Proline Gold Installation & Service Manual

Installation & Service Manual

5-Stage Reverse Osmosis Drinking Water System

WQA GOLD SEAL:

This System Conforms to (WQA S-300) for the reduction of TDS, Pentavalent Arsenic, Barium, Cadmium, Chromium +6, Chromium +3, Copper, Fluoride, Lead, Radium (226/228), Selenium and Turbidity as veri-

ed and substantiated by test data.

®

Congratulations on choosing the PROLINE®

5-Stage Reverse Osmosis (RO) Drinking Water System

This high quality unit has been designed to t under most kitchen and wet-bar

sinks. We suggest that you carefully review the following information booklet

before you attempt to install the reverse osmosis system.

Your Reverse Osmosis system is a highly sophisticated machine. We strongly

recommend using only trained & experienced technicians for installation and

troubleshooting. To locate the closest authorised service technician contact

your dealer or visit us at www.waterworldusa.com.

If you decide to install the unit yourself, please follow these installation

instructions, which have been simplied with color coded tubing. All your

local plumbing codes and regulations must be followed while installing your

RO system. For installation assistance, contact your local dealer.

Tools Required:

1) Hand drill for faucet hole. Use the appropriate 7/8” drill bit for the

surface you are drilling:

A) Titanium bit for metal sinks.

B) Glass and tile bit or Relton cutter for porcelain sinks.

C) Diamond core bit for granite.

2) Phillips head screwdriver.

3) Adjustable crescent wrench.

4) Basin wrench.

5) ¼” drill bit for drain clamp.

Your local dealer

1

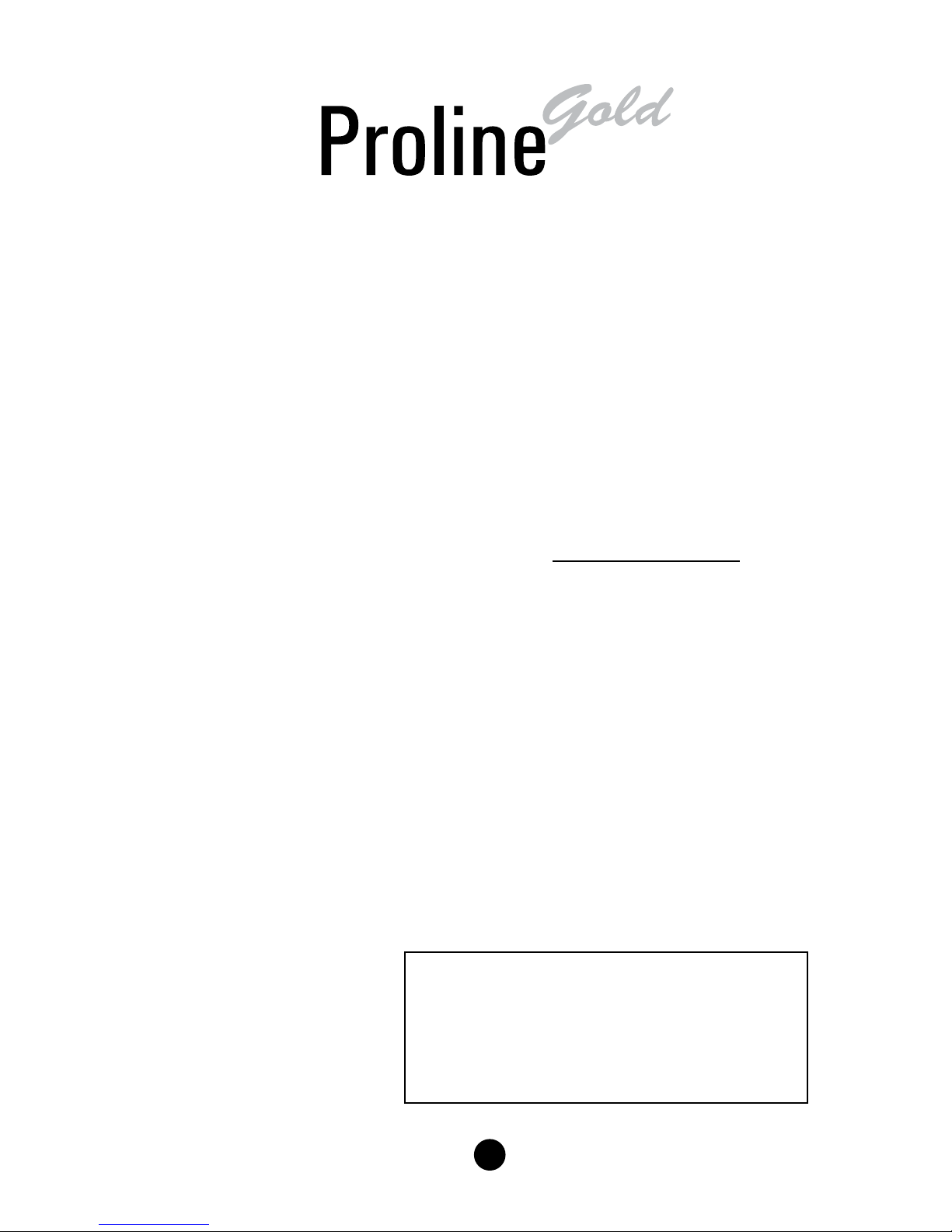

INSTALLATION DIAGRAM FOR PROLINE GOLD SYSTEM

3/8” red tubing

to drain clamp

(Fig. 1)

1/4” red tubing

from flow restrict

to air gap

WARNING:

CONNECT YOUR SYSTEM TO THE COLD WATER SUPPLY ONLY. DO

NOT USE WATER SUPPLY THAT IS MICRO-BIOLOGICALLY UNSAFE, OR

OF UNKNOWN SOURCE WITHOUT ADEQUATE DISINFECTION BEFORE

OR AFTER THE SYSTEM.

Tubing Directions

1/4” Green Feed water supply line to inlet. Feed ball valve labeled “TO FEED”

3/8” Blue Carbon post lter elbow labeled “TO FAUCET” to center threaded shank of faucet

3/8” Yellow Carbon post lter tee labeled “TO TANK” to ball valve on storage tank

1/4” Red Flow restrictor labeled “TO DRAIN” to air gap 1/4” drain/barb inlet at faucet air gap

3/8” Red 3/8” Barb on air gap to DC-38J Drain clamp

Color Coded Tubing

2

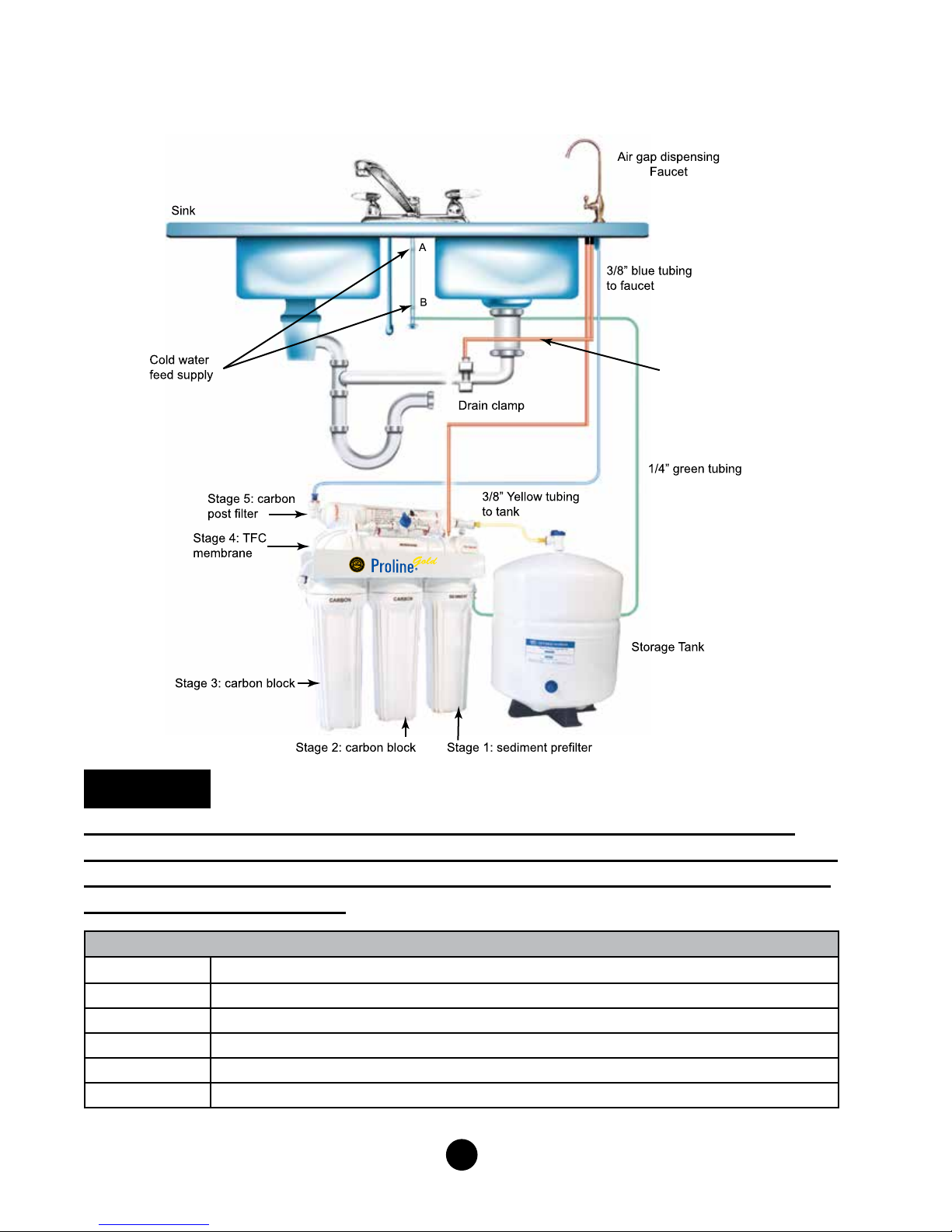

Installation Kit Contents

color tubing

SV-01

AD-4BC-3W BV-2BC

1. Color Coded Tubing:

Color Coded Tubing ( 5 coils, 4 colors)

¼’’ Green Tubing (approximately 8 feet)

¼’’ Red Tubing (approximately 6 feet)

3/8’’ Yellow Tubing (approximately 6 feet)

3/8’’ Blue Tubing (approximately 6 feet)

3/8” Red Tubing (approximately 5 feet)

Note: The color coded tubing matches

the color coded plugs on the PROLINE

2. SV-01:

SV-01 (Self Piercing Saddle Valve) for tapping

into cold water supply by piercing a hole in to copper

tubing. (See gure # 3)

3. BV-2BC (Chromed Ball Valve NPT ¼’’) and

AD- 4BC-3W (Chromed Adapter NPT ½’’) are used for

tapping into cold water supply at the top of undersink . If

you have a vinyl feed line or exible metal feed line use

the BV-2BC and AD- 4BC-3W. (see gure #2)

4. DC-38J

DC-38J (Drain Clamp) used for tapping into drainline for

discharge of the wastewater down the drain.

®

RO unit.

3/8” DC-38J (Drain Clamp)

Teon Tape

BV-103-EZ

Release Tool

WR-1W

5. Teon Tape:

Teon Tape is used on all threaded ttings to prevent

water leakage. Eight rotations (layers) are adequate

when using Teon tape to secure any threaded ttings.

The PROLINE® RO already has Teon tape on all of

its ttings.

6. BV-103- EZ:

BV-103-EZ (Storage Tank Ball Valve 3/8’’). In normal

operation, the Storage Tank Ball Valve must be in the

“open” position. Add 8 layers of Teon tape on top of

the Threaded tank outlet. Screw tank ball valve

securely on threaded 1/4” port.

7. Release Tool:

Release Tool (Quick Connect Release Wrench) allows

easier disconnecting of tubing ¼’’ and 3/8’’ from quick

connect ttings. Push release tool against collet of

quick connect tting and pull the tubing out of the

tting.

8. WR-1W :

WR-1W (White Wrench) Make sure the black rubber

O-ring is properly in place in the lter housing after

changing lters following any maintenance.

6FC6

9. 6FC6:

6FC6 (Faucet connector) to connect the faucet with

blue 3/8’’ tubing coming from the post lter labeled

TO FAUCET.

3

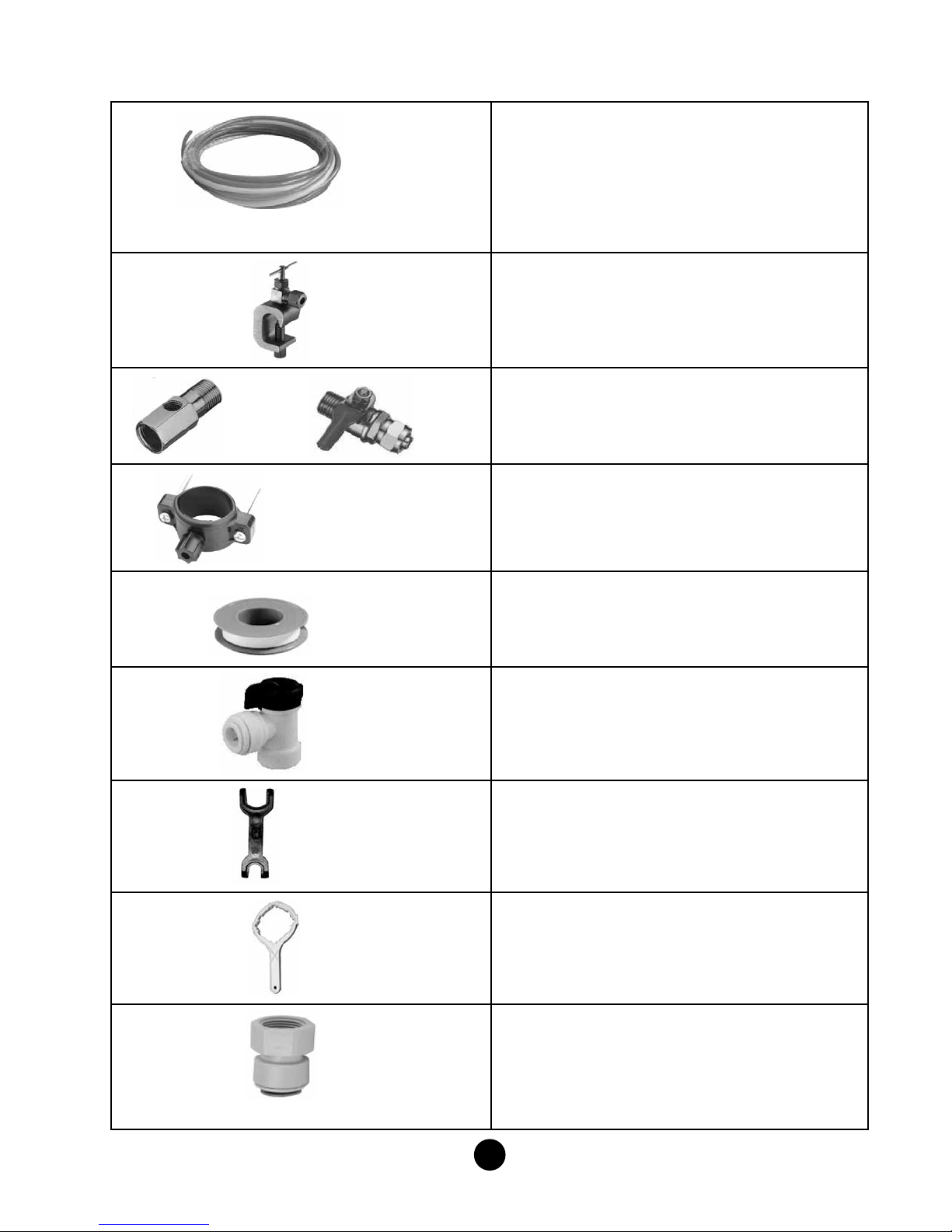

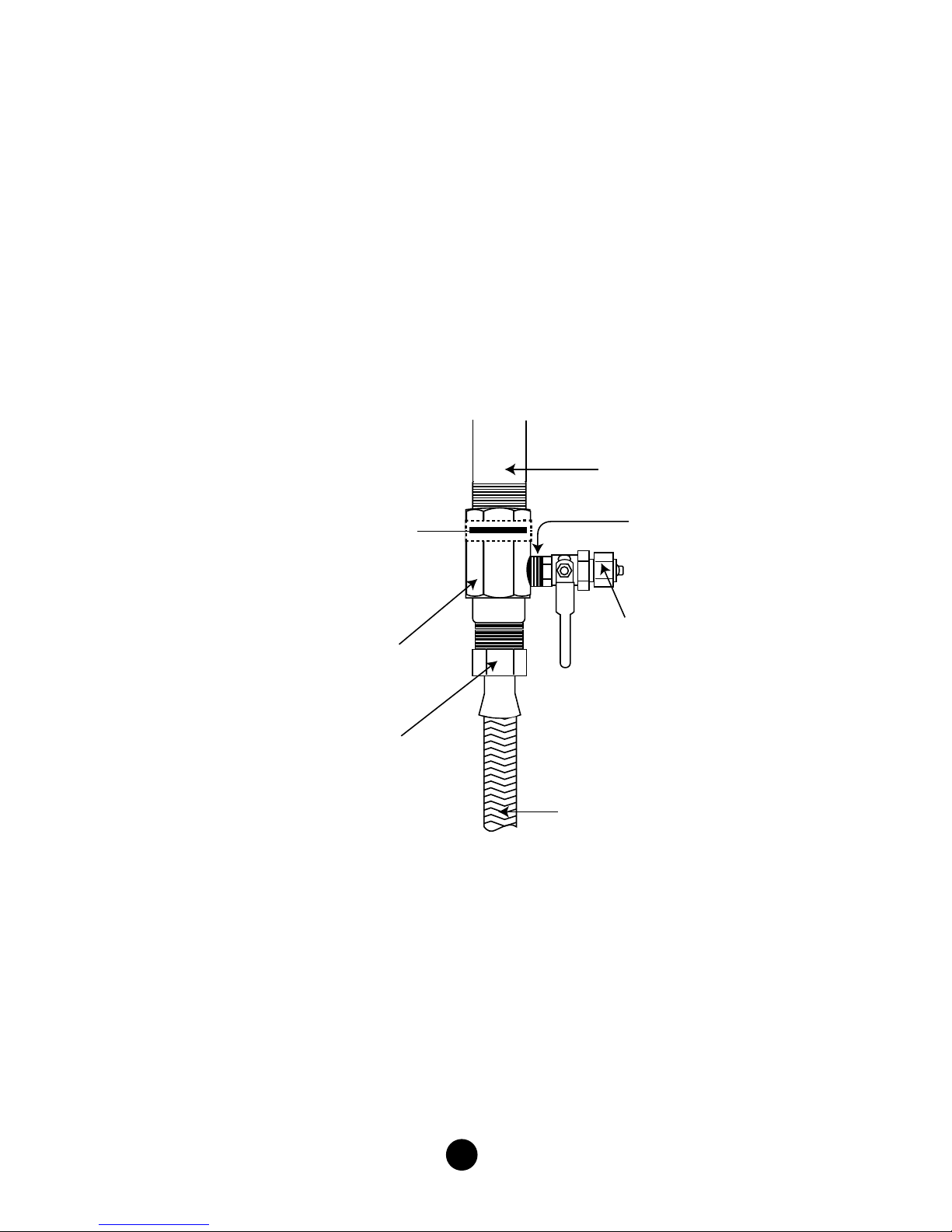

TAPPING INTO THE COLD WATER LINE

Flat washer

Water supply adapter

Ball valve

Apply teflon tape here

AD-4BC-3W

BV-2BC

(inside supply adaptor)

Base of the

cold water faucet

1/4” nut

1/2” threaded nut

with built in washer

Cold water supply

A - (Using the water supply adaptor Part # AD-4BC-3W & BV-2BC)

For ex metal or plastic line.

NOTE: The Proline® drinking water system must be connected to the COLD water

supply only.

1) Turn off the cold water supply to the sink faucet by locating the round or oblong

handle and turning clockwise until the water supply is off.

NOTE: If the cold water shut off valve fails to turn off the water, the house supply can

be turned off at the main water supply.

2) The water supply adapter (Fig. #2) may be installed at the faucet connection

(Fig. 2)

3) Disconnect the 1/2” threaded nut from the base of the faucet on the cold water

side. Place the at washer inside the female end of the water supply adapter.

Screw on the base of the cold water faucet.

4) Re-connect the 1/2” threaded nut onto the male threads of the adapter. “DO

NOT USE TEFLON TAPE ON THIS THREAD, RUBBER WASHERS WILL SEAL

THE CONNECTIONS”.

5) Place Teon tape on the 1/4” male threads of the ball valve supplied with the

adapter. Screw the ball valve into the 1/4” female port on the side of the adapter.

6) Remove the 1/4” nut from the ball valve, place the nut over the 1/4” Green tubing,

insert the tubing onto the barbed connection of the ball valve and tighten into

place with the 1/4” nut.

4

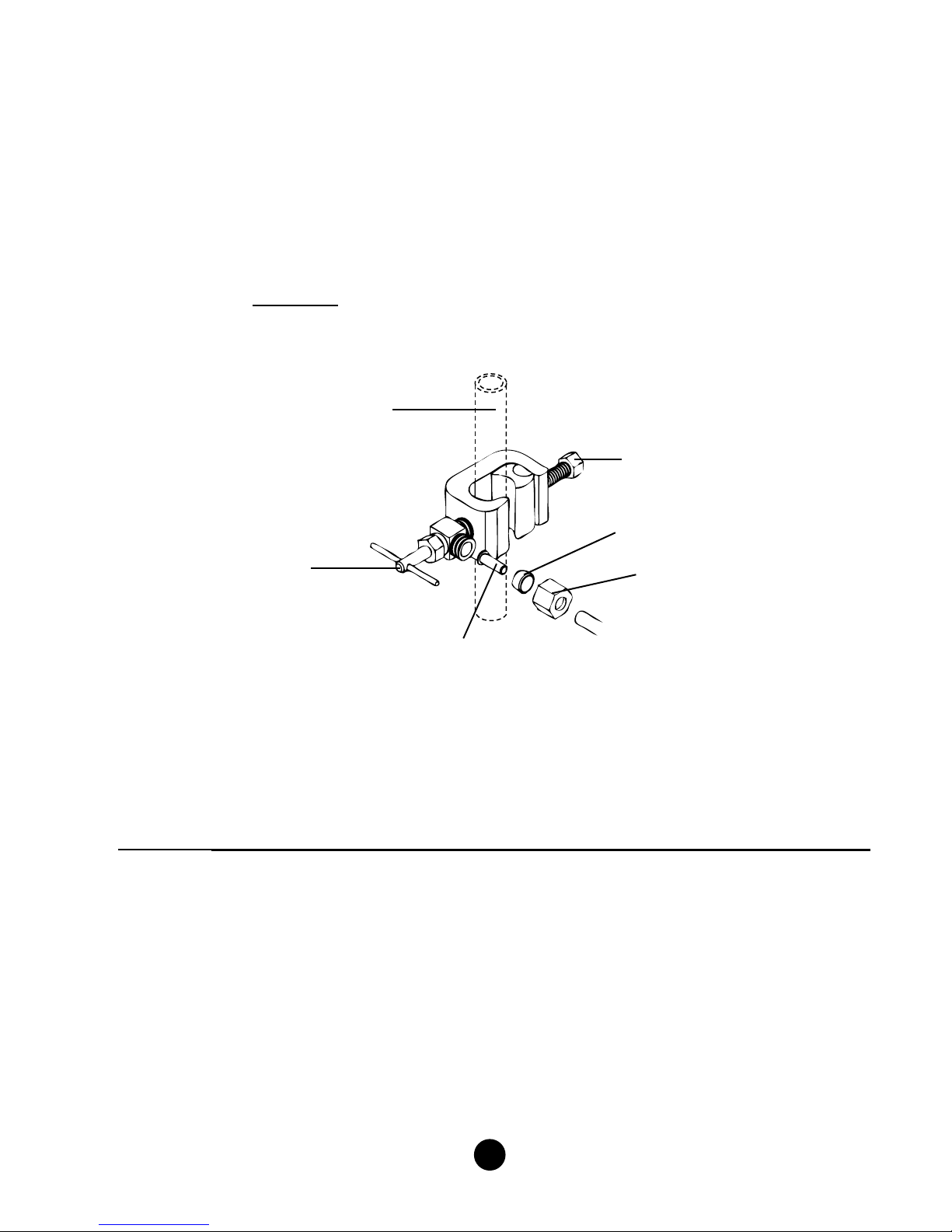

Brass nut

Cold water line

Brass insert

Plastic ferrule

Valve handle

Valve bolt

TAPPING INTO THE COLD WATER LINE

B - (Using self-piercing saddle valve Part # SV-01)

NOTE: This valve is designed for standard copper lines. If your cold water line is not

plumbed with copper line, use water supply adapter AD-4BC-3W & BV-2BC.

1) Turn off cold water supply under the sink and install the saddle valve to the cold line.

Clamp onto a smooth section and tighten valve bolt securely.

2) Turn the valve handle clockwise so that it pierces the copper cold water line.

3) Install the ¼’’ green tubing from the rst stage lter to the saddle valve (Fig. #3).

*Do not over tighten brass nut

(Fig. 3)

NOTE: All local plumbing codes must be followed to ensure proper installation and

use of your PROLINE® system.

NOTE: Use brass insert and plastic ferrule when connecting tubing to saddle valve.

Cold Water Supply Valve (Figure #3)

CAUTION: A pressure regulator is recommended for feedwater pressure above 80 psi.

5

Loading...

Loading...