Page 1

Pressure

Canner

and Cooker

Visit us on the web at www.GoPresto.com

Instructions and Recipes

Table of ConTenTs

Important Safeguards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Getting Acquainted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before Using the Canner for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

How to Use Your Canner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pressure Canning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How to Pressure Can Foods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pressure Canning Fruits and Tomatoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pressure Canning Vegetables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure Canning Meat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Canning Poultry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pressure Canning Fish and Seafood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pressure Canning Soups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Helpful Hints For Pressure Canning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

How To Can Foods Using Boiling Water Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pressure Cooking in Your Pressure Canner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

How to Pressure Cook Foods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Helpful Hints for Pressure Cooking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pressure Cooking Meat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pressure Cooking Entrees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pressure Cooking Poultry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pressure Cooking Soups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Pressure Cooking Desserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Recipe Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Service and Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

©2006 by National Presto Industries, Inc.

1

Page 2

This is a Listed appliance. The following Important Safeguards are recommended by most portable appliance manufacturers.

IMPORTANT SAFEGUARDS

To reduce the risk of personal injury or property damage, basic safety precautions should always be followed, including the following:

1. Read all instructions. Improper use may result in bodily injury or property damage.

2. Always check the vent pipe before use. Hold cover up to light and look through vent pipe to be certain it is clear.

3. Always check the air vent/cover lock to be sure it moves freely before use.

4. Do not fill pressure canner over 2⁄3 full when using for pressure cooking. For soup, rice, and dried vegetables which expand during cooking, do not fill canner over 1⁄2 full. Overfilling may cause a risk of clogging the vent pipe and developing excess pressure.

See food preparation instructions.

5. Do not pressure cook applesauce, cranberries, rhubarb, pearl barley, cereals, pastas, grains, split peas, or soup mixes containing

dry beans or peas. These foods tend to foam, froth, and sputter and may block the vent pipe, overpressure plug, and air vent/cover

lock.

6. This appliance cooks under pressure. Improper use may result in scalding injury. Make certain pressure canner is properly closed

before operating; cover handles must be directly above the body handles. See “How To Use” instructions.

7. Do not place the pressure canner or attempt to pressure can or cook in a heated oven.

8. Caution: Do not use pressure canner on an outdoor LP gas burner or gas range over 12,000 BTU’s.

9. Extreme caution must be used when moving a pressure canner containing hot liquids. Do not touch hot surfaces. Use handles or

knobs.

10. Do not open canner until internal pressure has been completely reduced, air vent/cover lock has dropped, and no steam escapes

when the pressure regulator is removed. See “How To Use” instructions.

11. Caution: To ensure safe operation and satisfactory performance, replace the overpressure plug every time you replace the sealing

ring or sooner if it becomes hard, deformed, cracked, worn, or pitted. It is recommended that the sealing ring and overpressure plug

be replaced at least every three years.

12. Close supervision is necessary when the pressure canner is used near children. It is not recommended that children use the pressure canner.

13. When normal operating pressure is reached, the pressure regulator will begin to rock. Gradually lower the heat as necessary to

maintain the pressure. If the pressure regulator is allowed to rock vigorously, excess steam will escape, liquid will be evaporated,

and food may scorch.

14. Do not use this pressure canner for other than intended use.

15. Do not use this pressure canner for pressure frying with oil.

SAVE THESE INSTRUCTIONS

THIS PRODUCT IS FOR HOUSEHOLD USE ONLY.

2

Page 3

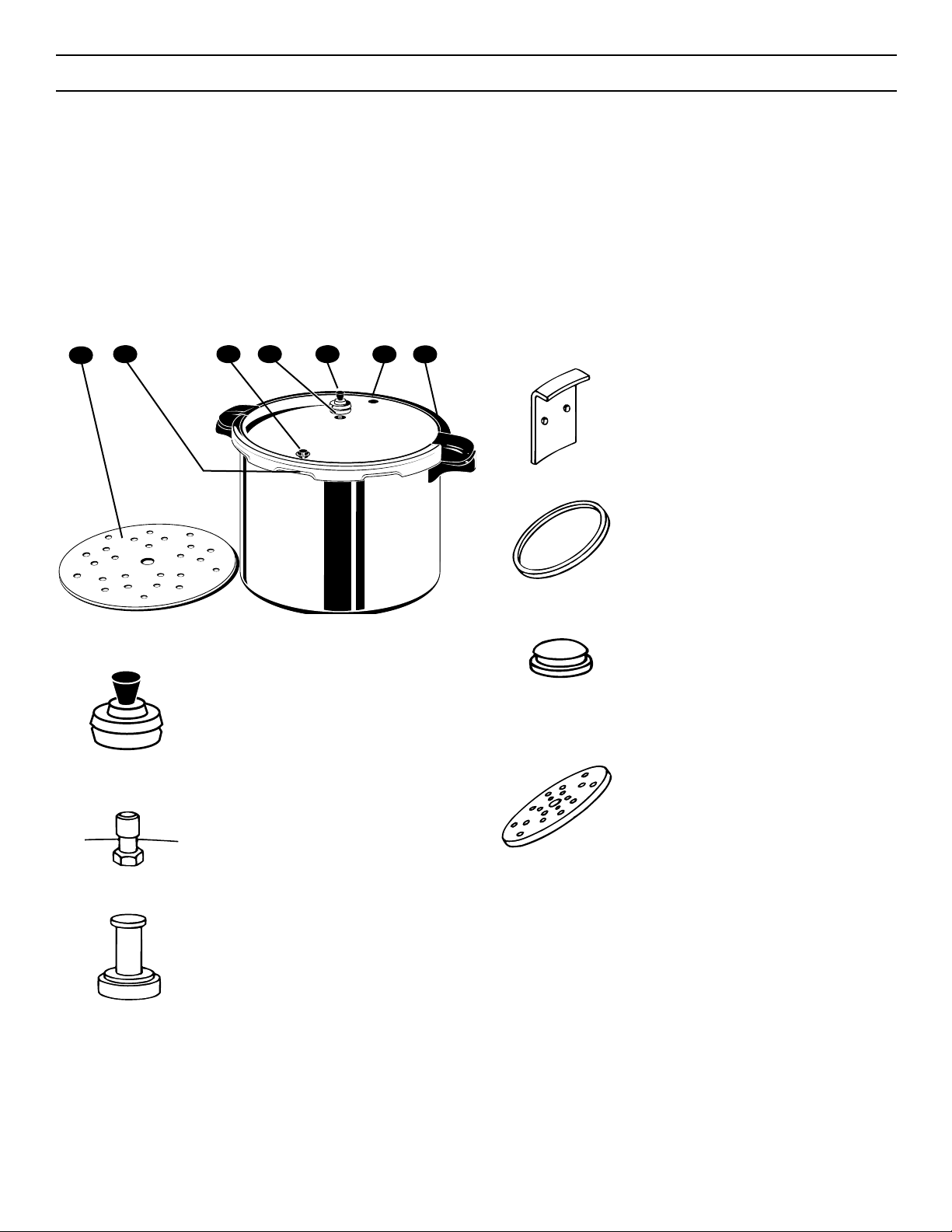

GeTTinG aCquainTed

Your canner is a special, large capacity pressure vessel designed for home canning a wide variety of fruits, vegetables, meats,

and poultry. The canner may also be used to fast cook many of your favorite foods in larger quantities than can be prepared in a

conventional size pressure cooker.

The canner uses pressure to achieve the high temperatures required for safely processing foods while canning. The United States

Department of Agriculture recommends the pressure canner as the only safe method for canning low-acid foods—vegetables,

meats, and poultry.

The canner will also cook many foods in one-third to one-tenth the time required by conventional methods. Pressure cooking

preserves flavor and nutrients and tenderizes tougher cuts of meat.

It is necessary to follow a few special rules in using and caring for your Pressure Canner. Become familiar with the various parts

as shown in the diagram below and read the “How To Use” sections beginning on Pages 4, 6, 18, and 20, before using for the first

time.

4 2

7

13

1. THREE-PIECE PRESSURE

REGULATOR

The pressure regulator controls and

maintains the correct pressure in the

canner. The correct pressure is obtained

when the pressure regulator begins a

gentle rocking motion.

2. VENT PIPE

The pressure regulator fits over the vent

pipe and allows excess pressure to be

released.

3. AIR VENT/COVER LOCK

The air vent/cover lock automatically

“vents” or exhausts air from the canner

and acts as a visual indication of pressure

in the canner. The small gasket must be

in place for the air vent/cover lock to seal

completely.

6

5

4. LOCKING BRACKET

The locking bracket on the inside of

the canner body engages with the air

vent/cover lock to prevent the cover from

being opened when there is pressure in

the unit.

6. SEALING RING

The sealing ring fits into the canner cover

and forms a pressure-tight seal between

the cover and body during canning and

cooking.

7. OVERPRESSURE PLUG

The overpressure plug is located in the

canner cover. It will automatically pop

out and release steam in case the vent pipe

becomes blocked and/or clogged and pressure cannot be released normally through

the vent pipe.

8. CANNING-COOKING RACK

The canning-cooking rack is placed in the

bottom of the canner to hold jars off the

bottom of the unit while canning. When

cooking, the rack is used for steaming

foods. It can also be used to hold foods

such as vegetables out of the cooking liquid

which allows several foods to be cooked

at the same time without an intermingling

of flavors. When it is desirable to blend

flavors, do not use the canning-cooking

rack. The canning-cooking rack must

always be used when canning.

REPLACEMENT PARTS

PRESTO Canner parts are available at most hardware stores or see parts information on page 35.

When ordering parts, please specify the seven digit model number found stamped on the side of the canner body.

3

Page 4

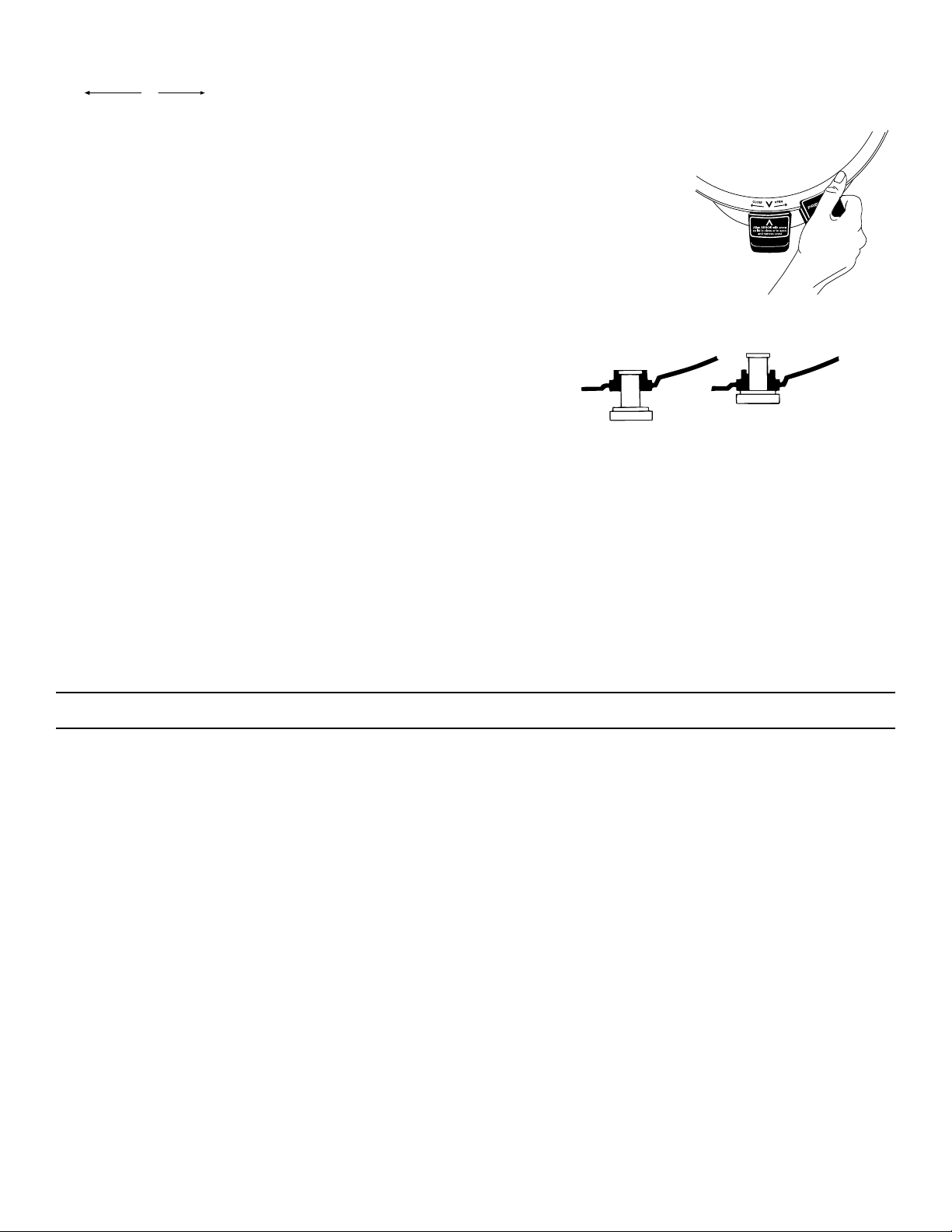

befoRe usinG CanneR foR THe fiRsT TiMe

1. Remove the air vent/cover lock from the canner

cover. The cup portion of the air vent/cover lock,

on the inside of the cover, unscrews from the pin

(Fig. A).

2. Remove the sealing ring by simply pulling it from

the sealing ring groove.

3. Remove the overpressure plug by pushing it out

of its opening from the top of the cover.

4. Wash the cover, body, and sealing ring with hot,

sudsy water to remove any manufacturing oils.

5. Reinsert the air vent/cover lock making sure the

small gasket is in place as shown (Fig. B).

6. Reinsert the overpressure plug by pushing the domed side of the

plug into the opening from the underside of the cover, until the

bottom edge is fully and evenly seated against the underside of the

cover (Fig. C). When the overpressure plug is properly installed,

the word (TOP) will be visible on the overpressure plug when

viewing the outside of the cover.

7. Replace the sealing ring in the sealing ring groove, making certain

to fit the ring under the stop tab located on the inside rim of the

cover (Fig. D).

8. The sealing ring is prelubricated. If necessary, to help make the

cover easier to open and close, a very light coating of cooking oil

may be applied to the sealing ring and underside of the body lugs

(Fig. E). The cover should open and close easily when following

the instructions on page 5.

Cup

Body Lug

Apply

Cooking

Oil Here

Fig. E

Pin

Fig. A

Cover

Small

Gasket

Cover

Overpressure

Plug

Apply

Cooking

Oil Here

Cover

Small Gasket

Cup

Top

Indented

Portion

Sealing Ring in

Sealing Ring

Groove

Fig. B

Pin

Fig. C

Cover

Stop Tab

Fig. D

How To use YouR CanneR

IMPORTANT: Read carefully. Do not attempt to use your Pressure Canner before reading these instructions.

Before using your canner for the first time, clean according to the instructions above.

Be sure the vent pipe is open before each use by holding the cover up to the light and looking through the vent pipe

(Fig. F). If the vent pipe is blocked, excess pressure cannot be released through it. Pressure may then build to unsafe levels.

Pressure will continue to build until the overpressure plug is forced out of its cover opening. Therefore, clean the vent pipe

with a small brush or pipe cleaner if it is blocked or partially blocked (Fig. G). Also clean the vent pipe nut as shown.

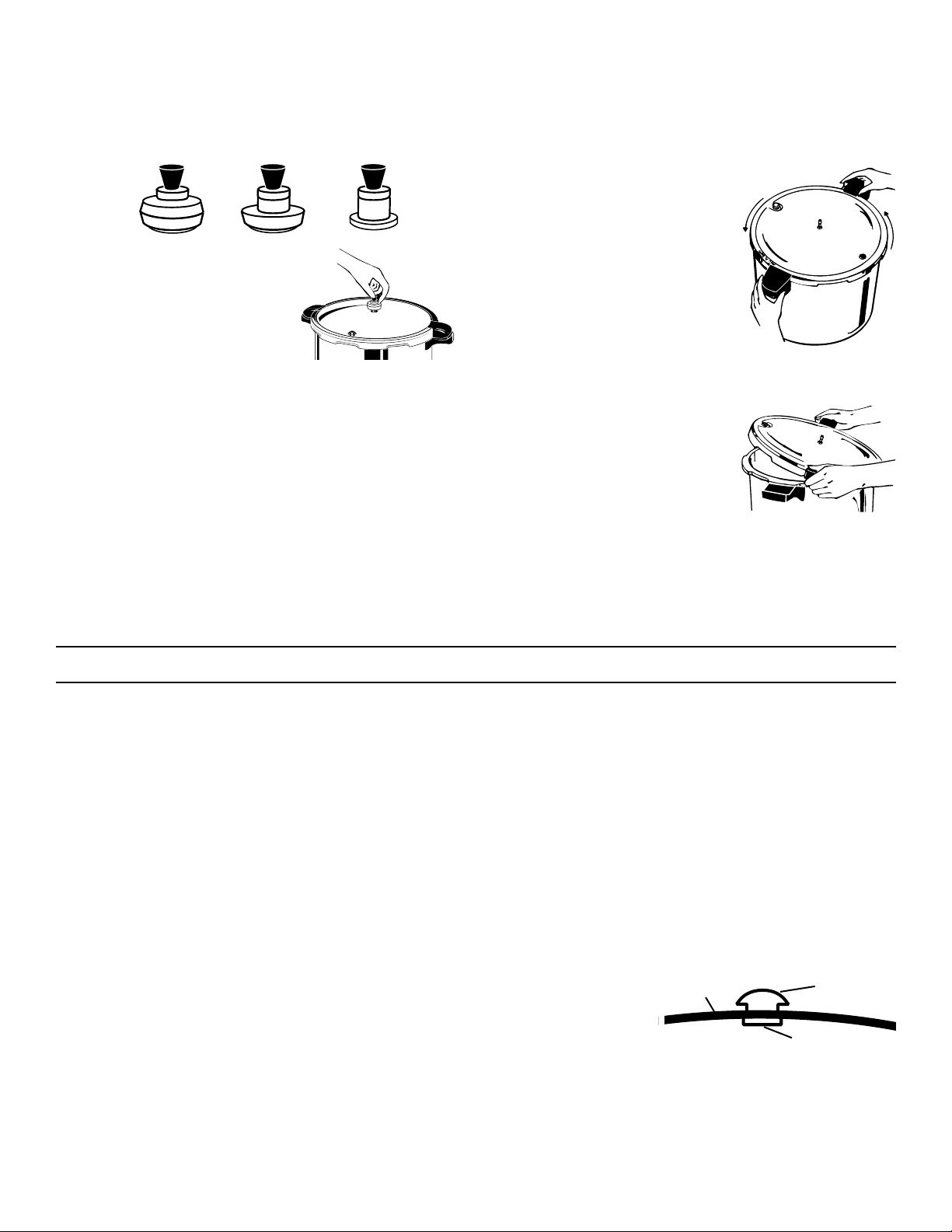

The correct pressure for canning and cooking is maintained by the pressure regulator. The regulator can be adjusted to maintain

any of three pressure levels (5 pounds, 10 pounds, or 15 pounds). Completely assembled, the regulator

will maintain 15 pounds of pressure.

When it is desirable to use another pressure level (see recipe section), the regulator can be adjusted by

removing the appropriate number of weight rings (Fig. H). When one ring is removed, the regulator will

maintain 10 pounds of pressure. With both rings removed, 5 pounds of pressure will be maintained.

Use the canner on a level burner and range only. Use on a tilted burner or range may interfere with

the operation of the pressure regulator. Caution: Do not use pressure canner on an outdoor LP gas

burner or gas range over 12,000

BTU’s.

15 POUNDS

PRESSURE

10 POUNDS

The canner has been designed so the

cover will go on in only one position and rotate in only the directions

indicated for closing and opening.

Fig. G

PRESSURE

Fig. H

Fig. F

5 POUNDS

PRESSURE

4

Page 5

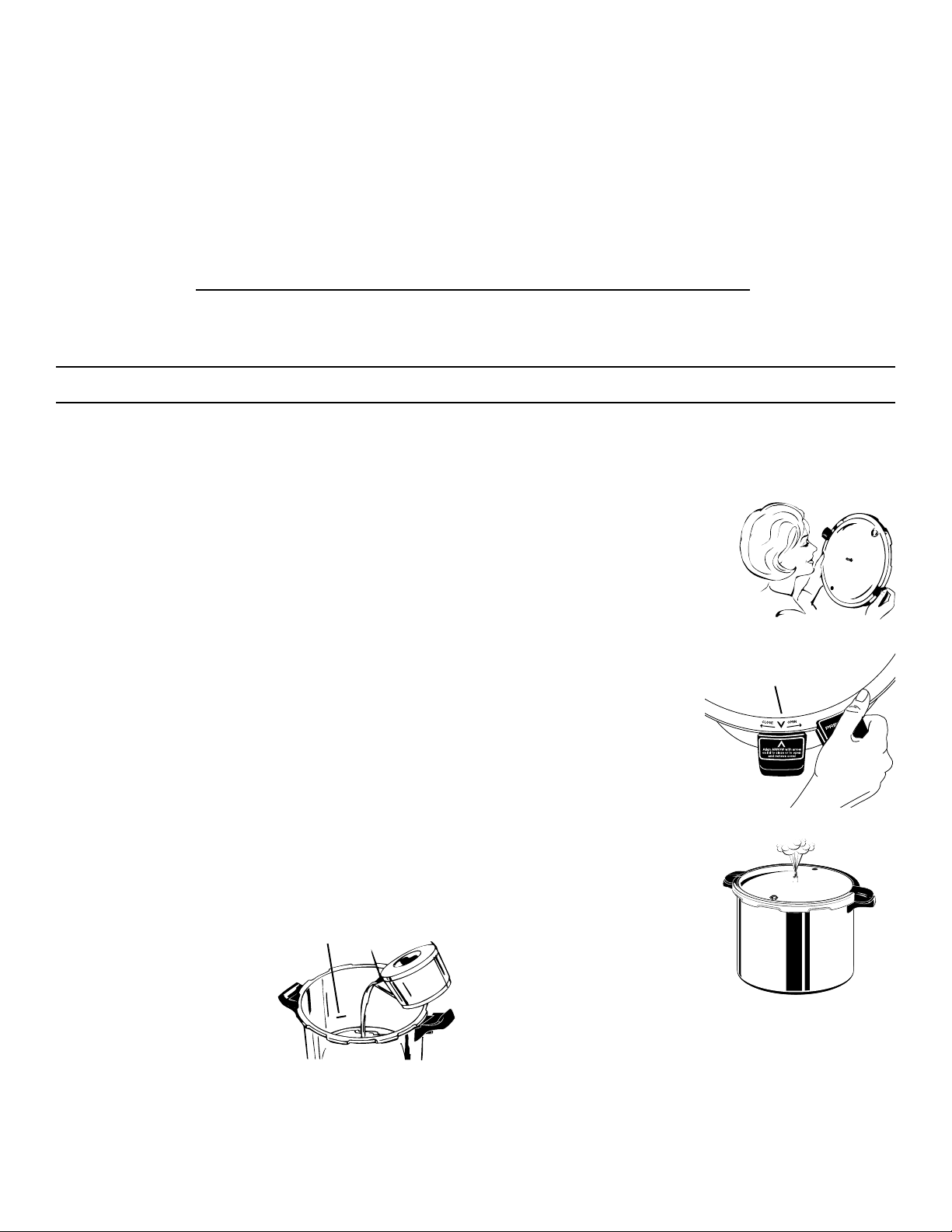

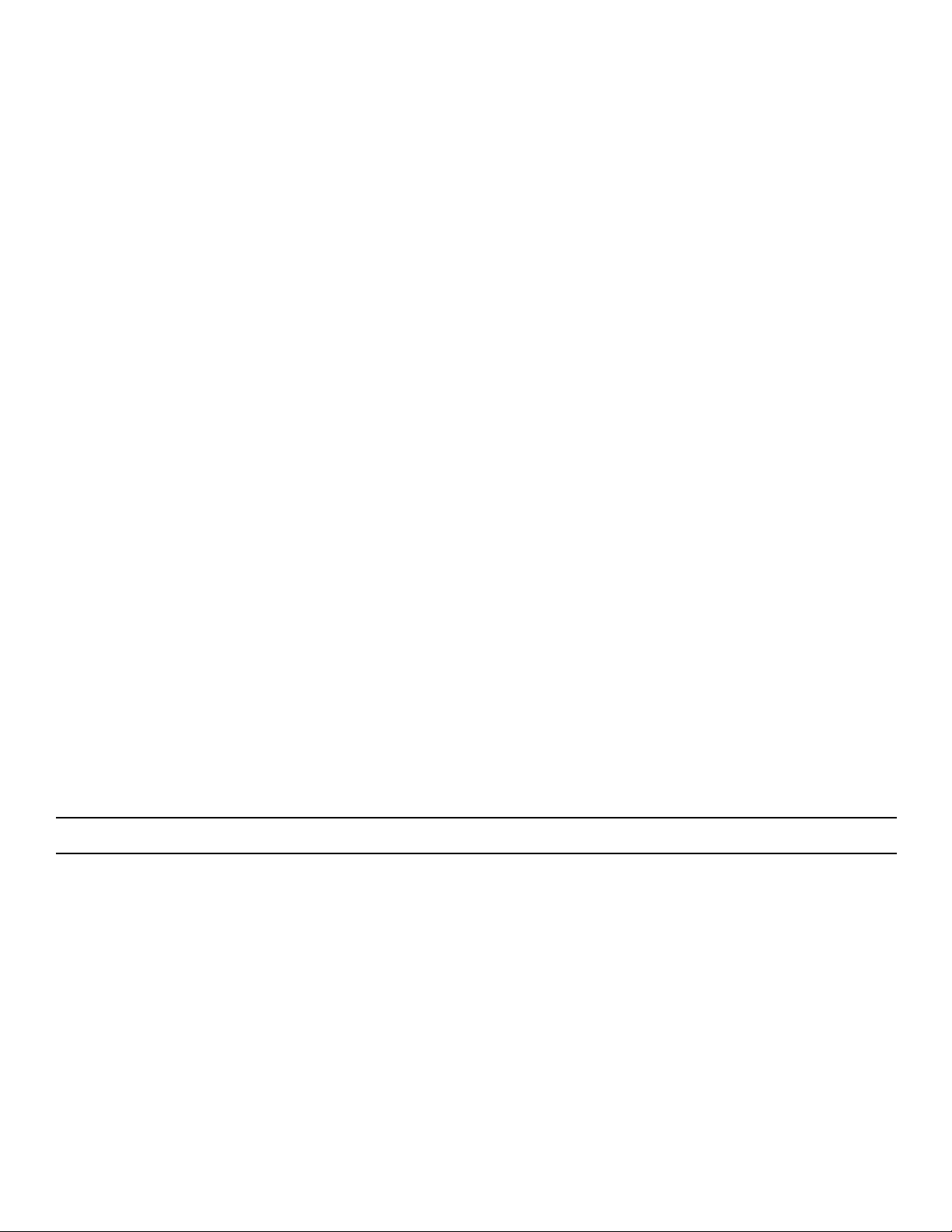

Press down on the cover handles to compress the sealing ring and make the cover easier to close. The cover has the words

CLOSE V OPEN embossed on the top surface near a cover handle. Align the V mark on the cover with the

V

mark on the

body handle for proper cover and body alignment (Fig. I). Turn the cover in the direction indicated to close (clockwise) until

the cover handles are centered directly above body handles. Do not rotate cover beyond this

point.

When the cover is rotated to the closed position, the air vent/cover lock passes under the

locking bracket. When the handles are aligned, one over the other, the pressure regulator is

Note: Cover is shown in open

position. Rotate clockwise

to close.

Cover

Handle

placed on the vent pipe, and heat is applied, pressure will begin to build within the canner.

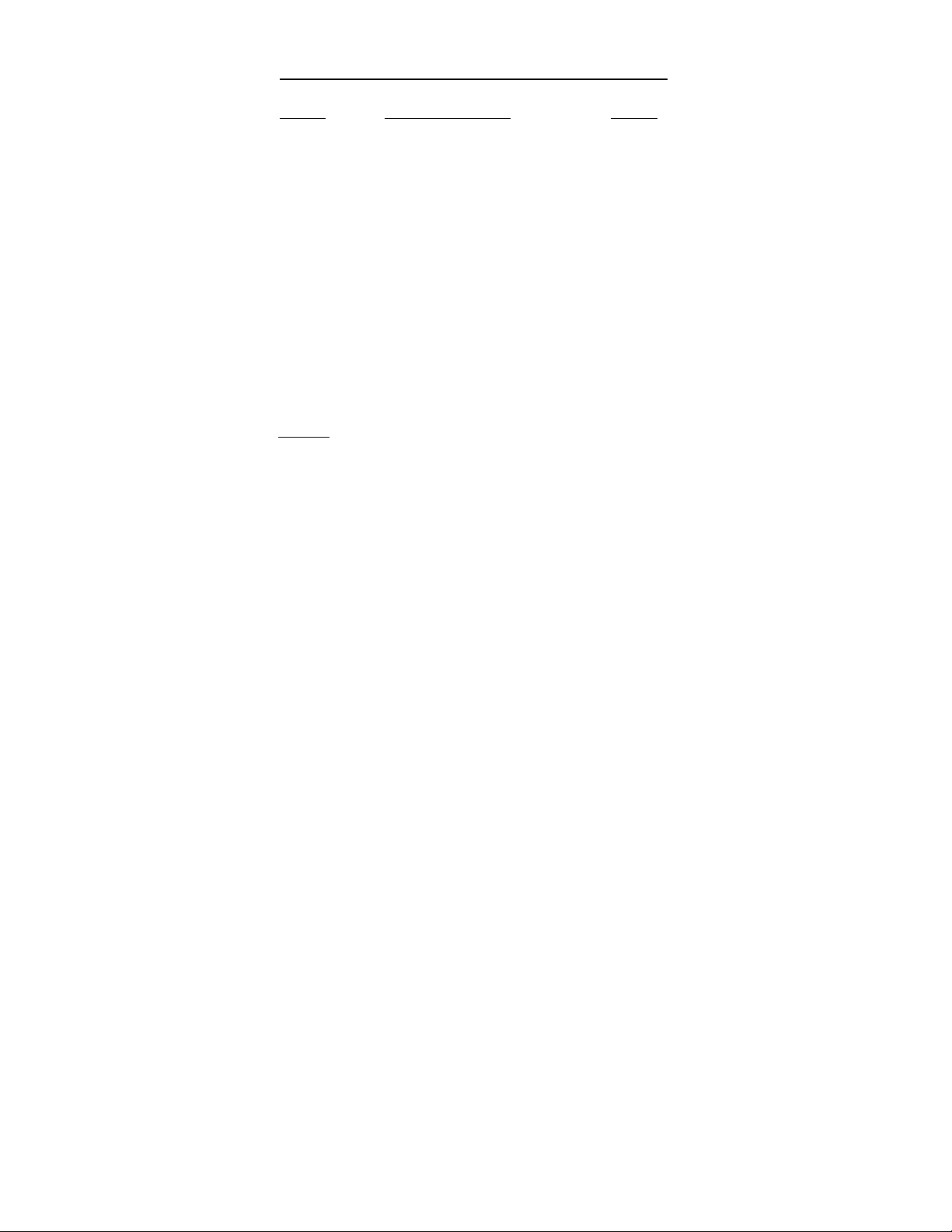

At this point, the air vent/cover lock lifts and locks the unit. The cover will remain locked

as long as there is pressure in the canner. When pressure is completely reduced, the air

vent/cover lock drops allowing the canner to be opened (Fig. J).

If the cover is not rotated sufficiently (cover handles directly above body handles), the air

Body Handle

Fig. I

vent/cover lock will only raise slightly and steam will continue to flow from it, preventing

pressure from building.

The pressure regulator is placed on the vent pipe following

the 10-minute exhaust period (see page 6, step 7). During

UNLOCKED

Fig. J

LOCKED

canning, moisture may appear near the pressure regulator,

overpressure plug, and air vent/cover lock. This is normally

due to condensation. This does not affect operation of the

canner.

Air Vent/Cover Lock

in DOWN Position.

No Pressure in Unit.

Air Vent/Cover

Lock in UP Position.

Pressure in Unit.

To reduce pressure at the end of the canning period, turn

burner off and remove the canner from the heat source. Pressure is completely reduced when the air vent/cover lock has

dropped and no steam escapes when the pressure regulator is tilted. Do not remove the pressure regulator until pressure is

completely reduced. Always remove the pressure regulator before opening canner.

If the air vent/cover lock remains in its raised position, there may still be pressure in the canner. Do not remove the pressure

regulator until the air vent/cover lock drops and no steam escapes when the pressure regulator is tilted. The cover should not

be forced open. You may tap the air vent/cover lock lightly with a spoon. If pressure is present, steam will escape and the air

vent/cover lock will pop back up. Continue to cool the canner until the air vent/cover lock drops.

HELPFUL HINT: To help yourself understand the operation of the pressure canner and cooker, pour 4 cups of water into the

canner and follow the step-by-step instructions beginning with step 5 on page 6. For actual usage of the canner/cooker, follow

the complete instructions beginning on page 6 for pressure canning and on page 20 for pressure cooking.

PRessuRe CanninG

The United States Department of Agriculture recommends the pressure canner as being the only safe method for canning low acid

foods—vegetables, meats, and poultry.

There are invisible microrganisms present all around us. Fruits, vegetables, and meat contain these microrganisms naturally, and

yet, they are not a problem unless food is left to sit for extended periods of time, causing food spoilage. This is nature’s way of

telling us when food is no longer fit to eat.

There are four basic agents of food spoilage—enzymes, mold, yeast, and bacteria. Canning interrupts the natural spoilage cycle

so food can be preserved safely. Molds, yeast, and enzymes are destroyed at temperatures below 212°F, the temperature at which

water boils (except in mountainous regions). Therefore, boiling water processing is sufficient to destroy those agents.

Bacteria, however are not as easily destroyed. The bacteria, Clostridium botulinum produces a spore that makes a poisonous toxin

which causes botulism. This spore is not destroyed at 212°F. In addition, the bacteria thrive on low acids in the absence of air. For

a safe food product, low acid foods need to be processed at 240°, which can be achieved only with a pressure canner.

In pressure canning, some of the water in the pressure canner is converted to steam, which creates pressure within the canner. As

pressure increases, temperature increases, 5 pounds pressure—228°F, 10 pounds pressure—240°F, 15 pounds pressure—250°F.

This pressurized heat destroys the potentially harmful bacterial spores. As the jars cool, a vacuum is formed, sealing the food within

and preventing any new microorganisms from entering and spoiling the food.

As a safeguard against using canned foods which may be affected with spoilage that is not readily detected, boil all low acid foods

and tomatoes for 10 minutes at altitudes below 1,000 feet. Extend the boiling time by 1 minute for each 1,000 foot increase in

altitude.

5

Page 6

Many times odors that cannot be detected in the cold product will become evident by these methods. If, after boiling, food does

not smell or look right, discard it without tasting.

MASON JARS: While there are many styles and shapes of glass jars on the market, only Mason jars are recommended for home

canning. Mason jars are available in ½ pint, pint, and quart capacities with threads on which a cap may be screwed. See the chart

below for the jar capacity of your canner. Additional information may be obtained from the manufacturers of Mason jars.

CLOSURES FOR MASON JARS: The two-piece vacuum cap consists of a flat metal lid held in place with a screw band. A rubber

compound on the underside of the lid forms a seal during processing. Follow the closure manufacturer’s directions for using the

two-piece cap and for testing for a proper seal. If the closure has not sealed, completely reprocess or use the food immediately.

Refer to the closure manufacturer’s directions for additional information.

CANNER JAR CAPACITIES FOR PRESSURE CANNING (MAXIMUM CAPACITY)

MODEL NO. ½ PINT 1 PINT 1 QUART

01745 12 10 7

Please note: To double deck pint and half pint jars, see page 17.

How To PRessuRe Can foods

IMPORTANT: Read carefully. Do not attempt to use your canner before reading these instructions.

Follow these step-by-step instructions for pressure canning in your canner. Prepare food according to the directions in specific

recipe.

1. Be sure your canner is thoroughly cleaned and working

properly. Before each canning season, check the sealing ring,

overpressure plug, and the rubber gasket of the air vent/cover

lock. Replace these parts when they become hard, deformed,

cracked, worn, pitted, or unusually soft.

2. Check Mason jars for nicks, cracks, and sharp edges.

Check screw bands for dents or rust. Use only jars, lids,

and bands in perfect condition so an airtight seal may be

obtained.

Wash and rinse jars, lids, and bands. Pour hot water into jars

and set aside until needed. Follow closure manufacturer’s

directions for bands and lids.

3. Select fresh firm food. Sort food according to size. Clean

food thoroughly. Prepare according to recipe. Fill hot Mason

jars promptly with food and liquid to recommended level. Allow

½-inch headspace for fruits. ALL vegetables and meats require

1-inch headspace due to expansion during processing.

Work out air bubbles with a clean nonmetallic spatula. Wipe

sealing edge clean with a damp cloth.

Adjust bands according to closure manufacturer’s direc

tions.

4. P l a c e 3 q u a r t s o f

3-quart water line

boiling wate r, cann ing

rack, and jars in canner.

To prevent water stains

on jars, add 2 tablespoons

wh ite vinegar to water

in ca nner. Always use

canning rack. Jars may

break if set directly on

bottom of canner.

5. Loo k th rou gh the vent

pipe to be certain it is open

before placing cover on

canner. To clean the vent

pipe, draw a pipe cleaner

or small brush through the

opening.

6. P l a c e c o v e r o n c an

ner, aligning the V mark on

the cover with the

on the body handle and

lock securely by turning in

the direction indicated to

close (clockwise). Cover

handles must be centered

over body handles. Do not

force beyond this position.

7. Exhaust air from the can

ner and jars by adjusting

-

heat to a relatively high

setting to obtain a free

flow of steam from the

ve nt pipe. Cons ult t he

instruction book which accompanied your range for

recommended heat setting.

Reduce heat to maintain a moderate steam flow. Allow

steam to flow for 10 minutes.

V

mark

-

Align the V mark on the

cover with the V mark on

the body handle.

-

6

Page 7

8. Assemble the three-piece pressure regulator to register

the desired canning pressure (see page 4 for assembly

instructions). See specific canning recipe to determine how

many pounds of pressure to use.

10 POUNDS PRESSURE

15 POUNDS

PRESSURE

5 POUNDS

PRESSURE

9. Place pressure regulator on

vent pipe. Set burner at a

relatively high heat setting, on

most range burners, and heat

canner until pressure regulator

begins to rock.

10. Processing time begins when the pressure regulator begins

to rock gently. Adjust heat to maintain a slow steady rocking

motion.

11. At end of processing time, turn burner to “OFF” and remove

canner from heat source. Caution: Lift pressure canner

to remove it from burner. Sliding cookware can leave

scratches on stovetops.

12.

Let pressure drop of its own accord, do not quick-cool.

Pressure is completely reduced when the air vent/cover

lock and overpressure plug have dropped and no steam

escapes when the pressure regulator is tilted. Do not use

the pressure dial gauge as an indicator for when pressure

is completely reduced. Attempting to speed the cooling of

the canner may cause jar breakage.

13. When pressure has been completely reduced, remove

pressure regulator from vent pipe and let canner cool for

10 minutes. Do not remove the pressure regulator until

pressure is completely reduced

an d the a ir vent/cover lock

has dropped. Always remove

pressure regulator before opening

the cover.

14. To remove cover, turn counterclockwise until cover hits stop.

Cover handles will be beyond

the body handles. If cover seems

to stick or is hard to turn, do

not force it open. Sticking may

indicate that there is still pressure

inside the canner. If in doubt

about pressure being completely

reduced, let the canner stand

until cool before removing the

cover.

15. Lift canner cover toward you to

keep steam away from you when

opening.

16. Remove jars from canner. Set jars apart on board or cloth

away from draft to cool. When jars are cold, test seal, remove bands, wipe jars, label, date, and store in a cool, dry

place.

CaRe and MainTenanCe

1. The outside surface may be kept bright and shiny by cleaning with a good silver polish or simply by washing with soap and

water. Iron and various minerals in water and foods may darken the inside of the canner but this discoloration will in no way

affect food cooked. These stains may be removed by using a solution of water and cream of tartar. For each quart of water,

use one tablespoon cream of tartar. Pour enough solution into the canner to cover the discoloration (do not fill over 2⁄3 full),

then close cover securely. Place regulator on vent pipe and heat until 15 pounds pressure is reached. Remove canner from

heat; allow canner to stand two to three hours. Remove regulator, open canner, and empty contents. Scour thoroughly with a

soap impregnated steel wool cleaning pad; wash, rinse, and dry.

Due to the acidic nature of the water supply in some areas, deterioration of the interior surface of the canner body may occur.

To minimize this effect, thoroughly scour the inside of the canner body with an abrasive cleanser at least once a year.

2. Each time the canner is washed, remove the sealing ring and wash in warm, sudsy water, rinse, dry, and replace in cover.

3. The air vent/cover lock may be removed for occasional cleaning or for replacing the small gasket (see page 4). Wash all parts

in warm, sudsy water. Use a soft cloth or small nylon brush to clean the cover hole. The small gasket must be in place when

reassembling the air vent/cover lock.

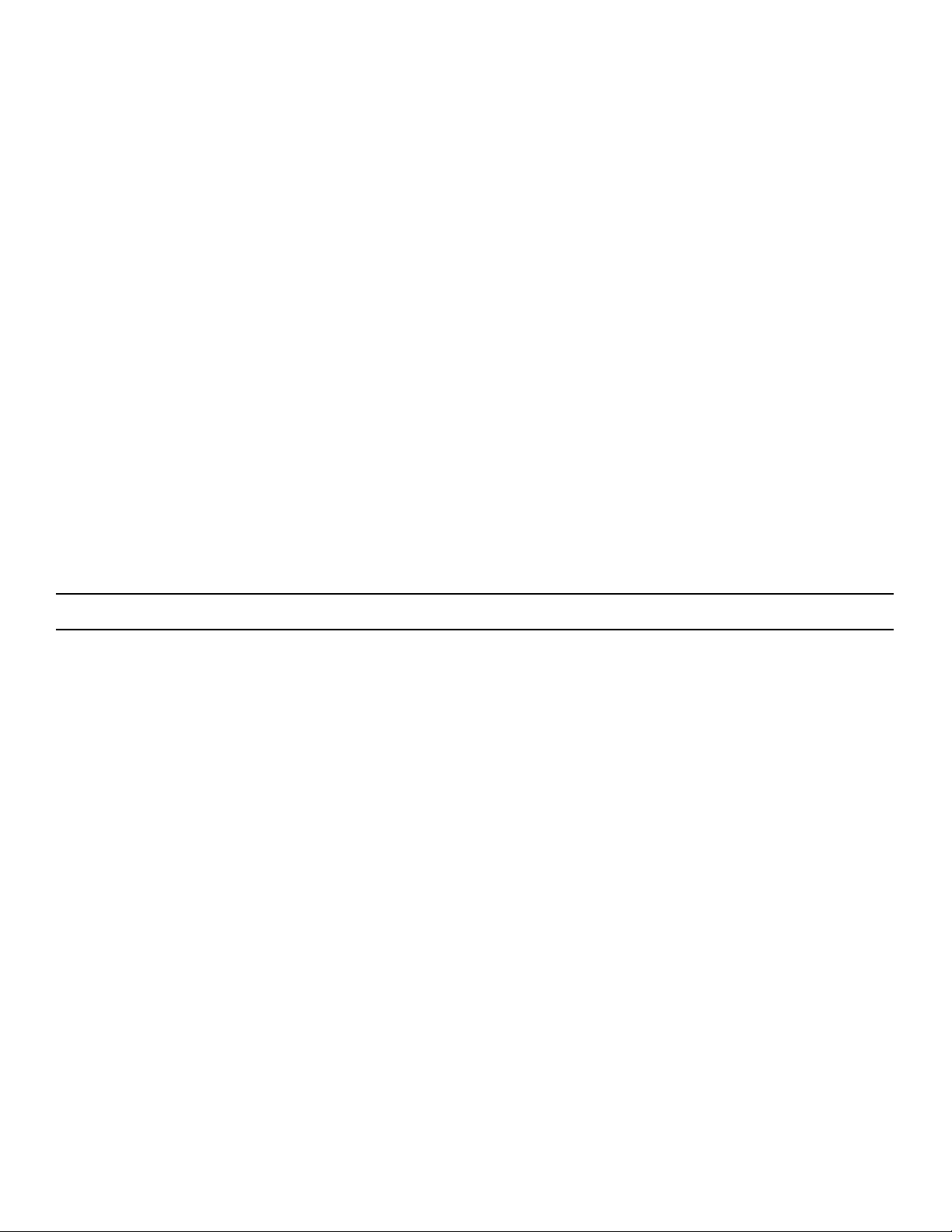

4. The overpressure plug can be removed for cleaning by pushing it out of its opening

from the top of the cover. After cleaning, reinsert the plug by pushing the domed side

of the plug into the opening from the underside of the cover, until the bottom edge

Cover

Top

is fully and evenly seated against the underside of the cover. When the overpressure

plug is properly installed, the word (TOP) will be visible on the overpressure plug

when viewing the outside of the cover.

If the overpressure plug is ever forced out of its cover opening due to excess pressure while cooking or canning, it is important

to call the Test Kitchen at 1-800-368-2194. Do not attempt to use the released overpressure plug.

Overpressure

Plug

Indented Portion

7

Page 8

5. Pouring water into a dry overheated canner may crack the metal.

6. Do not strike the rim of the canner body with any cooking utensil as this will cause nicks which may damage the rim and

allow steam to escape.

7. When your pressure canner is not in use, invert the cover on the canner body and store in a dry place. Storing the canner with

the cover locked on may cause unpleasant odors and deform the sealing ring.

8.

To ensure safe operation and satisfactory performance, replace the overpressure plug every time you replace the sealing

ring or sooner if it becomes hard, deformed, cracked, worn, or pitted. Replace the sealing ring and overpressure plug at least

every three years. Failure to follow these instructions could result in bodily injury or property damage.

9. If the canner body or cover handles become loose, tighten with a screwdriver.

10. If leakage of moisture or steam develops while using your canner, check the following possible causes:

The formation of a small amount of moisture under the pressure regulator is normal when cooking or canning first begins.

This condensation is a result of the temperature of the pressure regulator being lower than the rest of the canner. If excess

condensation continues, the vent pipe may be loose and should be tightened with an adjustable wrench.

Leakage between the cover and body is usually caused by shrinkage of the sealing ring after prolonged use. Replace the

sealing ring and overpressure plug.

A slight amount of leakage around the air vent/cover lock is normal when canning or cooking first begins. If leakage

continues, the cover handles may not be fully aligned with the body handles and, therefore, the cover lock cannot engage

(see page 5). Clean the air vent/cover lock occasionally to assure that it operates correctly (see page 4). Replace the small

gasket if cracked or nicked.

A small amount of steam or moisture may be visible around the overpressure plug as canning or cooking begins.

This will stop when the overpressure plug seals. If leakage continues, clean or replace the overpressure plug (see

page 7).

Do not operate your pressure canner with continual leakage. If the preceding steps do not correct the problem, return the entire

unit to the Presto Factory Service Department (see page 35).

11. If the pressure canner becomes difficult to open or close, replace the sealing ring.

12.

IMPORTANT: The sealing ring, overpressure plug, and rubber gasket of the air vent/cover lock may shrink, become hard,

deformed, cracked, worn, or pitted with normal use. Exposure to high heat, such as a warm burner or oven top, will cause

these parts to deteriorate rapidly. When this happens, replace the sealing ring, overpressure plug, and small rubber gasket of

the air vent/cover lock. Replace the sealing ring and overpressure plug at least every three years.

Before inserting a new sealing ring, clean the sealing ring groove with a brush. To insure safe operation of your pressure

canner, it is recommended that the overpressure plug be replaced whenever the sealing ring is replaced.

Any maintenance required for this product, other than normal household care and cleaning, should be performed by the Presto

Factory Service Department (see page 35).

PRessuRe CanninG fRuiTs and ToMaToes

Fruits and tomatoes may be processed using pressure canning or boiling water canning. The pressure processing method for fruits and

tomatoes gives a heat treatment equivalent to the much longer processing time required with the boiling water canning method.

Select firm, fully-ripened but not soft fruit or tomatoes. Do not can overripe foods. Some fruits tend to darken while they are being prepared. To prevent the darkening, place fruit in an ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water) or use ascorbic acid

or citric acid mixtures according to package instructions.

Although fruit has better color, shape, and flavor when it is canned with sugar, it may be canned unsweetened if desired. White sugar is

preferable to brown sugar for canning. Light corn syrup or honey may be used to replace up to one-half the sugar.

The amount of sugar desirable to use in preparing syrups will depend upon the tartness of the fruit and on family preference. It should be

remembered that fruit, when heated, releases some of its juices which will dilute the syrup in proportion to the juiciness of the fruit.

8

Page 9

SYRUPS FOR CANNING FRUITS

SUGAR PER YIELD OF

SYRUP QUART OF LIQUID SYRUP

Very Light 1 cup 4½ cups

Light 2 cups 5 cups

Medium 3 cups 5½ cups

Heavy 4¾ cups 6½ cups

Heat sugar with water or juice until sugar is dissolved. Add fruit and cook until heated through. Pack fruit into clean Mason jars to within

½-inch of top of jar. Cover with hot liquid leaving ½-inch headspace. The liquid may be syrup, fruit juice, or plain water. For steps on

boiling water canning, refer to page 18.

Altitude Adjustments

The processing times for pressure canning given in the specific fruit and tomato recipes are for altitudes of 1,000 feet or less. When

pressure canning fruit above 1,000 feet, process at 10 pounds of pressure. When pressure canning tomatoes above 1,000 feet, process at

15 pounds of pressure. Processing time is the same at all altitudes.

The processing times for boiling water canning given in the specific fruit and tomato recipes are for altitudes of 1,000 feet or less. When

processing at higher altitudes, process according to the chart below.

Altitude

1,001 – 3,000 ft. increase processing time 5 minutes

3,001 – 6,000 ft. increase processing time 10 minutes

6,001 – 8,000 ft. increase processing time 15 minutes

CANNING RECIPES: FRUITS AND TOMATOES

APPLES

Wash, peel, and cut apples into pieces. Place apples in an ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water) to prevent

darkening during preparation. Drain well. Boil apples in a light syrup or water for 5 minutes. Pack hot apples in clean, hot Mason jars,

leaving ½-inch headspace. Cover apples with hot syrup or water, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 8 minutes.

Boiling water canning: Process pints 20 minutes.

APPLESAUCE

Wash, peel, and core apples. If desired, slice apples into ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water) to prevent

darkening. Drain well. Place slices in a pan. Add ½ cup water. Cook until apples are tender. Press through food mill or sieve. Sweeten to

taste. Reheat sauce to boiling. Pack into clean, hot Mason jars, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints 8 minutes and quarts 10 minutes.

Boiling water canning: Process pints 15 minutes.

APRICOTS

Wash well-ripened, firm apricots. If peeled apricots are desired, dip 1 minute in boiling water, then in cold water, and peel. Cut apricots

in halves and remove pits. Place apricots in an ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water) to prevent darkening

during preparation. Drain well. Heat apricots through in a very light, light, or medium syrup or water (see above). Pack hot apricots, cut

side down, in clean, hot Mason jars, leaving ½-inch headspace. Cover with boiling syrup or water, leaving ½-inch headspace. Adjust jar

lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 10 minutes.

Boiling water canning: Process pints 20 minutes.

9

Page 10

BERRIES (EXCEPT STRAWBERRIES)

Wash firm berries carefully, removing caps and stems. Heat berries in boiling water for 30 seconds and drain. Pack hot berries in clean,

hot Mason jars, leaving ½-inch headspace. Cover with boiling syrup or water, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 8 minutes.

Boiling water canning: Process pints 15 minutes.

CHERRIES

Wash cherries and remove stems. Remove pits, if desired. If canning whole cherries, prick each cherry with a clean needle to prevent

splitting. Heat cherries with ½ cup water or syrup to each quart of cherries. Cover pan and bring to a boil. Pack hot cherries and cooking

liquid in clean, hot Mason jars, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints 8 minutes and quarts 10 minutes.

Boiling water canning: Process pints 15 minutes.

PEACHES

Wash fully-ripened but not soft peaches. Loosen skins by dipping peaches 1 minute in boiling water, then in cold water. Peel. Cut

peaches in half and remove pits. Slice if desired. Place peaches in an ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water)

to prevent darkening during preparation. Drain well. Heat peaches through in very light, light, or medium syrup or water (see page 9).

Pack hot peaches, cut side down, in clean, hot Mason jars, leaving ½-inch headspace. Cover with boiling syrup or water, leaving ½-inch

headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 10 minutes.

Boiling water canning: Process pints 20 minutes.

PEARS

Wash pears. Peel, cut in half lengthwise, and core. Slice pears, if desired. Place pears in an ascorbic acid solution (1 teaspoon ascorbic

acid to 1 gallon water) to prevent darkening during preparation. Drain well. Boil pears 5 minutes in very light, light, or medium syrup

or water (see page 9). Pack hot pears in clean, hot Mason jars, leaving ½-inch headspace. Cover with boiling syrup or water, leaving

½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 10 minutes.

Boiling water canning: Process pints 20 minutes.

PLUMS

Wash firm ripe plums. Remove stems. If plums are to be canned whole, prick each side with a fork. Freestone varieties may be cut in

halves and pitted. Heat plums to boiling in very light, light, or medium syrup (see page 9). Boil 2 minutes. Cover saucepan and let stand

20 to 30 minutes. Pack hot plums in clean, hot Mason jars, leaving ½-inch headspace. Cover with boiling syrup or water, leaving ½-inch

headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 10 minutes.

Boiling water canning: Process pints 20 minutes.

RHUBARB

Wash young, tender rhubarb. Remove ends and cut into ½-inch pieces. Add ½ cup sugar to each quart of rhubarb. Let stand until juice

appears. Heat rhubarb slowly to boiling. Pack hot rhubarb in clean, hot Mason jars, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 8 minutes.

Boiling water canning: Process pints and quarts 15 minutes.

TOMATOES—WHOLE OR HALVED

(packed raw without added liquid)

Wash medium, smooth, firm, ripe tomatoes. Loosen skins by dipping tomatoes 1 minute in boiling water, then in cold water. Peel and

remove core. Leave whole or halve. Add 2 tablespoons of bottled lemon juice or ½ teaspoon of citric acid per quart of tomatoes. For pints,

use 1 tablespoon bottled lemon juice or ¼ teaspoon citric acid. Add 1 teaspoon salt to each quart, ½ teaspoon to each pint, if desired. Fill

jars with raw tomatoes, pressing until spaces between them fill with juice. Leave ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 10 pounds pressure, pints and quarts 25 minutes.

Boiling water canning: Process pints 85 minutes.

10

Page 11

TOMATO JUICE

Wash ripe, juicy tomatoes. Remove stem ends and cut into pieces. To prevent juice from separating, quickly cut about 1 pound of fruit

into quarters and put directly into saucepan. Heat immediately to boiling while crushing. Continue to slowly add and crush freshly cut

tomato quarters to the boiling mixture. Make sure the mixture boils constantly and vigorously while adding the remaining tomatoes.

Simmer 5 minutes after all pieces are added. If juice separation is not a concern, simply slice or quarter tomatoes into a large saucepan.

Crush, heat, and simmer for 5 minutes before juicing.

Press heated juice through a sieve or food mill to remove skins and seeds.

Add 2 tablespoons of bottled lemon juice or ½ teaspoon citric acid to each quart. Add 1 tablespoon of bottled lemon juice or ¼ teaspoon

citric acid to each pint.

Heat juice again to boiling. Add 1 teaspoon of salt to each quart, ½ teaspoon to each pint, if desired. Fill jars with hot tomato juice,

leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 10 pounds pressure, pints and quarts 15 minutes.

Boiling water canning: Process pints 35 minutes.

TOMATO SAUCE

Prepare and press as for making tomato juice (see recipe above). Heat in large saucepan until sauce reaches desired consistency. Simmer

until volume is reduced by about one-third for thin sauce, or by one-half for thick sauce. Add 2 tablespoons of bottled lemon juice or

½ teaspoon of citric acid to each quart. Add 1 tablespoon of bottled lemon juice or ¼ teaspoon citric acid to each pint. Pour hot sauce in

clean, hot Mason jars, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 10 pounds pressure, pints and quarts 15 minutes.

Boiling water canning: Process pints 35 minutes.

SALSA

Process salsa using the boiling water method. Refer to page 19 for tested canning recipe.

PRessuRe CanninG VeGeTables

Pressure canning is the only safe method for canning vegetables.

Young, tender, fresh vegetables, slightly immature, are better for canning than those which are overripe. As a rule, vegetables are best if

canned immediately after picking, since flavor decreases upon standing and often unpleasant color changes take place. Avoid bruising

vegetables because spoilage organisms grow more rapidly on bruised vegetables than on unblemished ones.

Wash and prepare garden fresh vegetables as you would for cooking.

To raw pack vegetables, simply place the prepared vegetables into clean, hot Mason jars and cover with boiling water.

To hot pack vegetables, precook in boiling water until heated through. Pack pre-cooked vegetables into clean, hot Mason jars and cover

with boiling water. Whenever possible, the precooking water should be used as liquid to cover the vegetables after packing into Mason

jars. However, there are a few vegetables, such as greens and asparagus, which make the cooking water bitter and undesirable to use.

When packing vegetables, leave 1-inch headspace in Mason jars.

Foods may be processed with or without salt. If salt is desired, use only canning salt. Table salt contains a filler which may cause cloudiness in bottom of jars. Add ½ teaspoon canning salt to each pint jar, 1 teaspoon to each quart jar, if desired.

Follow step-by-step directions beginning on page 6 for canning procedure. Process specific vegetables according to the following

recipes.

Altitude Adjustment

The processing times given in the specific vegetable recipes are for altitudes of 1,000 feet or less. When pressure canning above 1,000

feet, process at 15 pounds of pressure. Processing time is the same at all altitudes.

11

Page 12

CANNING RECIPES: VEGETABLES

ASPARAGUS

Wash and drain asparagus. Remove tough ends and scales. Rinse. Leave asparagus whole or cut into pieces.

Raw Pack: Pack raw asparagus tightly in clean, hot Mason jars, leaving 1-inch headspace.

Hot Pack: Cover asparagus with boiling water and boil 2 or 3 minutes. Pack hot asparagus loosely in clean, hot Mason jars,

leaving 1-inch headspace.

Cover with boiling water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 30 minutes and Quarts 40 minutes.

BEANS OR PEAS—DRY

Sort out and discard any discolored seeds. Rehydrate beans or peas using one of the following methods:

Place dry beans or peas in a large pot and cover with water. Soak 12 to 18 hours in a cool place. Then drain.

Cover beans with boiling water in a saucepan. Boil 2 minutes, remove from heat and soak 1 hour. Then drain.

Cover beans soaked by either method with fresh water and boil 30 minutes.

Hot Pack: Fill clean, hot Mason jars with beans or peas and cooking water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds of pressure – Pints 75 minutes and Quarts 90 minutes.

BEANS—GREEN,WAX, ITALIAN

Wash young, tender beans thoroughly. Remove stem and blossom ends or any “strings”. Leave whole or cut into 1-inch pieces.

Raw Pack: Pack raw beans tightly in clean, hot Mason jars leaving 1-inch head space.

Hot Pack: Cover beans with boiling water and boil 5 minutes. Pack hot beans loosely in clean, hot Mason jars, leaving 1-inch

head space.

Cover with boiling water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 20 minutes and Quarts 25 minutes.

BEANS—FRESH LIMA

Shell and wash young, tender beans thoroughly.

Raw Pack: Pack raw lima beans loosely in clean, hot Mason jars, leaving 1-inch headspace in pint jars. For quarts, leave 1½-inches

headspace if beans are small; and 1¼-inches headspace if beans are large.

Hot Pack: Cover beans with boiling water and bring to a boil. Boil 3 minutes. Pack hot beans loosely in clean, hot Mason jars,

leaving 1-inch headspace.

Cover with boiling water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 40 minutes and Quarts 50 minutes.

BEETS

Trim tops of young, tender beets, leaving 1 inch of stem and roots to reduce bleeding of color. Wash thoroughly. Cover with boiling water

and boil 15 to 25 minutes or until skins slip off easily. Remove skins, stems, and roots. Small beets may be left whole. Cut medium or

large beets into ½-inch cubes or slices; halve or quarter very large slices. Pack hot beets in clean, hot Mason jars, leaving 1-inch headspace. Cover with boiling water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 30 minutes and Quarts 35 minutes.

CARROTS

Wash thoroughly and scrape young, tender carrots. Carrots may be left whole, sliced, or diced.

Raw Pack: Pack raw carrots tightly in clean, hot Mason jars, leaving 1-inch headspace.

Hot Pack: Cover carrots with boiling water, bring to a boil and simmer 5 minutes. Pack hot carrots in clean, hot Mason jars,

leaving 1-inch headspace.

Cover with boiling water leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 25 minutes and Quarts 30 minutes.

12

Page 13

CORN—WHOLE KERNEL

Husk and remove silk from young, tender, freshly picked corn; wash ears. Blanch 3 minutes in boiling water. Cut corn from cob at about

¾ the depth of the kernel. Do not scrape cob.

Raw Pack: Pack raw corn loosely in clean, hot Mason jars, leaving 1-inch headspace.

Hot Pack: To each quart of corn add 1 cup boiling water; heat to boiling and simmer 5 minutes. Pack hot corn loosely in clean,

hot Mason jars, leaving 1-inch headspace.

Cover with boiling water leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 55 minutes and Quarts 85 minutes.

GREENS

Sort young, tender, freshly picked greens discarding wilted tough leaves, stems, and roots. Wash greens thoroughly. Do not raw pack

greens. Place approximately 1 pound of greens at a time in a cheese cloth bag and steam 3 to 5 minutes or until well wilted. Pack hot greens

loosely in clean, hot Mason jars, leaving 1-inch headspace. Cover with fresh boiling water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 70 minutes and Quarts 90 minutes.

MUSHROOMS

Trim stems and discolored parts of mushrooms. Soak mushrooms in cold water for 10 minutes to remove soil. Wash in clean water. Leave

small mushrooms whole; cut larger ones in halves or quarters. Cover with water in a saucepan and boil 5 minutes. Pack hot mushrooms

in clean, hot Mason jars, leaving 1-inch headspace. For better color, add 1⁄8 teaspoon of ascorbic acid per pint. Cover with boiling water,

leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Half pints and Pints 45 minutes.

OKRA

Wash and trim young, tender okra pods. Remove stem, without cutting into pods if okra is to be canned whole. If desired, slice okra into

1-inch pieces. Cover okra with boiling water and boil 2 minutes. Pack hot okra in clean, hot Mason jars, leaving 1-inch headspace. Cover

with boiling water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 25 minutes and Quarts 40 minutes.

PEAS—GREEN

Wash and shell young, tender freshly picked green peas. Rinse.

Raw Pack: Pack peas loosely in clean, hot Mason jars, leaving 1-inch headspace. Do not shake or press down.

Hot Pack: Cover peas with boiling water and bring to a boil. Boil 2 minutes. Pack hot peas loosely in clean, hot Mason jars,

leaving 1-inch headspace. Do not shake or press down.

Cover with boiling water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints and Quarts 40 minutes.

PEPPERS—HOT OR SWEET

(including bell, chile, jalapeño and pimiento)

Preparation of Chile peppers—Cut two or four slits in each pepper, and blister using one of the following methods:

Oven or broiler method: Place chile peppers in a 400° oven or broiler for 6 to 8 minutes until skins blister.

Range-top method: Cover hot burner, either gas or electric with heavy wire mesh. Place chilies on burner for several minutes until

skins blister.

Allow peppers to cool. Place in a pan and cover with a damp cloth. After several minutes, peel peppers. Remove stems and seeds.

Preparation of other peppers—Remove stems and seeds; blanch 3 minutes.

Hot Pack: Small peppers may be left whole. Large peppers may be quartered. Pack peppers loosely in clean, hot Mason jars,

leaving 1-inch headspace. Cover with boiling water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds of pressure – Pints 35 minutes.

13

Page 14

POTATOES—SWEET

Wash sweet potatoes. Boil or steam just until partially soft (15 to 20 minutes). Remove skins and cut into pieces. CAUTION: Do not

mash or puree potatoes. Pack hot sweet potatoes in clean, hot Mason jars, leaving 1-inch headspace. Cover with boiling water, leaving

1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 65 minutes and Quarts 90 minutes.

POTATOES—WHITE

Wash, scrape, and rinse new potatoes 1 to 2½ inches in diameter. If desired, cut into ½-inch cubes. Place in ascorbic acid solution

(1 teaspoon ascorbic acid to 1 gallon water) to prevent darkening. Drain. Cover potatoes with hot water; bring to a boil and boil whole

potatoes for 10 minutes, cubes for 2 minutes. Pack hot potatoes in clean, hot Mason jars, leaving 1-inch headspace. Cover with boiling

water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 35 minutes and Quarts 40 minutes.

PUMPKIN AND WINTER SQUASH

Wash and remove seeds. Cut into 1-inch slices and peel. Cut flesh into 1-inch cubes. Boil 2 minutes in water. CAUTION: Do not mash

or puree. Pack hot squash cubes loosely in clean, hot Mason jars, leaving 1-inch headspace. Cover with boiling water, leaving 1-inch

headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 55 and Quarts 90 minutes.

PRessuRe CanninG MeaT

Pressure canning is the only safe method for canning meat.

All meat should be handled carefully to avoid contamination from the time of slaughtering until the products are canned. Animals should

be correctly slaughtered, canned promptly or kept under refrigeration until processed. If you slaughter your own meat, contact your local

county agricultural agent for complete information on slaughtering, chilling, and aging the meat.

Keep meat as cool as possible during preparation for canning, handle rapidly and process meat as soon as it is packed. Most meats need

only be wiped with a damp cloth. Use lean meat for canning; remove most of the fat. Cut off gristle and remove large bones. Cut into

pieces convenient for canning.

To prepare broth, place bony pieces in saucepan and cover with cold water. Simmer until meat is tender. Discard fat. Add boiling broth

to jars packed with precooked meat and poultry.

Meat should not be browned with flour nor should flour be used in the broth to make gravy for pouring over the packed meat. Pack hot

meat loosely, leaving 1-inch headspace in Mason jars.

Meats may be processed with or without salt. If salt is desired, use only canning salt. Table salt contains a filler which may cause cloudiness

in bottom of jar. Use ½ teaspoon salt to each pint, 1 teaspoon to each quart. More or less salt may be added to suit individual taste.

Follow step-by-step directions beginning on page 6 for canning procedure. Process meats according to the following recipes.

When pressure canning at altitudes of 2,000 feet or below, process according to specific recipe. When canning at higher altitudes, process

according to the following charts.

Altitude Adjustment

The processing times given in the specific meat, poultry, fish, and soup recipes are for altitudes of 1,000 feet or less. When pressure canning above 1,000 feet, process at 15 pounds of pressure. Processing time is the same at all altitudes.

14

Page 15

CANNING RECIPES: MEAT

CUT-UP MEAT (strips, cubes, or chunks)

Bear, Beef, Pork, Lamb, Veal, and Venison

Remove excess fat. Soak strong-flavored wild meats for 1 hour in brine water containing 1 tablespoon of salt per quart of water. Rinse.

Remove large bones and cut into desired pieces.

Raw Pack: Fill jars with raw meat pieces, leaving 1-inch headspace. DO NOT ADD LIQUID. Adjust jar lids.

Hot Pack: Precook meat until rare by broiling, boiling or frying. Pack hot meat loosely in clean, hot Mason jars, leaving 1-inch

headspace. Cover meat with boiling broth, water, or tomato juice (especially with wild game) leaving 1-inch headspace.

Adjust jar lids.

Process at 10 pounds pressure – Pints 75 minutes and Quarts 90 minutes.

GROUND MEAT

Bear, Beef, Pork, Lamb, Veal, and Venison

With venison add one part high quality pork fat to three or four parts venison before grinding. Use freshly made sausage, seasoned with

salt and cayenne pepper (sage may cause a bitter off-flavor). Add 1 teaspoon salt to each pound of ground meat if desired. Mix well.

Shape meat into patties or balls or cut cased sausage into 3-to 4-inch links. Cook until lightly browned. Ground meat may be sautéed

without shaping. Remove excess fat. Fill jars with pieces, leaving 1-inch headspace. Cover meat with boiling broth or water, leaving

1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 75 minutes and Quarts 90 minutes.

PRessuRe CanninG PoulTRY

Pressure canning is the only safe method for canning poultry.

Cut poultry into convenient pieces for packing and precook until medium done or until pieces, when cut, show almost no pink color at

the bone.

Precook by boiling in water or in a concentrated broth for more flavor. Make broth from bones and bony pieces, neck, back, and wing

tips. Pack hot meat in clean, hot Mason jars, leaving 1-inch headspace. Do not pack food tightly.

Poultry may be processed with or without salt. If salt is desired, use only canning salt. Table salt contains a filler which may cause cloudiness in bottom of jar. Use ½ teaspoon salt to each pint, 1 teaspoon to each quart.

Follow step-by-step directions beginning on page 6 for canning procedure. Process poultry according to the following recipes.

CANNING RECIPES: POULTRY

CUT-UP POULTRY

Cut poultry into serving size pieces. If desired, remove bone. Boil, steam, or bake poultry slowly to medium done. Poultry is medium

done when pink color in center is almost gone. Pack hot poultry loosely in clean, hot Mason jars, leaving 1¼-inch headspace. Cover

poultry with boiling broth or water, leaving 1¼-inch headspace. Adjust jar lids.

Process at 10 pounds pressure With Bone Without Bone

Pints 65 minutes 75 minutes

Quarts 75 minutes 90 minutes

RABBIT

Soak dressed rabbits 1 hour in water containing 1 tablespoon of salt per quart. Rinse and remove excess fat. Cut into serving size pieces.

Boil, steam, or bake to medium done. Rabbit is medium done when pink color in center is almost gone. Pack hot rabbit loosely in clean,

hot Mason jars, leaving 1¼ inch headspace. Cover rabbit with boiling broth or water leaving 1¼ inch headspace. Adjust jar lids.

Process at 10 pounds pressure With Bone Without Bone

Pints 65 minutes 75 minutes

Quarts 75 minutes 90 minutes

15

Page 16

PRessuRe CanninG fisH and seafood

Pressure canning is the only safe method for canning fish and seafood.

Only fresh fish should be canned and these should be bled and thoroughly cleaned of all viscera and membranes when caught, or as soon as

possible. Canning should be restricted to proven varieties where it is definitely known that a product of good quality may be obtained.

Follow step-by-step directions beginning on page 6 for canning procedure. Process fish and seafood according to the following recipes.

CANNING RECIPES: FISH AND SEAFOOD

CLAMS—WHOLE OR MINCED

Keep clams on ice until ready to can. Scrub shells thoroughly and rinse. Steam 5 minutes and open. Remove clam meat. Collect and save

clam juice. Wash clam meat in salted water using 1 teaspoon of salt for each quart of water. Rinse. In a saucepan, cover clam meat with

boiling water containing 2 tablespoons of lemon juice or ½ teaspoon of citric acid per gallon. Boil 2 minutes and drain. To make minced

clams, grind clams with a meat grinder or food processor. Fill jars loosely with pieces leaving 1-inch headspace and add hot clam juice

and boiling water if needed, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Half pints 60 minutes and Pints 70 minutes.

CRAB

Keep live crabs on ice until ready to can. Wash crabs thoroughly. Place crabs in water containing ¼ cup lemon juice and 2 tablespoons

of salt per gallon. Simmer 20 minutes. Cool in cold water and drain. Remove back shell and then remove meat from body and claws.

Soak meat 2 minutes in cold water containing 2 cups lemon juice or 4 cups of white vinegar and 2 tablespoons of salt per gallon. Drain

and remove excess moisture. Pack loosely into clean, hot Mason jars, leaving 1-inch headspace. Add ½ teaspoon citric acid or 2 tablespoons lemon juice to each half-pint jar; 1 teaspoon citric acid or 4 tablespoons lemon juice per pint jar. Add hot water, leaving 1-inch

headspace. Adjust jar lids.

Process at 10 pounds pressure – Half pints 70 minutes and Pints 80 minutes.

FISH—GENERAL METHOD

For all fish except tuna. Clean fish thoroughly; filet large fish or leave small pan fish whole. Cut into container length pieces. Pack with

skin side of fish to the outside of the Mason jar, leaving 1-inch headspace. DO NOT ADD LIQUIDS. Adjust jar lids.

Process at 10 pounds pressure – Pints 100 minutes.

TUNA

Clean fish thoroughly. Place fish belly side down on a rack, in the bottom of a large baking pan. Precook fish at 350° for 1 hour. Refrigerate

cooked fish overnight to firm the meat. Remove skin and backbone. Cut meat in pieces 1 inch shorter than Mason jars and pack solidly.

Fill jars with hot cooking oil or boiling water, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Half pints and Pints 100 minutes.

PRessuRe CanninG souPs

Pressure canning is the only safe method for canning soups.

Soup or soup stock is quickly and easily canned. Soup should always be cooked ready for serving, then poured into clean, hot Mason

jars, leaving 1-inch headspace. Generally, vegetable soups are more satisfactory if the stock and vegetable mixture is canned separately

and combined at the time of serving.

Follow step-by-step directions beginning on page 6 for canning procedure. Process soups according to the following recipes.

CANNING RECIPES: SOUP

BEEF STOCK

Saw or crack fresh trimmed beef bones to enhance extraction of flavor. Rinse bones and place in a large kettle, cover bones with water and

simmer 3 to 4 hours. Remove bones. Cool broth; skim off and discard fat. Remove bits of meat from bones and add to broth, if desired.

Reheat broth to boiling. Fill jars, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 20 minutes and Quarts 25 minutes.

16

Page 17

CHICKEN STOCK

Place large carcass bones in stockpot, add enough water to cover bones. Cover and simmer 30 to 45 minutes or until meat can be easily

removed from bones. Remove bones. Cool broth; skim off and discard fat. Remove bits of meat from bones and add to broth, if desired.

Reheat broth to boiling. Fill jars, leaving 1-inch headspace. Adjust jar lids.

Process at 10 pounds pressure – Pints 20 minutes and Quarts 25 minutes.

HelPful HinTs foR PRessuRe CanninG

Bubbles often appear in the jar after it is removed from canner because food is still boiling in jar. Ordinarily bubbles do not appear

once the product has been allowed to thoroughly cool.

Jar breakage during processing is caused by: (1) Packing jar too solidly or overfilling; (2) Weakened, cracked jars; (3) Jars touching

bottom of canner; (4) Lids improperly tightened; (5) Use of jars other than Mason jars.

Liquid lost from jars during processing is caused by: (1) Packing jar too solidly or overfilling; (2) Too high a temperature or too high

pressure; (3) Variation or sudden lowering of temperature in the canner. When processing food, pressure regulator should not be taken

off the vent pipe and cover should not be removed until air vent/cover lock has dropped and pressure has been completely reduced;

(4) Failure to adjust jar lids according to manufacturer’s directions.

The loss of liquid from jars during processing may be unattractive but it will not interfere with the keeping qualities of the food as

long as the jar was processed correctly and is sealed.

It is better to overprocess food than underprocess as overprocessing will do little harm, but underprocessing may result in spoilage

and unsafe food.

Flat sour, a type of food spoilage, is caused by canning overripe food or allowing precooked foods to stand in jar too long before

processing. It may be prevented by using fresh products and properly processing, cooling, and storing. Flat sour shows no indication

of spoilage until jar is opened.

Food spoilage or jars not sealing is caused by: (1) Failure to follow exact timetables and recipes; (2) Failure to wipe sealing edge of

jar clean before placing lid on jar; (3) Foods, seeds, or grease lodged between lid and jar; (4) Jars which are nicked or cracked or have

sharp sealing edges; (5) Failure to adjust jar lids according to manufacturer’s directions; (6) Turning jars upside down while jars are

cooling and sealing.

Mold can form only in the presence of air. Therefore, jars are not sealed if mold is present.

The black deposit sometimes found on the underside of a lid is caused by tannins in the food or hydrogen sulfide which is liberated

from the food by the heat of processing. This does not indicate spoilage.

If a jar does not seal, use the food at once, freeze or repack using different lids. Reprocess for the full recommended processing

time.

Two-piece vacuum caps seal by the cooling of the contents of the jar, not through pressure of the screw band on the lid. Therefore,

although the screw band is firmly tight, the jar is not sealed until cooled. During processing, the flexible metal lid permits air to be

exhausted from the jar.

Adjust two-piece vacuum caps by screwing bands down evenly and firmly until a point of resistance is met–fingertip tight. Do not

use undue exertion.

It is not necessary for the liquid on canned meats to congeal. The liquid will congeal only when there is a large amount of gelatin

from cartilage or connective tissue present.

The loss of color from beets, during canning, is usually due to the variety of beets used or beets that are too old. If possible, can

young, tender, very dark beets which are freshly gathered. Precook beets with 2 inches of the stem and all of the root on, as this helps

to retain the juices.

Discoloration of peaches and pears on the top of the jar is often due to enzyme activity which means that the processing time was not

long enough or the temperature not high enough to render enzymes inactive

Fruit which has been canned without sugar will often turn brown when exposed to air just as fresh fruit does.

The diameter of Mason jars may vary from one manufacturer to another. Before filling Mason jars, test load your canner. It may be

necessary to double-deck pint and ½ pint jars to reach the maximum capacity of your canner as shown in the chart on page 6. It is

recommended that you stagger the jars by placing one jar on top of two. Jars may touch. The canning rack which accompanied your

Pressure Canner/Cooker must be placed on the bottom of the canner to prevent jar breakage. Although it is not necessary to use a

rack between layers of jars, if you wish to do so, a rack can be ordered from the Presto Consumer Service Department. See page 35

for address.

17

Page 18

How To Can foods usinG boilinG waTeR MeTHod

Note: Your 16-quart canner can be used as a boiling water canner for ½ pint and pint jars only. It is not tall enough to allow

adequate space for quart jars.

1. Place cooking/canning rack on bottom of canner. Fill canner halfway with water.

2. Preheat water to 140°F for raw-packed foods and to 180°F for hot-packed foods.

3. Remove overpressure plug and pressure regulator from canner cover and set aside.

4. Use jar lifter to place filled jars, with lids and rings fastened according to manufacturer’s directions, on cooking/canning rack in

canner.

5. Check water level. Add more boiling water, if needed, so the water level is at least 1 inch above jar tops.

6. Turn heat to its highest setting until water boils vigorously.

7. Look through the vent pipe on the canner cover to be certain it is open before placing cover on canner. To clean the vent pipe, draw

a pipe cleaner or small brush through the opening.

8. Place cover on canner, aligning the V mark on the cover with the

direction indicated to close the cover (clockwise). Cover handles must be centered over body handles. Do not force beyond this

position.

9. Set a timer for the minutes required for processing the food based on tested canning recipe.

10. Lower the heat setting to maintain a gentle boil throughout processing.

11. Add more boiling water, if needed, to keep the water level above the jars.

12. When jars have been processed for the recommended time, turn off the heat and remove the canner cover.

13. Using jar lifter, remove jars and place them on a towel, leaving at least 1-inch spaces between jars during cooling.

14. Allow jars to cool naturally 12 to 24 hours before checking for a seal. Do not retighten bands.

V

mark on the body handle and lock securely by turning in the

CANNING RECIPES: BOILING WATER METHOD

The following recipes are safely canned by the boiling water method. Do not pressure can these recipes because the food quality

would be unacceptable.

APPLE BUTTER

16 medium apples (about 4 pounds) 2 teaspoons cinnamon

4 cups sugar ¼ teaspoon cloves

To prepare pulp: Wash apples; remove stem and blossom ends; do not peel or core. Cut apples into small pieces. Add 2 cups water;

cover; simmer 20 to 25 minutes or until apples are soft. Press through a sieve or food mill. Measure 2 quarts apple pulp.

To prepare butter: Combine apple pulp, sugar, and spices in a large saucepot. Cook slowly until thick enough to round up on a spoon.

As pulp thickens, stir frequently to prevent sticking. (If too thick, add a small amount of water or apple juice for desired consistency.)

Ladle hot butter into hot jars, leaving ¼-inch headspace. Adjust two-piece caps. Process 10 minutes using boiling water canning method

described above. Yield: about 5 pints.

RASPBERRY JAM

2 quarts raspberries 1 tablespoon lemon juice

1 package powdered pectin 1 tablespoon grated lemon peel

Combine raspberries, pectin, water, lemon juice, and lemon peel in a large saucepot. Bring to a boil over high heat, stirring frequently.

Add sugar, stirring until dissolved. Return to a rolling boil. Boil hard 1 minute, stirring constantly. Remove from heat. Skim foam, if

necessary. Ladle hot jam into hot jars, leaving ¼-inch headspace. Adjust two-piece caps. Process 10 minutes using boiling water canning

method described above. Yield: about 5 half-pints.

1

⁄3 cup water 6 cups sugar

18

Page 19

BREAD AND BUTTER PICKLES

4 pounds 4- to 6-inch cucumbers, 2 tablespoons mustard seed

cut into slices 2 teaspoons turmeric

2 pounds onions, thinly sliced 2 teaspoons celery seed

(about 8 small) 1 teaspoon ginger

2 cups sugar 3 cups vinegar, 5% acidity

1

⁄3 cup canning salt 1 teaspoon peppercorns

Combine cucumber and onion slices in a large bowl. Layer vegetables with salt; cover with ice cubes. Let stand 1½ hours. Drain; rinse.

Combine remaining ingredients in a large saucepot; bring to a boil. Add drained cucumbers and onions and return to a boil. Pack hot

pickles and liquid into hot jars, leaving ¼-inch headspace. Remove air bubbles. Adjust two-piece caps. Process 10 minutes using boiling

water canning method described on page 18. Yield: about 7 pints.

Note: For fresh pack pickled foods, allow 4 to 6 weeks for the product to cure and develop a satisfactory flavor.

DILL PICKLES

8 pounds 4- to 6-inch cucumbers, 1 quart vinegar, 5% acidity

cut lengthwise into halves 1 quart water

¾ cup sugar 3 tablespoons mixed pickling spices

½ cup canning salt Green or dry dill (1 head per jar)

Wash and drain cucumbers. Combine sugar, salt, vinegar, and water in a large saucepot. Tie spices in a spice bag; add spice bag to vinegar mixture; simmer 15 minutes. Pack cucumbers into hot jars, leaving ¼-inch headspace; put one head of dill in each jar. Ladle hot

liquid over cucumbers, leaving 1⁄4-inch headspace. Remove air bubbles. Adjust two-piece caps. Process pints 15 minutes using boiling

water canning method described on page 18. Yield: about 7 pints.

Note: For fresh pack pickled foods, allow 4 to 6 weeks for the product to cure and develop a satisfactory flavor.

ZESTY SALSA

10 cups chopped, seeded, 2½ cups chopped and seeded hot

peeled, cored tomatoes peppers (about 1 pound)

(about 6 pounds) 1¼ cups cider vinegar

5 cups chopped and seeded long 3 cloves garlic, minced

green peppers (about 2 pounds) 2 tablespoons cilantro, minced

5 cups chopped onions (about 1 tablespoon salt

1½ pounds) 1 teaspoon hot pepper sauce (optional)

Combine all ingredients in a large saucepot, adding hot pepper sauce, if desired. Bring mixture to a boil. Reduce heat and simmer 10

minutes. Ladle hot salsa into hot jars, leaving ¼-inch headspace. Adjust two-piece caps. Process 15 minutes using boiling water canning method described on page 18. Yield: about 6 pints.

Note: When cutting or seeding hot peppers, wear rubber gloves to prevent hands from being burned.

For boiling water canning information for fruits and tomatoes, refer to page 8.

For additional information and recipes, consult the Ball Blue Book or visit www.homecanning.com.

Recipes provided by Alltrista Consumer Products Company, marketers of Ball and Kerr home canning products.

PRessuRe CooKinG in YouR PRessuRe CanneR

Follow the step-by-step instructions (see “How To Pressure Cook Foods” on page 20) for cooking in your pressure canner. Prepare food

according to directions in specific recipe.

The canner should never be filled over 2⁄3 full. Many foods tend to expand when cooked. If the canner is filled over 2⁄3 full, it is possible

for food to expand enough to plug the vent pipe, air vent/cover lock, and overpressure plug. If all of these devices were to become blocked,

excess pressure would be unable to escape and would build up beyond safe control levels. Therefore, when cooking any food, do not let

any portion extend above the 2⁄3 full level.

Rice and dry beans and peas expand during cooking. When preparing these foods, do not fill the canner over ½ full. Always pre-soak

dry beans and peas overnight in oil, salt, and water (see recipes on pages 27-28). Never pressure cook applesauce, cranberries,

rhubarb, pearl barley, split peas, oatmeal or other cereals, dried soup mixes, or pasta. These foods tend to foam, froth, and sputter

and may block the vent pipe.

If the vent pipe becomes clogged, the pressure regulator will not rock and pressure cannot be released normally. When excess pressure

builds up in the canner, the overpressure plug will be forced out of its cover opening, releasing the excess pressure. If the overpressure

19

Page 20

plug is ever forced out of its cover opening due to excess pressure while cooking or canning, it is important to call the Test Kitchen at

1-800-368-2194. Do not attempt to use the released overpressure plug.

The canning-cooking rack can be used to hold foods above the liquid level. This will allow cooking several different foods

at the same time without an intermingling of flavors. When a natural blending of flavors is desired, do not use the canning-cooking rack. When cooking two or more foods at the same time, choose those which require the same length of

cooking time. The length of cooking time for a specific food varies greatly with the thickness of the food. For example,

a ½-inch thick slice of potato will be done in 3 minutes whereas a ¾-inch thick slice of potato will be done in 5 minutes. For foods which

do not require the same cooking time, the canner may be quick cooled when there is just enough cooking time left for the food requiring

the shorter cooking time. When the pressure is completely reduced, the cover may be opened and the food added. Then, again place the

cover on the canner and proceed with cooking.

Questions?

For answers to any questions regarding recipes or timetables, call or write: Test Kitchen, National Presto Industries, Inc., 3925

North Hastings Way, Eau Claire, Wisconsin 54703-3703, phone 1-800-368-2194. You may also contact us at our website

www.gopresto.com. When writing, please include a phone number and a time when you can be reached during weekdays if possible.

Inquiries will be answered promptly by letter, telephone, or email.

How To PRessuRe CooK foods

To assure the very best results every time, carefully follow these step-by-step instructions for pressure cooking. You may find it helpful

to refer back to the diagrams on page 3.

1. Prepare ingredients according to the directions in the pressure cooking recipe you have selected. Pour liquid into the canner body, as

specified in the recipe or timetable. This liquid is usually water. However, some recipes will call for other liquids, such as wine.

2. Place the cooking rack into the canner, if called for in the recipe (see Helpful Hints on page 22 for

guidance on when to use).

3. IMPORTANT: Look through the vent pipe to make certain that it is clear before closing the cover.

See safety information on page 21.

4. Place cover on canner, aligning the V mark on the cover with the

lock securely by turning in the direction indicated to close (clockwise). Cover handles must be

centered directly over body handles. Do not force beyond this position. If the cover is difficult to

lock at this point, it is due to expansion of the canner from heating. If this occurs, remove

cover and allow the canner to cool slightly. Do not replace canner on burner until cover is

in its fully closed position (cover handles directly above body handles).

5. Place the complete three-piece pressure regulator on vent pipe. Heat canner until the pressure

regulator begins to rock. A relatively high heat setting is necessary for most range burners.

Cooking time begins when the pressure regulator begins to rock gently. Gradually lower

the heat as necessary to maintain a slow, steady rocking motion. If the pressure regulator

is allowed to rock vigorously, excess steam will escape. Therefore, too much liquid will

evaporate and food may scorch. Never leave your pressure canner unattended at high heat

settings. It could boil dry and overheat excessively causing possible warping.

6. Cook for the length of time specified in recipe. When cooking time is completed, turn off gas burner or remove canner from electric

burner. Lift pressure canner to remove it from burner. Sliding cookware can leave scratches on stovetop. Reduce pressure

according to recipe.

7A. When recipe states “let pressure drop of its own accord”, set the canner aside to cool. Pressure is completely reduced when the air

vent/cover lock and overpressure plug have dropped and no steam escapes when the pressure regulator is tilted.