Promac JDG-0332 Operating Instructions Manual

EN Operating Instructions (Original)

1.0 About this Manual

This manual is provided by PROMAC, covering the safe operation and maintenance procedures for a PROMAC Model JDG-0332

Drill Grinder. This manual contains instructions on safety precautions, general operating procedures, maintenance instructions

and parts breakdown. The machine has been designed and constructed to provide consistent, long-term operation if used in

accordance with the instructions as set forth in this document.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

2.0 Table of Contents

Section Page

1.0 About this manual ....................................................................................................................................... 1

2.0 Table of contents ......................................................................................................................................... 1

3.0 Important safety instructions .................................................................................................................. 2~3

4.0 Specifications .............................................................................................................................................. 4

5.0 Machine description .................................................................................................................................... 5

6.0 Operations .............................................................................................................................................. 6~7

7.0 Clean and maintenance ............................................................................................................................... 7

8.0 Replacing the wheel .................................................................................................................................... 7

9.0 Replacement parts ................................................................................................................................ 8~19

10.0 Wiring diagrams ........................................................................................................................................ 20

3.0 IMPORTANT SAFETY

INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS GRINDER.

– To reduce risk of injury:

1. Read and understand entire owner’s manual before

attempting assembly or operation of this machine.

2. Read and understand the warnings posted on the machine

and in this manual.

3. Replace warning labels if they become obscured or

removed.

4. This machine is designed and intended for use by properly

trained and experienced personnel only. If you are not

familiar with the proper and safe operation of a metal

lathe, do not use until proper training and knowledge have

been obtained.

5. Do not use this machine for other than its intended use. If

used for other purposes, PROMAC disclaims any real or

implied warranty and holds itself harmless from any injury

that may result from that use.

6. Always wear approved safety glasses or face shield while

using this machine. (Everyday eyeglasses only have impact

resistant lenses; they are not safety glasses.)

7. Before operating this machine, remove tie, rings, watches

and other jewellery, and roll sleeves up past the elbows.

Remove loose clothing and confine long hair. Non-slip

footwear or anti-skid floor strips are recommended. Do not

wear gloves.

8. Wear hearing protection (plugs or muffs) during extended

periods of operation.

9. Some dust created by sawing may contain chemicals

known to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

Lead from lead based paint.

Crystalline silica from bricks, cement and other

masonry products.

Arsenic and chromium from chemically treated

lumber.

Your risk of exposure varies, depending on how often you

do this type of work. To reduce your exposure to these

chemicals, work in a well-ventilated area and work with

approved safety equipment, such as face or dust masks

that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the

influence of drugs, alcohol or any medication.

11. Make certain the switch is in the OFF position before

connecting the machine to the power supply. Turn off all

controls before unplugging.

12. Make certain the machine is properly grounded. Connect

to a properly grounded outlet only. See Grounding

instructions.

13. Make all machine adjustments or maintenance with the

machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of

checking to see that keys and adjusting wrenches are

removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine

is in use. If removed for maintenance purposes, use

extreme caution and replace the guards immediately after

maintenance is complete.

16. Check damaged parts. Before further use of the machine, a

guard or other part that is damaged should be carefully

checked to determine that it will operate properly and

perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

mounting and any other conditions that may affect its

operation. A guard or other part that is damaged should be

properly repaired or replaced.

17. Provide for adequate space surrounding work area and

non-glare, overhead lighting.

18. Keep the floor around the machine clean and free of scrap

material, oil and grease.

19. Keep visitors a safe distance from the work area. Keep

children away.

20. Make your workshop child proof with padlocks, master

switches or by removing starter keys.

21. Give your work undivided attention. Looking around,

carrying on a conversation and “horse-play” are careless

acts that can result in serious injury.

22. Keep an ergonomic body position. Maintain a balanced

stance at all times so that you do not fall or lean against the

moving parts. Do not overreach or use excessive force to

perform any machine operation.

23. Do not force a tool or attachment to do a job for which it

was not designed. The right tool will do the job better and

safer.

24. The machine is intended for indoor use. To reduce the risk

of electric shock, do not use outdoors or on wet surfaces.

25. Do not handle plug or machine with wet hands.

26. Use recommended accessories; improper accessories may

be hazardous.

27. Maintain tools with care. Keep tools sharp and clean for the

best and safest performance. Follow instructions for

lubricating and changing accessories.

28. Turn off machine and disconnect from power before

cleaning.

29. Never leave the machine running unattended. Turn the

power off and do not leave the machine until it comes to a

complete stop.

30. Remove loose items and unnecessary work pieces from the

area before starting the machine.

31. Pull the mains plug if the machine is not in use.

32. Make sure the workpiece is securely clamped.

3

Familiarize yourself with the following safety notices used in this manual:

WARNING: This means that if precautions are not heeded, it may result in serious, or possibly even fatal, injury.

CAUTION: This means that if precautions are not heeded, it may result in minor injury and/or possible machine

damage.

SAVE THESE INSTRUCTIONS

WARNING:

These symbols below advise that you follow the correct safety procedures when using this machine.

Read and understand the entire user

manual before attempting assembly or

machine operation.

Always wear approved working outfit

Wear safety goggles.

Wear ear protection.

Always wear the approved working outfit

Wear safety shoes.

Remove tie, rings, watches, jewellery.

Roll up sleeves above elbows.

Remove all loose clothing and confine

long hair

Make all machine adjustments or

maintenance with the machine unplugged

from the power source.

Do not operate this machine under the

influence of drugs, alcohol or medication

Do not wear gloves while operating this

machine

Connection and repair work on the

electrical installation may be carried out

by a qualified electrician only.

Never reach into the machine while it is

operating or running down.

4

4.0 Specifications

Model number .................................................................................................................................................................................... JDG-0332

Stock number……………………………………………………………………. ............................................................................................................ JDG-0332

Motor and electricals:

Motor type……………………………………………………. ............................................................................................................................. DC-motor

Motor power ......................................................................................................................................................................................0.25 kW

Motor speed................................................................................................................................................................................... 4,400 rpm

Power supply ...................................................................................................................................................................... 1~230V, PE, 50Hz

Grinding wheels:

CBN diamond grinding wheel ............................................................................................................................................................. for HSS

SDC diamond grinding wheel (optional) ......................................................................................................................................for Carbide

Collets:

ER20 .............................................................................................................................................................................. 11 collets, Ø3 to Ø13

Optional ER20 ............................................................................................................................................ 4 collets, Ø2.5, Ø3.5, Ø4.5, Ø5.5

ER40 ............................................................................................................................................................................ 13 collets, Ø14 to Ø26

Optional ER40 ...............................................................................................................................6 collets, Ø27, Ø28, Ø29, Ø30, Ø31, Ø32

Optional collet holder .......................................................................................................................................................... 2 sets, Ø31, Ø32

Dimensions and Weights:

Overall dimensions, assembled (L x W x H) .................................................................................................................. 355 x 215 x 300 mm

Shipping dimensions (W x D x H).................................................................................................................................. 400 x 280 x 330 mm

Net weight (approximate) ..................................................................................................................................................................... 34 kg

Shipping weight (approximate) ............................................................................................................................................................. 36 kg

L = length; W = width; H= height; D= depth

The specifications in this manual were current at time of publication, but because of our policy of continuous improvement, PROMAC

reserves the right to change specifications at any time and without prior notice, without incurring obligations.

5

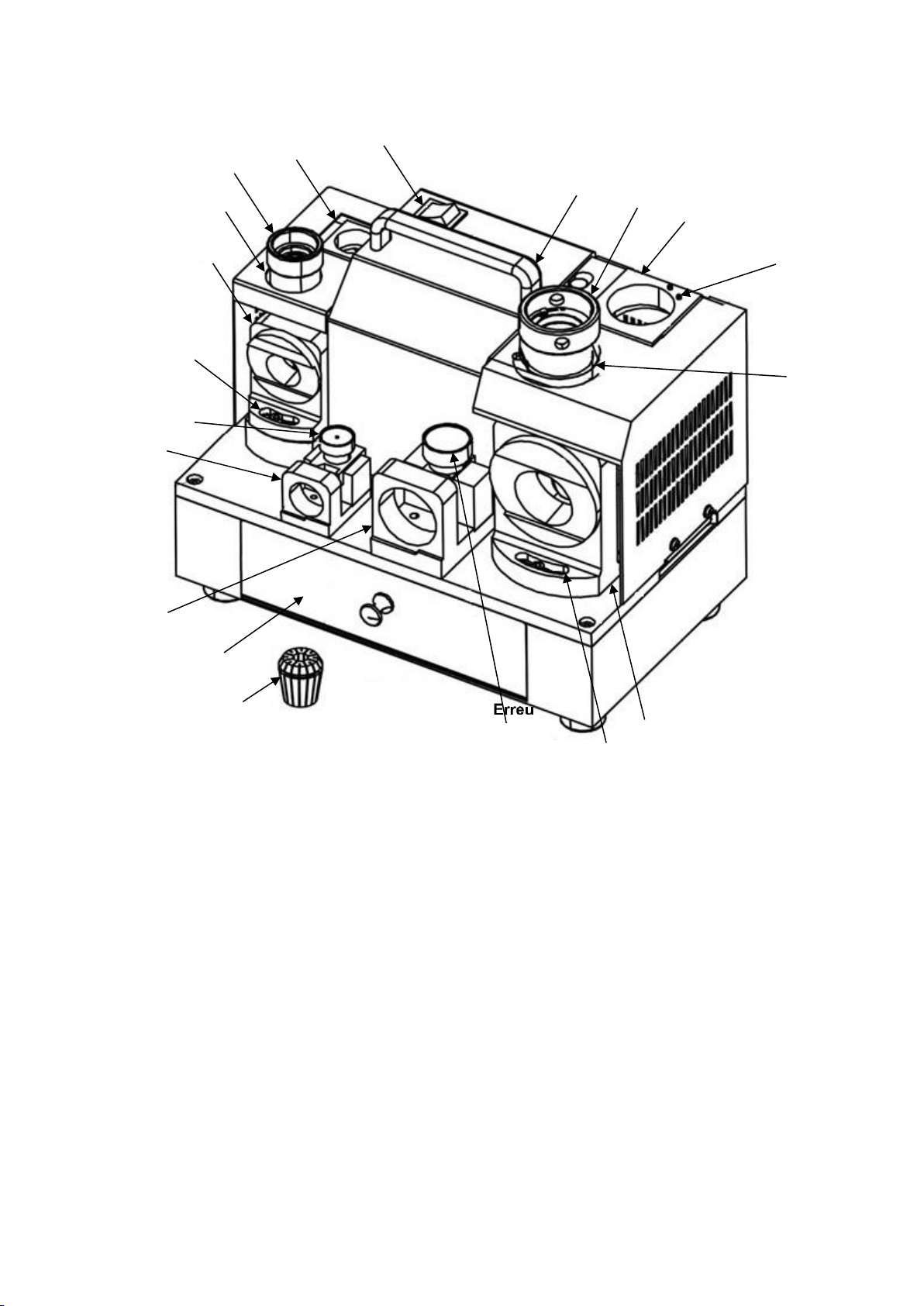

5.0 Machine Description

1.

Motor switch

10.

Drawer for collets

2.

Lip relief angle shelf A

11.

Collet

3.

Collet chuck A

12.

Adjustment scale B

4.

Point splitting shelf A

13.

Point angle adjustment B

5.

Point angle shelf A

14.

Point angle shelf B

6.

Point angle adjustment A

15.

Point splitting shelf B

7.

Adjustment scale A

16.

Pin

8.

Alignment base A

17.

Lip relief angle shelf B

(φ2mm – φ12mm)

18.

Collet chuck B

9.

Alignment base B

19.

Handle

(φ12.1mm – φ32mm)

Erreur !

Erreur !

Erreur !

Erreur !

Erreur !

Erreur !

Erreur !

Erreur !

6

6.0 OPERATIONS

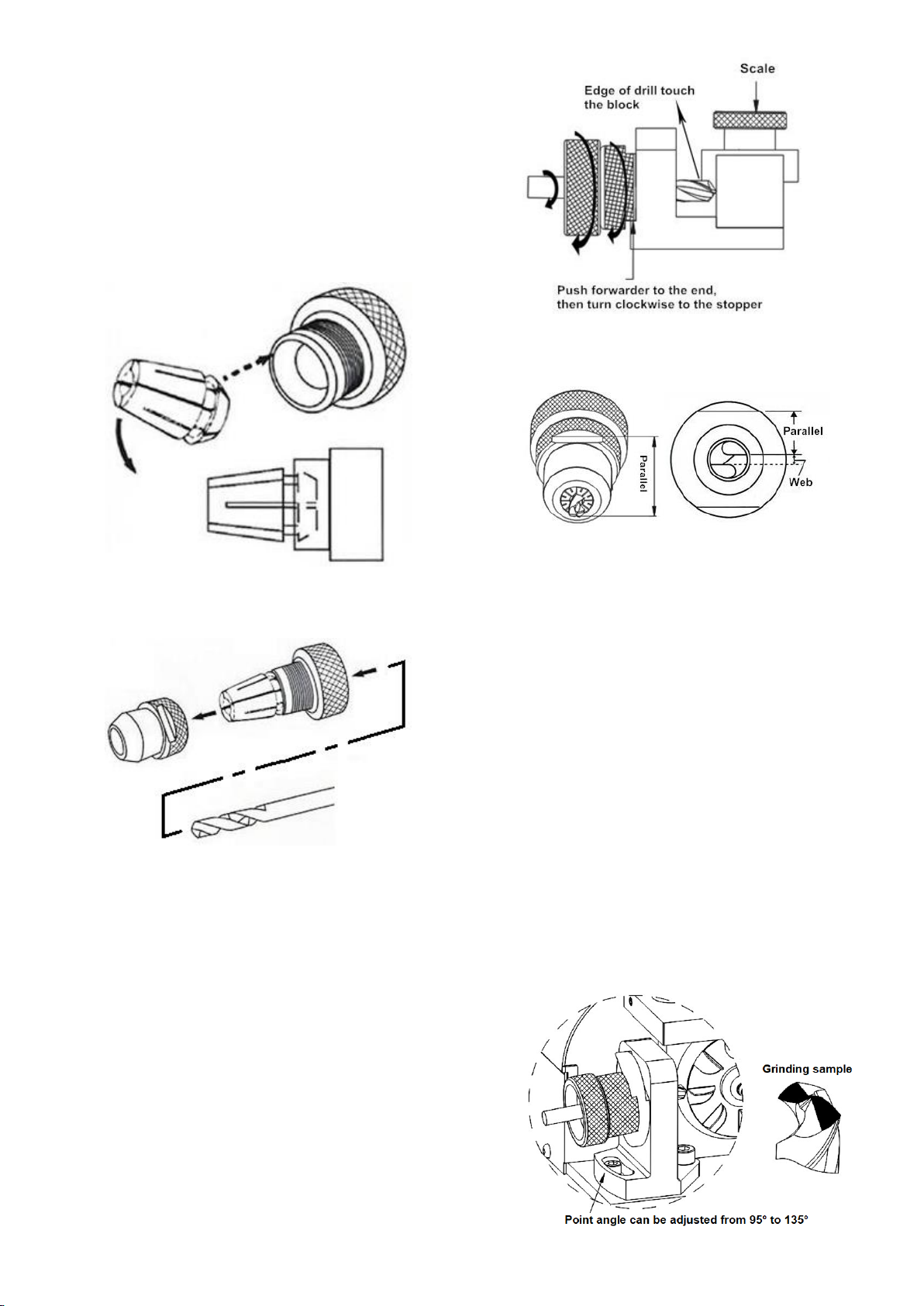

6.1. Setup the drill bit to the ER collet chuck

*Please follow step 6.1.1 and 6.1.2 to set up the drill bit to the

chuck (without tightening)

6.1.1. Determine diameter of your drill bit, and then select

the proper collet and collet chuck.

6.1.2. Insert collet into collet chuck by 45° angle, and tighten

the nut slightly.

6.1.3. Insert drill bit into collet chuck and nuts out 35mm or

so from the collet chuck, but do not tightened the drill

too tight.

6.2. Align drill bit

6.1.4. Reset the scale ring: turn the ring all the way clockwise,

and then turn it anti-clockwise to the number same as

the drill’s size.

6.1.5. Insert the chuck set into the web adjustment shelf.

Then connect it tightly. Turn it clockwise to the end.

6.1.6. Plug the drill to the end and turn it clockwise to the

end.

6.1.7. Turn the chuck set clockwise to the end and tighten it.

6.1.8. Turn the chuck set a little to the anti-clockwise and

taking it out gently.

*Make sure the cutting lip of drill is parallel with the slot of

clamping nut before grinding job started. If it is not parallel,

adjust it again.

Attention: If the cutting lip is downward, must increase the

scale of web adjustment shelf. If it is upward, please decrease

the scale of the web adjustment shelf.

When the flute length of a drill becomes shorter, the web

thickness of a drill would become thicker. So, for the same

diameter of drills, the shorter length of a drill, the higher scale

of web adjustment shelf need to be increased.

6.3. Grind the point angle

Turn the power switch on and wait until the motor rotation

is stable (about 10 seconds), put the chuck set into the point

angle grinding shelf.

The slot of clamping nut must fit with the two pins of the

grinding shelf. Insert the drill gently into grinding shelf until

reach the grinding wheel.

Grind the drill by moving left and right until the grinding

sound disappears. And then turn to the other side, do the

same to grind the drill.

* The grinding size of drill is 2mm-13mm(15mm)

* The point angle of drill is from 95°to 135°。

* While grinding, don’t hold the stem of drill, it will affect

the accuracy.

Loading...

Loading...