Promac SX-821DA Operating Instructions Manual

SX-821DA

METAL BANDSAW

Original:

GB

Operating Instructions

Translations:

D

Gebrauchsanleitung

F

Mode d´emploi

Schweiz / Suisse France

JPW (TOOL) AG. TOOL FRANCE SARL

Tämperlistrasse 5 9 Rue des Pyrénées, 91090 LISSES, France

CH-8117 Fällanden Switzerland www.promac.fr

www.promac.ch

M- SX-821DA 2019-07

CE-Conformity Declaration

CE-Konformitätserklärung

Déclaration de Conformité CE

Product / Produkt / Produit:

Metal band saw

Metallbandsäge

Scie à ruban portable

SX-821DA

Brand / Marke / Marque:

PROMAC

Manufacturer / Hersteller / Fabricant:

TOOL FRANCE SARL

9 Rue des Pyrénées, 91090 LISSES, France

We hereby declare that this product complies with the regulations

Wir erklären hiermit, dass dieses Produkt der folgenden Richtlinie entspricht

Par la présente, nous déclarons que ce produit correspond aux directives suivantes

2006/42/EC

Machinery Directive

Maschinenrichtlinie

Directive Machines

2014/30/EU

electromagnetic compatibility

elektromagnetische Verträglichkeit

compatibilité électromagnétique

designed in consideration of the standards

und entsprechend folgender zusätzlicher Normen entwickelt wurde

et été développé dans le respect des normes complémentaires suivantes

EN ISO 12100:2010

EN 13898:2003+A1:2009

EN 60204-1:2006+A1:2009

EN 61000-6-2:2005

EN 61000-6-4:2007+A1:2011

Responsible for the Documentation / Dokumentations-Verantwortung / Résponsabilité de Documentation:

Head Product-Mgmt. / Leiter Produkt-Mgmt. / Resp. Gestion des Produits

TOOL FRANCE SARL

2018-11-29 Christophe SAINT SULPICE, General Manager

TOOL FRANCE SARL

9 Rue des Pyrénées, 91090 LISSES, France

2

GB - ENGLISH

Operating Instructions

Dear Customer,

Many thanks for the confidence you have shown in us with the purchase of your new Promac-machine. This manual has been prepared for the owner

and operators of a Promac SX-821DA, metal band saw to promote safety during installation, operation and maintenance procedures. Please read and

undertand the information contained in these operating instructions and the accompanying documents. To obtain maximum life and efficiency from

your machine, and to use the machine safely, read this manual thoroughly and follow instructions carefully.

…Table of Contents

1. Declaration of conformity

2. Warranty

3. Safety

Authorized use

General safety notes

Remaining hazards

4. Machine specifications

Technical data

Noise emission

Contents of delivery

Machine description

5. Transport and start up

Transport and installation

Assembly

Mains connection

Starting operation

6. Machine operation

7. Setup and adjustments

Changing blade speed

Changing sawblade

Blade guides adjustment

Guide bearing adjustment

Blade tracking adjustment

Feed speed adjustment

Vise adjustment

Saw arm adjustment

8. Maintenance and inspection

9. Troubleshooting

10. Environmental protection

11. Available accessories

1. Declaration of conformity

On our own responsibility we hereby declare

that this product complies with the

regulations* listed on page 2. Designed in

consideration with the standards**.

2. Warranty

JPW (Tool) AG guarantees that the supplied

product(s) is/are free from material defects

and manufacturing faults.

This warranty does not cover any defects

which are caused, either directly or indirectly,

by incorrect use, carelessness, damage due

to accidents, repairs or inadequate

maintenance or cleaning as well as normal

wear and tear.

Further details on warranty (e.g. warranty

period) can be found in the General Terms

and Conditions (GTC) that are an integral

part of the contract.

These GTC may be viewed on the website of

your dealer or sent to you upon request.

JPW (Tool) AG reserves the right to make

changes to the product and accessories at

any time.

3. Safety

3.1 Authorized use

This machine is designed for sawing

machinable metal and plastic materials only.

Machining of other materials is not

permitted and may be carried out in specific

cases only after consulting with the

manufacturer.

Never cut magnesiumhigh danger to fire!

The proper use also includes compliance

with the operating and maintenance

instructions given in this manual.

The machine must be operated only by

persons familiar with its operation and

maintenance and who are familiar with its

hazards.

The required minimum age must be

observed

The machine must only be used in a

technically perfect condition.

When working on the machine, all safety

mechanisms and covers must be mounted.

In addition to the safety requirements

contained in these operating instructions and

your country’s applicable regulations, you

should observe the generally recognized

technical rules concerning the operation of

metalworking machines.

Any other use exceeds authorization.

In the event of unauthorized use of the

machine, the manufacturer renounces all

liability and the responsibility is transferred

exclusively to the operator.

3.2 General safety notes

Metalworking machines can be dangerous if

not used properly. Therefore the appropriate

general technical rules as well as the

following notes must be observed.

Read and understand the entire instruction

manual before attempting assembly or

operation.

Keep this operating instruction close by the

machine, protected from dirt and humidity,

and pass it over to the new owner if you part

with the tool.

No changes to the machine may be made.

Daily inspect the function and existence of

the safety appliances before you start the

machine.

Do not attempt operation in this case,

protect the machine by unplugging the mains

cord.

Remove all loose clothing and confine long

hair.

Before operating the machine, remove tie,

rings, watches, other jewellery, and roll up

sleeves above the elbows.

Wear safety shoes; never wear leisure shoes

or sandals.

Always wear the approved working outfit

Do not wear gloves while operating this

machine.

For the safe handling of saw blades wear

work gloves.

Insure that the workpiece does not roll when

cutting round pieces.

Use suitable table extensions and supporting

aids for difficult to handle workpieces.

Always adjust the blade guide close to the

workpiece.

Remove cut and jammed workpieces only

when motor is turned off and the machine is

at a complete standstill.

3

Install the machine so that there is sufficient

A

B

C

D

E

U

K L M

N

O

P

S

T

H

IJ Q

R

space for safe operation and workpiece

handling.

Keep work area well lighted.

The machine is designed to operate in closed

rooms and must be placed stable on firm and

levelled ground.

Make sure that the power cord does not

impede work and cause people to trip.

Keep the floor around the machine clean and

free of scrap material, oil and grease.

Stay alert!

Give your work undivided attention. Use

common sense.

Do not operate the machine when you are

tired.

Do not operate the machine under the

influence of drugs, alcohol or any medication.

Be aware that medication can change your

behaviour.

Keep children and visitors a safe distance

from the work area.

Never reach into the machine while it is

operating or running down.

Never leave a running machine unattended.

Before you leave the workplace switch off

the machine.

Do not operate the electric tool near

inflammable liquids or gases.

Observe the fire fighting and fire alert

options, for example the fire extinguisher

operation and place.

Do not use the machine in a dump

environment and do not expose it to rain.

Specifications regarding the maximum or

minimum size of the workpiece must be

observed.

Do not remove chips and workpiece parts

until the machine is at a complete standstill.

Never operate with the guards not in place –

serious risk of injury!

Connection and repair work on the electrical

installation may be carried out by a qualified

electrician only.

Have a damaged or worn cord replaced

immediately.

Make all machine adjustments or

maintenance with the machine unplugged

from the power source.

Remove defective saw blades immediately.

3.3 Remaining hazards

When using the machine according to

regulations some remaining hazards may still

exist

The moving saw blade in the work area can

cause injury.

Broken saw blades can cause injuries.

Thrown cutting chips and noise can be health

hazards.

Be sure to wear personal protection gear

such as safety goggles and ear protection.

The use of incorrect mains supply or a

damaged power cord can lead to injuries

caused by electricity.

4. Machine specifications

4.1 Technical data

SX-821DA:

Wheel diameter 295 mm

Cutting capacity 90° dia. 225mm

200 x 200mm

240 x 160mm

Cutting capacity 45° dia. 160mm

140 x 140 mm

155 x 115mm

Cutting capacity 60° dia. 90mm

90 x 90 mm

Arm swivel range 0° - 60°

Sawblade length 2455 mm

Blade width 27 mm

Blade thickness 0,9 mm

Cutting speeds 2 35/ 70 m/min

Coolant tank 8 litre

Coolant pump 0,07 HP

Overall(LxWxH) 1500x1100x1750mm

Weight 220 kg

Mains 400V ~3/PE 50Hz

Output power 1,1 kW (1,5 HP)-S1

Reference current 3.9 A

Extension cord (H07RN-F): 4x1,5mm²

Installation fuse protection 16 A

4.2 Noise emission

Acoustic pressure level (EN 11202):

Idling 75,2 dB (A)

Operating 86,2 dB (A)

The specified values are emission levels and

are not necessarily to be seen as safe

operating levels.

As workplace conditions vary, this

information is intended to allow the user to

make a better estimation of the hazards and

risks involved only.

4.3 Contents of delivery

Machine stand

Bimetal sawblade

Adjustable material stop

Hydraulic cylinder

Coolant facility

Assembly kit

Operating manual

Spare parts list

4

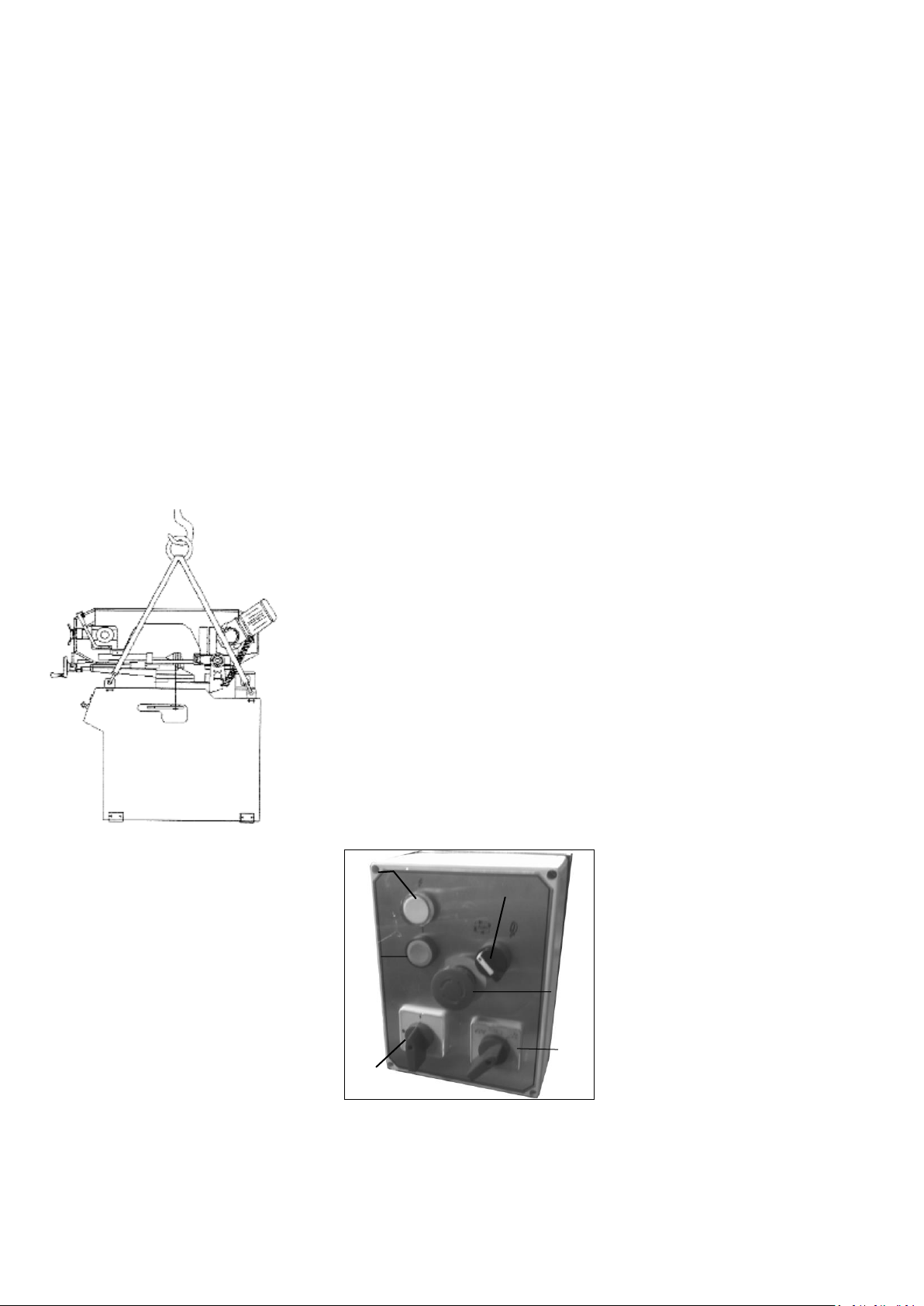

4.4 Machine description

Fig 1

A….Power indicator light

B….ON-button

C…. STOP/ Emergency off-button

D….Low / High speed switch

E….ON/OFF switch

U….Auto/Manual switch

F….Feed control valve

G….Feed ON/OFF valve

SX-821DA

Fig 2

H….Arm swivel lock

I.....Vise operating handwheel

J.....Quick lock for vise

A B C D E

U

K….Blade tension handwheel

L….Blade tension indicator

M…Sawarm downfeed handle with trigger

N.....Adjustable Blade guides

O…..Machine Vise

P…..Control box

Q….Coolant pump

R.....Material stop

S….Lifting holes

T…..Bolt down holes

5.1 Transport and installation

Lift machine off the pallet to the desired

location.

Use lifting straps and place them as shown in

Fig 3.

Fig 3

Warning:

The machine weight is:

SX-821DA ….…. 220 kg.

Assure the sufficient load capacity and

proper condition of your lifting devices.

Never step underneath suspended loads.

The machine is designed to operate in closed

rooms and must be placed stable on firm and

levelled ground.

The machine must be bolted to the floor.

For packing reasons the machine is not

completely assembled.

5.2 Assembly

If you notice any transport damage while

unpacking, notify your supplier immediately.

Do not operate the machine!

Dispose of the packing in an environmentally

friendly manner.

Clean all rust protected surfaces with a mild

solvent.

5.3 Mains connection

Mains connection and any extension cords

used must comply with applicable

regulations.

The mains voltage must comply with the

information on the machine licence plate.

The mains connection must have a 16A

surge-proof fuse.

Only use power cords marked H07RN-F

Connections and repairs to the electrical

equipment may only be carried out by

qualified electricians.

5.4 Starting operation

You can start the machine with the green

ON-button (B). The red Stop / Emergency

off-button (C) on the control box stops the

machine.

The ON/OFF (E) can be switched on and off

independently.

The High Speed/ Low Speed switch (D) may

only be operated when motor power has

been stopped before.

Auto and Manual switch (U) can be slected

for Auto or Manual swing. In manual mode,

the trigger(M) can used to control the turn

On/Off.

WARNING:

Do not change the speed while machine is

running.

Improper operation may damage the switch.

Fig 4

Note:

The saw is equipped with an automatic ShutOff.

The saw should stop just after the cut has

been completed. The stop tip has to be

adjusted accordingly.

6. Machine operation

Support long workpieces with helping roller

stands.

Work only with a sharp and flawless

sawblade.

Don’t take measurements when the machine

is running

Don’t chuck too short in vice.

Use the coolant facility to keep cutting

temperatures down, reduce friction and

extend the life of your sawblade.

Make sure the cutting liquid is properly

contained to the machine.

Use only water soluble cutting emulsions and

dispose of it in an environmentally friendly

manner.

Don’t cut magnesiumhigh danger to fire!

7. Setup and adjustments

General note:

Setup and adjustment work may only be

carried out after the machine is protected

against accidental starting by pulling the

mains plug.

7.1 Changing blade speed

The general rule is the harder the material

being cut, the slower the blade speed.

Low Speed (35 or 40 m/min)

for mild steel, alloy steel and bronzes.

High Speed (70 or 80 m/min)

for aluminium or other light materials.

WARNING:

Do not change the speed while machine is

running.

7.2 Changing sawblade

Disconnect the machine from the power

source.

The sawblade has to meet the technical

specification.

Check sawblade for flaws (cracks, broken

teeth, bending) before installation. Do not

use faulty sawblades.

5

Always wear suitable gloves when handling

H

sawblades.

Raise the saw arm to the vertical position

and lock in place (close both valves F and G).

Remove the wheel cover.

Move the blade guide assembly (N, Fig 2)

away from the wheel.

Remove the brush assembly.

Release the blade tension and remove the

blade.

Place new blade and make sure the teeth are

pointing the cutting direction (Fig 5).

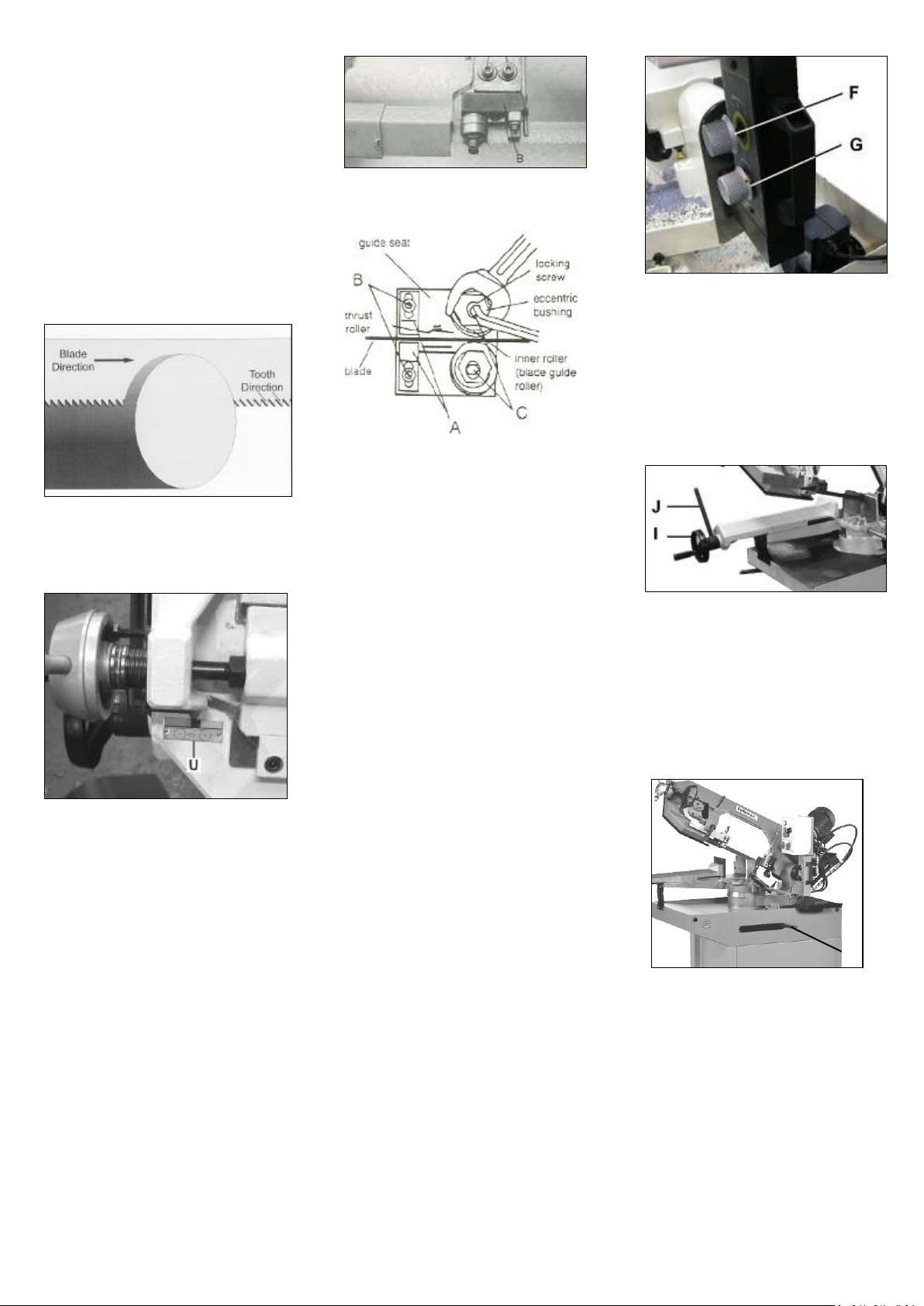

Fig 5

Turn the blade tension knob until the proper

blade tension is achieved at green block of

tension scale (U)

Fig 6

Place a few drops of lightweight oil on the

blade.

Install the red blade guard, the brush

assembly and the wheel cover.

Connect to the power source.

7.3 Blade guide adjustment

Slide the blade guide assembly (N, Fig 2) as

close as possible to the material being cut.

7.4 Guide bearing adjustment

Disconnect the machine from the power

source.

Loosen bolts and adjust assembly (B) so that

back roller bearing is approximately 0,1mm

from the back of the blade. Tighten bolt.

Fig 7

Fig 10….SX-821DA

The cutting of thin-walled workpieces

(profiles, tubes etc.) requires slow feeding to

avoid excessive wear of sawblade.

7.7 Vise adjustment

Use the quick lock handle (J) to open and

Fig 8

Loosen blade guides (A, Fig 8) by loosening

screws (B). Slide blade guides away from the

blade.

(SX-821DA only).

Loosen locking nuts with a hex wrench.

Turn eccentric shaft (C) to adjust bearing to a

clearance of 0,05mm.

Tighten nut to lock.

Slide blade guides (A) back into contact with

the blade and tighten screws (B).

(SX-821DA only).

7.5 Blade tracking adjustment

Warning:

Blade tracking adjustment requires running

the saw with the wheel cover open. This

adjustment must be completed by qualified

persons only.

Failure to comply may cause serious injury!

The blade tracking has been set at the

factory and should not need adjustments.

The tracking is sensitive, in case of need start

with minor( ¼ turn) adjustments.

7.6 Feed speed adjustment

You can control the sawblade downward

feeding with the valve control knob (F) and

lock the saw with the on/off valve (G).

close the vise for clamping.

For vise adjustment use the handwheel (I).

Fig 11

7.8 Saw arm adjustment

The saw arm can be adjusted for square and

mitre cuts.

Loosen handle (H) and move saw arm to the

desired angle.

Fig 12

Always check the angle setup with a

combination square against the blade and

vice.

8. Maintenance and inspection

General notes:

Maintenance, cleaning and repair work may

only be carried out after the machine is

protected against accidental starting by

pulling the mains plug.

6

Loading...

Loading...