Promac VBS-1610 Operating Instructions And Parts Manual

2019.01

Operating Instructions and Parts Manual

16-inch Metalworking Band Saw

Model : VBS-1610

Schweiz / Suisse France

JPW (TOOL) AG TOOL FRANCE SARL

Tämperlistrasse 5 9 Rue des Pyrénées, 91090 LISSES, France

CH-8117 Fällanden Switzerland www.promac.fr

www.promac.ch

2

CE-Conformity Declaration

CE-Konformitätserklärung

Déclaration de Conformité CE

Product / Produkt / Produit:

Metal band saw

Metallbandsäge

Scie à ruban

VBS-1610

Brand / Marke / Marque:

PROMAC

Manufacturer / Hersteller / Fabricant:

TOOL FRANCE SARL

9 Rue des Pyrénées, 91090 LISSES, France

We hereby declare that this product complies with the regulations

Wir erklären hiermit, dass dieses Produkt der folgenden Richtlinie entspricht

Par la présente, nous déclarons que ce produit correspond aux directives suivantes

2006/42/EC

Machinery Directive

Maschinenrichtlinie

Directive Machines

2014/30/EU

electromagnetic compatibility

elektromagnetische Verträglichkeit

compatibilité électromagnétique

designed in consideration of the standards

und entsprechend folgender zusätzlicher Normen entwickelt wurde

et été développé dans le respect des normes complémentaires suivantes

EN ISO 12100:2010

EN ISO 16093:2017

EN 60204-1:2006+A1:2009

EN 61000-6-2:2005

EN 61000-6-4:2007+A1:2011

Responsible for the Documentation / Dokumentations-Verantwortung / Résponsabilité de Documentation:

Head Product-Mgmt. / Leiter Produkt-Mgmt. / Resp. Gestion des Produits

TOOL FRANCE SARL

2018-12-20 Christophe SAINT SULPICE, General Manager

TOOL FRANCE SARL

9 Rue des Pyrénées, 91090 LISSES, France

3

1.0 Table of contents

Section Page

1.0 Table of contents ............................................................................................................................................ 3

2.0 Safety warnings .............................................................................................................................................. 4

3.0 Specifications ................................................................................................................................................. 6

4.0

Uncrating and assembly

5.0 Installation ...................................................................................................................................................... 7

6.0 Electrical connections .................................................................................................................................... 7

6.1 Three-phase test run .................................................................................................................................. 7

7.0 Controls .......................................................................................................................................................... 8

8.0 Adjustments ................................................................................................................................................... 9

8.1 Blade tensioning ......................................................................................................................................... 9

8.2 Blade tracking ............................................................................................................................................. 9

8.3 Blade guide adjustment .............................................................................................................................. 9

8.4 Top guide adjustment ............................................................................................................................... 10

8.5 Changing saw blades ............................................................................................................................... 10

8.6 Work lamp ................................................................................................................................................ 10

9.0 Blade selection ............................................................................................................................................. 10

9.1 Material composition ................................................................................................................................ 10

9.2 Tooth shape ............................................................................................................................................. 10

9.3 Set type .................................................................................................................................................... 10

9.4 Gage ......................................................................................................................................................... 11

9.5 Kerf ........................................................................................................................................................... 11

9.6 Width ........................................................................................................................................................ 11

9.7 Blade breakage ........................................................................................................................................ 11

10.0 Welder operation ........................................................................................................................................ 11

10.1 Shearing ................................................................................................................................................. 11

10.2 Removing Teeth ..................................................................................................................................... 12

10.3 Welding .................................................................................................................................................. 12

10.4 Annealing ............................................................................................................................................... 13

10.5 Blade grinding ........................................................................................................................................ 14

10.6 Secondary Annealing ............................................................................................................................. 14

10.7 Welder Clean-Up .................................................................................................................................... 14

11.0 Band saw operation ................................................................................................................................... 14

11.1 Blade break-in procedure ....................................................................................................................... 14

11.2 Setting blade speed ................................................................................................................................ 14

11.3 Evaluating cutting efficiency ................................................................................................................... 15

12.0 User-maintenance ...................................................................................................................................... 15

12.1 Lubrication schedule .............................................................................................................................. 15

12.2 Gearbox oil ............................................................................................................................................. 15

13.0 Troubleshooting ......................................................................................................................................... 16

13.1 Operating problems ................................................................................................................................ 16

13.2 Mechanical and electrical problems ....................................................................................................... 17

13.3 Welded blade inspection ........................................................................................................................ 18

13.4 Welder mechanical problems ................................................................................................................. 19

14.0 Speed and pitch chart ................................................................................................................................ 20

15.0 Typical Band Saw Operations .................................................................................................................... 21

16.0 Replacement Parts ..................................................................................................................................... 22

16.1.1 VBS-1610 Band Saw – Exploded View ............................................................................................... 22

16.1.2 VBS-1610 Band Saw – Parts List ........................................................................................................ 23

Gear Box Compound Assembly ...................................................................................................................... 23

16.1.3 VBS-1610 Band Saw (Welder Assembly) – Exploded View ............................................................... 27

17.0 Electrical diagram (VBS-1610) ................................................................................................................... 30

................................................................................................................................. 7

2.0 Safety warnings

Do not wear gloves while operating this machine.

In addition to the safety requirements contained in

these operating instructions and your country’s

applicable regulations, you should observe the

generally recognized technical rules concerning the

operation of woodworking machines.

Any other use exceeds authorization.

In the event of unauthorized use of the machine, the

manufacturer renounces all liability and the

responsibility is transferred exclusively to the

operator.

3.2 General safety notes

Woodworking machines can be dangerous if not used

properly. Therefore the appropriate general technical

rules as well as the following notes must be observed.

Read and understand the entire instruction manual

before attempting assembly or operation.

Install the machine so that there is sufficient space for

safe operation and workpiece handling.

Keep work area well lighted.

The machine is designed to operate in closed rooms

and must be bolted stable on firm and levelled table

surface or on the supplied cabinet stand.

Make sure that the power cord does not impede work

and cause people to trip.

Keep the floor around the machine clean and free of

scrap material, oil and grease.

Stay alert!

Give your work undivided attention.

Use common sense. Do not operate the machine

when you are tired.

Keep an ergonomic body position.

Maintain a balanced stance at all times.

Do not operate the machine under the influence of

drugs, alcohol or any medication. Be aware that

medication can change your behaviour.

Keep this operating instruction close by the machine,

protected from dirt and humidity, and pass it over to

the new owner if you part with the tool.

No changes to the machine may be made.

Daily inspect the function and existence of the safety

appliances before you start the machine.

Do not attempt operation in this case, protect the

machine by unplugging the power cord.

Before operating the machine, remove tie, rings,

watches, other jewellery, and roll up sleeves above

the elbows.

Remove all loose clothing and confine long hair.

Wear safety shoes; never wear leisure shoes or

sandals.

Always wear the approved working outfit:

- safety goggles

- ear protection

- dust protection

Never reach into the machine while it is operating or

running down.

Keep children and visitors a safe distance from the

work area.

Never leave a running machine unattended. Before

you leave the workplace switch off the machine.

Do not operate the electric tool near inflammable

liquids or gases.

Observe the fire fighting and fire alert options, for

example the fire extinguisher operation and place.

Do not use the machine in a dump environment and

do not expose it to rain.

Before machining, remove any nails and other foreign

bodies from the workpiece.

Work only with well sharpened tools.

Machine only stock which rests securely on the table.

Always close the chuck cover before you start the

machine.

4

Specifications regarding the maximum or minimum

size of the workpiece must be observed.

Do not remove chips and workpiece parts until the

machine is at a standstill.

Do not stand on the machine.

Connection and repair work on the electrical

installation may be carried out by a qualified

electrician only.

Have a damaged or worn power cord replaced

immediately.

Make all machine adjustments or maintenance with

the machine unplugged from the power source.

Environmental protection

Protect the environment.

Your appliance contains valuable materials which can

be recovered or recycled. Please leave it at a

specialized institution.

This symbol indicates separate collection for electrical

and electronic equipment required under the WEEE

Directive (Directive 2012/19/EC) and is effective only

within the European Union.

5

6

3.0 Specifications

Model number ......................................................................................................................................... VBS-1610

Stock number ............................................................................................................................................ 414485T

Blade speed ............................................................................................................................................... variable

Low range ....................................................................................................................................... 20-80 MPM

High range ................................................................................................................................. 250-1000 MPM

Capacities:

Height (max. thickness) ......................................................................................................................... 250 mm

Throat (max. width) ............................................................................................................................... 393 mm

Welder capacity .................................................................................................................................... 3-16 mm

Motor ................................................................................................ TEFC, 2HP (1.5kW), 3PH, 400V ,3.3A, 50Hz

Table size ......................................................................................................................................... 550 x 600 mm

Table height from floor at 90° ................................................................................................................... 1000 mm

Table tilt:

Front and Back ......................................................................................................................................... 8 deg.

Right ....................................................................................................................................................... 15 deg.

Left ......................................................................................................................................................... 12 deg.

Welder (KVA) ............................................................................................................................................. 2.4

Blade length (approximate) ....................................................................................................................... 3136mm

Blade width, maximum .................................................................................................................................. 16mm

Overall height ............................................................................................................................................ 1840mm

Floor space required ........................................................................................................................... 940x711mm

Gearbox oil capacity .................................................................................................................. 2500 cc (0.66 gal.)

Weights:

Net ............................................................................................................................................ 900 lbs. (408 kg)

Shipping ................................................................................................................................. 1122 lbs. (510 kg)

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, Promac reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

7

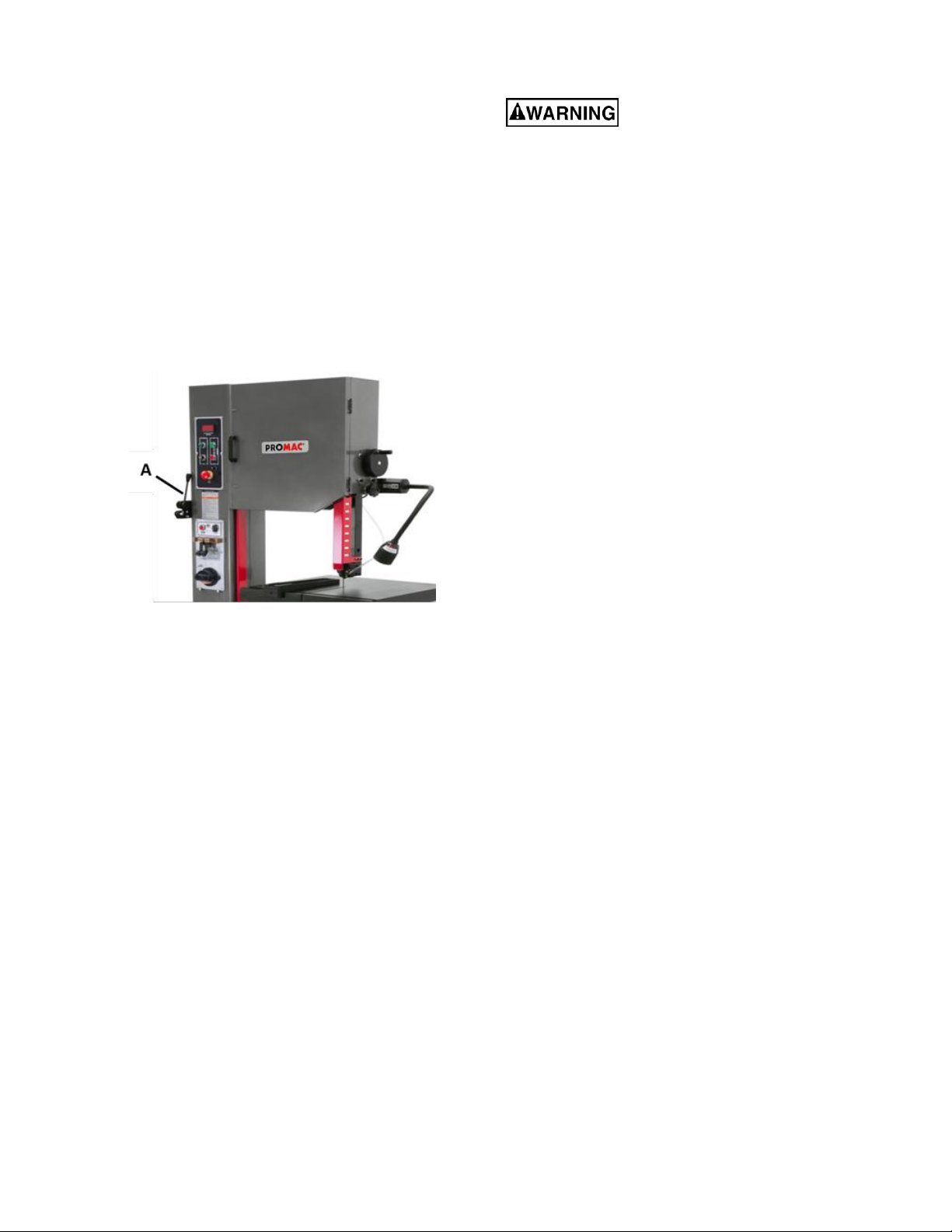

4.0

Uncrating and assembly

6.0 Electrical connections

1. Finish uncrating the band saw. Contact your

distributor if any damage has occurred during

shipping.

2. Remove any preservative with kerosene or

diesel oil. Do not use gasoline, paint thinner, or

any cellulose-based product, as these will

damage painted surfaces.

3. Remove two socket head cap screws from left

side of vertical column. Attach shear assembly

(A, Figure 1) to column by inserting hex cap

screws.

4. Place rip fence onto table and tighten with

locking knob.

Figure 1

All electrical connections must

be done by a qualified electrician. All

adjustments or repairs must be done with

machine disconnected from power source.

Failure to comply may cause serious injury.

The VBS-1610 Band Saw is rated at 400V and

without plug.

You may connect a proper plug suitable for 400 volt

operation, or "hard-wire" the machine directly to

your electrical panel provided there is a disconnect

near the machine for the operator.

The band saw must be grounded. A qualified

electrician can make the proper electrical

connections and confirm the power on site is

compatible with the saw.

Before connecting to power source, make sure

switch is in off position.

6.1 Three-phase test run

After wiring the band saw, you should check that the

wires have been connected properly. Connect

machine to power source and turn it on for an instant

to watch direction of blade movement.

If blade runs upward instead of downward,

disconnect machine from power, and switch any

two of the three leads in the motor junction box (see

section 18.0, Electrical diagram).

5.0 Installation

1. Remove three (3) nuts and washers holding

band saw to shipping crate bottom.

2. Use the lifting ring to lift band saw into its

permanent location. For best performance,

band saw should be bolted to floor after a level

position has been found.

3. Using a square, adjust table 90 degrees to

blade, both front to back and side to side.

Loosen the hex cap screws below the table to

move it and tighten to hold table in place. If

necessary, adjust the pointers to zero should

they read different once table is perpendicular

to blade in both directions.

4. To level the machine, place a machinist's level

on the table and observe in both directions.

5. Use metal shims under the appropriate hold

down screw. Tighten screw and recheck for

level.

6. Adjust with additional shims, as required, until

table is level when all mounting screws (or nuts)

are tight.

8

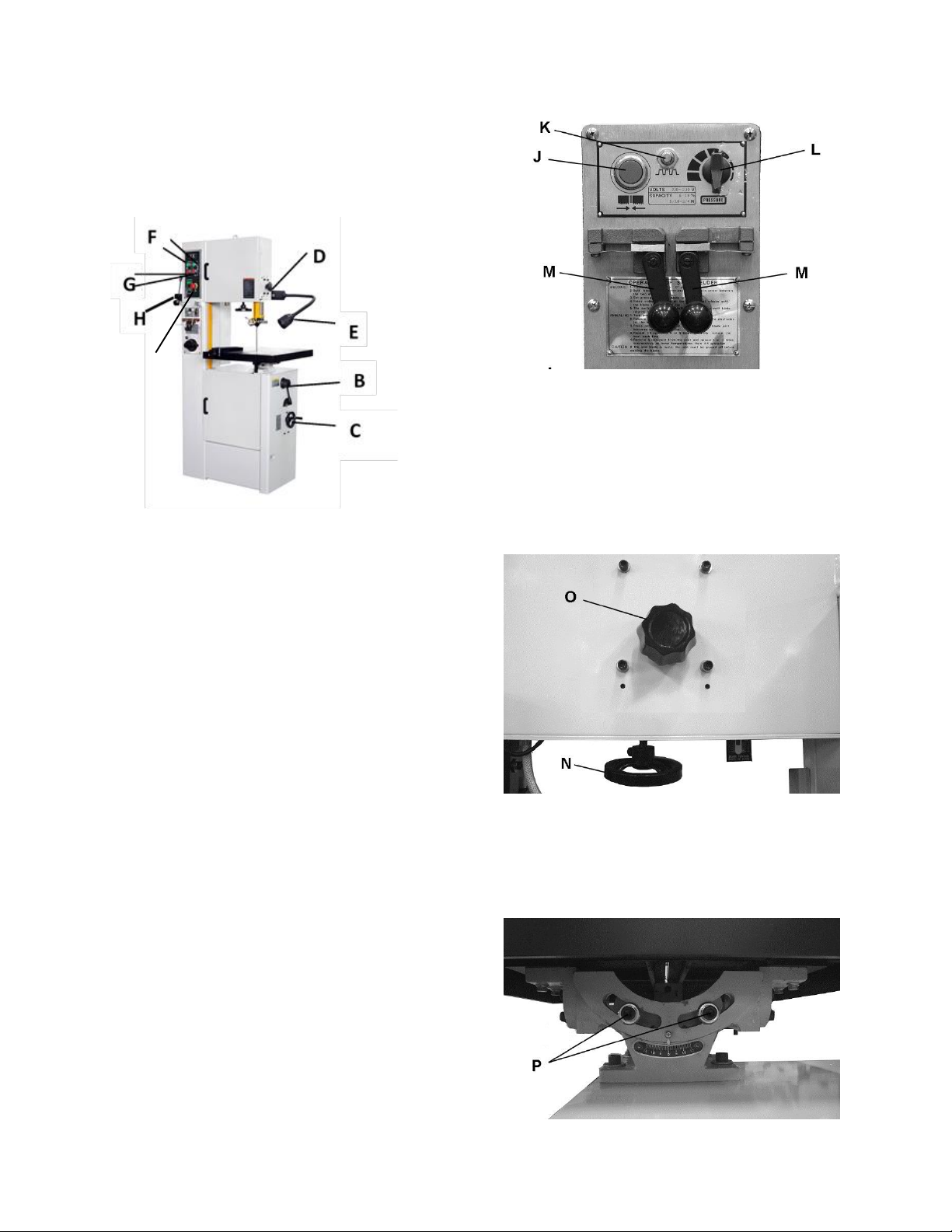

7.0 Controls

I

Low/High Range Shift Lever (B, Figure 2) – Pull

toward front of machine to shift into low speed range.

Push toward rear of machine to shift into high speed

range. CAUTION: Do not change speed range

while machine is running. Adjust only when

machine is stopped.

Figure 2

Variable Speed Handwheel (C, Figure 2) – Turn

clockwise to increase speed and counterclockwise

to decrease speed. CAUTION: Do not turn

handwheel while machine is stopped. Adjust

speed only when machine is running.

Upper Blade Guide Lock Knob (D, Figure 2) –Turn

counterclockwise to loosen and clockwise to tighten.

Work Lamp Switch (E, Figure 2) – on top of lamp

shade; turns lamp on and off.

Main Motor / Sand Wheel Start Switch (F, Figure

2) – Press to start band saw.

Main Motor / Sand Wheel Stop Switch (G, Figure

2) – Press to stop band saw.

Shear Lever (H, Figure 2) – UP position allows

insertion of blade end into shear. Pull lever DOWN

to cut blade.

Emergency Stop Switch (I, Figure 2) – Press to

stop all machine functions. Turn 90° to reset.

Weld Button (J, Figure 3) – located on blade welder

panel. Press and hold to start welding. Shuts off

automatically when weld is done. Release when

weld is completed.

Anneal Button (K, Figure 3) – located on blade

welder panel. Press and hold to anneal blade,

release to stop.

Blade Clamp Pressure Knob (L, Figure 3) –

located on blade welder panel. Sets pressure for

different width blades. Turn counterclockwise to

bring blade clamps closer together, clockwise to

separate.

Blade Clamps (M, Figure 3) – located on blade

welder panel. DOWN position allows insertion of

blade into clamp. UP position locks blade.

Figure 3

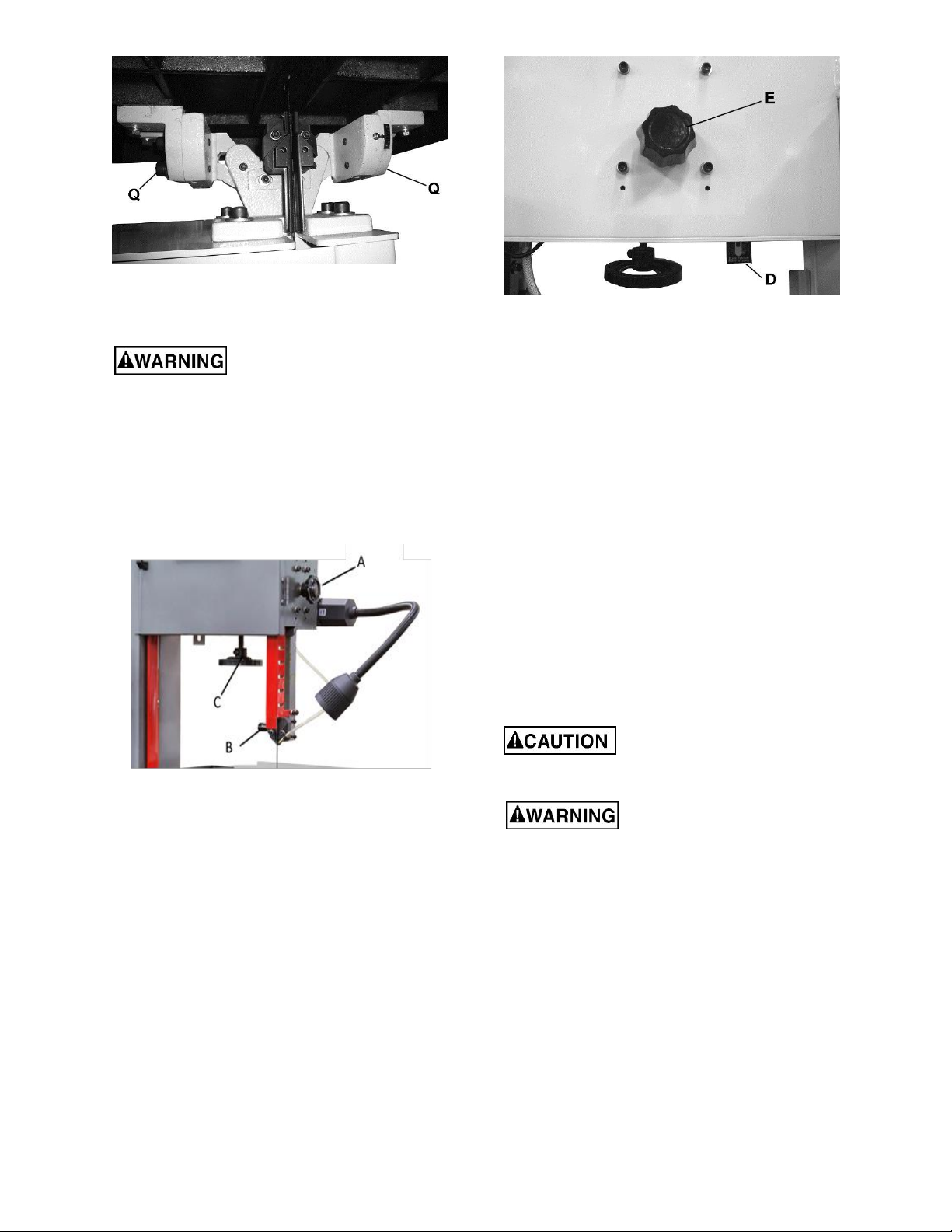

Blade Tension Handwheel (N, Figure 4) – located

on underside of upper frame. Turn clockwise to

tension blade; counterclockwise to release tension

on blade.

Blade Tracking Handle (O, Figure 4) – located at

upper rear of saw. Turn clockwise to track blade

toward front of blade wheel. Turn counterclockwise

to track blade toward rear of blade wheel.

Figure 4

Table Tilt Mechanism – located under work table.

To tilt table left or right, loosen two socket head cap

screws (P, Figure 5) at rear of mechanism. To level

table front to back, loosen four socket head cap

screws (Q, Figure 6) on either side of mechanism.

Figure 5

9

Figure 6

8.0 Adjustments

All adjustments or repairs to

machine must be done with power off and

machine disconnected from power source.

Failure to comply may cause serious injury.

8.1 Blade tensioning

1. Raise upper blade guide by loosening lock knob

(A, Figure 7) and lifting blade guide handle (B,

Figure 7) to its highest position.

Figure 8

8.2 Blade tracking

Blade tracking may be required periodically

depending upon blade size and tension. The blade

must be tensioned as outlined in section 9.1 Blade

tensioning. Disconnect machine from power source

and open upper blade wheel door. Shift high-low

gear box lever into neutral position. Turn upper

blade wheel by hand while observing blade position

on upper blade wheel. If adjustment is necessary:

1. Turn blade tracking knob (E, Figure 8)

clockwise to track blade toward front of blade

wheel.

2. Turn tracking knob counterclockwise to track

blade toward rear of blade wheel. Blade should

run next to, but not against, the wheel flange.

Note: Upper and lower blade guides should be

moved away and left loose from the blade while

tracking adjustments are being made.

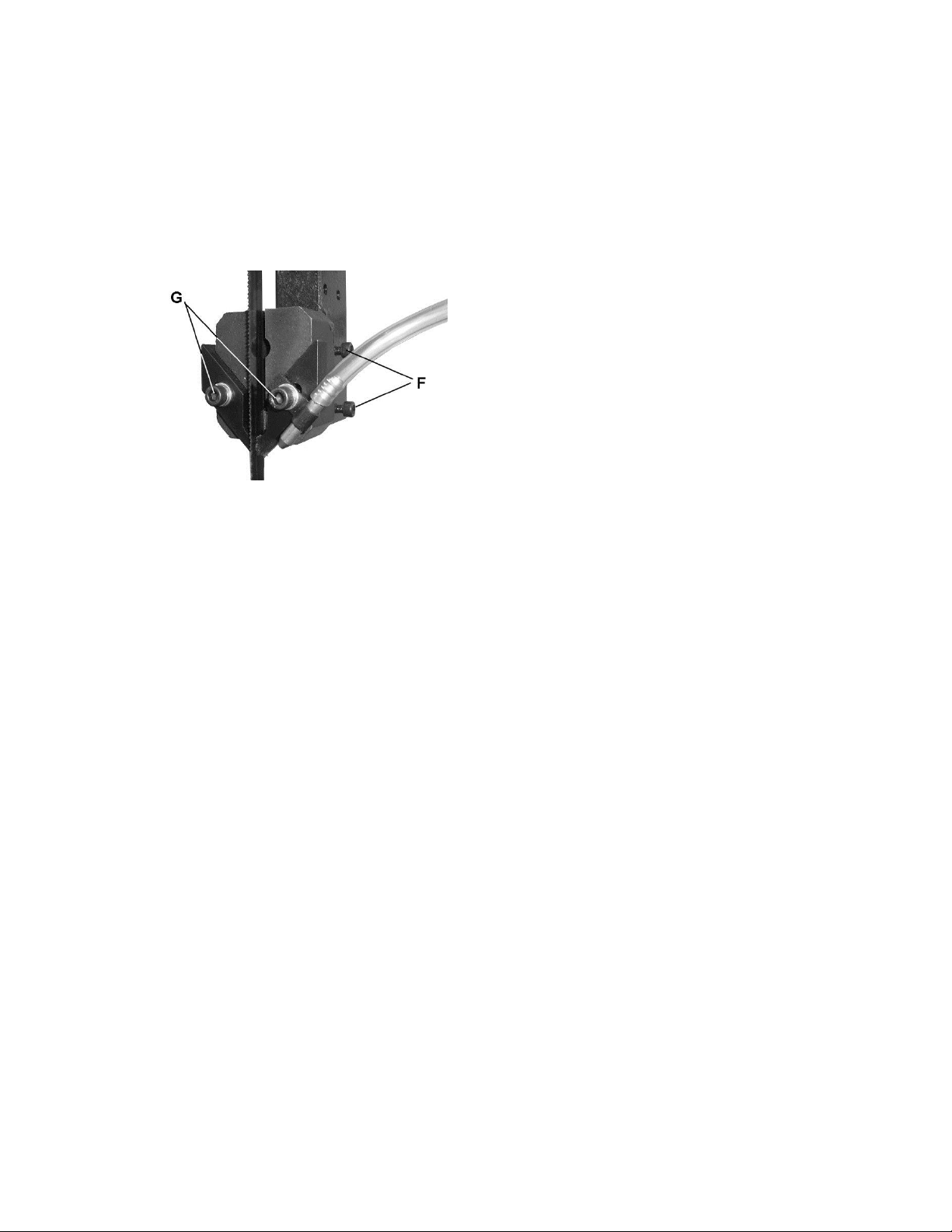

8.3 Blade guide adjustment

Figure 7

2. Apply finger pressure to blade. Travel from

vertical should be approximately 10mm each

way.

3. To tighten blade, turn handwheel (C, Figure 7)

clockwise. To loosen blade, turn handwheel

counterclockwise.

4. Use blade tension indicator (D, Figure 8) as

reference only. Blade should be tensioned

using the finger pressure method.

Blade guides must be properly

adjusted or damage may occur to blade and/or

guides.

Guard has been removed to

show detail. Always operate saw with guard in

place and properly adjusted. Failure to comply

may cause serious injury.

Blade guide adjustment has been set by the

manufacturer. Should future adjustment be needed,

proceed as follows.

1. Loosen upper blade guide lock knob and raise

guide assembly to half-way between table and

head, then tighten lock knob

2. Loosen two set screws (F, Figure 9) and adjust

guide so that blade guides are in back of saw

teeth. Blade guides must be adjusted far

enough back to clear saw blade even during

cutting operation when the blade is deflected

toward the rear.

3. Tighten the two screws (F, Figure 9).

10

4. Open upper access door and rotate blade

wheel by hand until weld portion of blade is

between the two fingers.

5. Loosen two socket head cap screws (G, Figure

9) and adjust each finger toward the blade.

They should not touch the blade. Adjust for

0.25mm clearance on either side.

6. Retighten the two screws (G, Figure 9) once

proper adjustment has been made. Be sure that

adjustment for air nozzle has not changed and

it directs the flow of air to the cut.

Figure 9

7. Adjust lower blade guides in similar manner.

Note: Even properly adjusted blade guides will show

wear after continual use. Readjust as necessary. If

the blade guides become difficult to adjust, switch

the left and right blade guides.

8.4 Top guide adjustment

Always position top guide to within 3mm of the top

surface of workpiece. This minimizes exposure of

operator’s hands to the saw blade.

8.5 Changing saw blades

7. Tension blade by turning tension handwheel.

Rotate wheel by hand and make sure blade is

properly seated in blade guides. Blade guides

will have to be adjusted if the replacement blade

is a different type and width.

8. Turn on saw and check blade tracking. Adjust

tracking if necessary.

8.6 Work lamp

The work lamp uses a standard 20W/24V Halogen

light.

9.0 Blade selection

Proper blade selection is just as important to band

saw operation as is blade speed and material feed.

Proper blade selection will impact blade life,

straightness of cut, cut finish, and efficiency of

operation. Excessive blade breakage, stripping of

teeth, and waviness of cut are some of the results of

improper blade selection.

Blades are classified by material composition, tooth

shape, tooth pitch, tooth set, gage of the band

material, and kerf of the set (width of cut).

9.1 Material composition

Carbon Steel – low cost, for use with non-ferrous

materials, wood, and plastics.

High Speed Steel – resists heat generated by dry

cutting. Used for ferrous metals.

Alloy Steel – tough and wear resistant, cuts faster

with longer blade life. Used on hard materials. More

expensive than carbon or high speed steel.

Carbide Tipped – for cutting unusual materials

such as uranium, titanium, or beryllium.

1. Disconnect saw from power source.

2. Move upper blade guide to its highest position

and lock in place.

3. Open both wheel doors. Turn tension

adjustment handwheel counterclockwise to

loosen tension on blade.

4. Remove blade from both wheels and maneuver

it around blade guard on column and protective

shield on upper blade guide. Use gloves when

handling blades.

5. Install new blade by maneuvering around blade

guard on column and protective shield on upper

blade guide.

6. Place it between the fingers of both blade

guides and onto both wheels. Position next to

both wheel flanges. Make sure teeth point down

toward table. NOTE: If teeth will not point

downward regardless of blade orientation, the

blade is inside-out. Twist blade outside-in and

reinstall.

9.2 Tooth shape

Note: When cutting thin materials, the rule for blade

pitch is to have a minimum of two teeth engaging

the material being cut at all times.

Standard Tooth - generally used to cut ferrous

metals, hard bronze, hard brass, and thin metals.

Skip Tooth - have better chip clearance (larger

gullet) and are used on softer, non-ferrous materials

such as aluminum, copper, magnesium, and soft

brass.

Hook Tooth - provides a chip breaker and has less

tendency to gum up in softer materials. Used in the

same materials as skip tooth but can be fed faster

than standard or skip tooth blades.

9.3 Set type

Straight Set – used for free cutting non-ferrous

materials; i.e., aluminum, magnesium, plastics, and

wood.

11

Wavy Set – used on materials of varying thickness

(pipe, tubing, and structural shapes).

Raker Set – used in large cuts on thick plate and

bar stock where finish of cut is not as important as

speed.

9.4 Gage

Gage is the thickness of material from which the

blade is produced. The thicker the material, the

stronger the blade.

9.5 Kerf

Kerf is the width of a cut. Kerf will vary according to

the set of the blade teeth.

10.0 Welder operation

Wear eye protection while

operating welder. Use care when handling blade

after welding to avoid burns.

The welding procedure involves the following steps:

Shearing the blade, grinding teeth to allow for the

weld area, the actual welding, inspection of blade,

annealing, grinding and a final inspection of blade.

This procedure can be accomplished using the

shear and welder assemblies on your band saw.

Proceed as follows:

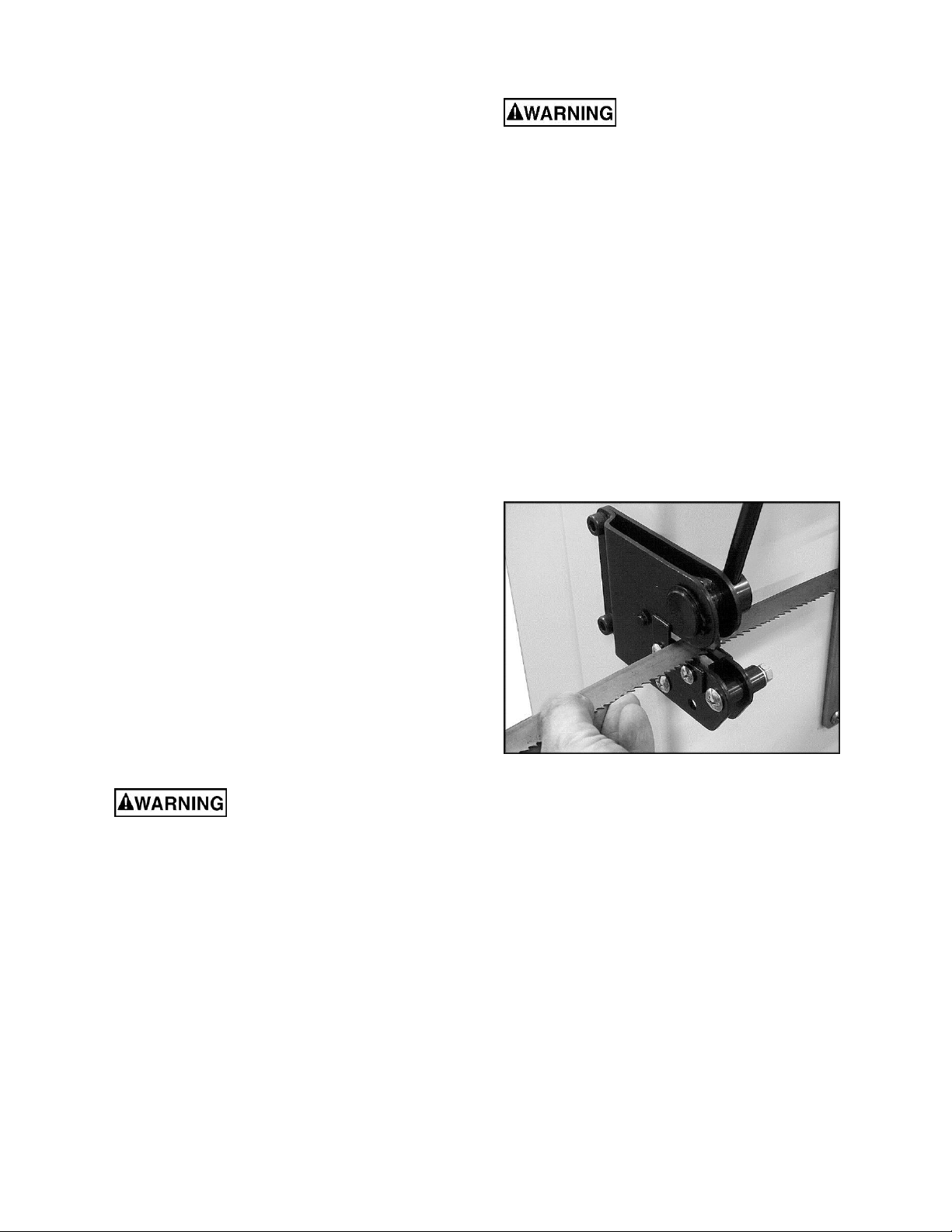

10.1 Shearing

9.6 Width

The thinner the blade, the tighter will be the

minimum radius of cut. Always use widest blade

possible for the job.

General rules for blade selection:

Select coarser pitch blades for thicker or softer

material.

Select finer pitch blades for thinner or harder

material.

Use fine pitch blades to obtain a smooth finish.

Use coarse pitch blades to obtain faster cutting

speeds (thick material).

To prevent premature blade wear, use fastest

practical speed.

Adjust feed rate to ensure continuous cutting

action.

Run the bandsaw with blade centered in upper

and lower guides, and guide fingers adjusted as

close as possible without touching the blade or

weld joint.

Never adjust guide fingers

while blade is running. Failure to comply may

cause serious injury.

9.7 Blade breakage

Band saw blades are subject to high stresses and

breakage may sometimes be unavoidable. However,

many factors can be controlled to help prevent most

blade breakage. Here are some common causes for

breakage:

1. Misalignment of blade guides.

2. Feeding workpiece too quickly.

3. Using a wide blade to cut a short radius curve.

4. Excessive tension.

5. Teeth are dull or improperly set.

6. Upper guides are set too high off the workpiece.

7. Faulty weld on blade.

Cut blade to longest length needed for band saw.

Using the shear to cut your blade will ensure that cut

ends are flat, square and smooth.

1. Place handle in upright position.

2. Position blade against back of square cutting

guide of shear. See Figure 10. Make sure blade

is held square with shear knife, so that cut will

be square with blade.

Figure 10

3. Position blade so that cut is made at a place that

allows for uniform spacing of teeth. See Figure

11.

4. Bring handle down firmly to cut blade.

IMPORTANT: If a blade has been cut by using snips,

the ends of the blade must be ground square before

welding them together, as shown in Figure 12.

Loading...

Loading...