Promac SY-350-ALU Operating Instructions And Parts Manual

1

Operating Instructions and Parts Manual

Miter Circle Saw 2016.03

Model SY-350-ALU

Schweiz / Suisse France

JPW (TOOL) AG. TOOL France / PROMAC

Tämperlistrasse 5 57, rue du Bois Chaland, Z.I. du Bois Chaland

CH-8117 Fällanden Switzerland case postale 2935 FR-91029 Evry Cedex

www.promac.ch www.promac.fr

2

CE-Conformity Declaration

Product: Miter Circle Saw

SY-350-ALU

Brand: PROMAC

Manufacturer:

JPW (Tool) AG, Tämperlistrasse 5, CH-8117 Fällanden, Switzerland

On our own responsibility we hereby declare that this product complies

with the regulations

* 2006/42/EC Machinery Directive

* 2014/35/EU Low Voltage Directive

* 2014/30/EU Electromagnetic Compatibility Directive

designed in consideration of the standards

** EN ISO 12100

EN 13898

EN 60204-1

EN 61000-6-2

EN 61000-6-4

Technical file compiled by: Hansjörg Meier, JPW (Tool) AG

2016-02-16 Alain Schmid, General Manager

JPW (Tool) AG, Tämperlistrasse 5, CH-8117 Fällanden, Switzerland

3

Table of Contents

Table of Contents……………………….…………………………………………………3

Warning………………………………………………..…………………………………4~5

Specifications………………………………………………..…………………………......6

Shipping Contents…………………………..……………………………………………..7

Contents of the Carton…………….……………………………………………………7

Assembly……………………………………………….…………………………………..7

Assembly…………………………………………………………………………………7

Controls and Indicators……………………………………………………………………8

Foreword…………………………………………………………………………………8

Warranty…………………………………………………………………………………8

Communication…………….……………………………………………………………8

Machine identification…………..………………………………………………………8

Use and limitations to use…………………...…………………………………………8

Expected machine life……………….…………………………………………………8

Machine disposal………………..………………………………………………………8

Operations………………………………………………………………………………….9

Cutting operation……………………………………………………………..…………9

Setting and Adjustments…………………………………………………………………10

Adjustment of the table angle……………………………………………….…………10

Adjusting the arm angle……………………………………….………………………11

Blade mounting and/or replacement……………………………….……………12~13

Maintenance…..…………………………………………………………………………..14

Other Risks…………………………………………………………………………..…14

Troubleshooting………………………………………………………………………15~16

Saw Assembly Drawing (1~2)………………………………..................................17~18

Stand Assembly Drawing..........................................................................................19

Saw and stand Assembly Parts………………………………………….................20~22

Wiring Diagram and Parts……………………………………………............................23

Warranty…………………………………………………………………………………..24

4

1. Read and understand the entire owner's manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply

with all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This band saw is designed and intended for use by properly trained and experienced personnel

only. If you are not familiar with the proper and safe operation of a band saw, do not use until

proper training and knowledge have been obtained.

5. Do not use this band saw for other than its intended use. If used for other purposes, PROMAC,

disclaims any real or implied warranty and holds itself harmless from any injury that may result

from that use.

6. Always wear approved safety glasses/face shields while using this band saw. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses.

7. Before operating this band saw, remove tie, rings, watches and other jewelry, and roll sleeves up

past the elbows. Remove all loose clothing and confine long hair. Non-slip footwear or anti-skid

floor strips are recommended. Do not wear gloves.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

Lead from lead based paint.

Crystalline silica from bricks, cement and other masonry products.

Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make certain the switch is in the OFF position before connecting the machine to the power supply.

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power

source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting and any other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

5

17. Provide for adequate space surrounding work area and non-glare, overhead lighting.

18. Keep the floor around the machine clean and free of scrap material, oil and grease.

19. Keep visitors a safe distance from the work area. Keep children away.

20. Make your workshop child proof with padlocks, master switches or by removing starter keys.

21. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play”

are careless acts that can result in serious injury.

22. Maintain a balanced stance at all times so that you do not fall or lean against the blade or other

moving parts. Do not overreach or use excessive force to perform any machine operation.

23. Use the right tool at the correct speed and feed rate. Do not force a tool or attachment to do a job

for which it was not designed. The right tool will do the job better and safer.

24. Use recommended accessories; improper accessories may be hazardous.

25. Maintain tools with care. Keep blades sharp and clean for the best and safest performance.

Follow instructions for lubricating and changing accessories.

26. Make sure the work piece is securely clamped in the vise. Never use your hand to hold the work

piece.

27. Turn off the machine before cleaning. Use a brush or compressed air to remove chips or debris —

do not use your hands.

28. Do not stand on the machine. Serious injury could occur if the machine tips over.

29. Never leave the machine running unattended. Turn the power off and do not leave the machine

until the blade comes to a complete stop.

30. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or

possibly even death.

6

- - SAVE THESE INSTRUCTIONS - -

Specifications

Model ........................................................................................................................................... SY-350-ALU

Stock Number ............................................................................................................................. SY-350-ALU

Cutting Capacity

Round at 90° (mm) ............................................................................................................................... 100

Round at 45° (mm) ............................................................................................................................... 100

Square at 90° (mm) .............................................................................................................................. 100

Square at 45° (mm) .............................................................................................................................. 100

Rectangle at 90° (mm) ............................................................................................................... 100 x 195

Rectangle at 45° (mm) ............................................................................................................... 100 x 135

Blade Size (mm) ................................................................................................................................ 350 x 30

Blade Speeds (RPM) .............................................................................................................................. 3300

Motor .................................................................................................................................. 1.5kW, 400V, 3Ph

Machine Dimension (mm) ................................................................................................... 700 x 700 x 1400

Machine Package (mm) ...................................................................................................... 660 x 900 x 1500

Net Weight (kg.) ........................................................................................................................................ 110

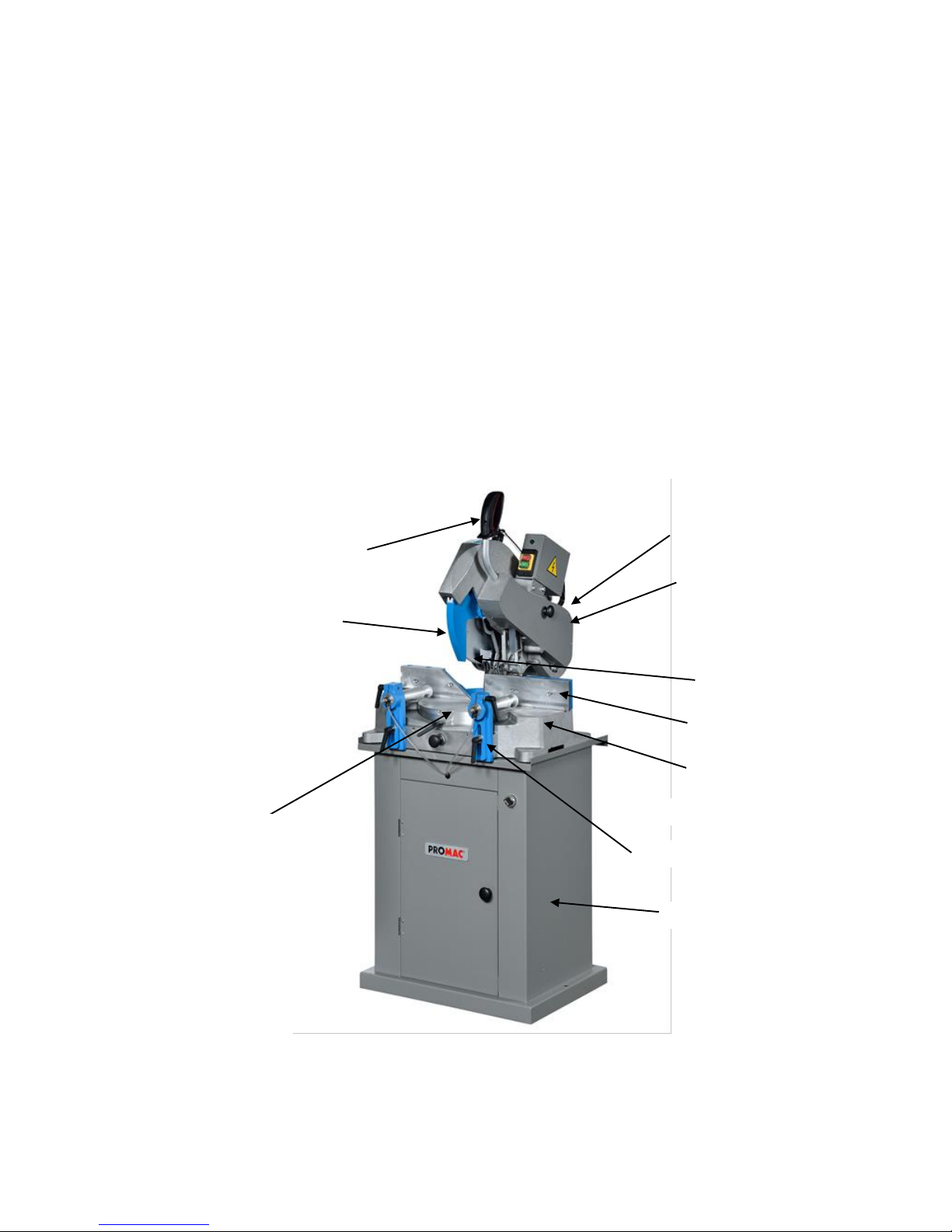

Fig 1

Table

Saw-Motor Arm

Turntable

Fences

Blade

Horizontal Vise

Internal Blade Guard

Operating handle

Motor

Base

Stand

7

Shipping Contents

Contents of the Carton

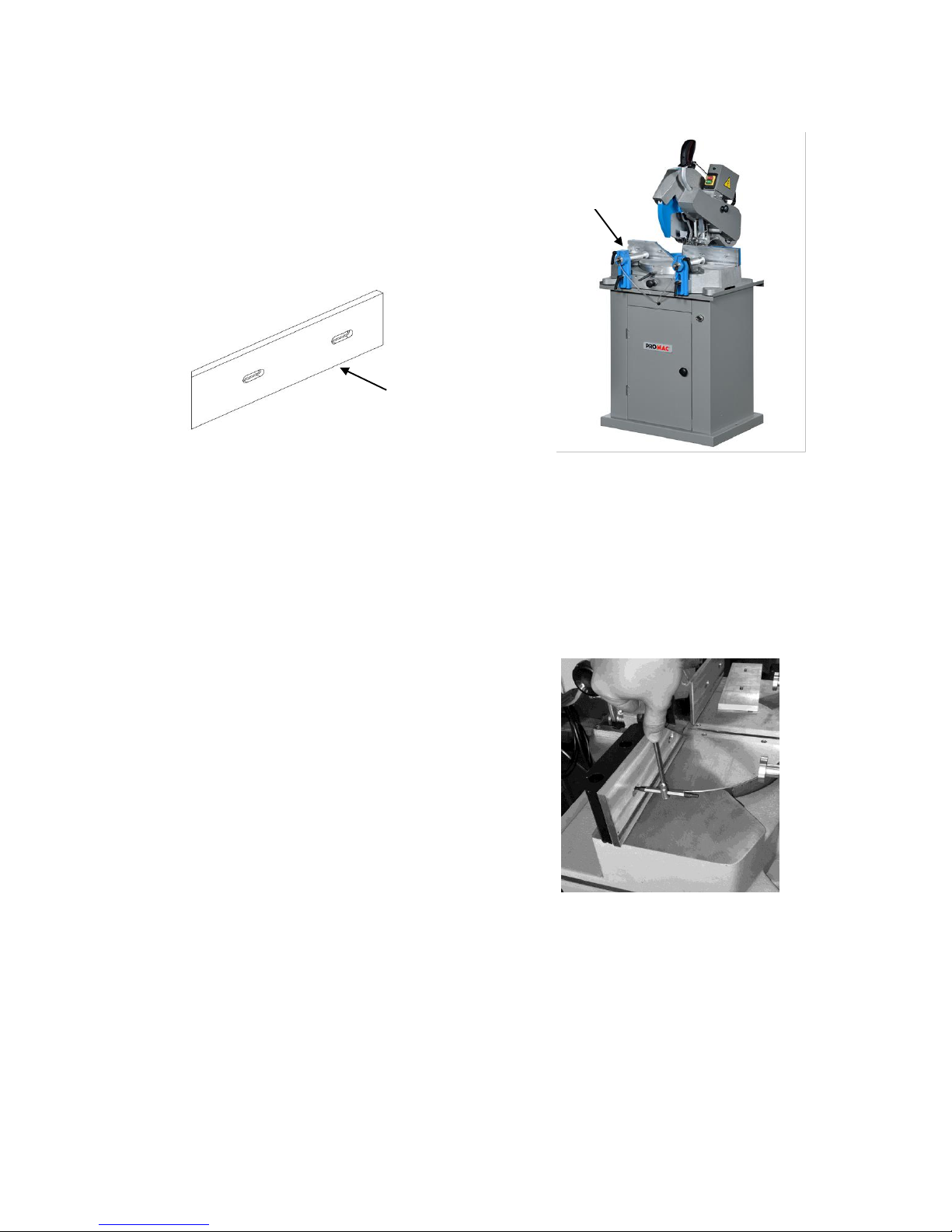

1 Machine body (A) FIG 2

1 Backgage Seat Right Plate (B) FIG 3

1 Operating Instructions/Parts List

(not shown)

Assembly

Assembly

You will replacement an vise plate as a

parts in side of machine stand.

Attention:

The vise plate only service for 90

degree cutting (saw arm angle).

Fig 3

B

Fig 2

A

Fig 4

Controls and Indicators

Voltage & frequency of the machine

Keep this manual in a good state and

available at a close distance from the

machine.

Foreword

For the preparation of this manual, we

have considered all operations referring

to normal use and regular maintenance

of the machine. Therefore, for correct

and optimal use of the machine, it is

necessary to carefully follow the

instructions described herein. The use

of the machine should be entrusted only

to authorized and skilled personnel.

Attention: It is recommended not to

carry out any repair or intervention

unless not indicated. All operations

requiring the disassembly of machine

parts should be entrusted to specialized

technical personnel.

Warranty

The machine is guaranteed for a period

of 24 months starting from the date of

the purchase invoice. It consists of a

free of charge replacement of all

mechanical parts showing material or

manufacturing defects.

All electric and electronic components

are excluded from this warranty. The

warranty does not cover breakages or

defects arising out of external factors,

maintenance mistakes or other causes,

improper use of the machine, use of the

machine overloaded, normal wear,

assembly mistakes which we may not

be held responsible for. Replacements

are shipped ex our factory. The machine

must be returned on a free port basis,

even when covered by the warranty.

Communication

For any written or verbal communication

with the Dealer or with the Firm about

the machine, it is necessary to supply

the following information:

Machine model

Serial number

Name of the dealer from which the

machine was purchased.

Description of the defect found, if any

description of the type of operation

carried out working hours per day.

Machine identification

The machine model is identified by a

plate situated at the front of the base,

showing the following data:

Serial number

Year of manufacture

Manufacturer’s name

Use and limitations to use

The machine is for professional use and

has been designed and conceived for

cutting wooden semi-finished materials

and their sub-products and, with suitable

adaptations (a suitable blade and a

“vise” accessory plastic materials (PVC)

or light alloys (aluminum).The protection

rating of the electrical installation is IP

54. Only the user may be held

responsible for any damage arising out

of a different use of the machine other

than that indicates.

Attention:

1. In particular, the machine is not

suitable for cutting ferrous materials.

2. The machine cannot be used in

explosive environments.

Expected machine life

The expected life of the machine under

conditions of normal use and regular

maintenance is to be considered of at

least 5 years.

Machine disposal

When the machine is no longer

operative, it can be disposed of by

means of a standard disposal center for

industrial wastes, as it is classified as

standard solid waste material.

8

Loading...

Loading...