Floorstanding cast iron boiler

Cascade conection possible

Output up to 150 kW

Grizzly

EN

verzion

XXXX - v.2 4/2005

Manual for instruction

and use of boiler

65, 85, 100, 130, 150 KLO

Protherm spol. s r.o.

Jurkovičova 45

909 01 Skalica

Tel.: 034 6966 101

Fax: 043 6644 017

www.protherm.sk

2

3

Dear Client,

You have just become an owner of a KLO /

KLO EKO (Grizzly) natural gas or propane gas fired cast iron boiler. We are confident that you will be satisfied with the

service this boiler will give you. However, you’ll have to comply with at least

minimum requirements when running

the equipment. Therefore please read

these Operating Instructions carefully

and comply with their guidelines.

Please pay careful attention to the following

important information:

1. The boiler with all its accessories must

be installed and used in accordance

with an installation design, all applicable

legal regulations, technical standards

and manufacturer’s instructions.

2. The boiler may be installed only in the

environment for which it has been designed and only in a correctly ventilated

room.

3. After installation, the boiler must be put

into operation by a service organisation

authorised by the manufacturer.

4. Please also contact authorised service

if you are experiencing any problems

with the equipment – unauthorised repairs may damage the boiler (as well as

the connected equipment!).

5. The service technician when putting

the boiler into operation for the fist time

must demonstrate its controls and show

you its various parts and how to control

them.

6. Check whether the boiler is complete.

7. Check whether it is the model you have

ordered.

8. Whenever you have any doubts how to

operate the boiler, find and study the

relevant information in these Operating

Instructions and proceed in accordance

with them.

In practice, situations might occur when the

following essential measures have to be

taken:

– prevent the boiler from being (even

accidentally) switched on while inspecting the fumes exhaust and gas

and water distribution routes, by disconnecting the boiler from power

supply by another means than just

with the boiler’s switch (e.g. by pulling the power cord plug out of the

socket),

– shut the boiler down every time when

flammable or explosive vapours are

present (even temporarily) inside

the premises from which combustion air is supplied to the boiler,

– if it is inevitable to drain water from

the boiler or the heating system, the

water must not be dangerously hot,

– when water leaks from the boiler’s

heat exchanger or when the exchanger is clogged with ice, do not try to

switch the boiler on until normal running conditions have been restored,

– during (even suspected) gas leaks or

after gas supply failure, switch the

boiler and the gas supply off and call

the gas company or authorised service.

Regulations and Directives

The PROTHERM KLO boiler may be

put into operation only by an authorised

service organisation in accordance with

UBP SR Notice No. 74/1996. Installations,

putting the boiler into operation, warranty

and post-warranty service are performed

by a network of the manufacturer’s contractual service organisations, which meet

the above-specified requirements. Installations must be carried out in accordance

with a design prepared in compliance with

applicable regulations detailed below.

9. When repairing the boiler, only original

parts must be always used. Internal wiring and factory settings must not be

changed or interfered with.

10. Do not remove or damage any signs

and labels on the boiler.

11. The boiler meets regulations applicable

in Slovakia. For use in other countries,

any potential differences must be identified and resolved.

12. At the end of life of the boiler’s parts and

components (or of the entire boiler), their disposal must be carried out ecologically – metal parts must be delivered to

a metal scrap yard, plastics, seals, and

insulation materials must be sorted out

as required, or a special disposal technology used, engaging the services of

companies authorised for such operations.

13. Before a protracted shutdown we recommend to turn off the gas supply and

disconnect the boiler from power supply.

This recommendation is part of general

conditions defined in this Operating Instructions.

15. The manufacturer shall not be held liable for any damages caused by the

user’s failure to:

– abide by the conditions defined in

these Operating Instructions,

– abide by applicable regulations and

standards,

– abide by installation and operating in-

structions.

– abide by the regulations specified in

the Warranty Certificate and Service

Book.

Such damages are not covered by the pro-

duct warranty.

a ) Heating systems:

STN 06 0310 – Central heating, design

and installations

STN 06 0830 – Safety equipment for central heating and hot water heating systems.

STN 07 7401 – Water and steam for heat

energy equipment of operating pressure

up to 8 MPa

b ) Gas distribution systems:

STN 38 6420 – Industrial gas pipelines.

STN EN 1775 – Gas supply – Gas pipelines in buildings – Maximum operating

pressure below 5 bar

STN 38 6413 – Steel gas pipelines and

connections

STN 07 0703 – Gas-fired boilers

STN 38 6405 – Gas equipment. Operating

principles.

Act No. 222/94 Coll. on business conditions and public service supervision in

the energy industry and on state energy

inspection.

c ) Electrical installation:

STN 33 2180 – Wiring of electrical instruments and appliances.

STN 33 2000-3 – Electrical installation in

buildings. Part 3: Definition of basic characteristics.

STN 33 2000-7-701 – Electrical installation in buildings. Part 7: Requirements on

special installations or premises. Section

701. Rooms with a bath-tub…

STN 33 2130 – Electrical engineering regulations. Interior electrical installations.

STN 33 0160 – Electrical engineering

regulations. Labelling terminals of electrical objects.

Execution regulations.

STN 33 0165 – Electrical engineering

regulations. Colour marking or numbering

of wires.

Execution regulations.

STN 33 2350 – Regulations for electrical

equipment in difficult climatic conditions.

4

5

STN 34 0350 – STN electrical engineering regulations. Regulations for loose cables and cords.

STN 33 1500 – Instructions for electrical

equipment.

STN EN 60 335-1 – Safety of household

and similar electrical appliances. Part 1

– General requirements.

d ) Chimney:

STN 73 4210 – Construction of chimneys

and fume exhausts and connecting fuel

appliances to them.

STN 73 4201 – Designing chimneys and

fume exhaust flues.

STN 06 1610 – Fume exhaust parts of

household appliances.

STN EN 297 – Gas-fired central heating

boilers. Boilers Type B11 and B11BS with

atmospheric burners and nominal thermal

output up to 70 KW.

e ) Fire protection regulations:

STN 92 0300 – Fire safety of local appliances and sources of heat.

STN 73 0823 – Fire technical properties

of materials. Degrees of flammability of

building materials.

f ) Utility hot water heating systems:

STN 06 0320 – Heating of utility hot water.

STN 06 0830 – Safety devices for central

heating and utility hot water heating systems.

STN 73 6660 – Internal water distribution

systems.

STN 83 0616 – Utility hot water quality.

Safety of Persons and Equipment

As products, boilers are verified for compliance with the following documents:

STN EN 437, STN EN 50165, STN EN

60335-1+A11, Act No. 513/1991 Commercial Code, Act No. 634/1992 and Ministry

of Health Public Notice No. 13/1977.

Boiler Features

The PROTHERM KLO / KLO EKO stationary, cast iron boiler is designed for heating

water for heating purposes and, if combined with an indirectly heated reservoir,

also for heating utility hot water. It is available in the following series of size:

a) 65, 85, 100, 130, 150 KLO

b) 65, 85, 100, 130, 150 KLO EKO

The boilers use as fuel natural gas and

both series have a dual-stage design (low

and high output).

Models 65 – 85 KLO/KLO EKO are single-stage and designed to run on propane

gas.

Both model series can be fitted with a Siemens Albatros RVA 43.222 equithermal

control unit. By combining it with other

RVA 43.222 control units, a cascade system can be created with multiple sources

of heat.

The central heating system water pump is

controlled by a thermostat and turned on

only when the heating water temperature

reaches a set value. This reduces the time

required to heat the water inside the boiler after a protracted break in the boiler’s

function. The heating water pump is part

of the delivery.

The boiler can work in conjunction with

an indirectly heated utility water tank. The

standard boiler configuration allows the

tank to be connected easily to the boiler’s

terminal box.

To guarantee correct functioning of the

system, we recommend using a PROTHERM reservoir heater of 95- to 200-litre

volume, equipped with a thermostat and a

switching contact. Using the RVA 43.222

control unit will allow water in the reservoir

to be topped up by a pump.

Important: For combined heaters (with

water heated also by electricity), it is essential to prevent the supply of alien volt-

The boiler (as well as its accessories)

complies with the type which has been

tested and certified by the Technical Testing Institute in Piešťany, SKTC-104, authorised to verify the compliance with the

requirements of the Slovak Bureau for

Standardisation, Metrology and Testing,

and the compliance with the technical requirements specified by Government Decrees Nos. 392/99, 393/99 and 393/99 as

set forth in Act No. 264/1999.

Hence the boilers (and their accessories)

meet the requirements of applicable technical and legal standards, a fact confirmed

in a “Certificate of Compliance” issued by

the manufacturer. Pursuant to applicable legislation, the Certificate is kept for

inspection and supervision authorities,

and for distribution purposes sufficient is

a written confirmation that the Certificate

has been issued.

When installing and using the boilers and

their accessories, other generally applicable documents must taken into account,

which also define requirements in addition

to those on the product itself, namely:

– in the areas of design and installation

(and maintenance and repairs): STN

06 0310, STN 06 0830, STN 07 0703,

STN EN 1775, STN 38 6413 and STN

38 6460, STN 73 4201and STN 73

4210, and Public Notice No. 48/1982

(in the wording of later regulations)

and binding work safety and health at

work regulations;

– . during transportation and operation:

STN 38 6405, Public Notice No. 718/

2002.

In addition to abiding with the requirements of these documents, it is necessary to proceed when using the boiler in

accordance with these Operating Instructions and other manufacturer’s documentation supplied with the boiler.

age to the boiler – i.e. the thermostat contacts must be separated from the heater’s

internal electrical wiring!!!

Utility hot water heating has priority before

heating water. This means that water in

the central heating (CH) system is heated

only after the utility hot water (UHW) has

been heated to the required temperature.

Setting this value above usual temperature (50-60°C) will result in longer heating

times and hence longer breaks in heating the building. The heating time will be

longer also when the boiler is set to low

output, or when the CH water temperature

is set too low.

Important: The boiler must not be used for

any other purposes than those described

in these Operating Instructions.

6

7

The PROTHERM KLO boiler consists of

the following components:

1. cast iron body of the boiler with thermal

insulation and water connection pipe section;

2. burner plate with gas connection route

and ignition device;

3. collector of combustion fumes with a

chimney thrust detector and SKKT thermostat.

4. boiler covers with control panel and

boiler terminal box;

5. boiler base.

The cast iron boiler body is made of seg-

ments and serves as a combustion chamber (including combustion fumes routes),

and also as a water reservoir (including

water routes). The segments are lateral

(right and left) and central (one kind). The

boiler body of the required size (including

combustion chamber and water reservoir)

is constructed by assembling and joining

together the segments. The assembled

boiler body is fitted with pipe sections for

water connection and is insulated against

heat loss and heat radiation. It also has

960

850

52

544

92

125

370

605

720

1195

A

B

75

111

Æ G 6/4"

G

1"

Æ G 6/4"

C

Æ D

770

objemový prùtok vody V (m /h)

3

tlaková ztráta p (Pa)

20000

18000

20

0

4681012

16000

14000

12000

10000

8000

6000

4000

2000

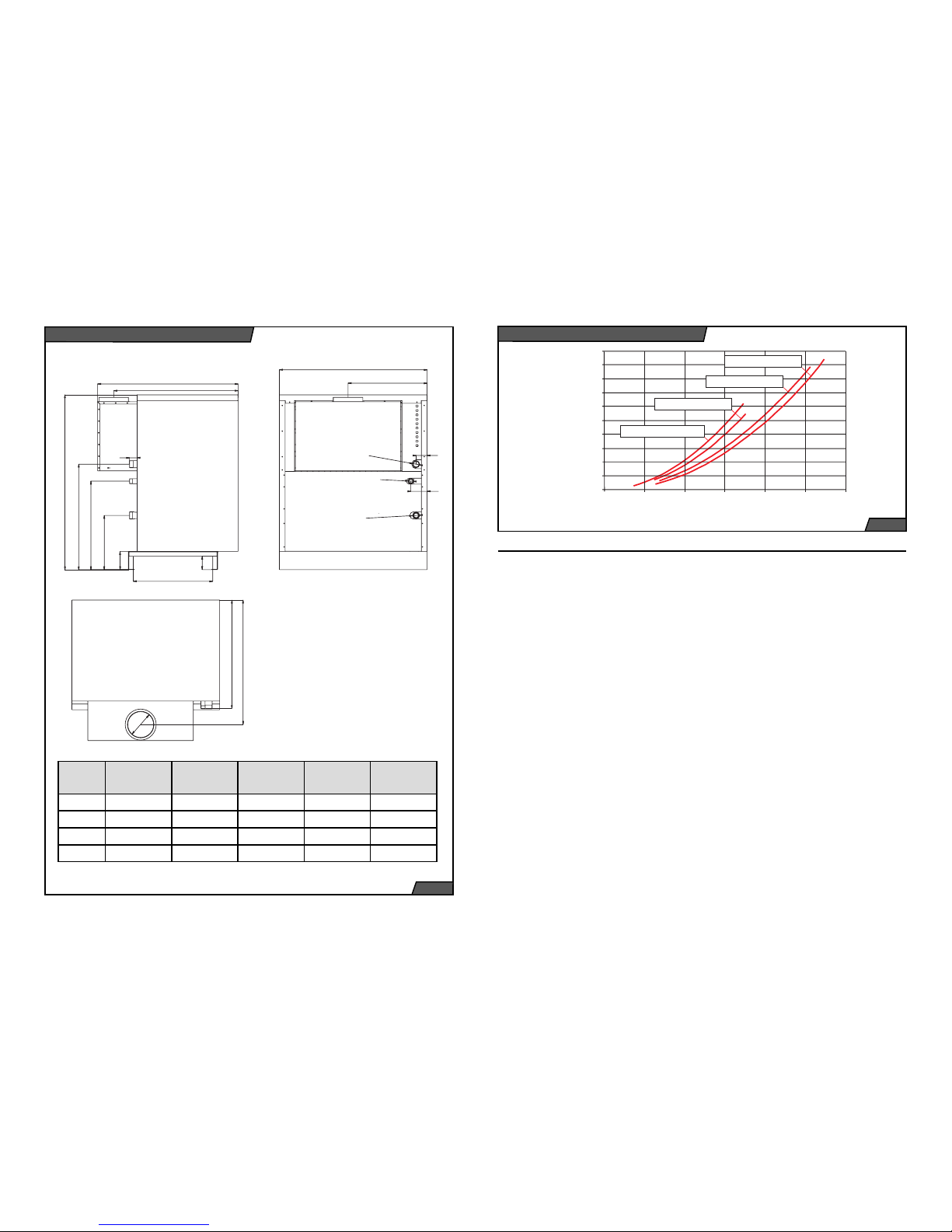

65, 85 KLO / KLO EKO

100 KLO / KLO EKO

130 KLO / KLO EKO

150 KLO / KLO EKO

Model 65 KLO /

KLO EKO

85 KLO /

KLO EKO

100 KLO /

KLO EKO

130 KLO /

KLO EKO

150 KLO /

KLO EKO

A 850 1010 1170 1410 1570

B 460,5 540,5 620,5 740, 5 820,5

C 860,3 850,3 840,3 825,3 825,3

D 180 200 220 250 250

brackets for fitting thermostat sensors and

a thermometer, and lugs on feet for connecting the body to the boiler base. The

KLO EKO series boilers use low-emission

burner tubes, the KLO series boilers use

standard tubes. Depending on the output,

the boiler has 7 to 16 burner tubes and a

complete gas route.

The burner plate is fitted with a gas distribution section, the actual burner tubes

and an ignition device. The gas route

consists of a gas supply pipe section terminated with a combined gas valve. The

combined gas valve controls the supply

of gas into the boiler depending on the

required and reached operating states of

the whole system (i.e. the boiler combined

with the heating system); its outlet is already the gas distribution section of the of

the burner plate, terminated with 7 to 15

jets (one for each burner tube).

Igniting the burner and watching that it is

running is done by a Polidoro low-emission ignition burner. When a request is

sent to ignite the main burner, after waiting

time T

w

= 10 seconds, the ignition burner

Accessories

Pressure loss (Pa)

Fig. 1

Basic and Connecting Dimensions

Pressure loss of the boiler´s body

Fig. 2

Flow of water volume V (m3/h)

8

9

is automatically ignited. It is ignited by an

ignition spark and its flame is detected by

an ionisation electrode. After the ignition

burner has steadied up and the ionisation

circuit closed, the main gas supply valve

to the main burner opens. If the ignition

burner does not ignite within a safety time

T

s

= 25 seconds, the gas supply to the

main burner and to the ignition burner is

automatically shut off. If the flame during

normal boiler operation goes out, the automatic ignition system will repeat the ignition cycle of the ignition burner. If the loss

of ionisation prevails, the boiler will switch

to a fault status (the light of the “Unlock

automatic fault signalling system” button

on the control panel lights up). After a

waiting time of approximately 10 seconds,

the fault status can be manually cancelled

by pressing the RESET button.

The ignition burner remains on while the

main burner is on.

In the event of power supply failure, the

gas supply to the burner is automatically

shut off. When power supply is restored,

the boiler will automatically restart itself.

KLO

1

2

3

4

5

6

7

8

10

9

11131415

16

18

22

20

21

19

2

3

4

5

6

7

8

10

9

12131415

16

18

19

20

1

21

22

11

17

17

1. Main control panel

2. Chimney thrust detector system cover

3. Fume exhaust

4. Chimney thrust detector

5. Fume thermostat

6. Heating water outlet

7. Gas supply

8. Cast iron body segments

9. Heating water inlet

10. Combustion chamber

11. Secondary air supply

12. Supply burning air

13. Burner

14. Supply burning air

15. Jet

16. Combining pipeline gas

17. Operator burner

18. Gas armatures*

19. Boiler covering

20. Case for sensors

21. Main control panel

22. Automotive ignition

automatics

* For models 130-150 KLO / KLO EKO is used only 1 gas armature.

KLO EKO

KLO

The combustion fumes collector is connected to a chimney thrust detector and

behind it is terminated in a boiler exhaust

outlet (on a fumes flue connection). The

collector is equipped with a removable

cleaning lid, which is accessible after removing the top boiler’s cover.

The chimney thrust detector system

(SKKT) works on the principle of monitoring the combustion fumes temperature

inside the collector. A thermostat situated

inside the collector reacts to an increase

of the combustion fumes temperature

caused by a reduced chimney effect will

shut the boiler down (by shutting off gas

supply to the burner).

The boiler has covers, which are rigidly

fixed to the rear and side-wall, a removable wall and a removable top cover. The

boiler’s control panel is located in the top

section.

The boiler body base is a single steelbase on which the body of the boiler and

the covers are mounted.

Boiler Installation Guidelines

The PROTHERM KLO / KLO EKO boilers can be put into operation only by an

authorised service organisation in accordance with UBP SR Public Notice No. 74/

1996. Installations, putting into operation,

warranty and post-warranty service are

done by a network of manufacturer’s contractual service organisations, which meet

the requirements specified above.

Connecting the boiler to gas supply

The PROTHERM Series KLO - ZP / KLO

EKO – ZP boilers are designed to run on

natural gas with nominal pressure in the

distribution network 1.8 kPa (18 mbar) and

a calorific value usually claimed between

9 and 10 kWh/cum. The internal gas distribution system as well as the gas meter

must be of sufficient size, taking into account also other user’s gas appliances.

The gas supply pipe must have an internal

diameter of at least the same size as the

gas connection pipe on the boiler (which

depends on the boiler size), but preferably

one size bigger.

The PROTHERM Series 65 – 85 KLO - P /

65 - 85 KLO EKO - P boilers are designed

to run on propane gas. Propane gas calorific value is given between 12.8 and 13

kWh/kg. Because supplying boilers from

pressure cylinders is problematic, particularly from the capacity and handling point

Fig. 3

Schematic operation diagram

10

11

of view, it is recommended that a reservoir

is installed near the building to be heated,

and refilled by an authorised organisation.

Adequately sized propane supply from

the reservoir to the boiler and to other gas

appliances will then be part of the design

and delivery of the reservoir. When installing a propane gas-fired boiler, an accurate

nominal pressure of 3.0 kPa (30 mbar)

must be secured by installing a reduction

valve (station) before the boiler.

Supply of combustion air

Ventilation must guarantee that sufficient

quantity of combustion air is supplied to

the boiler and that the maximum permissible concentrations of harmful gases

in the boiler’s vicinity are not exceeded

and that an acceptable temperature is

maintained there (all in accordance with

Ministry of Environment Public Notice No.

706/2002).

The stationary cast iron PROTHERM

KLO/KLO EKO boilers draw combustion

air from the space in which they are installed. The combustion air supplied to the

boiler must be free of dust and corrosive

and flammable substances (vapours, solvents, paints, adhesives, etc.). The supply of adequate quantity of combustion

air must meet the requirements of STN

070703 “Gas-fired boiler rooms”. Gas appliances connected to combustion fumes

flue must not be located in places where

negative pressure can be created by ventilation fans.

Combustion fumes exhaust

The boiler is designed for combustion

fumes to be removed into a chimney (via

a chimney connection point) with a stabilised thrust of at least 2 Pa. The boiler is

connected to the chimney by a flue of a

diameter corresponding to the flue diam-

quired by the water composition. Depending on the anticipated amount of sludge

trapped; is recommended to desludge the

boiler approximately a week after it has

been put into operation. Functional defects

caused by mechanical dirt are not covered

by the manufacturer’s overall warranty (refer to Warranty Terms and Conditions).

Important: When filling the boiler with

water, all air in the boiler as well as in

the heating system has to be thoroughly

bled.

Using antifreeze liquid

KLO and KLO EKO boilers may be filled

with an antifreeze liquid, namely product

called ALYCOL TERMO, produced by

Slovnaft Moravia. Using other antifreeze

products will invalidate the manufacturer’s

warranty on parts and related costs.

Properties of the heating system

and filling the system with water

The boiler must be connected to the heating system distribution pipes (G6/4”) and

to the gas supply pipe (G 1”) in such a way

that the connection end pieces are not

stressed by forces imposed by the heating system distribution pipes or by the gas

supply pipe. The connection end pieces

have an external thread.

We recommend equipping the connection

eter of the flue connection point (depends

on the boiler size). The flue is part of the

delivery.

It is forbidden to put inside the flue objects

obstructing the flow of combustion fumes

(e.g. various types of heat exchangers to

increase utilisation of the heat).

Construction of the flue and the chimney

must comply with STN 06 1610, STN 73

420 and STN 73 4201 standards.

By complying with requirements of these

standards, we prevent undesirable phenomena from occurring, such as excessive cooling of the fumes, penetration of

dampness into walls, fluctuations in the

chimney effect (thrust) and thus undesirable effects on the boiler’s functioning.

Requirements on heating water

quality

The PROTHERM KLO / KLO EKO boilers

are designed for heating water of up to

400 kPa (4 bar) gauge pressure, which is

in compliance with STN 07 7401.

The first fill as well as top up water must

be clear and colourless, and be free of

suspended substances; oil and chemically corrosive additives, under no circumstances may be acidic (i.e. have pH factor

greater than 7) and must have minimal

carbonate hardness.

For softening the first fill water can be used

trisodium phosphate or a one-off dose of

chelating agent.

It is recommended to install before the

boiler (i.e. to the return heating water pipe)

a sludge trap. Its design should allow the

device to be emptied in regular intervals

without draining a great deal of heating

water in the process. The sludge trap can

be combined with a filter, but the filter itself

would not provide adequate protection.

Both the filter and the sludge trap must

be checked regularly and cleaned, as re-

pipes with isolation valves, so that when

repairing the boiler it is not necessary to

drain water from the heating system.

The heating system should be designed

in such a way that a permanent circulation

of the heating water is possible at least

through some radiators.

The boiler does not have an expansion

vessel or a safety valve built in, therefore

these devices can be connected only to

an external system, designed in accordance with STN 06 0310 and safety features compliant with STN 06 0830.

The boiler can work in systems with both

an open and closed (pressurised) expansion vessel. However, when using the

boiler in systems with an open expansion

vessel, it is necessary to harmonise the

temperature setting of the emergency

thermostat (98°C) and limit the operation

range on the heating controls. This setting

must be done by authorised service only.

In open expansion vessels, correct water

level must be maintained (between the operating minimum and maximum). Closed

expansion vessels when being filled up

must be set according to the heating system.

For filling and draining purposes, the boiler

is equipped with a filling (draining) valve.

After being filled up, the system must be

thoroughly bled.

After reconstructions, in unsuitable building disposition, etc., the boiler may be

connected to the heating system and to

the gas supply by flexible hoses, but only

those designed for this purpose. When using flexible connections, these should be

as short as possible, protected against

mechanical and chemical stress and damage, and be always replaced before the

end of their life or before their parameters

deteriorate with new ones (as determined

by their manufacturer).

Fig. 4

Loading...

Loading...