FP5000 Series

User Manual

FP5000-MM01-EN-PDF_02

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries (hereinafter, referred to as Schneider Electric) shall be responsible or liable for misuse

of the information that is contained herein. If you have any suggestions for improvements or

amendments or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

Copyright © 2017 Schneider Electric Japan Holdings Ltd. All Rights Reserved.

2

FP5000 Series User Manual

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Model Number Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certifications and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Federal Communication Commission Radio Frequency Interference

Statement - For U.S.A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hazardous Location Installation - For USA and Canada. . . . . . . . . . .

European (CE) Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KC Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Device Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Parts Identification and Functions . . . . . . . . . . . . . . . . 27

FP-5600TPD/5700TPD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Structural Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touch Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DVI-D Input Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

FP-5600TPD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FP-5700TPD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Installation and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Wiring Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the DC Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 USB Cable Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

USB Clamp (Type B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

13

14

15

16

18

19

21

22

24

25

28

29

32

33

34

35

37

38

39

40

41

42

45

48

50

54

54

61

62

64

66

67

67

3

6.4 Front USB Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening the Front USB Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

70

70

Chapter 7 System Specifications and Launcher. . . . . . . . . . . . . . 73

7.1 System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating System, Drivers, Utilities. . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Launcher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About the Launcher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PC Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

74

75

76

77

79

80

81

83

87

Chapter 8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Regular Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Periodic Check Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Installation Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

After-sales Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

90

91

92

93

94

95

4

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

FP5000 Series User Manual

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

5

6

About the Book

At a Glance

Document Scope

This manual describes how to use this product.

Validity Note

This documentation is valid for this product.

The technical characteristics of the device(s) described in this manual also appear online at

http://www.pro-face.com.

The characteristics presented in this manual should be the same as those that appear online. In

line with our policy of constant improvement we may revise content over time to improve clarity and

accuracy. In the event that you see a difference between the manual and online information, use

the online information as your reference.

Registered Trademarks

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States

and/or other countries.

Product names used in this manual may be the registered trademarks owned by the respective

proprietors.

FP5000 Series User Manual

Related Documents

You can download the manuals related to this product, such as the software manual, from our

support site at http://www.pro-face.com/trans/en/manual/1001.html.

Product Related Information

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Remove all power from the device before removing any covers or elements of the system, and

prior to installing or removing any accessories, hardware, or cables.

Unplug the power cable form both this product and the power supply.

Always use a properly rated voltage sensing device to confirm power is off.

Replace and secure all covers or elements of the system before applying power to this

product.

This product uses 12 to 24 Vdc power. Using any other level of power can damage both the

power supply and this product.

Failure to follow these instructions will result in death or serious injury.

Critical alarm indicators and system functions require independent an redundant protection

hardware and/or mechanical interlocks.

When you cycle power, wait at least 10 seconds after it has been turned off. If this product is

restarted too quickly, it may not operate correctly.

DANGER

7

In the event the screen cannot be properly read, for example, if the backlight is not functioning, it

may be difficult or impossible to identify a function. Functions that may present a hazard if not

immediately executed, such as a fuel shut-off, must be provided independently of this product. The

machine’s control system design must take into account the possibility of the backlight no longer

functioning and the operator being unable to control the machine or making mistakes in the control

of the machine.

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths

and, for certain critical control functions, provide a means to achieve a safe state during and

after a path failure. Examples of critical control functions are emergency stop and overtravel

stop, power outage and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this product must be individually and thoroughly tested for proper

operation before being placed into service.

The machine control system design must take into account the possibility of the backlight no

longer functioning and the operator being unable to control the machine, or making errors in

the control of the machine.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest

edition), "Safety Standards for Construction and Guide for Selection, Installation and Operation of

Adjustable-Speed Drive Systems" or their equivalent governing your particular location.

WARNING

UNINTENDED EQUIPMENT OPERATION

The application of this product requires expertise in the design and programming of control

systems. Only persons with such expertise should be allowed to program, install, alter, and apply

this product.

Follow all local and national safety standards.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

8

FP5000 Series User Manual

WARNING

UNINTENDED EQUIPMENT OPERATION

Do not use this product as the only means of control for critical system functions such as motor

start/stop or power control.

Do not use this equipment as the only notification device for critical alarms, such as device

overheating or overcurrent.

Use only the software provided with this product. If you use another software, please confirm

the operation and safety before use.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

The following characteristics are specific to the LCD panel and are considered normal behavior:

LCD screen may show unevenness in the brightness of certain images or may appear different

when seen from outside the specified viewing angle. Extended shadows, or crosstalk may also

appear on the sides of screen images.

LCD screen pixels may contain black and white colored spots and color display may seem to

have changed.

When the same image is displayed on the screen for a long period, an afterimage may appear

when the image is changed.

The panel brightness may decrease when used for a long time in an environment continuously

filled with inert gas. To prevent deterioration of panel brightness, regularly ventilate the panel.

For more information, please contact customer support.

http://www.pro-face.com/trans/en/manual/1015.html

NOTE: Change the screen image periodically and try not to display the same image for a long

period of time.

CAUTION

SERIOUS EYE AND SKIN INJURY

The liquid in the LCD panel contains an irritant:

Avoid direct skin contact with the liquid.

Wear gloves when you handle a broken or leaking unit.

Do not use sharp objects or tools in the vicinity of the LCD panel.

Handle the LCD panel carefully to prevent puncture, bursting, or cracking of the panel material.

If the panel is damaged and any liquid comes in contact with your skin, immediately rinse the

area with running water for at least 15 minutes. If the liquid gets in your eyes, immediately rinse

your eyes with running water for at least 15 minutes and consult a doctor.

Failure to follow these instructions can result in injury or equipment damage.

9

10

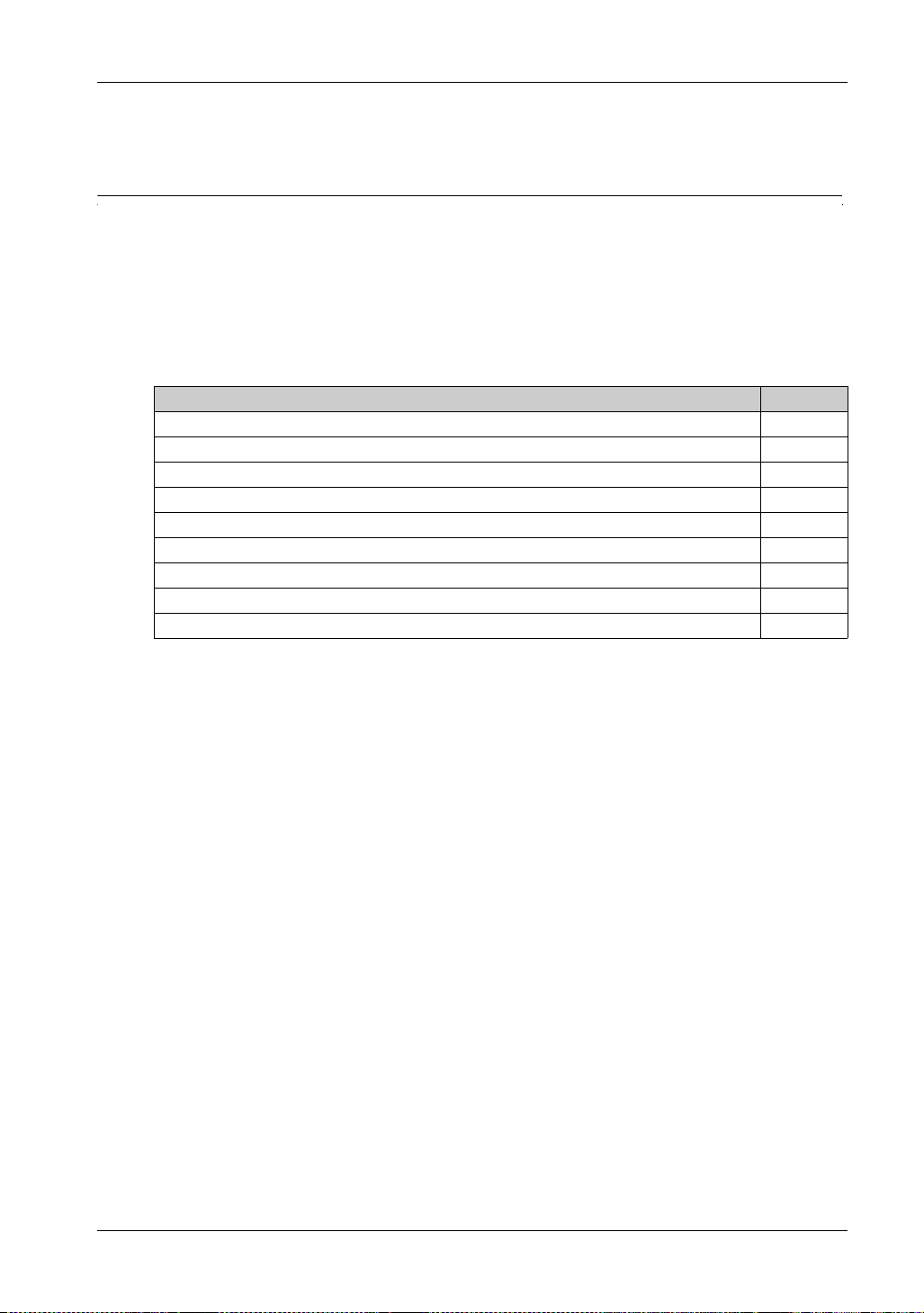

FP5000 Series User Manual

Overview

iDisplay_PF 12/2017

Overview

Chapter 1

Overview

Introduction

This chapter describes the panels of this product and general topics such as package contents and

standards.

What Is in This Chapter?

This chapter contains the following topics:

Model Number Configuration 12

Model Numbers 13

Package Contents 14

Revision 15

Certifications and Standards 16

Federal Communication Commission Radio Frequency Interference Statement - For U.S.A. 18

Hazardous Location Installation - For USA and Canada 19

European (CE) Compliance 21

KC Markings 22

FP5000 Series User Manual

Topic Page

11

Overview

Model Number Configuration

The following describes the configuration of model numbers.

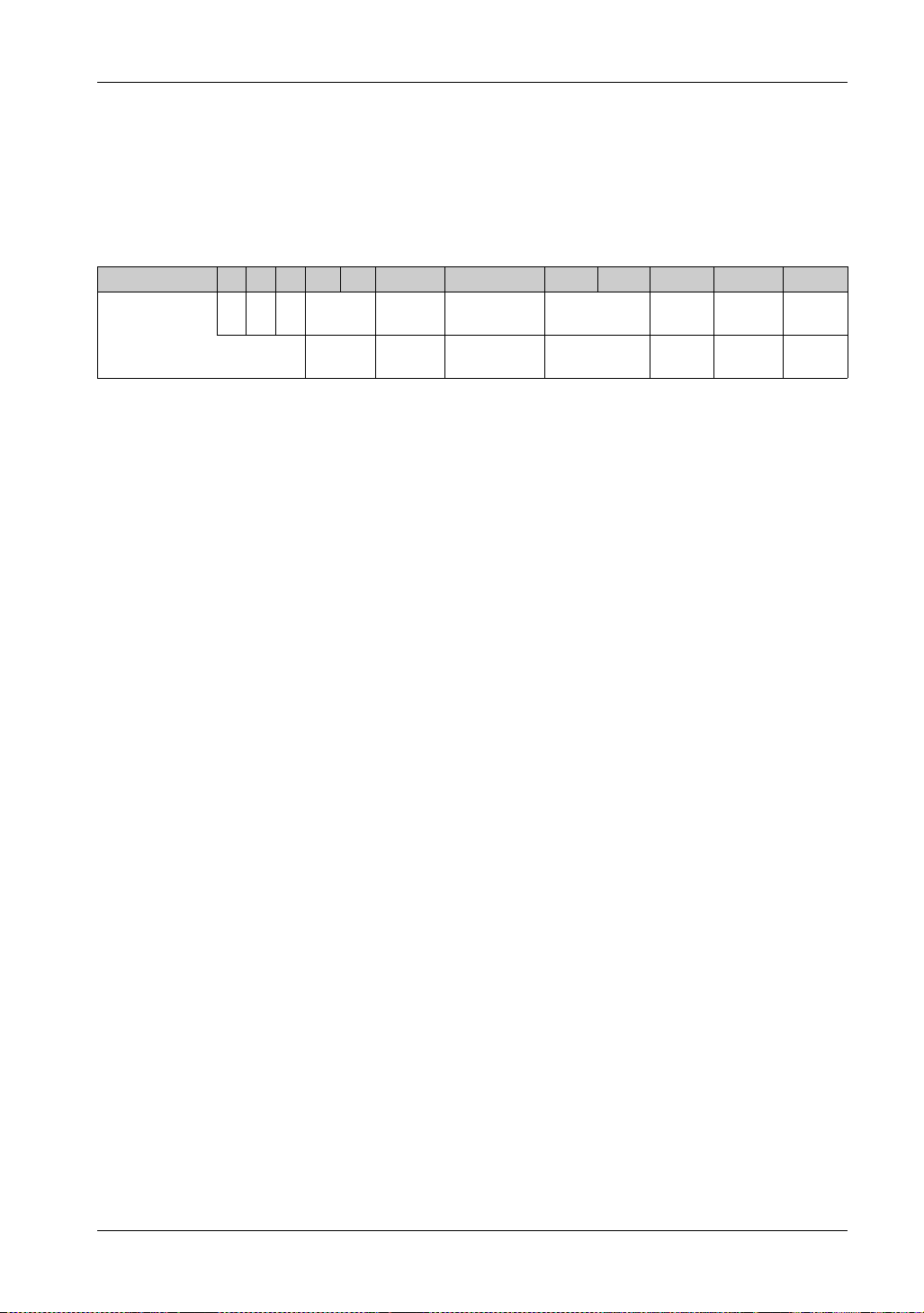

Digit position 1 2 3 4 5 6 7 8 9 10 11 12

P F X (model) (series) (size) (type) (LCD) (touch

FP 5 6: 12.1-inch

7: 15-inch

00: Standard T: TFT P: Multi D: DC

panel)

(power

supply)

12

Model Numbers

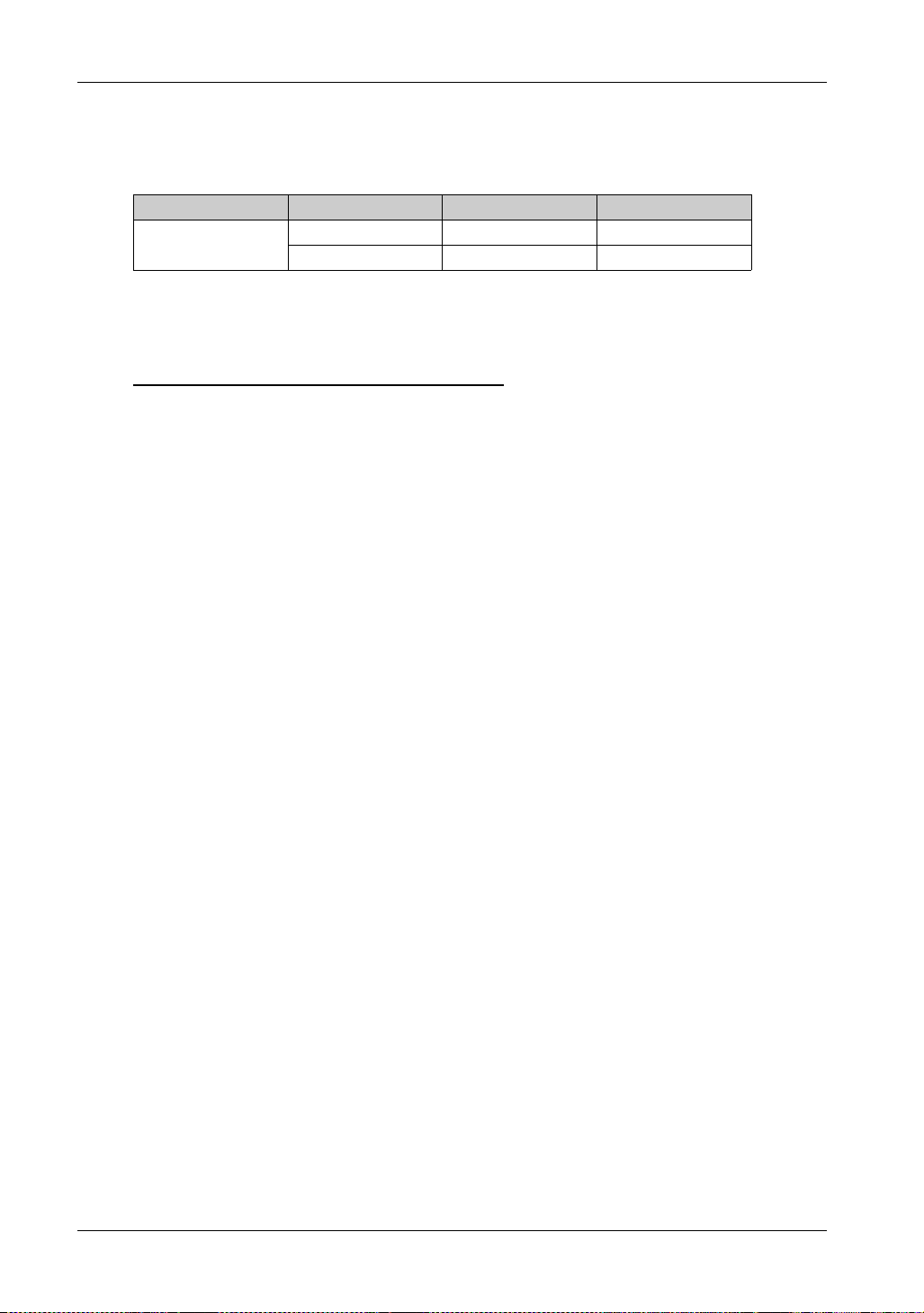

Series Display size Model names Model numbers

FP5000 Series 12.1-inch FP-5600TPD PFXFP5600TPD

Global Code

A global code is assigned to every Pro-face product as a universal model number. For more

information on product models and their matching global codes, please refer to the following URL.

http://www.pro-face.com/trans/en/manual/1003.html

FP5000 Series User Manual

15-inch FP-5700TPD PFXFP5700TPD

13

Overview

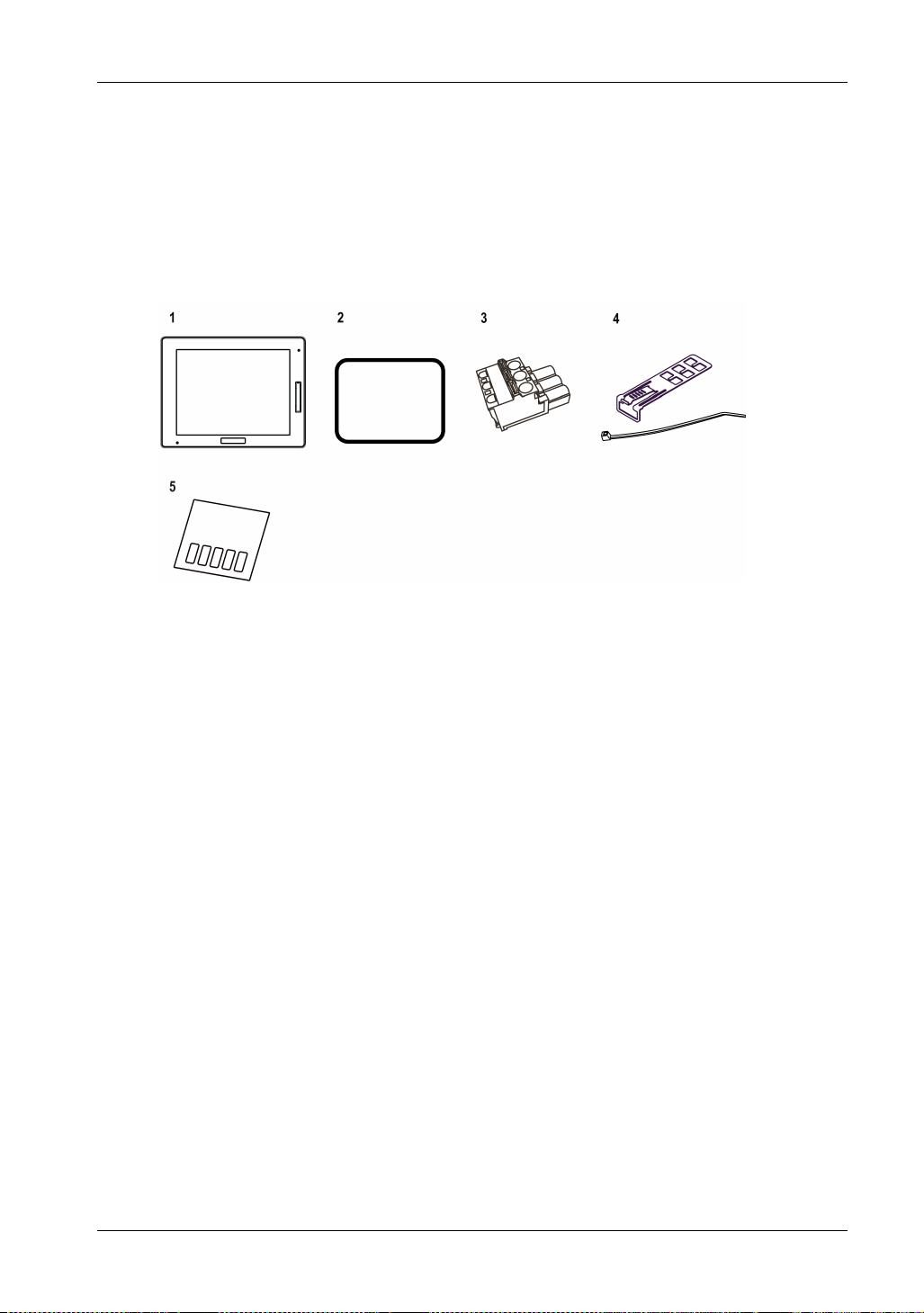

Package Contents

NOTE: This product has been carefully packed with special attention to quality. However, should

you find anything damaged or missing, please contact customer support immediately.

Verify all items listed here are present in your package:

1 FP5000 Series: 1

2 Installation gasket: 1 (attached to this product)

3 DC power supply connector (right angle): 1

4 USB clamp (Type B): 1 set (1 clip and 1 tie)

5 USB masking sticker (mini-B)

6 FP5000 Series Installation Guide: 1

7 Warning/Caution Information: 1

*1

: 1

*1 See Parts Identification and Functions (see page 27).

14

Revision

You can identify the product version (PV), revision level (RL), and the software version (SV) from

the product label.

FP5000 Series User Manual

15

Overview

Certifications and Standards

NOTE: Some products are not subject to certification and standards. And some products have not

received their certification and standards but are scheduled for assessment.

For information on certifications and standards, such as certified models and certificates, see the

product markings or the following URL:

http://www.pro-face.com/trans/en/manual/1002.html

Agency Certifications

Schneider Electric submitted this product for independent testing and qualification by third-party

listing agencies. These agencies have certified this product as meeting the following standards.

Underwriters Laboratories Inc., UL 508 and CSA C22.2 N

Underwriters Laboratories Inc., ANSI/ISA 12.12.01 and CSA C22.2 N

Equipment for Use in Class I, Division 2 Hazardous (Classified) Locations

IECEx/ATEX for use in zones 2/22

GOST-R or EAC certification (Russia, Belarus, Kazakhstan)

Germanischer Lloyd (GL)

Compliance Standards

Europe:

CE

Directive 2014/35/EU (Low Voltage)

Directive 2014/30/EU (EMC)

Programmable Controllers: EN 61131-2

EN61000-6-4

EN61000-6-2

Directive 94/9/EC (ATEX)

EN60079-0

EN60079-15

EN60079-31

Australia

RCM Mark

EN61000-6-4

Korea

KC Markings

KN11

KN61000-6-2

o

142, Industrial Control Equipment

o

213, Electrical

Qualifications Standards

Schneider Electric voluntarily tested this product to additional standards. The additional tests

performed, and the standards under which the tests were conducted, are specifically identified in

Structural Specifications (see page 35).

16

Hazardous Substances

This product is a device for use in factory systems. When using this product in a system, the system

should comply with the following standards in regards to the installation environment and handling:

WEEE, Directive 2012/19/EU

RoHS, Directive 2011/65/EU

RoHS China, Standard GB/T 26572

REACH regulation EC 1907/2006

FP5000 Series User Manual

17

Overview

Federal Communication Commission Radio Frequency Interference Statement For U.S.A.

FCC Radio Interference Information

This product has been tested and found to comply with the Federal Communications Commission

(FCC) limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a commercial, industrial

or business environment. This product generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause or be subject to

interference with radio communications. To minimize the possibility of electromagnetic interference

in your application, observe the following two rules:

Install and operate this product in such a manner that it does not radiate sufficient

electromagnetic energy to cause interference in nearby devices.

Install and test this product to ensure that the electromagnetic energy generated by nearby

devices does not interfere with the operation of this product.

WARNING

ELECTROMAGNETIC / RADIO INTERFERENCE

Electromagnetic radiation may disrupt the operation of this product leading to unintended

equipment operation. If electromagnetic interference is detected:

Increase the distance between this product and the interfering equipment.

Reorient this product and the interfering equipment.

Reroute power and communication lines to this product and the interfering equipment.

Connect this product and the interfering equipment to different power supplies.

Always use shielded cables when connecting this product to a peripheral device or another

computer.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate this product.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

18

Hazardous Location Installation - For USA and Canada

General

This product has been designed with the intention of meeting the requirements of Class I, Division

2 hazardous location application. Division 2 locations are those locations where ignitable

concentrations of flammable substances are normally confined, prevented by ventilation, or

present in an adjacent Class I, Division 1 location, but where an abnormal situation might result in

intermittent exposure to such ignitable concentrations.

While this product is a non-incendive device under ANSI/ISA 12.12.01 and CSA C22.2 N213, it is

not designed for, and should never be used within a Division 1 (normally hazardous) location.

This product is suitable for use in Class I, Division 2, Groups A, B, C, and D hazardous locations

or in non-hazardous locations. Before installing or using this product, confirm that the ANSI/ISA

12.12.01 or CSA22.2 N213 certification appears on the product labeling.

NOTE: Some products are not yet rated as suitable for use in hazardous locations. Always use

your product in conformance with the product labeling and this manual.

DANGER

POTENTIAL FOR EXPLOSION

Do not use this product in hazardous environments or locations other than Class I, Division2,

Group A, B, C, and D.

Substitution of any component may impair suitability for Class I, Division 2.

Do not connect or disconnect this product unless power has been switched off or the area is

known to be non-hazardous.

Always confirm that this product is suitable for use in hazardous locations by checking the

ANSI/ISA 12.12.01 or CSA C22.2 N213 certification appears on the product labeling.

Do not install any Pro-face or OEM components, equipment, or accessories unless these have

also been qualified as suitable for use in Class I, Division 2, Groups A, B, C, and D locations.

Do not attempt to install, operate, modify, maintain, service, or otherwise alter this product

except as permitted in this manual. Unpermitted actions may impair the suitability of this

product for Class I, Division 2 operation.

Failure to follow these instructions will result in death or serious injury.

FP5000 Series User Manual

DANGER

POTENTIAL FOR EXPLOSION

Always confirm the ANSI/ISA 12.12.01 or CSA C22.2 N213 hazardous location rating of your

device before installing or using it in a hazardous location.

To apply or remove the supply power from this product installed in a Class I, Division 2

hazardous location, you must either:

Use a switch located outside the hazardous environment, or;

Use a switch certified for Class I, Division 1 operation inside the hazardous area.

Do not connect or disconnect equipment unless power has been switched off or the area is

known to be non-hazardous. This applies to all connections including power, ground, serial,

parallel, and network connections.

Never use unshielded / ungrounded cables in hazardous locations.

Use only non-incendiary USB devices.

When enclosed, keep enclosure doors and openings closed at all times to avoid the

accumulation of foreign matter inside the workstation.

Failure to follow these instructions will result in death or serious injury.

19

Overview

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Remove all power from the device before removing any covers or elements of the system, and

prior to installing or removing any accessories, hardware, or cables.

Unplug the power cable form both this product and the power supply.

Always use a properly rated voltage sensing device to confirm power is off.

Replace and secure all covers or elements of the system before applying power to this

product.

Use only the specified voltage when operating this product. The DC unit is designed to use 12

to 24 Vdc. Always check whether your device is AC or DC powered before applying power.

Failure to follow these instructions will result in death or serious injury.

Make sure that this product is properly rated for the location. If the intended location does not

presently have a Class, Division and Group rating, then users should consult the appropriate

authorities having jurisdiction in order to determine the correct rating for that hazardous location.

Operation and Maintenance

The systems have been designed for compliance with relevant spark ignition tests.

DANGER

DANGER

POTENTIAL FOR EXPLOSION

In addition to the other instructions in this manual, observe the following rules when installing this

product in a hazardous location:

Wire the equipment in accordance with the National Electrical Code article 501.10 (B) for

Class I, Division 2 hazardous locations.

Install this product in an enclosure suitable for the specific application. IP65F, IP66F, IP67F,

Type 1, Type 4X [Indoor Use Only], or Type 13 enclosures are recommended even when not

required by regulations.

Failure to follow these instructions will result in death or serious injury.

NOTE: IP65F, IP66F and IP67F are not part of UL certification.

20

European (CE) Compliance

CE Compliance Note

The product described in this manual comply with the European Directives concerning

Electromagnetic Compatibility and Low Voltage (CE marking) when used as specified in the

relevant documentation, in application for which they are specifically intended, and in connection

with approved third-party products.

FP5000 Series User Manual

21

Overview

KC Markings

22

FP5000 Series User Manual

Device Connectivity

iDisplay_PF 12/2017

Device Connectivity

Chapter 2

Device Connectivity

Introduction

This chapter presents the equipment you can connect to this product.

What Is in This Chapter?

This chapter contains the following topics:

System Design 24

Accessories 25

FP5000 Series User Manual

Topic Page

23

Device Connectivity

System Design

24

*1 For image signal reception.

*2 Refer to Accessories (see page 25).

*3 You can also use a commercial type.

*4 For touch panel data transmission.

*5 When you connect a USB (Type B) interface to the host with a USB cable, you can use the front

USB (Type A) interface.

*6 You can use Pro-face products. Refer to our website (http://www.pro-face.com).

NOTE: When you connect more than one display to the host in the following combinations, a touch

operation on one display prevents touch operations on the other.

This Product + This Product

This Product + SP5000 Series Display Module

Be careful when you connect displays in any other combination, as touch operations become

possible from any of the displays.

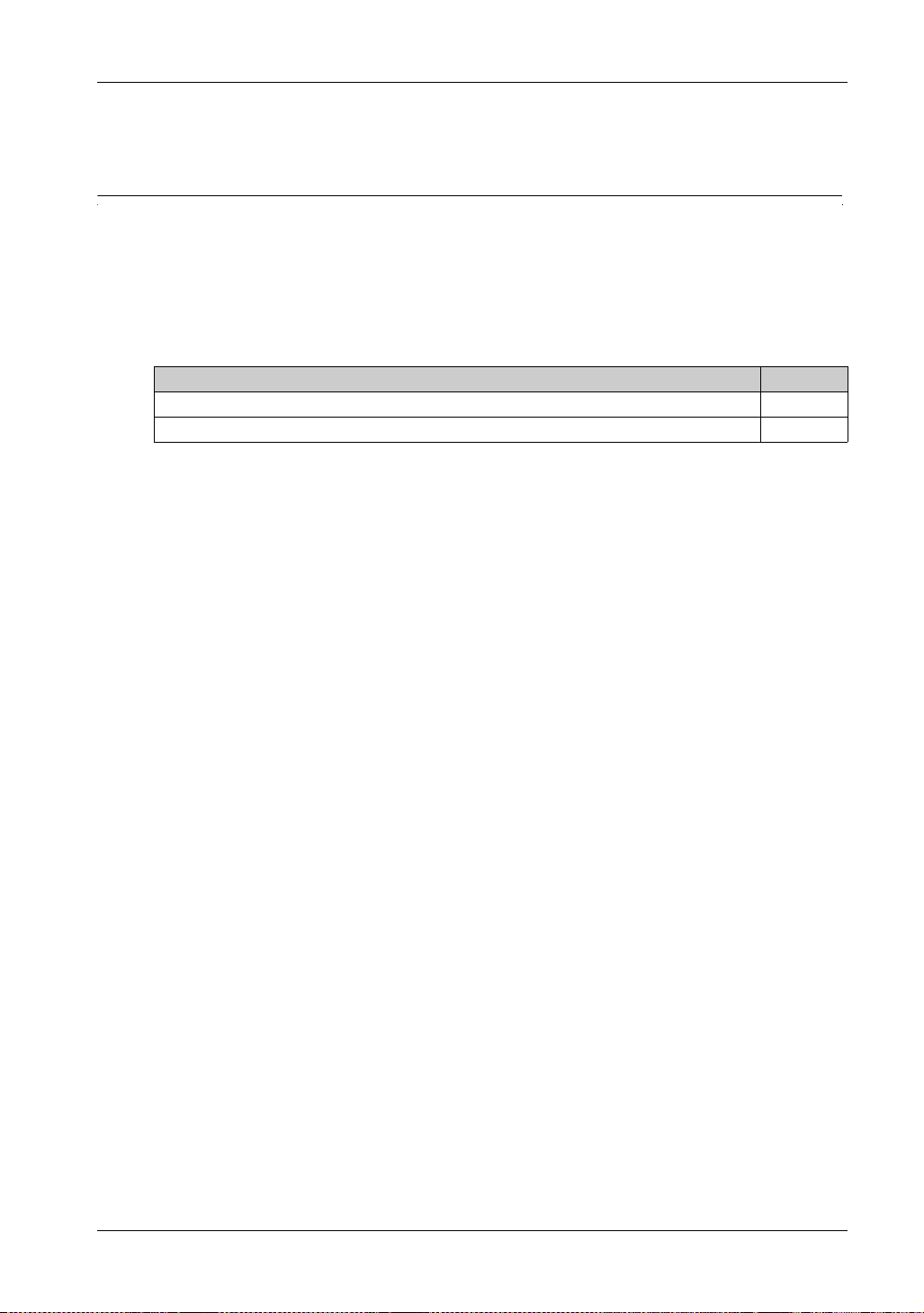

Accessories

Product name Product number Description

USB Cable (5 m)

USB (Type B) Interface

DVI-D Cable (5 m)

DVI-D Input Interface

12.1-inch Screen Protection Sheet CA7-DFS12-01 Disposable, dirt-resistant sheet for the display

15-inch Screen Protection Sheet CA3-DFS15-01

12.1-inch Environment Cover PFXZCDOP121 Environmental resistant cover for the display

15-inch Environment Cover PFXZCDOP151

Enhanced Front USB Cover (With

Screw)

DC Power Supply Connector

(Straight)

FP5000 Series User Manual

*1

FP-US00 Cable used for touch panel data transmission

between a host (USB Type A) and this product

(USB Type B).

*1

FP-DV01-50 DVI-D cable used to receive the image signal from

host.

DVI 1.0 compliant (DVI-D 24-pin plug) (5 m).

(5 sheets/set)

(1 piece)

PFXZCDCVUS1 Front USB cover with fixing screw, corresponding

to IP66F, IP67F, Type 1/4X Indoor Use Only/13 or

ATEX certifications (5 pieces/set)

PFXZCBCNDC1 Connector to connect DC power supply cables

(5 pcs/set)

*1 You can also use a commercial type.

Maintenance Accessories

Product name Product number Description

12.1-inch Installation Gasket PFXZCDWG121 Provides dust and moisture resistance when this

15-inch Installation Gasket PFXZCDWG151

DC Power Supply Connector

PFXZCBCNDC2 Right-angle connector to connect DC power

(Right-angle)

USB Clamp (Type B) PFXZFP5000USCLB1 Clamp to prevent disconnection of USB cable

25

product is installed into a solid panel (1 piece)

supply cables (5 pcs/set)

(USB/Type B, 1 port, 5 clamps/set).

Device Connectivity

26

FP5000 Series User Manual

Parts Identification and Functions

iDisplay_PF 12/2017

Parts Identification and Functions

Chapter 3

Parts Identification and Functions

Introduction

This chapter presents the part locations and functions.

What Is in This Chapter?

This chapter contains the following topics:

FP-5600TPD/5700TPD 28

LED Indications 29

FP5000 Series User Manual

Topic Page

27

Parts Identification and Functions

FP-5600TPD/5700TPD

NOTE: The figures below show FP-5600TPD.

Side FP-5600TPD/5700TPD

Front

Rear

28

Bottom

Part Name Description

A Brightness sensor Brightness sensor that automatically controls the

brightness of the backlight.

B Front USB cover USB (Type A) interface is located behind the front

USB cover.

C Front USB (Type A)

interface

D USB masking sticker

(mini-B)

E Status LED (see page 29)

F Power connector –

G DVI-D input interface DVI-D input interface

H USB (Type B) interface Conforms to USB 2.0 (Type B) x 1.

Conforms to USB 2.0 (Type A) x 1.

You cannot use the USB (mini-B) interface. Affix

the provided USB masking sticker.

LED Indications

Status LED

Color Indicator Description

Green ON In operation

Green/Orange Alternating Launcher is being configured (see page 81)

Orange Flashing Software is starting up

Red ON Power is turned ON

Orange/Red/Green Alternating

– OFF Power is turned OFF

*1 The product may be malfunctioning. Please contact customer support.

NOTE: If the screen does not display and the status LED is not in the LED fade state, this indicates

the backlight is burned out. When the screen does not display, always check the LED status and

do not perform touch operations.

FP5000 Series User Manual

LED fade Backlight is OFF (Standby Mode), or no video input

signal

Display unit error

*1

29

Loading...

Loading...