Promac 941A, 941VA Operating Instructions Manual

941A

METAL LATHE

Original:

G

B

O

perating Instructions

M-BD-941A-M

Schweiz / Suisse

JPW (TOOL) AG

Tämperlistrasse 5

CH-8117 Fällanden Switzerland

www.promac.ch

France

TOOL France / PROMAC

57, rue du Bois Chaland, Z.I. du Bois Chaland

case postale 2935 FR-91029 Evry Cedex

www.promac.fr

2016-05

CE‐ConformityDeclaration

CE‐Konformitätserklärung

DéclarationdeConformitéCE

Product/Produkt/Produit:

MetalLathe

Metalldrehbank

Touràmétaux

941A

Brand/Marke/Marque:

PROMAC

Manufacturer/Hersteller/Fabricant:

JPW(Tool)AG,Tämperlistrasse5,CH‐8117Fällanden

Schweiz/Suisse/Switzerland

Weherebydeclarethatthisproductcomplieswiththeregulations

Wirerklärenhiermit,dassdiesesProduktderfolgendenRichtlinieentspricht

Parlaprésente,nousdéclaronsqueceproduitcorrespondauxdirectivessuivantes

2006/42/EC

MachineryDirective

Maschinenrichtlinie

DirectiveMachines

2014/30/EU

electromagneticcompatibility

elektromagnetischeVerträglichkeit

compatibilitéélectromagnétique

designedinconsiderationofthestandards

undentspechendfolgenderzusätzlicherNormenentwickeltwurde

etétédéveloppédanslerespectdesnormescomplémentairessuivantes

ENISO12100:2010

ENISO23125:2015

EN60204‐1:2006+A1:2009

EN61000‐6‐2:2005

EN61000‐6‐4:2007+A1:2011

ResponsiblefortheDocumentation/Dokumentations‐Verantwortung/RésponsabilitédeDocumentation:

HansjörgMeier

HeadProduct‐Mgmt./LeiterProdukt‐Mgmt./Resp.GestiondesProduits

JPW(Tool)AG

2016‐05‐24AlainSchmid,GeneralManager

JPW(Tool)AG,Tämperlistrasse5,CH‐8117Fällanden

Schweiz/Suisse/Switzerland

1

Table of Contents

INTRODUCTION......................................................................................................................4

MAIN PARAMETERS……………………………………………………………………......5

SECTION 1: SAFETY...............................................................................................................7

SECTION 2: POWER SUPPLY...............................................................................................9

Availability………………………………………………………………………9

Circuit Requirements…………………………………………………………..9

Grounding & Plug Requirements…………………………………………….10

Extension Cords……………………………………………………………….10

SECTION 3: SETUP……………………………………………………………………...…11

Unpacking……………………………………………………………………...11

Inventory………………………………………………………………………11

Clean Up……………………………………………………………………….12

Installation Dimensions……………………………………………………….12

Check Gearbox Oil……………………………………………………………12

Open the Cover………………………………………………………………..13

Install belt and Chang speeds………………………………………………...13

Test Run Lathe………………………………………………………………...14

SECTION 4: OPERATE……………………………………………………………………..15

General…………………………………………………………………………15

Controls…………………………………………………………...……………15

Removing/Installing Chuck or Faceplate…………………………………...16

Dead Centers…………………………………………………………………..17

Tailstock Positioning…………………………………………………………..18

Changing Tool Posts…………………………………………………………..18

Cross Slide…………………………………………………………………......18

Compound Slide……………………………………………………………….19

Carriage Handwheel…………………………………………………………..20

Half Nut Lever…………………………………………………………………20

Carriage/Cross Feed Lever…………………………………………...………20

Carriage Lock………………………………………………………………….20

Gearbox Levers………………………………...……………………………...20

Threads and Change gears……………………………………………………21

Left threads and reverse cutting feed………………………………………...21

Clutch Overload…………………………………………………...…………..22

SECTION 6: MAINTENANCE……………………………………………………….……..23

Lubrication…………………………………………………………………….23

Ball oilers............................................................................................................23

Feed Rate Gearbox Oil Reservoir....................................................................24

Gibs…………………………………………………………………………….25

Bearing Preload……………………………………………………………….26

2

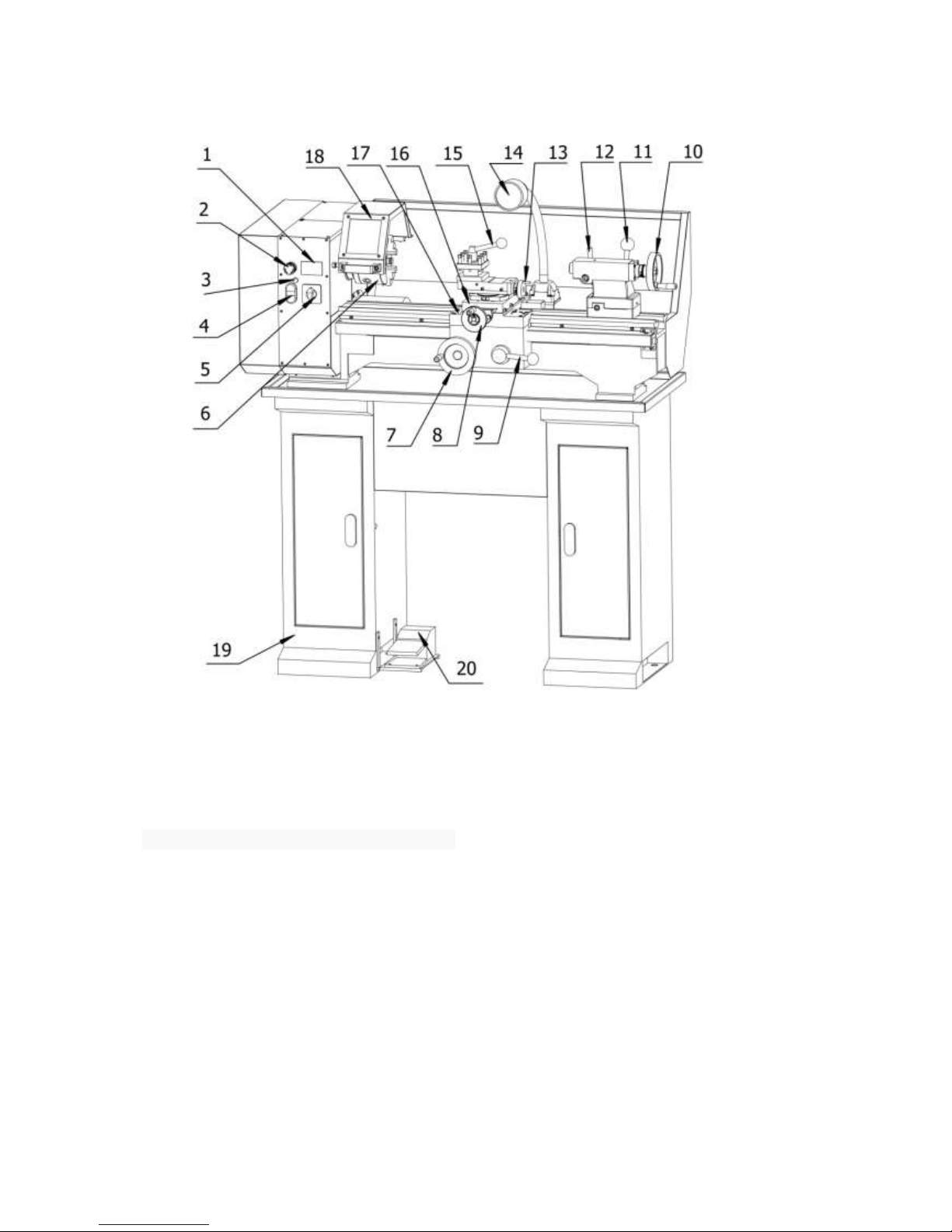

IDENTIFICATION

The following is a list of controls and components on the lathe. Please take time to become

familiar with each term and its location. These terms will be used throughout the manual

and knowing them is essential to understanding the instructions and terminology used in

this manual.

1. Speed of Spindle(rpm)

2. Emergency Stop Switch

3. Lathe Power Indicator Light

4. Lathe ON/OFF switch

5. Lathe Forward/Reverse Switch

6. Lathe Chuck

7. Carriage Handwheel

8. Cross Slide Handwheel

9. Half Nut Lever

10. Tailstock Barrel Handwheel

11. Tailstock Clamp Bolt

12. Tailstock Center Lock

13. Compound Slide Handwheel

14. Work Light

15. Tool Post

16. Cross Slide

17. Carriage

18. Headstock Eyeshield

19. Work Table

20. Foot Switch

3

Model 941A Main Parameters

Product Dimensions:

Weight..................................................................................................................................180kg

Width (side-to-side) x Depth (front-to-back) x Height.....................................114 x 60 x 120 cm

Shipping Dimensions:

Type.............................................................................................................................Wood Crate

Content..............................................................................................................................Machine

Weight.............................................................................................................................. 225 kg.

Length x Width x Height..................................................................................123 x 73 x 140.cm

Electrical:

Minimum Circuit Size.........................................................................................................10 amp

Switch..................................................................................................................Forward/Reverse

Motors: Main

Type........................................................................................................................... …..YL7134

Outpower...................................................................................................................... …..550W

Amps......................................................................................................................4.2 amp (230V)

Speed............................................................................................................... 1400 RPM (50Hz)

Speeds.......................................................................................................................................... 1

Power Transfer .................................................................................................Belt Drive to Gear

Bearings..............................................................................Shielded and Permanently Lubricated

Main Specifications:

Operation Info

Swing Over Bed................................................................................................................250 mm

Distance Between Centers................................................................................................555 mm

Swing Over Cross Slide.....................................................................................................150 mm

Swing Over Saddle............................................................................................................210 mm

Compound Travel............................................................................................................... 70 mm

Carriage Travel..................................................................................................................565 mm

Cross Slide Travel..............................................................................................................100 mm

Max. Turning Tool Size................................................................................................10 x 10mm

Headstock Info

Spindle Bore.................................................................................................................... Φ20 mm

Spindle Size................................................................................................................ Φ52x11mm

Spindle Taper..................................................................................................................... MT#3

Number of Spindle Speeds..........................................................................................................6

Spindle Speeds......................................................(50Hz) 125, 210, 420,620, 1000, 2000 rpm

Spindle Bearings...........................................................................Tapered Roller + Ball Bearing

4

Tailstock Info

Tailstock Taper.....................................................................................................................MT#2

Tailstock Barrel Diameter...............................................................................................Φ30 mm

Tailstock Barrel Travel........................................................................................................50mm

Threading Info of Metric Lathe

Number of Longitudinal Feeds...................................................................................................2

Range of Longitudinal Feeds............................................................................0.1 or 0.2 mm/rpm

Number of Inch Threads.............................................................................................................. 6

Range of Inch Threads..................................................................................................10 - 44 TPI

Number of Metric Threads..........................................................................................................15

Range of Metric Threads...............................................................................................0.4 - 3 mm

Dimensions

Bed Width..........................................................................................................................135 mm.

Lead screw Diameter............................................................................................................20mm

Lead screw Pitch....................................................................................................................2 mm

Lead screw Length.............................................................................................................792 mm.

Steady Rest Capacity.....................................................................................................6 – 40 mm

Follow Rest Capacity.....................................................................................................6 – 40 mm

Faceplate Size................................................................................................................Φ220 mm.

Floor to Center Height.......................................................................................................335 mm

Construction

Headstock........................................................................................................................ Cast Iron

Headstock Gears.....................................................................................................................Steel

Bed..................................................................................................Induction Hardened Cast Iron

Body.................................................................................................................................Cast Iron

Paint..................................................................................................................................... Epoxy

5

SECTION 1: SAFETY

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

RESULT IN PERSONAL INJURY.

Standard Safety Instructions

1. Thoroughly read the Instruction Manual before operating your machine.

Learn the applications, limitations and potential hazards of this machine. Keep

the manual in a safe and convenient place for future reference.

2. Keep work area clean and well lighted. Clutter and inadequate lighting invite

potential hazards.

3. Ground all tools. If a machine is equipped with a three-prong plug, it must be

plugged into a three-hole grounded electrical receptacle or grounded extension

cord. If using an adapter to aid in accommodating a two-hole receptacle, ground

using a screw to a known ground.

4. Wear eye protection at all times. Use safety glasses with side shields or

safety goggles that meet the appropriate standards of the American National

Standards Institute (ANSI).

5. Avoid dangerous environments. Do not operate this machine in wet or open

flame environments. Airborne dust particles could cause an explosion and severe

fire hazard.

6. Ensure all guards are securely in place and in working condition.

7. Make sure switch is in the OFF position before connecting power to

machine.

8. Keep work area clean, free of clutter, grease, etc.

9. Keep children and visitors away. Visitors must be kept at a safe distance

while operating unit.

10. Childproof your workshop with padlocks, master switches or by removing

starter keys.

11. Stop and disconnect the machine when cleaning, adjusting or servicing.

6

12. Do not force tool. The machine will do a safer and better job at the rate for

which it was designed.

13. Use correct tool. Do not force machine or attachment to do a job for which it

was not designed.

14. Wear proper apparel. Do not wear loose clothing, neck ties, gloves, jewelry,

and secure long hair away from moving parts.

15. Remove adjusting keys, rags, and tools. Before turning the machine on,

make it a habit to check that all adjusting keys and wrenches have been removed.

16. Avoid using an extension cord. But if you must use one, examine the

extension cord to ensure it is in good condition. Immediately replace a damaged

extension cord. Always use an extension cord that uses a ground pin and

connected ground wire. Use an extension cord that meets the amp rating on the

motor nameplate. If the motor is dual voltage, be sure to use the amp rating for

the voltage you will be using. If you use an extension cord with an undersized

gauge or one that is too long, excessive heat will be generated within the circuit,

increasing the chance of a fire or damage to the circuit.

17. Keep proper footing and balance at all times.

18. Lock your mobile base, if used, to prevent the machine from moving

during operation.

19. Do not leave machine unattended. Wait until it comes to a complete stop

before leaving the area.

20. Perform machine maintenance and care. Follow lubrication and accessory

attachment instructions in the manual.

21. If at any time you are experiencing difficulties performing the intended

operation, stop using the machine! Then contact our technical support or ask a

qualified expert how the operation should be performed.

22. Habits—good and bad—are hard to break. Develop good habits in your

shop and safety will become second-nature to you.

23. Be aware that certain metal shavings and cutting fluids may cause an

allergic reaction in people and animals, especially when cutting fumes can be

inhaled. Make sure you know what type of metal and cutting fluid you will be

exposed to and how to avoid contamination.

7

Loading...

Loading...