Premium PIAW12167B, PIAW12166A, PIA24265B, PIA24264A, PIAW9166A User Manual

...

Table of Contents |

Page |

1. Safety Precautions |

......................................................................................... 1 |

1.In case of Accidents or Emergency

2.Pre-Installation and Installation

3.Operation and Maintenance

2. Specifications................................................................................................. |

3 |

1.Model Reference

2.Electrical Wiring Diagrams

3. Product Features............................................................................................ |

9 |

1.Operation Modes and Functions

4. Maintenance and Disassembly..................................................................... |

17 |

1.Maintenance

2.Disassembly

5. Troubleshooting............................................................................................ |

57 |

1.Safety Caution

2.General Troubleshooting

3.Error Diagnosis and Troubleshooting Without Error Code

4.Quick Maintenance by Error Code

5.Troubleshooting by Error Code

Appendix.............................................................................................................. |

86 |

i)Temperature Sensor Resistance Value Table for T1,T2,T3 and T4 (°C – K)

ii)Temperature Sensor Resistance Value Table for TP (°C – K)

iii)T(°F)

iV) |

Pressure On Service Port |

|

|

|

|

Safety Precautions

|

Contents |

|

1. |

In Case of Accidents or Emergency....................................................................... |

2 |

2. |

Pre-Installation....................................................................................................... |

2 |

3. |

Operation and Maintenance................................................................................. |

2 |

Safety

Precautions

To prevent personal injury, or property or unit damage, adhere to all precautionary measures and instructions outlined in this manual. Before servicing a unit, refer to this service manual and its relevant sections.

Failure to adhere to all precautionary measures listed in this section may result in personal injury, damage to the unit or to property, or in extreme cases, death.

WARNING indicates a potentially hazardous situation which if not avoided could result in serious personal injury, or death.

CAUTION indicates a potentially hazardous situation which if not avoided could result in minor or moderate personal injury, or unit damage.

1. In case of Accidents or Emergency

WARNING

WARNING

•• If a gas leak is suspected, immediately turn off the gas and ventilate the area if a gas leak is suspected before turning the unit on.

•• If strange sounds or smoke is detected from the unit, turn the breaker off and disconnect the power supply cable.

•• If the unit comes into contact with liquid, contact an authorized service center.

•• If liquid from the batteries makes contact with skin or clothing, immediately rinse or wash the area well with clean water.

•• Do not insert hands or other objects into the air inlet or outlet while the unit is plugged in.

•• Do not operate the unit with wet hands.

•• Do not use a remote controller that has previously been exposed to battery damage or battery leakage.

CAUTION

CAUTION

•• Clean and ventilate the unit at regular intervals when operating it near a stove or near similar devices.

•• Do not use the unit during severe weather conditions. If possible, remove the product from the window before such occurrences.

2. Pre-Installation and Installation

WARNING

WARNING

•• Use this unit only on a dedicated circuit.

•• Damage to the installation area could cause the unit to fall, potentially resulting in personal injury, property damage, or product failure.

•• Only qualified personnel should disassemble, install, remove, or repair the unit.

•• Only a qualified electrician should perform electrical work. For more information, contact your dealer, seller, or an authorized Midea service center.

CAUTION

CAUTION

•• While unpacking be careful of sharp edges around the unit as well as the edges of the fins on the condenser and evaporator.

3. Operation and Maintenance

WARNING

WARNING

•• Do not use defective or under-rated circuit breakers.

•• Ensure the unit is properly grounded and that a dedicated circuit and breaker are installed.

•• Do not modify or extend the power cable. Ensure the power cable is secure and not damaged during operation.

•• Do not unplug the power supply plug during operation.

•• Do not store or use flammable materials near the unit.

•• Do not open the inlet grill of the unit during operation.

•• Do not touch the electrostatic filter if the unit is equipped with one.

•• Do not block the inlet or outlet of air flow to the unit.

•• Do not use harsh detergents, solvents, or similar items to clean the unit. Use a soft cloth for cleaning.

•• Do not touch the metal parts of the unit when removing the air filter as they are very sharp.

•• Do not step on or place anything on the unit or outdoor units.

•• Do not drink water drained from the unit

•• Avoid direct skin contact with water drained from the unit.

•• Use a firm stool or step ladder according to manufacturer procedures when cleaning or maintaining the unit.

CAUTION

CAUTION

•• Do not install or operate the unit for an extended period of time in areas of high humidity or in an environment directly exposing it to sea wind or salt spray.

•• Do not install the unit on a defective or damaged installation stand, or in an unsecure location.

•• Ensure the unit is installed at a level position

•• Do not install the unit where noise or air discharge created by the outdoor unit will negatively impact the environment or nearby residences.

•• Do not expose skin directly to the air discharged by the unit for prolonged periods of time.

•• Ensure the unit operates in areas water or other liquids.

•• Ensure the drain hose is installed correctly to ensure proper water drainage.

•• When lifting or transporting the unit, it is recommended that two or more people are used for this task.

•• When the unit is not to be used for an extended time, disconnect the power supply or turn off the breaker.

Page 2

Specifications

Contents

1. |

Model Reference.................................................................................................... |

4 |

|

2. |

Electrical Wiring Diagrams.................................................................................... |

5 |

|

|

2.1 |

Indoor Unit.................................................................................................... |

5 |

|

2.2 |

Outdoor Unit................................................................................................. |

7 |

Specifications

1. Model Reference

Refer to the following table to determine the specific indoor and outdoor unit model number of your purchased equipment.

Indoor Unit Model |

Outdoor Unit Model |

Capacity (Btu) |

Power Supply |

|

|

|

|

|

|

PIAW9166A |

PIAW9167B |

9K |

115V~, 60Hz, 1Phase |

|

|

|

|

||

PIAW12166A |

PIAW12167B |

12K |

||

|

||||

|

|

|

|

|

PIA24264A |

PIA24265B |

22K |

208/230V~, 60Hz, 1Phase |

|

|

|

|

|

Page 4

2. Electrical Wiring Diagrams

2.1Indoor unit

Abbreviation |

Paraphrase |

|

|

Y/G |

Yellow-Green Conductor |

|

|

ION |

Positive and Negative Ion Generator |

|

|

CAP |

Capacitor |

|

|

PLASMA |

Electronic Dust Collector |

|

|

L |

LIVE |

|

|

N |

NEUTRAL |

|

|

Heater |

The Electric Heating Belt of Indoor Unit |

|

|

T1 |

Indoor Room Temperature |

|

|

T2 |

Coil Temperature of Indoor Heat Exchanger Middle |

|

|

PIAW9166A, PIAW12166A: |

|

|

|

|

|

|

|

|

|

|

|

16022000020314 |

|

|

|

|

|

M |

M |

M |

|

|

|

|

|

|

|

|

|

|

3 |

~ |

3 |

|

|

|

|

|

|

|

|

|

|

CN12_1 |

|

|

|

|

|

RED CN13_1 |

CN12_2 |

|

|

2 |

|

|

BLACK |

CN13_2 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

1 |

3 |

|

|

|

|

|

|

|

|

INDOOR WIRING DIAGRAM |

|

||

|

|

|

|

|

|

Page 5 |

Specifications

PIA24264A

Specifications

|

|

SWING |

|

|

MOTOR |

Y/ G |

M |

2 |

|

~ |

3 |

|

|

MI RCO SWI TCH |

|

|

T2_pi pe T1_r oom |

Page 6

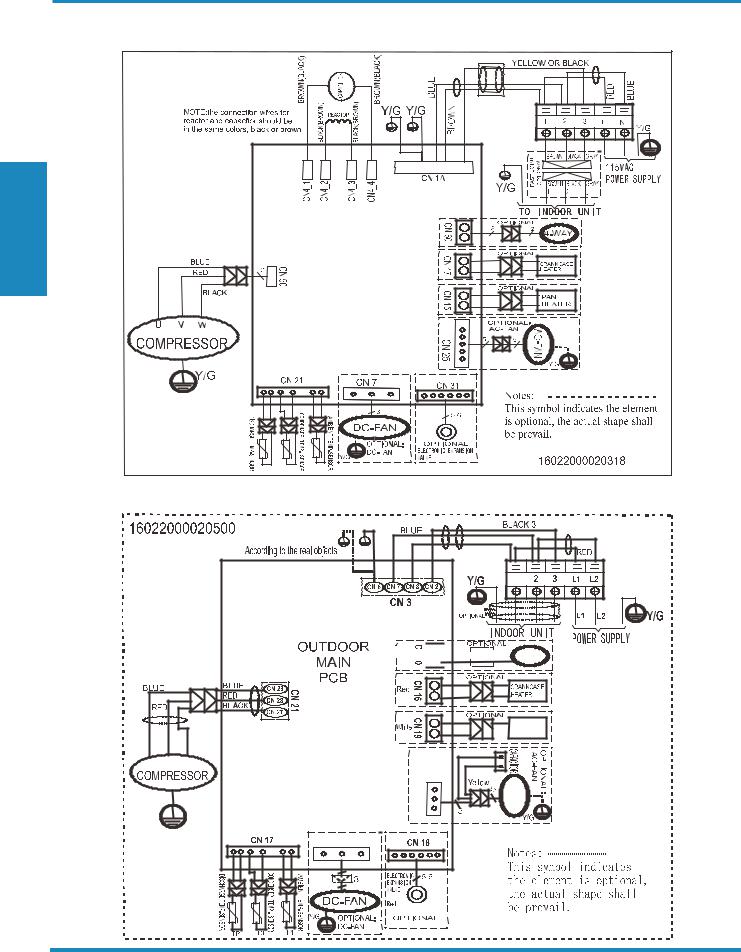

2.2 Outdoor Unit

Abbreviation |

Paraphrase |

|

|

4-WAY |

Gas Valve Assembly/4-WAY VALVE |

|

|

AC-FAN |

Alternating Current FAN |

|

|

DC-FAN |

Direct Current FAN |

|

|

CT1 |

AC Current Detector |

|

|

COMP |

Compressor |

|

|

L-PRO |

Low Pressure Switch |

|

|

H-PRO |

High Pressure Switch |

|

|

T3 |

Coil Temperature of Condenser |

|

|

T4 |

Outdoor Ambient Temperature |

|

|

TH |

Compressor Suction Temperature |

|

|

TP |

Compressor Discharge Temperature |

|

|

EEV |

Electronic expansion valve |

|

|

Specifications

Page 7

PIAW9167B. PIAW12167B:

Specifications

PIA24265B:

Y/G Y/G |

BLUE L2 |

|

BROWN 1 |

S |

1 |

|

|

|

BLACK |

U |

V |

W |

4-WAY

4-WAY

PAN

HEATER

HEATER

5 CN |

FAN -AC |

Y/G |

CN 414 |

Page 8

Product Features

Contents

1. |

Operation Modes and Functions......................................................................... |

10 |

|

|

1.1 |

Abbreviation................................................................................................ |

10 |

|

1.2 |

Safety Features............................................................................................. |

10 |

|

1.3 |

Display Function........................................................................................... |

11 |

|

1.4 |

Fan Mode.................................................................................................... |

11 |

|

1.5 |

Cooling Mode.............................................................................................. |

11 |

|

1.6 |

Heating Mode.............................................................................................. |

11 |

|

1.7 |

Auto-mode.................................................................................................. |

12 |

|

1.8 |

Drying Mode................................................................................................ |

12 |

|

1.9 |

Forced Operation Function........................................................................... |

12 |

|

1.10 |

Timer function............................................................................................. |

12 |

|

1.11 |

Sleep function.............................................................................................. |

13 |

|

1.12 |

Auto-Restart Function.................................................................................. |

13 |

|

1.13 |

Refrigerant Leakage Detection..................................................................... |

13 |

|

1.14 |

Louver Position Memory Function................................................................. |

13 |

|

1.15 |

8°C Heating(Optional)................................................................................. |

13 |

|

1.16 |

Self Clean(Optional).................................................................................... |

13 |

|

1.17 |

Follow Me(Optional).................................................................................... |

13 |

|

1.18 |

Silence Optional)....................................................................................... |

13 |

|

1.19 |

Information Inquiry...................................................................................... |

14 |

Features Product

1. Operation Modes and Functions

1.1Abbreviation

Unit element abbreviations

Abbreviation |

Element |

T1 |

Indoor room temperature |

T2 |

Coil temperature of evaporator |

T3 |

Coil temperature of condenser |

T4 |

Outdoor ambient temperature |

TS |

Set temperature |

TP |

Compressor discharge temperature |

1.2Safety Features

Compressor three-minute delay at restart

Compressor functions are delayed for up to one minute upon the first startup of the unit, and are delayed for up to three minutes upon subsequent unit restarts.

Temperature protection of compressor top

The unit will stop working when the compressor top temp. protector cut off, and will restart after the compressor top temp. protector restart.

Automatic shutoff based on discharge temperature

If the compressor discharge temperature exceeds 115°C for five seconds, the compressor ceases operation.

Automatic shutoff based on fan speed

If the indoor fan speed registers below 300RPM for an extended period of time, the unit ceases operation and the corresponding error code is displayed on the indoor unit.

Inverter module protection

The inverter module has an automatic shutoff mechanism based on the unit’s current, voltage, and temperature.

If automatic shutoff is initiated, the corresponding error code is displayed on the indoor unit and the unit ceases operation.

Indoor fan delayed operation

•When the unit starts, the louver is automatically activated and the indoor fan will operate after a period of 7 seconds.

•If the unit is in heating mode, the indoor fan is regulated by the anti-cold wind function.

Compressor preheating

Preheating is automatically activated when T4 sensor is

lower than 3°C.

Sensor redundancy and automatic shutoff

•If one temperature sensor malfunctions, the air conditioner continues operation and displays the corresponding error code, allowing for emergency use.

•When more than one temperature sensor is malfunctioning, the air conditioner ceases operation.

Refrigerant leakage detection

This function is active only when cooling mode is selected. It will detect if the compressor is being damaged by refrigerant leakage or by compressor overload. This is measured using the coil temperature of evaporator T2 when the compressor is in operation.

Zero crossing detection error protection

If AC detects time interval is not correct for continuous 240s, the unit will stop and the LED will display the failure. The correct zero crossing signal time interval should be between 6-13ms.

Page 10

1.3Display Function

Unit display functions

Function |

Display |

|

|||||||

Temperature |

Set temperature value |

|

|||||||

Temperature |

|

|

|

|

|

|

|

|

|

(fan and Drying |

Room temperature |

|

|||||||

mode) |

|

|

|

|

|

|

|

|

|

Activation of Timer |

|

|

|

|

|

|

|

|

|

ON, Fresh, Swing, |

|

|

(3s) |

|

|||||

Turbo, or Silent |

|

|

|

||||||

|

|

|

|

|

|

|

|

||

Cancellation of |

|

|

|

|

|

|

|

|

|

Timer OFF, Fresh, |

|

|

(3s) |

|

|||||

Swing, Turbo, or |

|

|

|

||||||

Silent |

|

|

|

|

|

|

|

|

|

Defrost |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warming in heating |

|

|

|

|

|

|

|

|

|

mode |

|

|

|

|

|

|

|

|

|

Self-clean (available |

|

|

|

|

|

|

|

|

|

on select units only) |

|

|

|

|

|

|

|

|

|

Heating in room |

|

|

|

|

|

|

|

|

|

temperature |

|

|

|

|

|

|

|

|

|

under 8°C |

|

|

|

|

|

|

|

|

|

ECO function |

|

|

|

|

|

|

set temperature |

||

|

|

|

|

|

|

||||

(available on select |

gradually illuminates to |

in |

|||||||

units only) |

|||||||||

one second interval |

|

||||||||

|

|

||||||||

1.5Cooling Mode

1.5.1Compressor Control

∆T is the programmed parameter of temperature compensation.

•When T1-Ts < ∆T-2 , the compressor ceases operation.

•When T1-Ts > ∆T+3 , the compressor continues operation.

•When the AC is operating in mute mode, the compressor operates at a low frequency.

•When the current exceeds the preset value, the current protection function activates and the compressor ceases operation.

1.5.2Indoor Fan Control

•In cooling mode, the indoor fan operates continuously. The fan speed can be set to high, medium, low, or auto.

•If the compressor ceases operations when the configured temperature is reached, the indoor fan motor operates at the minimum or configured speed.

1.5.3Outdoor Fan Control

•The outdoor unit will be run at different fan speed according to T4.

•For different outdoor units, the fan speeds are different.

1.5.4Condenser Temperature Protection

When condenser temperature is more than setting value, the compressor will stop.

1.5.5Evaporator Temperature Protection

When evaporator temperature drops below a configured value, the compressor and outdoor fan ceases operations.

Product Features

1.4Fan Mode

When fan mode is activated:

•The outdoor fan and compressor are stopped.

•Temperature control is disabled and no temperature setting is displayed.

•The indoor fan speed can be set to high, med, low, or auto.

•The louver operations are identical to those in cooling mode.

•Auto fan: In fan-only mode, AC operates the same as auto fan in cooling mode with the temperature set at 24°C.

1.6Heating Mode

1.6.1Compressor Control

∆T is the programmed parameter of temperature compensation.

•When T1-Ts>-∆T, the compressor ceases operation.

•When T1-TS<-∆T-1.5°C, the compressor continues operation.

•When the AC is operating in mute mode, the compressor operates at a low frequency.

•When the current exceeds the preset value, the current protection function activates and the compressor ceases operation.

Page 11

Features Product

1.6.2Indoor Fan Control:

•When the compressor is on, the indoor fan can be set to high/med/low/auto.

•When indoor unit coil temperature is low, the anti-cold air function will start and indoor fan motor will run

at low speed, the speed can’t be changed ,when the temperature is lower than setting value, the indoor fan motor will stop.

•When the indoor temperature reaches the setting temperature, the compressor will stop, the indoor fan motor will run at the minimum speed or setting speed.(The anti-cold air function is valid).

1.6.3Outdoor Fan Control:

•The outdoor unit will be run at different fan speed according to T4.

•For different outdoor units, the fan speeds are different.

1.6.4Defrosting mode

•The unit enters defrosting mode according to changes in the temperature value of T3 as well as the compressor running time.

•In defrosting mode, the compressor continues to run, the indoor and outdoor motor will cease operation, the defrost light of the indoor unit will turn on, and the “

” symbol is displayed.

” symbol is displayed.

•If any one of the following conditions is satisfied, defrosting ends and the machine switches to normal heating mode:

•T3 rises above TCDE1°C.

•T3 maintained above TCDE2°C for 80 seconds.

•Unit runs for 15 minutes consecutively in defrosting mode.

1.6.5Evaporator Temperature Protection

When the evaporator temperature exceeds a preset protection value, the compressor stops.

1.7Auto-mode

•This mode can be selected with the remote controller and the setting temperature can be changed between 17°C~30°C.

•In auto mode, the machine selects cooling, heating, or fan-only mode on the basis of ∆T (∆T =T1-Ts).

∆T |

Running mode |

∆T>2 |

Cooling |

-2 ≤∆T≤2 |

Fan-only |

∆T<-2 |

Heating* |

Heating*: In auto mode, cooling only models run the fan

•The louver operates same as in relevant mode.

•If the machine switches mode between heating and cooling, the compressor will keep stopping for certain time and then choose mode according to T1-Ts.

•If the setting temperature is modified, the machine will choose running function again.

1.8Drying mode

•Indoor fan speed is fixed at breeze and can’t be changed. The louver angle is the same as in cooling mode.

•All protections are active and the same as that in cooling mode.

1.9Forced operation function

• Forced cooling mode:

The compressor and outdoor fan continue to run and the indoor fan runs at low speed. After running for 30 minutes, the AC will switch to auto mode with a preset temperature of 24°C.

• Forced auto mode:

Forced auto mode operates the same as normal auto mode with a preset temperature of 24°C.

•The unit exits forced operation when it receives the following signals:

•Switch on

•Switch off

•Timer on

•Timer off

•Changes in:

•mode

•fan speed

•sleeping mode

•Follow me

1.10Timer function

•Timing range is 24 hours.

•Timer on. The machine will turn on automatically when reaching the setting time.

•Timer off. The machine will turn off automatically when reaching the setting time.

•Timer on/off. The machine will turn on automatically when reaching the setting “on” time, and then turn off automatically when reaching the setting “off” time.

Page 12

•Timer off/on. The machine will turn off automatically when reaching the setting “off” time, and then turn on automatically when reaching the setting “on” time.

•The timer function will not change the AC current operation mode. Suppose AC is off now, it will not start up firstly after setting the “timer off” function. And when reaching the setting time, the timer LED will be off and the AC running mode has not been changed.

•The setting time is relative time.

•The AC will quit the timer function when it has malfunction

1.11Sleep function

•The sleep function is available in cooling, heating or auto mode.

•Operation process in sleep mode is as follow:

•When cooling, the setting temperature rises 1 (be lower than 30 ) every one hour, 2 hours later the setting temperature stops rising and the indoor fan is fixed at low speed.

•When heating, the setting temperature decreases 1 (be higher than 17 ) every one hour, 2 hours later the setting temperature stops rising and indoor fan is fixed at low speed. (Anti-cold wind function has the priority).

•Operation time in sleep mode is 7 hours. After 7 hours the AC quits this mode and turns off.

•Timer setting is available.

1.12 Auto-Restart function

•The indoor unit has an auto-restart module that allows the unit to restart automatically. The module automatically stores the current settings (not including the swing setting) and, in the case of a sudden power failure, will restore those setting automatically within 3 minutes after power returns.

•If the unit was in forced cooling mode, it will run in this mode for 30 minutes and turn to auto mode with temperature set to 24°C.

•If there is a power failure while the unit is running, the compressor starts 3 minutes after the unit restarts. If the unit was already off before the power failure, the compressor starts 1 minute after the unit restarts.

1.13 Refrigerant Leakage Detection

With this new technology, the display area will show “EC” when the outdoor unit detects refrigerant leakage.

1.14 Louver Position Memory Function

When starting the unit again after shutting down, its louver will restore to the angle originally set by the user, but the precondition is that the angle must be within the allowable range, if it exceeds, it will memorize the maximum angle of the louver. During operation, if the power fails or the end user shuts down the unit in the turbo mode, the louver will restore to the default angle.

1.15 8°C Heating(Optional)

In heating mode, the temperature can be set to as low as 8°C, preventing the indoor area from freezing if unoccupied during severe cold weather.

1.16 Self clean(Optional)

•If you press “Self Clean” when the unit is in cooling or drying mode:

•For cooling models, the indoor unit will run in low fan mode for a certain time, then ceases operation.

•For heat pump models, the indoor unit will run in fan-only mode, then low heat, and finally in fanonly mode.

•Self Clean keeps the indoor unit dry and prevents mold growth.

1.17 Follow me(Optional)

•If you press “Follow Me” on the remote, the indoor unit will beep. This indicates the follow me function is active.

•Once active, the remote control will send a signal every 3 minutes, with no beeps. The unit automatically sets the temperature according to the measurements from the remote control.

•The unit will only change modes if the information from the remote control makes it necessary, not from the unit’s temperature setting.

•If the unit does not receive a signal for 7 minutes or you press “Follow Me,” the function turns off. The unit regulates temperature based on its own sensor and settings.

1.18 Silence (Optional)

Press “Silence” on the remote control to enable the SILENCE function. While this function is active, the compressor frequency is maintained at a lower level than F2. The indoor unit will run at faint breeze, which reduces noise to the lowest possible level.

Product Features

Page 13

1.19 Information Inquiry

•To enter information inquiry status, complete the following procedure within ten seconds:

•Press LED 3 times.

•Press SWING 3 times.

•If you are successful, you will hear beeps for two seconds.

•Use the LED and SWING buttons to cycle through information displayed.

•Pressing LED will display the next code in the sequence. Pressing SWING will show the previous.

•The table next shows information codes. The screen will display this code for two seconds, then the information for 25 seconds.

Features Product

Page 14

Displayed code |

Explanation |

Displayed |

Meaning |

|

Additional Notes |

|

value |

|

|||||

|

|

|

|

|

||

|

|

|

|

|

|

|

T1 |

Room temperature |

|

|

1. |

All displayed temperatures |

|

|

Indoor coil |

|

|

|

use actual values. |

|

|

|

|

|

|

||

T2 |

temperature |

-1F,-1E,-1d,-1c,- |

-25,-24,-23,-22, |

2. |

All temperatures are |

|

|

Outdoor coil |

|

displayed in °C regardless |

|||

|

1b,-1A |

-21,-20 |

|

|||

T3 |

|

of remote used. |

||||

temperature |

|

|

|

|||

|

-19—99 |

-19—99 |

|

|

||

|

|

3. |

T1, T2, T3, T4, and T2B |

|||

T4 |

Ambient |

|||||

|

|

|||||

temperature |

A0,A1,…A9 |

100,101,…109 |

|

display ranges from -25 to |

||

|

|

|||||

|

|

|

|

|

70 °C. TP display ranges |

|

|

Outlet temperature |

b0,b1,…b9 |

110,111,…119 |

|

||

TB |

|

from -20 to 130 °C. |

||||

of indoor coil |

|

|

|

|||

|

c0,c1,…c9 |

120,121,…129 |

4. |

The frequency display |

||

TP |

Discharge |

|||||

|

|

|||||

d0,d1,…d9 |

130,131,…139 |

|

ranges from 0 to 159HZ. |

|||

|

temperature |

|

||||

|

|

|

||||

|

|

|

|

|

||

TH |

|

E0,E1,…E9 |

140,141,…149 |

5. |

If the actual values exceed |

|

Suction temperature |

||||||

|

or fall short of the defined |

|||||

|

|

F0,F1,…F9 |

150,151,…159 |

|

||

|

|

|

||||

FT |

Targeted frequency |

|

range, the values closest |

|||

|

|

|

to the maximum and |

|||

|

|

|

|

|

||

|

|

|

|

|

minimum values will be |

|

FR |

Actual frequency |

|

|

|

||

|

|

|

displayed. |

|||

|

|

0 |

OFF |

N/A |

|

|

IF |

Indoor fan speed |

1,2,3,4 |

Low speed, Medium |

Used for some large capacity |

||

|

speed, High speed, |

motors. |

||||

|

|

|

||||

|

|

|

Turbo. |

|

|

|

|

|

14-FF |

Actual fan speed is |

Used for some small capacity |

||

|

|

|||||

|

|

|

equal to the display |

motors. |

||

|

Outdoor fan speed |

|

value converted to |

The display value is 14-FF |

||

OF |

|

decimal value and |

||||

|

(hexadecimal). The |

|||||

|

|

|

multiplied by 10. This |

|||

|

|

|

corresponding fan speed |

|||

|

|

|

is measured in RPM. |

|||

|

|

|

ranges from 200 to 2550RPM. |

|||

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Actual EXV opening |

|

|

|

|

|

|

value is equal to |

|

|

|

LA |

EXV opening angle |

0-FF |

the display value |

- |

|

|

converted to decimal |

|

|||||

|

|

|

|

|

||

|

|

|

value and then |

|

|

|

|

|

|

multiplied by 2. |

|

|

|

|

|

|

|

|

||

|

|

|

|

If the actual value exceeds |

||

|

Compressor |

|

|

or falls short of the defined |

||

CT |

continuous running |

0-FF |

0-255 minutes |

range, the value closest to the |

||

|

time |

|

|

maximum and minimum will |

||

|

|

|

|

be displayed. |

||

|

|

|

|

|

|

|

|

Causes of |

0-99 |

For a detailed |

- |

|

|

ST |

explanation, contact |

|

||||

compressor stop |

|

|||||

|

|

technical support. |

|

|

||

|

|

|

|

|

||

|

|

|

|

|

|

|

Product Features

Page 15

Features Product

Displayed code |

Explanation |

Displayed |

Meaning |

Additional Notes |

|

value |

|||||

|

|

|

|

||

|

|

|

|

|

|

A0 |

|

|

|

|

|

|

|

|

|

|

|

A1 |

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

0-FF |

|

|

|

4 |

|

|

|

||

|

|

2-28 |

|

|

|

5 |

Reserved |

- |

- |

||

|

5-20 |

||||

6 |

|||||

|

|

|

|||

L |

|

5-25 |

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

U |

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

|

|

|

|

|

|

|

|

Page 16

Maintenance and Disassembly

Contents

1. |

Maintenance |

......................................................................................................... |

18 |

|

|

1.1 |

First Time Installation Check......................................................................... |

18 |

|

|

1.2 |

Refrigerant ....................................................................................Recharge |

20 |

|

|

1.3 |

Re-Installation ............................................................................................. |

21 |

|

|

|

1.3.1 ................................................................................... |

Indoor Unit |

21 |

|

|

1.3.2 ................................................................................ |

Outdoor Unit |

23 |

2. |

Disassembly.......................................................................................................... |

|

25 |

|

|

2.1 |

Indoor ..................................................................................................Unit |

25 |

|

|

2.2 |

Outdoor ...............................................................................................Unit |

41 |

|

1. Maintenance

1.1First Time Installation Check

Air and moisture trapped in the refrigerant system affects the performance of the air conditioner by:

•Increasing pressure in the system.

•Increasing the operating current.

•Decreasing the cooling or heating efficiency.

•Congesting the capillary tubing due to ice build-up in the refrigerant circuit.

•Corroding the refrigerant system.

To prevent air and moisture from affecting the air conditioner’s performance, the indoor unit, as well as the pipes between the indoor and outdoor unit, must be be leak tested and evacuated.

Leak test (soap water method)

Use a soft brush to apply soapy water or a neutral liquid detergent onto the indoor unit connections and outdoor unit connections. If there is gas leakage, bubbles will form on the connection.

|

|

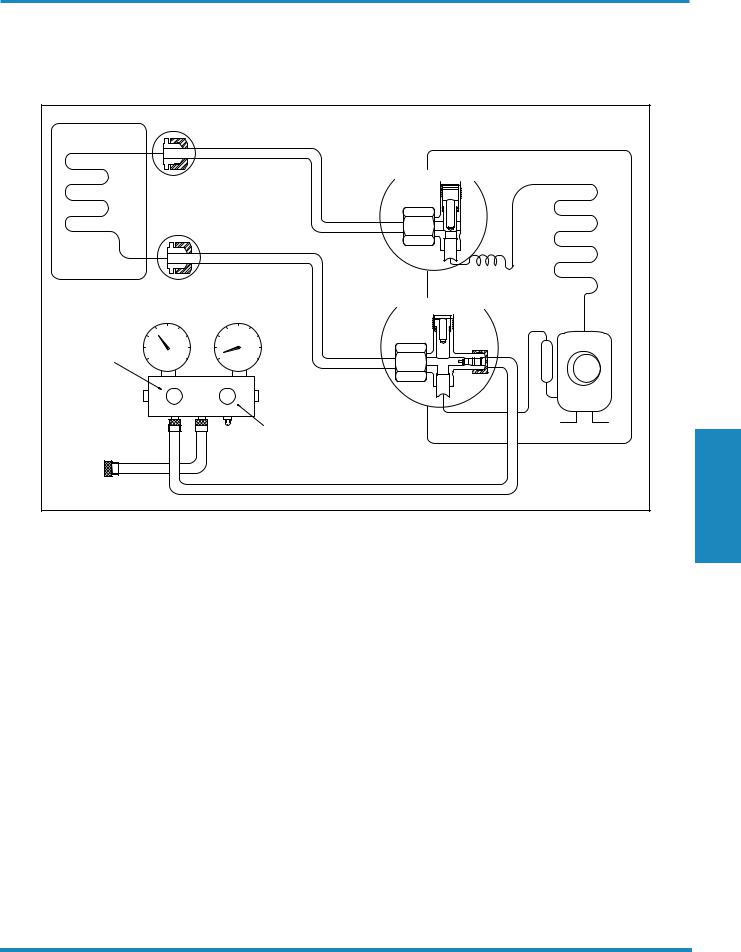

Air purging with vacuum pump |

|

|

|

||

|

|

|

|

|

|

-GY YOJK |

|

Disassembly |

and Maintenance |

|

)USVU[TJ SKZKX3GTOLURJ \GR\K6XKYY[XK |

||||

|

|

|

|

|

MG[MK |

||

|

|

36G |

|

|

|

||

|

|

.GTJRK 2U |

2U |

.O |

.GTJRK .O |

||

<GI[[S |

)NGXMK NUYK |

|

)NGXMK NUYK |

||||

|

|

V[SV |

|

|

|

|

|

|

|

<GI[[S |

|

|

|

|

|

|

|

V[SV |

|

|

|

|

|

:NXKK ]G_ \)RGRUYK\K

)RUYK

Page 18

Procedure:

1.Tighten the flare nuts of the indoor and outdoor units, and confirm that both the 2- and 3-way valves are closed.

2.Connect the charge hose with the push pin of Handle Lo to the gas service port of the 3-way valve.

3.Connect the charge hose of Handle Hi connection to the vacuum pump.

4.Fully open the Handle Lo manifold valve.

5.Using the vacuum pump, evacuate the system for 30 minutes.

a.Check whether the compound meter indicates -0.1 MPa (14.5 Psi).

•If the meter does not indicate -0.1 MPa (14.5 Psi) after 30 minutes, continue evacuating for an additional 20 minutes.

•If the pressure does not achieve -0.1 MPa (14.5 Psi) after 50 minutes, check for leakage.

•If the pressure successfully reaches -0.1 MPa (14.5 Psi), fully close the Handle Lo valve and cease vacuum pump operations.

b.Wait for 5 minutes then check whether the gauge needle moves after turning off the vacuum pump.

6.Loosen the flare nut of the 3-way valve for 6 or 7 seconds and then tighten the flare nut again.

a.Confirm the pressure display in the pressure indicator is slightly higher than the atmospheric pressure.

b.Remove the charge hose from the 3-way valve.

7.Fully open the 2- and 3-way valves and tighten the cap of the 3-way valve.

Disassembly

Maintenance and

Page 19

and Maintenance

Disassembly

|

/TJUUX [TOZ |

2OW[OJ YOJK |

|

5[ZJUUX [TOZ |

|

|

|

:]U ]G_ \GR\5VKT |

|||

|

)NKIQ \GR\K |

-GY YOJK |

|

|

|

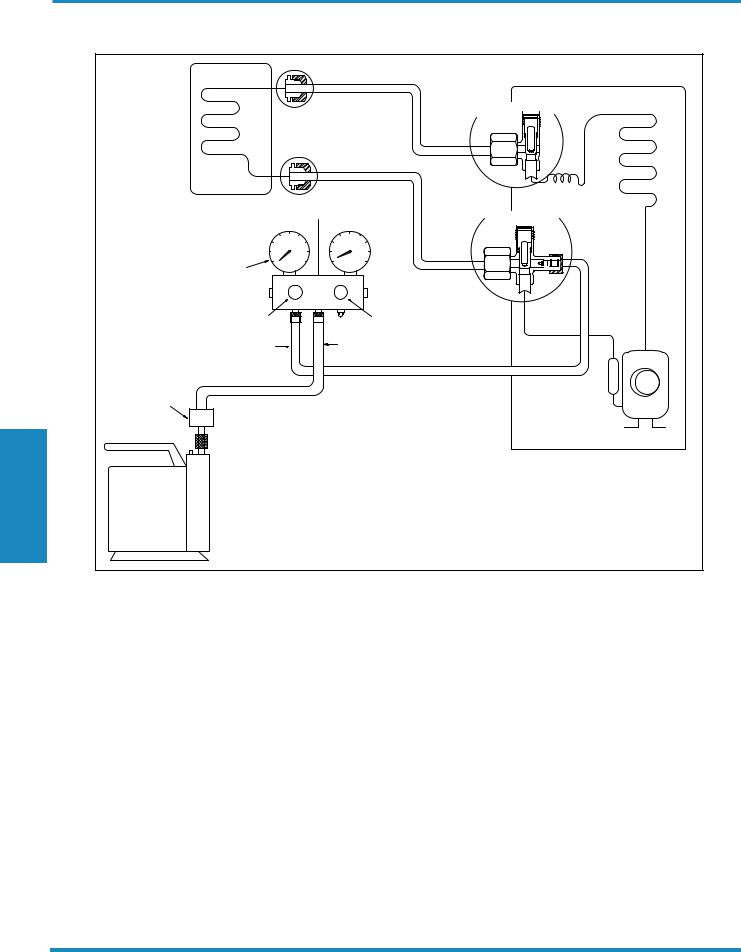

1.2 Refrigerant Recharge |

|

|

|

||

|

|

|

|

:NXKK ]G_ \GR\ |

|

|

|

|

|

5VKT |

|

)NGXMOTM |

|

|

|

|

|

I ROTJKX |

|

56+4 2U |

.O )259+ |

|

|

|

|

|

|

||

+RKIZXUTOI YIGRK |

|

|

|

|

|

Prior to recharging the refrigerant, confirm the additional amount of refrigerant required using the following table:

Models |

Standard length |

Max. elevation |

|

Max. length |

Additional refrigerant |

||

|

|

|

|

|

|

|

|

9k&12k |

7.5m (24.6ft) |

10m |

(32.8ft) |

|

25m |

(82ft) |

15g/m (0.16oz/ft) |

|

|

|

|

|

|

|

|

17k&18k |

7.5m (24.6ft) |

20m |

(65.6ft) |

|

30m |

(98.4ft) |

15g/m (0.16oz/ft) |

|

|

|

|

|

|

|

|

22k |

7.5m (24.6ft) |

20m |

(65.6ft) |

|

30m |

(98.4ft) |

30g/m (0.32oz/ft) |

|

|

|

|

|

|

|

|

24k&30k |

7.5m (24.6ft) |

25m |

(82ft) |

|

50m |

(164ft) |

30g/m (0.32oz/ft) |

|

|

|

|

|

|

||

36k |

7.5m (24.6ft) |

30m(98.4ft) |

|

65m(213.2ft) |

30g/m (0.32oz/ft) |

||

|

|

|

|

|

|

|

|

Procedure: |

|

|

|

|

|

|

|

1. Close both 2- and 3-way valves. |

|

|

3-way valves. |

|

|||

2.Slightly connect the Handle Lo charge hose to the 8. Operate the air conditioner in cooling mode to charge

3-way service port. |

the system with liquid refrigerant. |

3.Connect the charge hose to the valve at the bottom 9. When the electronic scale displays the correct weight

of the cylinder.

4.If the refrigerant is R410A, invert the cylinder to ensure a complete liquid charge.

5.Open the valve at the bottom of the cylinder for 5 seconds to purge the air in the charge hose, then fully tighten the charge hose with push pin Handle Lo to the service port of 3-way valve..

6.Place the charging cylinder onto an electronic scale and record the starting weight.

7.Fully open the Handle Lo manifold valve, 2- and

(refer to the gauge and the pressure of the low side to confirm), turn off the air conditioner, then disconnect the charge hose from the 3-way service port immediately..

10.Mount the caps of service port and 2- and 3-way valves.

11.Use a torque wrench to tighten the caps to a torque of 18 N.m.

12.Check for gas leakage.

Page 20

1.3Re-Installation

1.3.1Indoor Unit

Collecting the refrigerant into the outdoor unit

|

|

|

)RUYK |

|

|

-GY YOJK |

|

)RUYK |

|

|

:NXKK ]G_ \GR\K |

|

|

5VKT |

|

|

|

|

|

|

2U |

.O )RUYK |

|

Procedure:

1.Confirm that the 2- and 3-way valves are opened.

2.Remove the valve stem caps and ensure that the valve stems are opened (use as hexagonal wrench to open the valve stems).

3.Connect the charge hose with the push pin of Handle Lo to the 3-way valve’s gas service port.

4.Open the Handle Lo valve of the manifold valve to purge air from the charge hose for 5 seconds and then close it quickly.

5.Close the 2-way valve.

6.Operate the air conditioner in cooling mode. Cease operations when the gauge reaches 0.1 MPa (14.5 Psi).

7.Close the 3-way valve so that the gauge rests between 0.3 MPa (43.5 Psi) and 0.5 MPa (72.5 Psi).

8.Disconnect the charge set, and tighten the 2- and 3-way valve’s stem nuts (use a torque wrench to tighten the 3-way valves service port cap to a torque of 18 N.m).

9.Check for gas leakage.

Disassembly

Maintenance and

Page 21

|

|

|

|

/TJUUX [TOZ |

|

|

2OW[OJ YOJK |

:]U ]G_ \GR\K )RUYK5[ZJUUX [TOZ |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

-GY YOJK |

|

|

|

|

|

|

|

3GTOLURJ \GR\K |

|

:NXKK ]G_ \GR\K |

||

|

|

|

)USVU[TJ SKZKX |

|

|

6XKYY[XK |

)RUYK |

||

|

|

Air purging with vacuum pump |

|

|

|

MG[MK |

|||

|

|

|

|

|

|

|

|||

|

|

|

|

36G |

|

|

|

|

|

|

|

|

|

.GTJRK 2U |

2U |

.O |

.GTJRK .O |

|

|

|

|

|

|

)NGXMK NUYK |

|

)NGXMK NUYK |

|

||

|

|

<GI[[S |

|

|

|

|

|

|

|

|

|

V[SV |

|

|

|

|

|

|

|

Disassembly |

and Maintenance |

<GI[[S |

|

|

|

|

|

|

|

V[SV |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

Procedure:

1.Tighten the flare nuts of the indoor and outdoor units, and confirm that both the 2- and 3-way valves are closed.

2.Connect the charge hose with the push pin of Handle Lo to the gas service port of the 3-way valve.

3.Connect the charge hose of Handle Hi connection to the vacuum pump.

4.Fully open the Handle Lo manifold valve.

5.Using the vacuum pump, evacuate the system for 30 minutes.

a.Check whether the compound meter indicates -0.1 MPa (14.5 Psi).

•If the meter does not indicate -0.1 MPa (14.5 Psi) after 30 minutes, continue evacuating for an additional 20 minutes.

•If the pressure does not achieve -0.1 MPa (14.5 Psi) after 50 minutes, check for leakage.

•If the pressure successfully reaches -0.1 MPa (14.5 Psi), fully close the Handle Lo valve and cease vacuum pump operations.

b.Wait for 5 minutes then check whether the gauge needle moves after turning off the vacuum pump.

6.Loosen the flare nut of the 3-way valve for 6 or 7 seconds and then tighten the flare nut again.

c.Confirm the pressure display in the pressure indicator is slightly higher than the atmospheric pressure.

d.Remove the charge hose from the 3-way valve.

7.Fully open the 2- and 3-way valves and tighten the cap of the 3-way valve.

Page 22

1.3.2 Outdoor Unit

Evacuation for the whole system

|

|

|

|

|

5VKT |

|

|

|

-GY YOJK |

|

|

|

|

|

|

|

:NXKK ]G_ \GR\K |

|

56+4 |

|

|

|

5VKT |

|

|

|

|

|

|

<GI[[S V[SV |

|

2U |

.O |

)259+ |

|

Procedure:

1.Confirm that the 2- and 3-way valves are opened. 4. Close the valve (Low side) on the charge set and turn

2. |

Connect the vacuum pump to the 3-way valve’s |

|

off the vacuum pump. |

|

5. |

Wait a period of five minutes then check whether the |

|||

|

service port. |

|||

3. |

Evacuate the system for approximately one hour. |

|

gauge needle moves after turning off the vacuum |

|

|

pump. |

|||

|

Confirm that the compound meter indicates |

|

||

|

6. |

Disconnect the charge hose from the vacuum pump. |

||

|

-0.1 MPa (14.5Psi). |

Disassembly

Maintenance and

Page 23

Refrigerant charging |

/TJUUX [TOZ |

2OW[OJ YOJK |

|

5[ZJUUX [TOZ |

|

|

:]U ]G_ \GR\5VKT |

||||

)NKIQ \GR\K |

-GY YOJK |

|

|

||

|

|

|

|

:NXKK ]G_ \GR\ |

|

|

|

|

|

5VKT |

|

)NGXMOTM |

|

|

|

|

|

I ROTJKX |

|

56+4 2U |

.O )259+ |

|

|

|

|

|

|

||

+RKIZXUTOI YIGRK |

|

|

|

|

|

and Maintenance

Disassembly

Procedure: |

|

1. Connect the charge hose to the 3-way service port |

7. Open the valves (Low side) on the charge set and |

and then open the 2- and the 3-way valves. |

charge the system with liquid refrigerant. |

2.Connect the charge hose to the valve at the bottom 8. When the electronic scale displays the correct weight

|

of the cylinder. |

|

(refer to the gauge and the pressure of the low side |

|

3. |

If the refrigerant is R410A, invert the cylinder to |

|

to confirm), disconnect the charge hose from the |

|

|

3-way valve’s service port immediately and turn off |

|||

|

ensure a complete liquid charge. |

|

||

|

|

the air conditioner before disconnecting the hose. |

||

4. |

Open the valve at the bottom of the cylinder and close |

|

||

9. |

Mount the valve stem caps and the service port. |

|||

|

the check valve on the charge set to purge the air. |

|||

|

|

|

||

5. |

Place the charging cylinder onto an electronic scale |

10. |

Use a torque wrench to tighten the service port cap to |

|

|

a torque of 18 N.m. |

|||

|

and record the starting weight. |

|

||

|

|

|

||

6. |

Operate the air conditioner in cooling mode. |

11. |

Check for gas leakage. |

|

|

|

Note: 1. Mechanical connectors used indoors shall comply with local regulations.

2. When mechanical connectors are reused indoors, sealing parts shall be renewed. When flared joints are reused indoors, the flare part shall be re-fabricated.

Page 24

2. Disassembly

2.1Indoor unit

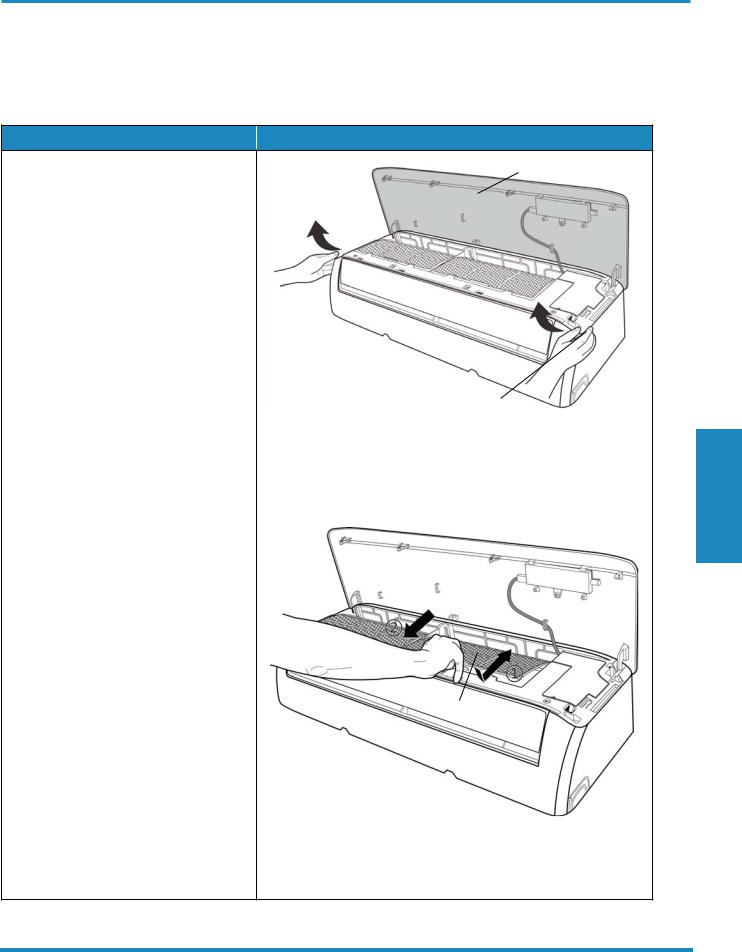

1.Front Panel

Procedure |

Illustration |

1)Hold the front panel by the tabs on the both sides and lift it (see CJ_AB_ INV_001).

2)Push up the bottom of an air filter (step 1), and then pull it out downwards (step 2) (see CJ_AB_ INV_002).

Front Panel

Tab

CJ_AB_INV_001

Filter

CJ_AB_INV_002

Note: This section is for reference only. Actual unit appearance may vary.

Disassembly

Maintenance and

Page 25

Loading...

Loading...