Page 1

R

Maintenance Manual

P3000 Printer

Page 2

Page 3

P3000 Printer

Maintenance Manual

P/N 111839–001, Rev C

R

Page 4

US and CANADA Radio Interference Note

Note: This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission limits.

The manufacturer is not responsible for any radio or television interference caused by using other than

recommended cables and connectors or by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user’s authority to operate the equipment.

The

input/output (I/O) cable must be shielded for the printer

to comply with FCC rules and regulations Part 15

governing the radiation limits for Class “A” equipment.

This Class A digital apparatus meets all requirements of the Canadian Interference–Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur

du Canada.

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Printronix, Inc. makes no representations or warranties of any kind regarding this material, including, but not

limited to, implied warranties of merchantability and fitness for a particular purpose. Printronix, Inc. shall not

be held responsible for errors contained herein or any omissions from this material or for any damages,

whether direct, indirect, incidental or consequential, in connection with the furnishing, distribution,

performance or use of this material. The information in this manual is subject to change without notice.

This document contains proprietary information protected by copyright. No part of this document may be

reproduced, copied, translated or incorporated in any other material in any form or by any means, whether

manual, graphic, electronic, mechanical or otherwise, without the prior written consent of Printronix, Inc.

All rights reserved. Revision C. January 1996.

17500 Cartwright Road, P.O. Box 19559

Irvine, California 92713

Telephone (714) 863–1900 FAX (714) 660–8682

Technical Support (714) 221–2686

COPYRIGHT 1988, 1989, 1996, PRINTRONIX, INC.

Page 5

Table of Contents

Paragraph Title Page

MAINTENANCE O

1-1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 P

1-3 Operation 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 General 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 F

2-3 P

2-4 P

2-5

2-6

2-7 P

3-1 General 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 P

3-3 Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Cleaning 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 P

3-6 Lubrication 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rinter Description

PRINCIPLES OF OPER

unctional Elements

aper T

ransport 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rinting Mechanism

Controller PCBA

Mechanism Driver PCBA

ower Supply PCBA

PREVENTIVE MAINTENANCE

reventive Maintenance Checks and Service (PMCS)

aper F

eed Belt T

ension Check

CHAPTER l

VERVIEW

CHAPTER 2

ATION

CHAPTER 3

1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. . . . . . . . . . . . . .

3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 4

TROUBLESHOOTING

4-1 General 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Common Causes of Malfunctions 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3

4-4 F

5-1 Introduction 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Tools, T

5-3 P

5-4

5-5

5-6 Bumpers 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7

5-8

Internal T

ault Isolation

aper Scale

Hammer T

Hammer Spring R

Stroke T

Hammer Phasing

esting 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORRECTIVE MAINTENANCE

est Equipment, and Supplies

Section II. ALIGNMENTS AND ADJUSTMENTS

ips 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iming 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 5

Section I. GENER

etensioning 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AL

4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iP3000 Maintenance

Page 6

Table of Contents

Paragraph Title Page

5-9 T

5-10 P

5-11

5-12

5-13

5-14

5-15 Cabinet 5-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16

5-17 Cover 5-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18

5-19

5-20

5-21

5-22 P

5-23

5-24 P

5-25

5-26

5-27

5-28

5-29

5-30

5-31 Encoder 5-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-32

5-33 Bumper 5-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-34 P

5-35 P

5-36

5-37

5-38 Tractor 5-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-39 P

5-40

5-41

5-42 P

5-43

5-44

5-45

5-46 Fan 5-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-47

5-48 A

5-49 P

iming Belt T

aper Drive Motor Pulley Alignment

Spline Shaft Skew A

Platen Angle A

Platen Gap A

Ribbon Guide Alignment

Control P

Display Control P

Control P

Controller PCBA

Mechanism Driver PCBA

ower Supply PCBA

Shuttle Cover

aper Scale

Motherboard PCBA

I/O Cable Assembly

Shuttle Assembly

Hammer Bank Cable Assembly

Hammer Spring

Hammer Coil

Encoder PCBA

aper F

aper Drive Motor

Spline Shaft

Support Shaft

aper Ironer

Platen

Interlock Cable Assembly

aper Detect Switch

Ribbon Drive Motor

Ribbon Guide

Blower Assembly

Circuit Breaker

C Input Filter

aper F

ension A

djustment 5-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

djustment 5-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

anel 5-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

anel Cable 5-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

eed T

iming Belt

eed Motor Pulley

djustment 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

djustment 5-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section III. REPLA

anel 5-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CEMENT

5-14. . . . . . . . . . . . . . . . . . . . . . . . . .

5-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P3000 Maintenanceii

Page 7

Table of Contents

Paragraph Title Page

APPENDICES

Appendix A

Appendix B

Index I-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronic Drawings

P

arts List

A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Tables

Table Title Page

1-1

1-2

1-3

2-1

3-1 P

3-2

4-1 Fault Codes 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2

4-3

External Controls and Indicators

Internal Controls and Indicators

Controls and Indicators for 3287 Option

Dot Matrices vs Speed/Density

reventive Maintenance Checks and Service

Physical Inspection

Supplimental T

Malfunction Sympton Index

ests 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8. . . . . . . . . . . . . . . . . . . . . . . . .

2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. . . . . . . . . . . . . . . . . . . . . .

3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 R

ecommended T

ools, T

est Equipment, and Supplies

5-2. . . . . . . . . . . . . . .

iiiP3000 Maintenance

Page 8

List of Illustrations

Figure Title Page

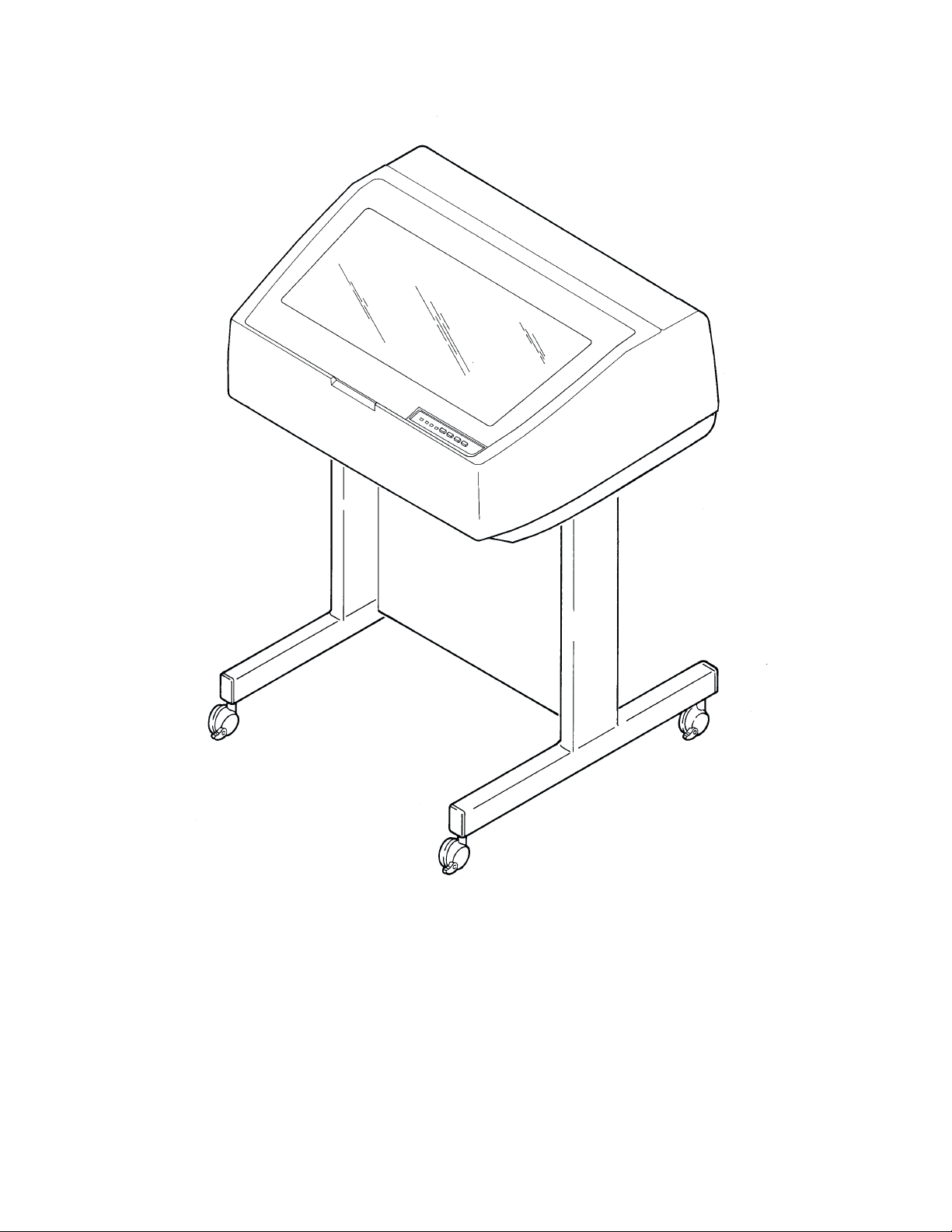

1-1 P

1-2

1-3

1-4

2-1 P

2-2 P

2-3 P

2-4

2-5 P

2-6

2-7

2-8 T

2-9

2-10

2-11

2-12

3-1

3-2

3-3

3-4

3-5 P

rinter with P

External Controls and Indicators

Internal Controls and Indicators

Controls and Indicators for 3287 Option

rinter F

aper T

rinting Mechanism

Hammer and Shuttle Arrangement, Cross Section

rint Hammer A

Standard Character F

Character F

ypical Character Dot P

Controller Block Diagram

Mechanism Driver Block Diagram

Hammer Bank L

Ribbon Driver Circuit

Cleaning Interior of Cabinet

Cleaning Hammer Bank Assembly

Cleaning P

Cleaning F

aper F

edestal 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

unctional Block Diagram

ransport 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ction 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ormation 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ormation by One Hammer

atterns, By Mode

ogic, Drivers, and W

aper Ironer

an 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

eed Belt T

ension Check

aveforms 2-16. . . . . . . . . . . . . . . . . . .

1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9. . . . . . . . . . . . . . . . . . . . . . . . .

2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6. . . . . . . . . . . . . . . . .

2-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10. . . . . . . . . . . . . . . . . . . . .

2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9 P

All Indicators Come on and Stay on at P

No Indicators Come on at P

Indicators on Both Control P

Switches or Indicators Operate Improperly on F

Control P

Digital Display Operates Improperly

CHECK Indicator Flashes--Display Shows

FAULT CONDITION P

CHECK Indicator Flashes--Display Shows

FAULT CONDITON PLATEN OPEN 4-16. . . . . . . . . . . . . . . . . . . . . . . . .

CHECK Indicator on Continuously--Display Shows

FAULT CONDITION DCU RAM, FONT PROM or MCU RAM 4-18. .

aper Doesn't F

anel Only

eed at All

ower-up 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

anels Operate Improperly

APER OUT

ower-up 4-7. . . . . . . . . . . . . . . . .

ront

4-11. . . . . . . . . . . .

4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-13. . . . . . . . . . . . . . . . . . . . . . . . . . .

4-14. . . . . . . . . . . . . . . . . . . . . . . . . . .

4-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P3000 Maintenanceiv

Page 9

List of Illustrations

Figure Title Page

4-10 P

4-11 P

4-12

4-13

4-14

4-15

4-16

4-17

4-18

4-19

4-20

4-21 P

4-22 P

4-23

4-24

4-25

4-26

4-27

4-28 R

4-29

4-30

4-31

4-32

4-33

4-34

4-35

4-36

4-37

4-38

4-39

4-40

4-41

4-42

4-43

aper F

eeds Erratically

aper Drags

Set T

op-of-F

Ribbon Does not Move at All

Ribbon F

Ribbon Does Not R

Ribbon Does Not Change Direction at End

Shuttle Does Not Move at All

Shuttle Jams or Moves too Slowly

Shuttle Moves Erratically

Shuttle Movement P

rinter Does Not P

rinter F

Missing Characters Example

Characters Missing Consistently

Characters Missing R

Missing Dots Example

Consistent Dropout of Dots

andom Dropout of Dots

Characters Light or Smeared Example

Character P

Dots Misplaced

Improper P

Improper P

Improper Horizontal Alignment Example

Improper V

Improper Horizontal or V

Characters Misformed V

Characters Misformed V

Compacted P

Compacted P

Garbled P

Expected Data Stream P

Blower Motor Not Operating

orm Does not Operate

olds Over 4-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

un Smoothly

roduces Knocking Sound

rint at All

ails to P

rint Only When Controlled by Host Computer

andomly 4-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ositions Light or Smeared (Dragging Hammer)

rint Density Example

rint Density

ertical Alignment Example

ertical Alignment

ertically Example

ertically 4-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rint Example

rint 4-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rint and/or Incorrect F

rintout 4-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ont 4-71. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-28. . . . . . . . . . . . . . . . . . . . . . . . . .

4-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-34. . . . . . . . . . . . . . . . . . . . .

4-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-43. . . . . . . . . . . . . . . . . . . .

4-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-45. . . . .

4-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-57. . . . . . . . . . . . . . . . . . . . . . . . .

4-58. . . . . . . .

4-59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-63. . . . . . . . . . . . . . . . . . . . . . .

4-64. . . . . . . . . . . . . . . . . . . . . . . . .

4-65. . . . . . . . . . . . . . . . . . . . . .

4-66. . . . . . . . . . . . . . . . . . . . . . .

4-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 P

5-2

5-3

5-4

aper Scale A

Hammer T

Hammer Spring R

Bumper A

djustment 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ip Alignment

djustment 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

etensioning 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vP3000 Maintenance

Page 10

List of Illustrations

Figure Title Page

5-5 T

5-6 P

5-7

5-8

5-9

5-10

5-11

5-12

5-13 Cover Removal/Installation 5-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-14

5-15

5-16

5-17

5-18 P

5-19

5-20

5-21 I/O Cable Removal/Installation 5-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-22

5-23

5-24

5-25

5-26

5-27

5-28

5-29 P

5-30 P

5-31

5-32

5-33 P

5-34

5-35

5-36 P

5-37

5-38

5-39

5-40 F

5-41

5-42 A

5-43 P

iming Belt A

aper Drive Motor Pulley Alignment

Spline Shaft Skew A

Platen Angle A

Platen Gap A

Ribbon Guide Alignment

Cabinet R

Control P

Display Control P

Control P

Controller and Mechanism Driver R

Controller PROM L

ower Supply PCBA R

Shuttle Cover and P

Motherboard PCBA R

Shuttle Assembly R

Hammer Bank Cable Assembly R

Hammer Spring R

Hammer Coil R

Encoder R

Encoder PCBA R

Bumper R

aper F

aper Drive Motor R

Spline Shaft R

Support Shaft R

aper Ironer R

Platen R

Interlock Cable Assembly R

aper Detect Switch R

Ribbon Drive Motor R

Ribbon Guide R

Blower Assembly R

an R

emoval/Installation 5-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Breaker R

C Input Filter R

aper F

djustment 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

djustment 5-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

djustment 5-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

djustment 5-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

anel R

emoval/Installation 5-27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

anel R

emoval/Installation 5-31. . . . . . . . . . . . . . . . . . . . .

anel Cable Removal/Installation 5-33. . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-35. . . . . . . . . . .

ocations 5-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-39. . . . . . . . . . . . . . . . . . . . . . .

aper Scale R

emoval/Installation 5-43. . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-47. . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-51. . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-53. . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-57. . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

eed T

iming Belt R

emoval/Installation 5-63. . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-67. . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-77. . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-79. . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-81. . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-83. . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-87. . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-89. . . . . . . . . . . . . . . . . . . . . . . . . . .

eed Motor Pulley R

emoval/Installation 5-41. . . . . . . . . . . . . .

emoval/Installation 5-49. . . . . . . . . . . . .

emoval/Installation 5-61. . . . . . . . . . . . . . . . . . . .

emoval/Installation 5-75. . . . . . . . . . . . . . . . . .

emoval/Installation 5-91. . . . . . . . . . . . . . . . . . .

5-15. . . . . . . . . . . . . . . . . . . . . . . . . . .

5-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P3000 Maintenancevi

Page 11

ABOUT THIS MANUAL

This

manual has been organized and written to make it easy to use. The following information will

help

you use this P3000 Maintenance Manual.

What This Manual Contains

This

manual contains the following information. Consult your table of contents to locate this infor

mation.

Ć

Introduction -

P

rovides brief printer description.

Principles of Operation - Describes functional operation of printer through the use of

block

diagrams and associated text.

Preventive

operation.

Troubleshooting

common

Maintenance

- Presents fault isolation procedures required to determine the source

malfunctions.

-

Lists

detailed procedures required to maintain normal printer

of

Corrective Maintenance - Presents procedures for printer adjustment and alignment

replacement of faulty hardware.

and

Electronic Drawings - Electronic drawings and schematics required for field mainteĆ

nance

are included here.

Parts List -

A parts lists, cross referenced to Chapter 5, Section III, is included here.

Controls and Indicators

Throughout

printer, with all capital letters. Controls and indicators that do not have labeled names are given

functional names that are printed with the first letter of each word capitalized. For example, the

POWER switch has two settings, ON and OFF. The Forms Thickness Adjustment Lever is operĆ

by raising and lowering.

ated

this manual, in text, controls and

indicators are printed exactly as they appear on the

Warnings, Cautions, and Notes

In this manual, extra information is given under the headings WARNING, CAUTION, AND

NOTE.

information about conditions that could lead to injury. Cautions provide information about condi

tions that could lead to equipment damage. Both warnings and cautions are printed in bold type.

Notes

They are set off from the text around

provide extra information and are printed in

them and appear in special typefaces. W

italics.

arnings give

What This Manual Does Not Contain

Detailed,

in

the maintenance manual.

specific information which appears in the User's R

eference Manual will not be repeated

viiP3000 Maintenance

Ć

Page 12

P3000 Maintenanceviii

Page 13

CHAPTER l

MAINTENANCE OVERVIEW

1-1. Introduction

This

manual contains information required to maintain and repair the

rinter (hereafter referred to as the P3000 Series, or simply, the printer).

P

The following documents provide detailed information which supplements this manual.

a.

P3000 P

Contains instructions for unpacking, installing, and operating the printer.

b.

P3000 P

Describes functions and applications available for the P3000 P

rinter Operator's Guide, P/N 111837-001.

rinter User's R

eference Manual, P/N 111838-001.

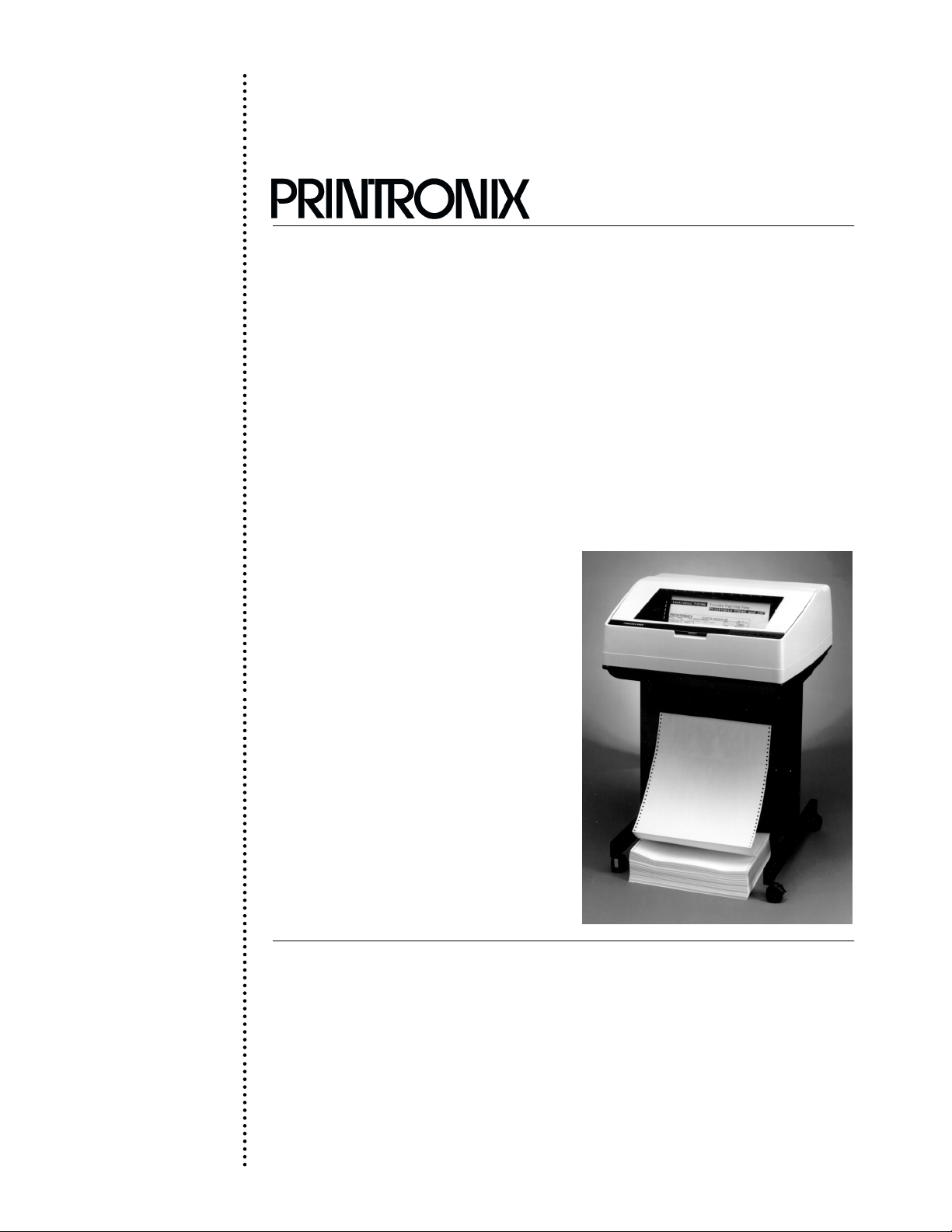

1-2. Printer Description (Figure 1-1)

Printronix P3040

rinter.

a. General

The Printronix

to

produce labels and characters, as well as the standard data processing and compressed

print

character lines and graphics at various densities.

b.

Standard F

l. Configurable

trol

2.

Multi-application character printing

3.

Graphics plotting

4.

Dynamic font selection:

5.

Double high characters

P3000 Series P

eatures

for P

code protocols

(a)

Selectable pitch - expanded, normal, and compressed

(b)

Shadow printing

(c)

Bold printing

(d) A

uto underlining

(e)

Superscripts and subscripts

rinter is a multi-purpose, dot matrix line printer designed

rintronix P Series matrix line printer or serial matrix printer con

Ć

6.

Selectable forms length

7.

Nonvolatile electronic vertical formatting

8. R

esident international character sets

1-1P3000 Maintenance Overview

Page 14

1-2. Printer Description-continued

b. Standard Features-continued

ă9.

Self-test and diagnostics

10. T

est pattern printing

11.

Configuration printout

12.

Datastream HEX code printout

13. R

esident serial and parallel interfaces

14.

Selectable alternate horizontal and vertical dot densities

15.

Configurable for 13.2 or 13.6 inch print width

c. Optional Features

ă1.

Intelligent Graphics P

(a) F

orms generation

(b)

Bar code printing

(c)

Expanded character printing

(d) R

everse image printing

(e) R

otated character printing

(f) L

ogo generation

ă2.

Optional character sets

rocessor (IGP)

ă3.

IBM interfaces

Ribbon fault detector

ă4.

1-3. Operation

a. Operating Procedures

For detailed operating instructions refer to P3000 Printer Operator's Guide, P/N

111837-001.

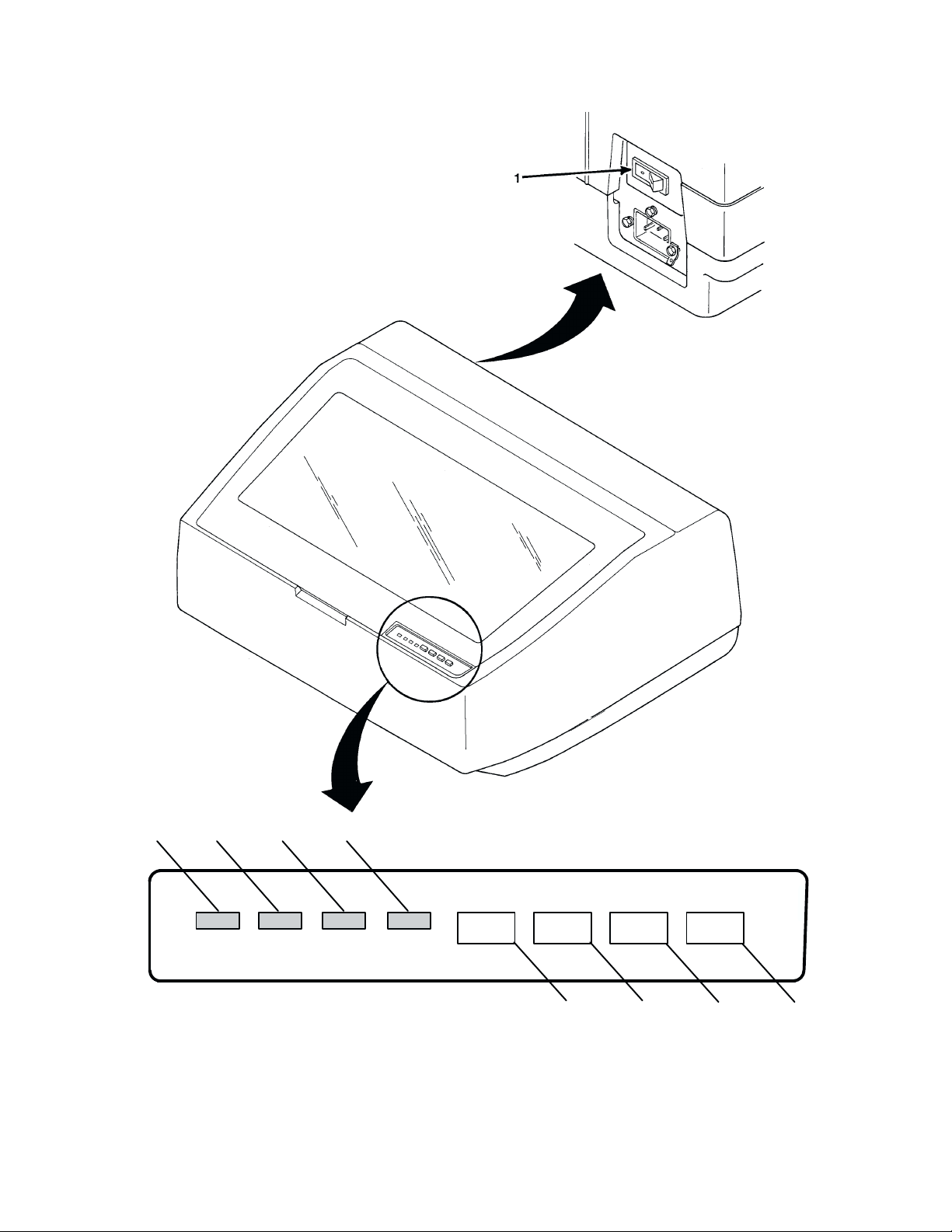

b. Controls and Indicators

NOTE:

functions. For a detailed discussion, refer to the User's R

optional controls and indicators refer to the PI 3287 User's R

(P/N 108174-001).

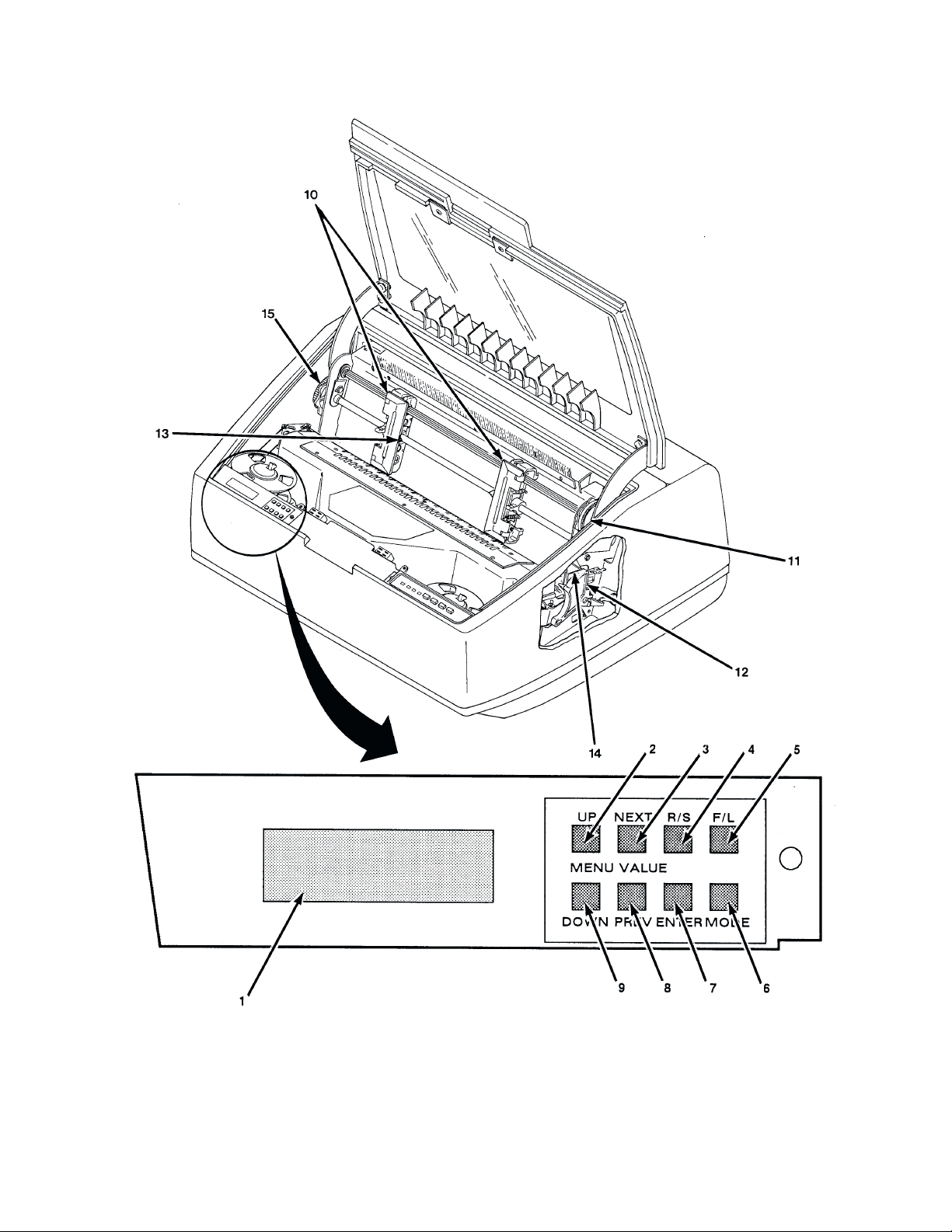

1. External

Figure

Internal Controls and

2.

Figure

(a) 3282/3287

(b) 5225/5224

The following tables contain a brief

Controls and Indicators. External controls and indicators

1-2 and described in T

Indicators. Internal controls and indicators are illustrated in

1-3 and described in T

able 1-1.

able 1-2.

summary of control and indicator

eference Manual. F

or

eference Manual

are illustrated in

3. Controls and Indicators for Options. Printers configured to emulate an IBM 3287

will have external controls and indicators as shown in Figure 1-4 and described in

Table 1-3.

P3000 Maintenance Overview1-2

Page 15

Figure 1-1. P

rinter with P

edestal

1-3P3000 Maintenance Overview

Page 16

Table 1-1. External Controls and Indicators

Key

(Fig 1-2) Control or Indicator Function

1

2

3

4

5

ON/OFF

ON LINE

switch

ON LINE

indicator

CLEAR

switch

CHECK

indicator

6

7

8

6/8LPI

switch

8LPI

indicator

PAPER ADV

switch

Applies and removes ac power to printer

Sets printer online or offline.

Illuminates steadily to indicate printer online

(ready for computer messages).

Flashes to indicate printer offline (not ready

to accept messages).

Resets check circuitry. Used to clear check

indicators after corrective action.

Illuminates to indicate printer problem. Steady

light indicates service is required. Flashing light

indicates operator correctable problem. Lighting

of indicator is accompanied by display of message

on internal display panel (see Table 4-1)

Selects line spacing of six lpi or eight lpi.

Illuminates when alternate lpi selected

Moves paper one line when pressed momentarily.

Moves paper to top of form when pressed for more

than 0.5 second.

NOTE:

Top of form must be reset each time new paper

is loaded (see operator's guide).

9

VFU

indicator

Illuminates when EVFU is loaded.

P3000 Maintenance Overview1-4

Page 17

357 9

ON LINE CHECK 8 LPI VFU

Figure 1-2. External Controls and Indicators

ON LINE

CLEAR

6/8 LPI PAPER ADV

2468

1-5P3000 Maintenance Overview

Page 18

Table 1-2. Internal Controls and Indicators

: The following electronic controls function only when the printer is of

NOTE

fline.

Key

(Fig 1-3) Control or Indicator Function

ELECTRONIC

1

2

3

4

5

6

7

Display

Panel

UP

switch

NEXT

switch

R/S

switch

F/L

switch

MODE

switch

ENTER

switch

Displays message for print mode, form length,

fault conditions, test patterns, or configuration options.

For details, refer to User's Reference Manual.

Steps display up to next menu

Used in conjunction with PREV switch to display individual configuration parameters and the current values

from within various menus.

Starts or stops certain printer functions.

Used to select form length.

Selects type of character print or density of graphic plot.

F

or details on how to select mode, refer to Operator's

Guide.

Used to enter a displayed value into memory.

Ć

8

9

MECHANICAL

10

11

12

13

14 Forms Thickness

15

PREV

switch

DOWN

switch

Tractors

Vertical Alignment

Knob (Spline Shaft

Knob)

Forms Thickness

(Platen) Lever

Top of Form

Pointer (indicator

on tractor doors)

Indicator

Horizontal Vernier

Adjustment Knob

Used in conjunction with NEXT switch to display individual configuration parameters and the current values

from within various menus.

Steps display down to next menu.

Provide horizontal positioning of forms.

Manually advances forms.

Opens paper path for insertion/removal of paper.

Adjusts platen opening to allow for paper thickness

A

or multiple copies.

Provides reference when setting top of form after

P

reloading paper.

Indicates setting of platen lever.

Provides fine horizontal positioning when tractors are

locked.

P3000 Maintenance Overview1-6

Page 19

Figure 1-3. Internal Controls and Indicators

1-7P3000 Maintenance Overview

Page 20

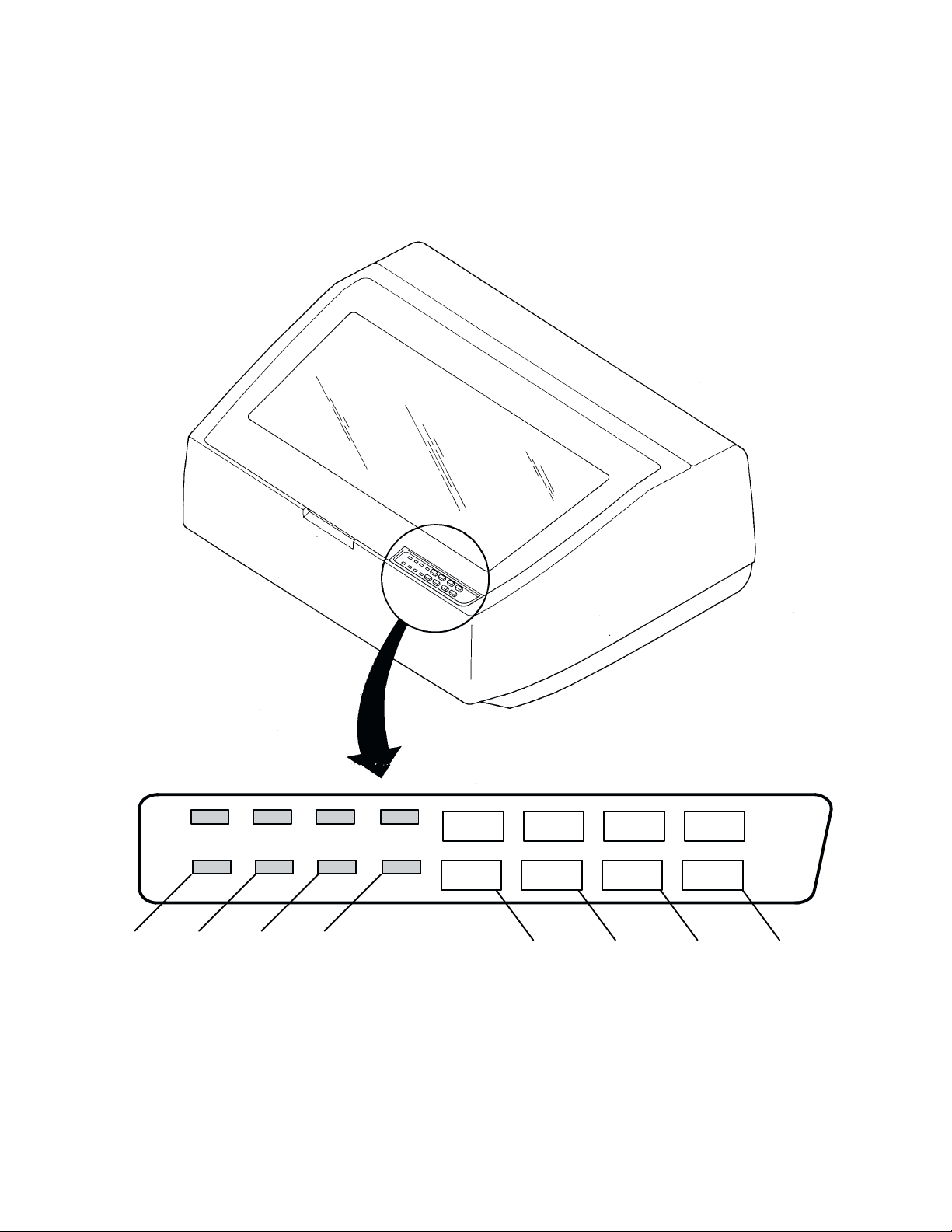

Table 1-3. Controls and Indicators for 3287 Option

NOTE:

panel

Key

(Fig 1-4) Control or Indicator Function

ELECTRONIC

1

2

3

4

Only those controls and indicators

(F

igure 1-3) are discussed below

ENABLE/HOLD

switch

HOLD

indicator

REPRINT/PA1

switch

CANCEL/PA2

switch

Places printer in hold print mode following completion

of line being printed. When pressed a second time, en

ables normal operation.

Lights to indicate printer is in hold print mode.

Causes reprint of all data in interface buffer in nonSCS modes. In SCS modes, sends intervention re

quired message to host processor. A

print mode.

When used in conjunction with AL

causes program attention signal to be sent to host proc

essor.

No effect in non-SCS modes. In SCS modes, causes

printing to stop and SCS print data to be cleared from

buffer. A

ctive only in hold print mode.

that are not present on the standard

.

Ć

Ć

ctive only in hold

T MODE switch,

Ć

5

6

7

8

ALT MODE

switch

READY

indicator

ERROR

indicator

ALT

indicator

Causes alternate switch functions P

come active. A

second time deactivates P

Lights to show that printer is ready to print (not in

hold print mode).

Indicates error condition exists.

Indicates alternate mode selected (P

ctive only in hold print mode. P

A1 and P

A1 and P

A2.

A1 and P

A2 to be-

ressing a

A2 active).

P3000 Maintenance Overview1-8

Page 21

ON LINE CHECK 8 LPI VFU

ENABLE/HOLD 6/8 LPI PAPER ADV

CLEAR

PA1

PA2

ALT MODE

HOLD READY ERROR ALT

2

67 8

REPRINT

1

CANCEL

345

Figure 1-4. Controls and Indicators for 3287 Option

1-9P3000 Maintenance Overview

Page 22

P3000 Maintenance Overview1-10

Page 23

CHAPTER 2

PRINCIPLES OF OPERATION

2-1. General

This chapter presents the principles of operation for the Printronix P3000 Series Line

Printer.

ing field maintenance. R

Theory is presented at the functional block diagram level as an aid for perform

efer to Appendix B for detailed schematic diagrams.

2-2. Functional Elements (Figure 2-1)

Ć

Functional

a. P

b. Printing Mechanism

c.

d.

e. P

elements of the printer consist of the following:

aper T

ransport

Controller PCBA

Mechanism Driver PCBA

ower Supply PCBA

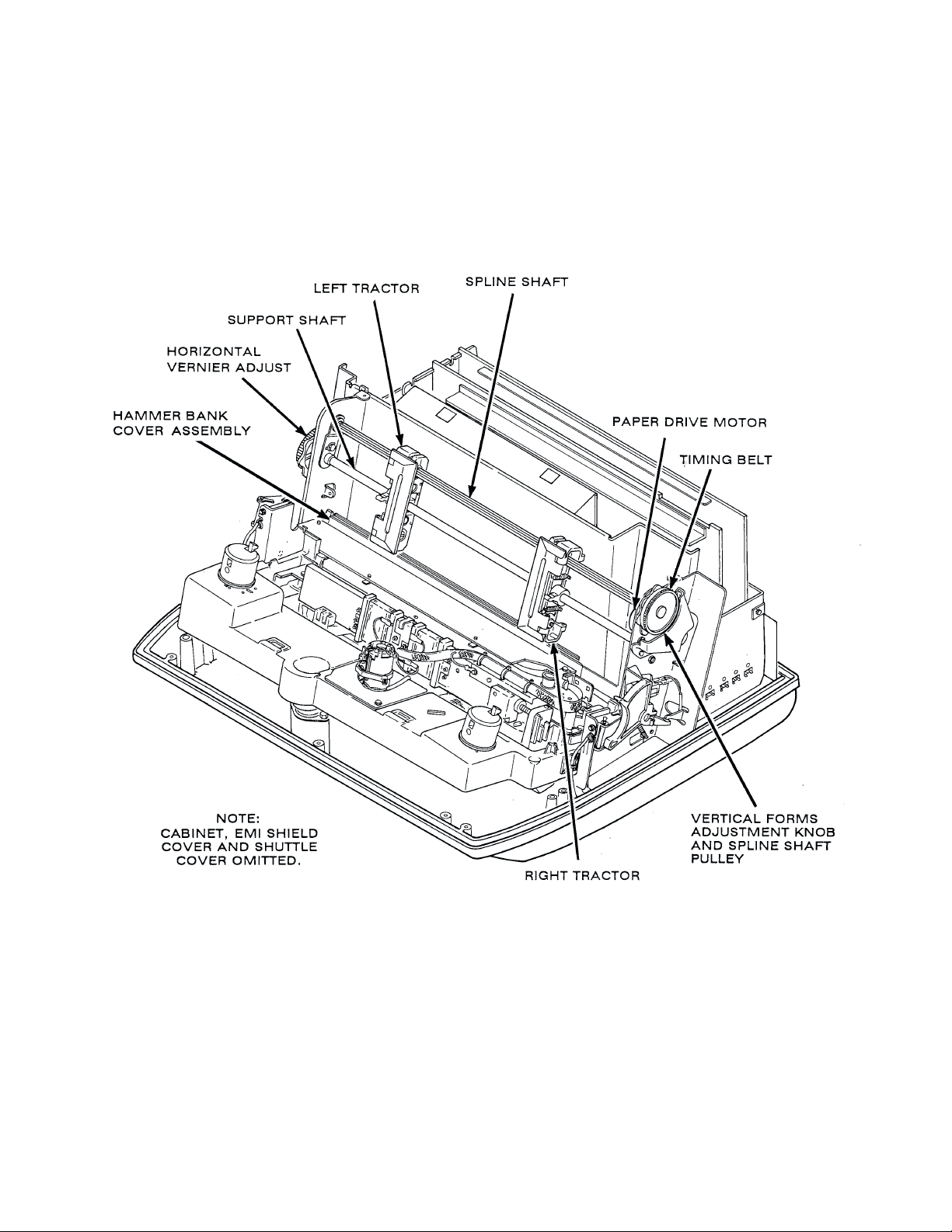

2-3. Paper Transport (Figure 2-2)

The paper transport accepts one to six part, continuous fan folded, edge perforated paĆ

per (or forms) from three to 16-inches wide. The spline shaft knob is used to manually

advance the paper supply vertically. Horizontal positioning of the paper is provided by

tractors which can be adjusted laterally along the spline and support shafts and by a

two

horizontal adjustment knob. When properly positioned, each tractor is then locked in

place. Each tractor provides five

tractors

nals

are belt driven by the paper drive motor. The paper drive motor is

from the two paper feed sections of the mechanism driver PCBA.

pin engagement of paper perforation. During printing,

driven by sig

Ć

2-1P3000 Principles of Operation

Page 24

+30V

AC

POWER

IN

TO/FROM

HOST

COMPUTER

DATA

CONTROL

STATUS

POWER SUPPLY

PCBA

CONTROLLER

PCBA

-16V

+5V

+12 V

-12 V

CONTROL

TIMING

SERIAL DATA

MECHANISM

DRIVER

PCBA

PAPER FEED

PLATEN OPEN/

INTERLOCK

HAMMER CONTROL

SHUTTLE CONTROL

SHUTTLE STALL

RIBBON CONTROL

RIBBON FAULT

BLOWER CONTROL

PRINT MECHANISM

PAPER TRANSPORT

HAMMERBANK/

SHUTTLE

RIBBON

TRANSPORT

BLOWER MOTOR

+5V

OPERATOR

CONTROLS

AND

INDICATORS

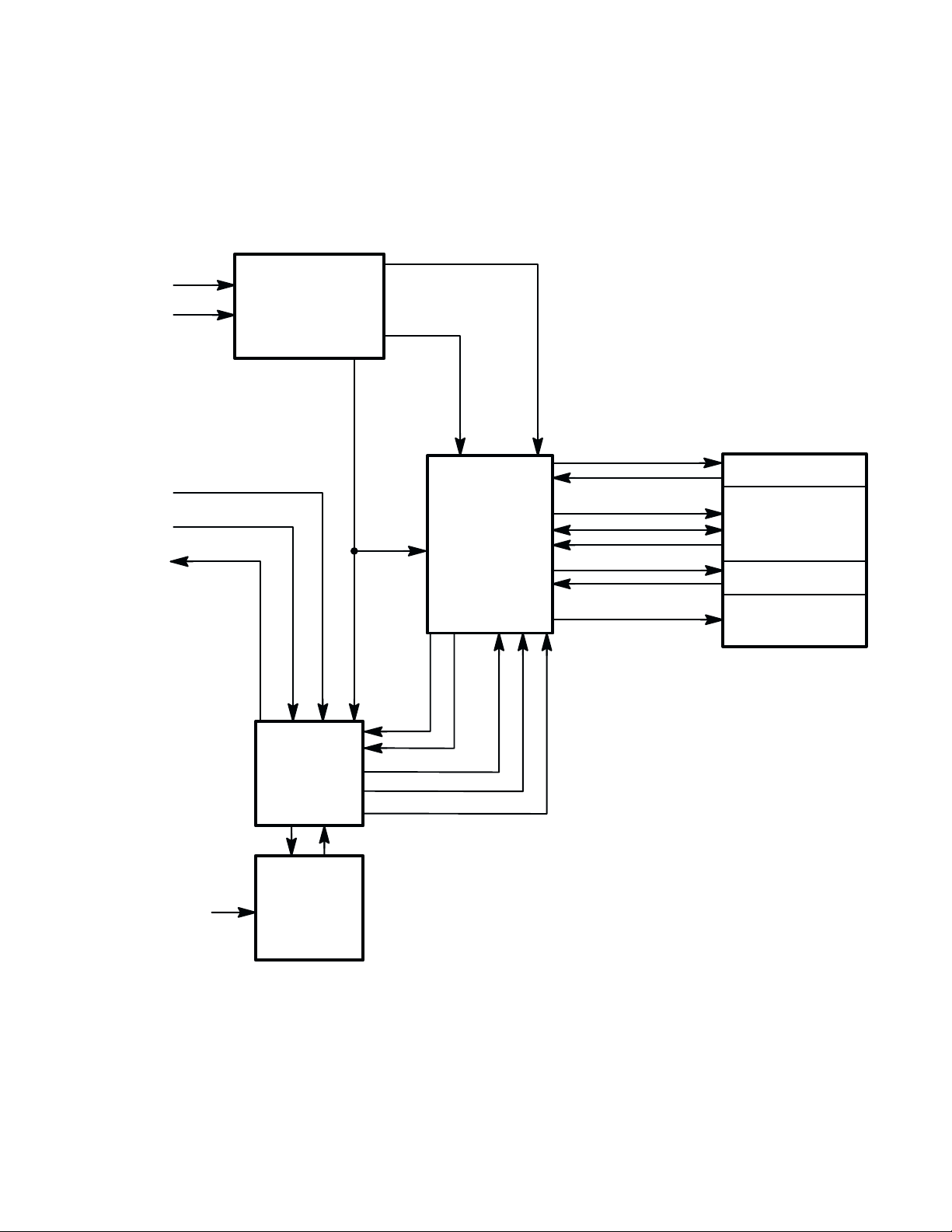

Figure 2-1.

P

rinter F

unctional Block Diagram

P3000 Principles of Operation2-2

Page 25

Figure 2-2. P

aper T

ransport

2-3P3000 Principles of Operation

Page 26

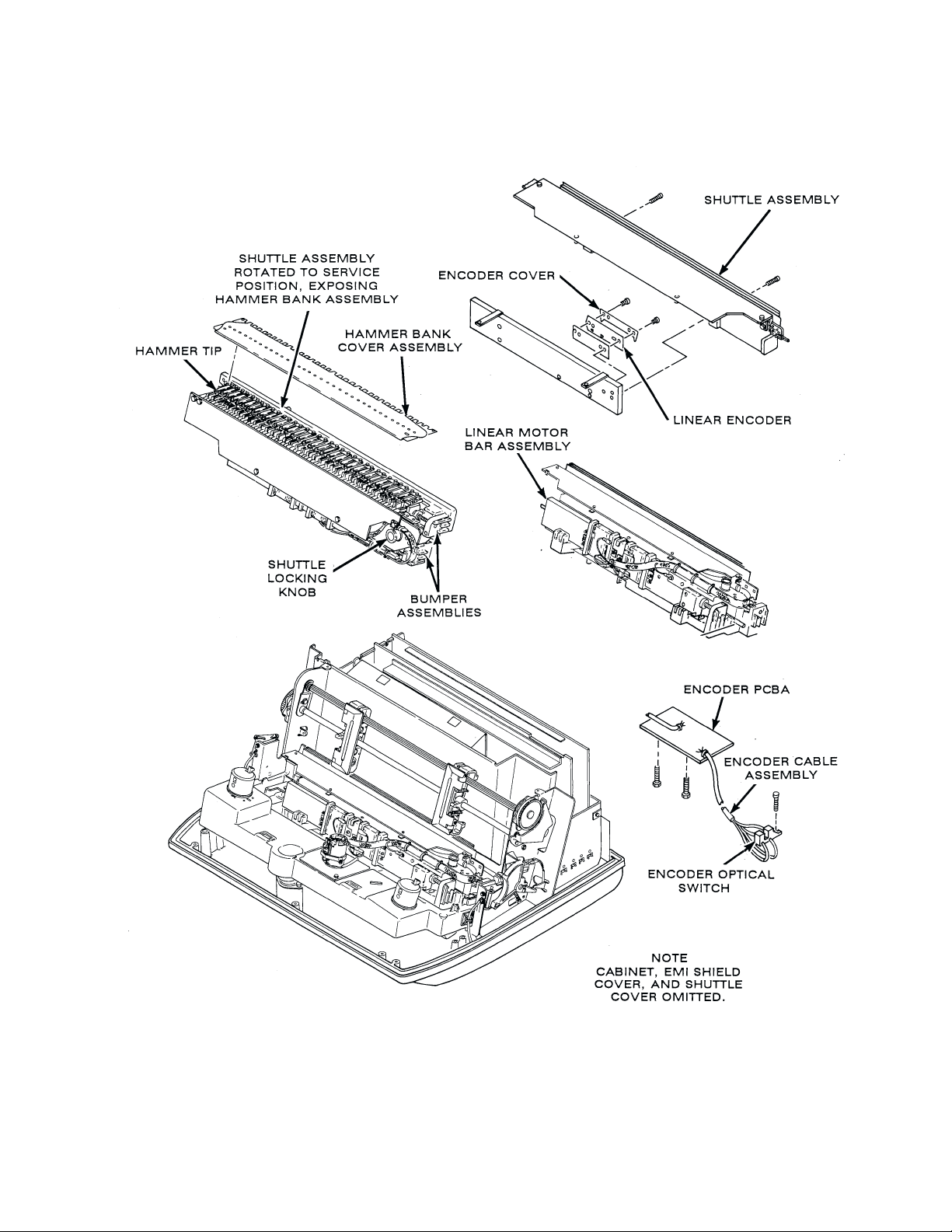

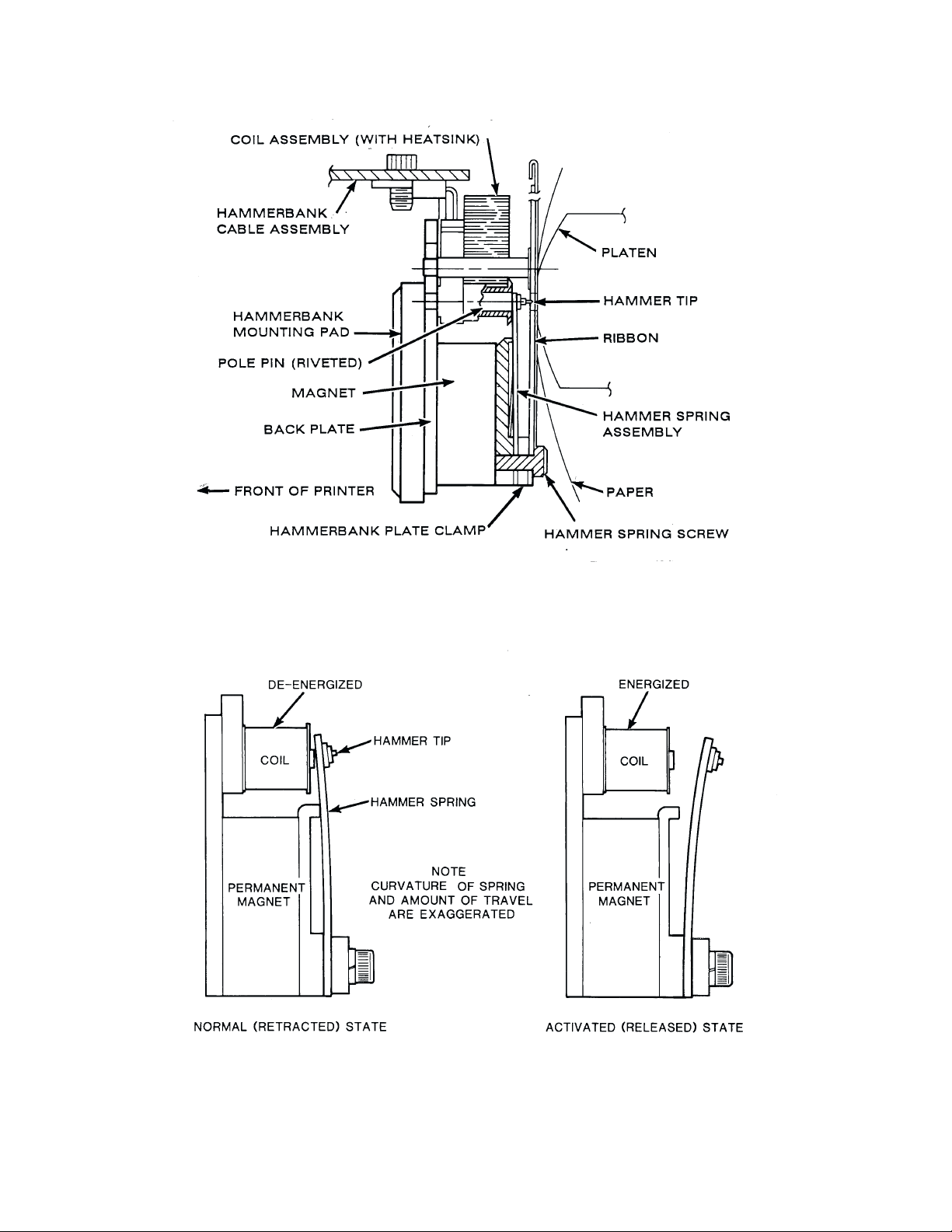

2-4. Printing Mechanism (Figure 2-3)

The

printing mechanism consists of the shuttle assembly on which the

sembly is mounted, and the ribbon transport.

a. Shuttle Assembly

The

shuttle assembly consists of the linear motor assembly, two bumper assemblies, two

drum assemblies, the hammer bank assembly, hammer bank cable assembly, encoder

and a linear

PCBA,

and

sweeps the hammer

each hammer. The bumpers rebound the hammer bank assembly's inertial energy

the

shuttle reaches either end of its travel and reverses direction. The drums, in conjunc

tion with a stainless steel band, provide a bearing action to the hammer bank assembly,

allowing it to move with low friction. The optical linear encoder produces timing pulses

that are used to determine hammer bank assembly position and speed to synchronize

printing.

Hammer Bank Assembly

b.

Printing is done by a row of 34 print hammers mounted on the hammer bank assembly.

Each hammer consists of a stiff leaf spring with a small, cylindrical tip on one end. It is

securely on the hammer bank by a screw passing through its other end. A permanent

held

magnet running the full length of the hammer bank and acting through individual pole

holds all 34 hammer springs in the retracted (tensioned) state.

pins

encoder. The linear motor is driven by the mechanism driver PCBA

bank assembly laterally across the 0.4-inch distance traveled by

hammer bank as

when

Ć

Ć

Each print hammer has associated with it a normally deenergized electromagnetic coil

mounted

end of the hammer spring keeping it under tension. When hammer driver logic deterĆ

mines

the resulting magnetic field opposes the field of the permanent magnet, releasing the

hammer

the

During flight time, the coil is deenergized. As the hammer rebounds after striking, the

permanent

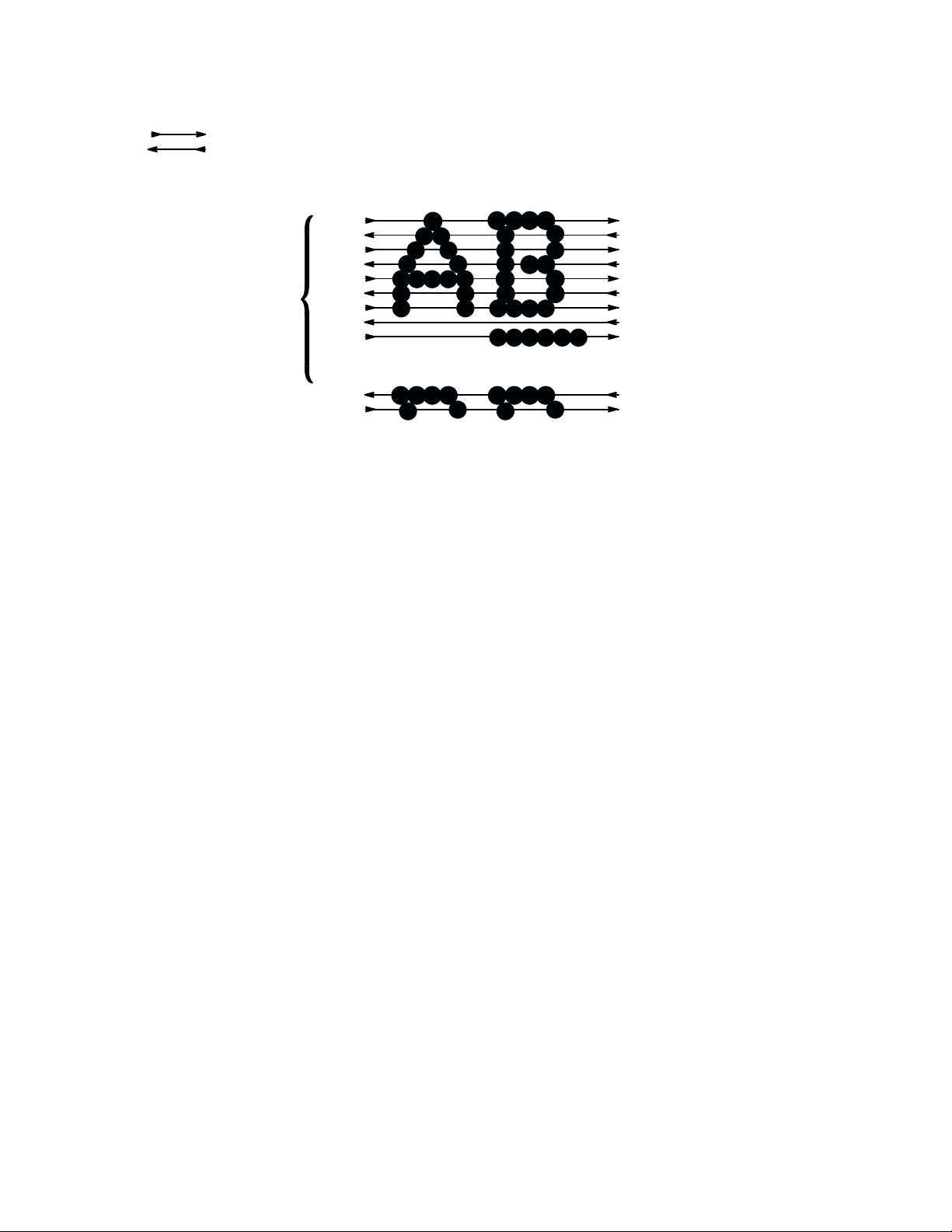

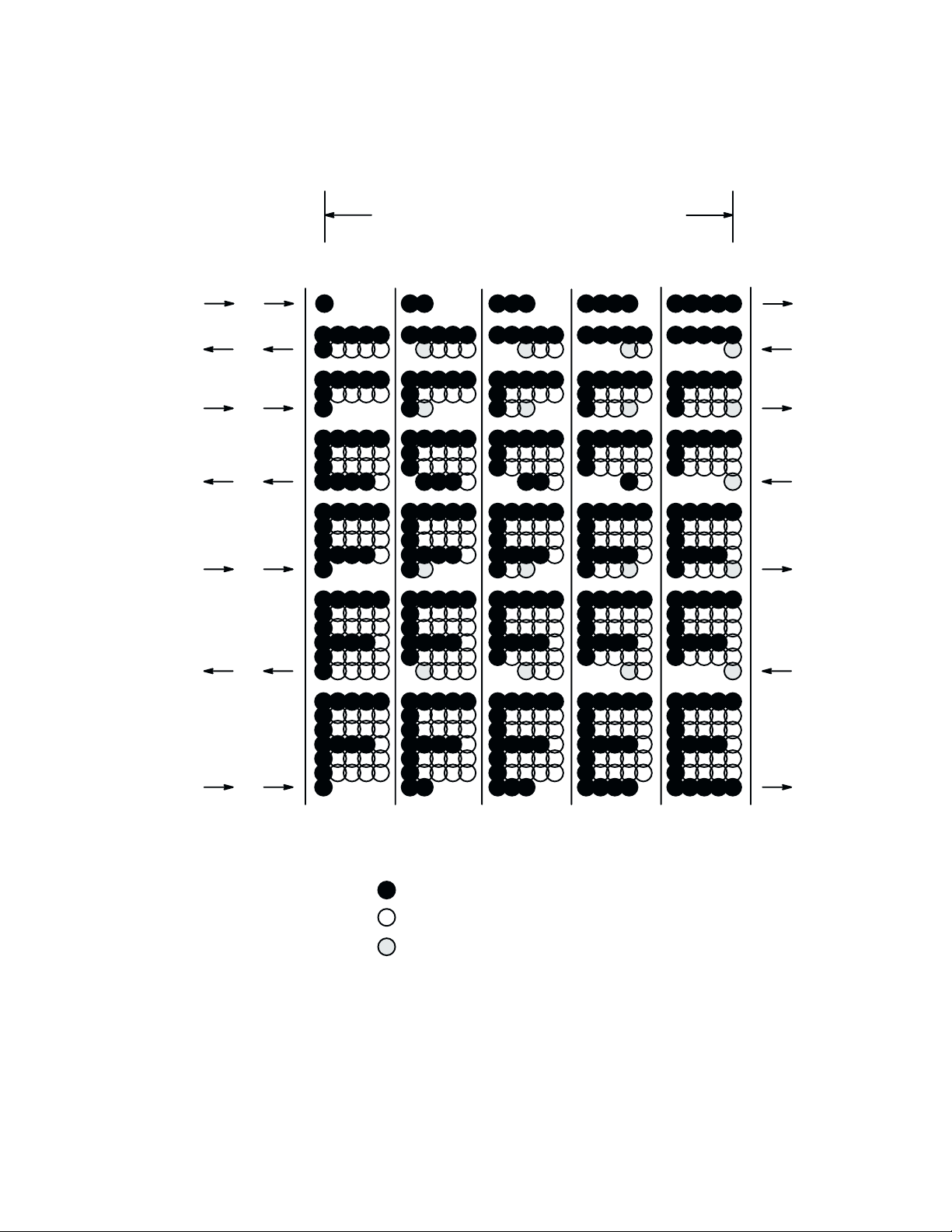

In correspondence (NLQ) and data processing (DP) modes, a line of characters is creĆ

ated

in a single scan as the shuttle moves from one side to the other through the character

columns

Figure 2-7 shows the order in which a single character is formed by a single print hamĆ

mer.

on the pole pin (Figure 2-4).

that the hammer is to print a dot, a current pulse energizes the coil. The polarity of

which allows it to impact the ribbon and paper (Figure 2-5) and leave a dot on

paper.

magnet recaptures the hammer and holds it ready for the next stroke.

by a scanning pattern (Figure 2-6). All dots in any row of the dot

(spaces).

The end of this pin magnetically attracts the free

matrix are printed

P3000 Principles of Operation2-4

Page 27

Figure 2-3. Printing Mechanism

2-5P3000 Principles of Operation

Page 28

Figure 2-4. Hammer and Shuttle Arrangement, Cross Section

Figure 2-5. P

rint Hammer Action

P3000 Principles of Operation2-6

Page 29

INDICATES DIRECTION OF SHUTTLE MOVEMENT

DOT

ROW START

PAPER

ADVANCES

1

2

3

ONE

CHARACTER

ROW

10

11

12

4

5

6

7

8

*

9

**

SPACE

0

PAPER

FEED

PAPER

ADVANCES

1

2

USED FOR LOWERCASE DESCENDER ONLY

*

USED FOR UNDERLINE AND LOWERCASE DESCENDER

**

NOTE: P3000 SHUTTLE SWEEPS THROUGH FOUR (IN 10 CPI) CHARACTER POSITIONS

Figure 2-6. Standard Character F

ormation

2-7P3000 Principles of Operation

Page 30

SUCCESSIVE HAMMER STROKES PER SCAN

SHUTTLE

SCAN

1

2

3

4

5

6

7

DOT

ROW

1

1

2

1

2

3

1

2

3

4

1

2

3

4

5

1

2

3

4

5

6

1

2

3

4

5

6

7

113135135713579

******

EVEN COLUMN DOT CENTERS WITHIN THE PRINTED CHARACTER

*

AREA AND CHARACTER SPACE HAMMER POSITIONS ARE NOT

ILLUSTRATED IN THIS DIAGRAM.

NOTE: = DOT

= NO DOT WHERE HAMMER HAS BEEN

= HAMMER POSITION

Figure 2-7. Character Formation by One Hammer

P3000 Principles of Operation2-8

Page 31

2-4. Printing Mechanism-continued

The

shuttle moves in alternate directions as it prints each successive

ters are formed by various dot matrices (Figure 2-8) according to the selected print

as shown in T

mode

able 2-1.

Table 2-1. Dot Matrices vs Speed/Density

row of dots. Charac

Ć

Print Mode

Correspondence (NLQ)

Data Processing

High Speed

In

the correspondence (NLQ) mode, for example, lower case

rows

of a 13 by 12 dot matrix. Seven overlapping dots are printed in

on

13 vertical centers for accurate character rendition.

The

dot printing process continues for the number

selected

advances the paper to the top dot row of the next character line to be printed. During

line

time,

c.

The

the

when

print mode. When an entire character line has been printed, the paper transport

advance, the hammer bank assembly continues the right/left sweeping motion; at this

however, the print hammers are disabled from printing.

Ribbon Transport

printer ribbon advances continuously on spool hubs. Ribbon motors are driven while

hammer bank assembly is running and stop when it stops. Ribbon motion is reversed

the foil at either end of the ribbon is detected.

Speed

(lpm)

175

300

400

Dots

Horizontal

7 on 13 centers

5 on 9 centers

5 on 9 centers

Vertical

9 plus 3 descenders

7 plus 2 descenders

5 plus 1 descender

characters are formed in 12

the horizontal plane

of dot matrix rows determined by the

the

Constant

circuit.

drawing the ribbon against the resistance exerted by the other motor. This system operĆ

ates to maintain a constant motor speed and constant ribbon tension. When the end of

the

ribbon tension is

While the hammer bank assembly is in motion, one motor acts as a driving

ribbon is detected, the two motors reverse direction.

maintained by controlling the motors with a differential drive

motor

2-9P3000 Principles of Operation

Page 32

175

LINES/MINUTE

13 X 9

300 LINES/MINUTE

9 X 7

NLQ

DATA PROCESSING

400 LINES/MINUTE

7 X 5

HIGH SPEED

Figure 2-8.

T

ypical Character Dot P

atterns, By Mode

P3000 Principles of Operation2-10

Page 33

2-5. Controller PCBA (Figure 2-9)

The controller PCBA contains logic circuits for communicating with the host data

the operator

source,

accept any one of three data formats, two parallel (Centronics, Data Products) and one

(RS 232).

serial

Functionally, the controller PCBA is divided into two sections: the data control unit

(DCU)

CPU

a.

The DCU microprocessor controls data operations between the host controller and the

printer.

The DCU receives coded information from the host that determines characters to be

printed,

paper

and the mechanism control unit (MCU). The DCU and MCU each contain a Z80

microprocessor to control their operation.

Data Control Unit (DCU)

font selection, line spacing, plotting, EVFU selection, elongated characters, and

movement. In turn, the DCU returns status data to the host.

Hammer Serial Data Multiplexer.

After data is received at the MCU RAM, the MCU, through the general purpose

interface

next character. The character from the MCU RAM buffer memory is loaded into

hammer serial data multiplexer.

the

control panels, and the mechanism driver PCBA. It is configured to

status register, then informs the DCU

that it is available for processing the

The output of the hammer serial data multiplexer is applied serially to the input of the

serial shift register on the mechanism driver PCBA. This is accomplished via the comĆ

pare (COM) line.

b. Host Interface (Parallel)

When the printer is on line and ready to operate, it sends ready" (READY) and on

line" (ONLINE) output signals to the host controller via the host interface. When the

host controller is ready to transfer a byte of code, it puts the byte on the host interface

lines: DATA 1 through DATA 8, followed by a data strobe (DATA STROBE) pulse.

data

DATA

STROBE loads the byte into the interface latches. DAT

data available (DA

Upon

receiving DAV, the CPU uses an input service subroutine in program memory. The

microprocessor sends addressing information to the DCU I/O port decoding logic. The

decoder

the

generates a write control (NDWR) signal, which is used to store the

dom access memory (RAM). NWRCTRL1 is applied to the host interface circuitry to

generate NACK. The NACK signal is sent to the host controller to indicate that the

printer

will generate a read host data (NRDHDATA) in response. This action transfers

host's data byte or control byte onto the DCU data bus (DD0-DD7). Next, the CPU

is ready to receive the next byte of data.

V) interrupt latch, which is polled by the microprocessor.

A STROBE also sets the

byte of data in ran

Ć

2-11P3000 Principles of Operation

Page 34

HOST

COMPUTER

IN

OUT

HOST INTERFACE

CIRCUITS

HAMMER

SERIAL

DATA

PAPER

MOTION

DETECTOR

PAPER

STEPPER

CONTROL

PANEL

PLATEN

OPEN/

PAPER

OUT

SW

DISP

+12V

-12V

PANEL INTERFACE

CIRCUITS

MISC

INTERFACE

CIRCUITS

POWER FAULT

DETECTION

CLOCK GENERATOR

DATA CONTROL

UNIT

4.9 MHZ SYSTEM

CLOCK

4 MHZ SYSTEM CLOCK

GENERAL

PURPOSE

INTERFACE

MECHANISM

CONTROL

UNIT

RIBBON

MOTION

CONTROL

HAMMER

FIRE

SIGNAL

DIRECTION

PDM

TIMING FENCE

Figure 2-9.

Controller Block Diagram

P3000 Principles of Operation2-12

Page 35

2-5. Controller PCBA-continued

c. Mechanism Control Unit (MCU)

The MCU controls the printing mechanism and the paper transport via the mechanism

PCBA, and monitors the shuttle direction and speed.

driver

1. P

aper A

dvance.

advance

Paper

generated in the MCU then sent to the mechanism driver PCBA which supplies

to the paper feed motor.

power

Paper

drive speed is controlled by three functions. As each motion command in the

printer

buffer is

the

amount of paper motion identified by that command.

A particular modulus of count is used to determine the spacing between dot rows.

spacing depends on the mode in effect.

The

Through the logical interaction of these functions, paper is moved. The motion is

either intermittent or steady with appropriate response to any required change of

at any time during the paper feed cycle.

speed

is controlled by paper feed pulses (PF1, PF2, NRUN1, and NRUN2)

encountered, a counter is loaded with a count value proportional to

2.

Ribbon Motion.

Ribbon

be applied to both ribbon motors causing ribbon motion to stop and by the RIB sig

nal

3.

Pulse Duration Modulator (PDM) Shuttle Drive Generator.

At

tle

immediately to the mechanism driver PCBA where it determines the direction the

hammer bank assembly is to take. Bits 1 through 7 are applied to the generator's

counter and are loaded into it when the 32 microsecond pulse is coincident to

MSYSCLK. The high order bit of the counter is set to a high or low state and reĆ

mains at that level until the counter count progresses far enough to change it. The

result is a pulse width modulated signal (NLMD) which is sent to the linear motor

driver to control shuttle speed. The width depends on the contents of the byte

latched

motion is controlled by

which allows the ribbon to move whenever the shuttle is in motion.

the PDM shuttle drive generator, a byte of motion data is presented to the shut

drive generator latch and is loaded into it by a NWRSTLMTR pulse. Bit

into the generator.

2-6. Mechanism Driver PCBA

The mechanism driver PCBA contains those circuits required to drive the printing

These

mechanism.

nism driver PCBA also produces, by use of regulators, the +12 Vdc and -12Vdc reĆ

by the controller PCBA for the serial interface. The +12 Vdc is derived from the

quired

+30 Vdc output of the power supply PCBA, while the -12 Vdc

Vdc

output of the power supply PCBA.

driver circuits are under control of the controller PCBA. The mecha

the RIB P

ARK signal which causes equal tension to

Ć

Ć

0 is sent

Ć

is derived from the -16

2-13P3000 Principles of Operation

Page 36

RIB

RIB PARK

RIBBON

GUIDES

SWR

SWL

RIBBON

MOTOR

DRIVER

LEFT

RIBBON

MOTOR

RIGHT

RIBBON

MOTOR

PF1/PF2

NRUN1/NRUN2

COM

NHSC

1/2 MCLK

NHCK

DIR

NLMD

NTA

FENCE

HAMMER SERIAL

DATA SHIFT REG

HAMMER RESET

LOGIC

ENCODER PULSE

SHAPER

BLOWER

PAPER FEED

STEPPER MOTOR

DRIVERS

HAMMER DATA

LATCHES

NHRS

OD

LINEAR MOTOR

DRIVER

ENC

MOTOR

DRIVER

HAMMER BANK

DRIVERS

DARLINGTON

PAIR

BLOWER

MOTOR

PAPER

FEED

MOTOR

HAMMER

COILS

SHUTTLE

LINEAR

MOTOR

ENCODER

PCBA

CONTROLLER

PCBA

+12V

-12V

MASTER

CLEAR

+12 V POWER

SUPPLY

-12V POWER

SUPPLY

POWER UP

RESET

MECHANISM DRIVER PCBA

Figure 2-10.

Mechanism Driver Block Diagram

+30V

-16V

+5V

+5V +30V -16V

P3000 Principles of Operation2-14

Page 37

2-6. Mechanism Driver PCBA-continued

The

mechanism

(Figure 2-10):

lows

driver PCBA contains driver circuits for the printing mechanism as folĆ

-Hammer Bank Drivers and L

-Linear Motor Driver

-Ribbon Motor Driver

-P

aper F

eed Motor Drivers

a.

Hammer Bank Logic

The hammer bank logic consists of a serial shift register. The serial data output (COM)

of the hammer serial data multiplexer on the controller PCBA is clocked into the shift

register by the hammer shift clock (NHSC). After the data is shifted in serially, it is

strobed

the controller PCBA. Each output of the shift register latch is connected directly to the

input

1.

2. Hammer Bank Drivers. The hammer bank drivers consist of identical drivers (one

to the shift

of the corresponding hammer driver circuit (Figure 2-11).

Hammer R

the signals, hammer reset (NHRS) and overdrive (OD). NHRS is used to

erate

able/disable

electromagnetic field which results in hammer release by causing an initial extra

current to be applied. NHRS causes the drivers to turn off. NHRS and OD

high

derived from signals from the controller PCBA: hammer clock (NHCK), which

data into the hammer data latches; and 1/2 MCLK, the system clock.

loads

for each hammer coil) and three identical Darlington drivers. Each Darlington

energizes a portion of the hammer coils while the others energize the remain

driver

hammer coils.

ing

register parallel outputs by hammer clock (NHCK) which is sent from

eset/Overdrive Logic. The hammer reset/overdrive logic is used to genĆ

the outputs of the shift register. OD is used to speed generation of the

ogic

-Blower Driver

-Optical Encoder Signal Conditioning

en

are

Ć

Ć

When

a hammer is to print, its hammer driver is turned on by the data

the

return path to -16 Vdc for the associated

the

Darlington drivers are turned on by OD, and +30 Vdc is applied to all the coils. Each

of the coils that has its hammer driver enabled by the data latch is energized. When the

is energized, the hammer is released to print.

coil

After

a time delay, +30 V HB is disconnected from the coil when OD turns off the

lington drivers. A constant -16 V is applied to the coils to sustain coil current and is

off when NHRS clears the data latch.

turned

b.

Linear Motor Driver

The linear motor driver provides drive for the two linear motor coils on the shuttle and

consists

drivers (NLMD, DIR, and NTA) come from the MCU section on the controller PCBA.

The linear motor drive pulse (NLMD) is a pulse-width modulated signal generated by

the

longer

of two push/pull drivers and control circuits.

shuttle drive generator. The shuttle speed is directly proportional to pulse width. The

the drivers are on, the faster the shuttle is driven by the linear motors.

hammer coil is completed. Simultaneously,

The three inputs to the linear motor

latch output, and

Dar

2-15P3000 Principles of Operation

Ć

Page 38

(OVER DRIVE) OD

+30V HB

V

COM

DARLINGTON

PAIR

COM

NHSC

NHCK

OD

+5V +5HL

A

B

CK

SHIFT REGISTER

LATCHES

NHCK

CK

NHRS

DATA

CATCH

DIODE

TYPICAL

HAMMER

BANK

DRIVER

COILS

-16V

I

C

+30V

CATCH

DIODE

DATA

V

COM

T

NHRS

C

Figure 2-11.

Hammer Bank Logic, Drivers, and W

aveforms

P3000 Principles of Operation2-16

Page 39

2-6. Mechanism Driver PCBA-continued

b. Linear Motor Drive

The

direction

ler PCBA and is used to

of

the NLMD pulses to

motor

drivers is the turnaround (NT

c.

Ribbon Driver.

The

ribbon driver circuits (Figure 2-12) drive the ribbon from one reel to the other as it

passes between the hammer bank and the platen. The direction of ribbon travel is reĆ

versed automatically as the end of ribbon is detected by sensors on the ribbon guide. A

strip at each end of the ribbon provides the end of ribbon indication.

metal

The

ribbon is driven by two dc motors in a servo circuit. F

motor is the driven motor, drawing the ribbon against resistance exerted by the other mo

tor. This system maintains constant motor speed and ribbon tension. When the end of

ribbon is detected, the two motors exchange roles. The ribbon is in motion only while

printing is taking place.This activity is controlled by the ribbon (RIB) and ribbon park

P

(RIB

Whenever

the opposite state of the cross coupled latch at the input of the ribbon driver circuit to

on the related FET

turn

FET

1 is turned off and

ribbon

the left ribbon motor as the higher torque motor, with the right ribbon motor providing

for ribbon tension.

drag

(DIR) input also is generated by the shuttle drive generator on the control

ARK) signals from the MCU on the controller PCBA.

an end-of-ribbon sensor (RIB SWR or RIB

motor driver is increased considerably by a voltage divider network. This connects

-continued

control the left and right shuttle direction by steering the polarity

the linear motor drivers. The remaining input signal to the linear

A) signal which is sent from the controller PCBA.

or either direction of travel,

SWL) is activated, it establishes

. If, for example, the left hand sensor (RIB SWL) resets the

FET 2 is turned on. W

ith FET 2 turned on, the output to the left

one

latch,

Ć

Ć

When right end of ribbon is detected, the latch is set to the opposite state and control

circuits and motors reverse roles. When no printing is taking place, RIB PARK is high

and both FETs are turned off. The motors then act in equal opposition to stop ribbon

RIB P

movement.

to

turn off the blower when printing is not in progress.

ARK also is applied to the blower motor driver circuit. There, it is used

2-17P3000 Principles of Operation

Page 40

+30 V +30 V

5 V 5 V

RIB PARK

+

-

RIGHT

RIBBON

MOTOR DRIVER

RIGHT

RIB

MOTOR

COMMON

FET 1 FET 2

MOTOR

LEFT

RIB

MOTOR

MOTOR DRIVER

+

-

LEFT

RIBBON

RIB SW R

RIB SW L

LATCH

Figure 2-12. Ribbon Driver Circuit

P3000 Principles of Operation2-18

Page 41

2-6. Mechanism Driver PCBA-continued

d. P

aper Drive Motor Drivers

The paper drive motor is an incremental (stepper) motor containing two pairs of coils.

One pair of coils is driven by paper feed motor driver signals PF1/NRUN1, while the

pair is driven by PF2/NRUN2. The paper

other

per feed pulses, PF1 and PF2. NRUN1 and NRUN2

tion with PF1 and PF2 to prevent spurious paper motion.

Paper feed pulses are under program control and require no manual intervention.

PF1/NRUN1 and PF2/NRUN2 pulses control the identical and essentially independent

circuits. Each drive circuit operates in like fashion.

drive

The

paper feed pulses are gated to a push-pull amplifier to provide current through that

pair of

the

motor coils. A constant current controller circuit is used to stabilize the induc

tive current pulses (smoothing paper drive operation and protecting circuit compoĆ

This controller circuit

nents).

the duration of the pulses applied to the push/pull driver. The effect of this circuit is to

maintain

shaft

The motor coil current is monitored across a 0.1 Ohm resistor connected to the ground

side

tion

signal to the controller circuit. The stages of the controlled circuit are referenced to

VREF and RAMP. RAMP and VREF work together with NRUN1 and NRUN2 to set

the

motor coil current at a relatively constant value, while still permitting the motor

to move at variable speeds.

of the push/pull driver. The voltage drop across this resistor controls the limiting ac

of the circuit and drives a low pass filter. The

pulse width of the signals sent to the paper feed motor.

monitors current flow through the motor coils and controls

feed motor drivers are controlled by pa

are

enable signals used in conjunc

filtered output signal is an error input

Ć

Ć

Ć

Ć

The output of the controller is a pulse with a duration proportional to the input error

signal. This variable width pulse is used to gate the paper feed pulses to the push/pull

drivers and consequently vary the duration of the motor drive pulses to control the curĆ

rent.

2-19P3000 Principles of Operation

Page 42

2-6. Mechanism Driver PCBA-continued

e. P

ower-up R

The

power-up reset logic is used to generate the master

is activated (NMC is low) by sensing the presence of +5 Vdc when power is turned on

initially.

+5

The

used to clear the microprocessors on the controller PCBA to

load

f.

The

shuttle. The function of this circuit is to shape the analog input (ENC) to digital pulses

(FENCE)

tations

g. Power Supplies.

The

The +12 Vdc supply is derived from the +30 Vdc input to and the -12 Vdc supply is

derived

Vdc charges an R

state.

Encoder Circuit

encoder circuit accepts the analog output of the encoder preamplifier located on

at the output. The output is applied to the controller PCBA for timing compu

which are used to maintain shuttle and print control.

+12 Vdc and -12 Vdc power supplies are located on the mechanism driver PCBA.

from the -16 Vdc input to provide -12 Vdc at the output.

eset Logic

C network which then turns the circuit off (NMC high). NMC is

clear signal (NMC). This circuit

establish

the initial program

the

Ć

2-7. Power Supply PCBA

The power supply PCBA is a switching power supply. Its regulated outputs are +5 Vdc,

-16 Vdc and +30 Vdc. While all outputs are supplied to the mechanism driver PCBA,

only +5 Vdc is supplied to the controller PCBA, the control panel PCBAs, and the enĆ

PCBA.

coder

P3000 Principles of Operation2-20

Page 43

CHAPTER 3

PREVENTIVE MAINTENANCE

3-1. General

This

chapter provides instructions necessary to maintain the printer in operating con

dition.

3-2. Preventive Maintenance Checks and Service (PMCS)

Printer

PMCS are listed in T

Remove power before performing PMCS. Failure to do so

result in injury or equipment damage.

could

NOTE: Perform PMCS every six months or after 500 hours of operation,

whichever comes first. Perform them more often when operating under seĆ

vere conditions.

able 3-l.

- WARNING -

Ć

Table 3-1. Preventive Maintenance Checks and Service

Item

No.

1

2

3 Entire Printer Run print sample, adjust hammers if/as required.

4

5

Name

Entire Printer

Entire Printer

Timing Belt

Tractor Belts

Procedure

Perform overall physical inspection per paragraph 3-3.

Do not disassemble for this inspection.

Clean per paragraph 3-4.

Check tension per paragraph 3-5.

Check tension per paragraph 3-5.

3-3. Inspection

Visually inspect printer using Table 3-2 as a guide. Perform no disassembly for this

inspection.

Correct any condition that could affect performance or reliability.

3-1P3000 Preventive Maintenance

Page 44

3-4. Cleaning

a. Exterior of Cabinet

- CAUTION -

Do

not use abrasive cleaners, particularly on window

drip

water into printer

. Damage to equipment will result.

. Do not

l. Wipe

2. Wipe

3. V

Item

Cabinet, Base,

Structure

Attaching

Hardware

Nameplates

Latches and

Catches (cover

and shuttle)

Hinges

Electrical

Connectors

cabinet with clean, lint free cloth dampened (not wet) with water and mild

detergent. Alternate method: spray exterior surfaces lightly with window

cleaner.

dry with clean, lint free cloth.

acuum ventilation slots at rear of cabinet.

Table 3-2. Physical Inspection

Inspection

Check for damage, cracks, breaks, dents, gouges, scratches, delamination, warpage, rust, corrosion and proper finish.

Inspect screws, bolts, nuts, washers for thread damage, rust, or

corrosion.

Inspect for legibility and damage.

Inspect for damage and loose or missing hardware.

Inspect for damage and loose or missing hardware.

Inspect for damage, bent or broken pins.

Controls and

Indicators

Window

Ribbon Cables

Circuit Boards

Fan and Motors

Bumpers

Inspect for damage.

Inspect for breaks, cracks, or discoloration.

Inspect for broken wire or strands, damaged insulation, pinched

wiring, and possible shorting conditions.

Inspect for breaks, warpage, evidence of overheated components.

Inspect for obvious damage.

Inspect for unusual wear. If cracked, chipped, or worn unevenly,

replace per paragraph 5-33.

P3000 Preventive Maintenance3-2

Page 45

3-4. Cleaning-continued

b. Interior of Cabinet (Figure 3-1)

l.

Disconnect ac power cord (1) from printer.

2.

Open cabinet cover (2).

3.

Move forms thickness lever (3) to full open. R

4.

Squeeze locking latch (4) and lift ribbon spools (5) from ribbon hubs (6).

5. Dislodge paper dust and ribbon lint with a soft brush. Vacuum up residue. Pay

particular

6. W

ipe spline shaft (10) with soft cloth.

7. Using cloth dampened with alcohol, clean ribbon guides (11) at each side of

cabinet.

attention to tractor (7), hammer bank (8), and base pan (9).

emove paper from printer.

Figure 3-1. Cleaning Interior of Cabinet

3-3P3000 Preventive Maintenance

Page 46

3-4. Cleaning-continued

c. Hammer Bank Assembly (Figure 3-2)

1. Loosen

to

2.

Unlock tractors (3) and move outward to sides.

3.

Lift up on shuttle lock knob (4) and pull toward front of printer.

4. When shuttle assembly (5) has rotated 90 degrees to service position, release

knob

5. Remove

of printer and lifting. Wipe with alcohol dampened cloth. Press ironer (1) back

into place.

two captive screws (1). Grasp shuttle cover (2) at both ends. Lift upward

free front tabs, then remove.

(4).

paper ironer (Fig 3-3, 1) by applying pressure at its edges toward rear

- CAUTION -

Shuttle (5) is magnetized. This may cause some difficulty in

performing the next step. Be careful not to bend cover (6).

6. Carefully lift ends of hammer bank cover (Fig 3-2, 6) from roll pins (7). Pivot

(6) onto its rear edge to about 45 degrees, then remove.

cover

7. Moisten clean soft cloth with alcohol. Wipe cover assembly to remove lint, ink

paper residue. Also clean holes between strips which make up cover (6).

and

- CAUTION -

Use

of excessive force could disturb alignment of hammers or

chip them.

8. Using stiff, non-metallic brush (such as a toothbrush) and alcohol, brush tips

to remove lint and ink accumulations.

(8)

9. V

acuum up any residual debris.

- CAUTION -

When reinstalling hammer bank cover (6), position it careĆ

fully and try to prevent the magnets from snapping it into

place.

10. Position

alignment

11.

Gently lower cover (6), steering it into place.

hammer bank cover (6) horizontally, slightly above hammer bank, over

holes adjacent to roll pins (7).

P3000 Preventive Maintenance3-4

Page 47

Figure 3-2. Cleaning Hammer Bank Assembly

3-5P3000 Preventive Maintenance

Page 48

3-4. Cleaning-continued

c.

Hammer Bank Assembly-continued

12. Pull out shuttle lock knob (4) and rotate shuttle to operating position. Release

knob.

13. Remove two screws (9). Lift blower (10) to expose fan wheel (11). Brush wheel

(11) to loosen dirt. Vacuum up residue. Return blower (10) to position. Install

screws (9).

two

14. Grasp

15.

d.

1. R

2. L

3. Vacuum

4.

5.

shuttle cover (2) with both hands. Slide tabs at front of cover into slots

front

of printer. P

captive

screws (1).

Close cabinet cover.

Fan (Figure 3-4).

emove cabinet per paragraph 5-15a.

oosen three screws (1) and remove EMI shield cover (2).

NOTE; Now is a good time to check paper feed timing belt per paragraph

3-5.

fan (3) to remove paper, lint, and chaff.

Install EMI shield cover (2) and tighten three screws (1).

Install cabinet per paragraph 5-15b.

ress down on cover (2) until it snaps into position. T

at

ighten two

P3000 Preventive Maintenance3-6

Page 49

Figure 3-3. Cleaning P

aper Ironer

3-7P3000 Preventive Maintenance

Page 50

Figure 3-4. Cleaning Fan

P3000 Preventive Maintenance3-8

Page 51

3-5. Paper Feed Belt Tension Check (Figure 3-5)

1. Remove

2. R

3.

Separate belt shield (2) from right side plate (3).

4. Depress center of upper span of belt (4) with finger. Ideal deflection is

1/16-inch.

5.

Place belt shield (2) against right side plate (3).

6.

Install two screws (1).

7. R

cabinet per paragraph 3-4d steps (1) through (3).

emove two screws (1).

If tension is incorrect adjust per paragraph 5-9.

eplace cabinet per paragraph 5-15, a and b.

3-9P3000 Preventive Maintenance

Page 52

Figure 3-5. P

aper F

eed Belt Tension Check

P3000 Preventive Maintenance3-10

Page 53

CHAPTER 4

TROUBLESHOOTING

4-1. General

This chapter provides procedures to fault isolate to field replaceable units. A working

knowledge of the P3000 Operator's Guide and the P3000 User's Reference Manual is

required

to perform fault isolation procedures contained in this manual.

4-2. Common Causes of Malfunctions

Improper

interface problems. Many problems can be corrected by replacing one of the PCBAs.

Other problems associated with poor print quality can be cleared up by adjusting hamĆ

mer

lems can be attributed to particular assemblies of the printing mechanism, or occasionĆ

ally,

printer operation may be caused by electronic failures,

alignment, platen gap, shuttle turnaround time, or

to cables or interconnecting PCBAs.

4-3. Internal Testing

a. Self Test.

The

printer continuously monitors some of its own

fault indications appear on the indicators and digital display. A summary of these indica

is presented in T

tions

Supplemental T

b.

The printer is capable of conducting additional tests which can be used to evaluate its

performance. These tests, which are summarized in Table 4-2, are useful as an aid to

F

troubleshooting.

or specific procedures, refer to User's R

4-4. Fault Isolation

able 4-1.

ests.

mechanical failures, or

belt tension. The remaining prob

functions. When a problem develops,

eference Manual.

Ć

Ć

Failures are divided into catagories as listed in the malfunction symptom index, Table

T

o fault isolate, locate your symptom

4-3.

chart which will guide you through the correct troubleshooting procedure. Note that

flow charts do not take multiple failures into consideration.

these

in the table. The table will direct you to a flow

4-1P3000 Troubleshooting

Page 54

Table 4-1. Fault Codes

CHECK

Indicator

Flashing

Flashing

Flashing

Flashing

Flashing

Steady

Steady

Display

(FAULT

PLATEN OPEN

SHUTTLE JAM

SHUTTLE STALL

FONT PROM

Readout

CONDITION)

PAPER OUT

PAPER JAM

DCU RAM

Operator

Correctable

Ye s

Ye s

Ye s

Ye s

Ye s

No*

No*

Description

Paper out

Platen open or shuttle cover off

No paper motion (PMD option)

Shuttle jammed

Shuttle not up to speed

DCU data RAM pattern check

Primary font PROM check sum

Steady