Page 1

P4

Level Loader

Model Number ___________________

Serial # _________________________

Date Placed in Service _____________

IMPORT ANT : READ CAREFULLY

BEFORE INST ALLING OR OPERA TING LIFT

Part orders are subject to a $50 miminum charge

May 2006

Page 2

INTRODUCTION

The P4 Level Loader is designed to allow faster, safer, and easier pallet loading and

unloading. Pallets may be loaded or unloaded in a single step, using a fork truck, or

hand pallet truck. Using a pushbutton or footswitch control, the operator can position

boxes or containers at a convenient working height. This allows workers to load or

unload without bending or stretching.

The unit includes a photo eye toe guard feature. A photo eye is positioned near the

front of the unit. If the operator’s toes block this photo eye, the unit stops immediately .

This manual contains instructions on the safe and proper installation, use, and

maintenance of a P4 Level Loader. Please be sure that this manual is available to

anyone who uses or services the P4 unit. Be sure that everyone who uses the P4 unit

has read this manual.

P4 Level Loaders may be used in a wide variety of industrial settings. The

instructions included in this manual are not necessarily all-inclusive, because

Presto Lifts cannot anticipate all conceivable or unique situations.

In the interest of safety, please read this whole manual carefully. Please

understand the material in the manual before you install, use, or service the P4

unit. If you have any questions about the instructions in this manual, please

contact your dealer or Presto Lifts Inc.

Presto Lift’s product warranty is shown on the rear cover of this manual. This instruction

manual is not intended to be or to create any other warranty , express or implied,

including any implied warranty of merchantability or fitness for a particular

purpose, all of which are hereby expressly excluded. As set forth more specifically

in the product warranty, Presto Lift’s obligation under that warranty is limited to the

repair or replacement of defective components, which shall be the buyer’s sole remedy ,

and Presto Lift shall not be liable for any loss, injury , or damage to persons or property ,

nor for any direct, indirect, or consequential damage of any kind resulting from the P4

Level Loader.

2 PRESTO P4 LEVEL LOADER OWNER’S MANUAL

Page 3

TABLE OF CONTENTS

INTRODUCTION...............................................................................................................2

SAFETY ........................................................................................................................4

INST ALLA TION INSTRUCTIONS ......................................................................................4

Preparation...................................................................................................... 4

Positioning the Unit .........................................................................................4

Electrical Connections .................................................................................... 5

Testing.............................................................................................................6

OPERATING INSTRUCTIONS ........................................................................................7

Safety Instructions .......................................................................................... 7

Loading the Unit .............................................................................................. 8

Raising the Platform ........................................................................................ 8

Lowering the Platform..................................................................................... 9

MAINTENANCE AND TROUBLESHOOTING ...............................................................10

Hazards .........................................................................................................10

Routine Periodic Maintenance......................................................................11

Troubleshooting Check List .......................................................................... 12

Repacking the Cylinder ................................................................................. 15

Adjusting the Chain Tension ......................................................................... 15

Ordering Replacement Parts ........................................................................16

LIST OF FIGURES

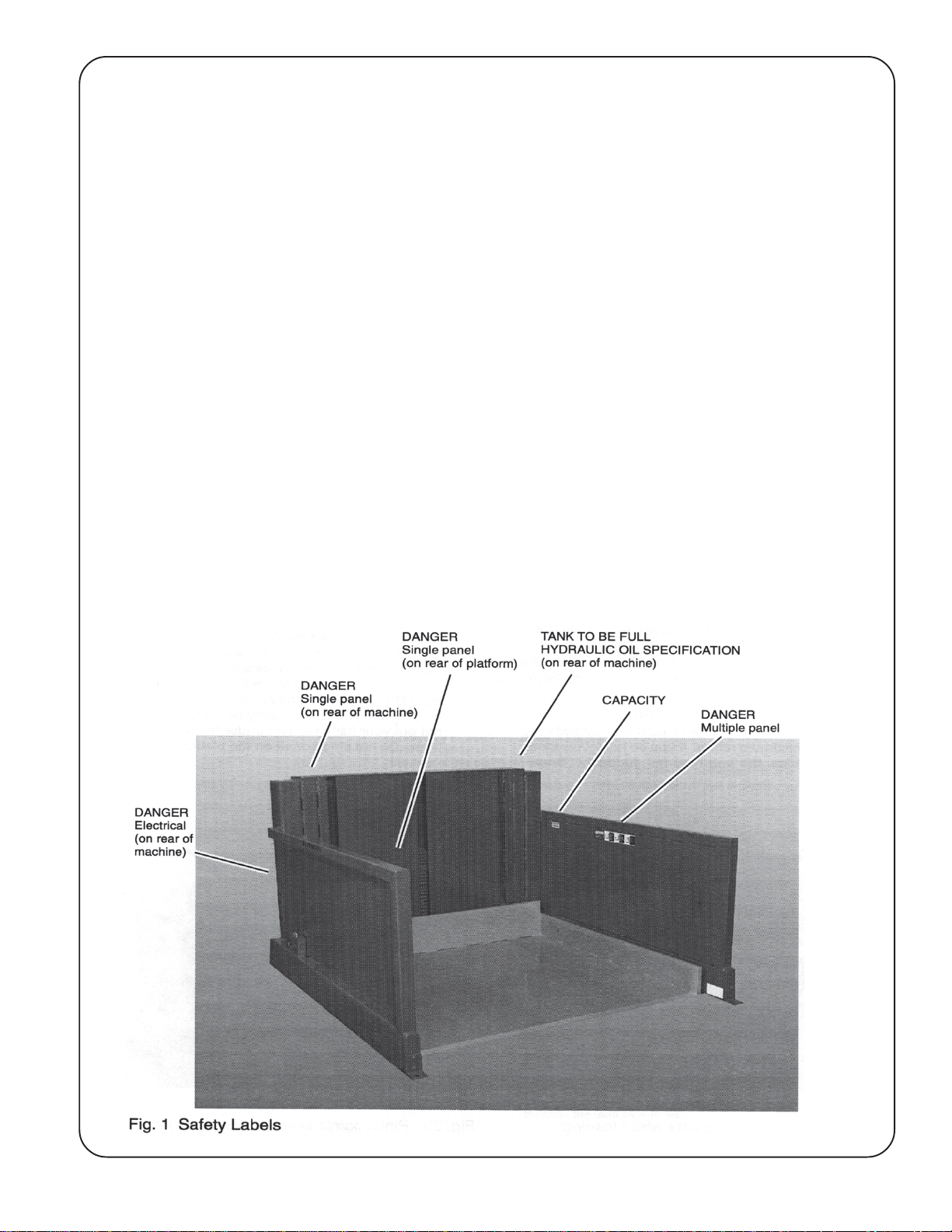

Fig. 1 Safety labels ....................................................................................................5

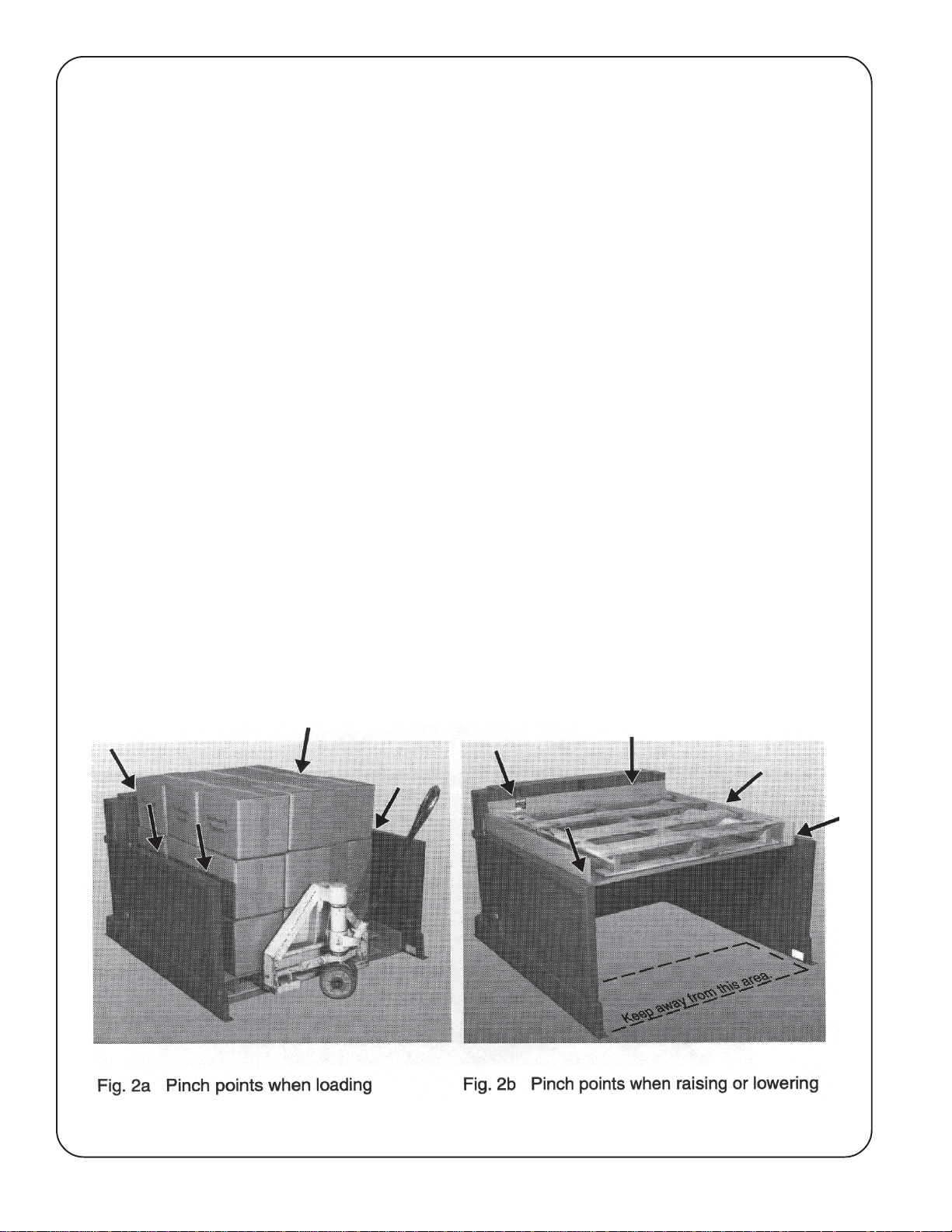

Fig. 2 Pinch points.....................................................................................................6

Fig. 3 Load the unit correctly..................................................................................... 7

Fig. 4. Electrical diagram ...........................................................................................8

Fig. 5. Hydraulic diagram ........................................................................................... 9

Fig. 6. Parts identification — Front view.................................................................... 12

Fig. 7. Parts identification — Rear view..................................................................... 13

Fig. 8. Hydraulic pump .............................................................................................13

Fig. 9. Down valve ....................................................................................................14

Fig. 10 Hydraulic oil specifications ........................................................................... 16

PRESTO P4 LEVEL LOADER OWNER’S MANUAL 3

Page 4

SAFETY

The safety of all persons installing, using, servicing, or working near the P4 Level Loader unit is of

paramount concern to Presto. The P4 Level Loader unit is a powerful machine with moving parts,

and is CAPABLE OF CAUSING PERSONAL INJURY IF PROPER PRECAUTIONS ARE NOT

T AKEN.

Therefore, throughout this manual, Presto has identified certain hazards which may occur in the

use of the P4 Level Loader unit, and provided appropriate INSTRUCTIONS or PRECAUTIONS

which should be taken to avoid these hazards. In some cases, Presto has also pointed out the

CONSEQUENCES which may occur if Presto’s instructions or precautions are not followed. Presto

uses the following system of identifying the severity of the hazards associated with its products:

PLEASE READ AND FOLLOW THIS INSTRUCTION MANUAL, INCLUDING ALL SAFETY

INSTRUCTIONS AND PRECAUTIONS, CAREFULLY AND COMPLETELY.

DANGER: Immediate hazard which will result in severe personal injury or death.

WARNING: Hazard or unsafe practice which could result in severe personal injury or death.

CAUTION: Hazard or unsafe practice which could result in minor personal injury or

property damage.

INSTALLATION INSTRUCTIONS

Preparation

1. Before you start to install the unit, check for

local codes and ordinances which may

apply. It is your responsibility to obtain any

necessary permits.

2. Read all of these installation instructions

carefully. Be sure to read and understand

all of the warnings.

3. The unit should be placed indoors, or

protected from the weather.

WARNING!

Protect the unit from rain or

moisture. If the electrical parts in the

power unit get wet, workers may be

hurt by electrical shock. The

electrical parts may fail if they are

wet.

WARNING!

The electric motor can create

sparks. Don’t install the unit in an

area where flammable gases may be

present.

4. You will need these tools to install the unit:

• A crane or lift truck that can lift the unit safely .

If you plan to lag the unit in place, you will

need these tools:

• Shims and lag bolts.

• A masonry drill and bit to drill the holes for the

lag bolts.

• Wrenches to fit the lag bolts

• Grouting material to fill any spaces under the

frame of the machine.

Positioning the Unit

1. Remove the shipping material. Unbolt the

lag screws at the lag angles on the corners.

(If you plan to bolt the unit in place, leave the

lag angles attached to the frame of the unit.

Otherwise, unbolt and remove the lag

angles.)

2. On the front of this manual, write down the

model number , serial number , and date the

unit is placed in service. You can find the

model number and serial number on the

name plate.

4 PRESTO P4 LEVEL LOADER OWNER’S MANUAL

Page 5

3. During shipping, the platform of the unit is

raised 5-1/2", and this platform is supported

on two pins. This allows a space under the

platform. When you want to move the unit,

put a pallet jack under the platform and lift

the unit. This is the best way of moving the

unit.

CAUTION!

If you place the unit on a surface

which is not firm or level, the

unit may shift as it operates. Y ou

may be hurt, or the unit or load

may be damaged.

CAUTION!

Always raise the platform and insert

the pins before you move the unit. If

you try to move the unit in another

way , the frame may be bent. Be sure

to remove the pins before you

operate the unit. If you do not do

this, the unit may be damaged. Once

the unit has power, raise the plat form

just a bit to take the load off of the

pins, then remove the pins.

4. The unit has an 10' power cord. Choose a

location where the cord can reach an outlet

easily , without stretching the cord tightly.

5. Move the unit into position, supporting the

platform of the unit. Place the unit on a firm,

level surface.

6. The unit may be operated without bolting

the frame to the floor. However, the

mounting arrangement is more secure if

you use lag screws. Bolt the unit to the

floor using four lag bolts. These should run

through the lag angles at the corners of

the base frame. Insert and tighten the lag

bolts to secure the unit. Grout under the

base rails to prevent vibration and distortion

of the base frame.

Electrical Connections

DANGER!

The unit uses a power supply of 115

volts AC. This voltage can kill you.

Don’t work with the electrical parts

unless you are a qualified electrician.

PRESTO P4 LEVEL LOADER OWNER’S MANUAL 5

Page 6

1. The unit is supplied with a power cord which

is 10' long. You must provide a two-prong

outlet within this distance from the unit. The

circuit should be provided with a 20 amp

circuit breaker or fuse.

WARNING!

To avoid fire danger, be sure to

provide a circuit breaker or fuse.

2. The standard unit has a foot switch

assembly. Position the control box in a

convenient location near the unit.

3. Check the level of the hydraulic fluid in the

tank. In order to check the level, lower the

unit completely and unplug the power cord.

Remove the rear cover on the unit. When

the unit is fully lowered, the oil should be 1/

2" to 3/4” (13 to 19 mm) below the top of the

tank. Add oil as necessary.

2. Warn others to stay away from the unit.

Operate the unit through its full range of

travel. The unit should rise smoothly with a

quiet humming sound, and lower smoothly

and quietly. Raise and lower the unit a few

times to check the lifting action.

WARNING!

As the platform moves up and clown,

“pinch points” are created at the

places shown in Fig. 2. If you are

standing too close to the unit when

it is moving, your arm or leg may be

caught in the moving parts, and you

may be hurt. Stay away from the pinch

points when the unit is moving.

3. Test the unit with the rated load. If the unit

does not rise, and you hear a loud squealing

noise, the pressure relief valve is operating.

Contact Presto Lifts for instructions.

Testing

1. Clear the area around the unit. Remove any

loose wires, lumber, or other materials

which might get in the way of the unit as it

raises or lowers.

WARNING!

Don’t continue to use the unit if this

happens - the pump will overheat

very quickly , and may be permanently

damaged. Do not try to adjust the

relief valve. If you change the setting

6 PRESTO P4 LEVEL LOADER OWNER’S MANUAL

Page 7

on the relief valve, you may overwork

the unit. This can cause the unit to

fail suddenly, and you may be hurt.

WARNING!

As you operate this lift, follow these

rules:

4. Clean up any spilled hydraulic fluid. Spilled

hydraulic oil is slippery, and may present a

fire hazard. If you clean up any spilled fluid,

you will be able to tell right away if the unit

begins to leak.

5. Figure 1 shows the safety labels on this

unit. Check to be sure all of the labels are in

place.

OPERATING INSTRUCTIONS

Safety Instructions

DANGER!

The unit uses a power supply of 115

Volts AC. This voltage can kill you.

DON’T WORK WITH THE

ELECTRICAL PARTS UNLESS YOU

ARE A QUALIFIED ELECTRICIAN!

• Do not put your hands or feet under

the lift platform.

• Do not work under the lift platform

without installing the safety pins.

(See Fig. 6 and the section on

“Maintenance.”)

• Do not stand, sit, or ride on the lift.

WARNING!

This unit includes a photo eye toe

guard. See Fig. 6. If something blocks

the light beam, the unit will stop

quickly. The control system will stop

the motor and close the down valve,

preventing the platform of the unit

from moving down. This is designed

to prevent the unit from lowering

PRESTO P4 LEVEL LOADER OWNER’S MANUAL 7

Page 8

onto the operator’s toes. If this safety

system is not working correctly, do

not operate the unit. Call a

maintenance worker right away .

Loading the Unit

1. Before operating the unit, please read and

understand all of this section.

2. Be sure that the load weighs no more than

the maximum rated for the unit. The

maximum rated load is listed on the data

plate. Remember that an empty pallet may

weigh 40 Ibs (18 kg) or more.

3. The load should always be balanced in the

side-to-side direction. Whenever possible,

place the load in the center of the pallet, as

shown in Fig. 3. If the load is off-center on

the pallet, place the heaviest part of the load

near the back of the platform - never near

the front!

suddenly. Someone may be hurt, or

the unit and load may be damaged.

• The unit is designed so it can lift

the rated load if

the load center is

placed over the center of the

platform. (The load center should be

24" or 61 cm from the rear of the

platform.) If the load is placed

“offcenter,” near the front of the

platform, the unit will not be able to

lift the rated load safely. It is also

important

that the load be centered

side-to-side. For these reasons, it is

very important to be sure the load is

centered in the platform area.

4. Sometimes the unit may be used to lift parts

which can roll. St ack the part s on the p allet

so they cannot roll. Be sure that all parts of

the load are secure, and will not move as

the unit is operated.

WARNING!

• Don’t try to lift a load that exceeds

the maximum rating. If you do not

follow these rules, the unit may fail

Raising the Platform

1. Before raising the platform, be sure all

workers are clear of the unit.

Fig. 4 Electrical diagram

8 PRESTO P4 LEVEL LOADER OWNER’S MANUAL

Page 9

WARNING!

As the platform moves up and down,

“pinch points” are created as shown

in Fig. 2. STAY AWAY FROM THESE

PINCH POINTS! Part of your body or

clothing may become caught, and

you may be hurt. Do not put your

hands or feet under the platform. Do

not stand or sit on the platform.

2. Before lifting, be sure the pallet is pushed

up against the back of the unit. Be sure the

fork lift or pallet truck is clear of the unit

before you begin lifting.

3. Plug in the electrical cord. Be sure the cord

cannot become caught in the moving parts

as the platform rises.

4. Operate the unit. Press and hold the Up

button to raise the platform, and Down to

lower it. If the unit does not operate right

away, unplug the power cord and call a

qualified maintenance worker .

WARNING!

If you hear a squealing noise from the

pump, the pressure relief valve is

operating. DON’T CONTINUE TO

USE THE UNIT! The pump will

overheat very quickly, and may be

permanently damaged. The relief

valve is included to protect the

machine operators - DO NOT

CHANGE THE SETTING ON THE

RELIEF V ALVE. If you do change the

setting, this may cause a hydraulic

part to fail. The platform may drop

suddenly . Someone may be hurt, and

the unit and load may be damaged.

The hydraulic parts in the unit are

designed to handle a certain amount

of pressure. The relief valve has

been included for the protection of

all of the workers who use the unit.

Lowering the Platform

1. Press the Down button to lower the platform.

PRESTO P4 LEVEL LOADER OWNER’S MANUAL 9

Page 10

2. Before lowering the platform, be sure all

workers are clear of the unit.

WARNING!

As the platform moves up and down,

“pinch points” are created as shown

in Fig. 2. STAY AWAY FROM THESE

PINCH POINTS! Part of your body or

clothing may become caught, and

you may be hurt.

3. There is a photoelectric toe guard near the

front of this unit. If anything blocks the

photoelectric beam, the unit will stop. This

is designed to prevent an operator from

lowering the platform onto his or her feet.

WARNING!

Stand back from the unit when

raising or lowering the platform.

Keep your feet away from the

platform when the unit is operating.

MAINTENANCE AND

TROUBLESHOOTING

All servicing should be done by qualified

personnel. Qualified personnel should be able

to read and understand wiring and hydraulic

diagrams. They should be able to troubleshoot

live electrical circuits safely and in accordance

with accepted practice. FOR SAFETY’S SAKE,

if in doubt, please contact your distributor or

Presto Lift’s Customer Service Department at

(800) 343-9322. Before servicing the unit,

please read and understand all of this section

and the section entitled “Operating Instructions.”

WARNINGS!

• As the unit moves up and down,

“pinch points” are formed as shown

in Fig. 2. KEEP HANDS, FEET AND

LOOSE CLOTHING AWAY FROM

THESE PINCH POINTS. If your hand

or arm or a part of your clothing is

caught, you may be hurt.

• Before performing any

maintenance on the unit, lower the

platform completely . Failure to do so

could result in severe personal

injury.

• You should not have to do any

maintenance work with the platform

raised. All normal maintenance can

be done with the platform lowered.

However, if you ever need to work

under the platform, you must be

careful to do this safely. Raise the

platform until you can insert the

safety pins on each side. The pins

are shown in Fig. 6. Finally, unplug

the power cord. DO NOT WORK

UNDER THE PLATFORM UNTIL YOU

HA VE INSERTED THE PINS. If you fail

to do this, the platform may drop

suddenly . You may be hurt.

• The relief valve has been included

for the protection of all of the

workers who use the unit. DON’T

CHANGE THE RELIEF SETTING! If

the relief valve does not open when

it should, the unit may fail. Someone

may be hurt, and the unit and load

may be damaged.

Hazards

There are several hazards you should be aware

of as you service the unit:

DANGER!

The unit uses a power supply of 115

Volts AC. This voltage can kill you.

DON’T WORK ON THE ELECTRICAL

PARTS UNLESS YOU ARE A

QUALIFIED ELECTRICIAN!

10 PRESTO P4 LEVEL LOADER OWNER’S MANUAL

• If the hydraulic fluid is released

under high pressure, it can cause

personal injury . Before you open any

part of the hydraulic system, BE

SURE TO RELEASE THE

HYDRAULIC PRESSURE. Y ou can do

this by lowering the platform all the

way down.

• The warning labels have been

included for the safety of the

Page 11

operator. If the labels are worn or

missing, or have been painted over,

REPLACE THEM before releasing

the lift for operation. Fig. 1 shows

the safety markings on this unit.

Routine Periodic Maintenance

Every month:

• Remove the plate on the rear of the unit and

check the mechanical parts. Inspect the leaftype chain which lifts the platform. Check for

signs of wear. If the machine is operated in a

very dusty environment, you may have to wipe

off the dust.

Sometimes the fittings can be worked loose by

the vibrations from the power unit.

WARNING!

If a hydraulic fitting becomes loose,

or if a hydraulic hose breaks, the

hydraulic fluid may escape from the

system under pressure. If the

platform is raised when this happens,

it can drop quickly. Someone may be

hurt, or the unit or load may be

damaged. To avoid this problem,

inspect all of the hydraulic hoses and

fittings regularly, and replace them

if they are worn or damaged.

• Check the bolts which anchor the ends of

the chain. The chain should be tight, and each

bolt should be locked in place.

• Check the level and appearance of the

hydraulic fluid. In order to check the level, lower

the unit completely and unplug the power cord.

Remove the rear cover on the unit. Remove the

red plastic vent plug on top of the hydraulic tank,

and use a dipstick to check the oil level. When

the platform is fully lowered, the oil should be

about 1/2’’ to 3/4’’ inch below the top of the tank.

Add oil if necessary. Change the oil if it has

darkened, or feels gritty or sticky .

CAUTION!

It is important to use hydraulic fluid

with the correct grade and

properties. See the hydraulic oil

specification in Fig. 10 of this manual.

Every six months or 500 hours of operation,

whichever comes first:

• Lubricate the lifting chain lightly with spray

lube or SAE 30 mineral oil.

• Lubricate the bushing inside the sheave or

pulley which supports the upper part of the

chain.

• Apply a light coat of grease to the vertical

guides for the rollers on the rear of the unit.

• The clear plastic vent line and the cylinder

rod should be free of hydraulic fluid. If you find

much fluid in either place, the cylinder seals

may be leaking. (It is also possible the tank

may be over-filled.) If the worn parts must be

replaced, see the section on “Repacking the

Cylinder.”

• Lower the platform and disassemble the

down valve as shown in Fig. 8. Blow the valve

plunger clean with compressed air.

Reassemble the valve and reinstall it.

• Drain and discard the hydraulic fluid. The

suction filter is in the tank, at the point where

the suction line runs out to the pump. Unscrew

the hydraulic line, then remove the filter. Blow

the filter clean with compressed air. Reinstall

the filter in the tank and reassemble the

hydraulic line.

• Refill the tank with new hydraulic fluid.

CAUTION!

If you continue to use fluid after it

has “worn out,” the moving parts in

the system will wear more quickly .

• Be sure all of the warning labels are in position

and legible. See Fig. 1. THE WARNING

LABELS ARE INTENDED TO PROTECT

YOUR WORKERS. If the labels are missing,

or if they have been painted over , replace them.

• Check all of the hydraulic fittings and hoses,

and tighten the connections if necessary.

PRESTO P4 LEVEL LOADER OWNER’S MANUAL 11

Page 12

Troubleshooting Check List

All servicing should be done by qualified

personnel. Qualified personnel should be able

to read and understand wiring and hydraulic

diagrams. They should be able to troubleshoot

live electrical circuits safely and in accordance

with accepted practice. FOR SAFETY’S SAKE,

if in doubt, please contact your distributor or

Presto Lifts at (800) 343-9322.

Before servicing the unit, read and understand

this entire section and the section entitled

“Operating Instructions.”

WARNING!

Before performing any maintenance

on this unit, lower the platform

completely.

If the platform will not raise:

CAUTION!

If the platform will not raise, do not

continue to hold the Up button for

more than 2 or 3 seconds. You may

damage the pump.

1. The sensor and reflector are mounted at

the front of the unit, near the floor level. There

may be something blocking the beam of the

photo eye toe guard. The reflector may need

to be cleaned or replaced.

2. The load may be too heavy . Check the actual

weight of the load. The rated capacity of the

unit is shown on the name plate.

WARNING!

DON’T CHANGE THE SETTING OF

THE RELIEF V AL VE. If you do change

the setting, this may cause a

hydraulic part to fail. The platform

may drop suddenly . Someone may be

hurt, and the unit and load may be

damaged. The hydraulic parts in the

lift are designed to handle a certain

amount of pressure. The relief valve

is set to relieve this pressure before

it becomes too great. The relief

12 PRESTO P4 LEVEL LOADER OWNER’S MANUAL

Page 13

Outer spring

R

Inner spring

elief valve poppet

Coupling – pump

to motor

Gasket

Relief valve cap

Retainer ring

Relief valve

adjusting screw

Down valve plunger

Down valve strainer

Nut

Down valve solenoid

Check valve cap

O-ring

Check valve spring

Check valve ball

Fig. 8 Pump

PRESTO P4 LEVEL LOADER OWNER’S MANUAL 13

Page 14

valve has been included for the

protection of all of the workers who

use the unit.

3. If the motor is not running, check the

electrical plug, the circuit breaker or fuse,

and the wiring to the motor .

4. The hydraulic oil level may be low. In order to

check the level, lower the unit completely

and unplug the power cord. Remove the rear

cover on the unit. When the platform is

lowered as far as possible, the oil should

be about 1/2’’ to 3/4’’ inch below the top of

the tank. Remove the red plastic plug on

top of the tank. Use a dipstick to check the

oil level.

5. The motor voltage may be too low. Check

the voltage at the starter when the motor is

under load. The supply voltage should be

within ±10% of the rating.

6. The tank vent may be plugged. Before

operating the unit, you must remove the solid

plug from the top of the tank and insert the

red plastic vented plug. The vent line must

be clear.

7. The suction filter may be clogged. Clean the

suction filter as described in the section on

“Periodic Maintenance.”

8. A vacuum leak may be allowing air into the

suction line, causing cavitation (loss of

suction) in the pump. Check all fittings in

the suction line, and tighten or replace them

if necessary.

CAUTION!

If cavitation is allowed to continue,

the pump may be damaged, and may

have to be replaced.

9. For the platform to raise, the down valve

must be de-energized and closed

completely. Check for a problem with the

wiring to the down valve. Check the solenoid

in the valve with a voltmeter. The valve must

be clean and free to operate. To check this,

remove the solenoid and then the valve. Look

for dirt or metal chips which could block the

valve action. Clean the valve plunger with

kerosene, then blow it clean with

compressed air. The expansion nut which

holds the solenoid should be finger tight

only).

10. If the pump has been changed, the coupling

may not have been installed between the

motor and pump. See the pump assembly

in Fig. 8.

If the platform elevates, but fails to hold a load:

1. The check valve may be leaking. Dirt on the

valve seat can prevent the valve from

closing fully . The check valve is mounted in

the base of the pump housing, as shown in

Fig. 8. Remove the check valve cap and

inspect the valve for dirt or metal chips

which may be preventing it from closing. Y ou

may be able to restore the seal by lightly

rapping the ball into the seat using a 1/4"

diameter rod and a small hammer.

2. The down valve may be energized. While

the unit is holding a load, the down valve

should be de-energized and fully closed.

Check the solenoid in the valve with a

voltmeter . The valve must be clean and free

to operate. To check this, remove the

solenoid and then the valve. Look for dirt or

metal chips which could block the valve

action. Clean the valve plunger with

kerosene, then blow it clean with

compressed air. The expansion nut which

holds the solenoid should be finger tight only!

3. The cylinder may be leaking. Look for oil on

the cylinder rod and in the vent line. (This

may also occur if the oil tank has been overfilled.) If you find much oil in either place,

and the tank is not over-filled, the cylinder

must be repacked. See the section in this

manual on “Repacking the Cylinder .”

If the platform fails to lower:

1. The sensor and reflector for the photo eye

toe guard are mounted at the front of the

unit, near the floor level. There may be

something blocking the beam of the photo

14 PRESTO P4 LEVEL LOADER OWNER’S MANUAL

Page 15

eye. The reflector may need to be cleaned

or replaced.

2. The down valve may be de-energized. While

the platform is lowering, the down valve

should be energized and fully open. Check

the solenoid in the valve with a voltmeter.

The valve must be clean and free to operate.

Remove the solenoid, then the down valve.

Look for dirt or metal chips which could block

the valve action. Clean the valve plunger

with kerosene, then blow it clean with

compressed air. Before reassembly,

depress the plunger manually several times

to be sure it moves freely . The expansion

nut which holds the solenoid should be

finger tight only! If these steps do not solve

the problem, please call the Presto Lifts

Customer Service Department at (800) 343-9322.

Repacking the Cylinder

The lift in the P4 Level Loader unit may use

several different types of cylinders. To order a

repacking kit and receive repacking instructions,

please call the Presto Lifts Parts Department

at (800) 343-9322. When ordering, specify the

model number and serial number of the unit.

Adjusting the Chain Tension

It is very important that the lifting chain be

tensioned correctly . As the chain is used, it will

tend to stretch a bit. Over time, this can cause

it to loosen. The adjustment mechanism is

located on the rear of the unit. See Fig. 7.

1. Lower the platform completely and unplug

the unit. Remove the plate on the rear of the

unit.

2. Loosen the two locking bolts.

3. Find the two tensioning bolts. Loosen the

locknuts so you can turn these bolts.

4. Turn the tensioning bolts in or out to change

the chain tension. The chain tension should

be as tight as possible without lifting the

platform off of the floor. The setting should

be the same on each side of the

mechanism.

5. When the tension is correct, tighten the lock

nuts.

6. Tighten the two locking bolt s.

PRESTO P4 LEVEL LOADER OWNER’S MANUAL 15

Page 16

Ordering Replacement Parts

Presto Lifts has carefully chosen the components in your unit to be the best available for the purpose. Replacement

parts should be identical to the original equipment. Presto Lifts will not be responsible for equipment failures

resulting from the use of incorrect replacement parts or from unauthorized modifications to the unit.

Presto Lifts can supply all replacement parts for your lift. With your order , please include the model number and

the serial number of the unit. You can find these numbers on the name plate. This plate is located on the lower

corner of the right side panel.

To order replacement parts, please call the Presto Parts Department. Parts are shipped subject to the following

terms:

• FOB factory

• Returns only with the approval of our parts department.

• Credit cards preferred (except parts covered by warranty).

• Freight collect for truck (except parts covered by warranty).

• Freight – prepaid and invoice for small parcel shipments (except parts covered by warranty).

Parts replaced under warranty are on a “charge-credit” basis. We will invoice you when we ship the replacement

part, then credit you when you return the worn or damaged part.

Presto Parts Department

21 Park Street

Attleboro, MA 02703

T elephone: 800-343-9322

F AX: 888-788-6496

Email: service@PrestoLifts.com

www.PrestoLifts.com

Table 10 – Hydraulic Oil Specifications

If the lift will be used at normal ambient temperatures, Presto Lifts supplies the unit

with Citgo AW 32 oil. This may be replaced by any other good quality oil with 150 SSU

at 100° F and rust and oxidation inhibitors and anti-wear properties.

If the lift will be used at ambient temperatures below 0°F, use aircraft hydraulic oil.

Use Type 15 aircraft hydraulic oil.

The following are equivalent to CITGO AW32:

TYPE MANUFACTURER

DTE 24 ..........................EXXON/MOBIL

NUTO H32 .................... EXXON/MOBIL

AMOCO AW32.............. CHEVRON (AMOCO CO.)

CAUTION!

It is very important to keep the hydraulic oil free of dirt, dust, metal

chips, water, and other contamination. Most of the problems with

hydraulic systems are caused by contamination in the oil.

16 PRESTO P4 LEVEL LOADER OWNER’S MANUAL

Page 17

RESTOCKING POLICY

Presto Lift, Inc.’s goal is for you to be satisfied with your order. Merchandise may be returned,

but returns will be subject to a restocking fee to cover the costs Presto Lift, Inc. incurs which

include but are not limited to handling, storage of the units, etc. Presto Lift, Inc. will issue refurbishing costs where end-user wear is apparent. We would prefer to not charge for these costs

but find it necessary any apologize for any inconvenience. Please review the RETURN MATERIALS AUTHORIZATION (RMA) PROCEDURES.

LIFTS

Lifts may be returned with a restocking fee according to the following schedule:

1. Standard unit or standard unit with stock options:

Three or less 20 %

With re-order 15%

Four or more of the same model Consult Customer Svc.

With re-order Consult Customer Svc.

2. Custom engineered/modified lifts: No Returns

PARTS

Standard parts may be returned with a 20% restocking fee. Modified or custom-engineered parts

are not returnable. Unfortunately, due to potentially concealed damage, all sales of electrical

assemblies are final.

QUALITY ISSUES

Should you feel there is a quality problem, please contact the seller to ask questions and gather

information on how to rectify the issue. Presto Lift Inc. reserves the right to determine potential

credits, as a result of factory defects, based on its inspection of the merchandise.

GENERAL

All products shipped from our factory have passed Quality Assurance inspection and testing.

The carrier of choice has signed for, and accepted the product in new working condition. The

customer should inspect to ensure it is not received damaged, has no concealed damage or is not

incomplete. Parts orders are determined to be complete based upon Presto Lift, Inc. inspection

sheets and carrier shipping weights.

PRESTO P4 LEVEL LOADER OWNER’S MANUAL 17

Page 18

RETURN MA TERIALS AUTHORIZA TION

(RMA) PROCEDURES

Although Presto Lift, Inc. is not legally obligated to issue a credit for any merchandise, the

RETURN MATERIALS AUTHORIZATION (RMA) PROCEDURE is provided as a cour-

tesy to our customers in the event they do not receive what they wanted.

If a customer wishes to return a Presto Lift, Inc. product, the first step in the process is to

request an RMA number from Presto Lift, Inc.’s Customer Service Department. This request

must be made on or before the thirtieth (30th) calendar day following the date of Presto Lift,

Inc.’ s invoice for the merchandise being returned.

The RMA number must appear on the outside of any packaging material for a return to be

accepted and processed by Presto Lift, Inc. Customers shipping returns back to Presto Lift,

Inc. from the Continental US, Canada and Mexico have thirty (30) days from the effective

date of the RMA to have the merchandise arrive freight prepaid at Presto Lift, Inc. Returns

from locations other than the Continental US, Canada and Mexico must be shipped within the

thirty (30) day period to arrive Free On Board (FOB) at Presto Lift Inc as soon as practical. If

a customer believes Presto Lift, Inc.’s merchandise is defective, freight will be reimbursed to

the original “Bill To” on the invoice if Presto Lift Inc. finds that the merchandise is defective.

Please remember that merchandise with RMA’s coming back to Presto Lift Inc. from the

Continental US, Canada and Mexico will not be accepted by Presto Lift Inc. if the returned

goods do not arrive freight prepaid at Presto Lift Inc. within the thirty (30) day effective period.

All credits issued are less restocking fees as applicable, plus any assessed outbound/inbound

in-transit damages.

Return addresses: please refer to your RMA for the address to which your product should be

returned.

Presto Lift Inc.

715 Highway 77

Manila, Arkansas 72442

T elephone: 800-343-9322

Fax: 888-788-6496

18 PRESTO P4 LEVEL LOADER OWNER’S MANUAL

Page 19

PRESTO P4 LEVEL LOADER OWNER’S MANUAL 19

Page 20

Presto Lifts Limited Warranty Policy

Presto Lifts warrants all of its products against defects in the welded structural frame and, if

applicable, scissor legs from faulty material and workmanship for a period of five (5) years from

the date of invoice.

A lifetime limited warranty is provided for the Airstroke Actuator

defect due to faulty material or workmanship.

All batteries are covered under a separate limited warranty from the battery manufacturer for a

period of one year from the date of invoice.

All other components have a limited warranty against defects in faulty material and workmanship

for a two (2) year period from the date of invoice and 30 day limited warranty on labor. Please

note that prior authorization from Presto Lifts is required on all warranty work.

There are no implied warranties of any kind, more specifically, there are no warranties of merchantability or fitness for any particular purpose. Presto Lifts' sole warranty shall be as set forth in

this limited warranty .

Presto Lifts will elect to repair or replace a defective component without charge, if any components should become defective within the limited warranty period. Proof of purchase is required

for warranty. The charge for shipping the defective component is the responsibility of the buyer

and must be accompanied with an RMA number. The shipping charge to return the component to

the buyer is the responsibility of Presto Lifts, Inc.

TM in all pneumatic lifts against any

This limited warranty does not cover labor expense for removal or reinstallation of components

after thirty days. This limited warranty shall not cover, among other things: damages resulting from

foreign matter or water, failure to provide reasonable and necessary maintenance, and if applicable, use of product while charger is plugged into an AC outlet, or failure to follow operating

instructions. The limited warranty is not valid for damage resulting from negligence, accident,

unreasonable use, abuse or misuse, exceeding data plate capacities or altering the product without

Presto Lifts authorization.

Presto Lifts expressly disclaims and excludes any liability for consequential, incidental, indirect or

punitive damages or financial loss to people or property resulting from any breach of warranty or

the operation or failure of this product.

Presto Lifts makes no representation that this product complies with local, state, or federal safety/

product standards codes. Should this product fail to comply in any way with those codes, it shall

not be considered a defect of materials or workmanship. Presto Lifts shall not be held liable for

any damages resulting from noncompliance. It is the dealer's responsibility to exercise this limited

warranty . This limited warranty is provided to the original purchaser (defined as the original end

user) and is nontransferable. This constitutes the complete and final agreement involving Presto

Lifts and limited warranty obligations for products.

20 PRESTO P4 LEVEL LOADER OWNER’S MANUAL

Loading...

Loading...