Page 1

FormsPro 4300, FormsPro 4500

and FormsPro 4503

SERIAL MATRIX PRINTERS

Operation Manual

Copyright 1994

Printek, Inc.

1517 Townline Road

Benton Harbor, MI 49022

(616) 925-3200 Printek Part Number 2975

Page 2

USER NOTIFICATION OF FCC RULES PART 15, SUBPART A FOR CLASS A

DEVICES (Sections 15.105 and 15.21)

This equipment has been tested and found to comply with the limits for a Class A Digital

Device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference in which case the user will be required to correct the interference at his

own expense.

The user is cautioned that any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

VDE - GENERAL PERMIT USERS MANUAL INFORMATION

Certificate of Manufacturer/Importer

This is to certify that the FormsPro 4300, FormsPro 4500, and FormsPro 4503 printers are

shielded against radio interference in accordance with the provisions of VDE 0871/6.78.

The German Postal services have been advised that this device is being put on the market and

are entitled to inspect the series for compliance with the regulations.

Interface cables: All interface cables to and from this device must be shielded.

Equipment which can be operated within a system together with other devices must comply

with the requirements of the class B limits as specified in DIN/VDE 0871/6.78, Section 3.2 as

well as the provisions specified in

is made of a General (Operating) Permit.

Bescheinigung des Herstellers/Importeurs

Hiermit wird bescheinigt, daß der FormsPro 4300, FormsPro 4500, und FormsPro 4503

printer in Ubereinstimmung mit den Bestimmungen der VDE 0871/6.78 funk-entstört ust,

Der Deutschen Bundespost wurde das Inverkehrbringen dieses Gerätes angezeigt und die

Berechtigung zur Überprufung der Serie auf Einhaltung der Bestimmungen eingeräumt.

Schnittstellenkabel: Alle Schnittstellenkabel zu und von diesem Gerät Müssen abgeschirmt

sein.

Geräte, die zusammen mit anderen Geraten innerhalb eines Systems betrieben werden

können, müssen sowohl den Anforderungen der Beschränkungen fur die Klasse B wie in

DIN/VDE 0871/6.78, Absatz 3.2 festgelegt, als auch die in

Vfg 1046/1984 festgelegten Bestimmungen entsprechen, wenn eine allgemeine (Betriebs-)

Erlaubnis verwendet wird.

Generell werden diese Bestimmungen nur erfüllt, wenn das Peripheriegerät in einem

serienmäßig hergestellten System betrieben wird, das mit dem VDE-Funkshutzaufkleber und

dem Index "0871-B" versehen ist.

s

2 section 1 and section 3 of the Vfg 1046/1984 when use

s

s

2, Absatz 1 und Absatz 3 des

s

Acknowledgements:

IBM and Proprinter are registered trademarks of International Business Machines Co., DEC

is a registered trademark of Digital Equipment Corporation, Epson is a registered trademark

of Seiko Epson, Printek and FormsPro are registered trademarks of Printek, Inc.

Specifications subject to change without notice.

Page ii

Page 3

TABLE OF CONTENTS

INTRODUCTION 1-1

HOW TO USE THIS MANUAL 1-1

CHAPTER 2 - INSTALLATION AND QUICK SETUP 2-1

SELECTING AN APPROPRIATE INSTALLATION LOCATION 2-1

INSTALLING THE RIBBON 2-3

INSTALLING PAPER 2-5

TESTING THE PRINTER 2-8

CONNECTING THE PRINTER TO A COMPUTER 2-8

Entering the Interface Menu at the Control Panel 2-9

MATCHING THE PRINTER TO YOUR APPLICATION SOFTWARE 2-11

CHAPTER 3 - OPERATION 3-1

INTRODUCTION 3-1

CONTROL PANEL DISPLAY AND INDICATORS 3-1

CONTROL PANEL BUTTONS 3-3

INTRODUCTION TO SETUP 3-6

Entering the Forms Setup Menu 3-6

Entering the Interface Setup Menu 3-10

CHANGING THE PAPER 3-13

CHANGING THE RIBBON 3-16

Using Printek Ribbons 3-16

Removing the Old Ribbon 3-16

Installing the New Ribbon 3-17

CHAPTER 4 - USING SPECIAL FEATURES 4-1

UNLOADING AND SELECTING FORMS 4-1

HANDLING A PAPER ERROR CONDITION 4-2

Standard Paper Error Handling 4-2

Page Reprint 4-2

USING THE RIBBON CHECK FEATURE 4-4

Matching the Ribbon Wear Indicator to Printer Use 4-4

Turning Off Ribbon Checking 4-4

CHECKING SETUP CONFIGURATION 4-4

PRINTING SETUP INFORMATION 4-5

PARKING THE FORMSPRO 4503 TRACTORS FOR SHIPMENT 4- 5

CHAPTER 5 - IN CASE OF DIFFICULTY 5-1

INTRODUCTION 5-1

SYMPTOMS AND POSSIBLE CAUSES 5-1

USING THE HEX DUMP MODE 5-4

SELECTING A QUALITY FORM 5-5

REPLACING THE AC POWER FUSE 5-5

APPENDIX A - ADVANCED CONTROL PANEL FEATURES A-1

SETUP: OPTIONS A-1

SETUP: SECURITY A-4

Page iii

Page 4

Table of Contents

APPENDIX B - OPTIONAL RS-422 INTERFACE B- 1

APPENDIX C - OPTIONAL COAXIAL/TWINAXIAL INTERFACE C- 1

COAXIAL OPERATION C- 1

Option Switches When Configured for Coaxial Operation C- 2

TWINAXIAL OPERATION C- 4

Option Switches When Configured for Twinaxial Operation C- 5

Twinaxial Address Switch C- 5

Twinaxial Installation Preparation C- 6

Getting On-line C- 6

Twinaxial Verification Problems C- 7

COAXIAL/TWINAXIAL INTERFACE DIAGNOSTICS C- 8

APPENDIX D - OPTIONAL BUFFER EXPANSION D- 1

APPENDIX E - ASCII CHARACTER TABLES E- 1

ASCII CONTROL CODE DEFINITIONS E- 1

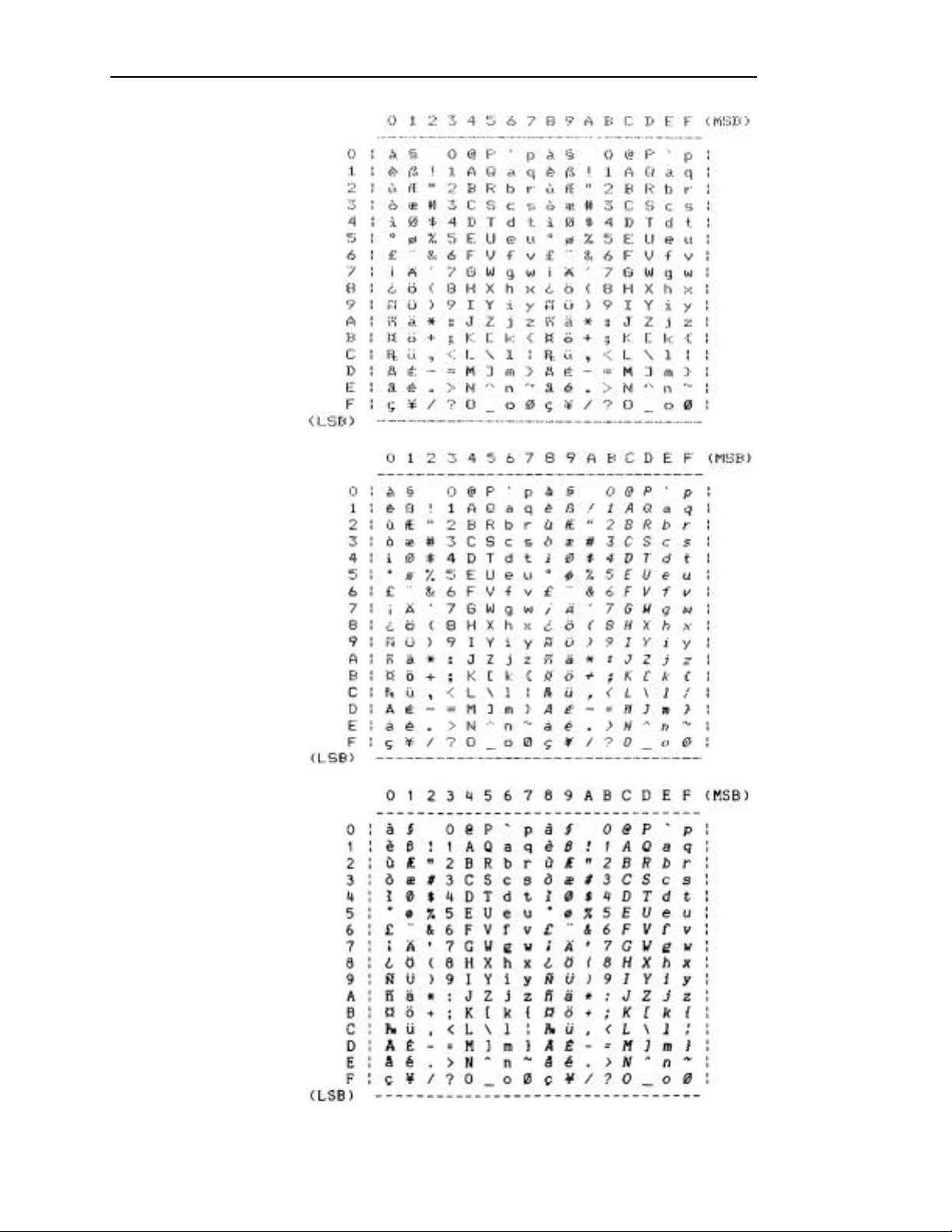

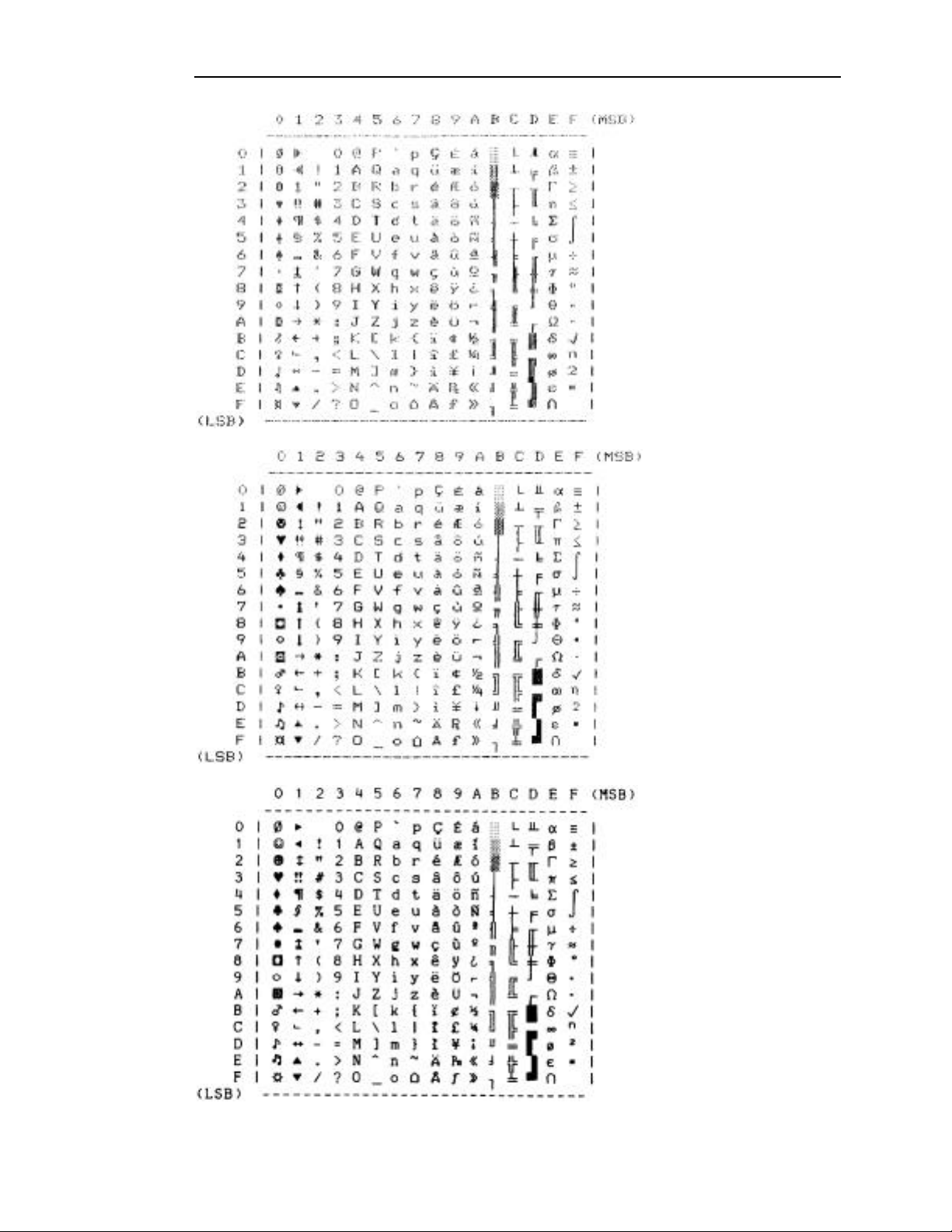

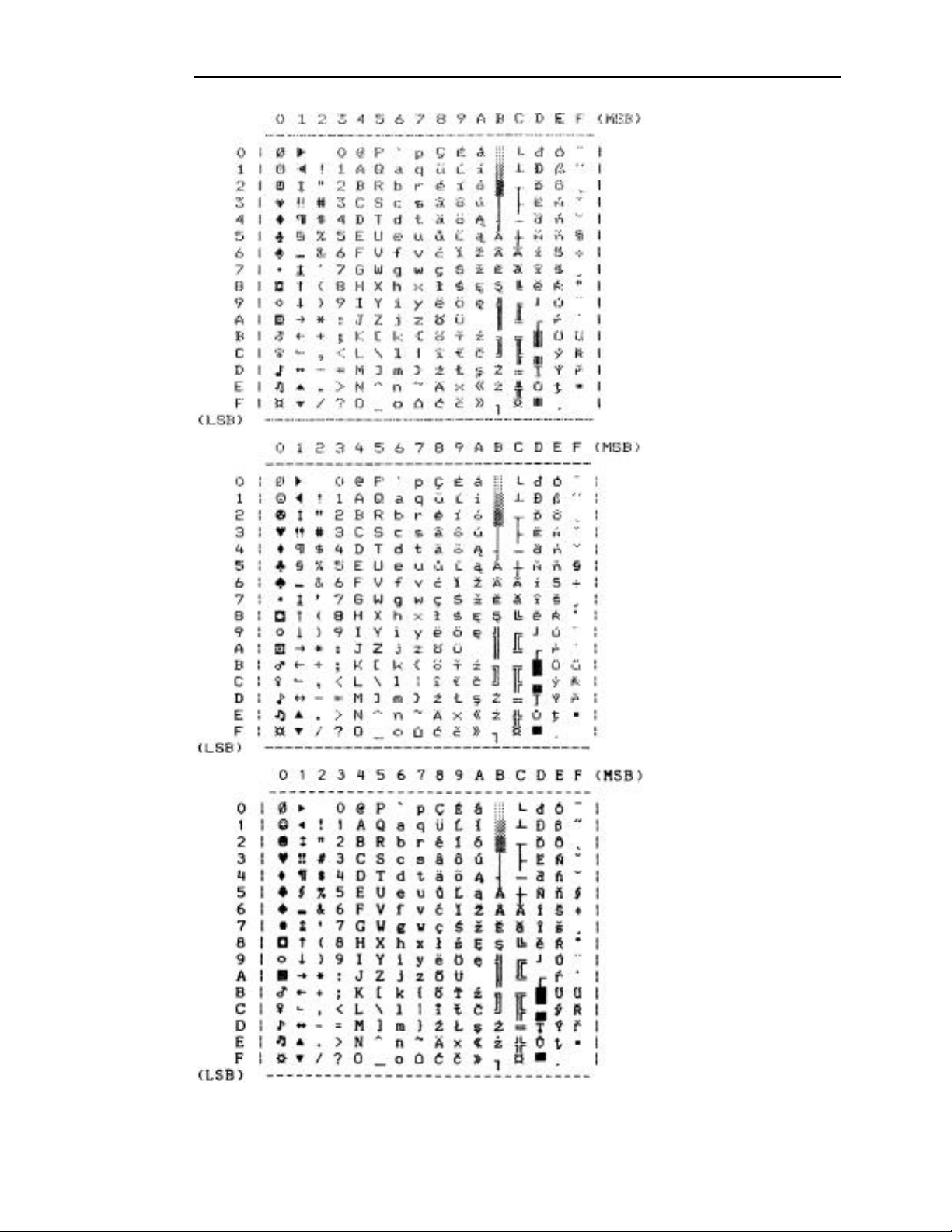

EPSON FX FONT SAMPLES E- 2

PC FONT SAMPLES E- 3

EBCDIC FONT SAMPLES E- 4

PC LATIN 2 (SLAVIC) FONT SAMPLES E- 5

OCR A FONT SAMPLE E- 6

OCR B FONT SAMPLE E- 6

DECIMAL-TO-ASCII CONVERSION TABLE E- 7

APPENDIX F - CONTROL CODE & ESCAPE SEQUENCE SUMMARIES F- 1

ANSI x3.64 EMULATION F- 1

EPSON FX EMULATION F- 2

IBM PROPRINTER EMULATION F- 4

LA-120 EMULATION F- 5

SIMPLE TTY EMULATION F- 6

PRINTEK EMULATION F- 7

APPENDIX G - PRINTER RESET CONDITIONS G- 1

APPENDIX H - CLONING PRINTER SETUP H- 1

CLONING FROM PRINTER TO PRINTER H- 1

Possible Cloning Errors H- 2

Information that is Cloned H- 2

USING A SETUP UNIT FOR CLONING H- 2

Cloning from a Printer to a Setup Unit H- 3

Cloning from a Setup Unit to a Printer H- 3

APPENDIX I - PRINTER SPECIFICATIONS I- 1

APPENDIX J - SETUP MENU SUMMARIES J- 1

GLOSSARY GLOSSARY- 1

Page iv

Page 5

INTRODUCTION

HOW TO USE THIS MANUAL

This manual provides information on how to install and operate your FormsPro 4000 series

printer. Below is a brief description of the information that is presented in each section. For

your convenience, a glossary of printer related terms is included at the back of this manual.

Introduction Provides you with an introduction to the capabilities and

operation of the FormsPro 4300, FormsPro 4500 and the

FormsPro 4503 printers.

Installation and Quick Setup Helps you select an appropriate location for the printer, and

then test and perform the initial setup of the unit.

Operation Describes the control panel and ways to modify the

operating parameters which may be set for each of the ten

form setups and the host computer interface. Changing the

paper, using the three tractor paths in the FormsPro 4503,

and changing the ribbon are also described.

Using Special Features Describes special messages which you may encounter when

you unload forms, how paper-error conditions are handled,

how ribbon usage is monitored, and how to use the Page

Reprint feature.

In Case of Difficulty Describes what you should do in the event you encounter

difficulty using your printer, and provides you with a list of

possible causes for various symptoms and error messages.

Also included is information about where you can obtain

service, if it is required.

Following the above sections are appendices containing ASCII character tables and font

samples, additional control panel features, detailed interface specifications for the optional

interfaces, information on how to clone setup information from one printer to another, and

printer specifications.

Page 1-1

Page 6

Introduction

PRINTER MODEL DESCRIPTIONS

AND KEY FEATURES

The Printek FormsPro 4000 series printers are heavy duty serial dot matrix printers. The

FormsPro 4300 is a medium speed printer and the FormsPro 4500 and FormsPro 4503 are

high-speed printers. They have been specifically designed for printing on hard to print forms

which are often not printed adequately by other printers. Of course, the FormsPro 4000 series

printers will also print on lighter forms.

All models provide straight paper paths for jam-free paper motion and a zero waste tear bar

for demand document applications.

You can permanently record up to ten complete sets of form parameters, which may then be

selected either at the printer's control panel or from the host computer. The FormsPro 4503

provides three sets of tractors, any of which may be selected in the form parameters for a

particular form. This allows the printer to automatically unload one form and load another

when it is selected either via the front panel buttons or a software command from the host

computer. When loading forms, the printer will automatically adjust the print head position

to match the thickness of the newly loaded form.

The printers come equipped with basic bar code capability, an industry standard parallel

interface and an RS-232C serial interface.

You can also order the printers with an optional RS-422 serial interface, or a

coaxial/twinaxial interface which emulates an IBM 3287 or 3262 printer, or an IBM 4214,

5225, or 5256 printer.

Other options include a 32K buffer, which increases the standard 4K character input buffer to

28K characters, the Imager and ImagerPlus bar code capabilities, and the FormsCutter which

may be used to cut each form as it is printed or to separate reports.

A specially designed print stand, which holds multiple paper supplies, is also available.

Page 1-2

Page 7

INSTALLATION AND QUICK SETUP

SELECTING AN APPROPRIATE INSTALLATION

LOCATION

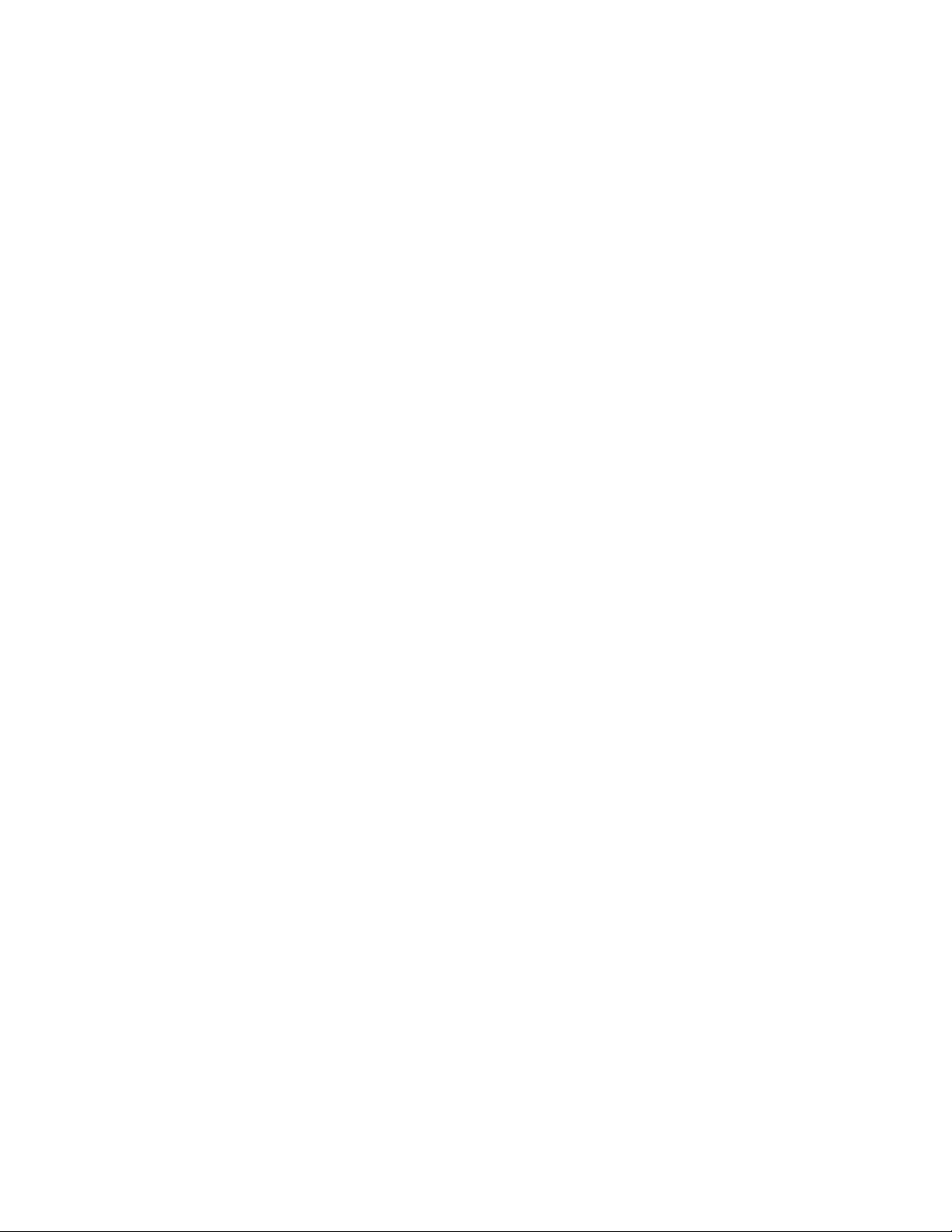

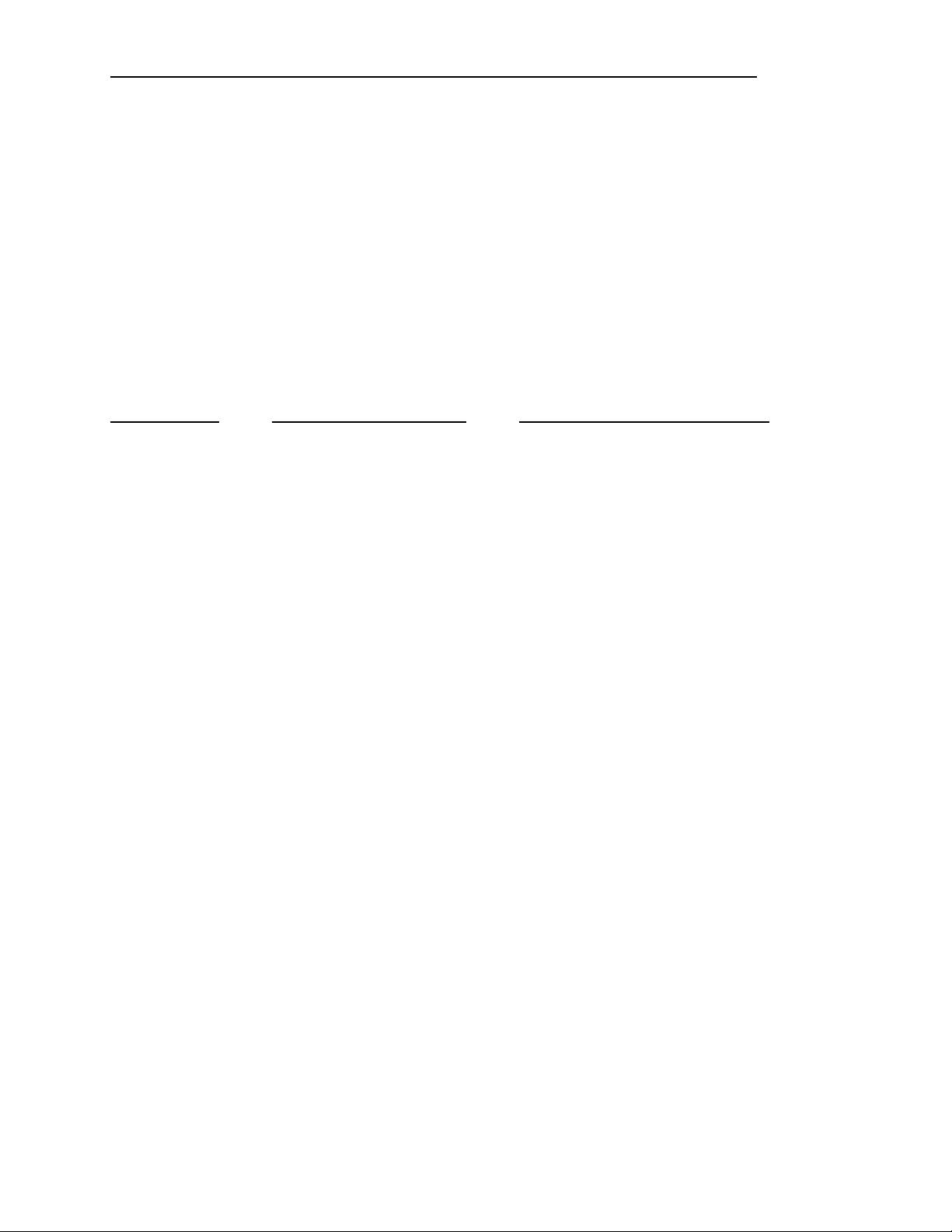

The FormsPro 4000 series printers are designed to be installed on a Printek print stand, or on

an open-top print stand that allows paper to be fed through the paper supply slot on the

bottom of the printer. Since the printer also draws air through this slot for cooling, make sure

that no part of the print stand obstructs this slot. After cooling the electronics, the motors,

and the print head, the air is exhausted through the paper exit slot on top of the printer.

The installation location also requires power for the printer, support for cabling requirements

to your computer, and space for the paper supply(s) and printed paper collection.

After you unpack the printer as described in the unpacking instructions (make sure all

packing materials are removed as described) and place the printer at the desired location,

connect the power cord to the rear of the unit and plug the other end into a proper wall outlet.

3

1

2

Page 2-1

Page 8

Installation and Quick Setup

1. Power Switch on Side of Printer.

2. Power Cord Connector.

3. Mounting Screws for Static Suppression Tinsel.

Page 2-2

Page 9

Installation and Quick Setup

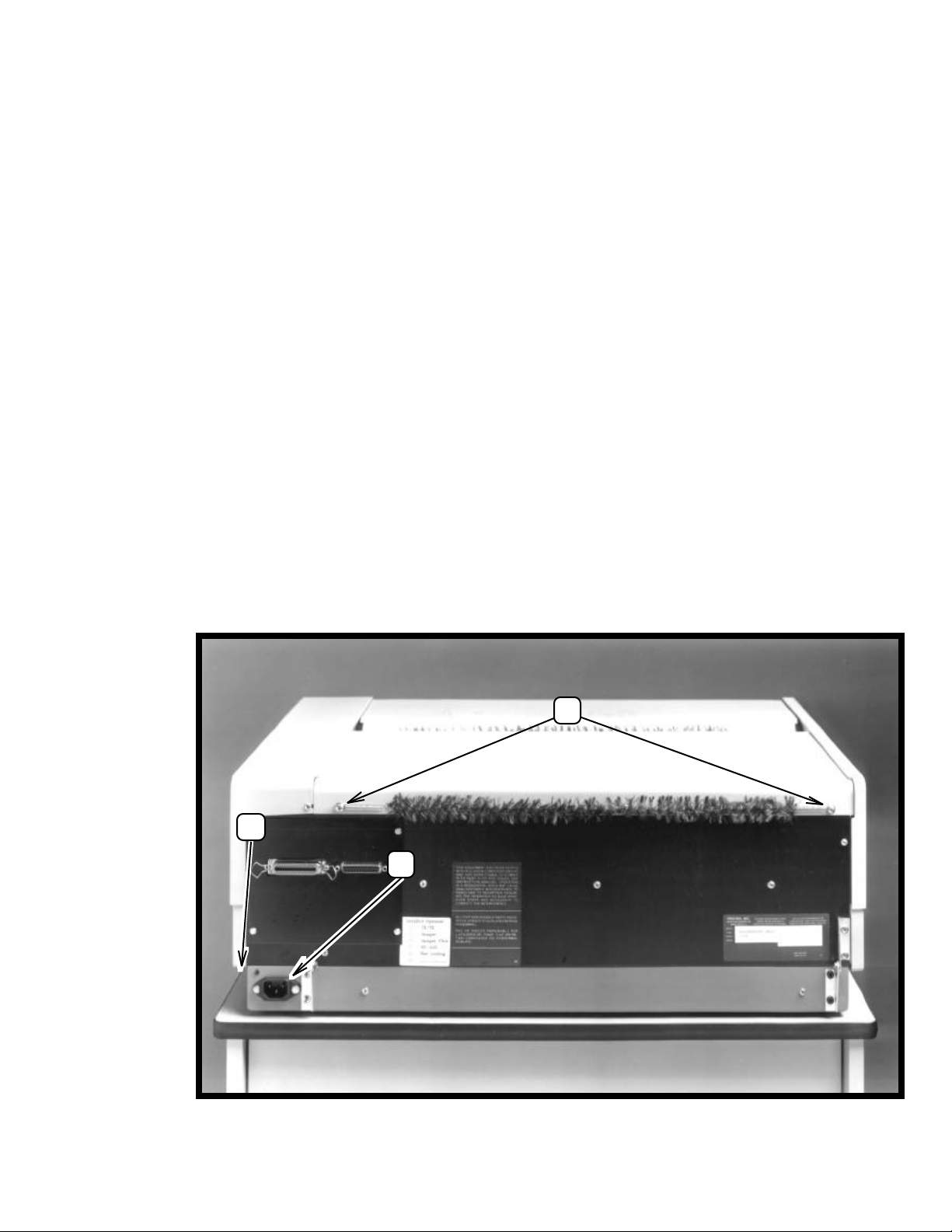

INSTALLING THE RIBBON

To install the ribbon, first lift the lid on the top of the printer; then lift the ribbon loading bail

as shown below.

1

2

1. Ribbon Loading Bail in up (open) position.

2. Ribbon Support Brackets.

Unpack the ribbon from its shipping container and remove the retainer from the slot on top of

the cartridge if present. Make sure the ribbon fabric is not twisted where it enters the

cartridge; then tighten the ribbon by turning the knob on top of the cartridge in the direction

indicated by the arrow on the cartridge.

Place the right end of the ribbon on the support bracket while you align the plastic tabs with

the slots in the bracket as shown on the next page. Then align and lower the left end of the

ribbon onto the left support bracket until it snaps into place. While doing so, the ribbon

fabric should lower into the area between the print head and the pins which support the metal

nose shield.

Page 2-3

Page 10

Installation and Quick Setup

Ribbon Cartridge Installation.

Next lower the ribbon loading bail as shown below. This automatically places the ribbon

between the ribbon guides and the print head as the print head is placed back into the printing

position.

Page 2-4

Lowering (closing) Ribbon Loading Bail.

Page 11

Installation and Quick Setup

INSTALLING PAPER

If the printer is not currently turned on, push the ON-1 side of the power switch on the right

side of the printer. After you turn on the printer, it performs several self tests. If the printer is

a FormsPro 4503, these tests also make sure that the tractors are properly positioned after

shipment.

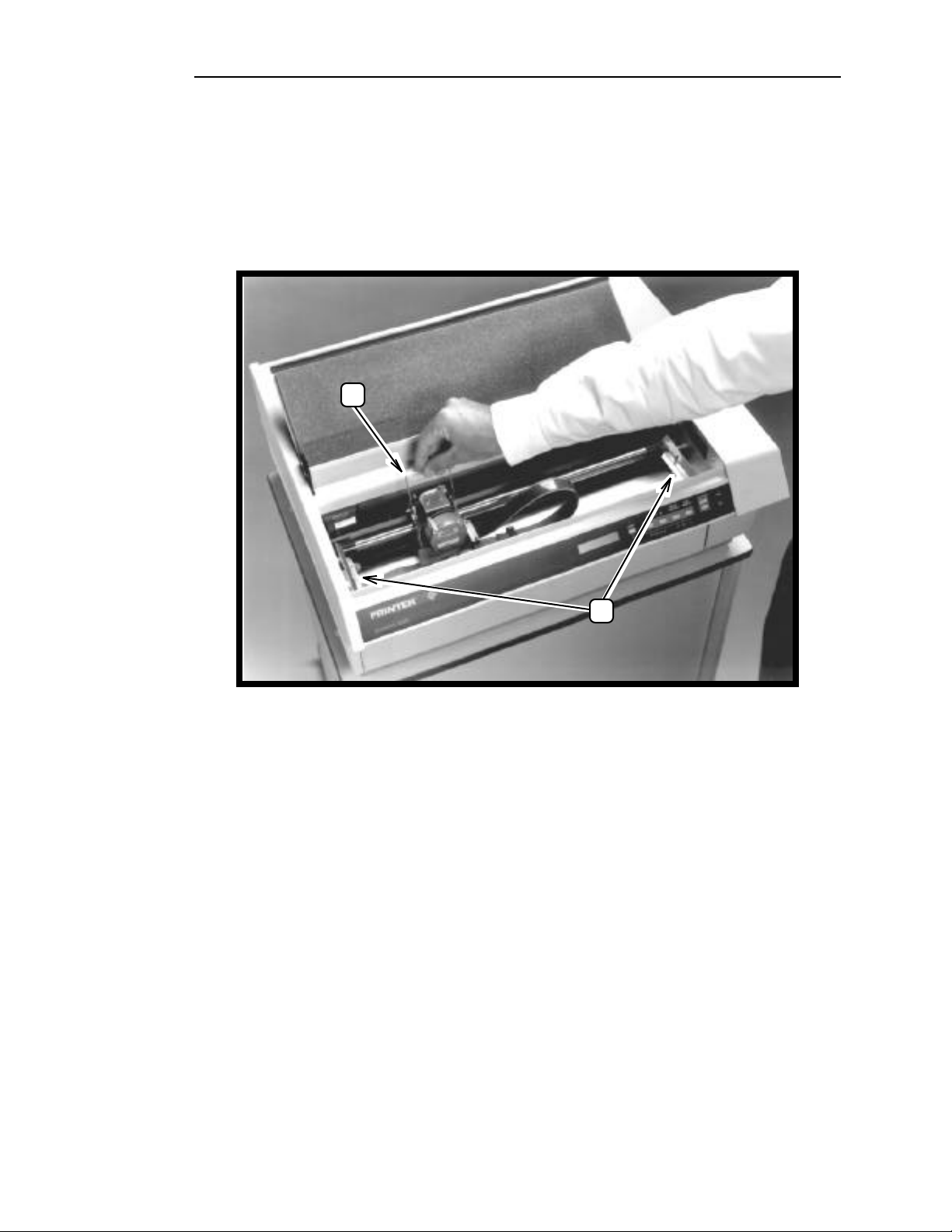

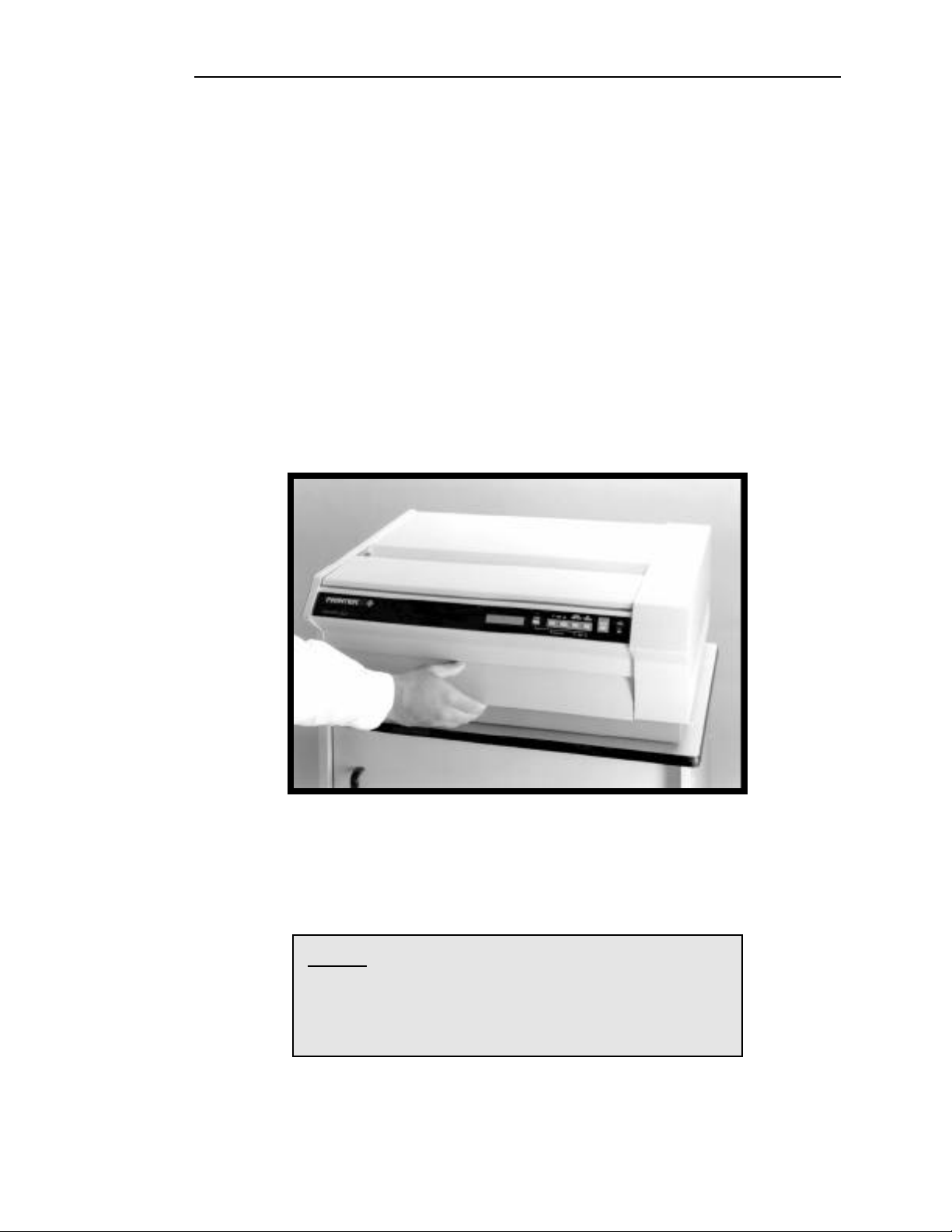

Paper is installed through the slot in the bottom of the printer. To open the unit so you can

install paper, pull outward on the bottom of the lower front panel of the printer as shown to

release the latch.

Opening Latch Panel.

While you pull outward on this panel, lift the front of the unit to expose the paper tractors.

The top of the unit will support itself in the up position while you load paper.

Caution: Do not open the unit in this fashion while the

printer is printing or forms are loaded. Doing so may

cause data to be printed incorrectly or paper to jam

when the cover is closed. Refer to the "Operation"

section for information about unloading forms.

Page 2-5

Page 12

Installation and Quick Setup

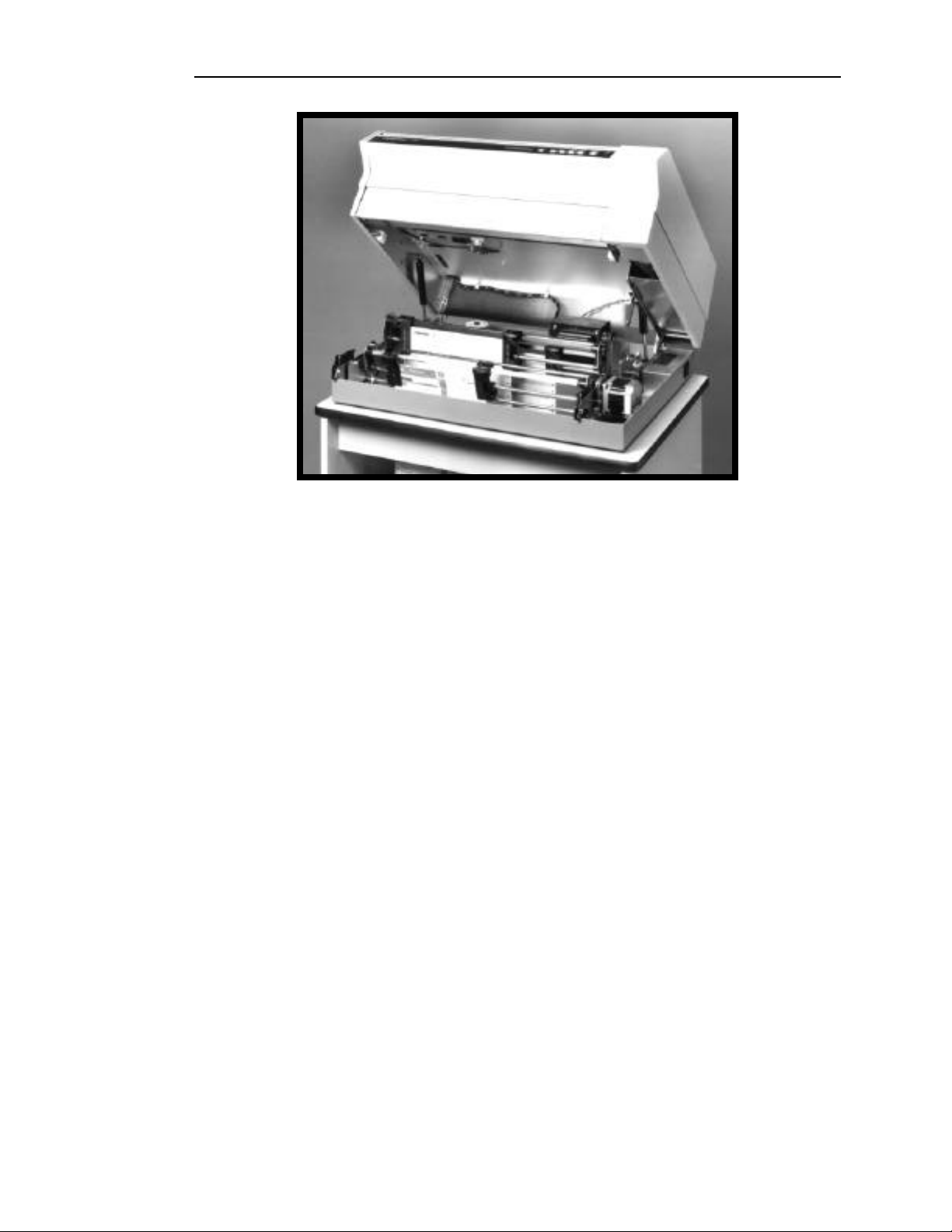

To load paper or forms, open the door on each tractor and position the holes in the paper over

the pins in the tractors; then close the doors. If the tractors are not set at the proper width for

the paper you are loading, simply move the lever beside the tractor door to the open position

and the tractor(s) will slide sideways. The tractors should be spaced far enough apart so that

the paper does not buckle in the center, but not so tight that the holes in the paper become

distorted by the pins in the tractors. A properly installed form is shown below. Note that the

form does not extend above the top of the tractor doors.

FormsPro 4503 With Form Installed

in Front Tractors.

Note that the forms do not extend above the tractor doors.

The FormsPro 4300 and FormsPro 4500 have only one set of tractors which are positioned in

the same location as the front tractors in the above picture. To install forms in the other sets

of tractors in the FormsPro 4503, press the FORM SELECT button on the front panel until

the desired form setup and tractor path is selected on the LCD display (this button's sequence

is 0 through 9, and back to 0, and may be operated while the case is either opened or closed).

Then press the LOAD button. This causes the selected tractors to move into position for

loading. Now load the paper or forms in the tractors as described in the previous paragraph.

Now close the case, select the form you desire (0 through 9), and press the LOAD button.

This places the form you have selected into position for printing. The following picture

shows a FormsPro 4503 with forms installed in all three sets of tractors and the center tractors

in place for operation.

Page 2-6

Page 13

Installation and Quick Setup

FormsPro 4503 With Forms in All Tractor Paths.

Center Path Positioned for Loading.

Page 2-7

Page 14

Installation and Quick Setup

TESTING THE PRINTER

When you turn the printer on, it automatically performs a series of self tests to assure that the

electronics and printer mechanisms are operational. In the FormsPro 4503, the shuttle

mechanism, which positions the tractors, also realigns itself if there is no paper installed or

the paper is not positioned above the tear bar.

If you wish to perform an actual printing test, perform the following steps to print a

barberpole test pattern:

1. Load plain paper that is eleven inches long. The pattern that is printed will be a

maximum of 80 columns wide.

2. Make sure that the printer is offline (the ONLINE indicator is not lit). If the printer is

on line, press the ONLINE button to turn the indicator off.

3. Press and hold the SETUP button until the second menu "Setup: INTERFACE" is

displayed; then release the SETUP button. Note that one beep will sound when the first

setup menu for forms is displayed, and two beeps will sound when the second menu for

interface is displayed.

4. Press the FUNCTION UP button until "Mode:" is displayed. The current emulation

mode will now be displayed. Remember which mode is currently displayed because

you will have to return to this value later for normal operation. If you wish, you can

record the mode here for future reference. Mode: ______________.

5. Press the VALUE UP button until "Mode: BarberPole" is displayed.

6. Press the SETUP button to exit setup mode. The printer will now reset and perform the

normal power-up diagnostics. Once these complete, the printer will begin to print the

barberpole pattern. To stop or resume printing the pattern, use the ONLINE button.

7. Once you have printed the pattern long enough to be sure the printer is operating

properly, press the ONLINE button to stop printing.

8. Press the FORM FEED button to advance the top of the next page to the tear bar and

tear off the printed page(s).

9. Return to the interface setup menu as described in step 3 above, and set the Mode value

back to its previous setting that you noted in step 4.

10. Press SETUP to exit setup mode. The printer will reset and return to normal operating

mode.

CONNECTING THE PRINTER TO A COMPUTER

The FormsPro 4000 series printers are supplied with an industry standard parallel interface

and an RS-232C interface as standard equipment. The printers are also available with an RS422 interface, or a coaxial/twinaxial interface.

Page 2-8

Page 15

Installation and Quick Setup

When the printer is shipped from the factory, the default configurations for these interfaces

are as shown below. If these are not appropriate for your installation, refer to the "Parallel

Interface" or "RS-232C Interface" sections which follow, or to one of the appendices if you

are using an optional interface.

Parallel and RS-232 Interface

Mode: Epson

I/O: Parallel

Data Bits: 8

RS-422 Interface

Mode: Epson

Baud Rate: 9600

Data Bits: 8

Parity: None

XON/XOFF: On

Coaxial/Twinaxial/Parallel and RS-232 Interface

Mode: Epson

I/O: CX/TX

Data Bits: 8

ENTERING THE INTERFACE MENU

AT THE CONTROL PANEL

In each of the following descriptions for connecting the printer to a computer, you may need

to access the printer's interface setup menu. The following paragraphs show you how to do

this.

After you connect the appropriate cable(s), as described in the section for the interface being

installed, turn the printer on.

If the printer is online (ONLINE indicator is on), press the ONLINE button on the front of the

printer to take the printer offline. This will cause the ONLINE indicator to turn off, and the

display will momentarily show an “OFFLINE” message to indicate that the printer is now

offline.

Next, press and hold the SETUP button. After approximately one second, the display will

show “Setup: FORMS” and beep once. Continue to hold the SETUP button for

approximately one more second until the display shows “Setup: INTERFACE” and beeps

twice. Then release the button. You have now entered the printer's interface setup menu and

can now proceed with the instructions listed below for the interface you desire to use.

Page 2-9

Page 16

Installation and Quick Setup

Parallel Interface

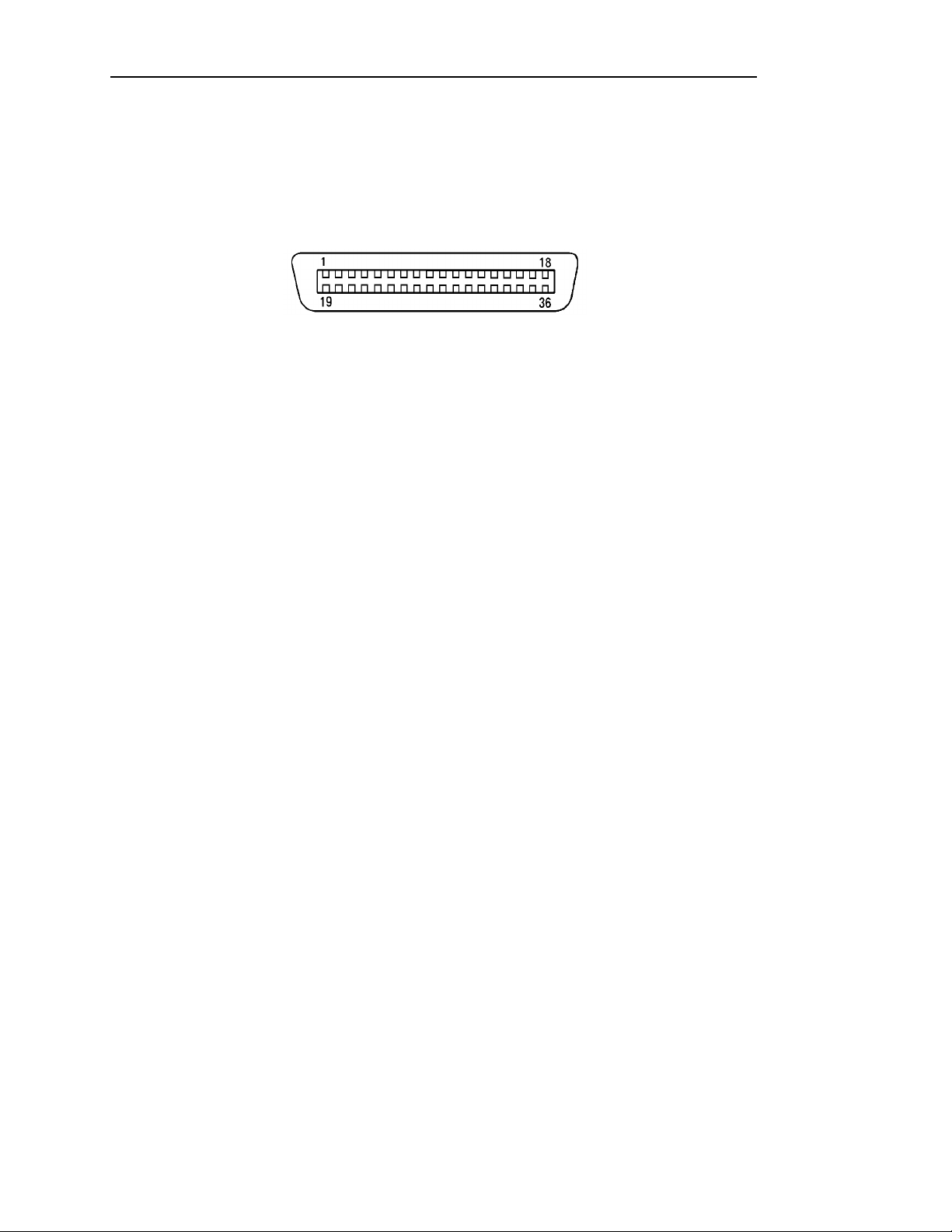

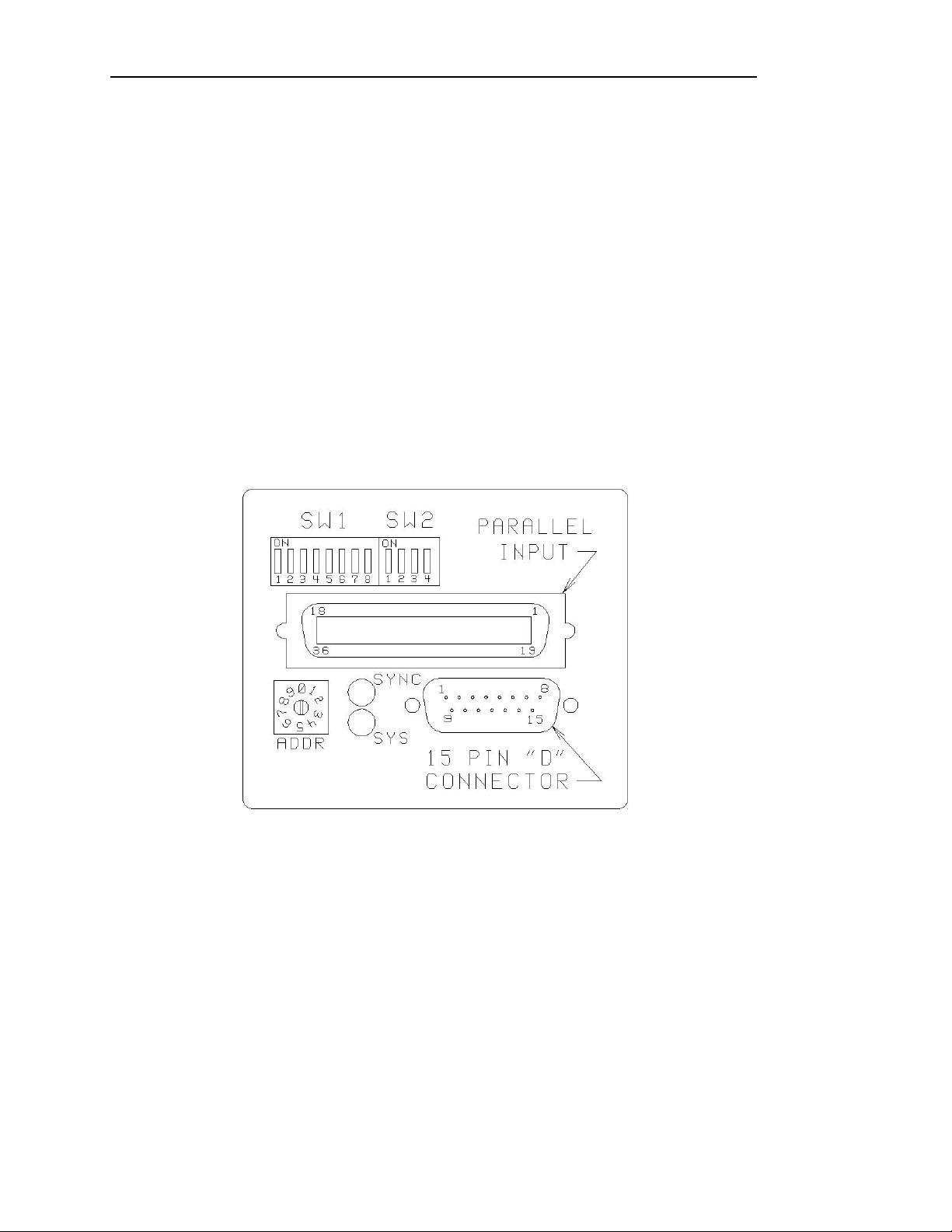

The 36-pin connector for the parallel interface is located on the rear of the printer

immediately above the power cord connector. Connect a shielded cable between your

computer and this connector. The pin-out for this connecter is shown in the following

diagram.

Pin Signal Definition Pin Signal Definition

____________________

1

DATA STROBE

19

DATA STROBE

RTN*

2

DATA 1

20

DATA 1 RTN*

3

DATA 2

21

DATA 2 RTN*

4

DATA 3

22

DATA 3 RTN*

5

DATA 4

23

DATA 4 RTN*

6

DATA 5

24

DATA 5 RTN*

7

DATA 6

25

DATA 6 RTN*

8

DATA 7

26

DATA 7 RTN*

9

DATA 8

27

DATA 8 RTN*

____________

10

ACKNLG

28

ACKNLG RTN*

A host generated signal

which signals that data

lines are stable and that

the data may be stored in

the printer buffer.

Host data bit 1 (LSB).

Host data bit 2.

Host data bit 3.

Host data bit 4.

Host data bit 5.

Host data bit 6.

Host data bit 7.

Host data bit 8 (MSB).

A printer generated

signal which is

transmitted after the

receipt of each data

character and negation of

the BUSY.

*RTN = Signal ground.

11

BUSY

29

BUSY RTN*

12

PE

13

SLCT

14

±0V

16

±0V

___________________

31

INPUT PRIME

30

INPUT PRIME

RTN*

_________

32

FAULT

A printer generated

signal which indicates

that the printer is unable

to receive data. Busy

will be set under the

following conditions:

Character received.

Input buffer is full.

Printer is not on line

(see SLCT).

Paper error (see PE).

Fault (see FAULT).

A printer generated

signal which indicates a

paper out or paper

jammed condition.

A printer generated

signal which indicates

that the printer is on line

and ready to receive data.

Signal ground.

Signal ground.

Ignored.

A printer generated

signal which indicates

that the printer requires

attention.

Parallel Interface Connector.

Enter the interface menu as described above. Then press the FUNCTION UP button to

display the “I/O:” function. Now press the VALUE UP button until “Parallel” is displayed

(or CX/TX if that option is installed). Now press the FUNCTION UP button again to display

the “Data Bits:” function. Use the VALUE UP button to select either 7 or 8 data bits as

required by your computer and/or software. This will normally be set to 8.

Finally, press the SETUP button to exit the setup mode and reset the printer. The printer is

now ready to receive parallel data.

Page 2-10

Page 17

Installation and Quick Setup

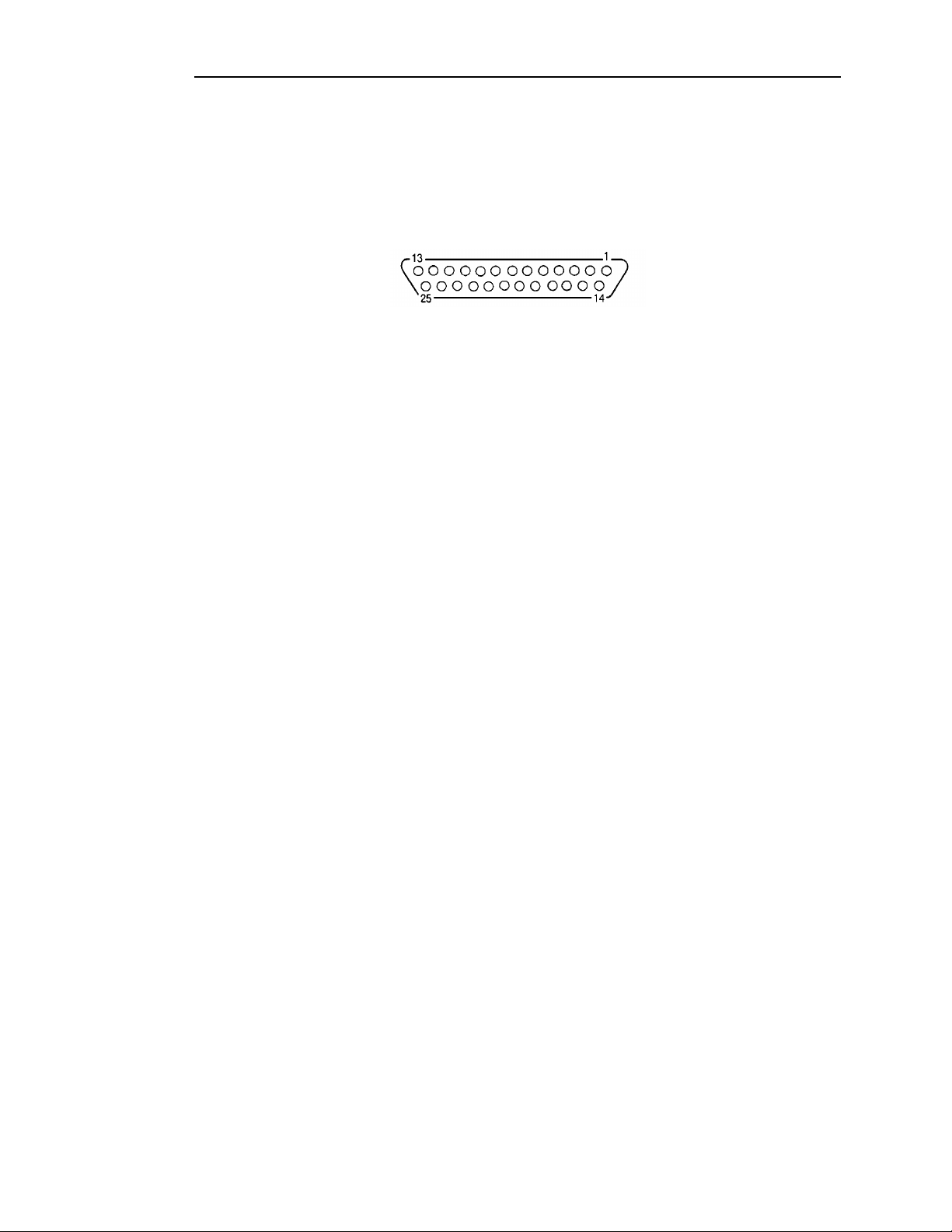

RS-232C Serial Interface

A 25-pin female “D” type connector is located on the rear of the printer immediately to the

right of the 36-pin parallel connector (or above it if the coaxial/twinaxial interface is

installed). Connect a shielded cable between your computer and this connector. The pin-out

for this connector is shown below.

Pin Signal

1

Chassis ground.

2

Transmit data. (Printer output).

3

Receive data. (Printer input).

4

Request to send (set). (Printer output).

5

Clear to send (ignored). (Printer input).

6

Data set ready (ignored). (Printer input).

7

Signal ground.

8

Carrier detect (ignored). (Printer input).

11

Printer busy. (Printer output).

20

Data terminal ready. (Printer output).

RS-232C Serial Interface Connector.

To configure the printer for serial data, more information is required than for some of the

other interfaces. In particular, you must know the baud rate, number of data bits, type of

parity checking, and flow control method required by your computer. Check your computer

manual or contact your computer dealer for this information.

Enter the interface menu as described above. Then press the FUNCTION UP button to

display the “I/O:” function. Now press the VALUE UP button until “Serial” is displayed.

Before proceeding, the factory default values for the RS-232C serial configuration are 9600

baud, 8-data bits, no parity, busy-polarity low, and XON/XOFF and ETX/ACK handshakes

off. If your computer requires you to change any of these parameters, please refer to

“Entering the Interface Setup Menu” in the Operation section of this manual. Otherwise,

simply press SETUP again to exit the setup mode and reset the printer. The serial interface

with the above parameters is now active.

MATCHING THE PRINTER TO YOUR APPLICATION

SOFTWARE

Many application programs output only printable characters and simple control codes.

However, some require special printer features and use a particular “language” or set of

control codes and escape sequences to direct the printer to enable or disable these features.

The FormsPro 4000 series printers supply emulations for the control codes and escape

sequences used by the ANSI X3.64 specification, Epson FX series printers, IBM Proprinter,

Digital Equipment Corporation's LA-120, a simple TTY emulation mode (which ignores

most control codes and escape sequences), and a special Printek emulation mode. The

Printek emulation may be used at any time to control features which are not supported by the

Page 2-11

Page 18

Installation and Quick Setup

other printers being emulated. To review the list of control codes and escape sequences

supported by these emulations, refer to the appropriate section in the Programmer's Manual.

The Programmer’s Manual may be obtained by returning the request form packed with the

printer.

To complete the initial setup of your printer, you will need to know which set of control

codes and escape sequences your applications will use to control the printer. Refer to your

computer and application software manuals or contact your computer and/or software dealer

for this information.

To select the desired emulation, you will need to first enter the interface setup menu as

described in the following paragraphs, and then proceed to the appropriate section below to

select the emulation.

If the printer is online (ONLINE indicator is on), press the ONLINE button on the front of the

printer to take the printer offline. This causes the ONLINE indicator to turn off, and the

display to momentarily show an “OFFLINE” message to indicate that the printer is now

offline.

Next, press and hold the SETUP button. After approximately one second, the display will

show “Setup: FORMS” and beep once. Continue to hold the SETUP button for

approximately one more second until the display shows “Setup: INTERFACE” and beeps

twice. Then release the button. You have now entered the printer's interface setup menu and

can now proceed with the instructions listed below for the emulation you desire to use.

Selecting ANSI X3.64 Emulation

Enter the interface menu as previously described. Press the FUNCTION UP button to display

“Mode: n”. Then use the VALUE buttons to select “ANSI X3.64”. Press SETUP again to

exit the setup mode and reset the printer. ANSI X3.64 emulation is now selected.

Selecting Epson Emulation

Enter the interface menu as previously described. Press the FUNCTION UP button to display

“Mode: n”. Then use the VALUE buttons to select “Epson”. Press SETUP again to exit the

setup mode and reset the printer. Epson emulation is now selected.

Selecting Proprinter Emulation

Enter the interface menu as previously described. Press the FUNCTION UP button to display

“Mode: n”. Then use the VALUE buttons to select “Proprinter”. Press SETUP again to exit

the setup mode and reset the printer. Proprinter emulation is now selected.

Page 2-12

Page 19

Installation and Quick Setup

Selecting DEC LA 120-RA Emulation

Enter the interface menu as previously described. Press the FUNCTION UP button to display

“Mode: n”. Then use the VALUE buttons to select “LA-120”. Press SETUP again to exit the

setup mode and reset the printer. LA-120 emulation is now selected.

Selecting TTY Emulation

Enter the interface menu as previously described. Press the FUNCTION UP button to display

“Mode: n”. Then use the VALUE buttons to select “TTY”. Press SETUP again to exit the

setup mode and reset the printer. TTY emulation is now selected.

Selecting Printek Emulation

Enter the interface menu as previously described. Press the FUNCTION UP button to display

“Mode: n”. Then use the VALUE buttons to select “Printek”. Press SETUP again to exit the

setup mode and reset the printer. Printek emulation is now selected.

Page 2-13

Page 20

Page 21

OPERATION

INTRODUCTION

This section assumes that your printer has already been installed according to the information

in “Installation and Quick Setup”, and describes the daily operation of the FormsPro 4000

series printers. In particular, using the control panel, changing paper or forms, and changing

the ribbon cartridge are discussed.

CONTROL PANEL OPERATION AND SETUP MENUS

The FormsPro 4000 series printers feature an intuitive, easy-to-use control panel which

provides immediate access to the controls required by most operators. Individual indicators

are available which provide a quick indication of printer status, as well as a 16-character

display which provides even more status information.

Many more features, including form and interface parameters, are available through the

SETUP mode. All features which are modified during setup are stored in nonvolatile

memory and are used each time the printer is turned on or reset. For more information, refer

to the appendix on “Printer Reset Conditions”.

The printer's control panel consists of six pushbutton switches, four LED indicators, and a 16character LCD as shown below.

Printer Control Panel.

The pushbutton switches (or buttons), the LCD, and the LED indicators provide you with the

following controls and status information:

CONTROL PANEL DISPLAY AND INDICATORS

Sixteen Character Display This display indicates the printer status. Normally, the

currently-selected form (and tractor path on the

Page 3-1

Page 22

Operation

FormsPro 4503) is displayed. ONLINE, OFFLINE, and

other informational and error messages are displayed

when the conditions occur and/or you press the ONLINE

button without clearing an error condition. This display

also indicates various parameters and their values when

the printer is in the setup mode.

POWER This green LED indicates that the printer is plugged into

a power source, the power switch is on, and the internal

power supply is functional.

ONLINE This green LED indicates that the printer is ready to

receive printable characters and/or commands from the

host computer, and print or perform as requested.

FAULT This red LED indicates that the printer has detected an

error condition, such as paper out, paper jam, or an

internal diagnostic error. Many internal diagnostics are

performed each time the printer is turned on or reset, and

some continue to monitor operation during printing. For

a list of error messages and suggested remedies, refer to

the “In Case of Difficulty” section of this manual.

SETUP This yellow LED indicates that the setup mode has been

entered.

Bell The printer sounds a tone when it is directed to do so by

a bell character (BEL) from the host computer. Other

tones also alert operators of error conditions, such as

paper out, and indicate when buttons are pressed.

Page 3-2

Page 23

Operation

CONTROL PANEL BUTTONS

ONLINE This button allows you to place the printer online or

offline, as indicated by the ONLINE indicator, and as

temporarily displayed on the 16-character display. It is

also used for starting and stopping the test pattern while

the printer is in the Barber Pole mode.

NOTE: The printer must be offline before you can use

any of the other buttons.

If you press and hold this button at power-up/reset,

internal printer information is displayed on the LCD.

For more information, refer to “Checking Printer

Configuration” in the “Using Special Features” section

of this manual.

LOAD / FORM FEED When no paper is currently loaded (a paper out condition

exists), this button loads the paper which has been

installed in the tractors by moving the top edge of the

paper to the tear bar. In the FormsPro 4503, this button

may also cause the tractor path to change if a form has

been selected which uses a different path (refer to

UNLOAD/FORM SELECT below).

If paper is already loaded, this button uses the currently

selected form length to advance the paper to the top of

the next form.

For a description of this button while the printer is in

setup mode, refer to “Introduction to Setup” later in this

chapter.

UNLOAD / FORM SELECT If paper is currently loaded (no paper out condition

exists), this button unloads the paper and places the top

edge of the paper in the tractors in the base of the unit.

This allows you to change the paper easily. A paper out

condition is displayed to indicate that the paper was

unloaded successfully.

The printer will attempt to unload up to 36 inches of

paper. If the top edge of the paper is not found, paper

motion will stop and “Too Much Paper” will be

displayed on the LCD. Normally, previous pages should

be torn off before you press UNLOAD. It is

recommended that you not use this method to unload

more than the current form.

When no paper or form is currently loaded, this button

selects one of ten preset form setups. In the

FormsPro 4503, this may also select a different set of

Page 3-3

Page 24

Operation

tractors to be used the next time you press the LOAD

button.

The printer will not allow you to change the form during

printing. If you press the FORM SELECT button while

there is still a line to print, the button press is rejected,

the bell sounds, and the message “Finish Printing!”

flashes on the LCD. If this happens, you should place

the printer back on-line, allow the form to finish

printing, and then place the printer off-line and select the

desired new form. For more information, refer to

“Finish Printing!” in the “Using Special Features”

section.

If you press and hold this button at power-up/reset on the

FormsPro 4503, and paper has not been loaded, the

tractor shuttle moves all the way forward to its parked

position. NOTE: The tractor shuttle should always be

parked whenever the printer is being transported.

For a description of this button while the printer is in the

setup mode, refer to “Introduction to Setup” later in this

chapter.

ALIGN UP This button is used to adjust the paper in respect to the

current form position. To adjust the top of form

position, you must insure that the printer is at the top of

form before you make this adjustment. You can

accomplish this by performing a Form Feed prior to

making the adjustment. Each time you press this button,

the paper moves up 1/72nd of an inch. If you hold this

button down, the paper advances the amount required to

complete a line feed (LF) at the currently selected line

pitch, and then continues to advance in full line

increments. The longer you hold this button, the faster

the paper will move.

For a description of this button while the printer is in the

setup mode, refer to “Introduction to Setup” later in this

chapter.

ALIGN DOWN This button is used to adjust the paper in respect to the

current form position. To adjust the top of form

position, you must insure that the printer is at the top of

form before you make this adjustment. You can

accomplish this by performing a Form Feed prior to

making the adjustment. Each time you press this button,

the paper moves down 1/72nd of an inch. If you hold

this button down, the paper moves the amount required

to complete a line feed (LF) at the current line pitch, and

then continues to move in full line increments. The

longer you hold this button, the faster the paper will

move.

Page 3-4

Page 25

Operation

For a description of this button while the printer is in the

setup mode, refer to “Introduction to Setup” later in this

chapter.

SETUP This button enters and exits the setup menus that are

used to set parameters for up to ten unique form

configurations, and for setting the parameters required

for the printer to communicate successfully with your

computer. This button and a detailed description of the

features of the setup mode are described in “Introduction

to Setup” which follows.

If you press and hold this button at powerup/reset, the

current setup configuration may be printed. Refer to

“Printing Setup” in the “Using Special Features” section

of this manual.

Page 3-5

Page 26

Operation

INTRODUCTION TO SETUP

The setup mode allows you to easily set form parameters for each of the ten form

configurations, and to set interface hardware and emulation parameters. To make it easier,

the menus and their functions are accessed in the order in which they are most often used.

You can access the setup menus by pressing and holding the SETUP button until the desired

menu is displayed on the LCD. When setup has been entered, the yellow SETUP indicator

lights. At this time, the buttons that have yellow labels below them perform as indicated by

those labels. To exit the setup mode, press the SETUP button.

While the printer is in a menu, you can use the FUNCTION UP and FUNCTION DOWN

buttons to select any function. Whenever you select a function, its current value is displayed.

To change the value or setting of a function, use the VALUE UP and VALUE DOWN

buttons. The function values that are entered in all menus are on a “what you see is what you

get” basis. Whatever value you leave displayed for any function will become the default

value until you change it again. All parameter values are saved in a nonvolatile memory that

is used during initialization the next time the printer is turned on or reset. The printer

automatically performs a reset when it exits the setup menus so that values just set can be

adopted immediately. Refer to appendix on “Printer Reset Conditions” for other values that

may be affected.

The next two sections describe the Forms Menu and the Interface Menu. For more advanced

features, Refer to the appendix on “Advanced Control Panel Features”.

ENTERING THE FORMS SETUP MENU

To change parameters for the currently selected form, first take the printer offline. Next,

press and hold the setup button until “Setup: FORMS” is displayed (approximately one

second) and the bell beeps one time to indicate the first setup menu has been reached. At this

time, you are able to view and/or edit the various function values for the currently selected

form.

The function values which may be modified and their respective value ranges for any of the

ten form selections are listed below. Although you can use the FUNCTION UP or

FUNCTION DOWN buttons to select functions, they are listed here in the order of function

up. The first function is “Form #:” which will display the form to be modified as you access

the other functions. This will initially display the form number that was selected when you

first entered setup (see the description of the UNLOAD/FORM SELECT button earlier in this

chapter). You may use the VALUE UP or VALUE DOWN buttons to select a different form

to modify. However, the form that was selected when you entered setup will still be selected

when you exit setup.

In the descriptions below, “F#” refers to “F0” through “F9” to indicate the number of the

form currently accessed. The factory default settings are indicated by an asterisk (*) where

applicable.

Page 3-6

Page 27

Operation

Function Possible Values Description

Form #: 0 through 9 Allows you to select the desired

form. The printer defaults to the

currently selected form.

F# Path: Front, Center, or Rear Sets the tractor path to be used for

the current form. This function is

available only on the

FormsPro 4503.

F# Auto Cut: Yes or No* Available only when the optional

FormsCutter is installed. See

FormsCutter manual for additional

information.

F# CPI: 10*, 12, 13.3, 15, 16.74,

17.14, or 20

F# Left Mar: 0* through 134 Sets the left margin in columns

F# Right Mar: 1 through 255, or MAX*. Sets the right margin in columns

F# LPI: 6* or 8 Sets the line pitch to 6 or 8 lines

F# Length: 1 through 227 (66*) Sets the form length in lines at the

Sets the character pitch in

Characters Per Inch.

(characters) from the leftmost print

position. Column width is based

upon CPI. The left margin must

be less than the right margin.

(characters) from the leftmost print

position. A value of MAX sets the

margin to the rightmost print

position, regardless of CPI. The

right margin must be greater than

the left margin.

per inch.

current line pitch. For example:

for an eleven inch form, enter 66 if

you are using six lines per inch or

88 if you are using eight lines per

inch.

F# Top Mar: 0* through 255 Sets the top margin by adding the

specified number of lines to the

top of the form.

F# Btm Mar: 0* through 255 Sets the bottom margin in lines

lines from the bottom of the form.

Page 3-7

Page 28

Operation

Function Possible Values Description

F# Scroll+: 0* through 127 Sets the distance in lines from the

top margin to the first print line of

the form (does not add these lines

to the form as the top margin

does). Scroll can be used to allow

existing software to take advantage

of the zero-waste capability. If the

first line is printed too high on the

paper after aligning the edge with

the tear bar, use Scroll to position

it lower on the page. Scroll does

not modify the top of form

position. It is not recommended to

use this with, or in place of, Top

Margin.

F# Cut Adj: -85 to +84, 0*, or Auto Available only when the optional

FormsCutter is installed. See the

FormsCutter manual for more

information.

F# Prnt Adj: -128 through 0*, or 0

through +127

Sets the print position in 72nds of

an inch from the top of the form.

This may be used to align the

vertical print position to match a

preprinted form which does not

begin at an even number of lines

from the top edge of the paper.

Page 3-8

Page 29

Function Possible Values Description

Operation

F# Font: FX FD Epson FX

Fast Draft

FX DF Epson FX Draft

FX LQ Epson FX

Letter Quality

PC FD Proprinter PC

Fast Draft

PC DF Proprinter PC

Draft

PC LQ Proprinter PC

Letter Quality

EB FD EBCDIC

Fast Draft

EB DF EBCDIC Draft

EB LQ EBCDIC Letter

Quality

OCRA OQOCR-A

Optical Qual

OCRB OQ OCR-B

Optical Qual

PCL2 FD PC Latin 2

(Slavic) Fast

Draft

PCL2 DF PC Latin 2

Draft

PCL2 LQ PC Latin 2

Letter Quality

Selects the font to be used. Fonts

not installed will not be displayed.

F# Impact: Norm* or High Sets the character printing mode to

normal or high impact.

F# Lang: USA*, France, Germany,

England, Denmark,

Sweden, Italy, Spain, or

Japan

F# Zero: Normal* or Slashed Sets the type of zero to be printed.

F# Unidir: Yes or No* Sets unidirectional printing instead

Sets the character substitution

table to be used for an alternate

language. (Epson font must be

selected).

of bidirectional printing.

Page 3-9

Page 30

Operation

ENTERING THE INTERFACE SETUP MENU

The setup menu for interface parameters is the second setup menu. To enter this menu, first

take the printer offline (refer to the ONLINE button described earlier). Then press and hold

the SETUP button approximately two seconds until “Setup: INTERFACE” is displayed and

the bell beeps twice to indicate that the second menu has been entered (Note that “Setup:

FORMS” will be displayed and the bell will beep once before the interface menu is

displayed. Continue to hold the button to pass through this menu and proceed to the interface

menu). At this time you are able to view and/or edit the values for the various interface

functions as listed below. While you may select functions with either the FUNCTION UP or

FUNCTION DOWN buttons, they are listed here in the order of function up.

The factory default settings are indicated by an asterisk (*).

Function Possible Values Description

Mode: n = Test, ANSI X3.64,

Epson*, Bar Codes,

Proprinter, LA-120, TTY,

Printek, Barberpole, or Hex

Dump

I/O: Parallel*, Serial, or CX/TX

(optional)

Baud Rate: 150, 300, 600, 1200, 2400,

4800, 9600*, or 19200

Data Bits: 7 or 8* Selects the number of data bits in

Parity: None*, Ignore, Odd, or

Even

Selects the current emulation mode,

barberpole mode, or hex dump

mode. The test mode is for factory

use only.

Selects the active I/O port. If the

CX/TX interface is installed, then

CX/TX also selects the parallel

port. Not available when the RS422 interface is installed.

Selects the baud rate for the serial

interface. Not available when

Parallel or CX/TX is selected.

the serial character frame and the

number of significant data bits in

each character received via all other

interfaces.

Selects the parity checking

requirements for the serial data bits.

Not available when Parallel or

CX/TX is selected.

Busy: Low* or High Selects the polarity of the busy

signal (pin 11 of the RS-232C

interface). Available only when the

RS-232C interface is installed and

Serial is selected.

Page 3-10

Page 31

Operation

Function Possible Values Description

DTR: Power*, Online, or Busy Selects the condition to be reflected

by the DTR signal (pin 20 of the

RS-232C interface). Available

only when the RS-232C interface is

installed and Serial is selected.

XON/XOFF: Off* or On Enables or disables the

transmission of the XON and

XOFF characters from the printer

to the host to control data flow to

the printer. Not available when

Parallel, or CX/TX is selected.

ETX/ACK: Off* or On Enables or disables the ACK

response to receipt of the ETX

character. Not available when

Parallel, or CX/TX is selected.

Auto CR: Off* or On Enables or disables automatic

Carriage Returns (CR) when a Line

Feed (LF), Vertical Tab (VT), or

Form Feed (FF) is received.

Auto LF: Off* or On Enables or disables automatic Line

Feeds (LF) when a Carriage Return

(CR) is received.

Long Line: Wrap* or Trunc Sets whether characters beyond the

right margin will be wrapped to the

next line or truncated.

Left Edge: Fixed or Float* Sets whether the left edge of the

line will be printed 1/2 inch from

the detected edge of the paper or be

fixed at position “0” on the ruler.

FF at TOF: Yes* or No Sets whether Form Feeds (FF) will

be performed when received from

the host computer if the paper is

already positioned at the top of

form (TOF).

Scroll Delay: 0, 1*, 2 through 15 Sets the number of seconds to delay

before scrolling the top of form to

the tear bar when the printer is idle

and a form boundary has been

reached.

Page 3-11

Page 32

Operation

Function Possible Values Description

Fault: Break Pg*, or Reprint Pg Selects whether a paper-out

condition causes a Page Break or

allows you to reprint the page. For

more information, refer to “Page

Reprint” in the “Using Special

Features”.

Page Size: 256* or 512 through 28160 Sets the page size in characters,

when Page Reprint is selected.

When you do not use page reprint,

leave the value set to 256. For

more information, refer to “Page

Reprint” in the “Using Special

Features” section.

Chars: Control* or Printable Selects whether certain control

character symbols will be printed

(emulation dependent), or be

treated as control characters.

Page 3-12

Page 33

Operation

CHANGING THE PAPER

This section assumes that you are familiar with the operation of the control panel buttons as

described in “Control Panel Buttons” earlier in this chapter.

Changing the Form in the Tractors

To unload the currently loaded paper or form, place the printer offline and press the

UNLOAD/FORM SELECT button. This positions the top of the paper in the tractors in the

base of the printer.

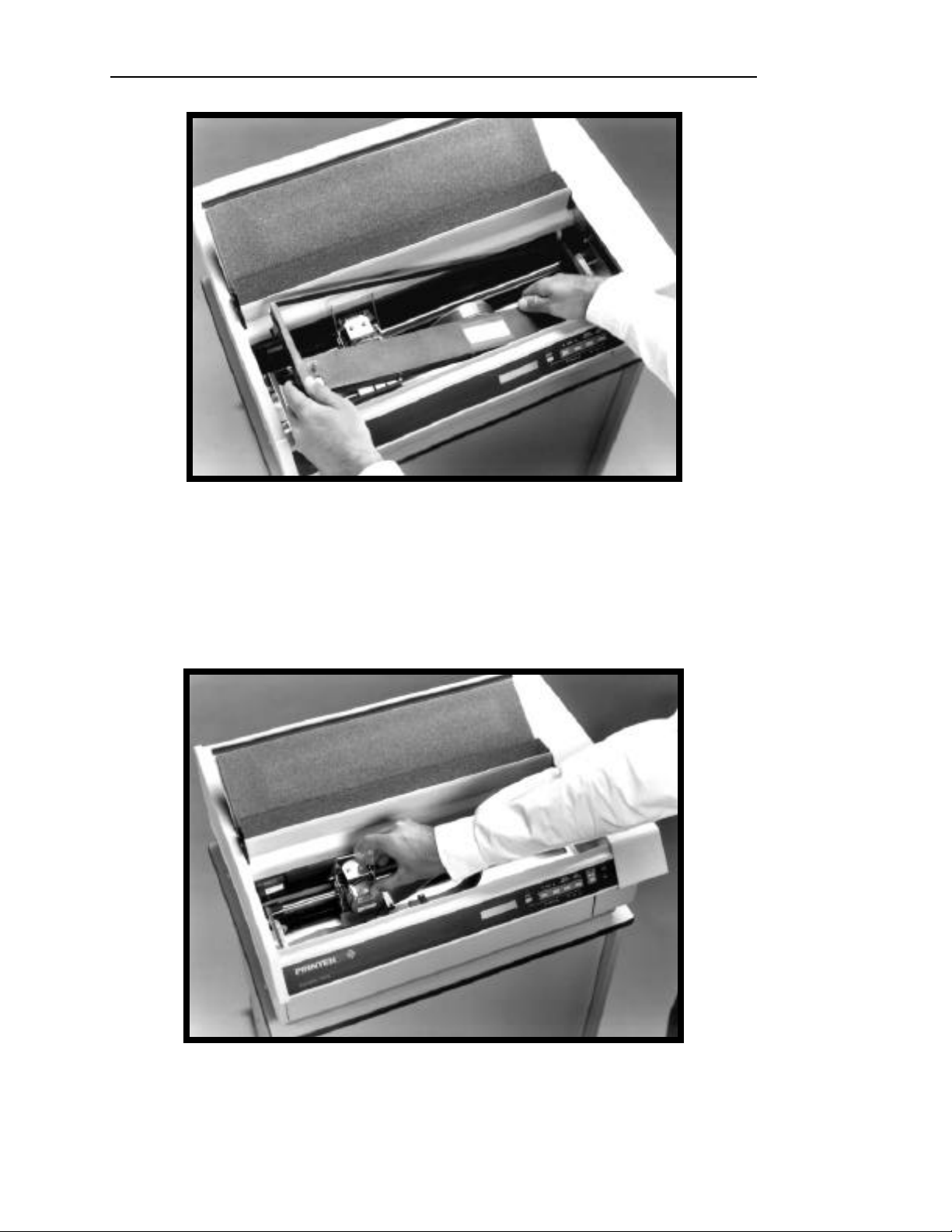

To open the case for access to the tractors, pull out on the bottom of the lower front panel of

the printer to release the latch as shown below:

Opening The Latch Panel.

While pulling out on this panel, lift the front of the printer to expose the paper tractors. The

top of the unit will support itself in the up position while you load paper.

Caution: Do not open the unit in this fashion while the

printer is printing or forms are loaded. Doing so may

cause data to be printed incorrectly or paper to jam

when the unit is closed. Refer to the section on Control

Panel Operation for instructions on unloading forms.

Page 3-13

Page 34

Operation

Open the doors on the tractors and remove the paper or form through the slot in the base of

the printer.

Bring the new paper up through the slot in the base and position the holes of the paper over

the pins in the tractors; then close the doors. Position the left tractor as shown on the label

located in the base of the printer. If the tractors are not set at the proper width for the paper

being loaded, simply move the lever beside the tractor door to the open position and slide the

tractor(s) sideways. Space the tractors far enough apart so the paper does not buckle in the

center, but is not so tight that the holes in the paper become distorted by the pins in the

tractors. A properly installed form is shown below. Note that the paper is not above the tops

of the tractor doors.

FormsPro 4503 With Forms Installed

in Front Tractor Path.

Note that the forms do not extend above the tractor doors.

If your printer is a FormsPro 4503, and you wish to install paper in the other tractor paths,

you may do so at this time. If your printer is a FormsPro 4300 or FormsPro 4500, or if you

do not wish to load other paths, proceed to the next paragraph. You can position the other

tractor paths for loading without closing the printer's case. To load another tractor path, press

the UNLOAD/FORM SELECT button on the front panel until the desired form and tractor

path is indicated on the LCD display. Then press the LOAD button. This causes the selected

tractors to move into position for loading. You may now install the paper in this tractor path.

Page 3-14

Page 35

FormsPro 4503 With Forms in All Tractor Paths.

Center Path Positioned for Loading.

Operation

Close the case of the printer by lowering it until the lower front panel closes. The printer

LCD will display “Case Closed” when you do this.

Check the LCD to make sure the correct form setup (0-9) has been selected. If necessary,

press the UNLOAD/FORM SELECT button until the correct one is displayed.

Now press the LOAD/FORM FEED button to position the top of the paper at the tear bar.

The printer LCD will display “Load Paper” when you do this. After the paper is loaded, the

LCD will display the form number, and if a FormsPro 4503, the path.

Paper installation is now complete. Press the ONLINE button to place the printer back online.

FormsPro 4503: Changing to a Form Installed in Another Path

To unload the currently loaded paper or form, first tear off any forms that have been printed.

Then take the printer offline and press the UNLOAD/FORM SELECT button. This positions

the top of the paper in the tractors in the base of the printer.

Press the UNLOAD/FORM SELECT button until the desired form and path are displayed on

the LCD. Then press the LOAD/FORM FEED button. The tractors will move to the

specified path (if necessary) and position the top of the selected form at the tear bar. Press

the ONLINE button to place the printer back into operation.

Page 3-15

Page 36

Operation

CHANGING THE RIBBON

Caution: When you access the ribbon loading bail as

described below, the print head may be hot if a long

report has just finished printing. Although the print

head should never be hot enough to cause a burn, you

may wish to wait several minutes before changing the

ribbon.

Using Printek Ribbons

The use of

Printek ribbons provide the maximum ribbon life and print head life possible. They also

allow the printer's automatic ribbon change indicator system to operate. While it is possible

to use non-Printek ribbons in your printer, doing so will limit the warranty on the print head

and other mechanisms which are used to advance the ribbon fabric. If you choose to use nonPrintek ribbons, you must disable the ribbon sensing system as described in the appendix

titled “Advanced Control Panel Features”.

ribbons provides several advantages. Most importantly,

Removing the Old Ribbon

To remove the old ribbon, first open the lid on the top of the printer and lift the ribbon

loading bail as shown below.

1

Page 3-16

2

1. Ribbon Loading Bail in Up (open)

Position.

2. Ribbon Support Brackets.

Page 37

Operation

Remove the old ribbon by lifting the left hand end of the ribbon off of the left support

bracket. Then lift out the other end of the ribbon and set the ribbon aside. If the printer

power is on, “Ribbon Removed” will be displayed as the ribbon is lifted out.

Installing the New Ribbon

Unpack the new ribbon from its shipping container and remove the retainer from the slot on

top of the cartridge if present. Make sure the ribbon fabric is not twisted where it enters the

cartridge; then tighten the ribbon by turning the knob on top of the cartridge in the direction

indicated by the arrow on the cartridge.

Place the right hand end of the ribbon on the support bracket as shown below while you align

the plastic tabs with the slots in the bracket. Then align and lower the left end of the ribbon

onto the left support bracket until it snaps into place. When you do this, the ribbon fabric

should lower into the area between the print head and the pins which support the metal nose

shield. If the printer power is on, “Ribbon Installed” will be displayed as the ribbon is

installed.

Ribbon Cartridge Installation.

Page 3-17

Page 38

Operation

Lower the ribbon loading bail as shown below. This automatically places the ribbon between

the ribbon guides and the print head as the print head is placed back into the printing position.

Lowering (closing) Ribbon Loading Bail.

Page 3-18

Page 39

USING SPECIAL FEATURES

This section describes some of the features which are unique to FormsPro 4000 series

printers. These features include instructional messages, which you may encounter when you

change forms, options available for handling a paper out condition, and how to set the ribbon

wear indicator to match how you use your printer. Also included are instructions for

checking the printer configuration and for printing a list of setup information, including all of

the form setup parameters.

UNLOADING AND SELECTING FORMS

When unloading forms, the printer may display the message “Too Much Paper”, “Tear Off

Paper”, or “Finish Printing!”. The cause and remedy for each message is described below.

“Too Much Paper”

This message is displayed when the UNLOAD button has been pressed and the printer senses

that there is too much paper to unload reliably. The solution is to simply press FORM FEED

to place the top of the next form at the tear bar for easy tearing, tear off any remaining

form(s), and then proceed with the unload operation. Note that the printer unload up to 36

inches of paper before displaying the error message, so it may be desirable to press FORM

FEED enough times to ensure that there are no partially printed forms left in the printer.

“Tear Off Paper”

This message is displayed when an escape sequence is used to select a new form and the

printer senses that there was a form already past the tear bar. When this occurs, the paper

will automatically be placed back to the position it was at before the escape sequence was

processed. To clear this condition, tear off the form(s) (you may need to press FORM FEED,

if the previous form was not completed) and place the printer back online. For more

information about loading different forms with escape sequences, refer to the FormsPro 4000

Series Programmer's Manual. The Programmer’s Manual may be obtained by returning the

form packed with the printer.

“Finish Printing!”

This message is displayed when a form has been unloaded, the FORM SELECT button has

been pressed and there is a partial line in the print buffer which may belong on the actual

form that is being unloaded. This condition may occur if the host computer has sent part of a

line, but has not terminated it with a Carriage Return, Line Feed, etc. To allow the printer to

finish this line and/or form, simply press LOAD to reload the form and press ONLINE to

allow the printer to complete the form.

Page 4-1

Page 40

Using Special Features

If you do not wish to finish printing this line/form, you may force the printer to delete this

partial line from its buffer by pressing and holding the UNLOAD/FORM SELECT button

through the following series of messages. When the printer displays “Finish Printing!”,

continue to hold the button. After two seconds the printer will display “Cancel Printing?”.

Continue to hold the button for two more seconds and the printer will display “Print

Canceled”. Now release the button and you may change the paper, or you may press the

FORM SELECT button to select another form.

HANDLING A PAPER ERROR CONDITION

Paper errors may be caused by either a paper out or a paper jam. The printer will deal with a

paper error condition in one of two ways. The factory default method is described below

under “Standard Paper Out Handling”. For a description of how paper errors are handled

when Page Reprint is enabled, refer to “Handling Paper Errors With Page Reprint Enabled”

in the “ Page Reprint” section that follows.

Standard Paper Error Handling

The standard way of dealing with a paper error is that printing will stop and the printer will

go off line as soon as a paper error condition is detected. In the case of paper out, the paper

will be ejected from the tractors. Printing will continue at the top of the next form when it is

loaded.

PAGE REPRINT

Page Reprint is a feature which may be used to reprint a page in its entirety after a paper error

occurs, rather than just resuming printing as described above. This may be used when you

are printing on preprinted forms to prevent splitting one form's data onto two separate pages.

Please read through all of the following topics concerning Page Reprint to make sure you

wish to use it before you enable it.

Enabling Page Reprint

To enable page reprint, first take the printer off-line. Press and hold the SETUP button until

“Setup: INTERFACE” is displayed. Then press the FUNCTION UP button until “Fault:” is

displayed. Now press a VALUE button to select “Reprint Pg”. You must now set the page

size as described below.

Setting the Reprint Page Size

After you select reprint page, press the FUNCTION UP button to display “Page Size:”.

Before you use the VALUE buttons to select the page size, please read the following

discussion, which describes the available values.

Page 4-2

Page 41

Using Special Features

Page size is set in increments of 256 characters. Ideally, the specified page size should be as

large as the largest page to be printed on any form. This includes non-printing characters

such as spaces, tabs, carriage returns, and line feeds. If the page size is not set large enough,

it will not be possible to reprint the page. If the size is large enough, the message “Reprinting

Page!” will be displayed after paper is loaded and the printer is placed back on-line. If the

size is not large enough, the printer will display “Cannot Reprint!” and will continue printing

just as though the reprint option is not enabled.

The buffer space for the page reprint is taken from the I/O buffer, so do not set the page size

unnecessarily large. The standard buffer size is 4096 characters. A buffer expansion option

is available which will increase the I/O buffer to a total of 28672 characters. At least 512

characters must be left allocated to the I/O buffer when you set the page size. Maximum

page sizes are 3584 characters and 28160 characters. The buffer expansion option is

recommended if page reprint is to be used, since it will allow a larger page size and still retain

a reasonable I/O buffer size.

Handling Paper Errors With Page Reprint Enabled

When a paper error occurs during printing, just load more paper and place the printer back on

line. The printer will sound the bell and display “Reprinting Page!”. Place the printer back

on-line and the printer will print the current form in its entirety and continue printing

subsequent pages.

Another feature of Page Reprint is the ability to save a form if printing begins and the wrong

form was accidentally selected. If this occurs, quickly take the printer off-line before the first

page finishes printing. Do not press FORM FEED. Pressing FORM FEED will cause the

current page to be “completed”, which will remove it from the reprint buffer and cause that

much of the form to be lost. Instead, unload the form and load the correct form. The bell will

beep and “Reprinting Page!” will be displayed. Place the printer on-line to reprint the first

page and continue printing subsequent pages.

Using Escape Sequences With Page Reprint Enabled

To reprint a page, the printer performs a carriage return at the top of the newly loaded form,

and then reprocesses all data received for the incomplete page. If escape sequences have

been used in the partially printed page, the printer may be left in a different state than when

the page began printing originally.

Escape sequences may be used successfully with page reprint, if you are careful. At the

beginning of each page, escape sequences should be sent to reset any default attributes that

may have changed. This will insure that reprinted pages look the same as they would have on

the first printing. For example, assume that the printer is set for normal print. Part way

through the page, an escape sequence is used to select bold print. If it is necessary to reprint

the page at this point, the beginning of the page will be reprinted in bold because bold was

never turned off. The problem may be avoided by sending an escape sequence to turn bold

off at the beginning of the page (even though it is already off under normal circumstances).

For more information on using escape sequences, refer to the FormsPro 4000 Series

Programmer's Manual.

Page 4-3

Page 42

Using Special Features

USING THE RIBBON CHECK FEATURE

The use of brand ribbons (Printek part number 90481) provides a number

of benefits in the use of your FormsPro 4000 series printers. First of all Printek ribbons offer

a 23,000,000 draft character life, substantially more than that of most imitations. The

specially formulated ink also provides the best lubrication for the print head and thus the

longest print head life. Be sure to insist on genuine Printek ribbons.

Using Printek brand ribbons also allows the printer’s ribbon checking feature to operate. The

ribbon checking feature will insure that your printer does not try to print when there is no

ribbon installed which could result in the loss of valuable data.

Matching the Ribbon Wear Indicator to Printer Use

The ribbon checking feature also will keep track of the number of draft characters (or draft

equivalent characters if printing other fonts or graphics) that have been printed since the

ribbon was last installed. Once the specified number of draft equivalent characters has been

printed (factory preset to 23,000,000), the printer will begin to flash “Change Ribbon” on the

LCD display. Printing will not be interrupted, but the message will continue to flash until the

ribbon is changed.

Your particular printing application may dictate that you change the ribbon after more or less

than fifteen million characters. If you wish to receive the Change Ribbon message after a

different amount of usage, you may change the number of draft equivalent characters to be

counted in the “Ribbon Life” function in the “Setup: OPTIONS” menu. See the appendix on

Advanced Control Panel Features.

Turning Off Ribbon Checking

You may wish to turn off the ribbon checking feature for one of two reasons. First of all, you

may not wish to receive the “Change Ribbon” message. Secondly, you must turn off this

feature if you wish to use non-Printek brand ribbons in your printer. If you want to turn this

feature off, set the “Ribbon Check:” function in the “Setup: OPTIONS” to “No”. For more

information, refer to the “Advanced Control Panel Features” appendix.

CHECKING SETUP CONFIGURATION

Certain configuration settings, installed options, firmware versions, and other information

may be viewed on the front panel LCD. To cause this information to be displayed, turn off

the power switch on the side of the printer, and then press and hold the ONLINE button while

you turn the power switch back on. Continue to hold the ONLINE button until

“FormsPro 4300”, “FormsPro 4500”, or “FormsPro 4503” is displayed on the front panel.

You may now release the button as the printer continues to show configuration information,

and then proceed with the normal power up process.

Page 4-4

Page 43

Using Special Features

PRINTING SETUP INFORMATION

Part or all of the setup configuration information may be printed. To do so, turn off the

power switch on the side of the printer, then press and hold the SETUP button while you turn

the power switch back on. The printer will display the message “Print SETUP?”. Continuing

to hold the SETUP button will cause the printer to print a list of options installed, certain

hardware adjustment values, the firmware versions, and all values set for the currently

selected form. If you are still holding the SETUP button, the printer will display “Print All

Forms?”. Continuing to hold the SETUP button will cause the printer to print the setup

values for all ten forms. Once this begins to print, you may release the SETUP button.

This information may prove to be helpful if forms or interface settings are accidentally

changed. This information can also be helpful if you need to call your dealer, distributor, or

Printek Technical Support or Customer Service for assistance or repair.

PARKING THE FORMSPRO 4503 TRACTORS FOR

SHIPMENT

In the event the printer ever needs to be shipped, the tractors should be “parked” toward the

front of the unit. To accomplish this, first remove the forms from all three tractor paths.

Then turn off the power switch on the side of the printer. Now press and hold the UNLOAD

button while you turn the power switch back on. Continue to hold the UNLOAD button until

the message “Park Shuttle ...” is displayed. After the shuttle stops moving and the park

shuttle message is no longer displayed, turn off the power switch and prepare the unit for

shipping.

Page 4-5

Page 44

Page 45

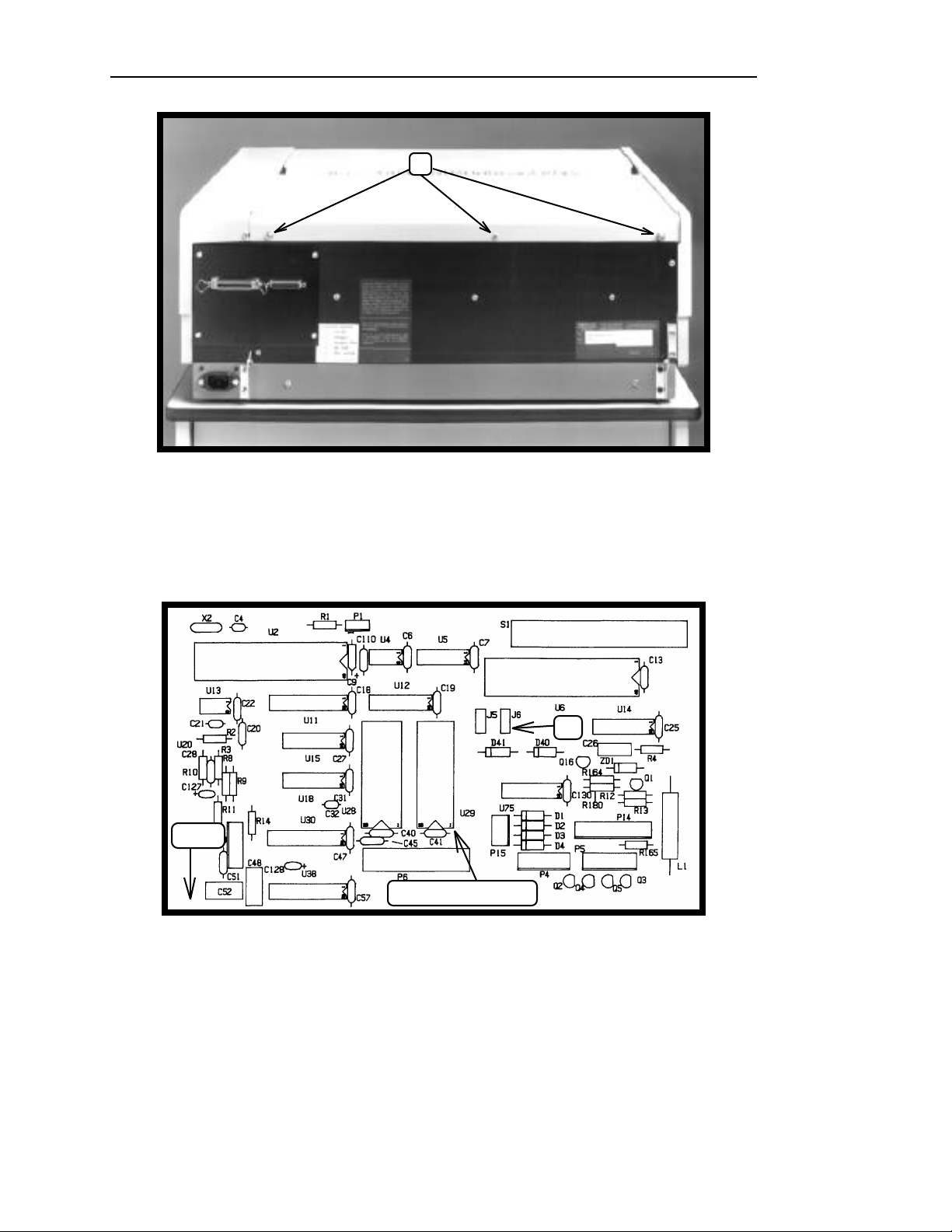

IN CASE OF DIFFICULTY

INTRODUCTION

A list is provided below which includes symptoms of possible problems and corresponding

causes and/or remedies. If you encounter a problem which you cannot solve with the

information in the following list, the company that sold you the printer can provide you with

local technical assistance and/or repairs. If you need further assistance, please contact

Printek, Inc. at 800-DOT-INFO (800-368-4636) and ask for “Customer Service” to obtain the

name of an authorized service center in your area, or to obtain factory repairs. DO NOT send

your printer to Printek, Inc. without first obtaining a Return Authorization number from

Printek's Customer Service department. When calling, please have available the name of the

company who sold you the printer, the date of purchase, the printer model number, the printer

serial number, and a list of any installed options (see option list on the back of your printer).

Also provide as much information as possible about the problem. If you return your printer

for repair, it is helpful if you can also return a print sample of the error if applicable.

Many authorized dealers, distributors, and service centers offer service contracts which

provide for the fastest possible repair for your printer. Printek, Inc. also provides several

types of factory level service contracts ranging from guaranteed 48 hour turnaround, to a

replacement printer shipped to you within 24 hours. For more information, contact the

company where you purchased the unit or contact Printek Customer Service at the above toll

free number.

SYMPTOMS AND POSSIBLE CAUSES

Problem or Symptom Possible Cause or Remedy

Green POWER LED

does not come on when

the printer is switched

on.

Power cord is not plugged into the wall outlet or the printer.

No power at the wall outlet.

Printer AC power fuse is blown (see “Replacing the AC Power

Fuse” later in this chapter).

Page 5-1

Page 46

In Case of Difficulty

Problem or Symptom Possible Cause or Remedy

“No/Wrong Ribbon”

message is displayed

when a ribbon cartridge

is actually installed.

Poor print quality. Worn or damaged ribbon.

Poor print quality on

multipart forms.

Paper misfeeds. Obstruction in paper path. Check both printer and print stand.

The battery in the ribbon sensing circuit may need to be replaced

(normal battery life exceeds ten years).

A non-Printek ribbon has been installed. While not

recommended, the use of non-Printek ribbons is allowed.

However, only Printek ribbons will allow the ribbon sensing

system and ribbon wear indicator to function. To configure your

printer to be able to use non-Printek ribbons, refer to the

appendix titled “Advanced Control Panel Features”.

Ribbon not installed properly on drive mechanism.

Note: If the ribbon cartridge and/or fabric is damaged, replace it

with a new ribbon. Continued use of a damaged ribbon may

cause damage to the ribbon drive mechanism or the print head.

The form requires the high impact character mode. Set Impact to

High in the form setup menu.

Poor carbon or carbonless form quality. Refer to “Selecting a

Quality Form” later in this section.

“MP: I/O Overflow”

error message.

“MP: Parity Error” error

message.

Torn or ragged edge on paper.

Paper misaligned in tractors.

Left and right tractors too close to each other allowing paper to

“droop”.

Tractor doors not closed.

Paper too difficult to pull from box (dragging on sides of box).

Remove forms from box or cut away sides of box.

Tractor blocking paper out detector.

Poorly constructed forms. Refer to “Selecting a Quality Form”

later in this section.

The printer's input buffer has been exceeded. Check the

interface setup to assure that the handshaking or flow control

method required by your computer has been selected. Also

check the cabling for proper pin-out or broken wires.

A serial character was received with improper parity. Check the

interface setup to assure that the parity (odd, even, ignored, or

none) is set to match the parity setting required by your

computer. Also check the cabling for intermittent connections

Page 5-2

Page 47

Problem or Symptom Possible Cause or Remedy

In Case of Difficulty

“PE: Head Stall” error

message.

Other MP: or PE: error

message.

Will print barberpole,

but will not print data

from the computer.

Paper drops out of the

tractors during load.

Carriage path is obstructed. Clear the obstruction and turn the

printer off and back on again to clear the error.

Carriage shaft is dirty. Wipe completely with a clean cloth.

Ribbon cartridge is worn or damaged and will not advance

ribbon.

The printer has detected an internal error condition. Report the

message to an authorized service agent.

The interface is not configured properly. Refer to the

“Operation” section and review the interface settings to make

sure they match what is being generated by the computer.

The interface cable is not wired properly. Refer to the

appropriate section or appendix for pin-out specifications for the

interface being used.

The paper out sensor is blocked. This may be caused by paper

that is extending above the tractors in another path or a tractor

that is blocking the paper out detector.

Page 5-3

Page 48

In Case of Difficulty

USING THE HEX DUMP MODE

The Hex Dump mode provides a way to print, in a readable form, all of the data received by

the printer. This tool is often useful to programmers for diagnosing problems encountered

when sending the printer control codes and escape sequences used to control the various print

modes and setup features of the printer. Hex Dump may also be used to detect what

commands are being sent by a particular software application to help determine which

emulation mode is needed for that application.

To select Hex Dump, refer to the “Operation” section and review the information about

setting the emulation mode (“Mode:”) in the interface menu. Be sure to note the emulation

currently being used before you change it to Hex Dump.