Page 1

90cm Dual Fuel Range Cooker

Electric Ovens and Grill with Gas Hob

DF90

User Guide & Installation Handbook

®

Page 2

User’s Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 22

Before Using Your Cooker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About Your Cooker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hob & Cooker Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chip Pan Fires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Using The Minute Minder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using Your Gas Hob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Using Your Grill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Grilling Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Using Your Main Oven(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Oven & Grill Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fanned Oven Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cooking Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Roasting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

General Baking Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleaning Your Gas Hob. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning Your Cavities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cleaning Your Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cook Shop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 - 24

Before You Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Changing Light Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 - 32

Installing Your Cooker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Service Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Customer Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Contents

If you smell gas:

Do not try to light any appliance. Do not touch any electrical switch.

Call the Gas Emergency Helpline at TRANSCO on: 0800 111999

Page 3

Before Using Your Cooker

Before using this appliance please make sure that

you have removed all packaging and wrapping.

Some of the furniture inside this

appliance may have additional wrapping.

It is also advised that you turn the ovens and/or

grill on for a short while, this will burn off any

residues left from manufacturing. There may be a

smell which accompanies this process - but this is

nothing to worry about and is harmless.

We also recommend that you wash the oven

shelves, the baking tray, the grill pan, and the grill

pan trivet before their first use in hot soapy water,

this will remove the protective oil coating.

Although every care has been taken to ensure this

appliance has no burrs, or sharp edges, we

recommend that you wear protective gloves when

installing and moving this appliance.

This will prevent any injury.

Our policy is one of constant development and

improvement. Strict accuracy of illustrations and

specifications cannot be guaranteed. Modification

to design and material may be necessary

subsequent to publication.

Please bear in mind that not all the sections inside

this handbook are relevant to your appliance, but

you should read carefully the sections which are

relevant before installation and use. This will save

you time.

Always use a registered installer for this appliance.

Environmental protection:

Glen Dimplex Home Appliance brands are

committed to protecting the environment and

operates and Environmental Management System

which complies with BS EN ISO 14001.

All packaging with this appliance is recyclable and

environmentally friendly.

Please recycle whenever possible - contact your

local authority for your nearest recycling centre.

!!!

3

i

i

!!!

i

i

!!!

Page 4

About Your Cooker

Fanned

oven

Fanned

oven

Fascia

panel

Grill

Large

burner

Wok

burner

Small

burner

Medium

burner

Medium

burner

4

Page 5

Hob & Cooker Safety

4Always ensure that pan bases are dry, and flat before

using them on the hob.

4Always position pans over the centre of the burner, and

turn the handles to a safe position so they cannot be

knocked or grabbed.

4Always use pans which are no smaller than 100mm

(4”), or larger than 250mm (10”).

4 Always take care when removing food from the oven

as the area around the cavity may be hot.

4 Always use oven gloves when handling any utensils

which have been in the oven as they will be hot.

4Always make sure that the oven shelves are resting in

the correct position in between two runners. Do not

place the oven shelves on top of the highest runner,

this will lead to spillage and injury if the baking tray, or

dish falls.

6 Never use double pans, rimbased pans, old or

misshapen pans, or any pan which is not stable on a

flat surface.

6 Never leave cooking fat, or oil, unattended.

6 Never use commercial simmering aids, or heat

diffusers, as they create excessive heat and can

damage the surface of the hob.

6 Never use the hob for any other purpose than cooking

food.

6 Plastic cooking utensils can melt if they come into

contact with a warm hob. Never leave them close to,

or on top of, the hob.

6 Never leave the burner alight without a pan covering it.

This causes a fire hazard.

6 Do not place items on the door while it is open.

6 Do not wrap foil around the oven shelves, or allow it to

block the flue.

6 Do not drape tea towels near the oven while it is on,

this will cause a fire hazard.

6 Do not pull heavy items, such as turkeys, or large

joints of meat, out fr

om the o

v

en on the shel

f, as they

may overbalance and fall.

6 Do not use this appliance to heat anything other than

food items, and do not use i

t f

or heating the r

oom.

5

Always make sure that the

burner caps, rings and

pansupports are correctly

placed. This will prevent pans

becoming unstable while in

use, and ensure an

uninterrupted gas flow.

Call Customer Care for a

service engineers visit if:

lThe cooling fan fails to

work.

i

WARNING: Parts of

the appliance may

become hot while in

use, always make sure

that children are

supervised when they

are near to the

appliance.

!!!

Page 6

Chip Pan Fires

What causes a chip pan fire?

l Chip pan fires start when oil of fat overheats and catches fire,

or when oil or fat spills on to the cooker because the pan has

been filled too high.

l They can also start when wet chips are put into hot oil,

making it bubble up and over flow.

Preventing a chip pan fire

l Never fill the pan more than a third full with oil of fat.

l Never leave the pan alone with the heat on - even for a few

seconds.

l Dry chips before putting them in the pan.

l Never put chips in the pan if the oil has started smoking.

Turn off the heat and leave the oil to cool down, or else it

could catch fire.

In the event of a chip pan fire

l If your chip pan does catch fire - don’t panic, and don’t move

the pan. Serious burns are often caused by picking up the

pan and running outside with it.

l If it is safe to do so, and you don’t have to reach across the

pan, turn off the heat.

l Never throw water, or use a fire extinguisher.

l If you can, drape a damp cloth or towel over the pan to

smother the flames.

l Leave the pan to cool down for at least half an hour.

l If you can’t control the fire yourself, close the door, get out

and tell everybody else to get out.

l Call the fire brigade. Don’t go back inside whatever the

reason.

6

Page 7

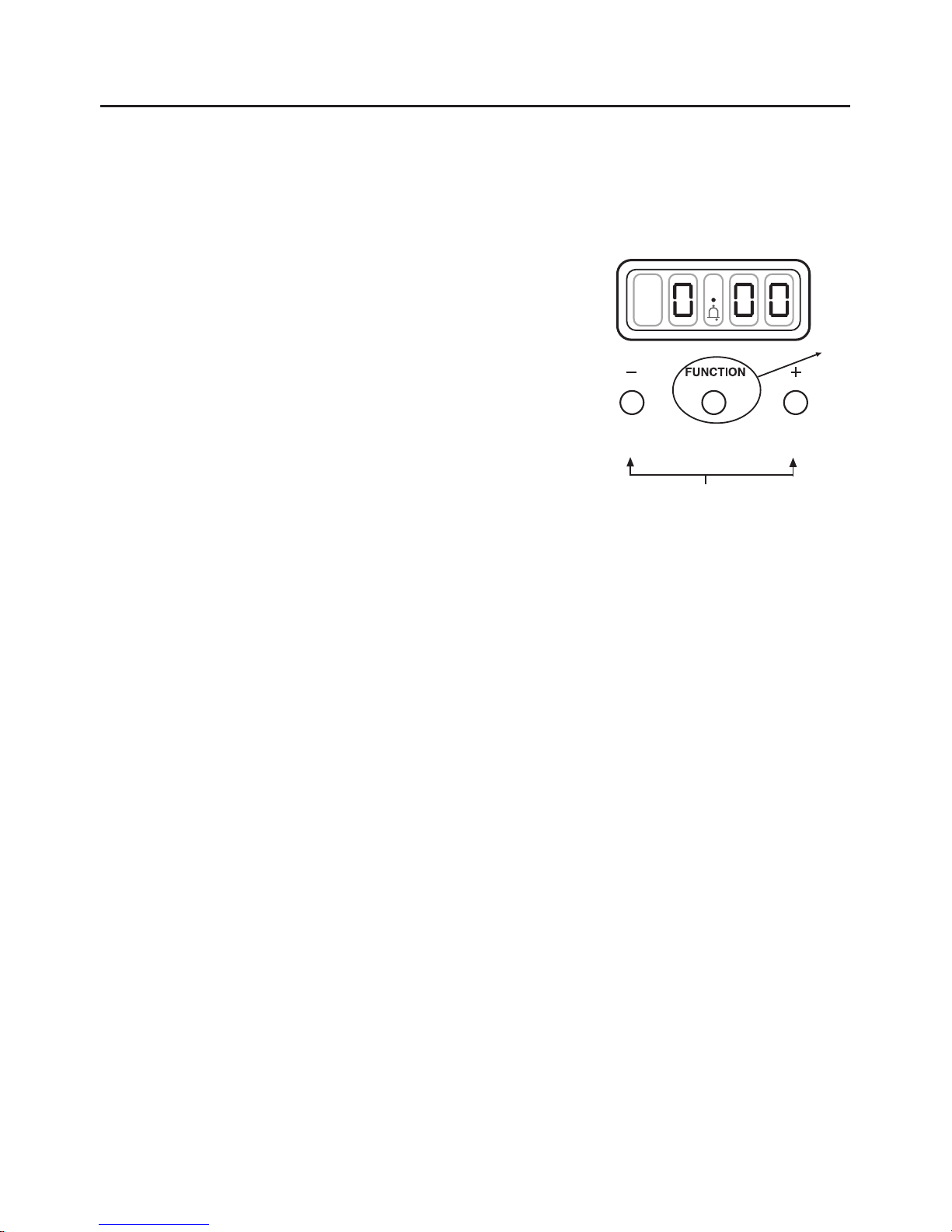

Using The Minute Minder 7

The digital timer enables you to set the time of day (24

hour clock) and the minute minder alarm.

Setting the time of day

u Press the Plus and Minus buttons together for a few

seconds and release.

u Set the time of day using the Plus and Minus buttons.

Press once for single digit increase, press and hold for

rapid increase..

u Once the time of day has been set, wait approx 10

seconds until the ‘

l’ stops flashing.

u Use the appliance as normal.

Changing the time of day

1. Press the function button once.

2. Set the time of day, using the

plus

and

minus

buttons.

3. The time will be set 7 seconds after the last

plus

or

minus

operation.

Alarm tones

After setting the time of day, you can select one of three

alarm tones.

u Press the

minus

button to listen to the first tone, then

release the

minus

button and press again to listen to

the second tone, etc.

u Releasing the

minus

button after a tone has sounded

will automatically select that tone.

Use to set

the correct time

Minus

button

Plus

button

Function

select

Press &

release:

to set

the time

Page 8

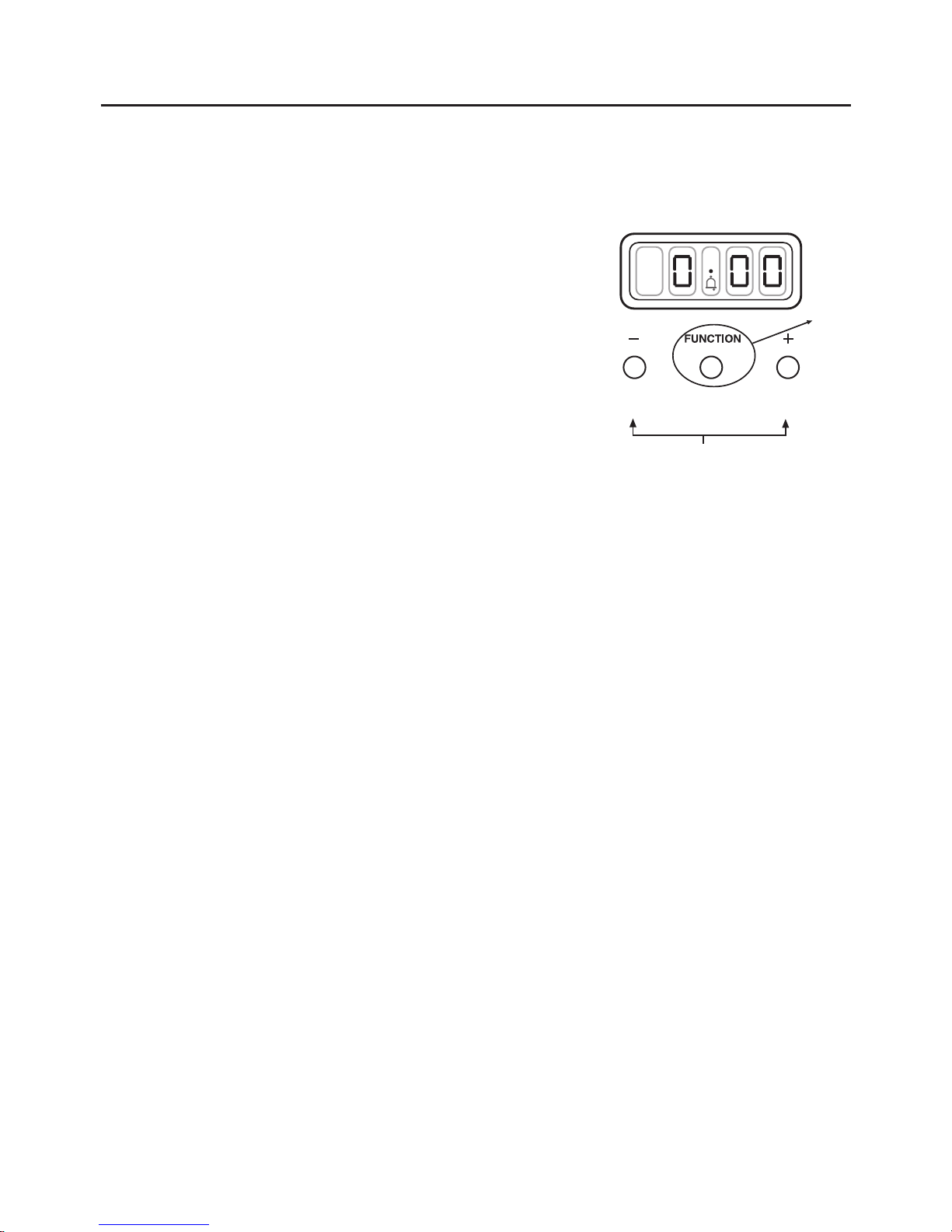

Using The Minute Minder 8

Setting the minute minder

1. Press and release the

plus

button, to change the display from clock to minute minder - the bell symbol will

light.

2. Use the

plus

and

minus

buttons to set the length of

time before the alarm tone will sound. The display will

increase / decrease in units of 10 seconds up to 99

minutes, 50 seconds, and in units of 1 minute from 1

hour 40 minutes upwards. The maximum period which

may be set is 10 hours.

u The display format will change after 99 minutes and 50

seconds to 1 hour and 40 minutes.

u During countdown, the minute minder has priority on

the display, which will show (in

minutes : seconds, or

hours : minutes

) the time remaining.

u When countdown is complete, the tome will sound for

7 minutes, or it can be reset with one touch of any

button.

To cancel the minute minder at any time.

u Run down the set time with the

minus

button. The

display will show the time of day

Use to set

the correct time

Minus

button

Plus

button

Function

select

Press &

release:

to set

the time

Page 9

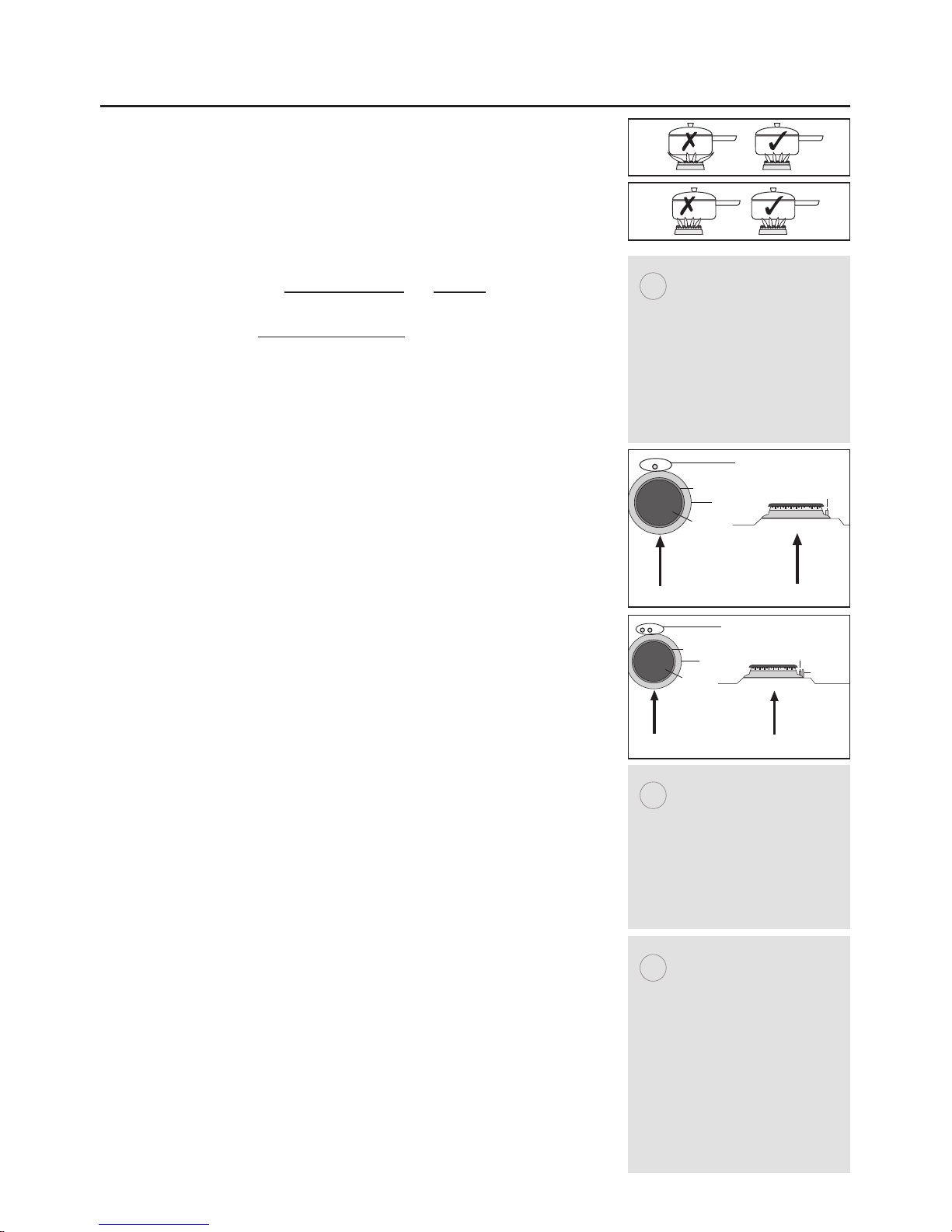

Using Your Gas Hob

Hob Ignition

Models without thermocouples:

l

To turn on

, place your pan onto the pansupports above

the burner you wish to use.

l Push in and turn the selected control knob

anticlockwise, to the full on symbol.

l If your hob has an ignition button or switch on the

fascia, press it in until your burner lights.

l If your hob has automatic ignition it will spark next to

the burner when you push in the control knob.

l

To simmer

, turn the control knob to the small flame

symbol. This will ensure that the flame is just large

enough to gently heat the contents of the pan.

l

To turn off

, turn the control knob clockwise to the ‘off’

position.

l Always make sure that your pans are place correctly on

the burners as shown, and do not allow the flame to

extend over the base of the pan.

Models with thermocouples:

Igniton as above, but:

l Hold the control knob in for 15 seconds. Do not hold

the control knob in for any longer than 15 seconds. If

the burner fails to light within this time, release the

control knob and wait one minute before attempting to

re-ignite.

Energy Saving

l Position pans centrally over the elements.

l Only heat the amount of liquid you need.

l Once liquids have been brought to the boil, reduce the

heat setting to a simmer.

l Consider using a pressure cooker if possible.

l Vegetables in small pieces will cook quicker.

l Use a pan which is a close match to your element size.

l Smaller elements are ideal for simmering and stewing

in smaller pans, while the larger elements are ideal for

frying and boiling

9

Front

of the appliance.

Burner cap

Burner ring

Burner skirt

Electrode

Electrode

Viewed from the side

of the burner

Front

of the appliance.

Burner cap

Burner ring

Burner skirt

Thermocouple and electrode

Thermocouple

Electrode

Viewed from the side

of the burner

How can I tel

l if my hob

has thermocouples?

Picture A below:

shows a burner without

thermocouples.

Picture B below:

shows a burner with

thermocouples.

i

A

B

In the event of a power

failure, or the ignition

not working:

Push in and turn the

control knob to start the

gas, then hold a lighted

match or taper to the

burner until it lights.

i

Use flat based pans

which are the correct

size for your burners

and suitable for your

hob type.

W

e recommend the

following sizes:

100mm or 4” min.

250mm or 10” max.

Smaller or larger pan

sizes may lead to slower

cooking times.

i

Page 10

Using Your Grill

Before you start grilling. . . .

Before you use the grill, make sure you have placed the

grill shelf in the position you need as once the grill is on

you may injure yourself if you try to move the shelf.

l Do not close the door while the grill is in use.

l Turn the selector control knob to the heat setting you

require.

l To switch off, return the control knob to the ‘off’

position.

l The cooling fan will come on during use, and may

continue to run for some time afterwards.

l To adjust your results, you can turn the grid over, or

remove it altogether.

If your grill is a dual grill:

l The

dual grill

uses all of the top element and is ideal for

grilling large quantities of food.

l The

single grill

uses part of the element only, and is

better suited to grill smaller amounts of food.

The grill pan

This appliance comes with a grill pan, grill pan handle and

a grid.

The handle of the grill pan is detachable to allow you to

remove it while the pan is in use, this stops it from

getting hot.

To attach the handle:

Place the handle over the narrow edge of the grill pan

and slide to the centre as shown in the diagrams.

Shelf & Grid adjustments

Speed of grilling can be adjusted by changing the shelf

position or the turning the grill pan grid.

l High: For thin foods and toasting.

l Low: For thicker meat pieces.

Aluminium Foil

Never cover the grill pan or grill trivet with foil, or allow fat

to build up in the grill pan, as this creates a fire hazard.

10

Warning: Accessible

parts may become hot

when the grill is in use.

Chidren should be kept

away.

handle

grill pan

grid

handle position

indicators

Please note: the grill

pan handle is designed

for sliding the grill pan

into and out of the grill

cavity. It is not to be

used for lifted the pan.

Types of grill

Fixed rate grill: has a

full ‘on’ setting and ‘off’.

V

ariable rate grill: has

adjustable heat settings

1 (low) to 8 (high) or 5

(high) - depending on

the model.

Single gri

ll: has one grill

element.

Dual grill: has two grill

elements which can be

used together, or as a

single grill.

i

i

i

For best results:

Pre-heat the grill for

about 3 minutes.

i

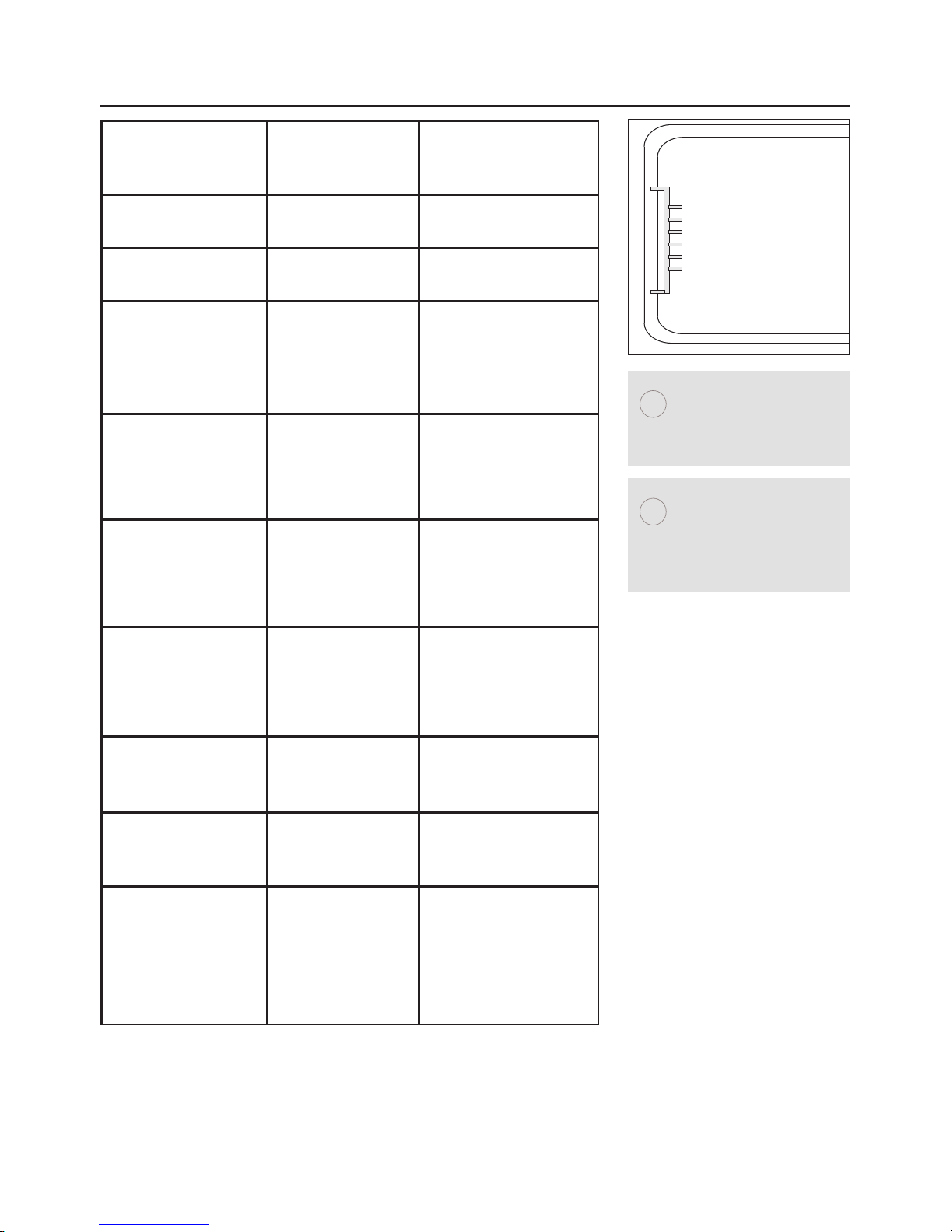

Page 11

Grilling Guide

Food

Type

Shelf

Position

Time Approx

(mins)

Bacon 5 8 - 15

Sausages 5 12 - 15

Chops

l Lamb

l Pork

4

3

10 - 15

15 - 25

Toast

l 2 rounds

l 4 rounds

5

5

1 - 2 (per side)

1 - 2 (per side)

Bread products

l Buns

l Tea cakes

4

4

1 - 2 (per side)

1 - 2 (per side)

Cheese on toast

l 2 rounds

l 4 rounds

5

5

4 - 5

4 - 5

Fish:

l fillets 2 10 - 15

Chicken:

l fillets

Depends on thickness

1 - 2

20 - 30

Beef Steaks:

l rare

l medium

l well done

Gammon Steaks

5

4

4

5

7 - 10

10 - 15

15 - 20

12 - 15

11

1

2

3

4

5

Note:

Shelf positions are

counted from the

bottom up.

i

As with any cooking

guide, all times are

approximate and can be

adjusted to suit

personal taste.

i

Page 12

Using Your Main Ovens

Switching on the fanned oven

l Use the main oven control to turn your oven on, and

select your temperature.

l The thermostat indicator will come on to show that the

oven is heating, and once the temperature is achieved,

it will go out.

l To switch off the main oven, simply turn the control

knob back to the ‘

l ‘ position.

l The cooling fan will come on during use, and may

continue to run for some time afterwards.

12

Page 13

Oven & Grill Functions

Main Oven Function Recommended Uses

Base Heat Only Used to finish off the bases of food following cooking using the conventional

or fanned modes. The base heat can be used to provide additional

browning for pizzas, pies and quiche. Use this function towards the end of

cooking.

Top Heat Only The heat is ideal from browning off the tops of food as it is not as fierce as

the grill following conventional or fanned cooking. Provides additional

br

owning for dishes like Lasagna or Cauliflower cheese. Use this function

towards the end of

cooking.

Conventional Oven This function is ideal for traditional roasting. The meat is placed in the

middle of the oven, roast potatoes towards the top.

Intensive Bake Suitable for food with a high moisture content, such as quiche, bread and

cheesecake. It also eliminates the need for baking pastry blind.

Fanned Grill The fan allows the heat to circulate around the food. Ideal for thinner foods

such as bacon, fish and gammon steaks. Foods do not require turning. Use

with the oven door closed.

Fanned Oven The even temperature in the oven makes this function suitable for batch

baking, or batch cooking foods.

Defrost To defrost foods, such as cream cakes/gateaux, use with the oven door

closed. For cooling dishes prior to refrigeration, leave the door open.

Dual Grill This function cooks food from the top and is ideal for a range of food from

toast to steaks. As the whole grill is working, you can cook larger quantities

of food.

Single Grill For smaller quantities of food, but is still ideal for

anything from toast to steaks.

Base Heat with Fan Used to cook open pies (such as mince pies) the base element ensures that

the base is cooked while the fan allows the air to circulate around the filling

- without being too intensive.

Lights only Use when the oven is switched off and cold to aid cleaning the oven cavity.

The chart below details all of the functions which are available. Your oven may

not have all of the functions shown here.

13

Page 14

Fanned Oven Guide 14

Conventional

temp (˚C)

‘A’ Efficiency oven

(˚C)

Gas mark

100

110

130

140

150

160

180 - 190

200

220

230

250

100

110

120

130

140

150

160

170

180

190

200

1/4

1/4

1/2

1

2

3

4 - 5

6

7

8

9

l Some adjustment will have to be made to conventional

cooking temperatures.

l The table below shows conventional cooking

temperatures, fanned temperatures and gas marks.

For optimum results using the fanned oven setting,

conventional temperatures need to be converted to the

fanned oven temperatures.

l For example and item which would cook at 180˚C will

now cook at the fanned oven temperature of 160˚C.

l This is a high efficiency oven, you may notice an

emission of steam when the door is opened.

l When cooking chilled or frozen foods, use the

recommended cooking times and temperature on the

packaging.

Always make sure the food is piping hot

throughout before serving.

l There are no zones of heat, and no flavour transfer when

using a fanned oven - allowing you to cook a greater

variety of foods together.

l If you are cooking on more than one shelf, you may need

to slightly increase the cooking time.

l Always make sure that there is enough space between

dishes, to allow food to rise, and to air to circulate.

Page 15

Pre-heating

To get the best results from your oven, we recommend

pre-heating for around 5 to 15 minutes before placing

your dishes in. This is especially important for items

which are chilled, frozen, batter based, yeast based or

whisked sponges.

If you are using a fanned function, you should still preheat but for a shorter time.

The items in the cooking guide below are based on a

pre-heated oven, but can be adjusted to take into account

personal taste.

Oven and bakeware

Always use high quality trays and tins for cooking. Poor

quality tins and trays can warp in the oven producing

uneven results.

Never use dishes which are cracked, damaged or not oven

proof as heating may lead to shattering inside the oven.

Food Type Temp.

Setting ˙C

Time

Approx.

Shelf

Position

Cakes

Small cakes

Victoria sandwich

Semi rich fruit cake

Christmas cake

Fanned

160

160

125

125

15 - 25

20 - 30

2

1/2

- 3hrs

2

1/2

- 3hrs

7 & 13

7

5

3

Puddings

Bread & butter

pudding

Fruit crumble

150

175

45 - 1hr

40 - 1hr

9

9

Miscellaneous

Yorkshire pudding:

large

small

Shortcrust pastry

200

200

180

40 - 45

15 - 20

depends on

fi

l

l

ing

11

12

top - middle

Cooking Guide 15

Page 16

Roasting Guide

l Roasting times depend on the weight, shape and texture

of the meat and personal preference. In order to

calculate the roasting time, weigh the meat or poultry,

including the stuffing, and follow the times given

below.

l Frozen meat must be thoroughly thawed before

cooking. For large joints, it is advisable to thaw

overnight.

l Frozen poultry must be thoroughly thawed before

cooking. The time required depends on the size of the

bird - eg: a large turkey may take up to 48 hours to

thaw.

l When cooking stuffed meat or poultry, calculate the

cooking time from the

total weight of the meat plus the

stuffing.

l Cooking joints in foil, covered roasters, lidded

casseroles, or roasting bags will help to reduce meat

shrinkage, give a more moist result and may reduce fat

splashing. However, a slightly longer cooking times will be

required,

add 5 - 10 minutes per 450g (1lb) to the

calculated cooking time. When using roasting bags do

not exceed the temperatures recommended by the

manufacturer, and do not allow the roasting bag to touch

the sides or top of the oven.

l Use of a trivet with the roasting tin will reduce fat

splashing during open roasting, and will help to keep the

oven interior clean.

l The use of a roasting tin larger then that supplied is not

advised, as this may impair performance and lead to

extended cooking times.

Meat joints (including chicken) should be roasted at

180 - 200˚C Conventional/ 160 - 180˚C Fanned for

20 - 30 mins per 450g/1lb, plus 20 minutes on shelf

position 2.

16

Page 17

Roasting Guide

Roast turkey

l Roasting turkey perfectly involves cooking two different

types of meat - the delicate light breast meat, which

must not be allowed to dry out, and the darker leg meat,

which takes longer to cook.

l The turkey must be roasted long enough for the legs to

cook, so frequent basting is necessary. The breast meat

can be covered once browned.

l The turkey can be open roasted, breast side down, for

half of the cook time, and then turned over for the

remainder of the cooking time.

l If the turkey is stuffed, add 5 minutes per 1lb to the

cooking time.

l If roasting turkey covered with foil, add 5 minutes per

1lb to the cooking time.

l To test if the turkey is cooked, push a fine skewer into

the thickest part of the thigh. If the juices run clear, the

turkey is cooked. If the juices are still pink, the turkey

will need longer cooking. Always make sure that the

turkey is cooked properly before serving.

The

mmaaxxiimmuum

m

size Turkey for this appliance is: 20lbs

approximately 9kgs.

Please do not attempt to roast a Turkey larger than this, as

the results cannot be guaranteed.

TTuurrkkeeyy RRooaassttiinngg ttiimmeess.

.

Most Turkeys are measured by the kilogram. Timing should

be calculated in either of these ways:

40 minutes per 1kg plus 10 minutes per 1/4 kg.

or

20 minutes per 1lb, plus 20 minutes.

Turkey should be roasted at 180 - 200˚C

Conventional/ 160 - 180˚C Fanned for 20 - 30 mins

per 450g/1lb, plus 20 minutes.

17

Page 18

General Baking Guide 18

Trouble-shooting - Fruit Cakes

Trouble-shooting - Sponge Cakes

PROBLEM POSSIBLE CAUSE

Fruit sinking to the bottom Low oven temperature which may cause the cake to

take longer to set, allowing the fruit to sink. Or, too

much liquid, or raising agent. The fruit may not have

been properly washed and dried.

Cake sinking / dipping in the centre Too much raising agent in the mixture. Too hot, or too

cool an oven. Or, not enough liquid or insufficient

creaming.

Surface cracks Too small a tin, or too much mixture in the tin. Too

much raising agent in the mix, plus not enough liquid

or insufficient creaming. The oven may be too hot.

Hard outer crust with a damp patch inside Oven too hot, therefore the cake baked too quickly.

Too much sugar, or insufficient liquid.

Burnt outside Oven temperature too high. Oven too small for the

size of cake. Insufficient protection around the tin.

Cake baked on too high a shelf.

Texture with pronounced holes. Too much raising agent. Flour unevenly mixed.

Texture too close and cake insufficiently risen. Not enough raising agent. Not enough liquid. Too cool

an oven. Insufficient creaming.

Cake crumbles when cut Not enough liquid. Baked for too long. Not enough

sugar. Too much baking agent.

Too dry Over baking. Insufficient egg or liquid. Too much rais-

ing agent.

Domed top Insufficient creaming of mixture. Cake baked on too

high a shelf position, or at too high a temperature.

Paper liners can cause the outer edge not to rise and

the centre to peak.

Hollowed / sunk

en top

Too much r

aising agent. Oven temperature too low, or

incorrect shel

f position. Cake removed from oven

bef

ore it’s cooked. Use of soft tub margarine.

Very pale, but cooked Oven temperature too low. Baked too low in the oven

Ov

erflowing tin

Tin too smal

l for the amount of mixture

Page 19

Cleaning your Gas Hob

Sometimes when a hob is not working well, it is because

it needs cleaning.

Enamel parts

l Use a mild cream cleaner for example ‘Cif’. Stubborn

marks can be removed with a soap filled pad.

Stainless steel surfaces

l Only use a clean cloth wrung out with warm, soapy

water and dried off with a soft cloth. For stubborn

marks use a specialist stainless steel cleaner.

l Do not use steam cleaners.

l Sharp implements and objects can mark the surface of

stainless steel, however they do become less noticeable

in time.

Cast iron parts

l Ensure the parts have fully cooled and scrape off any

stubborn marks, and bits of food with a plastic, or

wooden cooking implement. Rinse in warm soapy

water and dry with a tea towel.

l Do not clean in a dishwasher.

l If you notice any rusting on your griddle, or

pansupports, simply clean in warm soapy water, then

re-season.

Burner caps and heads

The slots in the burner head where the flames burn

should be cleared of deposits.

l Clean with a nylon brush, rinse and then dry

thoroughly. There may be brownish coloured markings

on your burners, these are carbon deposits or fat stains

and can be removed using a soap filled pad.

l Do not put burners in the dishwasher or soak them.

Using dishwasher powders, washing up liquids and

caustic pastes can damage the burners.

l Burner caps and heads must be repositioned correctly

so that they sit squarely on to the hob as shown on the

the left.

l This is particularly important with stainless steel models

as failure to reposition the caps correctly may result in

discolouration of the stainless steel around the burners.

Painted & Plastic parts

l Only use a clean cloth wrung out in hot soapy water.

19

Baby oil can be used to

r

estore stainless steel

finishes - but only use a

few drops. Don’t use

cooking oils as they can

contain salts which will

damage the metal.

Always allow your

appliance to cool

down, and switch off

the electricity before

you clean any part of

it.

!!!

i

Don’t use:

undiluted bleaches,

products containing

chlorides, wire wool or

abrasive cleaners on

aluminium, stainless

steel, or plasitic/painted

parts they can damage

the appliance. Nylon

pads can also be

unsuitable

i

incorrect

burner cap not central

incorrect

angled

correct

parallel

burner cap

burner head

Page 20

Cleaning your Cavities

Cleaning the oven cavities

l Some foods can cause fat to spit, especially if you have

open roasted, this leaves the inside of the cavity

greasy.

l It is important to clean the oven cavity as a build up of

fat can damage the appliance and may invalidate your

guarantee.

Chrome plated parts.

l Use a moist soap filled pad, or place in a dishwasher.

l Shelf runners can be removed to enable you to clean

then thoroughly. Make sure they are cool to touch and

then grasp the runners and slide out of their hanging

holes.

Vitreous enamel surfaces

l The enamel can be cleaned by wiping the surfaces

with a clean cloth which has been wrung out in hot,

soapy water.

l Stubborn marks can be cleaned using a moistened

soap filled pad, or a mild cream cleaner.

l Rinse well, and allow to dry before use.

20

Pull out to clean

Always allow your

appliance to cool

down, and switch off

the electricity before

you clean any part of

it.

!!!

Don’t use:

Caustic or abrasive

cleaners, bleaches,

coarse wire wool or

hard impliments,

these will damage

your appliance.

i

Using a trivet while

roasting meat may help

to reduce fat splashes.

i

Page 21

Baby oil can be used to

restore stainless steel

finishes - but only use a

few drops. Don’t use

cooking oils as they can

contain salts which will

damage the metal.

Take extra care when

cleaning over symbols

on fascia panels,

excessive cleaning can

lead to the symbols

fading.

Always allow your

appliance to cool

down, and switch off

the electricity before

you clean any part of

it.

Cleaning your Appliance

Painted & Plastic parts

l Only use a clean cloth wrung out in hot soapy water.

l Do not use abrasive cleaners, such as “Cif”, wire or nylon

cleaning pads on these parts.

Stainless steel & Aluminium surfaces

l Only use a clean cloth wrung out in hot soapy water, and

dry with a soft cloth.

l Stubborn marks can be removed using a stainless steel

cleaner. Supplies can be purchased from the Customer

Care Centre.

l Sharp objects can mark the surface of stainless steel, but

will become less noticeable with time.

l Wipe any spillage immediately, taking care to avoid burn-

ing your hands.

l Some foods are corrosive eg; vinegar, fruit juices and

especially sal

t - they can mark or damage the metal if

they are left on the surface.

Enamel surfaces & parts

l Clean with warm, soapy water and a clean cloth.

l Dry with a soft clean towel or cloth.

l Do not use steam cleaners.

Glass parts

l Only use a clean cloth wrung out in hot soapy water, or

a specialist glass cleaner.

l Rinse away any excess cleaner and dry with a soft cloth.

l Do not use abrasives or polishes as they will scratch and

damage the glass.

l The inner door glass panel can be removed for cleaning

but it must be replaced the right way up. If there is any

writing on the glass, you must be able to read it clearly

when the cavity doors are open.

l Always make sure that the glass is pushed fully into the

Stop position.

l To remove the glass panel, open the door wide, hold the

top and bottom edges and slide out.

l

WWaarrnniinng

g

:

Do not

operate the appliance without the glass

panel correctly fitted.

21

!!!

i

i

Don’t use:

undiluted bleaches,

products containing

chlorides or abrasive

cleaners on aluminium

or stainless steel, they

can damage the

appliance.

i

Glass door panels

For your safety, glass door

panels are made of toughened

glass. This ensures that, in

the unlikely event that a panel

breaks, it does so into small

fragments to minimise the risk

of injury.

Please take care when

handling, using or cleaning all

glass panels, as any damage

to the surfaces or edges may

result in the glass breaking

without warning or apparent

cause at a later date.

Should an

y glass panel be

damaged, we strongly

recommend that it is replaced

immediately

.

Page 22

Cook Shop

Product

description

Product

code

Quantity Where used

Rectangular

carbon filters

082612620 2 Hoods

Round carbon

filters

082611571 1 Hoods

Ceramic hob

scraper kit

082606781 1 All ceramic glass

hobs including

induction.

Ceramic hob

cleaner and

conditioner

082606780 1 All ceramic glass

hobs including

induction

Sealed hotplate

conditioner

082606783 1 All sealed / solid

plate hobs.

Stainless steel

cleaner

082606764 1 All stainless steel

parts

Oven cleaner

spray

082606786 1 All cookers, inside

cavities and on

glass.

Multi-purpose

kitchen

cleaner

082606782 1 General kitchen

cleaner.

E-cloth 082813300 1 All cookers, for

cleaning glass and

stainless steel

To order or enquire about any

of these products, please call

the Spares Sales team on:

0870 458 9961.

22

Page 23

Before you call. .

Problem? Advice

The ignition won’t work.

(Gas and dual fuel models)

l Check ther

e is a spark when the

igni

tion button is depressed. If

there is no spark, check the

electrici

ty supply is switched on at

the sock

et.

l Check that the gas supply is

switched on.

l Try another appliance in the

socket, if that works replace the 3

amp fuse in the cooker plug.

There’s condensation on the

doors.

Condensation is caused by hot,

moist air meeting a cooler surface

(i.e. the oven door). You cannot

always prevent it, but you can

minimise it when it happens by

doing the following:

l Pre-heat the oven at a high

temperature before putting food in

the oven, and cover the food you

are cooking wherever possible.

l Whenever you can, cook wet

foods at higher temperatures.

l Don’t leave food in the oven to

cool down.

Automatic cooking will normally

produce condensation when the

oven is cooling down with food

inside.

There’s been a power failure

and the oven won’t work.

(models with clocks and

automatic programmers)

l Switch off the electricity supply.

l When the power returns - re-set

the programmer/Clock to the

correct time of day.

This will allow you to use your

appliance.

23

Page 24

No. of

lamps

Bulb

Location

Oven

type

Instruction for

changing the bulb

2

(@25W)

side All Wait until the oven is cool,

then remove the oven

shelves.

Grasp the lens cover on the

light fitting and pull it away

from the side of the oven.

Unscrew the bulb.

1

(@25W)

rear Fanned /

Multifunction

Wait until the oven is cool,

then remove the shelves.

The oven light is at the rear

of the oven cavity.

Remove the loose oven back

- unscrew the 4 securing

screws (one at each corner).

Unscrew the lens cover (turn

anticlockwise). Unscrew the

bulb and replace. Replace

lens cover and replace oven

back.

1

(@25W)

r

ear

Con

ventionalWait until the oven is cool,

then remove the oven

shelves.

The ov

en light is at the rear

of the o

ven cavity.

Unscrew the lens cover (turn

anticlockwise). Unscrew the

bulb and r

eplace. R

eplace

lens cover.

Changing Light Bulbs

Warning: There is a risk of electric shock, so always

make sure you have turned off and unplugged your

appliance.

Not all appliances have the same number and type of

bulbs. Before replacing your bulb, open the top/main

oven door and see which type you have. Then use the

table to help you change your bulb correctly.

Please remember that bulbs are not covered by

your warranty.

Bulbs can be purchased from hardware stores (always

take the old bulb with you).

24

There is no need to remove

the oven back on the 90DF

model.

Page 25

Installing Your Cooker 25

Clearances

This cooker may be fitted flush to the base units of your

kitchen.

l No shelf, overhang, cupboard, or cooker hood should

be less than 650mm above the hob top, but please

check this with the hood manufacturers instructions.

l If your appliance has a side opening door, we

recommend a side clearance of 60mm to allow the

oven door to fully open.

l The cooker must have a side clearance above hob level

of 90mm up to a height of 400mm.

l The important dimensions are those around the

appliance.

650mm

minimum

400mm

clearance

Flush fit to

base units

Flush fit to

base units

90

mm

90

mm

For all appliance sizes:

700mm

800mm

900mm

1000mm

1100mm

1200mm

Page 26

Installing Your Cooker

The information below is crucial to installing this appliance

correctly and safely.

Where standards have been revised - always use the most

recent edition.

Failure to install appliances correctly is dangerous

and could lead to prosecution.

Ventilation Requirements

The room containing the appliance should have an air

supply in accordance with BS 5440:Part 2.

l All rooms require an openable window, or equivalent,

and some will require a permanent vent as well.

l For room volumes up to 5m

3

an air vent of 100cm3is

required.

l If the room has a door which opens directly to the

outside, or exceeds 10m3- no air vent is required.

l For room volumes between 5m

3

and 10m3and air vent

of 50cm2is required.

l If there are other fuel burning appliances in the same

room, BS 5440:Part 2 should be consulted to determine

the air vent requirements.

l This appliance must not be fitted into a bed sitting room

of less than 20m3or into a bath or shower room.

Windows and vents should not be blocked or removed

without first consulting a competent engineer.

LPG only - do not install this appliance below ground

level. This does not preclude installation into rooms which

are basements with respect to one side of the building, but

open to ground level on the opposite side

.

26

Page 27

Installing Your Cooker

The information below is crucial to installing this appliance

correctly and safely.

Failure to install appliances correctly is dangerous

and could lead to prosecution.

UK Regulations & Standards

always refer to the most recent issue of the standards

l Gas Safety Regulations.

l Building Regulations - issued by the DEFRA.

l Building Standards (Scotland) (Consolidated) - issued by

the Scottish Development Department.

l I.E.E. Wiring Regulations.

l Electricity at Work Regulations.

l BS 6172 Installation of Domestic Gas Cooking. For LP

Gas, refer to BS 5482 Part 1, Part 2 or Part 3 as

relevant.

l Installation and Servicing Instructions for this appliance.

For installation in countries other than the UK, the appliance

must be connected in accordance with all local gas and

electrical regulations.

In the Republic of Ireland installers should refer to IS 813

Domestic Gas Appliances.

27

Page 28

Fitting the plinth (if applicable)

l Make sure the appliance is raised to a height of 915mm

or above before beginning.

If the appliance is below

915mm - you can only fit the plinth cover labelled

X

X

.

You can adjust the height using the feet (1) of the

appliance.

If your appliance has a storage drawer at the bottom,

you access the required holes through the base of the

drawer after lifting the mat.

l Open the appliance doors, and loosen screw A located

on bracket (2). Do not remove this screw entirely.

l Insert screw B, through slot (3) and screw into the small

hole at the bottom of bracket (2).

Make sure that the plinth cover is flush to the appliance,

but not over tightened.

Fitting the splashback (if applicable)

l Loosley fit screw A and nut B into hole 1 at both ends of

the rear surface of the appliance.

l Locate fitted screw A through the slots in both of the

metal splashback plates.

l Tighten screw A and nut B.

l Now locate and tighten screw C and nut D through hole

(2) at both ends of the rear surface of the appliance.

Make sure that the splashback is securely attached, but

avoid over tightening.

Fitting the towel rail (if applicable)

l On the towel rail there are two hole, top (A) and bottom

(B), these holes have corresponding holes on the fascia

at each end.

l The scr

ew f

or the top hole (A), must be screwed into

the supplied adaptor, whereas the remaining screw just

goes thr

ough the bot

tom hole (B). B

oth scr

ews ar

e M6

scr

ews. Using the al

len key provided, tighten the screws

making sure that the towel rail is flush to the fascia,

but not over tightened.

Installing Your Cooker 28

B

A

(1)

(2)

(3)

X

Y

Door

Plinth cover

Oven cavity

B

(1)

A

D

C

(2)

A

B

Page 29

Stabilising and Securing

Your cooker may come with a stability chain, if it does not

we recommend that you buy a stability bracket from your

local supplier, this will keep the cooker from moving and

will prevent damage to the flexible hosing at the back of

the cooker.

Your stability chain

Your cooker must be secured to a wall or a solid partition

behind the cooker.

Your stability bracket

You can buy a stability bracket from your supplier and it

can fitted as follows:

l Place the cooker in position and draw a pencil line level

with the front edge.

l Remove the cooker and mark off 450mm from the

pencil line to locate the front edge of the lower

bracket.

l Fix the bracket to the floor. Measure from floor level to

engagement edge in the back of the cooker and add

3mm.

l Assemble the underside of the top part of the bracket

to this height.

l See the drawings for the location of the bracket and

the recommended positioning.

Levelling

Once your cooker is secure:

Place a spirit level onto a baking tray, on an oven shelf.

These cookers are fitted with adjustable feet which will

allow you to adjust the height of the appliance until it is

level. The adjustable feet are at the rear of the cooker.

Installing Your Cooker 29

Stability Hook

(not supplied)

Rear of cooker

Firmly fix chain

to cooker rear

Stability chain to

be as short as

possible

Cooker stability chain not designed

with bracket engagement slot

Stability bracket

1 Pencil line

on floor

2 Centre

of range

3

450

mm

Front edge for

lower bracket

4

5 Underside of top bracket

slots into engagement

edge in back of cooker.

Rear wall

Gas inlet pipe

Centre of appliance

Model viewed from rear

Locate stability bracket here

X

Rear

plinths

Back panels

Rear feet and

wheels

Page 30

Installing Your Cooker

Connecting the electricity supply

Warning: This appliance must be earthed!

l This appliance must be fitted using a double pole unit

of 30 ampere minimum capacity with 3mm minimum

contact at all poles.

l Access to the mains terminal is gained by opening the

terminal block cover at the rear of the appliance - use

a flat bladed screw driver for this.

l Connection should be made with a 6.0mm

2

twin and

earth cable.

l First strip the wires. then push the cable through the

cable clamping the terminal block cover.

l Connect the cable to the terminal block and tighten the

cable clamp screw - see diagram.

l Close the terminal box, ensuring that the cover is

engaged on the locking tabs.

l Sufficient cable should be used to allow the cooker to

be pulled out, but must hang clear of the floor so it

does not become twisted or trapped when the cooker

is pushed back.

Please ensure that the user has this copy of the

handbook, and the appliance is in place. Thank you.

1

2

3

4

5

Cable

clamp

Earth

(Green / Yellow

or sleeving)

Live

(Red or Brown)

Neutral

(Black or Blue)

30

Page 31

Installing Your Cooker

Connecting to the gas supply

The inlet to the appliance is ISO 7 - Rp

1

⁄2

” internal thread

situated towards the top right corner of the rear.

Fit the bayonet connection. This should be located so as

to ensure that the flexible hose does not kink.

Use a 900mm - 1125mm length of flexible hose.

Ensure that all pipe work is of the correct rating.

Natural Gas - Flexible connections should comply with

BS 669. Parts of the appliance likely to come into contact

with a flexible connector have a temperature of less than

70˙C.

LP Gas - For flexible connections use a bayonet type

hose, suitable for use on LP Gas up to 50mbar pressure

rise and 70˙C temperature rise. The flexible hose should

be coloured black with a red stripe, band or label. If in

doubt, contact your supplier.

After installation make sure all connections are gas

sound.

Commissioning

Pressure settings:

G20 Natural Gas @ 20mbar

G30 Butane @ 28-30mbar

G31 Propane @ 37mbar

Hob

Turn on gas supply and check for soundness at the hotplate injector. Light two burners and check that the pressure is correct.

31

Page 32

Technical Data - Notes 32

Type of gas:

Natural Gas I2H

Natural Gas II2H3+*

LP Gas I3+

Please see your data badge for specified gas

type.

* Can be converted from Natural gas to LP Gas

Never attempt to convert an appliance unless the data badge states that you can.

Burner Aeration:

Fixed

Pressure setting:

G20 Natural Gas @ 20mbar

G30 Butane @ 28-30mbar

G31 Propane @ 37mbar

Electrical supply:

220 - 240V ~ 50Hz

Countries of destination:

GB

!!!

Page 33

Technical Data - Notes 33

Fuel Type Hotplate Burner /

Element

Nominal Rate

Qn

Butane

g/h

Propane

g/h

Injectors

used

Natural Gas

Hob - small

Hob - medium

Hob - Large

Hob - wok

Total heat input

l

5 burners

1.0kW

2.0kW

3.0kW

3.5kW

11.5kW

-

-

-

-

-

-

-

-

-

-

77

104

129

121 & 63

LP Gas

Hob - small

Hob - medium

Hob - Large

Hob - wok

Total heat input

l

5 burners

1.0kW

2.0kW

3.0kW

3.5kW

11.5kW

73

145

218

254

72

143

215

250

50

70

87

87 & 35

Fuel Type Dual Variable

grill

Multifunction

oven

Fanned oven

Electric

@ 230V

1.6 - 2.5kW 2.3kW 2.3kW

Slow cook

oven

(if fitted)

Oven lamps Maximum load

0.16kW 25W each 7200W

Page 34

Service Record 34

Date of purchase Installer stamp / Printed name Date of installation

Place of purchase:

Date Part(s) replaced Engineers Stamp/

Printed Name

Model Number

Serial Number

Please record your model number and serial number in the space below.

Where are my model and serial numbers?

Freestanding HL appliances: base of storage drawer

Freestanding appliances: front frame near oven cavity

Built in oven: front frame near oven cavity

Hobs: base plate of the hob

Having these numbers to hand will help us to help you, quickly and more efficiently.

When contacting us, please use the Customer Care number on the back cover of this

handbook.

Page 35

If something doesn’t seem to work. . .

If there is something about your appliance which you do not undertand and you live in

the UK you can phone our help line during normal office hours on:

0113 279 3520

If you need a service engineer please phone the number on your sale receipt.

Calls are charged at standard rates.

We apologise for any inconvenience caused by minor inconsistencies in these instruc-

tions, which may occur as a result of product improvement and development.

08 27361 00 © 07.2007

®

Prestige

®

is a registered trademark of Meyer Intellectual Properties Limited and is sold

pursuant to l

icense

Loading...

Loading...