Page 1

Proline

GAS HOB

Model

TCG40IX

Instruction Book

Page 2

Operating and Installation Instructions

GB

Page 3

Technical data and specifications . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . 3-6

Ventilation. . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking your hob . . . . . . . . . . . . . . . . 4

Positioning . . . . . . . . . . . . . . . . . . . . . . . 4

Fixing . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Gas connection . . . . . . . . . . . . . . . . . . . 4

Conversion to LP gas . . . . . . . . . . . . . . . 5

Replacing the injectors . . . . . . . . . . . . . . 5

Minimum setting . . . . . . . . . . . . . . . . . . . 5

Electrical connection. . . . . . . . . . . . . . . . 5

For the user. . . . . . . . . . . . . . . . . . . . . 6-7

Ventilation. . . . . . . . . . . . . . . . . . . . . . . . 6

Igniting the burners. . . . . . . . . . . . . . . . . 6

Using the hob . . . . . . . . . . . . . . . . . . . . . 6

Cleaning and maintenance . . . . . . . . . . . 6

Figures . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Important notes and precautions for use

Dear User,

We would ask that you read carefully the instructions contained in this booklet.

It provides information for a safe installation, use

and maintenance. Keep this booklet in a safe

place for future reference.

The installation and maintenance operations listed must only be carried out by qualified personnel.

The appliance must only be used for its original

purpose, that is, cooking for domestic use.

Any other use is considered improper and as

such dangerous.

The manufacturer cannot be held responsible for

any damage to persons or property resulting

from an incorrect installation, maintenance or use

of the appliance.

The manufacturer disclaims all responsibility if

these instructions are not following.

The appliance was designed and made in accordance with the following European Standards:

- EEC 90/396

- EEC 73/23 and 93/98

- EEC 89/336 (radio-frequency interference)

- EEC 89/109 (contact with foods)

Index Introduction

2

Page 4

Technical data

Installation

Cat.: see nameplate on cover; Class 3

Type “X” hobs

EQUIPMENT

For the LAYOUT OF HOTPLATES see figure 1

at the back of this manual.

INSTALLATION

The installation, adjustments, conversions and

maintenance operations listed in this part must

only be carried out by qualified personnel. The

manufacturer cannot be held responsible for any

damage to persons or property resulting from an

incorrect installation of the appliance.

The safety and automatic adjustment devices of

the appliance may, during its life, only be modified by the manufacturer.

The hob must be installed by a qualified person

in accordance with the Gas Safety (Installation

and use) (Amendment) Regulations 1990 and

the relevant building / I.E.E.

Failure to install the appliance correctly could invalidate any manufacturers warranty and lead to

prosecution under the above quoted regulation.

The following British Standards should be used

as reference when installing this appliance:

BS6172 1990, BS5440 part 2 1989 and BS6891

1988.

In the UK C.O.R.G.I. registered installers are authorised to undertake the installation and service

work in compliance with the above regulations.

All Comet authorised installers are C.O.R.G.I.

registered.

Before installation, make sure that local distribution conditions (gas and electrical) are compatible with the appliance's adjustment.

As it is not connected to a device for the evacuation of the products of combustion, it must be installed in accordance with the current regulations

and used in a well ventilated location.

Particular attention must be paid to the regulations on ventilation.

VENTILATION

All rooms require an openable window or equivalent, while some rooms require a permanent vent

in addition to the openable window.

The appliance should not be installed in a room

of volume less than 6m3 (for instance say

3

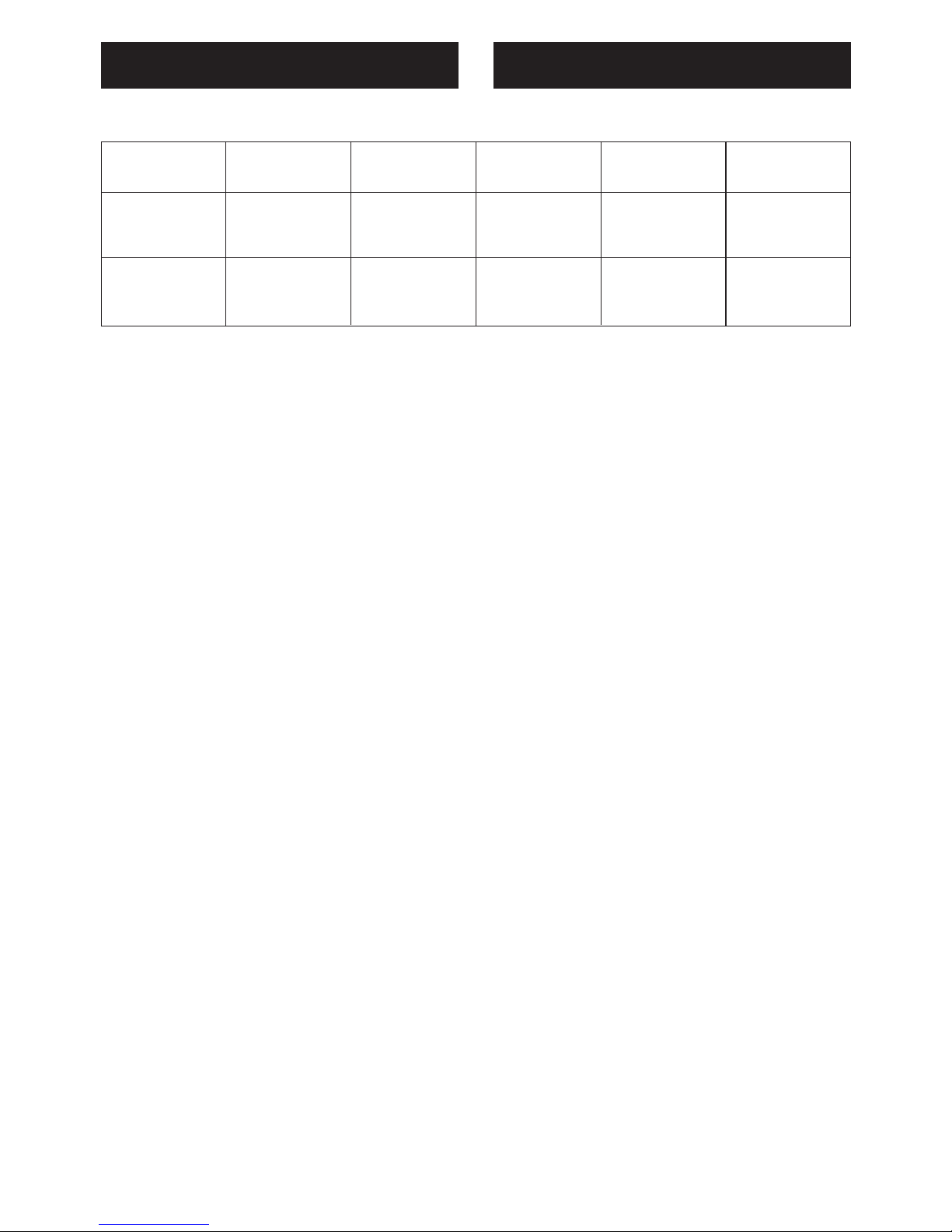

GAS Burner Injector Consumption low flow-rate

nominal flow-rate

(kW) (kW)

G20 auxiliary 76 95 l/h 0,45 1,00

20 semi-rapid 94 157 l/h 0,60 1,65

mbar rapid 128 276 l/h 0,95 2,90

G30/G31 auxiliary 50 73 g/h 0,45 1,00

28-30 mbar semi-rapid 65 120 g/h 0,60 1,65

37 mbar rapid 85 211 g/h 0,95 2,90

GAS BURNERS CHARACTERISTICS

Page 5

4'x7'x7'6" high). If it is installed in a room of volume between 6m3 and 9m3 an air vent of effective areas 65m2 is required. If it is installed in a

room of volume between 9m3 and 11m3 an air

vent of effective areas 35cm2 is required, while if

the room volume exceeds 11m3 no air vent is required. However, if the room has a door that

opens directly to the outside, no air vent is required even when the room volume is between

6m3 and 11m3.

The above requirements allow also for the use of

a gas oven and grill but, if there are other fuel

burning appliances in the same room, BS5400

1976 should be consulted to determine the required air vent requirements.

If the appliance is installed in a cellar or basement, it is necessary to provide an air vent of effective area 65m2 irrespective of the room volume.

The use of a gas appliance results in production

of heat and moisture in the room in which it is installed. Ensure that the kitchen is well ventilated,

keep natural ventilation holes open or install a

mechanical ventilation device (mechanical extraction hood).

Prolonged intensive use of the appliance may call

for additional ventilation, for example increasing

the level of mechanical ventilation where present.

UNPACKING YOUR HOB

Once the packaging has been removed, thoroughly check that the appliance is in perfect condition.

If you have any doubts do not use the appliance

and call Comet Service Centre on 0870 5425425.

Some parts mounted on the appliance are protected by a plastic film. This protection must be

removed before using the appliance. We recommend slitting the plastic film along the edges with

a sharp knife or pin.

Position

To fit the hob into the unit make an opening of the

dimensions given in fig 2 remembering that:

• Inside the unit there must be a space of at least

30mm between the bottom of the hob and the

top of a shelf.

• Any wall to the side of the hob must be at least

100mm away (fig 2).

• The wall behind the hob must be at least 58mm

away (fig 2).

• When there is a wall unit or hood above the hob

there must be at least 750mm between the hob

and the unit or hood.

• If the hob is not installed over a built in oven, it

is essential to install a heat baffle between the

bottom of the hob and the underlying unit.

• If the hob is installed over a built in oven, there

must be a distance of at least 30mm between

the two appliances. The two appliances should

be connected to the gas supply with independent connections, in compliance with the current

laws in force.

Fixing

A self adhesive seal (A fig 3) is supplied with the

hob. This must be placed under the edge of the

hob top, as close as possible to the edge (fig 3).

The seal must run all round the unit to ensure a

perfect seal and prevent moisture from seeping

under the hob.

Place the hob in the hole in the worktop, making

sure that there is a good seal between the edge

of the hob and the worktop (fig 4).

Secure the hob to the worktop using the brackets

(C fig 5) and screws supplied, do not over tighten

the screws.

GAS CONNECTION

Important

This appliance is supplied for use on NATURAL

GAS ONLY and cannot be used for any other gas

without modification. This appliance is supplied

with a replacement set of injectors for use with

LPG, but conversion for use on other gases must

only be undertaken by a C.O.R.G.I. registered installer. For information for use on other gases

contact your local Comet Service Centre.

Note: The installation of the hob to Natural gas or

LP Gas must be carried out by a C.O.R.G.I. registered installer. Installers shall take account of

the provisions of the relevant British Standards

Code of Practice, the Gas Safety Regulations

and the Building Standards (Scotland) (Consolidation) Regulations issued by the Scottish Development Department.

The appliance complies with the provisions of the

following EEC Directives:

90/396 + 93/68 regarding gas safety.

The minimum distance from hob top to an overhanging cupboard or hood must be at least

750mm.

The hob is supplied with an elbow connection

(fig 6) and is adjusted to work with mains gas.

Installation to Natural Gas

Installation to Natural Gas must conform to the

Code of Practice etc. The supply pressure for

Installation

4

Page 6

Natural Gas is 20 mbar (8 inch W.G.).

Installation to LP Gas

This appliance must only be connected to LPG

after an LPG conversion kit has been fitted (see

section conversion to LPG). When operating on

Butane gas a supply pressure of 28 mbar (11

inch W.G.) is required. When operating on

Propane gas a supply pressure of 37 mbar (14

inch W.G.) is required. The installation must conform to the relevant British Standards.

Warning: Only a C.O.R.G.I. registered installer,

also with technical knowledge of electricity

should install gas hobs. They should observe the

Regulations and Codes of Practice governing

such installation of gas hobs.

Important: After installation check that all

connections are airtight.

CONVERSION TO LP GAS

Warning: Replacement of injectors must only be

undertaken by a qualified gas engineer and when

changing injectors to a different type of gas supply the instructions on adjustment and installation

on the particular category of gas supply must be

observed.

After conversion always carry out a gas leak test.

REPLACING INJECTORS (FIG. 7)

To replace the injectors proceed as follows: The

hob is preset with natural gas. The appliance is

preset with the injectors necessary for adaptation

to bottled gas (butane or propane), comprising a

hose connection.

If the hob has to be changed from natural gas,

proceed as follows:

- Remove the pan supports, the burner caps (A),

and the burners (B);

- Unscrew and remove the injector in the bottom

of each injector holder (C);

- replace the injector in accordance with the table

in page 3, tighten and screw right down;

- check that the system is gas-tight;

- replace the burners, the burner caps and the

pan supports.

IMPORTANT:

- Never over-tighten the injectors;

- after replacing, check that all the injectors are

airtight.

SETTING HOB BURNER MINIMUM LEVELS

If the hob is to work on bottled gas (butane/

propane), the tap by-pass must be screwed right

down. The hob may be equipped with type A

taps, with by-pass inside (accessed by inserting

a small screwdriver into the rod) or type B taps,

with by-pass on the outside on the right (accessed directly). See figure 8.

If the hob is to work on natural gas, proceed as

follows for both types of tap:

- Ignite the burner at maximum flame;

- pull off the knob, without using a lever against

the control panel, which might be damaged;

- access the by-pass with a small screwdriver

and back off by about 3 turns (turning the

screwdriver anti-clockwise);

- turn the tap rod anti-clockwise again until it

stops: the burner will be at maximum flame;

- screw the by-pass slowly back in, without pushing the screw-driver, until the flame has apparently shrunk to 1/4 of the maximum size, checking that it is sufficiently stable even in quite

strong draughts.

ELECTRICAL CONNECTION

For your safety please read the following information

Warning: This appliance must be earthed.

The appliance must be connected to a 220-240

volts 50 cycle AC supply by means of a three pin

socket, suitably earthed and should be protected

by a 3 amp fuse in the plug or a15 amp fuse in

the consumer unit.

The appliance is supplied with a rewireable 13

amp 3 pin plug fitted with a 3amp fuse. Should

the fuse require replacement, it must be replaced

with a fuse rated at 3 amp and approved to

BS1362.

If the mains plug is unsuitable for the socket outlet in your home or is removed for any other reason, then the cut off plug should be disposed of

safely to prevent the hazard of electric shock.

There is a danger of electric shock if the cut off

plug is inserted into any 13 amp socket outlet.

How to wire a 3 amp plug

5

Installation

Page 7

6

Important

The wires in the mains lead on this appliance are

coloured in accordance with the following code:

Green and Yellow - Earth

Blue – Neutral

Brown – Live

As the colours may not correspond with the

markings identifying the terminals in your plug

proceed as follows.

The green and yellow wire must be connected to

the terminal in the plug which is marked with the

letter E or with the earth symbol or coloured

green and yellow.

The blue wire must be connected to the terminal

marked N or coloured black.

The brown wire must be connected to the terminal marked L or coloured red.

IMPORTANT: the manufacturer declines all liability for damage due to failure to comply with the

regulations and standards in force.

ELECTRIC IGNITION

The correct gap between the electrode and the

burner is shown in figure 9.

If no spark is generated, do not keep on trying as

this might damage the generator.

Possible causes of malfunctions:

- spark plug damp, dirty or broken;

- electrode-burner gap not correct;

- spark plug wire broken or without sheathing;

- spark discharging to earth (to other parts of the

hob);

- generator or microswitch damaged;

- air has built up in the pipes (particularly if the

hob has been out of use for a long time);

- air-gas mixture incorrect.

HOW TO USE THE HOB

VENTILATION

All gas cooking appliances produce heat and

moisture in the rooms where they are installed.

Ta ke care to ensure that the kitchen is well ventilated; keep the ventilation openings unobstructed

or install an extractor hood with fan.

In case of intensive or prolonged use, additional

ventilation may be required; open a window, or increase the extractor fan power.

IGNITING THE HOB BURNERS

- Press the knob and turn it anti-clockwise until it

reaches the symbol on the control panel

(maximum flame position);

- at the same time, press and hold the ignition

button until the burner lights;

- to reduce the flame, turn the knob further in the

same direction until its pointer is against the

symbol (minimum flame position).

IMPORTANT

- Difficulty in igniting burners is normal if the hob

has been out of use for some time. The air accumulated in the pipes will be expelled in a few seconds;

- Never allow too much unburnt gas to flow from

the burners. If ignition is not achieved within a relatively short time, repeat the procedure after returning the knob to the off position (•);

HOW TO USE THE HOB BURNERS

Use pans of diameter suitable for the burner type.

The flames must not project beyond the base of

the pan. Recommended sizes:

- for auxiliary burners = pans of at least 8 cm

- for semi-rapid burners = pans of at least 14 cm

- for rapid burners = pans of at least 22 cm.

N.B.: Never keep the knob at settings between

the maximum flame symbol and the off position ( •).

CLEANING AND MAINTENANCE

General tips

• Before cleaning the hob switch it off and wait for

it to cool down.

• Clean with a cloth, hot water and soap or liquid

detergent.

• Do not use products which are abrasive, corrosive or chlorine based.

• Do not use steel pads.

• Do not leave vinegar, coffee, milk, salty water or

juice of lemon or tomato on the hob surface for

any length of time.

Installation For the user

Page 8

Enamelled parts

All enamelled parts must be washed only with a

sponge and warm soapy water or other non abrasive products. Dry carefully.

Stainless steel parts

Clean with special products for stainless steel

which are available on the market. Dry preferably

using a chamois leather.

Note: Regular use will cause discolouring around

the burners, this is due to the high temperature of

the flame

Burners and pan supports

These pieces can be removed and washed with

a sponge and warm soapy water or other non

abrasive products. After cleaning dry them well

and replace them correctly. Keep the electrodes

clean so that the sparks always strike.

Note: To avoid damage to the electric ignition do

not use it when the burners are not in place.

Control knobs

The control knobs can be removed for cleaning

by just pulling.

Gas taps

Regular lubrication of the gas taps must only be

performed by qualified engineers.

If the gas taps are not working properly contact

your nearest Comet Service Centre on 0870

5425425.

INFORMATION AND SERVICE

For any information you require about the product

contact the Proline helpline on 0113 2793520

If you require a service call contact your nearest

Comet Service Centre on 0870 5425425.

The manufacturer declines all responsability for

injury or damage deriving from poor installation

or incorrect use of the hob.

For the user

7

Page 9

8

Figure

A = AUXILIARY

SR = SEMIRAPID

R = RAPID

1

2

3

4

Page 10

9

Figure

9

5

6

7

8

Page 11

Page 12

Page 13

ED. 12/09/2003 334995

Loading...

Loading...