Page 1

®

P5000LJ Series Printers

User’s Manual

Page 2

Page 3

®

P5000LJ Series Printers

User’s Manual

Page 4

READ THIS SOFTWARE LICENSE AGREEMENT BEFORE

USING THIS PRINTE R

Software License Agreem ent

CAREFULLY READ THE FOLLOWING TERMS AND CONDITIONS

BEFORE USING THIS PRINTER. USING THIS PRINTER INDICATES

YOUR ACCEPTANCE OF THESE TERMS AND CONDITIONS. IF YOU DO

NOT AGREE TO THESE TERMS AND CONDITIONS, PROMPTLY RETURN

THE PRINTER AND ALL ACCOMPANYING HARDWARE AND WRITTEN

MATERIALS TO THE PLACE YOU OBTAINED THEM, AND YOUR MONEY

WILL BE REFUNDED.

Definitions.

“Software” shall mean the digitally encoded, machine-readable data and

program. The term “Software Product” includes the Software resident in the

printer and its documentation. The Software Product is licensed (not sold) to

you, and Printronix either owns or licenses from other vendors who own, all

copyright, trade secret, patent and other proprietary rights in the Software

Product.

License.

1. Authorized Use. You agree to accept a non-exclusive license to use the

Software resident in the printer solely for your own customary business or

personal purposes.

2. Restrictions.

a. To protect the proprietary rights of Printronix, you agree to maintain

the Software Product and other proprietary information concerning

the typefaces in strict confidence.

b. You agree not to duplicate or copy the Software Product.

c. You shall not sublicense, sell, lease, or otherwise transfer all or any

portion of the Software Product separate from the printer, without the

prior written consent of Printronix.

d. You may not modify or prepare derivative works of the Software

Product.

e. You may not transmit the Software Product over a network, by

telephone, or electronically using any means; or reverse engineer,

decompile or disassemble the Software.

f. You agree to keep confidential and use your best efforts to prevent

and protect the contents of the Software Product from unauthorized

disclosure or use.

3. Transfer. You may transfer the Software Product with the printer, but only

if the recipient agrees to accept the terms and conditions of this

Agreement. Your license is automatically terminated if you transfer the

Software Product and printer.

Page 5

Limited Software Product Warranty

Printronix warrants that for ninety (90) days after delivery, the Software will

perform in accordance with specifications published by Printronix. Printronix

does not warrant that the Software is free from all bugs, errors and omissions.

Remedy

Your exclusive remedy and the sole liability of Printronix in connection with

the Software is replacement of defective software with a copy of the same

version and revision lev el .

Disclaim er of Warra n ti e s and Limi tation of Re med i es

1. THE PARTIES AGREE THAT ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY ARE EXCLUDED.

Printronix does not warrant that the functions contained in the Software

will meet your requirements or that the operation of the Software will be

uninterrupted or error free.

Printronix reserves the right to make changes and/or improvements in the

Software without notice at any time.

2. IN NO EVENT WILL PRINTRONIX BE LIABLE FOR LOST PROFITS,

LOST DATA, BUSINESS INTERRUPTIONS, OR ANY OTHER DIRECT,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING

OUT OF THE USE OF OR INABILITY TO USE THIS PRODUCT, EVEN

IF PRINTRONIX HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES, OR ANY DAMAGES CAUSED BY THE ABUSE OR

MANIPULATION OF THE SOFTWARE. SOME STATES DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU.

3. Printronix will not be liable for any loss or damage caused by delay in

furnishing a Software Product or any other performance under this

Agreement.

4. Our entire liability and your exclusive remedies for our liability of any kind

(including liability for negligence except liability for personal injury caused

solely by our negligence) for the Software Product covered by this

Agreement and all other performance or nonperformance by us under or

related to this Agreement are limited to the remedies specified by this

Agreement.

5. California law governs this Agreement.

Termination of License Agreement

This License shall continue until terminated. This license may be terminated

by agreement between you and Printronix or by Printronix. If you fail to

comply with the terms of this License and such failure is not corrected within

thirty (30) days after notice. When this License is terminated, you shall return

to the place you obtained them, the printer and all copies of the Software and

documentation.

Page 6

U.S. Government Restricted Rights

Use, duplication or disclosure by the Government is subject to restrictions as

set forth in the Rights in Technical Data and Computer Software clause at

FAR 242.227-7013, subdivision (b) (3) (ii) or subparagraph (c) (1) (ii), as

appropriate. Further use, duplication or disclosure is subject to restrictions

applicable to restricted rights software as set forth in FAR 52.227-19 (c) (2).

Acknowledgment of Terms and Conditions

YOU ACKNOWLEDGE TH AT YOU HAVE READ THIS AGREEMENT,

UNDERSTAND IT, AND AGREE TO BE BOUND BY ITS TERMS AND

CONDITIONS. NEITHER PARTY SHALL BE BOUND BY ANY STATEMENT

OR REPRESENTATION NOT CONTAINED IN THIS AGREEMENT. NO

CHANGE IN THIS AGREEMENT IS EFFECTIVE UNLESS WRITTEN AND

SIGNED BY PROPERLY AUTHORIZED REPRESENTATIVES OF EACH

PARTY. BY USING THIS PRINTER, YOU AGREE TO ACCEPT THE TERMS

AND CONDITIONS OF THIS AGREEMENT.

Printronix makes no representations or warranties of any kind regarding this

material, including, but not limited to, implied warranties of merchantability

and fitness for a particular purpose. Printronix shall not be held responsible

for errors contained herein or any omissions from this material or for any

damages, whether direct, indirect, incidental or consequential, in connection

with the furnishing, distribution, performance or use of this material. The

information in this manual is subject to change without notice.

This document contains proprietary information protected by copyright. No

part of this document may be reproduced, copied, translated or incorporated

in any other material in any form or by any means, whether manual, graphic,

electronic, mechanical or otherwise, without the prior written consent of

Printronix.

COPYRIGHT © 2000, 2003 PRINTRONIX, INC.

All rights reserved.

Page 7

T rademark Acknowledgments

Hewlett-Packard, HP, HP-UX, Bi-Tronics, HP in a circle, Hewlett Packard,

PCL and HP rounded rectangle are registered trademarks of Hewlett-Packard

Company.

AIX, AS/400, IBM, NetView, Proprinter and OS/2 are registered trademarks,

and AFP, Intelligent Printer Data Stream, IPDS, Print Services Facility, and

PSF are trademarks of International Business Machines Corporation.

IBM and Proprinter are registered trademarks, and PC-DOS is a trademark of

International Business Machines Corporation.

Portions of this manual used by permission of Wyndham Technologies, Inc.

Copyright © 1991-1999 Wyndham Technologies Inc.

ANSI is a registered trademark of American National Standards Institute, Inc.

Centronics is a registered trademark of Genicom Corporation.

DEC is a registered trademark of Digital Equipment Corporation.

DG/UX is a registered trademark of Data General Corporation.

EIA is a registered trademark of the Electronic Industries Association.

ENERGY STAR is a registered trademark of the United States

Environmental Protection Agency. As an

Packard has determined that this product meets the

guidelines for energy efficiency.

ENERGY STAR

ENERGY STAR

®

Partner, Hewlett-

®

Epson is a registered trademark of Seiko Epson Corporation.

Ethernet is a trademark of Xerox Corporation.

Frontier Technologies and SuperTCP are trademarks or registered

trademarks of Frontier Technologies Corporation.

FTP Software and OnNet are trademarks or registered trademarks of FTP

Software, Inc.

IGP, PGL, LinePrinter Plus, Network Interface Card (NIC) and Printronix are

registered trademarks, and RibbonMinder is a trademark of Printronix, Inc.

IRIX is a registered trademark of Silicon Graphics, Inc.

LINUX is a registered trademark of Linus Torvalds.

Magnum and QMS are registered trademarks, and Code V is a trademark of

Quality Micro Systems, Inc.

Microsoft, MS, MS-DOS, Windows, and Windows NT are registered

trademarks of Microsoft Corporation.

PKZIP and PKUNZIP are registered trademarks of PKWARE, Inc.

NetManage and Chameleon are trademarks or registered trademarks of

NetManage, Inc.

Netscape and Netscape Navigator are registered trademarks, and the

Netscape Communications logo is a trademark of Netscape Communications

Corporation.

Page 8

Novell and NetWare are registered trademarks of Novell, Inc.

PostScript is a registered trademark of Adobe Systems Inc.

Solaris is a registered trademark of Sun Microsystems, Inc.

Ultrix is a registered trademark of Digital Equipment Corporation.

Unix is a registered trademark of X/Open Company Limited.

This product uses Intellifont Scalable typefaces and Intellifont technology.

Intellifont is a registered trademark of Agfa Division, Miles Incorporated

(Agfa).

CG, Garth Graphic, Intellifont, and Type Director are registered trademarks,

and Shannon and CG Triumvirate are trademarks of Agfa Division, Miles

Incorporated (Agfa). CG Bodoni, CG Century Schoolbook, CG Goudy Old

Style, CG Melliza, Microstyle, CG Omega, and CG Palacio are products of

Agfa Corporation. CG Times, based on Times New Roman under license

from The Monotype Corporation Plc is a product of Agfa.

Univers is a registered trademark of Linotype AG and/or its subsidiaries.

Letraset is a registered trademark, and Aachen, Revue and University Roman

are trademarks of Esselte Pendaflex Corporation.

Futura is a registered trademark of Fundición Tipográfica Neufville, S.A.

ITC Avant Garde Gothic, ITC Benguiat, ITC Bookman, ITC Century, ITC

Cheltenham, ITC Clearface, ITC Galliard, ITC Korinna, ITC Lubalin Graph,

ITC Souvenir, ITC Tiepolo, ITC Zapf Chancery, and ITC Zapf Dingbats are

registered trademarks of International Typeface Corporation.

Albertus, Gill Sans, and Times New Roman are registered trademarks, and

Monotype Baskerville is a trademark of The Monotype Corporation Plc,

registered in the U.S. Pat. and TM office and elsewhere.

Hiroshige and Marigold are trademarks of AlphaOmega Typography, Inc.

Page 9

Table Of Contents

1 Introduction..........................................................17

About This Manual .................. ...... ....... ...... ....................................... ....17

Warnings, Cautions, And Notes.......................................................17

Printing Conventions Used In This Manual ......................................17

Related Documents..........................................................................18

Printer Overview....................................................................................19

The Printronix P5000LJ Series Printer Family .................................19

Taking Care Of Your Printer.............................................................21

Standard Features ...........................................................................21

Graphics Options .............................................................................23

Protocols And Emulations................................................................23

Line Matrix Printing ..........................................................................24

Printing Speed..................................................................................25

Network Interface Card (NIC)................................................................26

What Special Features Are Available?.............................................26

NIC...................................................................................................27

2 Downloading Function Code In

P5000LJ Series Printers......................................29

Introduction............................................................................................29

Downloading In A Nutshell...............................................................29

Preparation For Downloading... ....... ...... ....... ...... ....... ...... .................30

Copying Function Code To Your Computer ..........................................31

Loading Function Code To Flash Memory In The Printer .....................32

Installing Printer Emulations....................... ....... ...... ....... ...... ....... ...... ....32

Downloading Software Through the Serial

or Parallel Port .................................................................................33

Downloading Software Through the

Network Interface Card (NIC)...........................................................37

Downloading Optional Font Files to Flash Memory..........................39

Page 10

Table of Contents

3 Configuring The Printer ........................................45

Overview ...............................................................................................45

Configuring The Printer .........................................................................45

Operating Modes..............................................................................48

The Configurations...........................................................................48

Locking And Unlocking The ENTER Key.........................................48

Changing And Saving Parameter Settings.......................................49

Factory Default Configuration Values ..............................................50

Changing Parameters ...........................................................................54

Example ...........................................................................................54

Saving Your New Configuration.......................................................56

Printing The Current Configuration ..................................................58

Loading Configuration Values..........................................................60

The Power-Up Configuration............................................................62

Deleting Configurations....................................................................64

Protecting Your Configurations ........................................................66

Configuring NIC.....................................................................................67

Connecting To The Network ............................................................67

Configuration Setup .........................................................................67

Configuration Using The Printer Control Panel................................68

Configuration Alternatives................................................................69

4 The Configuration Menus.....................................73

Overview ...............................................................................................73

Configuration Main Menu......................................................................74

Config. Control Menu ............................................................................77

Active Emulation Menu..........................................................................79

Emulation Menu ....................................................................................80

PCL-II Emulation..............................................................................81

LP Plus Emulation............................................................................86

P-Series Emulation ..........................................................................90

Proprinter XL Emulation ..... ....... ...... ...... ....... ...... ....... .......................93

Epson FX Emulation ........................................................................95

Serial Matrix Emulation ....................................................................97

P-Series XQ Emulation ..................................................................100

IGP/PGL Emulation........................................................................102

IGP/VGL (Code V) Emulation ........................................................107

Maint/Misc Menu .................................................................................114

Page 11

Table of Contents

Host Interface Menu............................................................................115

Bi-Tronics Submenu.......................................................................116

Centronics (Parallel) Submenu ......................................................117

Serial Submenu..............................................................................119

Ethernet Submenu .........................................................................122

Auto Switching Submenu...............................................................123

Ethernet Params Menu .......................................................................125

Printer Control Menu ...........................................................................127

Diagnostics Menu................................................................................129

RibbonMinder......................................................................................132

RibbonMinder Menu.......................................................................133

5 Approaches To Network Printing ....................... 137

Overview .............................................................................................137

Peer To Peer Networks..................................................................137

Print Job Servers............................................................................138

Logical Printer Architecture............................................................138

6 Embedded NIC Web Page.................................141

Overview .............................................................................................141

Configuration.......................................................................................142

Configuration Network.........................................................................143

TCP/IP Network .............................................................................143

Windows Network (NetBIOS TCP/IP) ............................................144

Novell Network...............................................................................144

Configuration Print Path ......................................................................145

Destination Settings .............................. ....... ...... ....... ...... ....... ...... ..145

Current Model Settings ..................................................................146

Current Log Path Settings..............................................................147

Configuration - Print Model..................................................................147

Configuration - Log Path .....................................................................148

Configuration - I/O Port .......................................................................149

Parallel Port (PRN).........................................................................149

Configuration – SNMP.........................................................................150

Configuration - Administration.............................................................154

System Information ........................................................................154

Passwords......................................................................................154

Configuration - System........................................................................155

Status ..................................................................................................155

Status - I/O Port...................................................................................155

Status - Network..................................................................................155

Page 12

Table of Contents

7 TCP/IP Configuration .........................................157

TCP/IP NIC Configuration ...................................................................157

Before You Begin...........................................................................157

Creating Aliases.............................................................................158

Methods For Setting TCP/IP Values ..............................................159

Assign TCP/IP Values....................................................................160

Using BOOTP ................................................................................163

8 HP e3000/NIC Configuration..............................165

Overview .............................................................................................165

HP e3000 / MPE-XL / MPE / iX: Host Configuration ...........................165

NIC Configuration Verification.............................................................168

Methods Of Adjusting Paper Position..................................................170

Method 1 ........................................................................................170

Method 2 ........................................................................................171

Using Page Level Recovery On P5000LJ Printers..............................171

HP e3000 / MPE-XL / MPE / iX: DTC Configuration ...........................173

MPE-XL / MPE / iX Typical Configuration ......................................173

9 Windows Configuration ......................................175

Overview .............................................................................................175

Windows Environment Description......................................................175

Windows NIC Configuration ................................................................176

Mandatory ......................................................................................176

Optional..........................................................................................176

Communicating Across Routers............ ....... ...... ....... ...... ....... ...... ..177

Changing Workgroup Names.........................................................177

Changing Destination Names ........................................................178

Windows Host Configuration ...............................................................179

Windows NT 3.51 Host Setup........................................................179

Windows NT 4.0 Host Setup ..........................................................180

Windows 95/98/ME Host Setup .....................................................186

Windows 3.1 Host Setup................................................................187

Windows Troubleshooting Tips ...........................................................187

NIC Cannot Be Found On The Network.........................................188

HTML Configuration Forms Will Not Display..................................188

Errors Occur When Defining An LPR Printer .................................188

Cannot Browse The NIC On The Network.....................................189

Printer Errors When Printing Or No Output....................................189

TCP/IP Access Problem.................................................................189

Page 13

Table of Contents

Web Browser/HTTP Problem.........................................................191

Windows NT 4.0 or 2000 Host Setup Problems.............................191

Installing Microsoft TCP/IP Printing. ...... ....................................... ..191

10 Unix Configuration ............................................. 193

Overview .............................................................................................193

Unix Environment Description ..................................................... ...... ..194

Unix NIC Configuration............................... ....... ...... ....... ...... ....... ........195

Mandatory ......................................................................................195

Optional..........................................................................................195

Communicating Across Routers...... ...... ....... ...... ....... ...... ....... ........195

Unix Host Configuration .......... ...... ....... ...... ....... ...... ....... ...... ....... ...... ..196

Printing Setup On HP-UX...............................................................196

Printing Setup On Sys V ...............................................................198

LPR/LPD Printing Setup On BSD Systems

(Sun 4.x, DEC‚ Ultrix‚, Free BSD, etc.)...........................................200

FTP Printing ...................................................................................201

Remote Shell Printing ........ ...... ....... ...... ....... ...... ....... .....................20 1

Unix Troubleshooting Tips............. ....... ...... ....................................... ..202

Nothing Prints.................................................................................202

Stair-stepped Output ......................................................................203

No Form Feed Or Extra Page Comes Out.....................................203

11 Novell Configuration........................................... 205

Overview .............................................................................................205

Novell Environment Description ..........................................................206

Novell NIC Configuration.....................................................................206

Using HTML Forms........................................................................207

Novell Host Configuration....................................................................208

NetWare Version 3.x PSERVER Setup..........................................208

NetWare Version 3.x RPRINTER Setup ........................................210

NetWare Version 4.x and 5.x PSERVER Setup.............................211

NetWare Version 4.x and 5.x RPRINTER Setup............................213

Novell Troubleshooting Tips................................................................215

NetWare 3.x - No PSERVER Connection......................................215

NetWare 4.x and 5.x - No PSERVER Connection .........................216

Page 14

Table of Contents

12 Novell Configuration For 10/100Base-T

Interfaces............................................................217

Overview .............................................................................................217

Novell NIC Configuration (10/100Base-T)...........................................217

Preferred File Server (NDS & Bindery) ..........................................218

Setting Password Security (NDS & Bindery)..................................221

Adjusting Polling Time (NDS & Bindery) ........................................222

Changing The Print Server Name (NDS & Bindery) ......................223

Changing The Frame Type (NDS & Bindery).................................225

Changing The Print Server Mode (NDS & Bindery) .......................226

Setting The NIC Context (NDS) .....................................................227

Setting The Print Server Preferred NDS Tree (NDS).....................228

Novell Host Configuration (10/100Base-T)..........................................229

NDS PSERVER Setup (Netware 4.x and 5.x)................................229

Bindery PSERVER Setup (Netware 3.x, 4.x, and 5.x) ...................231

Referencing A Bindery Queue In NDS

(Netware 3.x, 4.x, and 5.x) .............................................................231

RPRINTER/NPRINTER Setup (Netware 3.x, 4.x, and 5.x)............232

NPDS Configuration (Netware 4.11 and Above) .................................234

Troubleshooting (10/100Base-T).........................................................236

PSERVER Setup............................................................................236

RPRINTER/NPRINTER Setup........ ...... ....... ...... ....... ...... ....... ...... ..239

Printing Related..............................................................................240

13 Commands.........................................................243

Command Shell Overview...................................................................243

Access Methods.............................................................................243

Main Command Shell Prefixes.......................................................243

Getting Command Help................................ ...... ....... ...... ....... ...... ..243

Complete Command List.....................................................................244

Store Commands ...........................................................................244

Set Commands ..............................................................................247

List Commands .................................................. ....... ...... ....... ...... ..254

Debug Commands .........................................................................255

Miscellaneous Commands . ....................................... ...... ....... ...... ..256

Page 15

Table of Contents

14 Extra Features ................................................... 259

NIC Security ........................................................................................259

Users And Passwords............................................... ...... ....... ........259

TCP Access Lists..................... ....... ...... ....... ...... ....... .....................26 1

Printer Monitoring And Logging...........................................................262

Printer And Print Job Monitoring ....................................................262

Printer Logging Through Logpaths.................................................263

NIC Naming Schemes.........................................................................264

15 Interfaces ........................................................... 265

Overview .............................................................................................265

Centronics Parallel Interface ...............................................................266

Centronics Interface Signals ..........................................................267

Centronics Parallel Interface Configuration....................................267

Bi-Tronics Parallel Interface ................................................................268

Operating Modes............................................................................268

The Negotiation Phase...................................................................269

Signals ...........................................................................................269

RS-232 And RS-422 Serial Interfaces.................................................271

RS-232 And RS-422 Serial Interface Signals.................................272

RS-232 And RS-422 Serial Interface Protocol ...............................273

RS-232 And RS-422 Serial Interface Error Handling.....................273

RS-232 And RS-422 Serial Interface Configuration.......................274

16 Routine Service And Diagnostics.......................275

Routine Service...................................................................................275

Exterior Cleaning............................................................................275

Interior Cleaning.............................................................................275

Diagnosing Problems ........................... ...... ....................................... ..278

Printer Self-Tests ...........................................................................278

Printing A Hex Dump......................................................................280

Fault Messages..............................................................................282

A Printer Specifications And Regulatory

Information......................................................... 291

Ribbon Specifications..........................................................................291

Genuine Printronix P5000LJ Supplies.................................................293

Printer Dimensions ..............................................................................294

Environmental Characteristics.............................................................294

Electrical Characteristics.....................................................................295

Material Safety Data Sheets................................................................296

Communication Notices .... ...... ...... ....... ...... ....... ...... ............................297

Page 16

Table of Contents

B Paper Specifications And Forms Design............301

Introduction..........................................................................................301

General Paper Specifications..............................................................301

Paper Guidelines.................................................................................303

Terms And Definitions....................................................................303

Environmental Considerations .......................................................305

Form Types....................................................................................305

Form Weight...................................................................................305

Form Thickness..............................................................................305

Form Evenness..............................................................................305

Tractor Pin Engagement ................................................................305

Methods Of Forms Attachment ................................. ...... ....... ...... ..306

Chaff Content.................................................................................307

Form Design Checklist ........................................................................308

Summary.............................................................................................310

Storage And Handling ....................................................................310

C Standard ASCII Character Set...........................313

D Monitoring Prin te r s .................. .. ... .............. .. ... ...315

Implementing Remote Management Software (RMS).........................315

Agent/Manager Model....................................................................315

MIB.................................................................................................315

SNMP.............................................................................................316

Monitoring Tools..................................................................................317

Monitoring With AIX NetView/6000................................................317

Monitoring With Web JetAdmin......................................................317

OS/2 TCP/IP ..................................................................................317

Setting The SNMP Community Name............................................317

Page 17

1 Introduction

About This Manual

This manual explains how to configure and perform routine service on the

Printronix

®

P5000LJ Series printers for maximum efficiency.

Warnings, Cautions, And Not es

Read and comply with all information highlighted under special headings:

Warning Warning messages call attention to situations that could hurt you or

damage the equipment.

Caution Conditions that could damage the printer or related equipment.

Note A note gives you helpful hints about printer operation and maintenance.

Printing Conventions Used In This Manual

• UPPERCASE print indicates control panel keys.

Example: Press the CLEAR key, then press the ON LINE key.

• Quotation marks (“ ”) indicate messages you see on the Liquid Crystal

Display (LCD).

Example: Press the ON LINE key. “OFFLINE” appears on the LCD.

• The + (plus) symbol represents key combinations.

Example: “Press

(DOWN) key at the same time.

=

+ >” means to press the = (UP) key and the >

17

Page 18

Chapter 1 About This Manual

• Command syntax and examples are formatted as follows:

• The Courier font in boldface indicates commands that you type:

Example: $ ping ftp.HP.com

• Regular Courier font indicates displayed results:

Example: ftp.HP.com is alive

• Variable values are shown in italics in command syntax, output, and

in text.

Example: ping ipname

Example: ipname is alive

Related Documents

Following is a list of related documentation shipped with every Printronix

P5000LJ printer.

• P5000LJ Series Printers Installation Instructions, Cabinet and Pedestal

Models — Explains in a step-by-step process how to set up the printer for

operation.

• P5000LJ Series Printers Quick Reference Guide — Describes the keys

on the control panel and provides qui ck refere nc e informa t io n on dail y

printer operations such as loading paper and replacing ribbons. Italian,

French, German, and Spanish are included.

Note This manual and the reference manuals listed below are located on the

software starter CD shipped with your P5000LJ printer.

• P5000LJ Series Printers PCL-II/LinePrinter Plus Technical Reference

Manual — Describes the host control codes and character sets for the

LinePrinter Plus

®

and PCL®-II emulations.

• P5000LJ Series Printers IGP/VGL Technical Reference Manual —

Explains how to write graphics programs using the optional QMS

V™ Printronix

the user to create and store forms; generate logos, bar codes, and

expanded characters; create other graphics; and merge graphics with

alphanumeric data as a document is printed.

®

emulation. This graphics programming language allows

®

Code

• P5000LJ Series Printers IGP/PGL Technical Reference Manual —

Explains how to write graphics programs using the optional PGL

Printronix IGP

the user to create and store forms; generate logos, bar codes, and

expanded characters; create graphic images; and merge graphics with

alphanumeric data as a document is printed.

®

emulation. This graphics programming language allows

®

18

Page 19

Printer Overview

The Printronix P5000L J Series Printe r Family

The P5000LJ series of line matrix printers consists of 500, 1000, and 1500

lines per minute (lpm) models packaged in various configurations. All of the

models offer software versatility and the latest refinements in line matrix

printing technology. The model numbers indicate printing speed and physical

configuration:

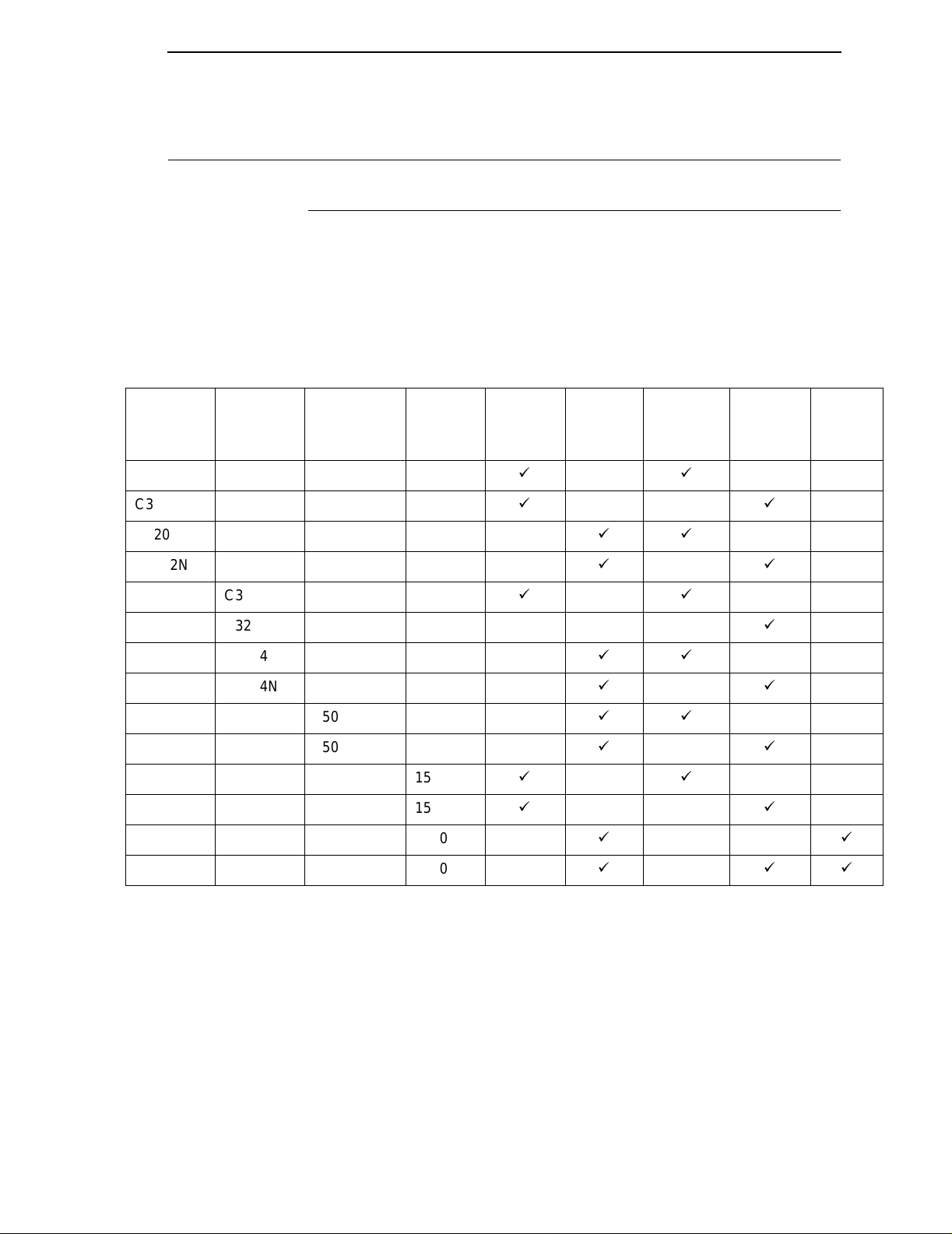

Table 1. The P5000LJ Series Printer Family

The Printronix P5000LJ Series Printer Family

Model

Number

US

C3201D C3201E 500P 500 lpm

C3201ND C3201NE 500P 500 lpm

C3202D C3202E 500Q 500 lpm

C3202ND C3202NE 500Q 500 lpm

C3203D C3203E 1000P 1000 lpm

C3203ND C3203NE 1000P 1000 lpm

C3204D C3204E 1000Q 1000 lpm

C3204ND C3204NE 1000Q 1000 lpm

C3205D C3205E 1500Q 1500 lpm

C3205ND C3205NE 1500Q 1500 lpm

C3206D C3206E 1500P 1500 lpm

C3206ND C3206NE 1500P 1500 lpm

C5640D C5640E 1500QS 1500 lpm

Model

Number

Europe

Nameplate

Print

Speed

Serial/

Pedestal Cabinet

Parallel

Interface

Serial/

Ethernet

Interface

Power

Stacker

C5640ND C5640NE 1500QS 1500 lpm

Most line matrix printers have specialized architectures which enable the

printer to emulate, or behave like, another printer. These specialized

architectures are restricted. The P5000LJ printer, however, introduces an

open architecture concept that is not available on any other line matrix printer.

The P5000LJ printer offers the standard emulation of Hewlett-Packard's

Printer Control Language, PCL Level II, to allow easy online programming

capabilities and compatibility with Hewlett-Packard systems. The Printronix

P5000LJ Series printers are fully compatible with HP LineJet and LP Series

printers.

19

Page 20

Chapter 1 Printer Overview

Additionally, the P5000LJ printer offers the following three emulations as part

of its LinePrinter Plus grouping: Proprinter

®

III XL, Epson® FX-1050, and

Serial Matrix P-Series. No matter what emulation is configured, your printer is

very easy to use. The message display and indicator on the control panel

communicate with you directly and clearly. You can select every function on

your printer at the control panel, or you can send commands from the host

computer.

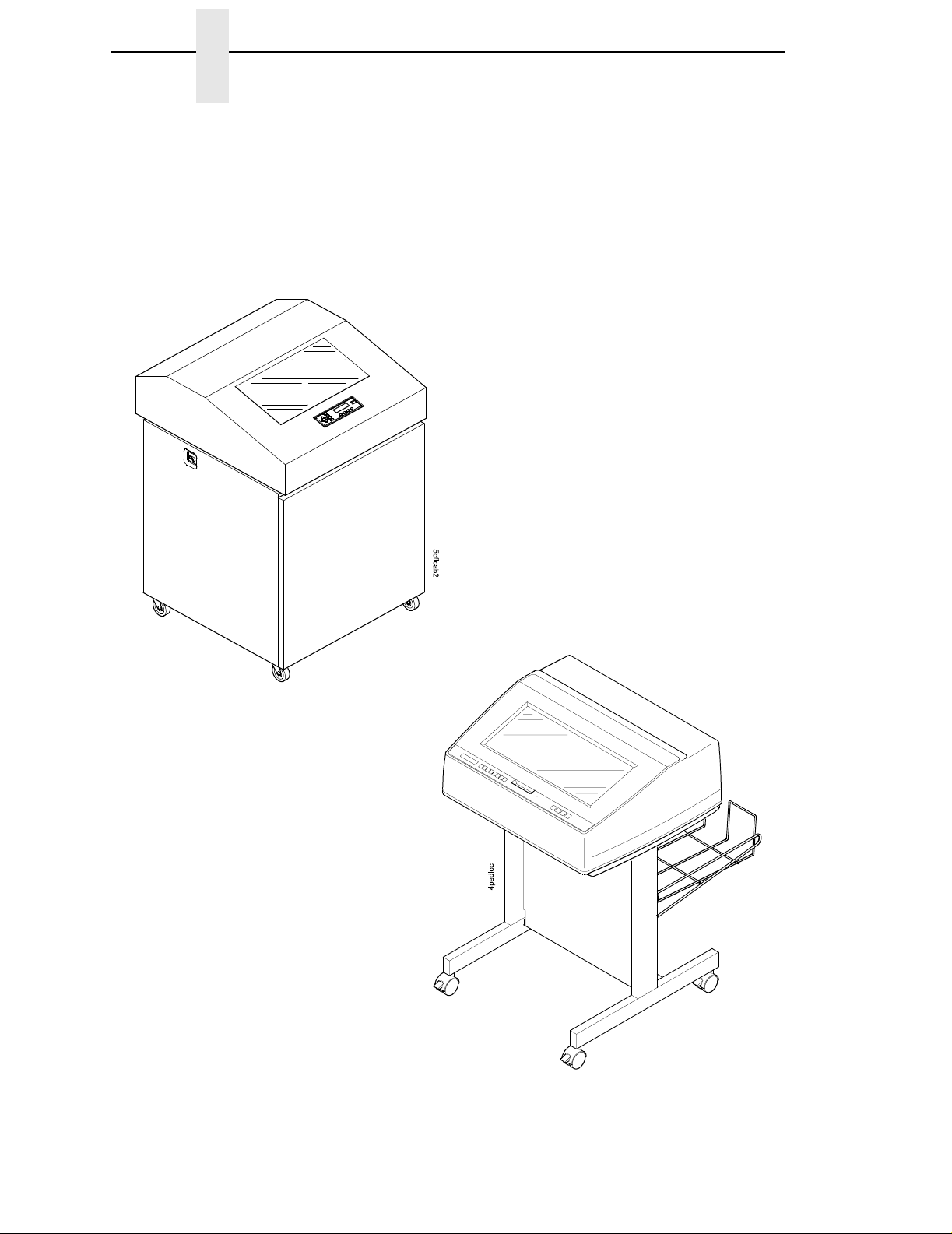

500Q

1000Q

1500Q

1500QS

20

P5000LJ

500P

1000P

1500P

Figure 1. The P5000LJ Printers

Page 21

Taking Care Of Your Printer

Taking Care Of Your Printer

Your printer will produce high quality print jobs if it is well taken care of.

Periodic cleaning, handling the printer properly, and using the correct printer

supplies, such as paper and ribbons, will ensure optimum performance.

Chapter 16 explains how to clean the printer, and printer supplies are listed in

Appendix A.

Whenever it is necessary to service the printer, remember these important

maintenance concepts:

• Use only the ribbons specified in Appendix A. Use of incorrect ribbons

can cause ink migration problems, degraded print quality, and expensive

damage to the printer.

• Incorrect closure of the forms thickness lever can cause smearing,

degraded print quality, paper jams, and damage to the platen and shuttle

assembly. Never close the forms thickness lever too tightly.

• Excessive printing outside of the boundaries of the paper will degrade

print quality and cause hammer bank damage. Never print outside of the

paper width.

St andard Fea tures

All of the printers offer a wide range of horizontal and vertical dot densities,

operate quietly, and can load an emulation very easily. Other features are

specified in the following secti ons.

Host Computer Interfaces

The following host computer interface choices are available:

• Bi-Tronics

• RS-232 serial interface

• RS-422 serial interface

• Centronics

• Ethernet™ (optional on 500P and 500Q only)

Printer Emulations

The following printer emulations (or protocols) are selectable at the control

panel:

• HP

• LP Plus, which consists of:

®

Printronix P-Series

Epson FX-1050

IBM

®

®

PCL-II (the default)

®

Proprinter III XL

• QMS (optional)

• PGL (optional)

Each emulation provides a different set of configuration menus, control codes,

and character sets.

21

Page 22

Chapter 1 Printer Overview

Output Control

Depending on the active emulation, the printers have the following output

control features:

• Four modes for printing text:

1. Correspondence (High Density)

2. Data Processing (DP) (Standard Density)

3. Sparse (high speed) (Sparse Density)

4. OCR A and OCR B

• Selectable forms length and width

• Character attribute specification:

1. Selectable pitch: normal, expanded, and compressed

2. Emphasized (shadow) printing

3. Automatic underlining and overscoring

4. Superscript and subscript printing

5. Double high and wide printing

• Resident multinational cha ra cte r sets and bar code s

Graphics and V ertical Form atting

Several graphics and vertical formatting features are available:

• Built-in graphics genera tors :

1. IBM Proprinter III XL bit-image graphics

2. Epson FX-1050 dot graphics mode

3. P-Series Plot

4. PCL raster graphics

• Programmable electronic vertical formatting provides rapid vertical paper

movement to specified lines for printing repetitive and continuous forms.

You can choose from the following methods:

1. Vertical tabbing in Proprinter III XL and Epson FX emulation modes

2. Electronic Vertical Format Unit (EVFU) in P-Series emulation mode

3. PCL vertical forms control (VFC)

Built-in Diagnostic Tools

The following diagnostic tools are provided with the printer:

• Comprehensive diagnostic self-tests permanently stored in the printer

• Configuration printout

22

• Data stream hex code printout

• Symbol set printout

Page 23

Graphics Options

Graphics Options

The PGL and VGL emulations allow you to create and store forms; generate

logos, bar codes, and expanded characters; and create other graphics.

Alphanumerics and bar code data are added as the form is printed.

Protocols And Emulations

A protocol is a set of rules governing the exchange of information between the

printer and its host computer. These rules consist of codes which manipulate

and print data and allow for machine-to-machine communication. A printer

and its host computer must use the same protocol.

Most impact printers use single ASCII character codes to print text, numbers,

and punctuation marks. Some characters, both singularly and in groups of two

or more, are defined as control codes. Control codes instruct the printer to

perform specific functions, such as underlining text, printing subscripts,

setting page margins, etc. The main difference between most printer

protocols is in the characters used to create control codes and the ways in

which these characters are formatted.

When the printer executes the character and control codes of a particular

printer protocol, it is “emulating” that printer. For example, if the printer uses

the Proprinter III XL protocol, it is emulating an IBM Proprinter III XL printer; if

the printer is using the Epson FX-1050 printer protocol, it is in Epson FX-1050

emulation mode. As used in this manual, “protocol” and “emulation” mean the

same thing.

23

Page 24

Chapter 1 Printer Overview

Line Matrix Printing

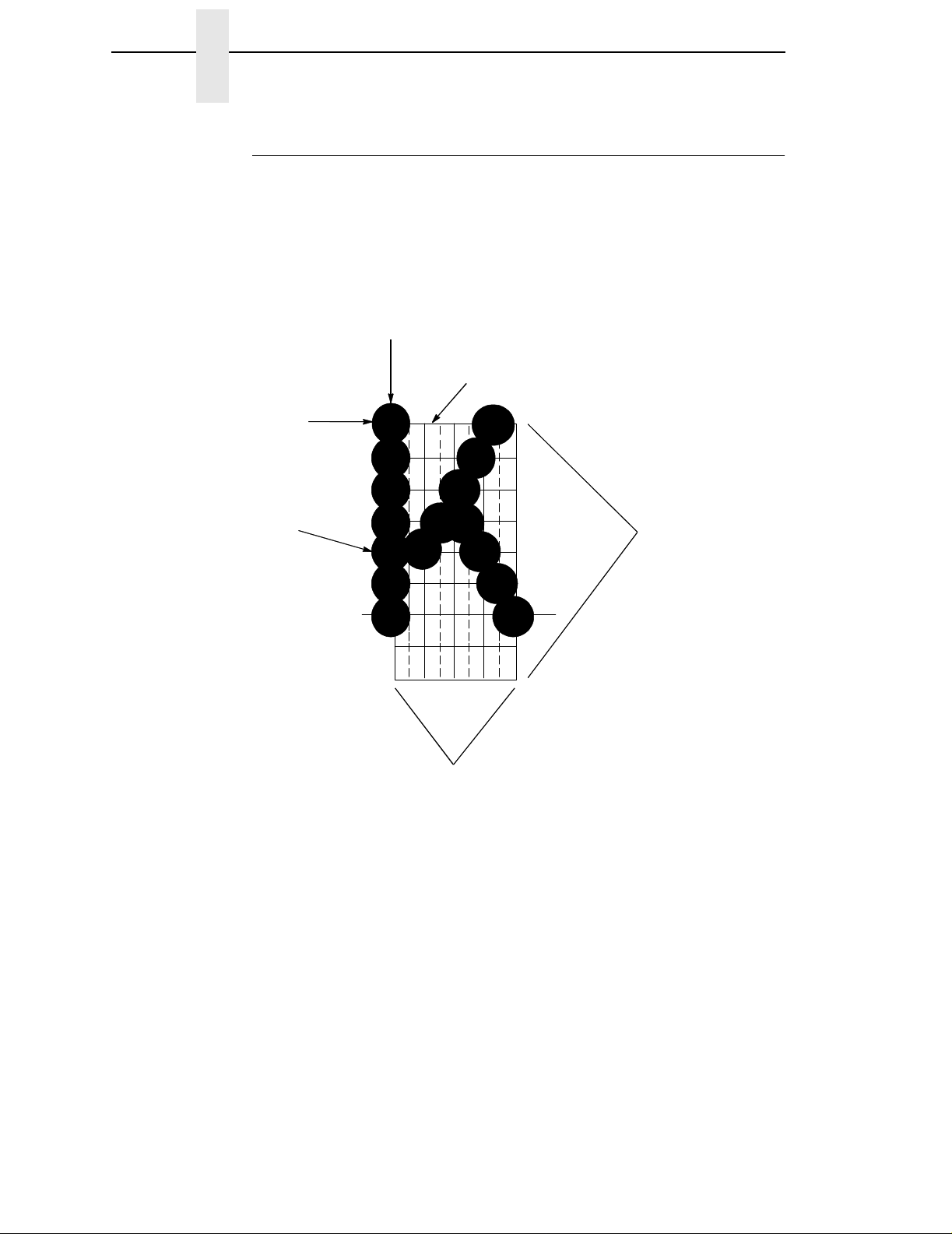

Your printer is an impact printer; it creates characters by printing ink dots on

paper. The dots are printed on an invisible matrix mapped in printer memory

(see Figure 2). Dot impressions are made by an array of steel hammers

mounted on a rapidly oscillating shuttle. The hammers strike the paper

through a moving ink ribbon.

Dot Row

Dot Column

Matrix visible only to

the printer

Ink dots formed by

hammer tips.

Serial matrix printers use a moving printhead with pins to form single

characters sequentially along the printed line. Unlike serial matrix printers, the

P5000LJ printer is a line matrix printer. Line matrix printers divide every

printable line into horizontal dot rows, then print a dot row of the entire line at

every lateral sweep of the shuttle.

During each sweep, hammers are activated to print dots at the required

positions in the dot row. When the shuttle reache s the end of a sweep, it

reverses direction, the paper advances one dot row, and the hammers print

the next row of dots as the shuttle sweeps in the opposite direction, as shown

in Figure 3.

Character Row

Character Column

Figure 2. Dot Matrix Character Formation

24

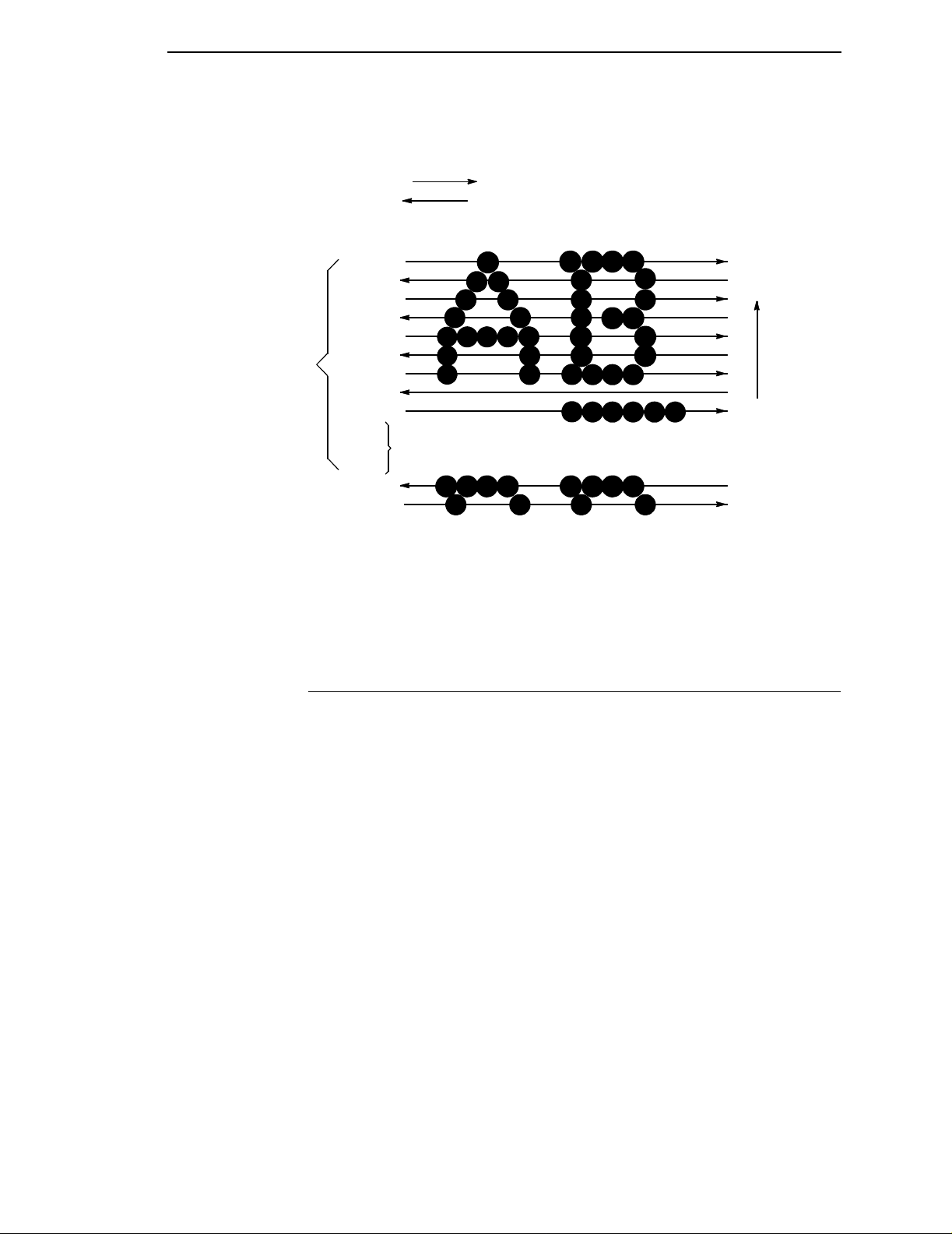

After a line of characters is printed, the paper advances to the first dot row of

the next print line. This creates a number of blank rows between lines of

characters, depending on the print mode and line spacing you selected.

Page 25

One

Text

Line

Dot

Row Start

1

2

3

4

5

6

7

8

*

9

**

10

11

Number of rows is determined by line spacing.

n

1

2

Printing Speed

Direction of Shuttle Movement

Paper

Feed

Direction

This row is used only for lowercase descenders.

*

This row is used for underlining and lowercase descenders.

**

Figure 3. Dot Matrix Line Printing

Printing Speed

The speed at which text prints is measured in lines per minute (lpm). This

speed is directly proportional to the number of dot rows required to produce a

character line, regardless of the number of characters in the line. More dot

rows are required to print lowercase characters with descenders;

consequently, those character lines print at a fractionally lower rate.

The printer also prints dot-addressable graphic images. The speed at which

graphics are plotted is measured in inches per minute (ipm). Unidirectional

plotting produces slightly better print quality and takes about twice as long as

bidirectional plotting. You can select either plotting mode from the control

panel.

Printing and plotting rates also vary according to the print mode you select.

Print mode refers to the way you instruct the printer to create characters. If,

for example, you select standard quality (data processing) mode, the printer

uses more dot rows to form characters than if you choose Sparse (high

speed) mode. Character formation and print speed are faster in Sparse mode,

because the printer prints fewer dot rows to form characters. Vertical dot

density is a factor in printing speed.

Nominal printing rates are charted in Appendix A.

25

Page 26

Chapter 1 Network Interface Card (NIC)

Network Interface Card (NIC)

Network Interface Card (NIC) allows you to attach printers on a local area

network (LAN) rather than attaching them directly to a host system. Following

simple configuration steps, these peripherals can be simultaneously shared

with users on the network whether you are using TCP/IP, NetBIOS over TCP/

IP, or IPX (Novell

NIC contains a network interface card to attach itself and the printer to the

network. This Ethernet™ 10/100Base-T interface connector is what allows the

printer to communicate with the network, and the interface itself has a number

of options, status indicators, and switches which are described in “NIC” on

page 27.

What Special Features Are Available?

NIC offers an extensive list of features including:

• built-in HTML forms for easy cross-platform configuration

).

• availability of printer manager software

• a detailed and easy-to-use command shell built in to the firmware

• multi-level configuration security through passwords, permission levels,

and access lists

• Wide Area Network (WAN) communication access

• numerous printer logging methods (e.g., automatic email) to record

printer errors and usage

• remote management through HTML forms, Telnet sessions, rsh/

rcmd/remsh

commands, SNMP, and pre-defined log methods

• extensive built-in troubleshooting tools

• built-in telnet and ping clients

• configurable memory usage by disab ling pr otoc ols and destination

services

• multiple destinations/queues for versatile printer manipulation and distinct

print setups

• header and trailer strings to instruct printers on font, pitch, printing, etc.

• flexible naming conventions

• automatic network connection and frame type sensing

• simultaneous printing across all I/O ports and all supported protocols

26

• multiple network protocol support

Page 27

NIC

NIC

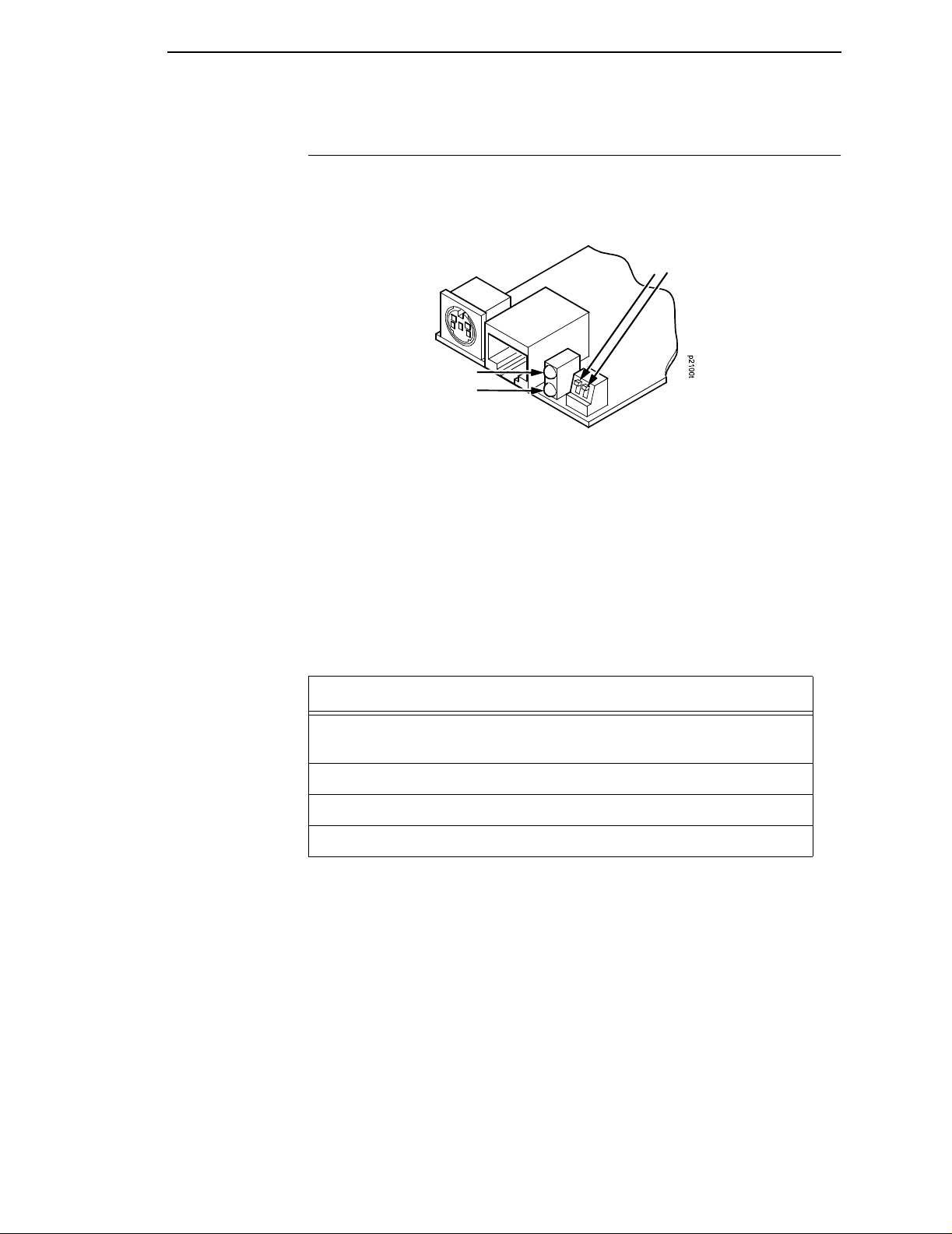

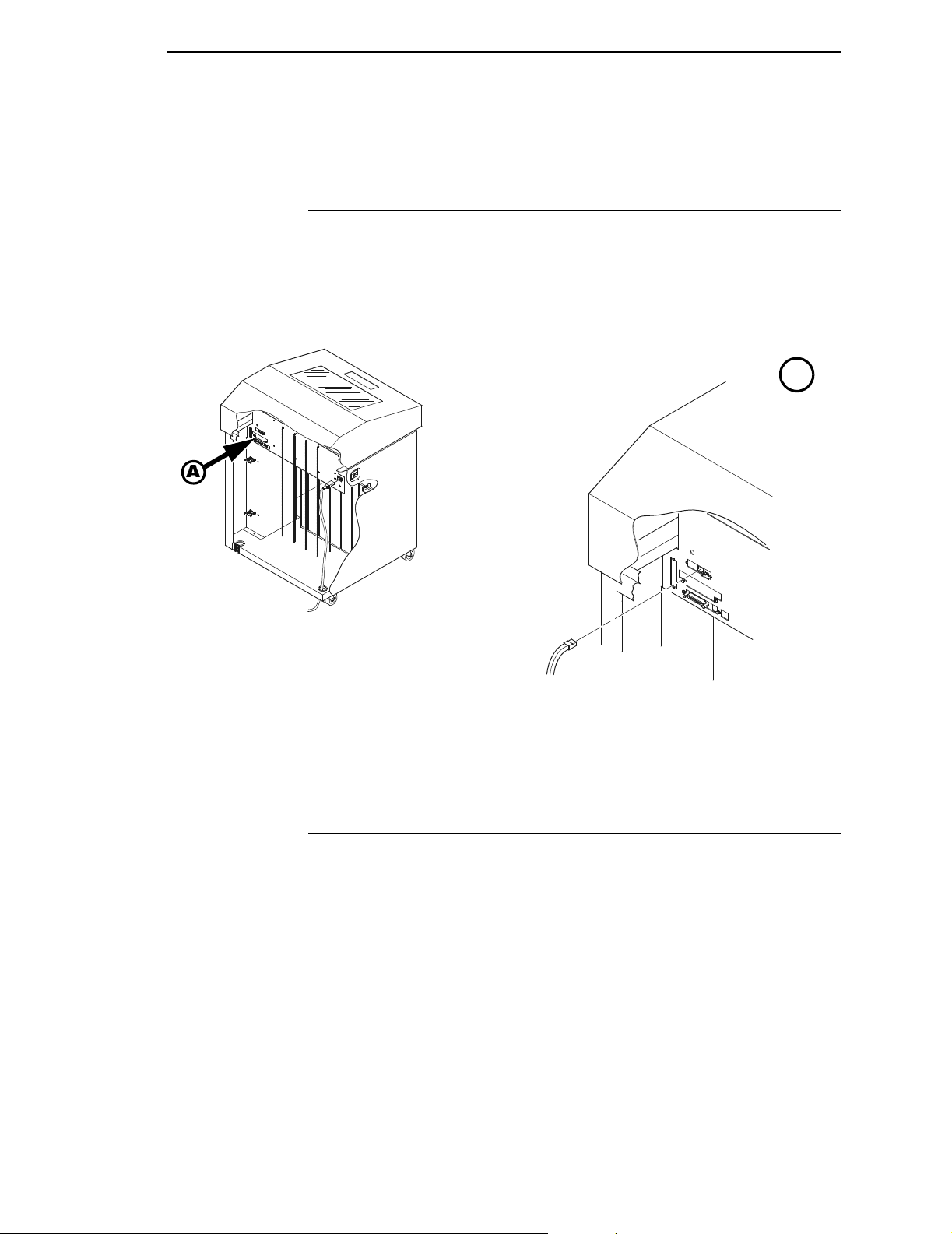

The NIC at the rear of the printer has two indicator lights and two dipswitches,

as shown in Figure 4.

Dipswitches

Shown in OFF

2

1

(default) position

STAT (System Status)

NET (Data to Network)

Figure 4. Status Indicator Lights and Dipswitches

Run and Auto Reset Modes

Run Mode is the normal operating state of NIC. Auto Reset mode is entered

when the watchdog timer is triggered and the Print Server resets itself. In

either mode, the STAT LED flashes at a varying rate, depending on whether

the unit IP address is configured. The Run Mode and Auto Reset Mode

indicator descriptions are given in Table 2.

Table 2. Indicator Modes

STAT Indication Description

OFF flashes on once per second Normal Mode, IP address

configured

OFF flashes on twice per second IP address not configured

ON flashes off once per second Download (MOS)

ON flashes off twice per second Error

27

Page 28

Chapter 1 Network Interface Card (NIC)

Network Indicator

The NET LED displays the status of the network link. When the NET LED is

on, link integrity is confirmed. The NET LED flashes off for 1/3 second when a

data packet is being transferred. When the NET LED is off, the network

connection has been severed.

Dipswitches

On the back of the interface, you will find a small window where you can

access two dipswitches labeled 1 and 2 (see Figure 4). The functions of the

dipswitches are explained in Table 3.

Table 3. Dipswitch Functions

Dipswitch

12

Comments

OFF OFF Normal operation. With both dipswitches in the OFF

position, the NIC boots up using the settings in flash

memory rather than the default settings.

ON OFF Factory default settings. With the dipswitches in this

configuration, the NIC boots up and erases all settings

stored in flash memory except the Ethernet address

and key value.

OFF ON Default IP. With the dipswitches in this configuration,

the NIC boots up with factory default settings.

However, the stored settings in flash memory are

intact. Setting dipswitch 2 to ON does not clear any

settings stored in flash memory ; inste ad, it boots the

unit with the IP settings in flash memory temporarily

ignored.

ON ON Reserved. This dipswitch setting is not for customer

use.

28

Page 29

2 Downloading Function

Introduction

Code In P5000LJ Series

Printers

Downloading the function code is equivalent to updating firmware in the

printer. This chapter explains how to load function code into P5000LJ printers.

You must download function code when:

• you require upgraded firmware for maintenance or other reasons;

• the CMX controller board is replaced;

• the flash memory SIMM is replaced;

• the NIC is installed or replaced;

• you need different emulation software or buy the VGL or PGL graphics

option after the printer is installed.

Downloading In A Nutshell

Updating the function code in a P5000LJ printer consists of three tasks:

1. Obtaining the appropriate download file and loading it into the PC or

laptop you will use to download the code into the printer.

2. Obtaining the appropriate interface cable if necessary.

3. Printing all saved configurations in the printer, making the function code

upgrade, and restoring your saved printer configurations.

29

Page 30

Chapter 2 Introduction

Preparation For Downloading

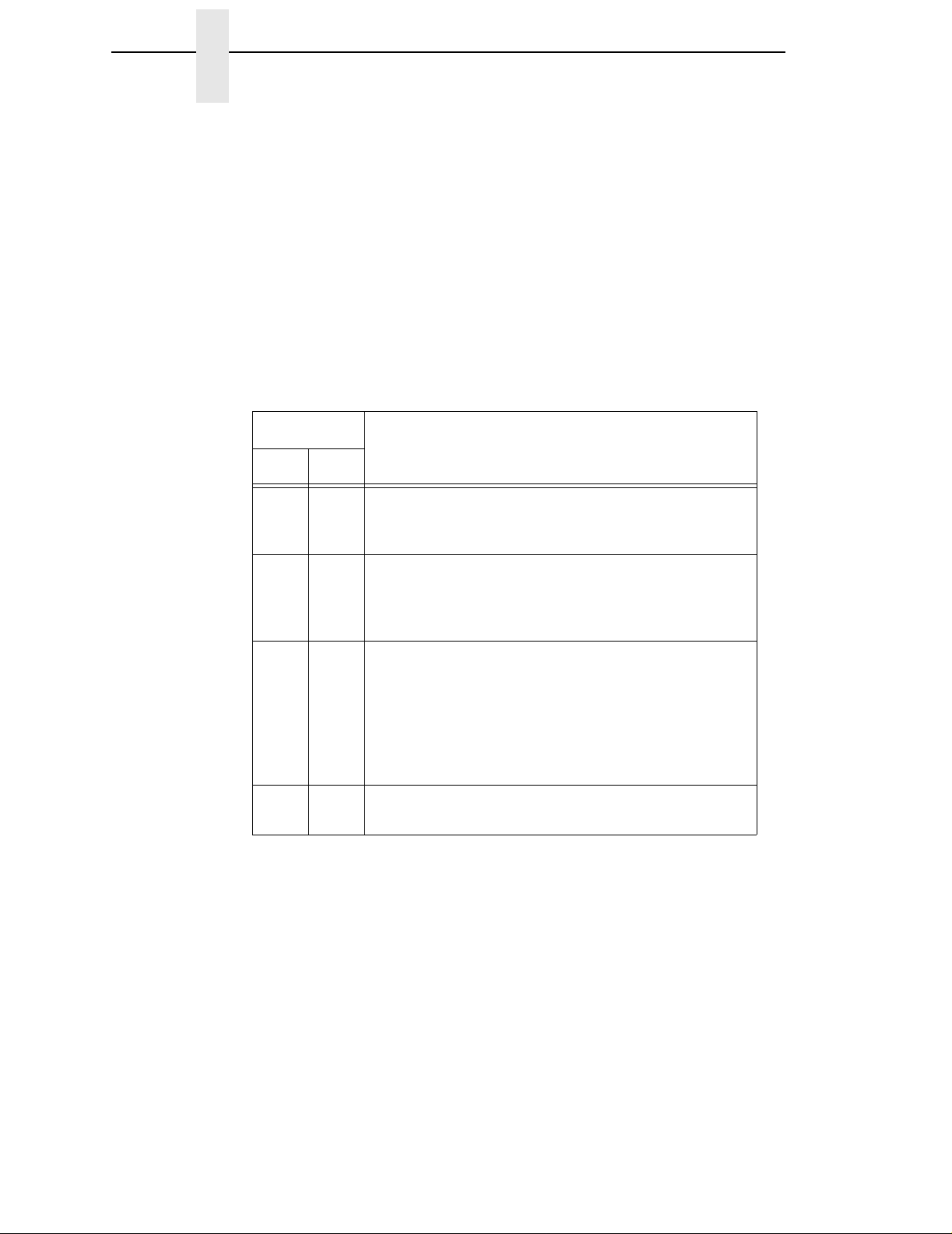

There are several function code files available for the P5000LJ printers. The

file you use depends on the printer emulation in use.

Note Always upgrade the function code to the latest version available that meets

the minimum flash memory and DRAM SIMM sizes listed in Table 4.

To verify what function code is already installed, observe the control panel

display when the printer is online. If a configuration printout is available, the

function code file version is printed at the top of the configuration printout on

the line that begins “Program File Version.” For example, if the line is

“Program File Version (2.07P Part No. 356351), the number “356351” is the

function code download file active at the time the configuration printout was

generated.

You can download function code from a networked PC or laptop computer

which contains the function code. If the printer has the NIC installed, the

function code must be updated via the network to successfully update the NIC

firmware. Loading function code via the network is done using the Printronix

Remote Management (RMS) software available on the PrintNet Enterprise

CD or using the file transfer protocol (ftp) procedure.

30

Page 31

Preparation For Downloading

Table 4. P5000LJ Series Printers Function Code Chart

Description

If Serial or Parallel Connected

Printers using

PCL-II emulation

Printers using

VGL emulation

Printers using

PGL emulation

If Network Connected

Printers using

PCL-II emulation

Printers using

VGL emulation

Printers using

PGL emulation

* ONLINE - SERL / PCL II or ONLINE - SERL / LP PLUS if serial port is the selected host interface

1 If the internal network card is not installed or was removed, download via the parallel or serial port. If the printer

Function Code is downloaded with the NIC removed, or a NIC card is added to the printer after downloading, the

Ethernet port will not function with RMS. In this case, do the following:

1. Press the up/down/right/left arrow keys simultaneously. Printer displays “FACTORY / Printer Management.”

2. Press the down arrow key. Printer displays “Diagnostic Port.”

3. Press the down arrow key. Printer displays “Debug Serial.”

4. Press the right arrow key. Printer displays “Debug Ethernet.”

5. Press ENTER. Printer displays “Debug Ethernet*.” Press ONLINE to exit.

Control Panel Displays:

(Emulation in Use)

ONLINE-PARL / PCL II* (or)

ONLINE-PARL / LP PLUS*

ONLINE-PARL / PCL II / VGL*

ONLINE-PARL/LP PLUS/PGL*

ONLINE-ETHERNET / PCL II (or)

ONLINE-ETHERNET / LP+

ONLINE-ETHERNET / LP+ (or)

ONLINE-E-NET / CODE V / PCL

ONLINE-ETHERNET/PGL/LP+ (or)

ONLINE-ETHERNET/PCL-II

NOTES

Download

File (as

shipped)

xxxxxx.exe

(Note 2)

xxxxxx.exe

(Note 2)

xxxxxx.exe

(Note 2)

xxxxxx.exe

(Note 2)

xxxxxx.exe

(Note 2)

xxxxxx.exe

(Note 2)

Download

Method

Parallel or

Serial Port

Parallel or

Serial Port

Parallel or

Serial Port

Via Network

(Note 1)

Via Network

(Note 1)

Via Network

(Note 1)

Minimum

Flash/DRAM

Required

4 MB Flash

4 MB DRAM

4 MB Flash

4 MB DRAM

4 MB Flash

4 MB DRAM

4 MB Flash

4 MB DRAM

4 MB Flash

4 MB DRAM

4 MB Flash

4 MB DRAM

2 Check with T echnical Support, (Customer Service Center) to confirm the latest available Function Code

download file.

Copying Function Code T o Your Computer

In order to download function code to a printer if using a serial or parallel port,

the function code file must reside in a PC or laptop computer running any of

the following operating systems: MS-DOS

Windows 95/98, Windows NT or Windows 2000.

Note that the downloaded file, xxxxxx.exe, is a compressed executable file.

Leave the file as it is. Do not try to execute the file.

®

, PC-DOS™, or DOS session on

31

Page 32

Chapter 2 Loading Function Code To Flash Memory In The Printer

Loading Function Code T o Flash Memory In The Printer

This section contains two loading techniques:

• How to load function code through the parallel or serial port of the printer.

• How to load function code through the Ethernet port using the file transfer

protocol (ftp).

Note If Ethernet is installed, you must install the code through the Ethernet port

using ftp.

Installing Printer Emulations

Printer emulation software is stored in flash memory. Flash memory is

contained in single in-line memory modules (SIMMs) located on the controller

board. Printer emulation and operating system software are loaded into flash

memory at the factory, but you will install software in some situations:

• A printer software upgrade is installed

• The printer controller board has been replaced

• The flash memory SIMM has been replaced

Emulation and operating system software are stored on a CD. You will copy

the appropriate file to your computer’s hard disk, then download that file to the

printer.You can load software through the serial, parallel, or Ethernet NIC port

of the printer:

Note Each printer type, line matrix, laser, and thermal has its own CD with the

specific file types for that printer. Be sure to use the appropriate CD for

your printer type when downloading software.

Note When downloading emulation and operating system software to the

printer, all other optional font files, customer-supplied logos, setup files,

and TIFF files will be erased. You will then need to reload those files.

Before starting a download procedure, be sure that you have all the

necessary files on hand.

32

Page 33

Downloading Software Through the Serial or Parallel Port

• Serial or Parallel Port: If you are going to load memory through the

serial or parallel port of the printer, see “Downloading Software Through

the Serial or Parallel Port” on page 33.. The load commands are different,

depending on the printer port you use. These differences are explained in

the note following step 22., page 36.

• NIC: If the printer has the NIC installed, see “Downloading Software

Through the Network Interface Card (NIC)” on page 37.

• Font Files: If you need to load optional font files, see “Downloading

Optional Font Files to Flash Memory” on page 39.

Downloading Softwa re Through the Serial

or Parallel Port

1. Make a printout of all saved configurations. (Installing new software

erases all saved configurations. You will use the printouts to restore the

printer configurations.)

2. Set the printer power switch to O (Off).

3. If the printer is already connected to the serial or parallel port of an

IBM-compatible computer running the PC-DOS™ or MS-DOS operating

system, go to step 9. If not, go to step 4.

4. Unplug the AC power cord from the printer.

5. Disconnect all data input cables from the printer interfaces.

6. Connect a parallel data cable to the LPT1 port or a serial data cable to the

COM1 port of an IBM-compatible computer running the PC-DOS or

MS-DOS operating system.

Note You can connect the cable to the LPT2 port if the LPT1 port is already in

use. The load commands are different if you use this port, as described in

the note after step 22.

7. Connect the data cable to the appropriate I/O port of the printer.

8. Plug the AC power cord into the printer.

9. On the printer control panel, press and hold down the ONLINE + PAPER

ADVANCE keys. Without releasing the keys, power the printer on.

Continue holding down the keys.

10. When you see “TESTING HARDWARE PLEASE WAIT” on the LCD,

release the keys.

11. Wait until you see “WAITING FOR PROGRAM DOWNLOAD” on the LCD

before proceeding. This can take up to 30 seconds to appear, depending

on the emulations and interfaces installed in the printer.

12. Press the

PORT=CENTRONICS” appears on the LCD.

⇒ (NEXT) key. “SELECT DOWNLOAD

33

Page 34

Chapter 2 Installing Printer Emulations

Note The default port is CENTRONICS; this is the standard load through the

parallel port. If you want to use the default, continue at step 14.

13. Press

14. When the printer download port you want to use is displayed on the LCD,

15. Using Windows Explorer, create a directory named download at the root

16. Insert the printer emulation software CD into your computer.

⇒ (NEXT) again to cycle through the download ports available in

the printer:

RS232-9600 (RS-232 serial, 9600 baud)

RS232-19.2K (RS-232 serial, 19200 baud)

RS232-38.4K (RS-232 serial, 38400 baud)

RS232-115K (RS-232 serial, 115000 baud)

RS422-9600 (RS-422 serial, 9600 baud)

RS422-19.2 (RS-422 serial, 19200 baud)

RS422-38.4K (RS-422 serial, 38400 baud)

RS422-115K (RS-422 serial, 115000 baud)

DEBUG

press the ENTER key. “WAITING DOWNLOAD / PORT = <your

selection>” appears on the display.

level of your C: hard drive.

34

Figure 5. Navigating to the Appropriate Emulation File on the CD

Page 35

Downloading Software Through the Serial or Parallel Port

17. Using Windows Explorer, navigate to the appropriate file on the CD based

on the printer model number and desired emulation, e.g., T5000

(See Figure 5.)

18. Make note of the file name, which is a six digit number plus .exe,

e.g., 123456.exe.

This is the file you will download into the printer.

IGP.

Figure 6. Copying the Emulation File to the Download Directory

19. Copy the file to the download directory.

Note You may need to hold Ctrl to make sure a + appears to the right of the

pointer. (See Figure 6.)

20. Start a command prompt session. (The Start Menu icon is usually labeled

MS-DOS Prompt or Command Prompt.)

21. At the command prompt type:

C:<Enter>

cd \download<Enter>

35

Page 36

Chapter 2 Installing Printer Emulations

22. At the command prompt on the computer type:

filename.exe -pb<Enter>

where filename.exe is the file name you noted in step 18. This command

decompresses the file on the hard drive and copies it as a binary file into

the flash memory on the printer controller board.

Note If you are loading the file using the LPT2 port on the computer, enter the

following command:

filename.exe -pb2 <Enter>

The 9600 baud rate is the only selection older versions of MS-DOS can

use. The baud rate information entered in the following commands must

match the selection you made in step 13.

If you are loading the file through the printer serial port, enter the following

commands:

mode COM1:9600,N,8,1,P<Enter>

filename.exe -pbc1<Enter>

Caution Do not interrupt the downloading process once it has started.

Interrupting a download will damage the flash memory on the

controller board and the NIC.

While the file is copied into memory, the printer LCD informs you of the

load process and status.

23. When the new program has successfully loaded into memory and the

printer has reset itself, set the printer power switch to O (Off).

24. Unplug the AC power cord from the printer.

25. Remove the CD from the host computer and store it with the printer.

26. Power off the computer.

27. If you had to install a data cable to the computer and printer in step 6.,

disconnect it from the computer and printer.

28. If required, reconnect the data input cable(s) to the printer.

Using the configuration printout(s) you made in step 1., reconfigure the printer

and reload any optional font files.

36

Page 37

Downloading Software Through the Network Interface Card (NIC)

Downloading Softwa re Through the

Network Interface Card (NIC)

1. Make a printout of all saved configurations. (Installing new software

erases all saved configurations. You will use the printouts to restore the

printer configurations.)

2. Set the printer power switch to O (Off).

3. On the printer control panel, press and hold down the ONLINE + PAPER

ADVANCE keys. Without releasing the keys, power the printer on.

Continue holding the ke ys down.

4. When you see “TESTING HARDWARE PLEASE WAIT” on the LCD,

release the keys.

5. Wait until you see “WAITING FOR PROGRAM DOWNLOAD” on the LCD

before proceeding. This can take up to 30 seconds to appear, depending

on the emulations and interfaces installed in the printer.

6. Using Windows Explorer, create a directory named download at the root

level of your C: hard drive.

7. Insert the printer emulation software CD into your computer.

Figure 7. Navigating to the Appropriate Emulation File on the CD

8. Using Windows Explorer, navigate to the appropriate file on the CD (using

the Unzipped directory) based on the printer model number and desired

emulation, e.g., Unzipped

T5000IGP. (See Figure 7.)

37

Page 38

Chapter 2 Installing Printer Emulations

Note You must use the Unzipped directory, since this contains the

uncompressed files necessary for NIC download.

9. Make note of the file name, which is a six digit number plus .prg,

e.g., 123456.prg.

This is the file you will download into the NIC.

10. Copy the file to the download directory.

11. Start a command prompt session. (The Start Menu icon is usually labeled

MS-DOS Prompt or Command Prompt.)

12. At the command prompt type:

C:<Enter>

cd \download<Enter>

13. Start the FTP protocol by typing:

ftp xxx.xxx.xxx.xxx<Enter>

(where xxx.xxx.xxx.xxx represents the IP Address of the printer.)

14. Log in to the printer by typing:

root<Enter>

You are given a password prompt.

Note The default is no password. If the FTP program requires a password,

contact your system administrator.

15. At the password prompt, press <Enter>.

16. Once logged in, type the following sequence at the command prompt to

download the filename.prg file to the printer:

cd dest<Enter>

cd d1prn<Enter>

bin<Enter>

put filename.prg<Enter>

(where filename.prg is the file name you noted in step 9.)

Caution Do not interrupt the downloading process once it has started.

Interrupting a download will damage the flash memory on the

controller board and the NIC.

38

17. As the file downloads, the FTP program shows the progress as a

percentage. Once the download is complete, exit out of the FTP program

by typing:

quit<Enter>

Page 39

Downloading Optional Font Files to Flash Memory

18. When the new program has successfully loaded into flash memory and

the printer has reset itself, set the printer power switch to O (off).

19. Unplug the AC power cord from the printer.

20. Remove the CD from the host computer and store it with the printer.

21. Using the configuration printout(s), reconfigure the printer and reload any

optional font files.

Downloading Optional Font Files to Flash Memory

Optional font files are stored on a 3.5 inch floppy diskette that contains file

names comprised of a part number with a .dwn extension. You will insert the

diskette in your IBM-compatible computer and use either the parallel or serial

port to download the desired font file(s) to the printer’s flash memory.

1. Set the printer power switch to O (off).

2. Connect a parallel data cable to the LPT1 port or a serial cable to the

COM1 port of an IBM-compatible computer running the PC-DOS or

MS-DOS operating system.

Note You can connect the cable to the LPT2 port on the computer if the LPT1

port is already in use. The load commands are different if you use this port,

as described in the notes after step 15.

3. Verify that the data cable is connected to the appropriate I/O port on the

printer and to the host computer.

4. Power on the computer and allow it to boot up.

5. On the printer control panel, press and hold down the ONLINE + PAPER

ADVANCE keys while powering the printer on. Continue holding the keys

down.

6. When you see “WAITING FOR PROGRAM DOWNLOAD” on the LCD,

release the keys.

Note The printer default port is CENTRONICS; if you want to use this port,

continue to step 15.

7. Press the

CENTRONICS” appears on the LCD.

⇒ (NEXT) key; “SELECT DOWNLOAD PORT =

39

Page 40

Chapter 2 Installing Printer Emulations

8. Press the

available in the printer:

RS232-9600 (RS-232 serial, 9600 baud)

RS232-9600 (RS-232 serial, 19200 baud)

RS232-9600 (RS-232 serial, 38400 baud)

RS232-9600 (RS-232 serial, 115000 baud)

RS422-9600 (RS422 serial, 9600 baud)

RS422-9600 (RS422 serial, 19200 baud)

RS422-9600 (RS422 serial, 38400 baud)

RS422-9600 (RS422 serial, 115000 baud)

DEBUG

9. When the printer download port you want to use is displayed on the LCD,

press the ENTER key. “WAITING DOWNLOAD / PORT” = <your

selection> appears on the display.

10. Insert the optional font diskette into diskette drive A (or B) of the

computer.

11. Start a command prompt session. (The Start Menu icon is usually labeled

MS-DOS Prompt or Command Prompt.)

12. Make the diskette drive the active drive by typing:

A:<Enter> (if the diskette is in drive B, type B:<Enter>)

13. List the contents of the diskette at the command prompt by typing the

following:

⇒ (NEXT) key again to cycle through the download ports

dir<Enter>

You will see a directory listing containing files with a .dwn extension, e.g.,

94021.dwn, 94022.dwn, 94023.dwn .

14. Make note of the file name with the .dwn extension of each file you want

to download to the printer.

Note The numeric portion of the file name will match the numbers of the font

typefaces listed in Appendix E of the PGL and VGL Programmer’s

Reference Manuals and provide you with a description and print sample of

the typeface.

15. At the command prompt type:

copy /b filename.dwn LPT1<Enter>

(where filename.dwn is file name you noted in step 14.)

40

Page 41

Downloading Optional Font Files to Flash Memory

Note If you are loading the file using the LPT2 port on the computer, type the

following command:

copy /b filename.dwn LPT2<Enter>

(where filename.dwn is a file you noted in step 14.)

If you are loading the file using the serial port on the computer,

type the following commands:

mode COM1:9600,N,8,1,P<Enter>

copy /b filename.dwn COM1<Enter>

(where filename.dwn is a file you noted in step 14.)

The 9600 baud rate is the only selection older versions of MS-DOS can

use. The baud rate information entered in the above commands must

match the selection you made in step 8.

You can download the optional font files one at a time by entering one file

name per the copy command or you can copy multiple files in one copy

command.

To download one file at a time, enter the following at the command

prompt:

copy /b filename.dwn LPT1<Enter>

To download multiple files, enter the following at the command prompt,

for example:

copy /b filename1.dwn+filename2.dwn+...LPT1<Enter>