Page 1

3 1/2 Digital Multimeter w/EK-1

MT-1910

User’s Manual

1

©2010 Copy Right by Prokit’s Industries Co., Ltd.

st

Edition, 2010

Table of Contents

1. Introduction.............................................................1

2. Safety note................................................................1

3. Explanation of controls and indicators..................2

3-1 Meter illustration

3-2. Functional push button

3-3. Display indicators

4. Specification...........................................................4

4-1. General Feature

4-2. Electrical Specification

5. Measurement operation..........................................7

5-1. DC & AC voltage measurement

5-2. Resistance measurement

5-3. Diode/Continuity check

5-4. Capacitance measurement

5-5. Transistor check

5-6. Frequency measurement

5-7. DC/AC mA/10A measurement

5-8. Inductance measurement

5-9. Temperature measurement

6. Maintenance...........................................................11

6-1. Replacing the battery

6-2. Fuse replacement

6-3.Cleaning and Decontamination

Page 2

1. Introduction

This Meter is a handheld and battery operated Digital Multi Meter (DMM)

with multi function which designed to meet IEC-61010-1 CAT III 1000V over

voltage category and double insulation. The entire outer surface of the case has

been formed with thermo plastic elastomeric, giving the main body, though

downsized, high resistance against the shock of a drop. This user’s manual

covers information for safety and caution. Please read relevant information

carefully and observe all the warnings and note strictly. The DMM is a general

measurement tool and widely used in the school, laboratory, factory etc.

2. Safety note

War ning

To avoid possible electric shock or personal injury and to avoid possible damage

to the meter or to the equipment under test, adhere to the following rule:

z Do not apply more than the rated voltage of marked on the meter

z Do not apply voltage between COM and OHM terminal, in the

resistance measuring state.

z Do not measure current with test lead inserted into voltage or OHM

terminal.

z Do not expose the instrument to the direct sun light, extreme

temperature and humidity or dew full.

z Inspect the test lead for damaged insulation or exposed metal.

z Before measuring current, check the Meter’s fuses and turn off power

to the circuit before connecting the meter to the circuit.

z Disconnect circuit power and discharge all high voltage capacitors

before testing continuity, diode, resistance, capacitance or current.

Note: international Electrical Symbol.

Dangerous Voltage

AC(Alternating

current)

DC (Direct Current)

Ground

Warni ng see

explain in manual

Double insulation

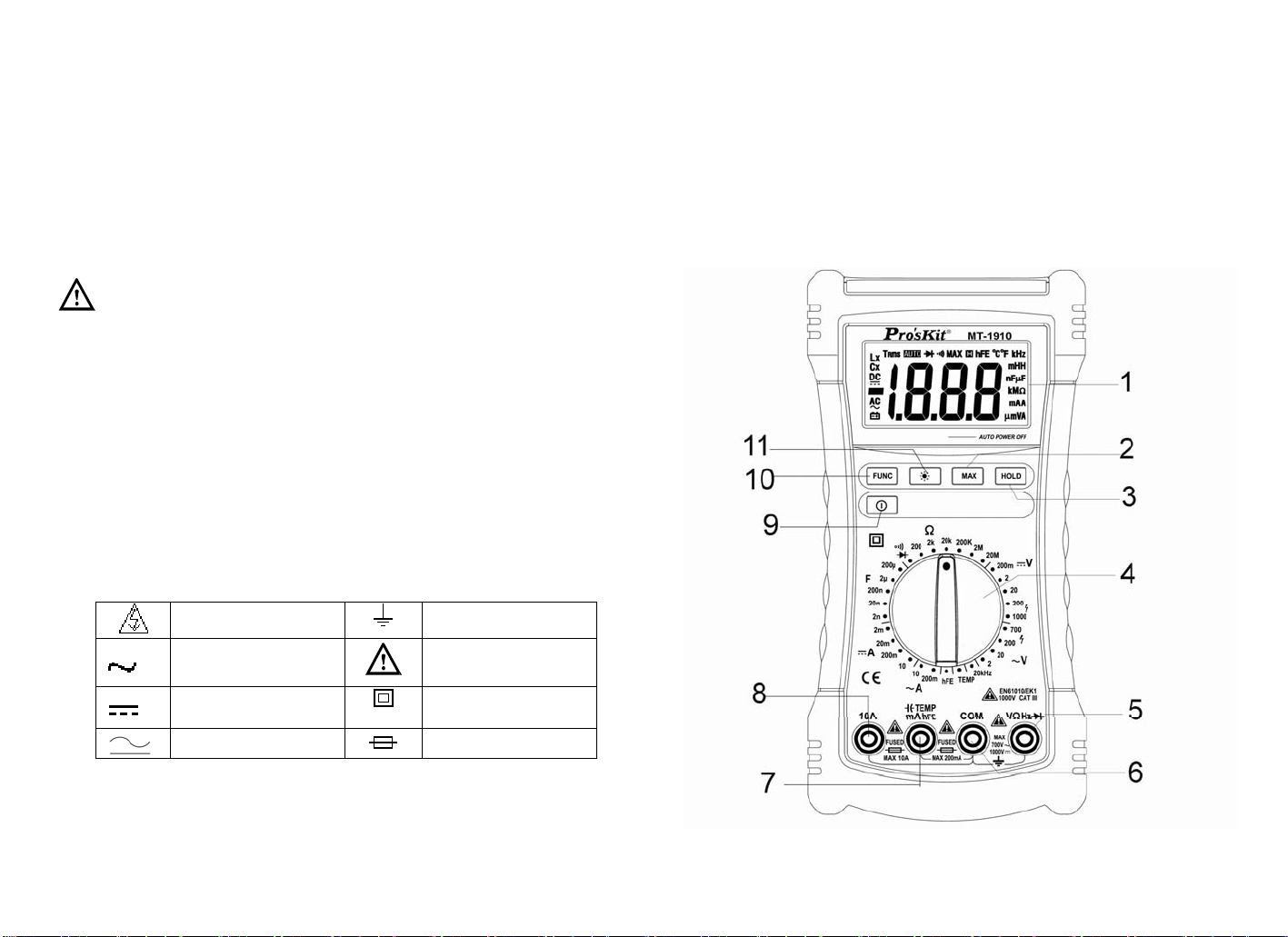

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

1

Rotary Switch (Knob)

“V. Ω. Hz” Input terminal

“COM” terminal

“μA.mA. .Cx.Lx.hFE”℃ Input terminal

“10A” input terminal

Power switch(ON.OFF)

“FUNC” push button

“BKLIT” push button

AC or DC

Fuse

3. Explanation of controls and indicators

3-1 Meter illustration

LCD display

①

“MAX” push button

②

“HOLD” push button

③

Page 3

2 3

g

3-2. Functional push button

Push button Function

FUNC

HOLD

MAX/MIN

Backlight

*

ON/OFF Lock type Power Switch.

“FUNC” key is the function select key that acts with

trigger. Use the key as switch of DC/AC voltage,

DC/AC current, Resistance/Continuity and / .℃℉

Press “HOLD” to enter and exit the hold mode in any

mode. That act with trigger.

This key is act with trigger. Press this key once, the

maximum value is holding (Will displays ‘MAX’

symbol in the LCD).

After pressing the key, A/D will keep working and the

display value will up dated and kept the maximum

value. (The actual gained value is not the peak value.).

This key is used to control Backlight and acts as trigger.

When press the key, will enable Backlight for 15 sec.

Press the key again within 15 sec, Backlight will

disable.

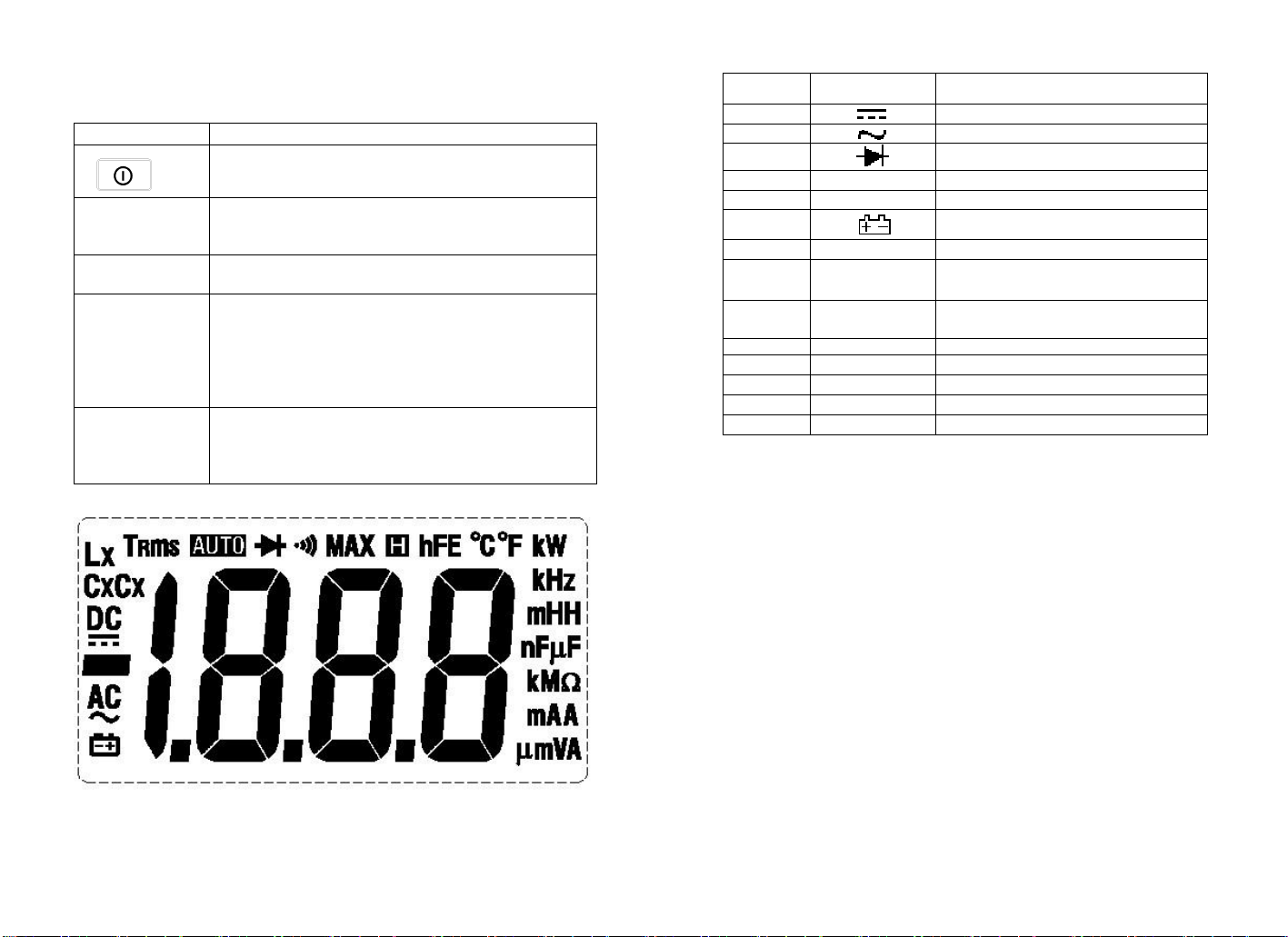

3-3. Display indicators

FIG 2 LCD

Number Indicator Meaning

1

2

3

4 MAX Maximum value

5 HOLD Data hold

6

7 MKΩ Ω KΩ MΩ is unit of resistance

8 /℃℉

9 µmVA

10

11 Cx Capacitance Indicator

12 Lx Inductance Indicator

13 mH/H Inductance Units

14 nµmF Capacitance Units.

-

DC voltage or current

AC voltage or current

Diode

Low battery indicator

The unit of temperature

( : Centigrade; : Fahrenheit)℃℉

uV mV V is unit of voltage

uA mA A is unit of current

Indicate negative readin

4. Specification

4-1. General Features

● Manual ranging DMM, that full scale is 1999 counts

● Display: 3 1/2 digit LCD display.

● Overload protection: Used the PTC protection circuit for Resistance, Capacitance

and Frequency measurement.

● DATA HOLD function

● MAX value measurement function

● Back Light / Low battery indication

● Auto power off

● Operating temperature & Humidity: 0 ~ 40℃ (32 ~104 ℉) & < 80% RH

● Storage temperature & Humidity: -10 ~ 50℃ (14 ~ 122 ℉) & <70%RH

● Power Supply: 1.5V Battery (AA Type)×4

● Safety Class: IEC-61010-1, 1000V CAT III, 600V CAT Ⅳ, EK-1 safety rating

standard

● Dimension (L×W×H) & Weight: 205 mm×102 mm×58mm, Approx. 390g.

Accessory: 1.K-type thermocouple probe x 1pcs, 2. Socket for temperature

measurement x 1pcs, Test Lead x 1set, Carrying bag x 1pcs

Page 4

4-2. Electrical Specification (at 23±5℃; <75% RH)

4.2.1 DC Voltage

Range Resolution Accuracy

200mV 0.1mV

2V 0.001V

20V 0.01V

200V 0.1V

1000V 1V

* Input impedance: 10MΩ

* Over load protection: 250V DC/AC(rms) at 200mV Range.

* Max input voltage: 1000VDC

±(0.5% rdg + 2dgt)

4.2.2 AC Voltage

Range Resolution Accuracy

200mV 0.1mV

2V 0.001V

20V 0.01V

200V 0.1V

700V 1V

* Input impedance:10MΩ

* Over load protection: 250V DC/AC(rms) at 200mV Range.

* Frequency response: 40~400Hz

* Average rectifier type.

* Max input voltage:750V AC rms

±(0.8% rdg + 3dgt)

±(1.0% rdg + 5dgt)

4.2.3 Resistance

Range Resolution Accuracy

200Ω 0.1Ω

2kΩ 0.001kΩ

20kΩ 0.01kΩ

200kΩ 0.1kΩ

2MΩ 0.001MΩ

20MΩ 0.01MΩ

* Over load protection:250V DC/ AC rms

±(0.8% rdg + 3dgt)

±(1.5% rdg + 5dgt)

4.2.4 Diode check

Range Resolution Function

* Over load protection:250V DC/ AC rms

0.001V Will display the forward drop

voltage.

5 4

4.2.5 Continuity

Range Function

* Over load protection:250V DC/ AC rms

If measured resistance less than 30Ω, will buzzer is

sounded.

4.2.6 DC Current

Range Resolution Accuracy

2mA 1μA

20.00mA 0.01mA

200.0mA 0.1mA

10.00A 0.01A

* Over protection:use the fuse(F250mA/1KV) at mA range and use the

fuse(F10A/1KV) at 10A range.

* Max input current::200mA at ‘mA’ jack and 10A at ‘10A’ jack. .

(1.0% rdg + 3dgt)

(2.0% rdg + 3dgt)

4.2.7 AC Current

Range Resolution Accuracy

2mA 1μA

20mA 0.01mA

200.0mA 0.1mA

10.00A 0.01A

* Over protection use the fuse (F250mA/1KV) at mA range, and use the

fuse(F10A/1KV) at 10A range.

* Max input current::200mA at ‘mA’ jack and 10A at ‘10A’ jack. .

* Frequency response:40 ~ 400Hz

(1.5% rdg + 5dgt)

(3.0% rdg + 10dgt)

4.2.8 Temperature

Select Centigrade [ ] or ℃ Fahrenheit [ ] by℉ press “FUNC” key.

Range -20 ~ 1000℃℃

Resolution 1℃

-20 ~0℃℃

Accuracy 0 ~400℃℃

400 ~1000℃℃

Fahrenheit Temperature [ ] ℉

Range 0 ~1800℉℉

Resolution 1℉

-0 ~50℉℉

Accuracy 50 ~750℉℉

750 ~1800℉℉

*Over load protection:use the fuse[ F250mA/1KV].

(5.0% rdg + 4dgt)

(1.0% rdg + 3dgt)

(2.0% rdg + 3dgt)

(5.0% rdg + 4dgt)

(1.0% rdg + 3dgt)

(2.0% rdg + 3dgt)

Page 5

6 7

4.2.9 Capacitance

Range Resolution Accuracy

2nF 0.001nF

20nF 0.01nF

200nF 0.1nF

2µF 0.001µF

20uF 0.01µF

200µF 0.1µF

* Over load protection:use the fuse[F250mA/1KV]

(4.0%rdg +5dgt)

(5.0%rdg + 10dgt)

4.2.10 hFE

Range Function

hFE

* Over load protection:use the fuse [F250mA/1KV ]

hFE: 1~1000

4.2.11 Frequency

Range Resolution Accuracy

20kHz 1 Hz

* Sensitivity: 200mV -5V AC rms

* Over load protection:250V DC/AC rms

±(1.5%rdg+5dgt)

4.2.12 Inductance

Range Resolution Accuracy

2mH 0.001mH

20mH 0.01mH

200mH 0.1mH

2H 1mH

20H 10mH

* Over load protection:use the fuse [ F250mA/1KV]

(4.0% rdg + 8dgt)

(4.0%rdg + 3dgt)

(4.0%rdg + 3dgt)

(4.0%rdg + 3dgt)

(4.0%rdg + 5dgt)

5. Measurement operation

5-1 DC & AC voltage measurement

To avoid harms to you or damage to the meter from electric

shock. Please do not attempt to measure voltage higher than

DC 1000V/AC 700Vrms although readings may be obtained.

The DC voltage ranges are 200.0mV, 2.000V, 20.00V, 200.0V and 1000V.

The AC voltage ranges are 200.0mV, 2.000V, 20.00V, 200.0V and 750.0V.

To measure DC/AC voltage:

1. Insert the red test lead into the “VΩ” input terminal and the black test lead

into the COM terminal.

2. First, default mode is DC measurement mode, you can select the AC voltage

mode by press ‘FUNC“ key.

3. Set the rotary switch to proper DC/AC mV or V range.

4. Connecting the test lead across with the object be measured. The measured

value will be showed on the LCD display.

6. If the “OL” symbol is displayed on the LCD, please set the rotary switch to

the higher range.

Note:

In the range of 200mV in DC/AC and 2V AC, even in the absence of input or

connectivity test lead, there also have something display on LCD. In this case,

short-circuit "V" and "COM", the LCD display will back to zero.

5-2. Resistance measurement

To avoid damage to the Meter or to the equipment under

test, disconnect power and discharge all high-voltage

capacitors before resistance measurement.

The resistance range: 200Ω, 2.000kΩ, 20.00kΩΩ, 200.0k, 2.000MΩ, 20.00MΩ

To measure resistance, connect the meter as follows:

1. Insert the red test lead into the ”VΩ” terminal and the black test lead into the

COM terminal.

2. Set the rotary switch to proper resistance range.

3. Connect the test lead across with the object be measured. The measured value

will be display on the LCD

Note:

The test lead can add 0.1Ω to 0.2Ω of error to resistance measurement. To obtain

precision reading in low-resistance measurement, that is the range of 200.0Ω,

short the input terminal before measuring. Then the contact resistance will be

displayed on the LCD. You can subtract the contact resistance value from the

measured value.

z For high-resistance measurement (>10MΩ), it is normal taking several

second to obtain stable reading.

z The LCD display “OL” indicating open-circuit for the tested resistor or the

resistor value is higher than the maximum range of the meter.

5-3. Diode/Continuity check

To avoid damage to the Meter or to the equipment under

test, disconnect power and discharge all high-voltage

capacitors before Diode/Continuity check.

1. Insert the red test lead into the “VΩ” terminal and the black test lead into the

COM terminal.

2. Set the rotary switch to

3. For forward voltage drop reading on any semiconductor component, place the

red test lead on the component anode and place the black test lead on the

component cathode. The measured value show on the LCD.

4. Select the continuity check mode by the “FUNC” key.

The buzzer may be sound if the resistance of a circuit under test is less than

30Ω.

Ω position.

Page 6

8 9

5-4. Capacitance measurement

To avoid damage to the Meter or to the equipment under

test, disconnect power and discharge all high-voltage

capacitors before measuring capacitance. You can use the

DC voltage function to confirm that the capacitor is

discharged.

Capacitance ranges are 2.000nF, 20.00nF, 200.0nF, 2.000uF, 20.00uF,

200.0uF.

To measure capacitance, connect the Meter as follows:

1. Set the rotary switch to “ F” proper position, according to about

capacitance value of capacitor under measured.

2. For user conveniently, there has a Multi Function Socket as accessory. First,

please insert the Socket to the “

and then insert the capacitor to the two holes on the Socket. The pin marked

“Cx/Lx/Temp” is pointed to the “ ” input terminal, and the pin marked

“COM” is pointed “COM” input terminal respectively. The measured value

will be displayed on the LCD.

Note:

z To measuring large capacitance of capacitor, stabilize the reading will take

some time.

z To increase the accuracy of capacitance measurement when measuring

under 5nF capacitance, you can Connecting 0.15uF Capacitor in parallel

with the capacitor be measured , or use relative measurement mode to

automatically subtract the capacitance build-in equalized capacitance and

residual capacitance of PCB lead wire from the result.

5-5. Transistor check

Do not attempt to apply DC/AC voltage more than 250V

between the two ‘COM’ and ‘hFE’ terminal to avoid damage

To check and measure transistor please use the Transistor Socket.

1. Set the rotary switch to the hFE position.

2. Use the special multi-function socket, and then it’s ‘hFE’ pin must be

3. Transistor( TO-92 package type) 3 pins must be correctly inserted to the

to the meter from electric shock.

inserted to the “hFE” input terminal and “COM” pin should be inserted to

the “COM” terminal.

‘e’,’b’,’c’ insert hole of the multi-function socket respectively according

to the NPN or PNP type. The hFE value will displayed on the LCD.

5-6. Frequency measurement

To avoid damage the Mete or electric shock the voltage

must less than 250V DC or AC rms between ”COM” and”

hFE”

1. Set the rotary switch to“20KHz”position.

2. Insert the red test lead into the “Hz” input terminal and the black test lead

into the “COM” terminal.

” input terminal and “COM” terminal,

3. Connect the test leads across with the circuit under testing. The

measured value shown on the LCD display.

Note: Input signal level must be higher than 0.2V (it is sensitivity).

5-7. DC/AC mA/10A measurement

When the voltage more than 250V between open-circuit

and ground, do not try to measure the current. If the

measurements were blown fuse, this may damage the

instrument or injury to yourself. In order to avoid damage

instrumentation or test equipment, before measurement

current, please check the instrument fuse. The input

socket, the functional profile and range should be use

correctly when measure current. When the test leader was

inserted at the current input socket, do not attempt to the

other side of the test leader connect any circuit.

DC Current range: 2.000mA, 20.00mA, 200.0mA, and 10A AC Current

range are2.000mA, 20.00mA, 200.0mA and 10A.

1. Turn off power to the circuit and discharge all high-voltage capacitors

before measuring capacitance, Set the rotary switch to the proper

DC/AC mA position.

2. Break the current path to be tested. Connect the red test lead to the more

positive side of the break and the black test lead to the more negative

side of the break.

3. Turn on power to the circuit the measured value show on the LCD.

4. If the “OL” symbol displayed on the LCD, please set the rotary switch

to the higher range.

5. When the currency between 200mA and 10A , insert the red test lead

into the input terminal marked as “10A”.

6. The measuring procedure is same as that of 1-4 section.

Note:

z For safety sake, the measuring time for high current should be less than

10 second for each measurement and the interval time between two

measurements should be greater than 5 minutes.

z When current measurement has been completed, disconnect the

connection between the testing lead and the circuit under test.

5-8. Inductance measurement

The inductance range is 2.000mH, 20.00mH, 200.0mH, 2.000H and 20.00H.

To measure inductance, connect the meter as follows:

1. Insert the red test lead into the ”Lx” terminal and the black test lead into the

COM terminal.

2. Set the rotary switch to proper inductance range.

Connect the test lead across with the inductor being measured. The

inductance value will be displayed on the LCD.

Page 7

10

5-9. Temperature measurement

To measure temperature, please use the Multi-Function Socket.

1. Set the rotary switch to the “TEMP” range, then the “OL” displayed on the

LCD.

2. Insert the Socket to the two “COM” and “TEMP” terminals.

3. Insert the K-type temperature probe to the two insert holes of Socket. User

should take note of it’s polarity.

4. The measured temperature value will be displayed on the LCD.

Note:

The two “Temp” & “COM” pins of Socket must be direct at the two “TEMP”

& “COM” terminal respectively.

6. Maintenance

6-1. Battery replacement

When meter display the battery must be replace to maintain normal

operation.

1. Disconnect and remove all test probes from any live source and meter.

2. Open the battery cover on the bottom case by screwdriver.

3. Remove old battery and snap new one into battery holder

6-2. Fuse replacement

Replacing the defective fuse should the done according to the following

procedure.

1. Remove the test lead and turn off power.

2. Open the battery cover on the bottom.

3. Remove the defective fuse and insert a new fuse of the same size and

rating.

4. Replace the bottom case and reinstall all the screw.

6-3.Cleaning and Decontamination

The meter can be cleaned with soft clean cloth to remove any oil, grease or

grim. Do not use liquid solvent or detergent.

11

PROKIT’S INDUSTRIES CO., LTD

Certificate Number: TW98/12323QA

http//:www.prokits.com.tw

e-mail: pk@mail.prokits.com.tw

Loading...

Loading...