Promac 213A User Manual

Drill Press

Säulenbohrmaschinen

Perceuses à colonne

213A

Switzerland France

JPW (TOOL) AG TOOL France / PROMAC

Tämperlistrasse 5 57, rue du Bois Chaland, Z.I. du Bois Chalan

CH-8117 Fällanden Switzerland case postale 2935 FR-91029 Evry Cedex

www.promac.ch www.promac.fr

05-2016

CE-Conformity Declaration

CE-Konformitätserklärung

Déclaration de Conformité CE

Product / Produkt / Produit:

Drill Press

Säulenbohrmaschine

Perceuse à colonne

213A

Brand / Marke / Marque:

PROMAC

Manufacturer / Hersteller / Fabricant:

JPW (Tool) AG, Tämperlistrasse 5, CH-8117 Fällanden

Schweiz / Suisse / Switzerland

We hereby declare that this product complies with the regulations

Wir erklären hiermit, dass dieses Produkt der folgenden Richtlinie entspricht

Par la présente, nous déclarons que ce produit correspond aux directives suivantes

2006/42/EC

Machinery Directive

Maschinenrichtlinie

Directive Machines

2014/30/EU

electromagnetic compatibility

elektromagnetische Verträglichkeit

compatibilité électromagnétique

designed in consideration of the standards

und entspechend folgender zusätzlicher Normen entwickelt wurde

et été développé dans le respect des normes complémentaires suivantes

EN ISO 12100:2010

EN 12717:2001+A1:2009

EN 60204-1:2006+A1:2009

EN 61000-6-2:2005

EN 61000-6-4:2007+A1:2011

Responsible for the Documentation / Dokumentations-Verantwortung / Résponsabilité de Documentation:

Hansjörg Meier

Head Product-Mgmt. / Leiter Produkt-Mgmt. / Resp. Gestion des Produits

JPW (Tool) AG

2016-05-24 Alain Schmid, General Manager

JPW (Tool) AG, Tämperlistrasse 5, CH-8117 Fällanden

Schweiz / Suisse / Switzerland

GB - ENGLISH

Operating Instructions

NOTE:

It is advisable for user to read this

Instruction Manual in order to avoid

accident. If the operation method used in

this drilling machine us the same as the

method used in ordinary machine,

possible hazard may occur during the

process. Therefore, it is imperative that

user should pay extra caution and make

sure that his operating method is correct.

Slight negligence to any of the safety

measures will certainly cause accident to

the user.

The manufacturer designed this machine

especially focusing on its scheduled using

scope. Therefore, it is advisable that the

user should pay attention not to exceed

the said using scope. Also, do not make

any modification to the spare parts and

structure of the machine.

If you have any question regarding and

operating method of this machine and

Cannot find the solution in the Instruction

Manual, please contact your vendor

directly.

Correct Operation Instruction of This

Machine

1 For your own safety, do not start the

said machine before reading the

Instruction Manual carefully. One of

the necessary safety measures is to

understand its operation principle and

operation method first.

2. Do not alter any of the protective

pieces in order to maintain its

completeness

3. Plug the fan plug for power supply into

the socket with earth wire. If your

socket dose not have an earth wire,

then connect the earth terminal of this

machine.

4. Before starting this machine, it is

imperative to take away all wrenches

and latch handle not connected to the

machine. Also, your should make it a

habit to check the surrounding of the

said machine every time before suing,

to see there is any small spare part

around that may cause running fault

( breakdown).

5. Before installing the machine, clean

your working ground on order to

prevent any accident occurring.

6. Do not use this machine in a highly

dangerous place. Also, do not install

the machine in a humid or water

leaking place. During the process of

work, the user should make sure to

keep its working ground clean anytime.

7. Do not let any unauthorized or

ignorant person or children near the

said machine, and should be sure to

keep a proper distance from the

machine anytime.

8. Put a safety lock on the door of your

working ground in order to prevent

children from starting the machine.

9. Avoid overloading the machine. Also,

for your own safety, be sure to abide to

its using scopes.

3/50

10. Do not use the machine outside its

using scope.

11. Wear proper clothes while working.

Do not wear any clothes that can

easily be ripped by the machine while

operating, such as clothes that flutter,

ordinary gloves scarf, ring, and small

chain. You should also wear anti-skid

shoes and hat (cap) that can fully hold

in long hairs.

12. When operating this machine, you

should wear a goggle and dust-proof

mask anytime. Besides, make sure to

abide to the related safety measures

specified by the government's Bureau

of Works.

13. Use a hand vice or other fixing device

to fix all the spare parts for processing.

Do not use your hands to fix them in

order to avoid serious accident and

unable to operate the said machine.

14. Stand firmly in front of this machine

while working (both feet's position,

body equilibrium, etc.)

15. Keep the machine and its pointed

edges clean at all time in order to get

the best working efficiency. Also,

should follow the instructions in the

Instruction Manual carefully in

changing the tools, coating grease,

and cleaning.

16. Before cleaning this machine or

changing the tools (such as saw blade,

drill), pull off the power plug first to

avoid electrocution.

17. Use the tools suggested by the

manufacturer of this machine while

working and abide to the related

instruction in the Instruction Manual,

because using spare parts not related

to this machine is an unsafe behavior.

18. Avoid touching the machine

unintentionally. Also, before plugging

in the plug into the socket, check if

switch button is as [OFF] position or

not.

19. Do not stand on the machine in order

to avoid slipping down carelessly or

hitting the blade and cause injury.

20 Remember to check abnormal part in

the running process of the machine

carefully.

It is advisable that you should change

the said part or protective piece

before continuing the work.

21 Do not leave the working ground

while the machine is running. It is

necessary for your to leave, turn off

the power and wait for the machine

to stop completely before leaving.

22 Do not use this machine if you had

taken any alcohol (liquor or wine),

medicine, or drugs.

4/50

I PARTS 213A

Unpack carton, check your machine to see parts listed below:

A. Main Parts:

1 Head assembly 1 pc.

2. Column with flange 1 pc.

3. Arm of table and bracket 1 sets.

4. Table 1 pc.

5. Base 1 pc.

B. Accessories

1 Clamp bolt, table bracket 1 pc

2. Feeding handle and knobs 3 pcs

3. Screw and washer 1 set

4. Heigth adjusting handle, table bracket 1 set

5. Knob, upper pulley cover 1 pc

6. Allen wrenches (3mm, 5mm) 1 set

7. Arbor and wedge 1 set

8. Chuck 1 pc

9. Chuck guard 1 pc

Note: If you find and parts missing or damaged, contact thr dealer for exchange or

replacement

5/50

6/50

Motor and Specification:

Motor

1/2HP 230V 4 P 1420RPM, 8 A 1PH 50Hz

Drills to Center of Circle

340 mm

Drilling Capacity Mild Steel

16 mm

Distance Column to Spindle

170 mm

Number of Spindle Speeds

12

Range of Spindle Speeds (RPM)

260-2900

Column Diameter

73 mm

Spindle Taper

MT-2

Spindle Travel

80 mm

Spindle Distance to Base

1235 mm

Spindle Distance to Table (Max.)

725 mm

Table Size (L x W)

235 * 235 mm

Base Dimensions

458 * 265 mm

Machine Overall Dimension

(W x D x H)

L600 x W340 x H1570 mm

Packing Dimension (L x W x H)

L1380 x W470 x H250 mm

Net Weight

58 kg

Gross Weight

61 kg

II PARTS 213A

1. Assembly the Column

* Place column assembly on base and align holes in

column support with holes in base.

* Secure the column with four or three bolts and

washers provided.

2. Install table bracket

2-1 Take off collar and rack

2-2 Install table bracket together with rack. Fig. 2.

2-3 Install collar and fix it firmly. Fig.3.

3. Install bracket handle and clamp bolt. Fig. 4, 5.

Fix handle with attached set screw.

Install clamp bolt to fix table bracket.

7/50

II PARTS 213A

4. Install table and clamp with bolt. Fig. 6

5. Attach the Head Assembly

* Carefully put the head assembly over column and

slide it onto column into position. Align head frame

with table and base.

* Fix set screws in right side of head to lock head into

position then tighten with Allen wrench. Fig. 7

6. Install the Feeding Handles.

* Screw knob on each feeding handle, install them into

hub of pinion shaft. Fig. 8

7. Attach the Arbor and Chuck

7-1 Insert abor into spindle first. Pull feeding handle

down to press abor inward. Fig.9

7-2 Open chuck jaws completely by turning attached

chuck key counter clockwise to the end. Put a piece

of scrap wood on the table to protect chuck nose.

7-3 Install chuck to the arbor tightly. Fig.10

8. Install knob and screw of upper pulley cover. Fig.11

8/50

III PARTS 213A

1. Table Adjustment

A. Height Adjustment

To adjust up or down, loosen the clamp bolt

then adjust the table to your desired position

by swing the table bracket handle. Fig. 12

B. Tilting Adjustment:

Loosen the table bevel lock bolt with

adjustable wrench.

Tilt table to desired angle and retighten the

bolt. Fig. 13

C. Swing 360 °

Loosen clamp bolt then swing table to

appropriate position and retighten clamp

bolt. Fig. 14

2. Feed Depth Adjustment

2-1 Depth control scale sleeve type Loose

the clamp bolt and move to the

desired depth then retighten the

clamp bolt. Fig. 15-1, 15-2

9/50

III PARTS 213A

Size

Diameter

Cast steel

Tool steel

Cast iron

Mild steel

Alum. & copper

Cutting speed

m/min

ft/min

m/min

ft/min

m/min

ft/min

m/min

ft/min

m/min

ft/min

12

40

18

60

24

80

30

100

60

200

mm

inch

Cutting speed revolution per minute

2

1/16

1910

2445

2865

3665

3820

4890

4775

6110

6550

12225

3

1/18

1275

1220

1910

1835

2545

2445

3185

3055

6365

6110

5

3/16

765

815

1145

1220

530

1630

1910

2035

3820

4075

6

1/4

610

610

955

915

1275

1220

1590

1530

3180

3055

8

5/16

480

490

715

735

955

980

1195

1220

2390

2445

10

3/8

380

405

570

610

765

815

955

1020

1910

2035

11

7/16

350

350

520

525

700

700

870

875

1740

1745

13

1/2

300

305

440

460

590

610

735

765

1470

1530

16

5/8

240

245

360

365

480

490

600

610

1200

1220

19

3/4

190

205

285

305

380

405

480

510

955

1020

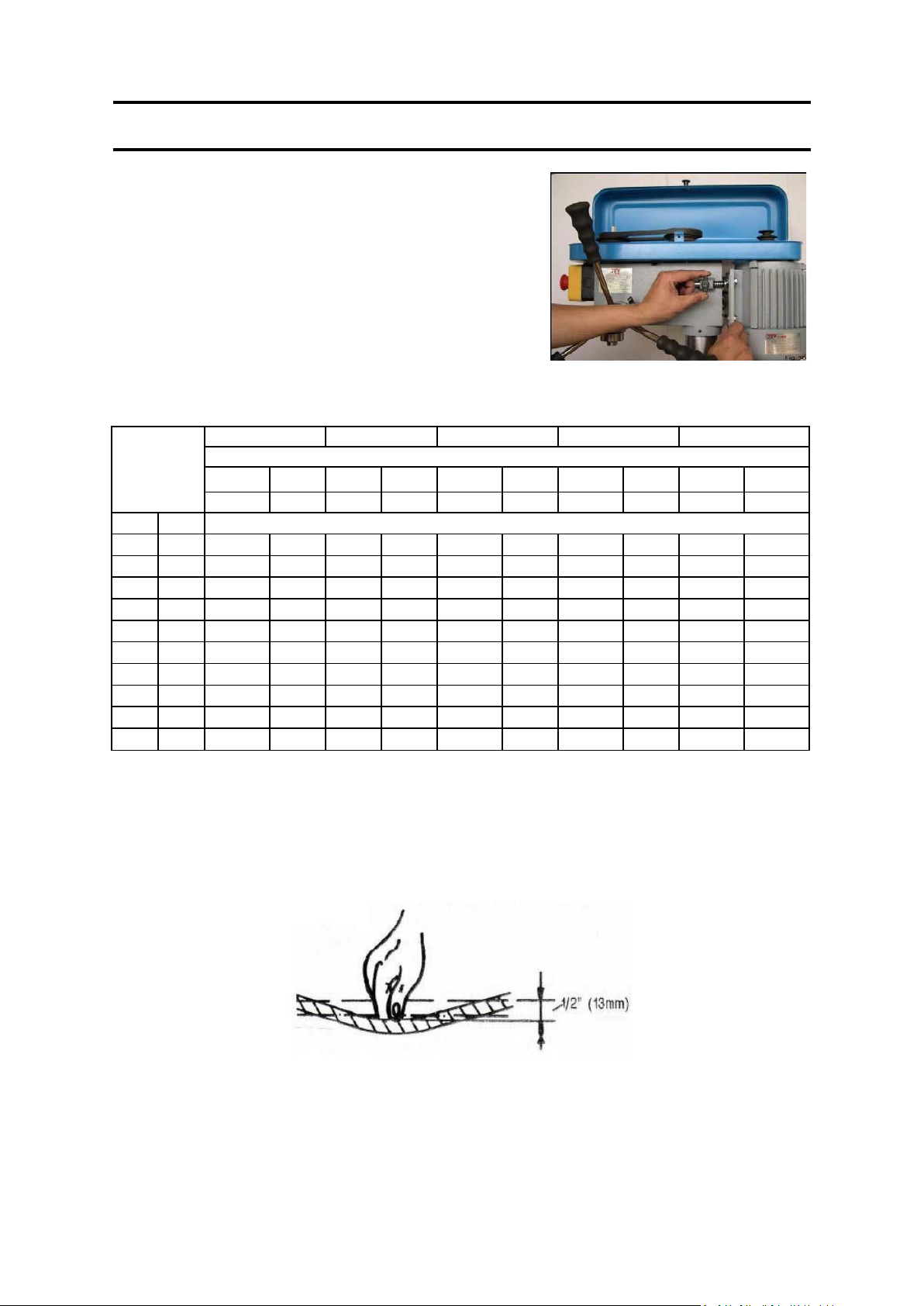

3. Speed Adjustment

3-1 1. Open the pulley case and 1 the belt tension

lock handle.

2. Choose speed for drilling operation and move

belt to correct position for desired speed.

3. Push motor backward until moderate belt

tension is acquired. Then retighten the lock

handle again. Fig. 16

The proper drill speed for a given drill bit size is as on following table:

4. Belt Tension Adjustment

For proper belt tension: Use 10 lbs pressure or hand pressure on the belt as shown

below. The distance is 1/2" (12mm)+10%

10/50

FACEPLATE AND OPERATION PANEL 213A

MAIN SWITCH

(I/O)

EMERGENCY ENCY SWITCH

11/50

Special Safety Rules For Drill Press:

1. Caution : This drill press is intended

for use only with drill bits. This use of

other accessories may be hazardous.

2. Correct drilling speeds : Factors which

determine the best speed to use in

any drill press operation are :

Kind of material being worked, size of

hold, type of drill or other cutter, and

quality of cut desired.

The smaller the drill, the greater the

required RPM. In soft materials, the

speed should be higher than for hard

metals.

3. Drilling in metal: Use clamps to hold

the work when frilling in metal. The

work should never be held in there

bare hand, the flutes of the drill may

seize the work at any time, especially

when breaking through the stock. If

the piece is whirled out of the

operator's hand, he may be injured,

in any case, the drill will be broken

when the work strikes the column.

4. The work must be clamped firmly

while drilling: Any tilting, twisting, or

shifting results not only in a rough

hole, but also increases drill breakage.

For flat work, lay the piece on a

wooden base and clamp it firmly

down against the table to prevent it

from turning. If the piece is of

irregular shape and cannot be laid flat

in the table, it should be securely

blocked and clamped.

5. The chuck shall be securely fastened

to the spindle and so that it can't

separate from spindle.

6. Remove Key from chuck after

adjustment.

7. The tool is to be disconnected from

the power supply while the motor is

being mounted, connected or

reconnected.

8. Secure the tool to the supporting

structure if, during normal operation,

there is any tendency for the tool to

tip over, slide, or walk on the

supporting surface.

9. The set screws of head frame should

be screwed tightly before suing this

machine.

10. Connect to a supply circuit protected

by a circuit breaker or time delay fuse.

11. Fasten base to floor or worktable

before using the drill press.

VII. Important Notice For CE

Handling of Machine

1. The total weight of this machine

must be ensured before handling.

2. It is better to handle this machine

with the help of lifting tools.

Environment Requirements for

Installation

1. Be sure to provide sufficient light for

operation according to the codes or

regulations published for local area.

If you do not get the information

about lighting, a light intensity of 300

Lux is the least value to be supplied.

12/50

2. The place where machine install

must be flat and big enough for the

operation.

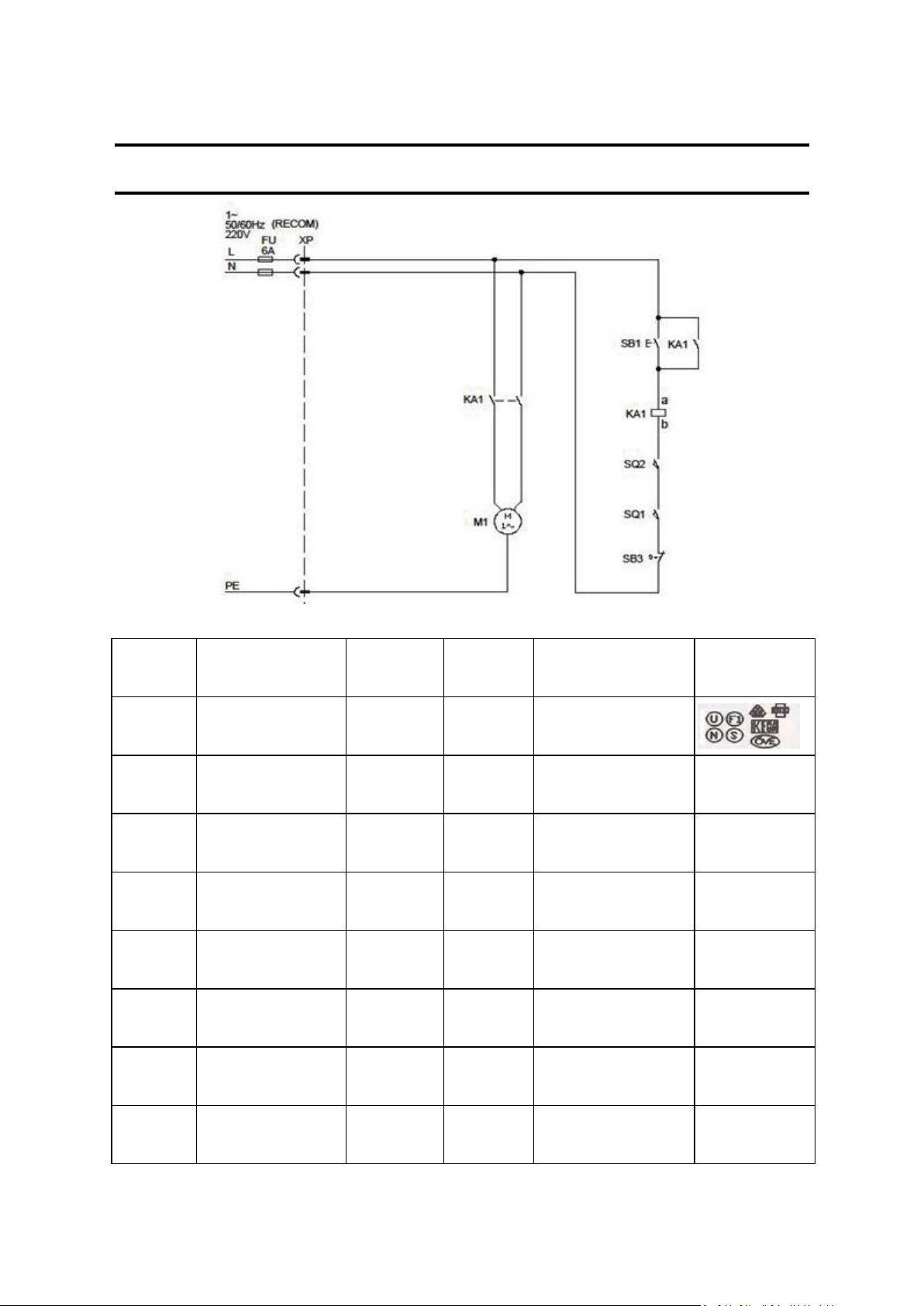

VII Electric

ELECTRICAL CONNECTION/DISCONNECTION & OPERATION

Noise Level

1. The noise level of this machine is

about 75 db(A)during operation.

2. While taking provisions for the risk of

noise, the noise level of working

environment should be taken into

consideration also.

For three phase :

1. Electrical connection:

1. A cable with four wires is equipped

to connect your machine into the 3

phase power supply.

Please connect your machine into

the power supply with handoperated disconnecting device,

which is in compliance with

subclause 5.3 of EN 60204-1, such as

on fuse breaker or plug/socket

combination.

2. For the protection of control device,

we recommend the operation to

supply a fuse with 6 A current

rating of fuse, and the total length

between fuse and connection

terminal shall not exceed 1.5m.

3.The exact power source voltage,

frequency, and number of

phase shall be checked according to

the installation diagram and circuit

diagram.

4. The correct direction of drilling

press should be checked after

connecting.

2. Electrical disconnection:

1. The disconnection is carried out by

hand-operated disconnection device.

2. Be sure to disconnect this machining

from power source, when you want

to stop the job, Maintenance, and

adjustment.

3. Grounding

The grounding of the drilling press is

carried out by connecting the

Yellow/Green terminal of supply

cable to the grounding terminal of

power source. Be sure to ground your

machine before connecting machine to

power source in any situation.

13/50

WARNING !

Do not disconnect grounding

terminal before disconnecting

power source.

For single phase :

1. The connect, disconnection, and

grounding is carried out through the

plug, equipped on the drilling press.

For the safety reason, Do not change

this plug into any the other type

in any situation.

2. For the protection of control device, we

recommend the operated to supply a

fuse with 8 A current rating of

fuse, and the total length between

fuse and connection terminal shall not

exceed 1.5m.

3. The exact power source voltage,

frequency, and number of phase

shall be checked according to the

installation diagram and circuit diagram.

Operation:

1. "START": Push the button marked

with " I ".

2. "STOP": Push the button marked with

" O ".

3. "Interlock Switch": Limit switch in

the pulley cover.

WARNING !

Do not stop machine with interlock

switch in normal operation.

14/50

Item

designation

Description & function

Maker

Type

Technical data

Making of

conformity granted

XP

Plug for supply Three

phase

LIAN DUNG

LT-32

10~16A , 250V

Supply cable Three

phase

TIEN TUNG

H05W-F

3G 0.75m/m2 250V/440V

VDE/ROHS

SB1

Start switch

KED V

JD3

230V/10A

CE TUV

SB3

Emergency-Stop switch

XINQUANG

KB2-BE102

10A

CE

SQ1

Micro switch

HIEHLY

VS 10N

250V/10A

UL

KA1

Magnetic Conductor

KEDU

JD3

AC230V/50HZ 12A

CE TUV

M1

Motor

K & K

AC380V/50Hz 1420rpm

CE TUV

SQ2

Micro switch

Zhejiang Tiande

CT-303

250V/10A

CE

Electrical circuit diagram 213A

15/50

Loading...

Loading...