Presto M100, M200, M300, M400 Installation Manual

Foot Operated Lifts

M100, M200,

M300 & M400

Installation, Operation

and Service Manual

Model Number ___________________

Serial # _________________________

Date placed in service _____________

IMPORTANT: READ CAREFULLY

BEFORE INSTALLING OR OPERATING LIFT

Part orders are subject to a $50 minimum charge.

H-1819

PAGE 1 OF 27 072 0 I H-1819V ND

This label (part # 10095524)

is required by California law.

For more information visit

www.65Warnings.ca.gov.

This label (part # 10095524)

is required by California law.

For more information visit

www.P65Warnings.ca.gov.

This manual was current at the time of printing. To obtain the latest, most updated version,

please contact Presto Lifts Customer Service Department or go to our website: www.Pre-

stoLifts.com -- you will nd a complete list of current owner’s manuals to print.

H-1819

PAGE 2 OF 27 072 0 I H-1819V ND

Limited Warranty Policy

Presto Lis warrants this product to be free from defects in material or workmanship for the duration

of the warranty period. Warranty periods vary and begin on the date of shipment. For specic warranty

information, contact Presto Lis with the machine’s serial number.

Any claim for breach of this warranty must be received in writing by Presto Lis within the warranty

period. Warranties shall not cover failure or defective operation, caused by misuse, misapplication,

negligence or accident, exceeding recommended capacities, or any alteration or repair of the item purchased which has not been authorized by Presto Lis. Except as set forth herein, Presto Lis makes no

other warranties, express or implied, including THE WARRANTIES OF MERCHANTABILITY AND

OF FITNESS FOR A PARTICULAR PURPOSE, all of which ARE HEREBY EXCLUDED.

Presto Lis meets the labeling requirements of California’s Proposition 65. Presto Lis makes no warranty or representation with respect to the compliance of any product with other State or local safety

or product standard codes and any failure to comply with such codes shall not be considered a defect

of material or workmanship under this warranty. Presto Lis shall not be liable for any direct or consequential damages arising out of such non-compliance.

Presto Lis’ obligations under any warranty or for any other damages which may arise under any sale,

agreement, or contract, are limited to the replacement or repair of defective components at its factory

or another location at Presto Lis’ discretion. is is buyer’s sole remedy under any such warranty, sale,

agreement, or contract. Presto Lis will not be liable for consequential, incidental, exemplary, or punitive damages of any kind resulting from a breach of any warranty that it has provided or for breach of

any term of any sale, agreement, or contract. Any warranty may be altered only in writing by Presto

Lis.

All commodities, soware, or technology purchased from Presto Lis are subject to the export and

re-export control laws and regulations of the United States, including but not limited to the Export

Administration Regulations (“EAR”) and Department of the Treasury Oce of Foreign Asset Controls (“OFAC”) Regulations. Presto Lis expects all distributors and customers to comply with these

laws and regulations. Without limiting the foregoing, the distributor/customer cannot, without proper

authorization from the applicable United States Government Agency, export, re-export, or transfer

any commodity, soware, or technology purchased from Presto Lis, either directly or indirectly, to

any entity, country, or national of any country in breach of such laws and regulations. Furthermore,

Presto Lis expects that the distributor/customer shall indemnify and hold harmless Presto Lis from

and against any claim, proceeding, action, ne, loss, cost and damages arising out of or relating to any

noncompliance with export control regulations by distributor/customer, and distributor/customer are

expected to compensate Presto Lis for all losses and expenses resulting thereof, unless such noncompliance was clearly not caused by fault of the distributor/customer.

H-1819

PAGE 3 OF 27 072 0 I H-1819V ND

C O N T E N T S

WARANTY .........................................................................................................................3

S E C T I O N 1:

Introduction .............................................................................................................5

Responsibility of Owners and Users .......................................................................6

S E C T I O N 2:

Safety ......................................................................................................................7

Safety Alert Symbols and Signal Words .................................................................8

S E C T I O N 3:

Installation ...............................................................................................................9

S E C T I O N 4:

Operation .................................................................................................................9

S E C T I O N 5:

Maintenance ............................................................................................................9

S E C T I O N 6:

Service ...................................................................................................................10

S E C T I O N 7:

Troubleshooting ....................................................................................................10

RESTOCKING POLICY .................................................................................................23

RETURN MATERIALS AUTHORIZATION (RMA) PROCEDURES ..........................24

ORDERING REPLACEMENT PARTS ........................................................................... 25

L I S T O F F I G U R E S :

Table 1: Hydraulic Oil Specications ..............................................................................................9

Figure 1: Wheel Identication ....................................................................................................... 11

Figure 2: Chain Roller Assembly ...................................................................................................11

Complete Cylinder breakdown by Part Number (Text) ........................................................... 12-13

Figure 3: M100-10 Pump Body Complete.....................................................................................14

Figure 4: M400-20 Cylinder Assembly Repair Kit ........................................................................15

Figure 5: M400-30 Pump Plunger Assembly.................................................................................16

Figure 6: M400-40 Cylinder Packing Kit ......................................................................................17

Figure 7: M400-50 Release Pin Assembly .....................................................................................18

Cylinder Assembly..........................................................................................................................19

Hydraulic Repair Kit for M Series Star Cylinder...........................................................................20

Figure 8: Backplate Assembly .......................................................................................................21

Figure 9: Platform Assembly .........................................................................................................22

Figure 10: Stacker Assembly .........................................................................................................23

Figure 11: Label Placement Diagram ............................................................................................ 24

H-1819

PAGE 4 OF 27 072 0 I H-1819V ND

S E C T I O N 1

INTRODUCTION

This manual attempts to provide all of the information

necessary for the safe and proper installation, operation

and maintenance of Presto Lifts Inc.'s MSeries Stackers. It is important that all personnel involved with the

installation, maintenance or operation of the stacker

read this manual. Where unique situations arise, that are

not covered in this manual call Presto Lifts for further

instructions. Additional manuals are available upon

request or on our web site at www.prestolifts.com.

The stacker has a nameplate that provides the load ca-

pacity ratings, serial number and model identications.

Please refer to these numbers when ordering parts or

requesting further information.

WHERE UNIQUE SITUATIONS ARISE, THAT ARE

NOT COVERED IN THIS MANUAL, CALL PRESTO

LIFTS SERVICE DEPARTMENT FOR FURTHER

INSTRUCTIONS.

H-1819

PAGE 5 OF 27 072 0 I H-1819V ND

Responsibility of Owners and Users

Inspection and Maintenance

The device shall be inspected and maintained in proper working order in accordance with Presto’s

owner’s manual.

Removal from Service

Any device not in safe operating condition such as, but not limited to, excessive leakage, missing

rollers, pins, or fasteners, any bent or cracked structural members, cut or frayed electric, hydraulic,

or pneumatic lines, damaged or malfunctioning controls or safety devices, etc. shall be removed from

service until it is repaired to the original manufacturer’s standards.

Repairs

All repairs shall be made by qualied personnel in conformance with Presto’s instructions.

Operators

Only trained personnel and authorized personnel shall be permitted to operate PowerStak.

Before Operation

Before using the device, the operator shall have:

• Read and/or had explained, and understood, the manufacturer’s operating instructions and safety

rules.

• Inspected the device for proper operation and condition. Any suspect item shall be carefully ex-

amined and a determination made by a qualied person as to whether it constitutes a hazard. All

items not in conformance with Presto’s specication shall be corrected before further use of the

PowerStak.

During Operation

The device shall only be used in accordance with this owner’s manual.

• Do not overload.

• Ensure that all safety devices are operational and in place.

Modications or Alterations

Modications or alterations to any Presto industrial positioning equipment shall be made only with

written permission from Presto.

H-1819

PAGE 6 OF 27 072 0 I H-1819V ND

S E C T I O N 2

SAFETY

The M Series stackers are very capable of causing serious injury or damage if adequate precautions are not

taken. By reading and following this manual, operator

injury may be prevented.

DO NOT INSTALL OR OPERATE THESE LIFTS

WITHOUT CAREFULLY READING THIS MANUAL. In order to provide for the safe operation of these

stackers, Presto Lifts Inc. has identied certain hazards

that may occur during the installation, maintenance and

use of these lifts.

WARNING!

• Do not perform any repair work on lifts if there is

a load on the platform or forks are in the raised or

lowered position.

• All personnel must stand clear of the lift when the

lift is in motion.

• Do not put hands or feet under forks or platform

while in motion.

• Do not put hands or feet on or near the mast

while the forks or platform is in motion.

• Do not stand, sit or climb on the lift.

• Do not exceed the load capacity.

• Place all loads centrally located on the lift forks

or platform.

• Do not place a load on a moving lift.

• Do not use the lift on soft, uneven or unstable

surfaces.

• Do not shock load the forks or platform. Materi-

als must be carefully placed rather than dropped.

H-1819

PAGE 7 OF 27 072 0 I H-1819V ND

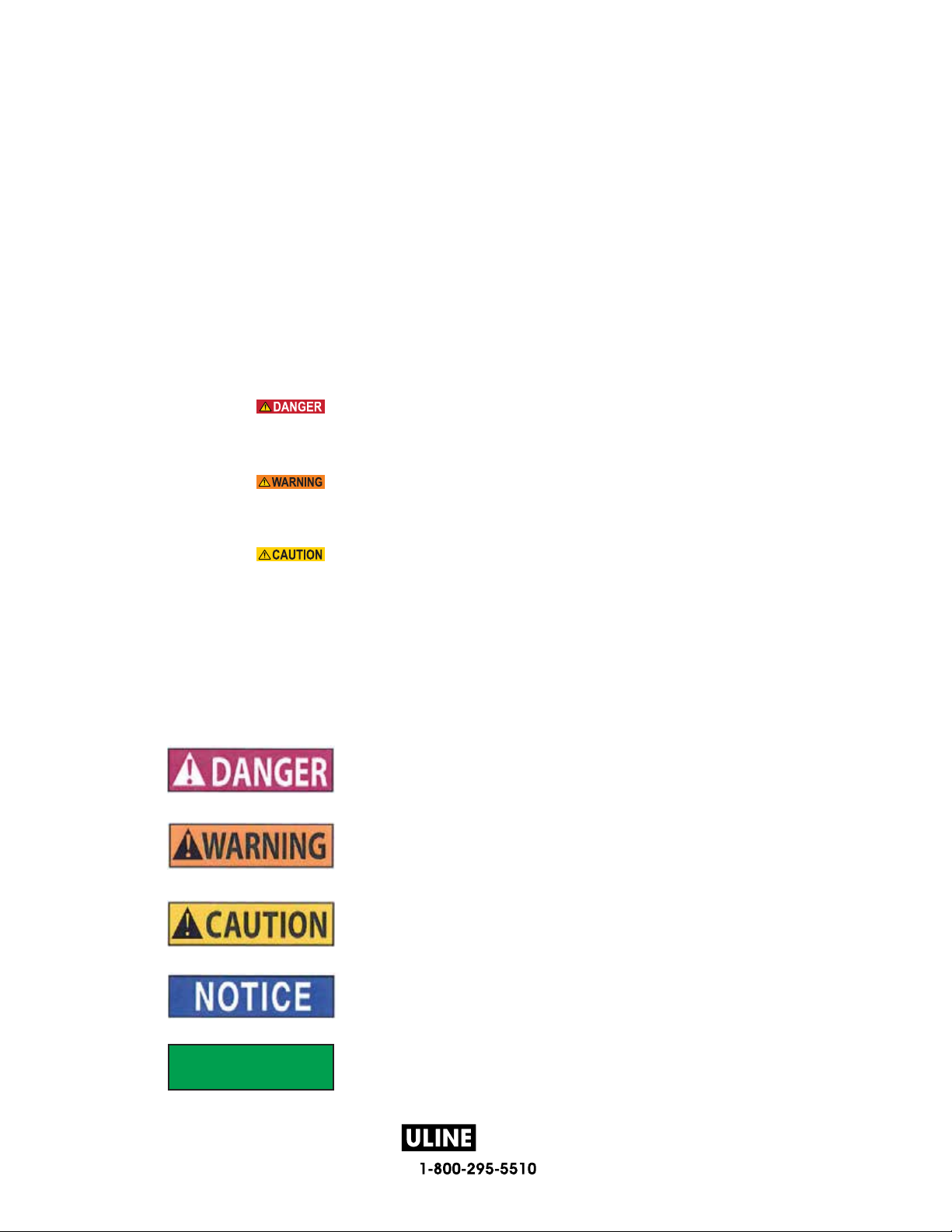

SAFETY ALERT SYMBOLS AND SIGNAL WORDS

The safety of all persons operating, maintaining, repairing, or in the vicinity of this equipment is of paramount

concern. This is a powerful machine with moving parts, and is capable of causing personal injury if proper

precautions are not taken. Therefore, throughout this manual, certain hazards have been identied which may

occur in the use of the machine, and there are appropriate instructions or precautions which should be taken to

avoid these hazards. In some cases, there are consequences which may occur if instructions or precautions are

not followed. Below are the symbols and signal words along with their denitions referenced from ANSI Z535.4

- Product Safety Signs and Labels.

Safety Alert Symbols

These are the safety alert symbols.. They are used to alert you to potential physical injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

For use with DANGER signal word

(Red Background)

For use with WARNING signal word

(Orange Background)

For use with CAUTION signal word

(Yellow Background)

Signal Words

The meaning of different signal words as dened by ANSI Standard Z535.4 indicates the relative

seriousness of the hazardous situation.

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

(Red Background)

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

(Orange Background)

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or

(Yellow Background)

moderate injury.

NOTICE is used to address practices not related to personal

injury.

(Blue Background)

SAFETY

INSTRUCTIONS

(Green Background)

SAFETY INSTRUCTIONS (or equivalent) signs indicate safetyrelated instructions or procedures.

H-1819

PAGE 8 OF 27 072 0 I H-1819V ND

S E C T I O N 3

INSTALLATION

INSTALLATION

When the stacker arrives on a pallet the following steps

are to be followed:

2). To lower lift, press release pedal down. Pressure on

release pedal controls speed of descent of load.

S E C T I O N 5

1. Through the use of a forklift or overhead hoist, pick

the stacker unit up taking into consideration the center

of gravity. The center of gravity of the unit should be

adequately supported.

2. Once the unit is lifted from the pallet by a couple of

inches, remove the pallet from under the stacker.

3. Follow the next sections to ensure proper operation.

S E C T I O N 4

OPERATION

METHOD OF OPERATION:

In order to operate the lift follow these operating procedures.

1). To raise the platform or forks, pump foot pedal until

platform reaches desired height.

MAINTENANCE

ROUTINE MAINTENANCE:

1). Grease wheels and casters at least once a month to

maintain easy roll of lift.

2). Do not overload the lift. All foot operated Presto

Manual Stackers have a maximum rated capacity

of 1000 lbs.

3). Use only hydraulic oil in the hydraulic system.

NEVER USE HYDRAULIC BRAKE FLUID.

Table 1 – Hydraulic Oil Specications

If the lift will be used at normal ambient temperatures, Presto Lifts supplies the unit with Conoco Super Hydraulic

32 oil. This may be replaced by any other good quality oil with 150 SSU at 100° F and rust and oxidation inhibitors

and anti-wear properties.

If the lift will be used at ambient temperatures below 0°F, use aircraft hydraulic oil. Use Type 15 aircraft hydraulic oil.

The following are equivalent to Conoco Super Hydraulic 32:

TYPE MANUFACTURER

AW32 .......................................... CITGO

DTE 24 ....................................... EXXON/MOBIL

NUTO H32 ................................. EXXON/MOBIL

AMOCO AW32 ........................... CHEVRON (AMOCO CO.)

CAUTION!

It is very important to keep the hydraulic oil free of dirt, dust, metal chips, water, and other

contamination. Most of the problems with hydraulic systems are caused by contamination in the oil.

H-1819

PAGE 9 OF 27 072 0 I H-1819V ND

Loading...

Loading...