fumes thermostat and the heating water

pump thermostat are located in the service section of the control panel (see Fig.

X). The emergency and fumes thermostat

are provided with an unlocking button and

a temperature setting scale (see Fig. X).

Unlocking can be done after unscrewing the cover by pressing the unlocking

button. The emergency thermostat can

be unlocked only after the heating water

temperature has dropped. The same applies to the combustion fumes thermostat,

which can be unlocked only after its sensor has cooled off.

Important:

– After reactions of safety devices (emer-

gency and combustion fumes thermo-

stat), the boiler may be put back into

operation only after the cause, which

lead to the shutdown has been identi-

fied.

– The boiler must never be run with the

emergency devices disabled or repla-

ced by other devices that the ones spe-

cified by the manufacturer. After every

servicing of these devices, their correct

functioning has to be checked.

Fig. 10

Fig. 9

Page 15

28

29

Preparing and starting up the boiler

Before actually starting up the boiler, the

following basic tasks have to be carried

out:

a) Fill up the heating system with water.

Check the water pressure on the boiler’s

pressure gauge.

b) Check the boiler’s connection to the fu-

mes exhaust system,

c) Open the gas isolation valve and let

gas into the boiler. Measure the supply

pressure. Bleed the gas connection

pipe.

d) Set the thermostats:

– emergency thermostat (open systems

to 97°C – factory setting, closed sys-

tems with expansion vessel may have

the temperature set to 105°C),

– fumes thermostat to 70°C (can be set

within the range 70-110°C. Setting

change must be approved by the manu-

facturer),

– operating heating water and UHW ther-

mostat (when auxiliary reservoir is used)