Page 1

Operation

Manual

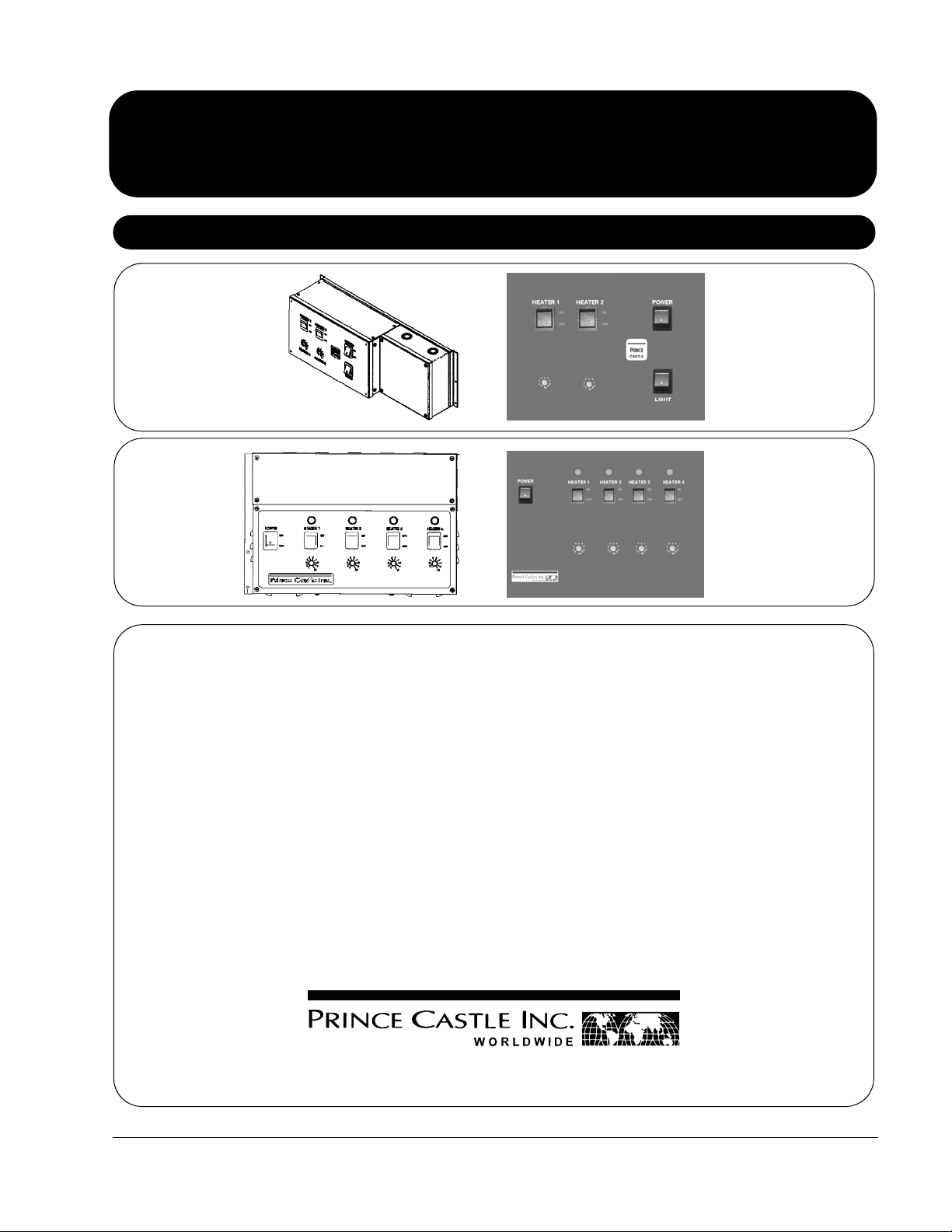

HPC-2A/2AF

HPC-4

Heater Panels

and Controllers

Product Identification

This product is warranted to be free from defects in material and/or

workmanship for a period of 1 year from date of original installation, not to

exceed 18 months from the date of manufacture.

Any component which proves to be faulty in material and/or workmanship

will be replaced or repaired (at the option of Prince Castle, Inc.) without

cost to the customer for parts and labor. This warranty covers on-location

service (i.e. trip charges and/or mileage). Travel mileage is limited to 100

miles (200 Kilometers) round trip (one trip warranty) from an authorized

service agency or its sub-service agency.

This warranty is subject to the following exceptions/conditions:

• Use of any non-genuine Prince Castle parts voids this warranty.

• All labor to be performed during regular work hours. Overtime premium

(the incremental amount) will be charged to the customer.

• Damage caused by carelessness, neglect and/or abuse (e.g., dropping,

tampering or altering parts, equipment damaged in shipment, by fire,

flood or an act of God) is not covered under this warranty.

• All problems due to operation at voltages other than that specified on

equipment nameplates are not covered by this warranty. Conversion to

correct voltage is the customer’s responsibility.

• This equipment must be serviced by Prince Castle Authorized Service

Agency or a Prince Castle Service Technician during the warranty

period.

355 East Kehoe Blvd. • Carol Stream, IL 60188 USA

Telephone: 630-462-8800 • Toll Free: 1-800-PCASTLE

Fax: 630-462-1460 • www.princecastle.com

LIMITED WARRANTY

TABLE OF CONTENTS

Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Heater Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Setting Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Exploded View and Parts List — Controllers . . . . . . . . . . . . . . . . . . 6, 7

Exploded View and Parts List — Heater Panels . . . . . . . . . . . . . . . . 8, 9

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

528-510revD Printed in USA 2/08 © 2008

Page 2

Heater Panels

and Controllers

Remove unit from carton and inspect for signs of damage. If there is damage to the unit:

1

• notify carrier within 24 hours of delivery.

• save carton and packaging material for inspection purposes.

• contact your local dealer, or if purchased directly, the Prince Castle Sales Department at 800-772-7853 or 630-462-8800 to arrange for a

replacement unit.

Specifications

Model Volts Max. Watts Hertz

HPC-2A/2AF 208/240 3900 50/60

HPC-4 208/240 7800 50/60

NOTE: Wattage depends on the size of the Heater Panels.

Controller Installation

Attach controller to the counter.

2

Attach the input power leads to the Controller Wiring Box. Connect

3

the power leads to the ter minals as shown in the Input Power

Terminal Block wiring label.

NOTE: The required voltage is 208 to 240 V, Single Phase. All

wiring to be in rigid or flexible conduit.

A. The wire connections are:

• L1 to Red

• L2 to Black

• Neutral to White

• Earth Ground to Green/Yellow

B. The panel will draw a maximum of 17 amps or 4100 Watts at 208 to

240 volts.

NOTE:The HPC-2 should be wired to a dedicated 25-amp circuit.

The HPC-4 should be wired to a dedicated 40-amp circuit.

All wiring to and from the controller must be in either

flexible or rigid metal conduit.

Connect the Green with yellow stripe ground wire to one of the

4

terminals shown in either of the Heater Terminal Block wiring

diagrams.

If the heater panel has a fluorescent light, connect the optional red

5

and orange leads for the fluorescent light to the terminals as

shown on the Light Terminal Block Wiring Diagram.

Turn the power switches on.

6

Turn the heater and light switches on.

7

Allow 45 minutes for the unit to warm up.

8

Printed in USA 2/08 © 2008 2 528-510revD

Page 3

Heater Installation

Heater Panels

and Controllers

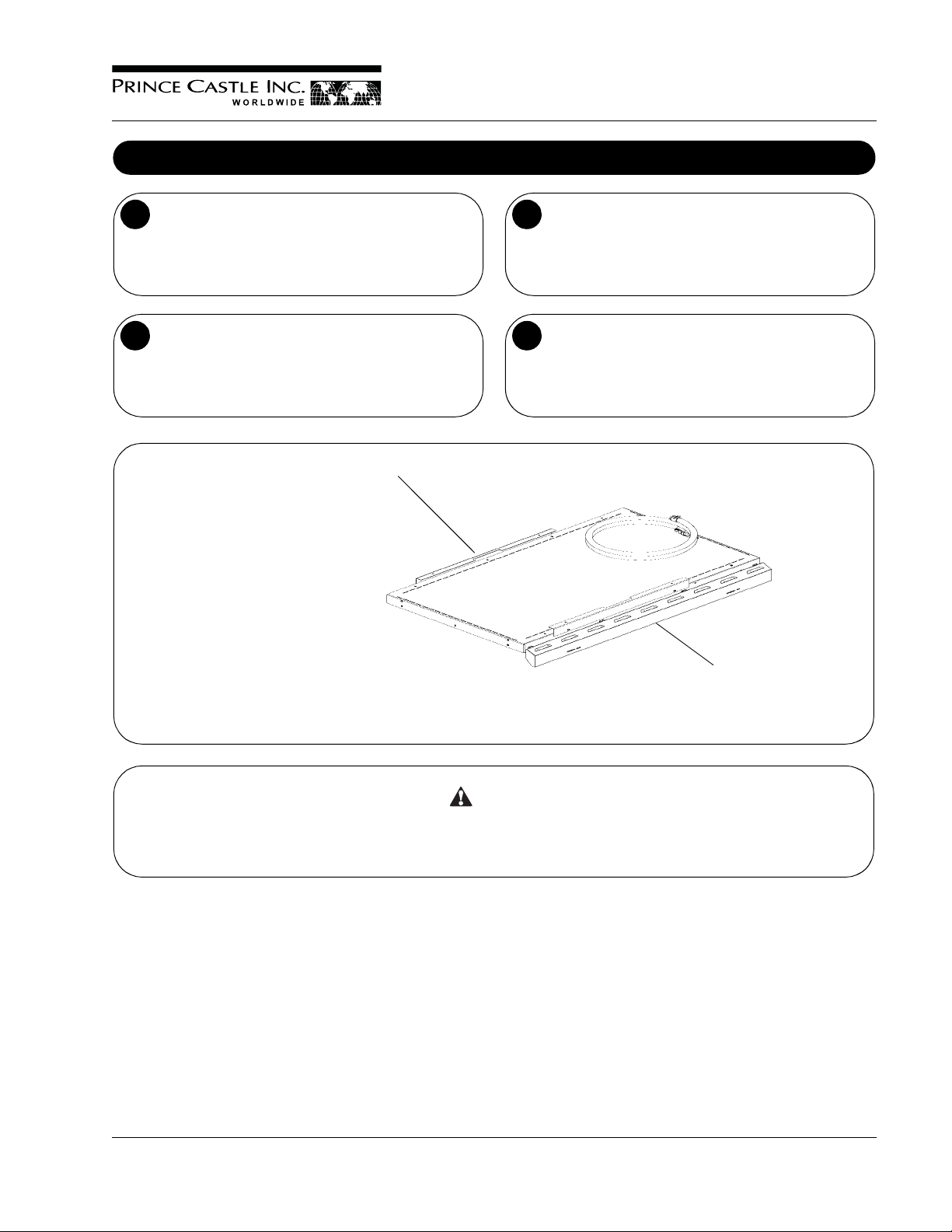

The brackets may either be mounted along the length or width of

1

the heater panel. For heater panels with lights, please allow 1/4" of

space above the light housing.

Remove mounting brackets from the heater panel and save the

2

screws.

1

1. Measure the mounting clips or remove

them and use them as a template when

mounting the panel.

Attach the mounting bracket to the mounting studs.

3

Position the heater panel to the mounting brackets and secure the

4

panel in place using the screws from step 2.

2. Light Housing depending on the model.

CAUTION

To reduce the risk of fire, this appliance should be installed in non-combustible surroundings only. There should be no combustible material

within 18 inches of the sides, front, or rear of the appliance or within 40 inches above the appliance. The appliance is to be mounted to noncombustible surfaces and radiate to non-combustible floors. These surfaces and floors should extend no less than 12 inches beyond the

appliance on all sides.

2

528-510revD 3 Printed in USA 2/08 © 2008

Page 4

Heater Panels

and Controllers

Start Up

NOTE: During the first few hours of operation, the heaters may produce a faint odor. This is normal and the odor will disappear after the first few hours

of use.

The heater panel and control are tested and calibrated at the factor y before shipment. However, temperature and climate changes during shipment

can allow the insulation in the heater panel to absorb moisture. During the first few hours the unit is in use, this moisture is driven from the insulation

while the insulation dries. The drying insulation often gives off a faint odor which will disappear after a few hours.

Setting Recommendations

Due to different airflow patterns found in each store, the actual heater settings for each store will be different. Air flow patterns are affected by drivethrough windows, open front and rear doors, air conditioning and make up air vents. All of these sources of air will draw heat away from the food. Below

are some recommended settings that may be used as a starting point before making final adjustments for each restaurant.

NOTE: A higher temperature setting will yield hotter food temperatures; however, the higher temperature will result in more moisture being driven from

the food. At the end of the maximum hold time, an ideal temperature setting will result in food that is at or above the minimum serving temperature and

still meets all quality requirements.

Distance versus Temperature Setting

Style 1

If the maximum distance between the heating surface and the surface

on which the food is placed is 20 inches, the recommended

adjustment range is from 7 to 10.

Distance versus Temperature Setting

Style 2

If the maximum distance between the heating surface and the surface

on which the food is placed is 15 inches, the recommended

adjustment range is from 4 to 7.

Temperature Adjustment

Each heater panel has a separate On/Off switch and a separate temperature adjustment. To adjust the temperature, put a blade screwdriver in the

temperature adjustment pot. Turn the pot counterclockwise to decrease the temperature and clockwise to increase the temperature. Stop turning the

pot when the blade is pointing at the desired value.

Printed in USA 2/08 © 2008 4 528-510revD

Page 5

Heater Panels

and Controllers

Cleaning

CAUTION

This unit is NOT water tight. Do NOT clean with Water Jet/Jet Spray. Before cleaning, make sure the power switches are in the OFF position.

Turn the power switch to the OFF position.

1

Allow the bin to cool down (approximately 35 minutes).

2

Wipe down surface with a damp cloth. Do not use a green Scotch

3

Bright pad, or unapproved cleaner.

Turn power on after all surfaces are dry.

4

528-510revD 5 Printed in USA 2/08 © 2008

Page 6

Heater Panels

and Controllers

Exploded View and Parts List — Controllers

HPC-2A/2AF

6

7

1

5

4

2

3

Ref. No. Description

1 428-440S Main PCB

2 78-218S Rocker Switch

3 78-184S Lighted Rocker Switch

4 528-359S Ballast Kit, HPC-2A

528-736S Ballast Kit, HPC-2AF

5 65-058S Relay Kit

6 65-048-07S Relay Kit, HPC-2A

65-048-10S Relay Kit, HPC-2AF

7 537-388S Transformer Assy, HPC-2A

528-443S Transformer Assy, HPC-2AF

Printed in USA 2/08 © 2008 6 528-510revD

Page 7

Exploded View and Parts List — Controllers

HPC-4

Heater Panels

and Controllers

8

3

2

Ref. No. Description

1 428-440S Main PCB

2 78-218S Rocker Switch

3 78-184S Lighted Rocker Switch

4 528-442S Ballast Kit

5 65-058S Relay Kit

6 65-048-07S Relay Kit

7 528-443S Transformer Kit

8 71-135-1S Amber Pilot Light Kit

4

1

7

6

5

528-510revD 7 Printed in USA 2/08 © 2008

Page 8

Heater Panels

and Controllers

Exploded View and Parts List — Heater Panels

HPL52-26, HP52-26

HPL45-26, HP45-26

If the Heater Panel model number (part listing) is not

shown in this manual, check the Prince Castle Web site

for the part page specific to your model.

OR

In the U.S. call 1-800-PCASTLE (722-7853).

NOTE: Heaters and glass are not field replaceable.

HPL52-26/HP52-26

Ref. No. Description

1 88-682S Lampholder Kit

2 88-793-03S Fluorescent Lamp Kit

HPL45-26/HP45-26

Ref. No. Description

1 88-682S Lampholders Kit

2 88-793-02S Fluorescent Lamp Kit

1

2

1

Printed in USA 2/08 © 2008 8 528-510revD

Page 9

Exploded View and Parts List — Heater Panels

HPL35-26, HP35-26

HPL27-26, HP27-26

HPL19-26, HP19-26

HPL12-26, HP12-26

HPL35-26/HP35-26

Ref. No. Description

1 88-682S Lampholder Kit

2 88-793-02S Fluorescent Lamp Kit

HPL27-26/HP27-26

Ref. No. Description

1 88-682S Lampholder Kit

2 88-793-01S Fluorescent Lamp Kit

Heater Panels

and Controllers

HPL19-26/HP19-26

Ref. No. Description

1 88-682S Lampholder Kit

2 88-793-01S Fluorescent Lamp Kit

HPL12-26/HP12-26

2

1

Ref. No. Description

1 88-682S Lampholder Kit

2 88-793-01S Fluorescent Lamp Kit

NOTE: Heaters and glass are not field replaceable.

528-510revD 9 Printed in USA 2/08 © 2008

Page 10

Heater Panels

and Controllers

Wiring Diagrams

Flex Conduit

Brown = Heater 1

Brown = Heater 1

HPC-2

Heater 1

Light (Not on HP Series)

Yellow = Light

Red = Light

Green/ Yellow = Ground

Printed in USA 2/08 © 2008 10 528-510revD

Page 11

Wiring Diagrams (Continued)

Heater Panels

and Controllers

HPC-2CE

528-510revD 11 Printed in USA 2/08 © 2008

Page 12

Heater Panels

and Controllers

Wiring Diagrams (Continued)

HPC-4CE

Printed in USA 2/08 © 2008 12 528-510revD

Loading...

Loading...